Page 1

ARF200

Paperless Recorder

Operation Manual

No. CP-UM-5613E

Thank you for purchasing the ARF200

Paperless Recorder.

This manual contains information for

ensuring the correct use of the ARF200

Paperless Recorder. It also provides necessary information for installation, maintenance, and troubleshooting.

This manual should be read by those who

design and maintain equipment that uses

the ARF200 Paperless Recorder. Be sure

to keep this manual nearby for handy

reference.

Page 2

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden.

The information and specifications in this manual are subject to change

without notice.

Considerable effort has been made to ensure that this manual is free from

inaccuracies and omissions. If you should find an error or omission, please

contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect, special or

consequential damages as a result of using this product.

© 2011-2017 Azbil Corporation All Rights Reserved.

Page 3

Conventions Used in This Manual

About Icons

The safety precautions described in this manual are indicated by various icons. Please be sure you read and understand the icons and their meanings described below before reading the rest of the manual.

Safety precautions are intended to ensure the safe and correct use of this product, to prevent injury to the operator

and others, and to prevent damage to property. Be sure to observe these safety precautions.

Warnings are indicated when mishandling this product might result

WARNING

in death or serious injury.

CAUTION

Examples

Cautions are indicated when mishandling this product might result

in minor injury to the user, or only physical damage to the product.

Use caution when handling the product.

The indicated action is prohibited.

Be sure to follow the indicated instructions.

i

Page 4

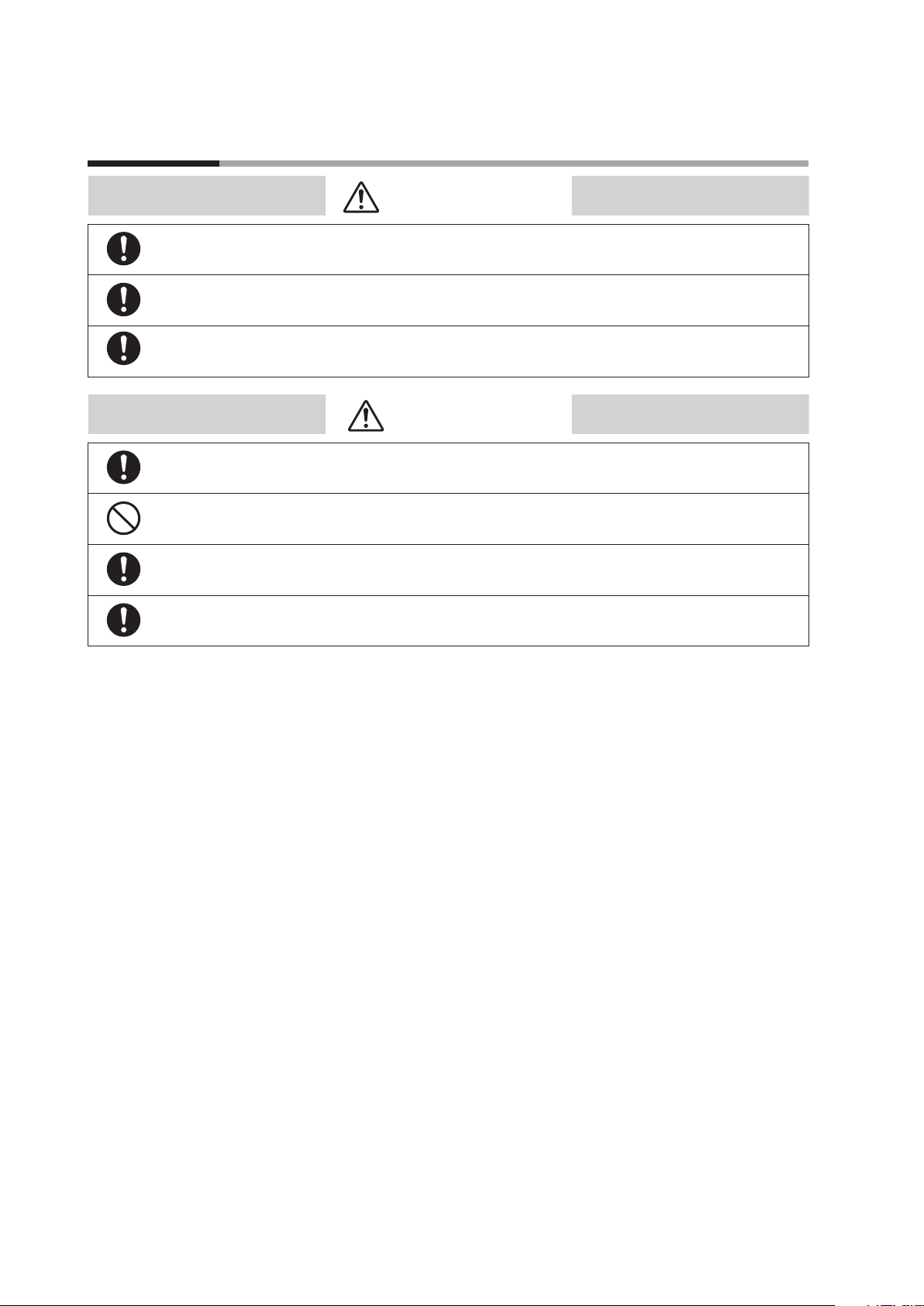

Safety Precautions

Be sure to turn OFF the power supply before connecting wires to the power or input/output terminals to prevent an electric shock.

To prevent electric shock, connect the protective ground terminal to a ground of less than 100 Ω.

To prevent electric shock, attach the terminal cover after wiring.

Wire the recorder following the instructions in this manual, using the specified type of power leads

and installation methods. Failure to do so might cause electric shock, fire or faulty operation.

Do not disassemble the recorder or touch components inside it. Doing so might cause electric

shock or faulty operation.

If some hazardous condition arises — for example, if there is smoke from the recorder or if there is a

smell of something burning — immediately turn the power off.

WARNING

CAUTION

When disposing of this recorder, treat it appropriately as industrial waste in accordance with local

regulations.

ii

Page 5

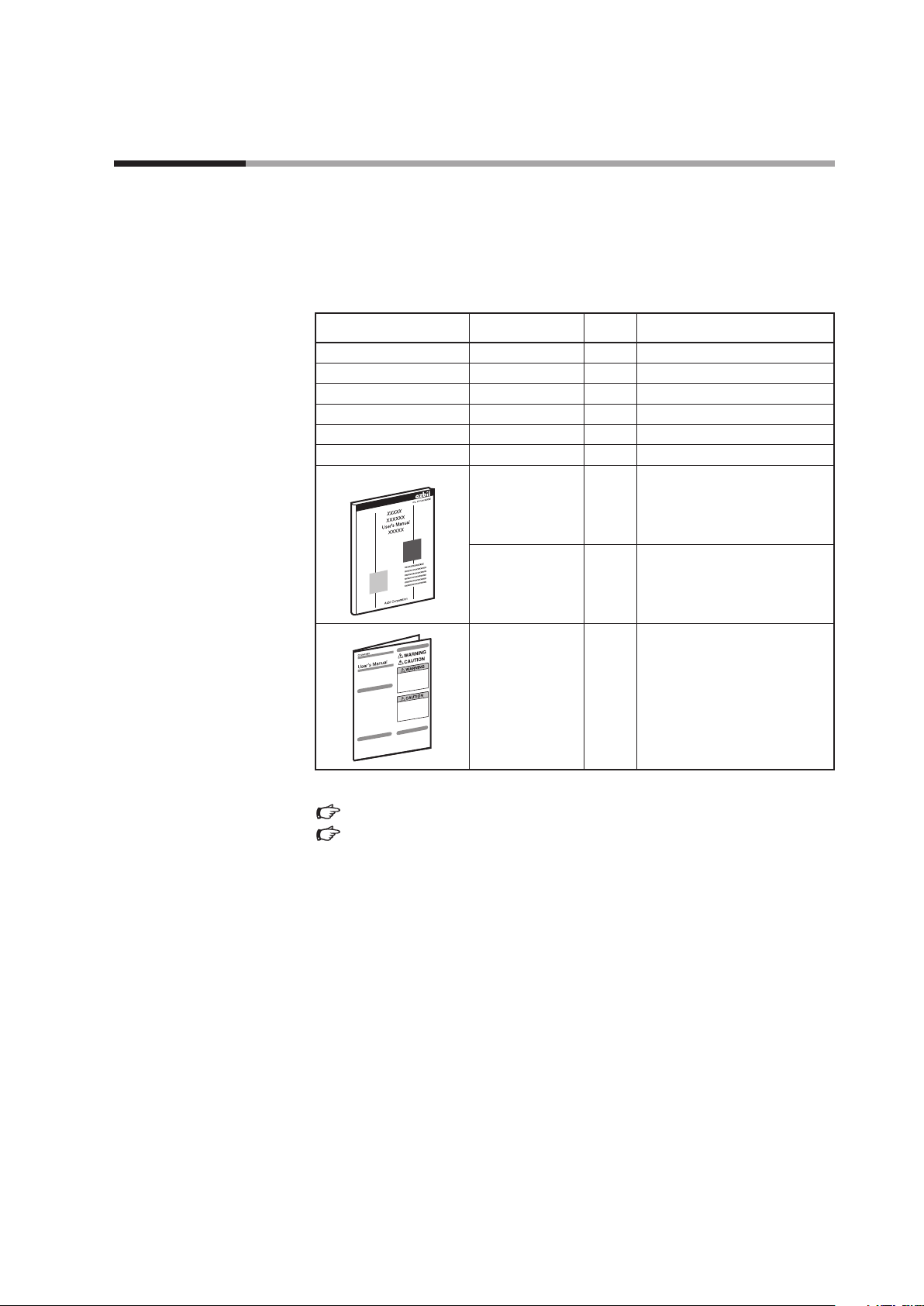

Unpacking

Check the following items when removing the ARF200 from its package:

1. Check the model number to make sure you received the correct product.

2. Check for any obvious damage.

3. Check the contents of the package against the packing list to make sure that all items are included.

Handle the ARF200 and its accessories with care to prevent damage or loss of parts.

If there is some problem with your order, please contact your dealer immediately.

Name Model No. Q’ty Remarks

ARF200 1

Mounting bracket 1

Wrench 1

CF Card ARF910CF0128 (128MB)

Screws (spare) 5 M3.5 X 8 bind

Stylus 1

User’s Manual

CP-UM-5613E 1 This manual

CP-UM-5612E 1 ARF200 Paperless Recorder

Installation and Wiring

CP-UM-5484JE 1 CF Card Instructions

The model No. label is located on the top of the unit.

Chapter 2. PART NAMES AND FUNCTIONS, page 4.

1-2 Model Selection Guide, page 2.

iii

Page 6

Contents

Safety Rrecautions

Unpacking

Chapter 1. OVERVIEW

1.1. Introduction .................................................................... 1

Main Features ................................................................ 1

Additional functions .......................................................... 1

1.2. Model Selection Guide .......................................................... 2

Model number configuration.................................................. 2

Optional parts................................................................ 3

Data analysis software ........................................................ 3

Chapter 2. PART NAMES AND FUNCTIONS

Main unit .................................................................... 4

Rear terminals................................................................ 4

Chapter 3. MOUNTING AND WIRING

3.1. Installation Site ................................................................. 5

3.2. Mounting ...................................................................... 5

Panel cutout dimensions ...................................................... 5

Mounting methods ........................................................... 6

3.3. Wiring Precautions.............................................................. 7

3.4. Terminal Block .................................................................. 8

3.5. Wiring of Power and Protective Ground Terminals................................. 9

3.6. Wiring of Measurement Input Terminals ......................................... 10

3.7. Alarm Output Wiring (for applicable models) .................................... 12

3.8. Digital Input Terminals (for applicable models) ..................................15

3.9. Ethernet Connections .......................................................... 17

Chapter 4. SETUP ...................................................................... 18

Chapter 5. FRONT PANEL

5.1. Parts and Functions ............................................................ 19

5.2. Functions of Keys ..............................................................20

5.3. Character Input ................................................................ 21

5.4. How to Operate the Touch Panel ................................................ 22

5.5. Operations in 4-frame Split Screen Display ...................................... 28

iv

Page 7

Chapter 6. SWITCHING SCREENS .....................................................29

Chapter 7. OPERATION SCREENS

7.1. Common Key Functions ........................................................ 31

7.2. Status Bar Information ......................................................... 35

7.3. Real-time Trend Screen ......................................................... 37

7.4. Bar Graph Screen .............................................................. 38

7.5. Numeric Display Screen ........................................................ 38

7.6. Historical Trend Screen ......................................................... 39

7.7. Dual Trend Screen.............................................................. 41

7.8. Alarm Display Screen........................................................... 41

7.9. Internal Memory Screen ........................................................ 43

7.10. CF Card/USB Memory Screen ................................................... 45

7.11. Marker Screen ................................................................. 46

Chapter 8. INITIAL SETTINGS ......................................................... 47

Chapter 9. MENU STRUCTURE ........................................................ 51

Chapter 10. HOME SCREEN

10.1. Quick Recorder Setup .......................................................... 52

10.2. Specifications Display .......................................................... 54

Chapter 11. MENU SCREEN

11.1. Overview ...................................................................... 55

11.2. Input Settings ................................................................. 59

11.3. Display settings................................................................ 68

11.4. Alarm Settings................................................................. 78

11.5. File Settings Screen ............................................................ 81

11.6. Totalizer Settings .............................................................. 85

11.7. Schedule Settings.............................................................. 87

11.8. Marker Settings................................................................ 88

11.9. Memory Operations............................................................ 89

11.10 Network Settings .............................................................. 91

11.11. System Settings...............................................................101

v

Page 8

Chapter 12. WEB SCREEN

12.1. Remote Monitoring and Configuration .........................................108

Chapter 13. RECORDING TO USB MEMORY

13.1. Overview .....................................................................115

13.2. Connectable Media ...........................................................115

13.3. Method of Use ................................................................115

Chapter 14. CALIBRATION

14.1. Overview .....................................................................116

14.2. Conditions....................................................................116

14.3. Preparation...................................................................116

14.4. Connections ..................................................................117

14.5. Zero and Span Adjustment ....................................................120

Chapter 15. PART REPLACEMENT

15.1. Replacement Intervals ........................................................124

Chapter 16. TROUBLESHOOTING .....................................................125

Chapter 17. DISPOSAL .................................................................127

Chapter 18. SPECIFICATIONS

General specifications ......................................................128

Standards .................................................................128

Input specifications.........................................................129

Recording specifications ....................................................130

Display specifications.......................................................130

Setting and operation specifications.........................................130

Alarm specifications ........................................................131

Measurement range, indication accuracy, and display resolution ..............132

External dimensions ........................................................134

vi

Page 9

1

Chapter 1. OVERVIEW

1.1. Introduction

The ARF200 Paperless Recorder is able to measure temperature and various other industrial process

quantities from 12 through to 24, 36 and 48 channels, and display various data in real time on a

12.1-inch TFT color LCD. This recorder can also store measured data in its internal memory or on a

memory card (CF card or USB memory). Stored data can be loaded into off-the-shelf software like

Excel, and data analysis software especially designed for the ARF200 is also available.

Main Features

・ A variety of screen displays

Real-time trends, bar graphs, data in table format, and combined displays of real-time

trends plus bar graphs, real time trends with numeric values, and real time trends plus

historical trends can be freely selected and monitored in the most suitable display format

for your requirements. Other displays include a summary of past alarm activity and a list

of annotations made with the marker function. In addition, up to 6 channel groups can be

registered, allowing easy switching between them and 4-split screen display.

・ Marker function

Symbols and annotations (up to 30 alphanumeric characters) can be written on trend

screens. Annotations can be written freely, and also up to 50 can be assigned to key

combinations for easy writing. Annotations can be written on stored and replayed trend

screens, too. Adding a symbol only without text is also possible.

・ Various memory functions

Start/stop of data storage can be executed by user-selected conditions like key operation,

alarm occurrence, time, etc. and simultaneous storage to as many as 6 files is available.

In normal operation, data is stored in internal memory and can be saved on a CF memory

card.

・ Analog recorder feeling

Since the trend screen displays data in chart format with scales and “pens,” monitoring

the data has the feel of monitoring an analog recorder.

・ Easy setup

Parameters are set easily and interactively by selecting an item from the menu and then

by opening a window. Fast setup of essential parameters can be done on the Home screen.

・ Consumables not required

Since it is paperless, this recorder does not require the consumables needed by other

recorders, like charts, pens and ink.

・ Easy data management

Older data stored on a CF card can be read and managed using off-the-shelf software like

Excel (a registered trademark of Microsoft Corporation).

・ Availability of software package

Data analysis can be executed conveniently on a PC with a dedicated software package,

ARF Data Analysis Tool, sold separately (ARF990DA0000, for Windows).

Additional functions

Additional functions are as follows:

Alarm outputs: Alarm relay outputs

Contact inputs: Digital (non-voltage contact) inputs

Page 10

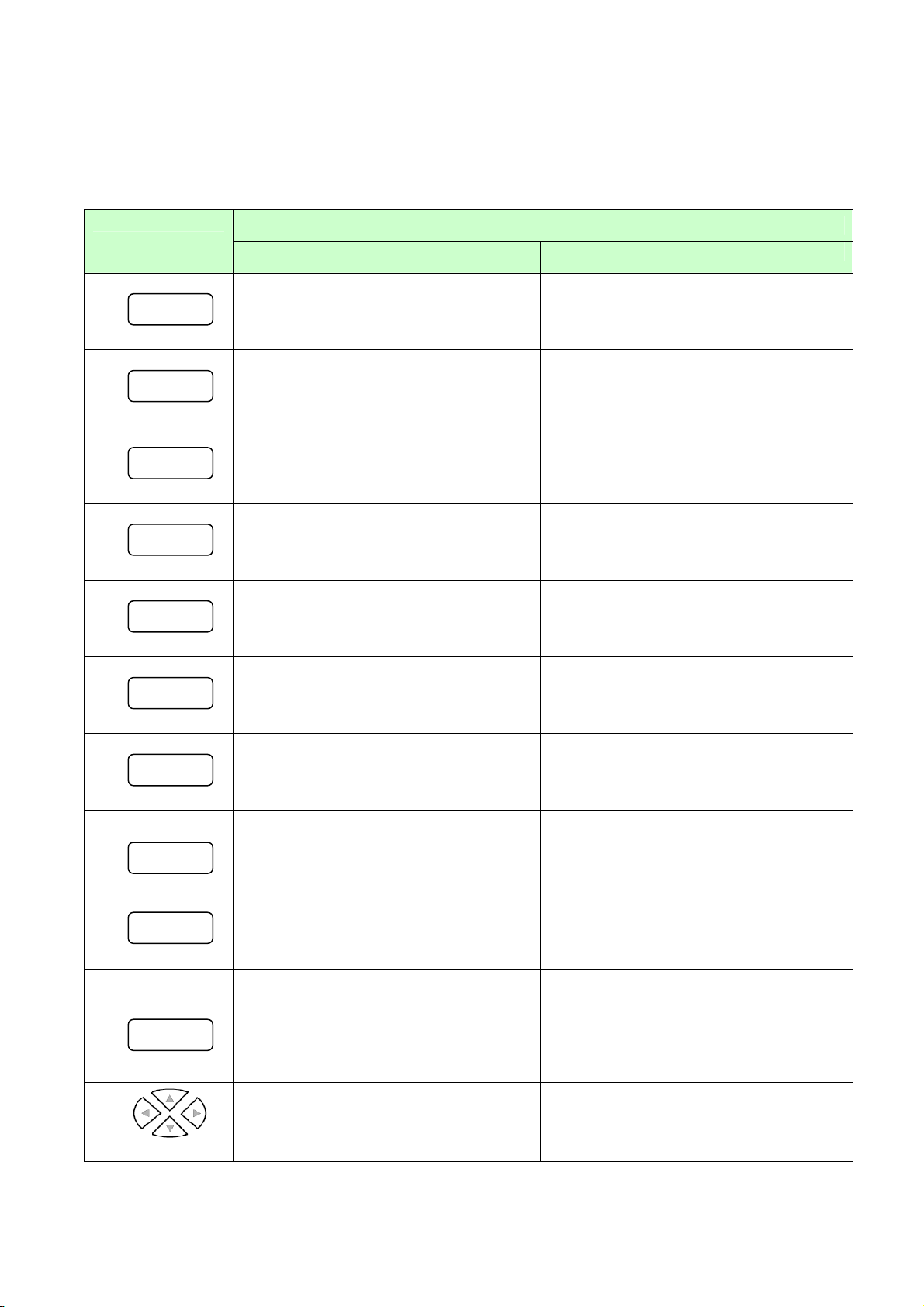

2

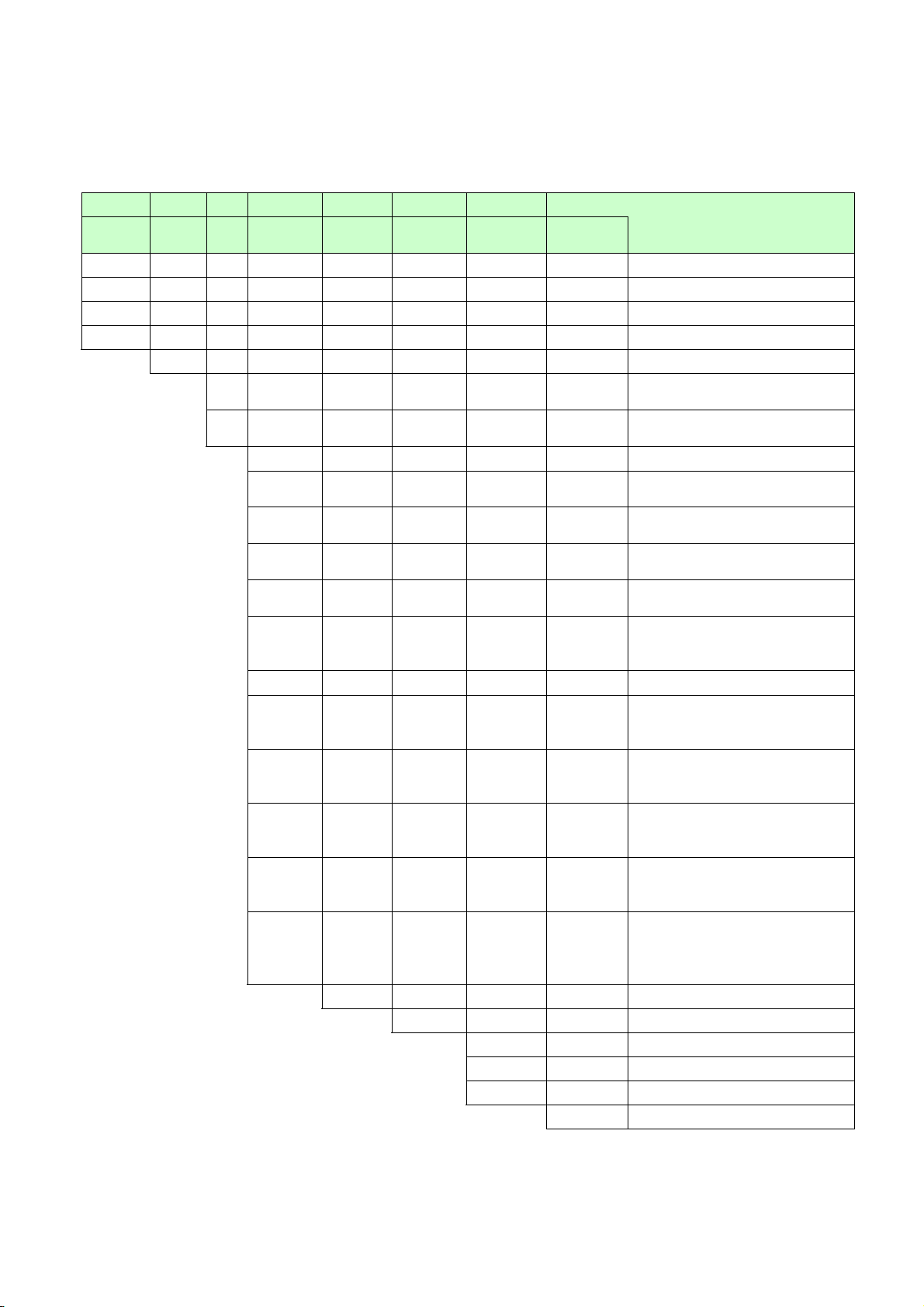

1.2. Model Selection Guide

Model number configuration

I

II

III

IV V VI

VII

VIII

Basic

model No.

Power

supply

Input

Option 1

Option 2

Option 3

Addition 1

Addition 2

Notes

ARF212

12 inputs

ARF224

24 inputs

ARF236

36 inputs

ARF248

48 inputs

A

100-240Vac, 50/60Hz

S

Standard multi-input (100 ms

specifications)

L

Standard multi-input (1 s

specifications)

0

None

1

12 relay outputs (normally open

contacts)

2

6 relay outputs (normally

closed contacts)

3

24 relay outputs (normally open

contacts)

4

12 relay outputs (normally

closed contacts)

5

12 relay outputs (normally open

contacts) + 6 relay outputs

(normally closed contacts)

A

8 non-voltage contact inputs

B

8 non-voltage contact inputs +

12 relay outputs (normally open

contacts)

C

8 non-voltage contact inputs +

6 relay outputs (normally

closed contacts)

D

8 non-voltage contact inputs +

24 relay outputs (normally open

contacts)

E

8 non-voltage contact inputs +

12 relay outputs (normally

closed contacts)

F

8 non-voltage contact inputs +

12 relay outputs (normally open

contacts) + 6 relay outputs

(normally closed contacts)

0 None

0

None

0 None

D With inspection results

Y With traceability certification

0

None

Page 11

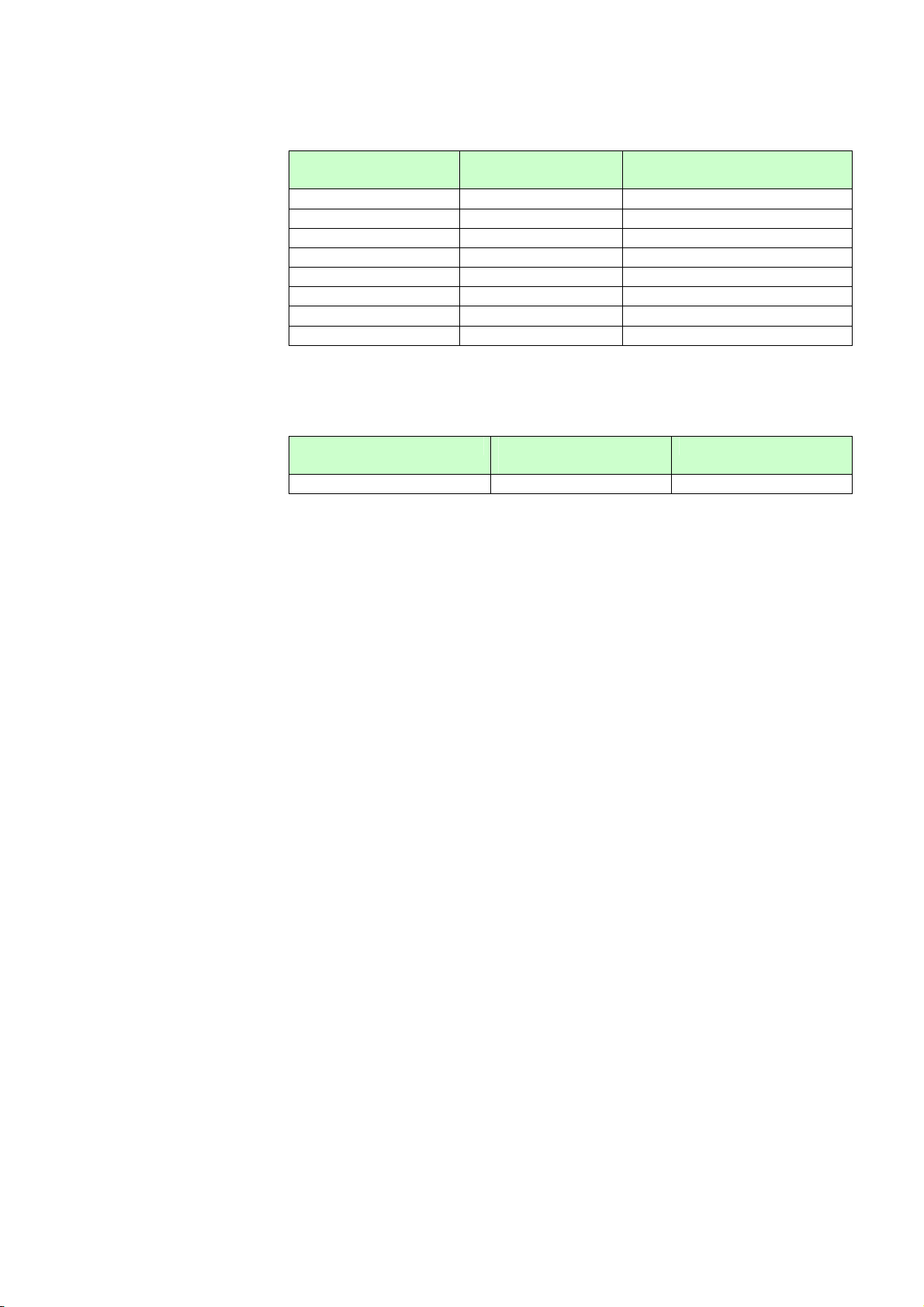

Optional parts

Name Model number Notes

CompactFlash car d ARF910CF0128 128 MB

CompactFlash car d ARF910CF0256 256 MB

CompactFlash car d ARF910CF0512 512 MB

CompactFlash car d ARF910CF1000 1 GB

CompactFlash car d ARF910CF2000 2 GB

PC card adapter AR F910ADP000

Resistor 81401325 250 ± 0.02 % (qty.: 1)

Resistor 81446642-001 250 ± 0.05 % (qty.: 2)

Data analysis software

Name Model number Notes

ARF Data Analysis Tool ARF990DA0000

3

Page 12

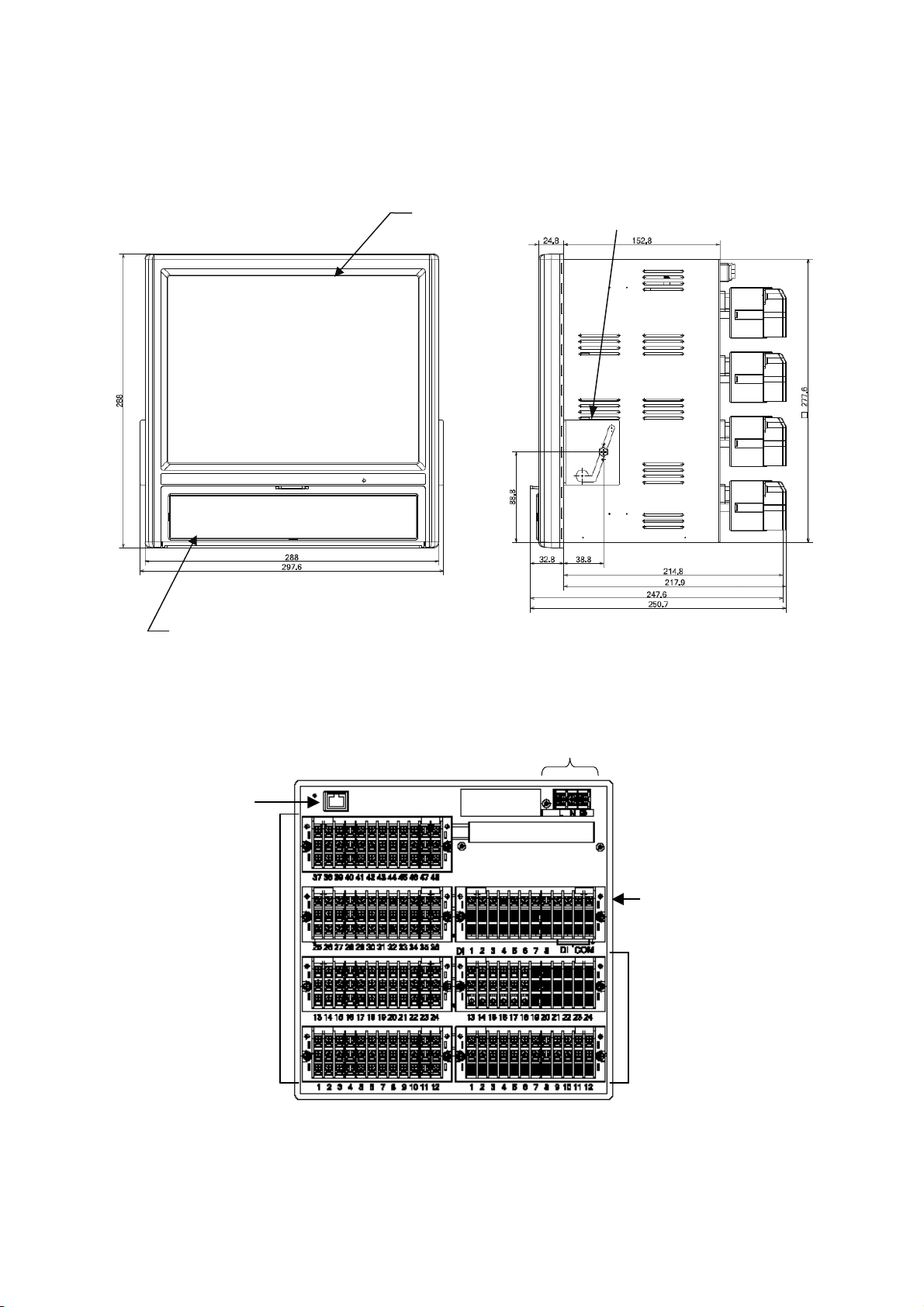

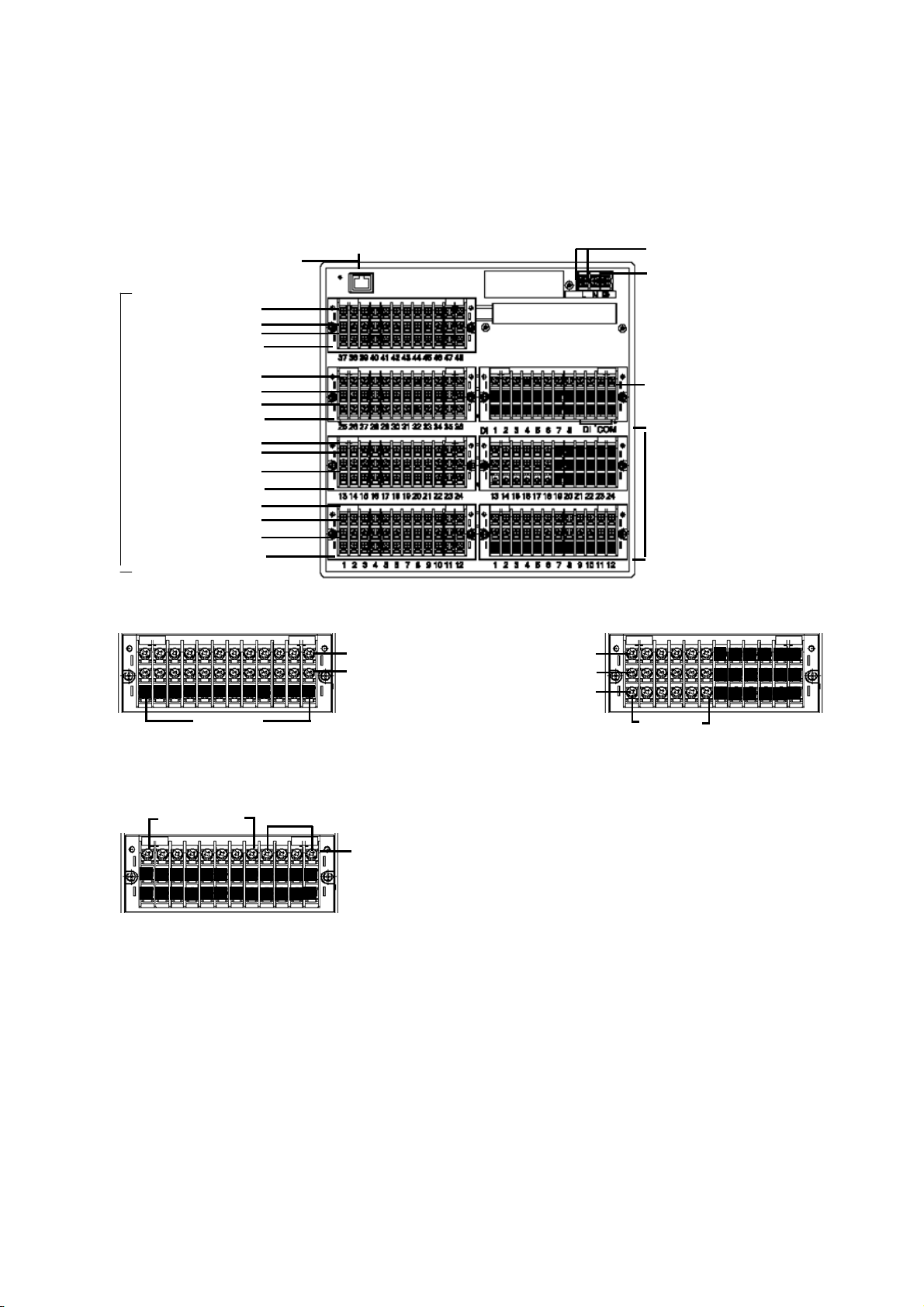

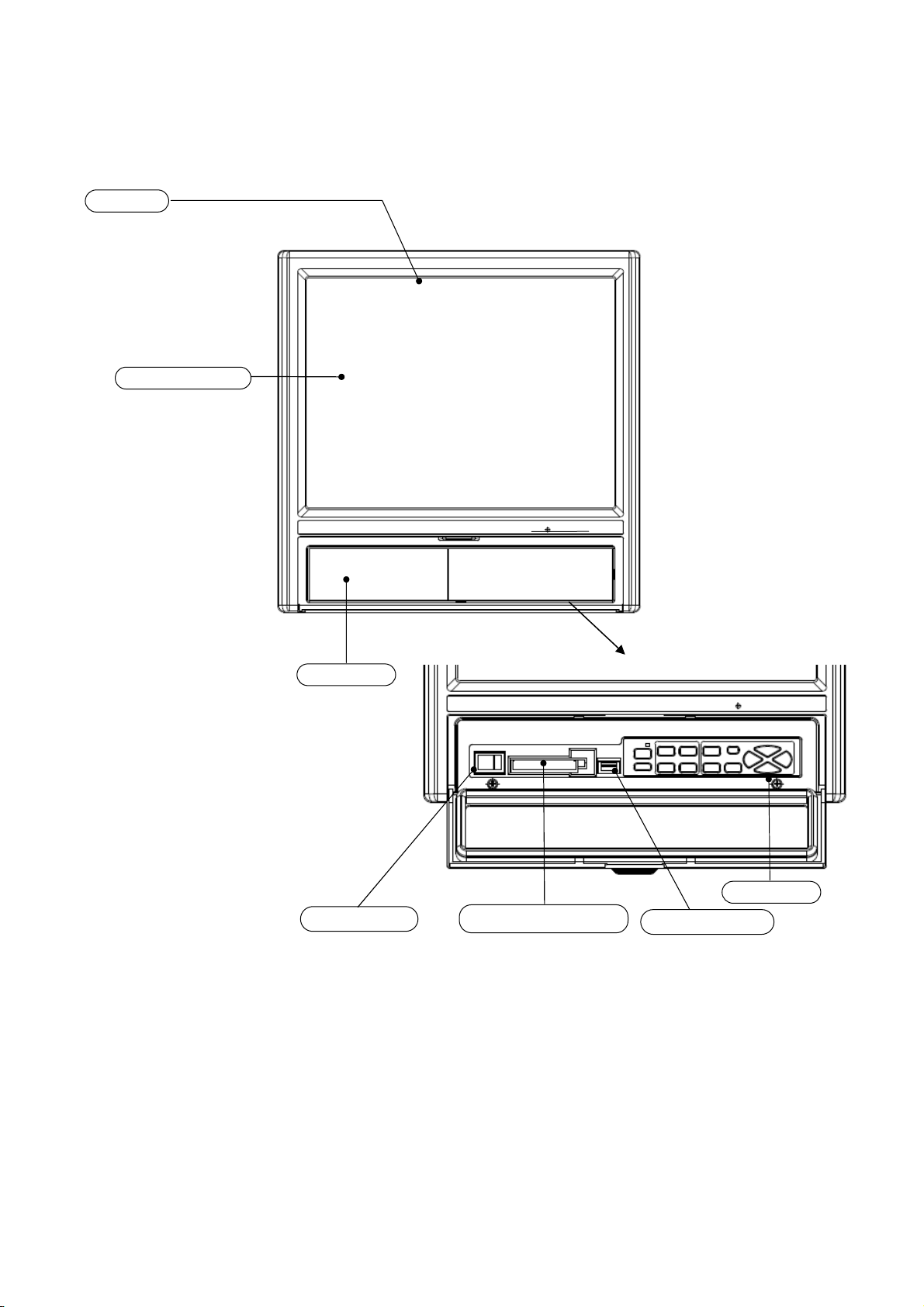

4

Chapter 2. PART NAMES AND FUNCTIONS

Main unit

(With options attached)

(With options attached)

Key cover (for the functions of keys, see chapter. 5 )

Display

Mounting bracket (2, left + right)

Rear terminals

Power and protective ground terminals

Non-voltage contact input terminals

Measurement input terminals

Alarm relay output terminals

Ethernet connector

Page 13

Chapter 3. MOUNTING AND WIRING

3.1. Installation Site

The ARF200 recorder is designed for indoor use. Install it in a location with the following

char

・ S

・ Free from d

・ Not subject to excessive mechanical vibration and shock

・ Far from the sources of electri

・ Not near flammable liquid or gas

・ Protected from d

・ Where terminals are not near a heat source (to maximize measurement accuracy)

Handling Precautions

・ To prevent temperature rise, do not put in an airtight enclosure.

・ T

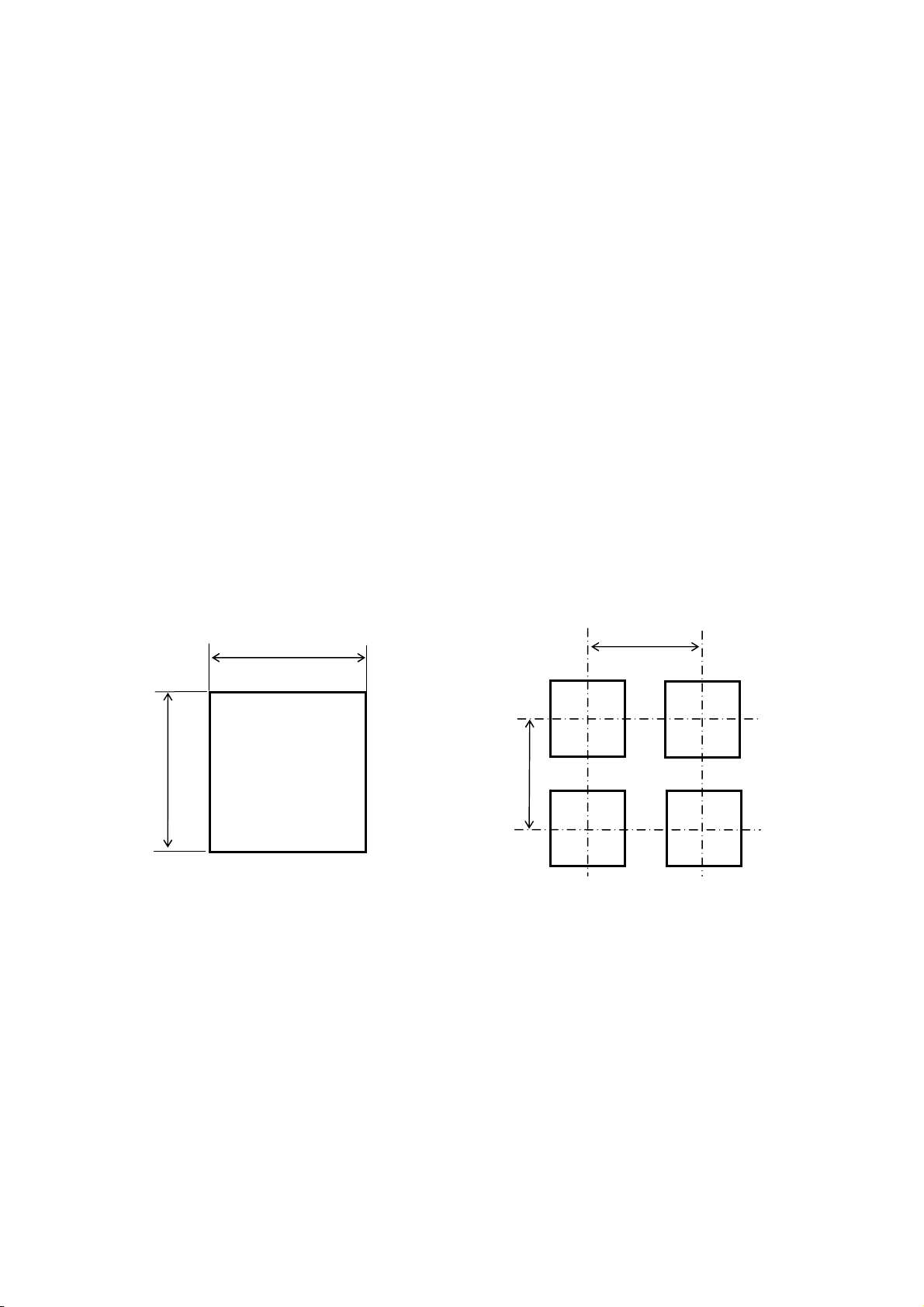

3.2. Mounting

Panel cutout dimensions

stic

+1

-0

281

s:

ust,

smoke, steam, etc.

irect sunlight

パネルカット

281

cal or magnetic fields

+1

-0

Unit: mm

● Minimum interval for gang-mounting

360

360

acteri

teady ambient temperature and humidity of about 23 °C, 50 % RH

o prevent deformation of the front panel, do not expose to hot air exhaust (50 °C or more).

5

Page 14

6

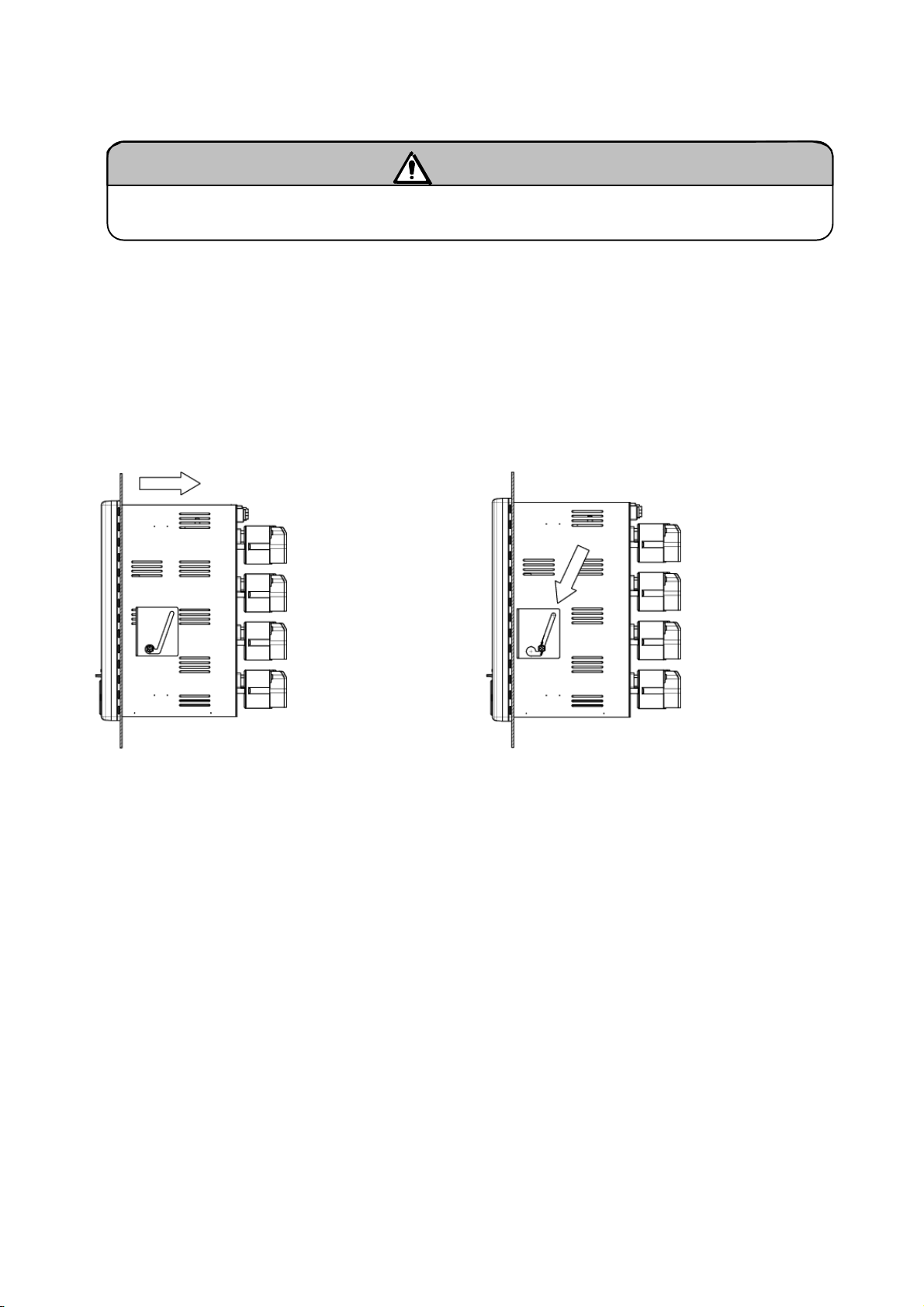

Mounting methods

(1) Insert the ARF200 into the panel cutout on the instrument panel.

(2) There are two screw holes, one on the left side and one on the right side of the ARF200. Lightly screw

in the 2 screws provided.

(3) Next, put the hexagon head of the screws inserted above into the round holes of the mounting brackets,

and firmly press the ARF200 against the instrument panel (from the front) while sliding as shown in the

figure. In this state, tighten the mounting screws with the provided wrench or Phillips screwdriver.

Note that the left and right mounting brackets are different. (Installation should be done by two

people.)

Handling Precautions

・

The recommended tightening torque is 1.0 N・m. Tightening the mounting bracket screws to a higher

torque might deform or damage the case.

・ In mounting, the top surface should not be tilted down toward the back more than 20°, and it should

not be tilted up at all. Do not tilt toward the right or left sides.

・ Mount on a panel made of steel plate 2 to 6 mm thick or a panel having equivalent strength.

Slide

• For mounting the recorder on the panel, be careful of injury by dropping it.

Warning

Page 15

3.3. Wiring Precautions

・

Be sure to turn OFF the power supply before connecting wires to the power or input/output

terminals to prevent an elect r ic shock.

・ Attach crimp terminals to the ends of wires to prevent looseness or disconnection of terminals

and short-circuit between terminals. Use the crimp terminals with an insulating sleeve to prevent

electric shock.

・ Arrange and secure connected wires so that a passing person or object cannot easily be caught

on them. Otherwise disconnection, electric shock, or other problems may occur.

・ To prevent electric shock, connect the protective ground terminal to a ground of less than 100

.

・ To prevent electric shock, attach the terminal cover after wiring.

Handling Precautions

・ Use a single-phase power supply having a stable voltage without any waveform distortion to prevent

malfunction.

・ Do not place the input/output wires close to, or in parallel with, power lines or high-voltage circuits. If

run parallel to each other, keep the I/O wires 50 cm or more apart.

they

・ For thermocouple (TC) inputs, keep the input terminals away f rom a heat source (a heating body) to

reduce a refere

nce junction compensation error. Don’t expose the input terminals to direct sunlight,

etc.

・ Don’t use any unused terminals for relaying; otherwise the electr ic circuits may be damaged.

・ To prevent malfunction, keep all connected wires as far from sources of electrical noise as possible.

Use a counter

measure (see below) if wires are unavoidably close to a noise source.

Warning

Electromagnetic switch, etc.

Major noise sources Power line with waveform distortion

Inverter

Thyristor regulator

Counter-measure

Insert noise filters between power terminals and input/output terminals.

A CR f ilt er is often used.

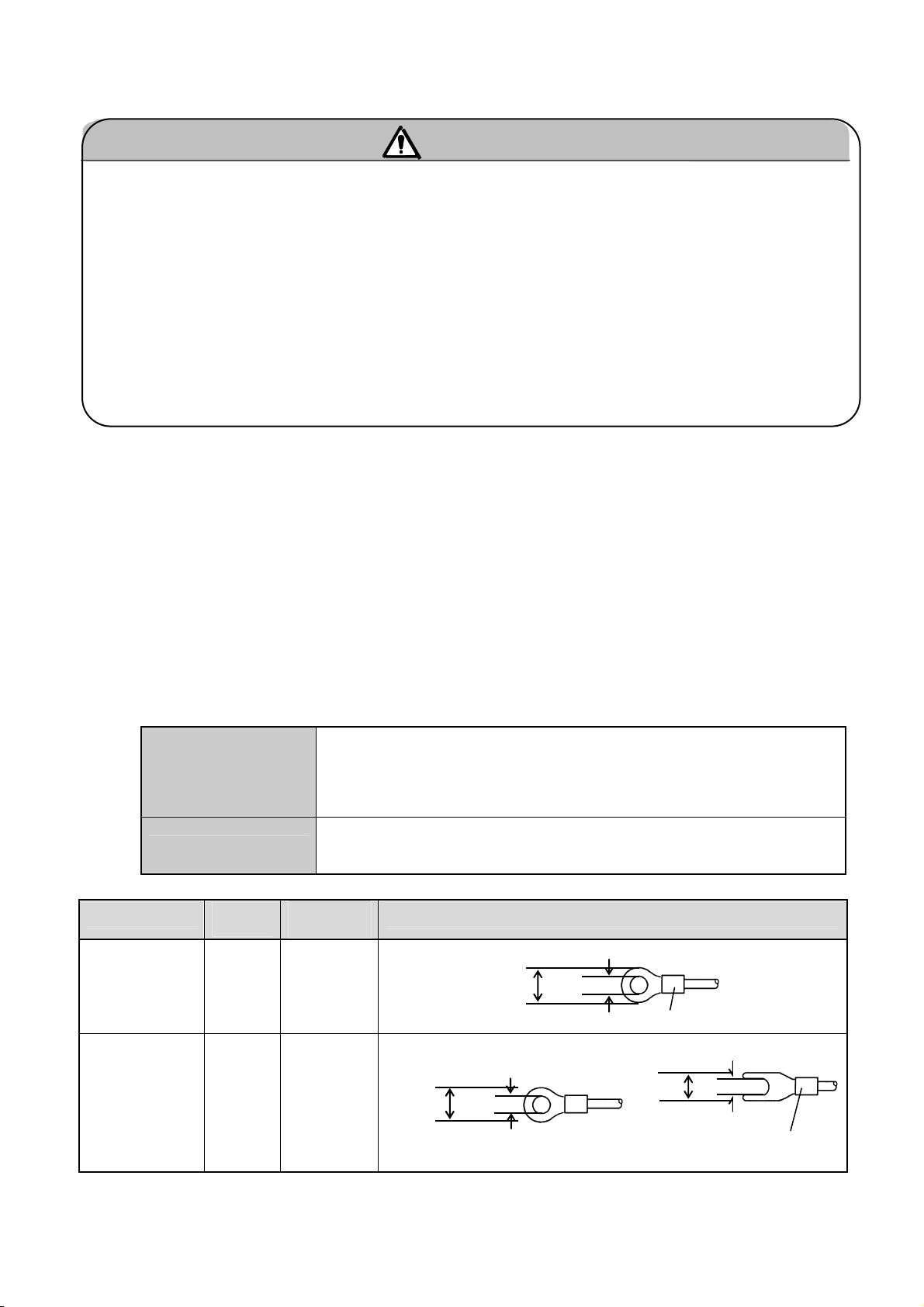

Terminal type and crimp terminal dimensions

Terminal

Power and

protectiv

e

ground

Screw

size

M4

Tightening

torque

Round type

1.2N・m

terminals

Round type

Other

terminals

M3.5

0.8N・m

8 or less

Note: Use the round type if possible.

Crimp terminal dimensions (unit: mm)

8.5 or less

Thickness: 0.8

3.7 or more

4.3 or more

With an insulating sleeve

Fork type

8 or less

With an insulating sleeve

With an insulating sleeve

Thickness: 0.8

Thickness: 0.8

3.7 or more

7

Page 16

r

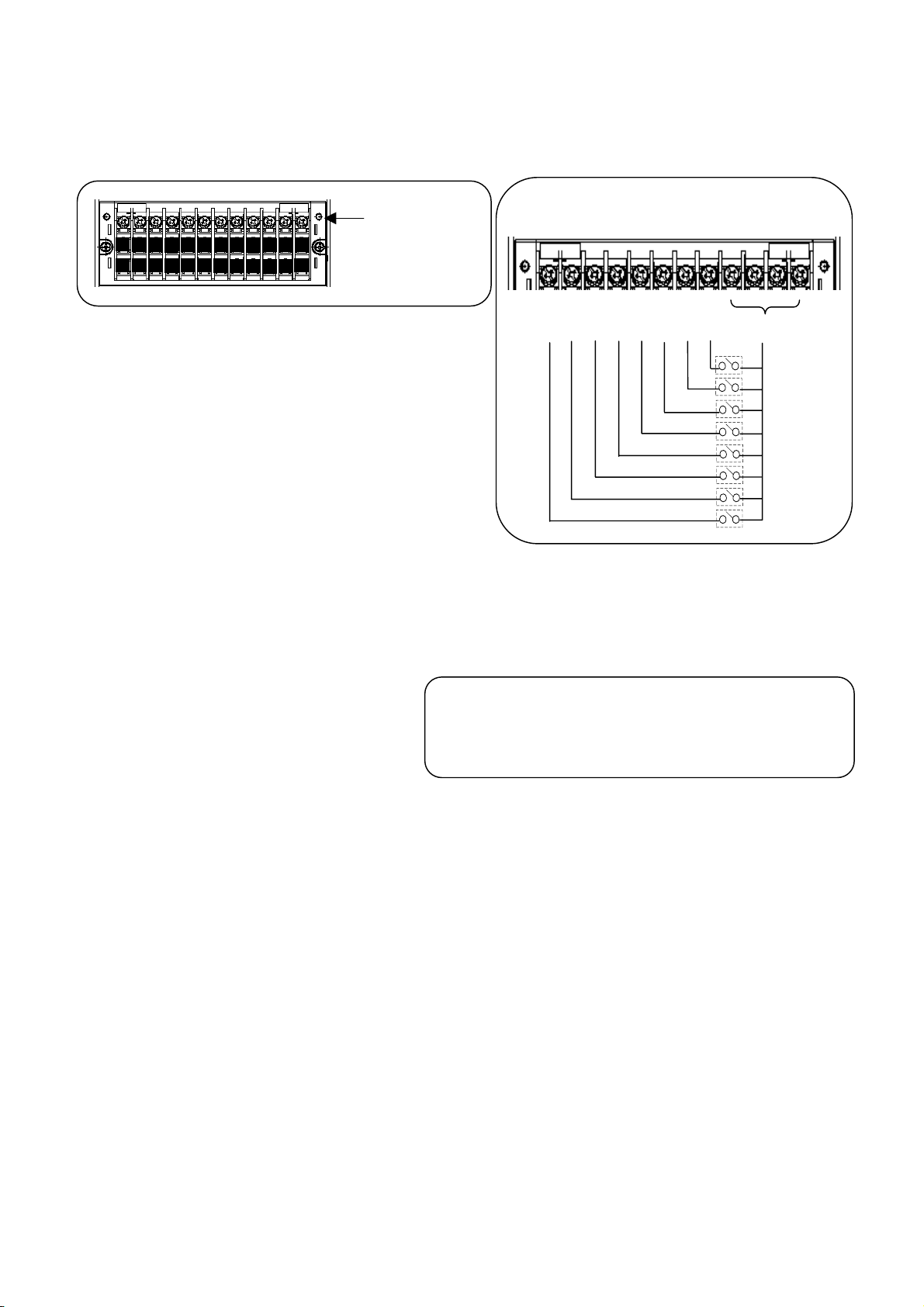

3.4. Terminal Block

The following figure shows the terminal block as configured for options (alarm relay outputs [12

Form A contacts, 6 Form C contacts] and 8 contact inputs). The Ethernet connector is the standard

type.

TC, mV(+), RTD (A) terminals

TC, mV(-), RTD (B) terminals

Measurement input terminal blocks

TC, mV(+), RTD (A) terminals

TC, mV(-), RTD (B) terminals

TC, mV(+), RTD (A) terminals

TC, mV(-), RTD (B) terminals

TC, mV(+), RTD (A) terminals

TC, mV( -), RTD ( B) t er min als

[Option terminal blocks (* Subject to change)]

• Alarm relay ou tputs ( 12 no rmall y open contact s)

• 8 non-voltage contact inputs

Ethernet connecto

RTD (B) terminals

[CH37-48]

RTD (B) terminals

[CH25-36]

RTD (B) terminals

[CH13-24]

RTD (B) terminals

[CH1-12]

Terminal

Nos.1-12

Terminal Nos.1- 8

COM terminals

N.O. terminals

COM terminals

Non-voltage contacts inputs

• Alarm relay outputs (6 normally closed contacts)

N.C. terminals

COM terminals

N.O. terminals

Power terminals

Protective ground terminals

Non-voltage contact inpu ts (optio n)

• 8 non-voltage contact inputs (common)

Alarm relay outputs ( 2 opt ions)

• 12 N.O. contact terminal block

• 6 N.C. contact te rmin al bloc k

* ARF2 _ _ _ _ 5 _ _ _ _,

ARF2 _ _ _ _ F _ _ _ _

• Upper: Terminal block for N.O. output

• Lower: Terminal block f or N .C. ou tput

Terminal

Nos.1 -6

8

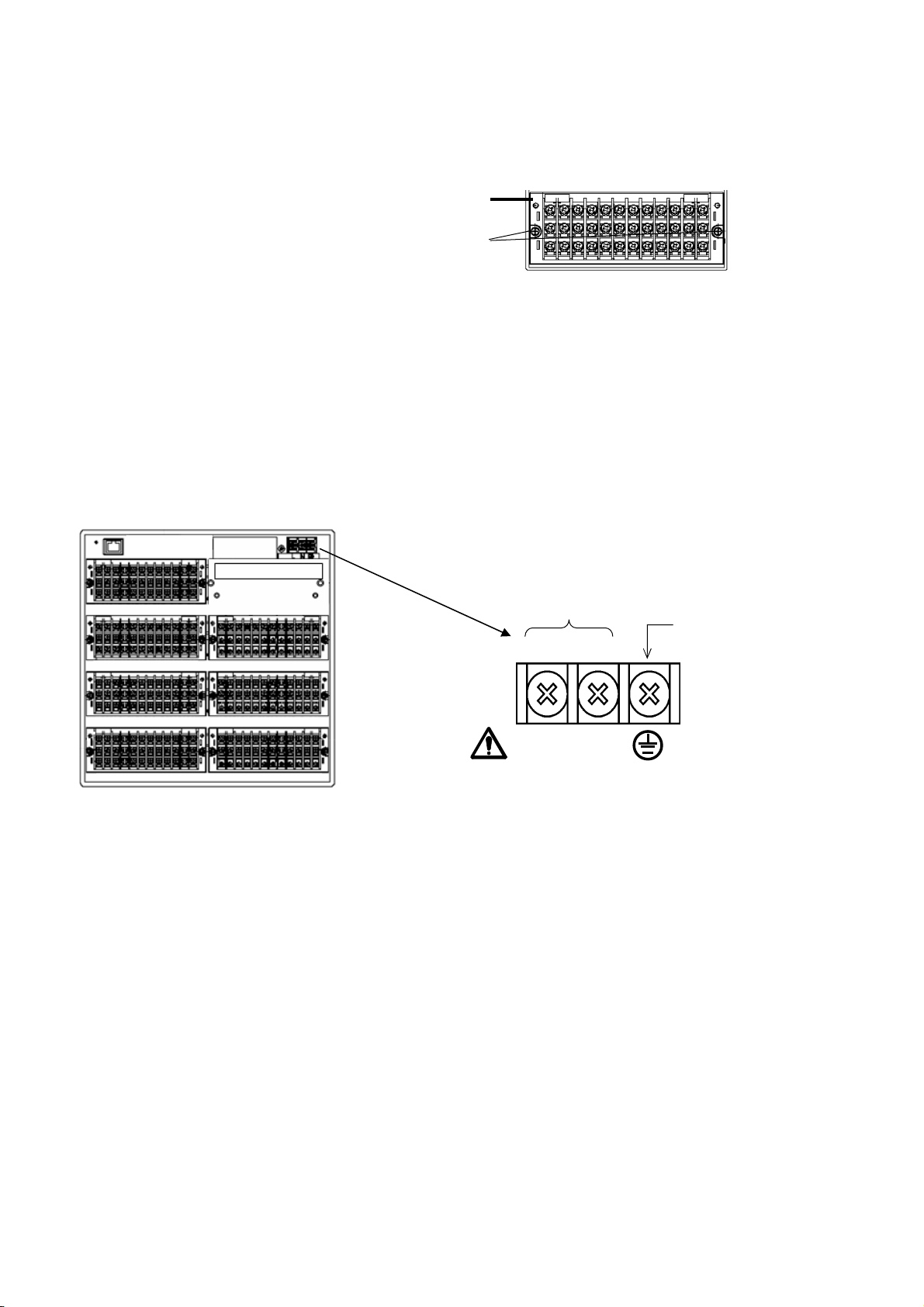

Page 17

Note: The input, alarm, and contact input terminal blocks can be removed to facilitate wiring. Because

the terminal block is connected by connectors, it can be removed easily by loosening two

screws.

Terminal block

Moun

ting screws

Handling Precautions

・ The thermocouple input terminal block cannot be repositioned or replaced wi th a terminal block for

another instrument. Measure ment error w i ll occur.

・ Before mounting or dismounting a terminal block, turn off the external power switch to prevent the

rical circuits fro m be i ng damaged.

elect

3.5. Wiring of Power and Protective Ground Terminals

(1) Power and protective ground terminals

Power terminals

L

100-240VAC 50/60Hz 65VA MAX

N

(2) Connection of power terminals

For connection to the power terminals, use a 600 V PVC-insulated cable terminated by crimp

terminals with insulating sleeve.

Note: Use a cable conforming t o t he standards below.

IEC 227-3

ANSI/UL817

CSA C22.2 No. 21 and No. 49

Protective

ground

terminal

(3) Connection of protective ground terminal

Be sure to connect this terminal to the protective ground of the power supply facility. For this

connection, use a cable terminated by a crimp terminal with an insulating sleeve.

• Ground wire: copper, 2 mm

2

or more in cross-sectional area (green/yellow)

Handling Precautions

・ To prevent electric shock, attach the terminal cover after wiring.

9

Page 18

A

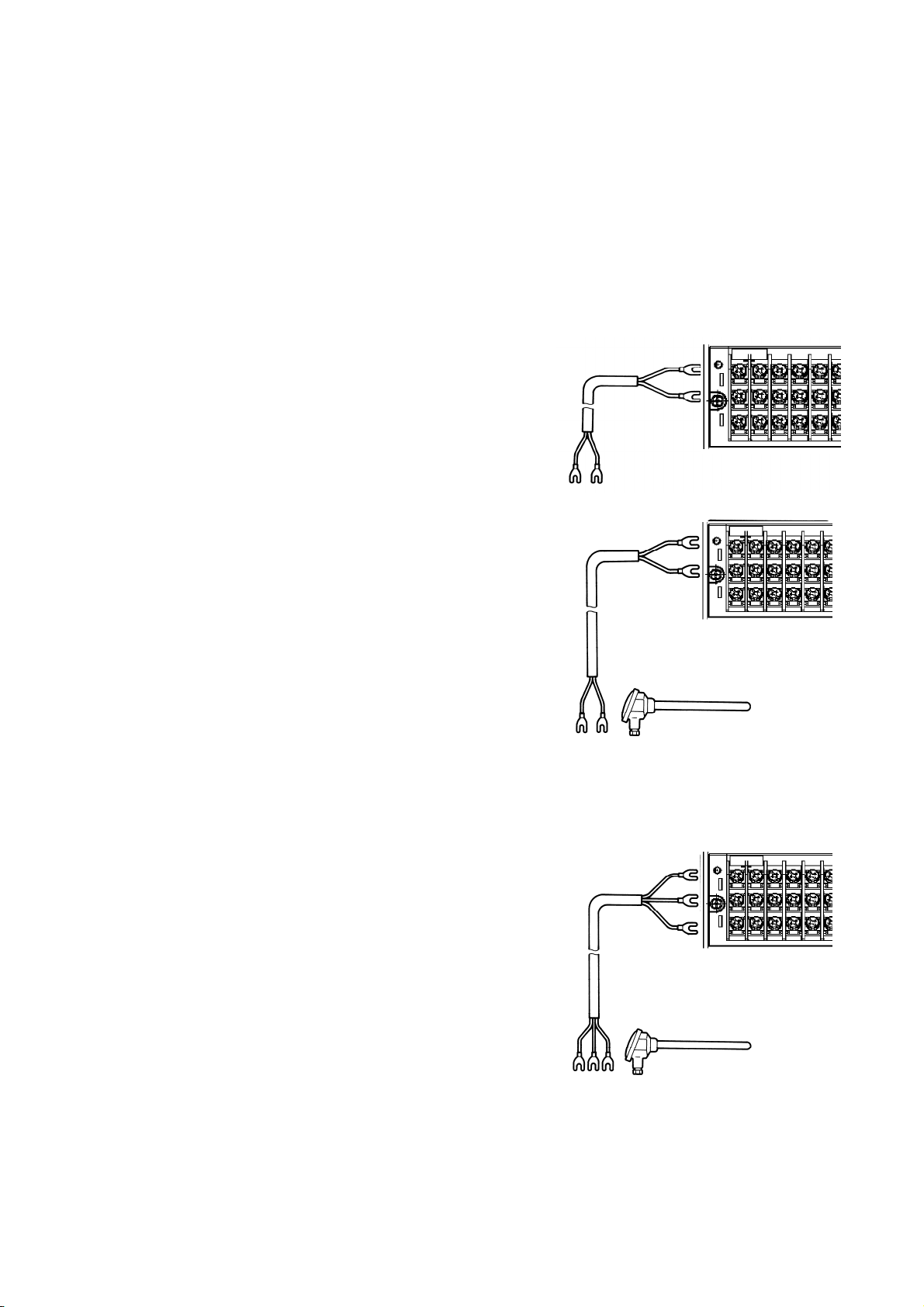

3.6. Wiring of Measurement Input Terminals

(1) Allowable input voltage

•Thermocouple input (burnout disabled), DC voltage input (±2 V max.): ± 10 Vdc max.

•DC voltage input (±5 to ±50 V): ±60 V max.

•Thermocouple input (burnout enabled), resistance thermometer (RTD) input: ±6 Vdc max.

Handling Precautions

•Use crimp terminals with insulating sleeves on the end of wires connected to the inp ut terminals.

(2) DC voltage (or current) input

For input, use twisted cable made for instrumentation

use, in order to suppress noise. For current input,

connect a shunt resistor between the current input

terminals of that channel before wiring.

(3) Thermocouple (TC) input

Be sure to use thermocouple wire (or compensating leads)

to the input terminals of this recorder. If copper wire is

used part of the way, a significant measuring error will

occur. Avoid connecting a pair of thermocouple wires to

another device (controller, etc.) in parallel because such a

connection may affect the measurement of each device. If a

parallel connection is unavoidable, check whether the

effects are within the allowable range under the following

conditions:

•Set the burnout to disabled.

•Ground the device that you wish to connect in parallel at one point. In addition, install the device near the ARF200 and if possible

use t

he same power supply.

•Do not shut off the power of either device during operation.

DC voltage

input

Twisted cable

for

instrumentation

Compensating

wire

(+)

(-)

Red (+)

White (-)

Thermocouple

(4) Resistance thermometer (RTD) input

Use a 3-core cable in which each lead has equal resistance.

Also, do not connect a single RTD in parallel with more

than one recorder (controller, etc.).

3-core cable, each wire having the

same diameter, same length, and

same resistance (each less than

10 ).

B

C

Resistance thermometer

Handling Precautions

・ The allowable amount of noise on the measurement input terminals is 30 Vac (or 60 Vdc) or less.

Because of common mode noise and t he l ike, take care that the allowable noise level is not exceede d.

After wiring, attach the terminal cover to prevent electric shock and protect the input wires. Also, the

terminal cover can reduce the reference j unction compensation error for thermocouple input.

Channels are isolated from each other. Note, however, that the C terminals for RTDs are

・

short-circuited on the AR F _ _ _ AS (100 ms input cycle models) between channels 1 & 4, 5 & 8, and 9

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

10

Page 19

&12 in each input terminal block, and on the ARF _ _ _ AL (1 s input cycle models) the C terminals are

short-circuited between a l l channels in each input terminal block.

11

Page 20

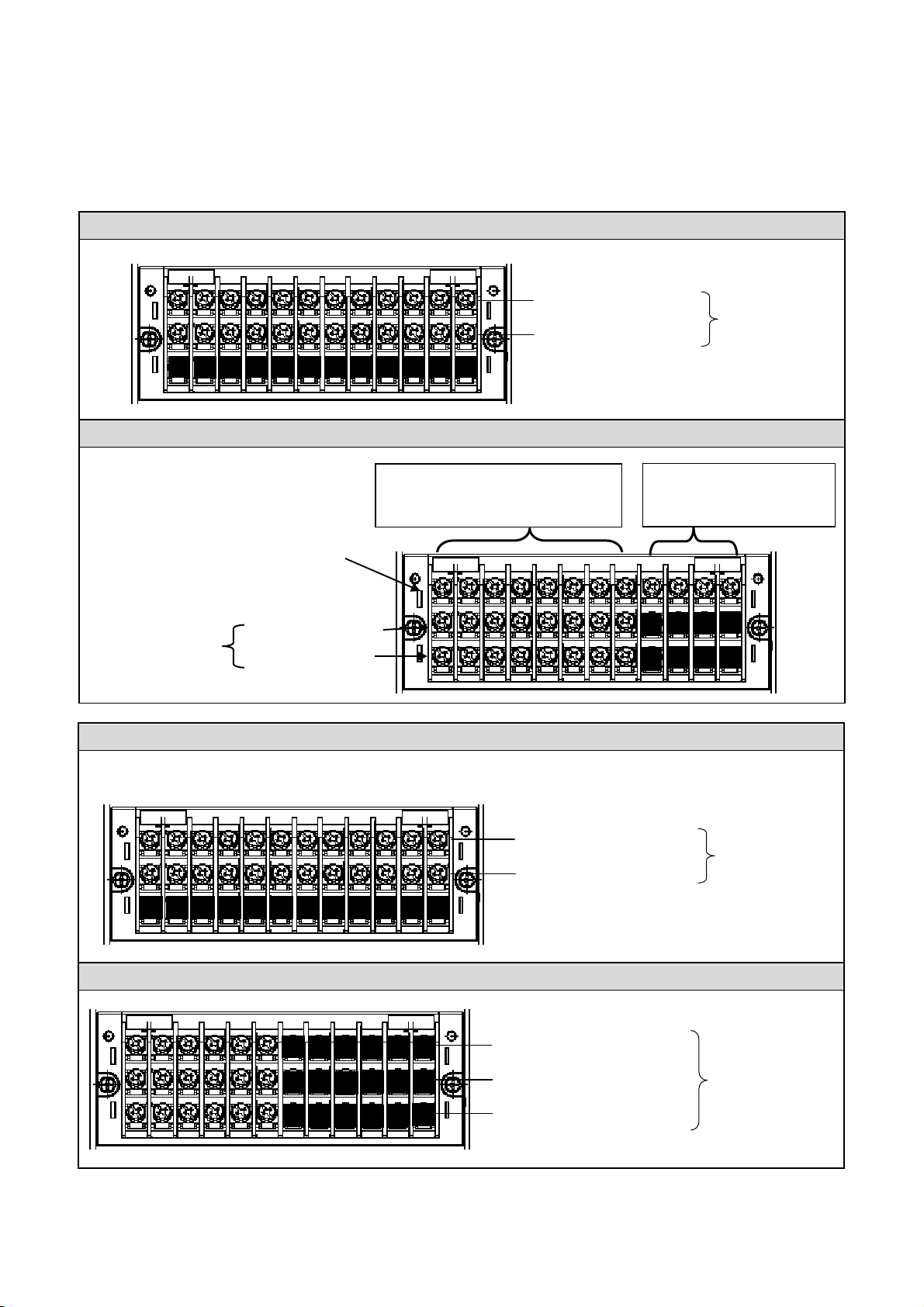

A

3.7. Alarm Output Wiring (for applicable models)

(1) Alarm output terminal layout

The terminal arrangement depends upon the type of alarm output.

Alarm relay output (1a)

MOS alarm relay

outputs (8)

Digital inputs (8)

COM terminals (M3.5)

. te

N.O rminals (M3.5)

N.O. terminals (M3.5)

COM terminals (M3.5)

MOS alarm relay output (1a)

(From left) DI1, DI2, . . . –DI8

Digital inputs (8)

Alarm relay output (1a)

Alarm relay

outputs (12)

Digital input (DI) COM

(4 comm

on inputs)

1 2 3 4 5 6 7

N.O. terminals (M3.5)

COM te

Alarm relay output (1c)

N.C. terminals (M3.5)

COM terminals (M3.5)

N.O. terminals (M3.5)

rminals (M3.5)

Alarm relay

outputs (12)

larm relay

outputs (6)

12

Page 21

y

r

(2) Wiring

Turn off the power supply and buffer relay power supply before wiring to prevent electric shock.

Connect leads to the load via a buffer relay.

Use leads with crimp terminal lugs (with insulating sleeves).

If a voltage of 30 V

ac/60 Vdc or more is applied to the output terminals, connect the

signal lead by a cable terminated by a round crimp terminal lug (with insulating sleeve).

Also, use double insulation (2300 Vac withstand voltage or more) for signal leads to

which a voltage of 30 Vac/60 Vdc or more is applied, and basic insulation (1390 Vac

withstand voltage or more) for other signal leads. After wiring, be sure to attach the

terminal cover to prevent electric shock.

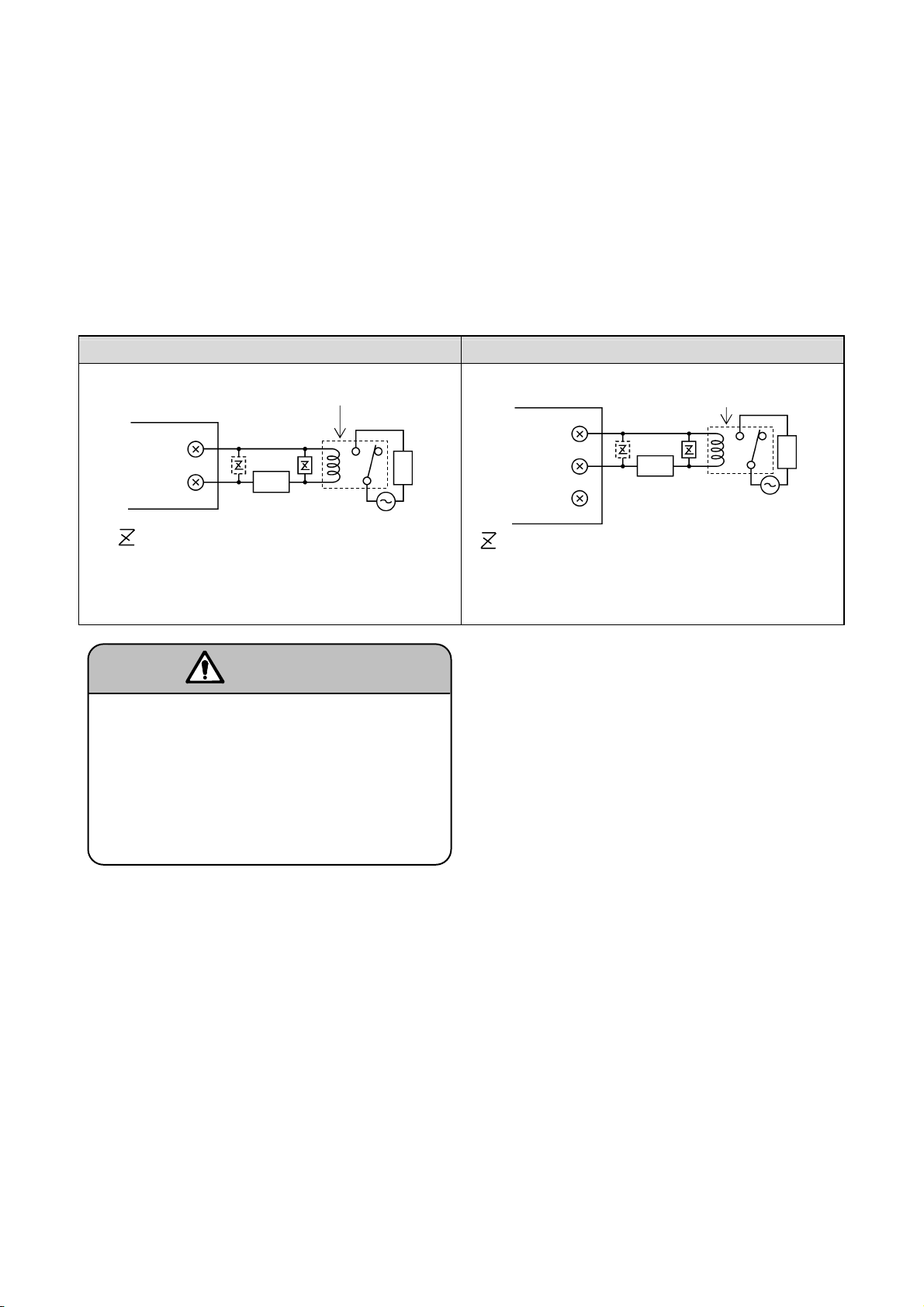

Example of mechanical re lay Form A contact output Example of mechanical re lay Form C contact output

Buffer relay

ARF200

Buffer rela

ARF200

Power

a

Load

Load

COM

: Contact point protective surge absorber

(placement on the “a” side is recommended)

Powe

N.O

COM

N.

C

*

: Contact point protective surge absorber

(placement on the “a” side is recommended)

* The operation of N.C. terminals is opposite to that of

. terminals. They open when an alarm occur s.

N.O

b

Connect a load that is with in t he specified

contact capacity of the alarm output terminals.

Since the power for the buffer re lay is applied

to the alarm output terminals, touching these

terminals will r e sult in an electric shock. Be

sure to attach the terminal cover after wiring.

Warning

Handling Precautions

・ The alarm output device can be damaged by a spark from the buffer relay or breakdown of the surge

absorbing element. Be sure t o take appropriate safety measures as necessary.

13

Page 22

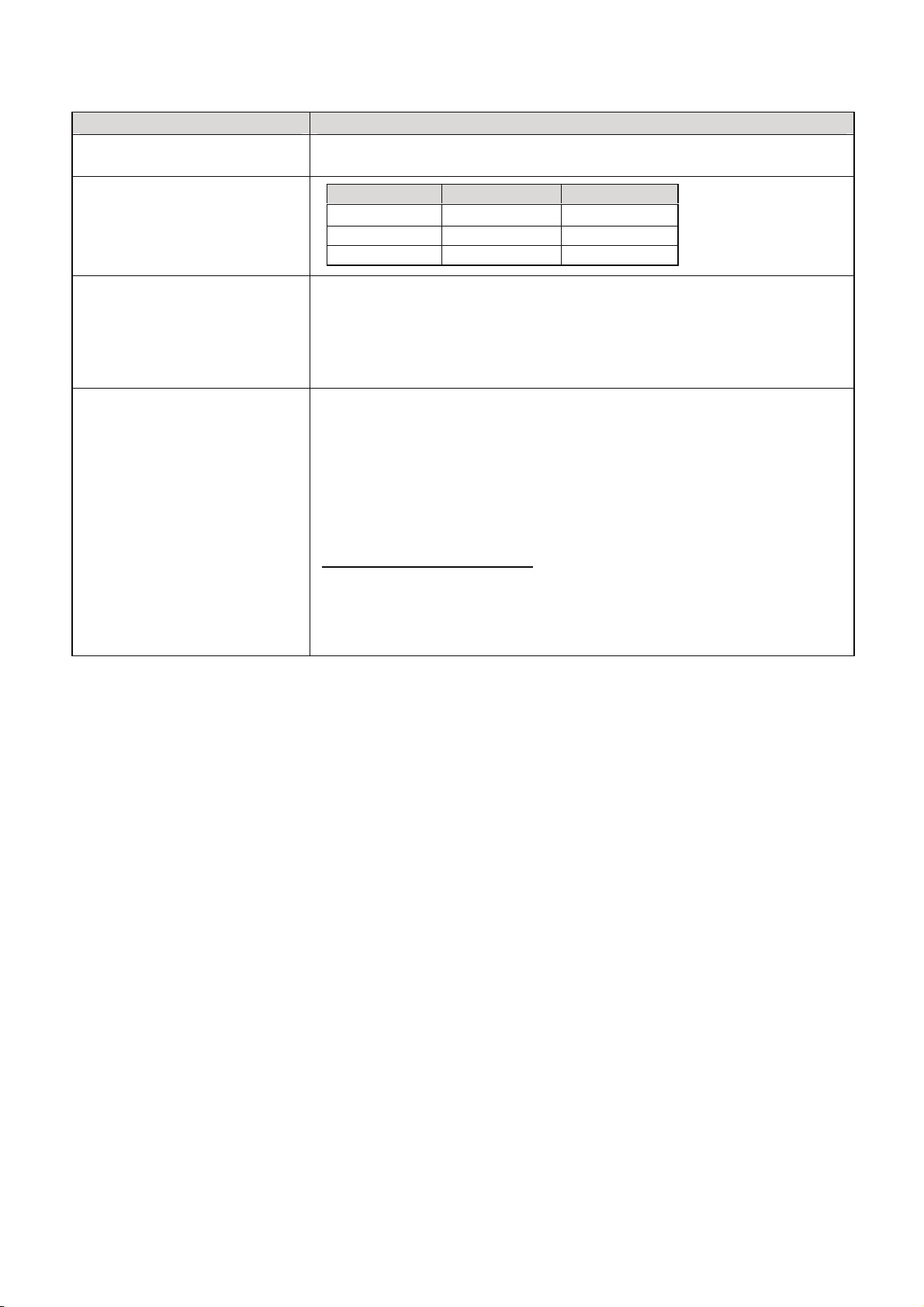

(3) Specifications for wiring

Item Description

Contact rating of mechanical relay

outputs (both Form A and Form C

contacts)

Selection of buffer relay

Selection of surge absorber and

mounting

•

Power supply Resistive load Inductive load

100 Vac 0.5 A 0.2 A

240 Vac 0.2 A 0.1 A

30 Vdc 0.3 A 0.1 A

• Coil rating: less than the contact rating of the output terminals

• Contact rating: more than twice the load current

Minimum load: 100 A

and 100 mVdc

A relay wi th a built-in coi l surge absorption element is recommen ded. Add an

additional buffer relay if the buffer relay does not satisfy the load rating.

• Use an appropriate surge absorber element to protect the contacts if the

buffer relay does not already have one .

• The MOS relay might burn out if a signal exceeding the contact rating is

applied, even momentarily .

• To prevent malfunction caused by a li ght load, the most effective mounting

position for the surge absorber is on the coil si de of the buffer relay (‘a’ in the

wiring diagram in section 3.7, (2)).

• The surge absorber is generally composed of a capacitor (C) and resistor

(R).

Refer ence values for C and R

C: 0.01 F (rating about 1 kV)

R: 100 to 150 (rating about 1 W)

Azbil Corporation’s surge absorber is No. 81446365 -001 (qty. 10).

Handling Precautions

The common terminal of each alarm output is separate from the others.

14

Page 23

・ 3.8. Digital Input Terminals (for applicable models)

(

1) Digital input terminals

Contact input terminals

(2) Wiring

Turn off the power before wir ing to prevent an electric shock.

Use a non-voltage contact signal for digital input terminals.

Use crimp terminals with insulating sleeves on the end of

wires connected to the digital input terminals.

Digital input specifications

Volt age with contact s open: Approx. 5 V

Current when contacts close: Approx. 4 mA short-circu it)

■ Connection example

DI 1 2 3 4 5 6 7 8 COM

15

Page 24

Handling Precautions

・ Relays and switches connected to the contact input terminals should be designed for low voltage/current

load use.

■ DI terminal functions

(1) Digital input Detects ON/OFF (closed/open) state. Set the range type to DI.

(2) Pulse input For pulse input, set the range type to either Pulse (+) or Pulse (-).

(Se

(3) Integration rese t Resets the cum ulative count. When the specified digital input te rminal is energized, the

(See 11.

(4) Marker Writ

(See 11.

(5) File write Starts/stops recording of data in an internal memory file. Recording starts when the digital

(Se

(6) Time correction Adjusts the time when the digital input terminal turns ON.

(See 11.1

S

ee 11.2, “Input Settings.”)

(

e 11.2, “Input Settings.”)

cou

nt is reset.

6, “Totalizer settings.”)

es annotations. Annotations can be written on trends while the digital input terminal is

ON.

8, “Marker settings.”)

inp

ut terminal turns ON.

e 11.5, “File Settings Screen.”)

1, “System Settings.”)

16

Page 25

3.9. Ethernet Connections

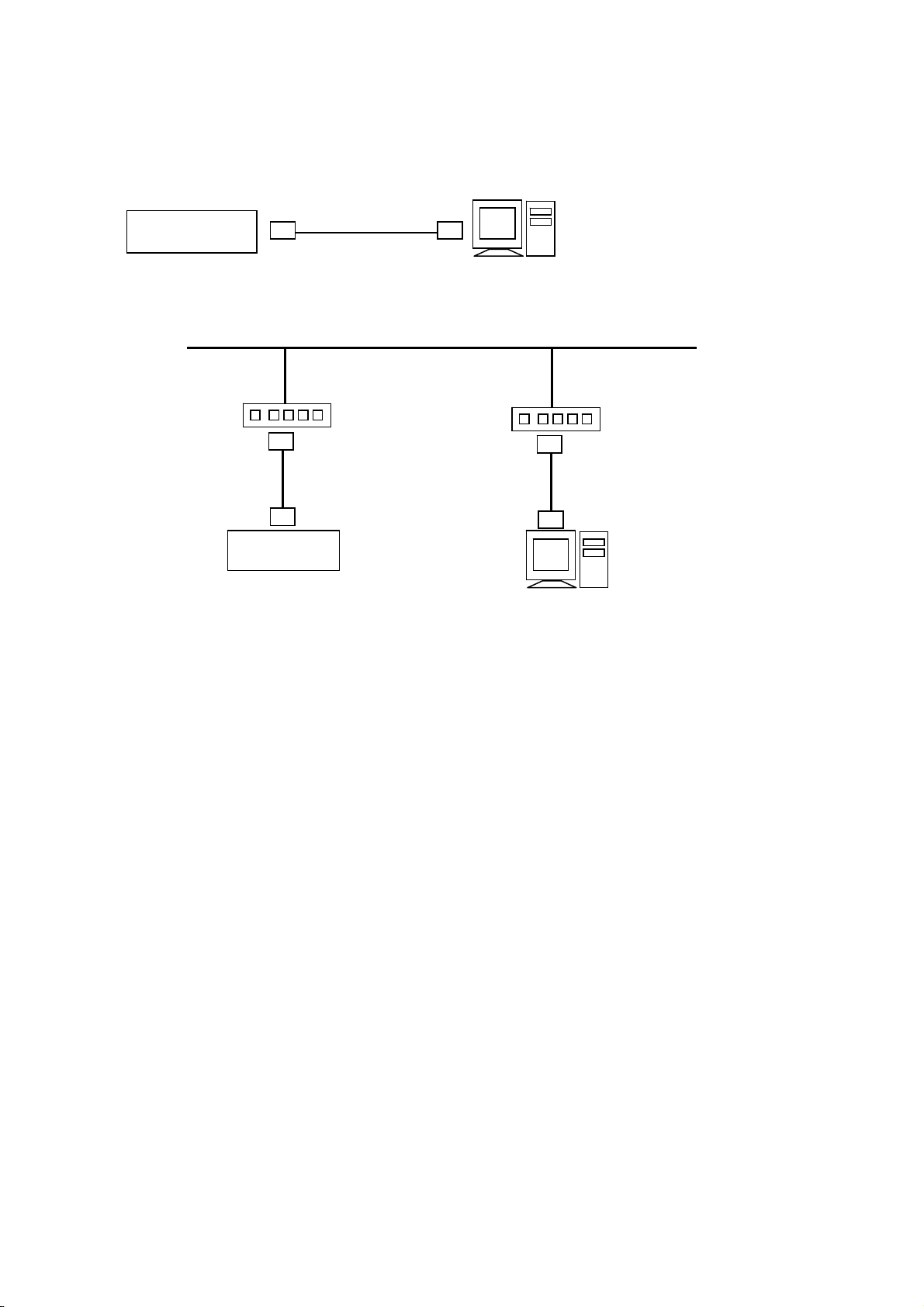

1-to-1 c onne ction with a PC

T o connect the PC and the ARF200 in a 1-to-1 connection, use a crossover cable or a hub.

ARF200

N-to-N connections with PCs

When connecting to multiple PCs or to an existing LAN, use a hub and straight cables between the hub

and ARF or PC units.

ARF200

Crossover cable

PC

(With LAN function)

LAN

Hub Hub

Str aight cable

Str aight cable

PC

(With LAN function)

17

Page 26

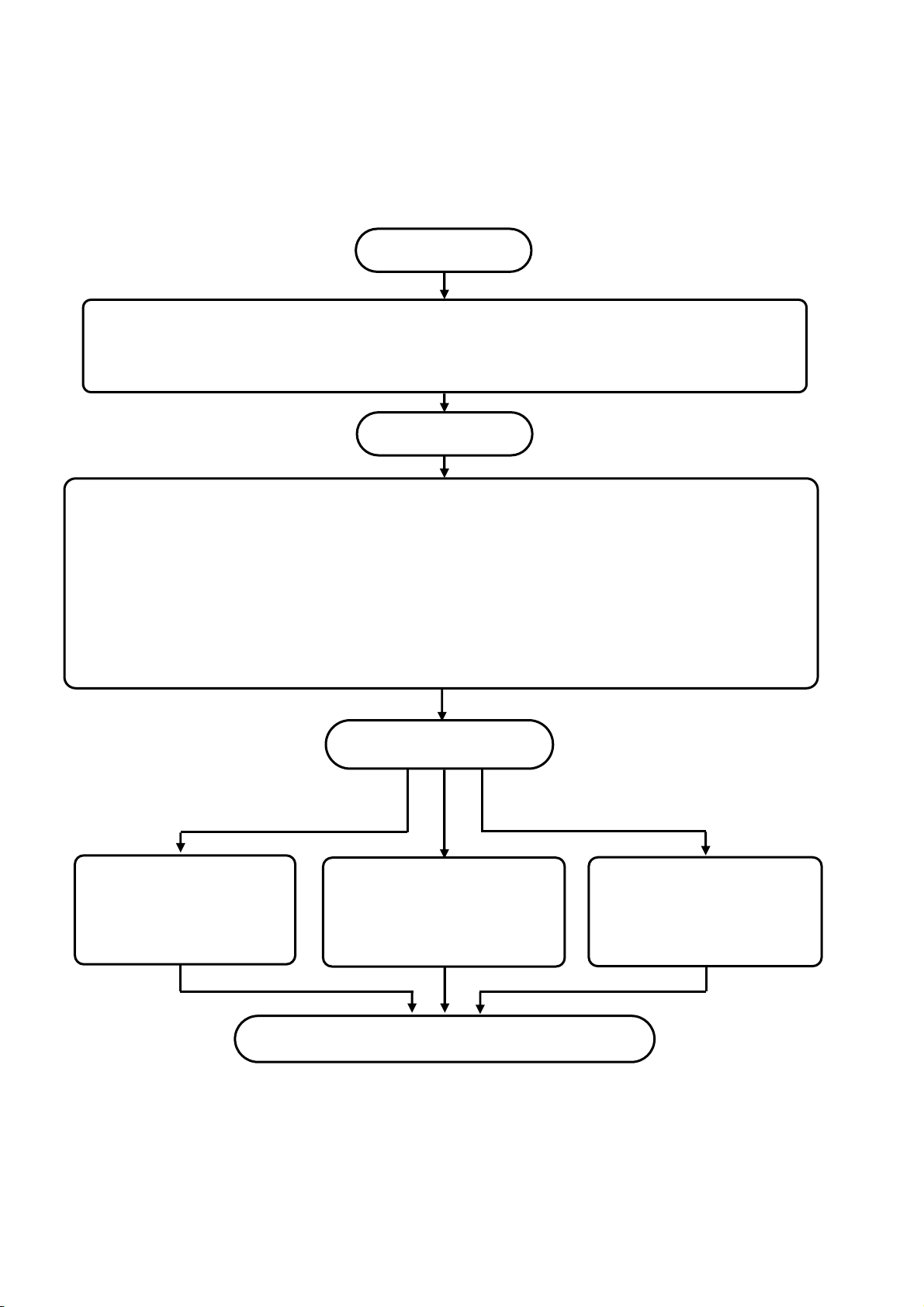

Chapter 4. SETUP

Start

,

,

The ARF200 is shipped with default factory settings. For actual operation, however, be sure to do

the following setup procedures.

Preparations for operation

Mount the ARF200 in a panel and wire it properly .

PowerON

The A R F200 is shipped with default settings, but be sure to change the following settings as

appropriate for the actual application environment and measurement objective.

1. Initial settings (Chapter 8, INITIAL SETTINGS)

2. Settings for input processing, display, and recording, which can be changed either all at once or

separately.

All settings at once: HO ME SCREEN (10.1, Quick Recorder Setup)

Individual settings: MENU SCREEN (11.2, Input Settings; 11.3, Display Settings; 11.5, File

Settings Screen)

Operation

Setting

Screen switching

Chapter 6

St art/stop recording

11.5

File settings screen

Saving to a memory

card

Stop and Power OFF

Note)

On portions of the LCD screen, some pixels may be always lit or always not lit, and there may be

unevenness in brightness due to t he characteristics of the liquid crystals, but these are not malfunctions.

18

Page 27

Chapter 5. FRONT PANEL

5.1. Parts and Functions

Display

12.1-inch TFT color LCD.

For operation screens,

see Chapter 7.

Touch panel

View with key cover open.

Key cover

Keyboard

Power switch

CF card drive

USB connector

Handling Precautions

・ The front panel is ma de of glass. To avoid injuries due to broken glass, protect it from impact.

19

Page 28

5.2. Functions of Keys

The usage and functions of the keys is different depending on whether an operation screen or a

settings screen is displayed. All key operations can also be done on the touch panel, so all operations

are possible with the key cover closed.

Key

START

Starts recording Not used

STOP

Stops recording Not used

SCROLL

Switches the scroll mode on and off, or

moves to the historical trend screen

CURSOR

On the historical trend screen, switches

the cursor mode on and off.

MARKER

Writes an annot ation on the trend

screen

DISP

Displays the DISP menu

Main Functions

Operation screen Settings screen

Not used

Invalid

Not used

Takes a snapshot when pressed and

held

HOME

MENU

Displays the HOM E screen Quits the Home scr een

Displays the MENU screen or returns

from MENU screen to previous screen

Returns to the previous sc r een

ESC

ENTER

Cancels a menu or returns to the

previous screen

Confirms a menu item selection or

displays a menu (the “ENTER menu”)

with varying contents, depending on the

screen.

Returns to the operation screen or to t he

previous screen

Opens the selected menu or ent ers the

numeric value, character, etc. selected

by the cursor. Also, returns to the

operation screen, or stores a para met er.

Arrow keys

These keys select (highlight) a menu

item or change the display group or

channel number.

Arrows move the cursor left, right, up

and down.

20

Page 29

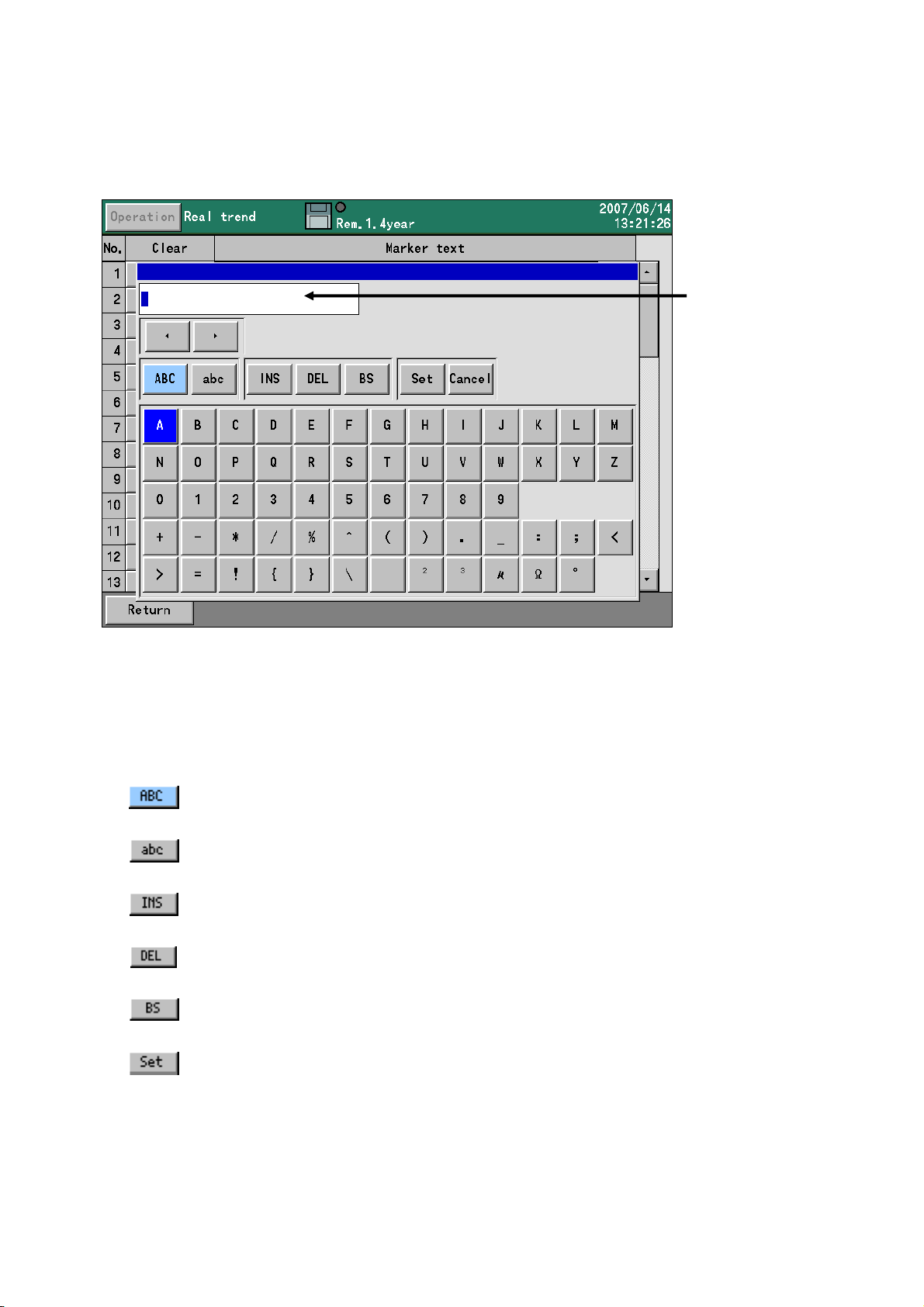

5.3. Character Input

The character input screen seen below is used for setting or entering tags (labels for the channels),

annotations using the marker function, and passwords. Pressing ENTER from a relevant screen displays

the character input screen.

On the character input screen, after moving the focus (indicated in blue) to uppercase letters or

lowercase letters, pushing the down arrow key moves the focus to the row of letters below. Then,

use the arrow keys to move the focus to the desired character, and press the [ENTER] key. The

selected character is then displayed in the character input space.

When selected, uppercase letters, symbols and numerals can be entered.

When selected, lowercase letters, symbols and numerals can be entered.

Insert key. Toggles character input between insert mode and overwrite mode.

Delete key. Deletes the character selected in the character input space.

Backspace key. Deletes the character before the cursor position.

Accepts the string of characters input in the character input space. The

same result can be obtained by pressing the [ENTER] key when the input

Character input space

21

Page 30

5.4 How to Operate the Touch Panel

(

)

All ARF200 operations can be done on the touch panel. If the touch panel is not operating normally or if the same

operation method as on the ARF100 series is preferred, the keyboard can be used.

The ARF200 can be operated intuitively with the touch panel. The following describes basic screen operation

methods. For details on each individual screen, see the descriptions in Chapter 7, OPERATION SCREENS.

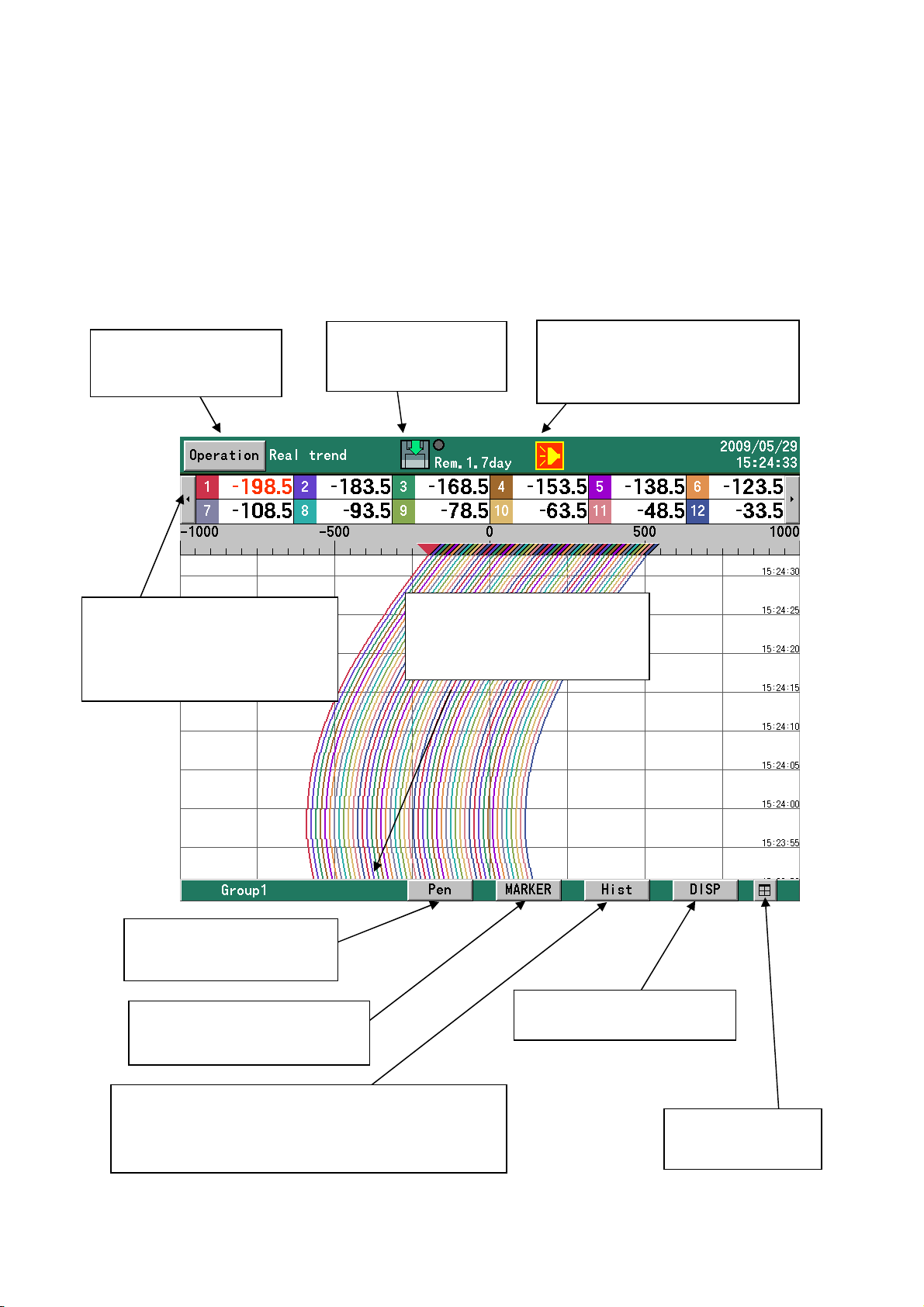

5.4.1 Touch Operations on the Operation Screen

[Operation] button

Displays the operation

menu.

Disk icon

Touching this icon

starts/stops recording.

Channel selection button

This is displayed when all

registered channels cannot be

displayed. Clicking this button

selects the display channels.

Handwritten input on trend s

is possible. (See 5.4.3.)

[Pen] button

[Marker] button

Writes markers on trends. (See

7.3 and 7.6.)

Displays historical trends. While a historical trend is

displayed, [Real] is displayed, and when a trend is

opened from a file list, etc., [Back] is displayed.

[Hist] button

Touching this icon when an alarm

is generated acknowledges the

alarm.

Group selection button

This is displa yed when th ere ar e

multiple groups in use. Clicking

this button selects the group.

[DISP] button

Displays the DISP menu.

Alarm icon

See 7.2.

[Split] button

Displays the screen

split into 4 sections.

22

Page 31

<[Operation] menu>

Menu Item Description

Start recording Starts recording. Same as the START key

Stop recording Stops recording. Same as the STOP key

HOME setting Opens the HOME settings. Same as the HOME key

MENU setting Opens the MENU settings. Same as the MENU key

<[DISP] menu>

Menu Item Description

Select display Changes the operation screen type.

Select group Changes the display group.

Automatic switching Turns automatic switching of groups and channels ON/OFF. A

checkmark indicates that this item is ON. It is disabled when "0" is

set for the automatic selection time.

Snapshot Saves a hard copy of the screen to the CF card (SNAPSHOT)

folder.

Pause Stops screen refreshing except for the status bar. Press any k ey to

resume. During a pause, compilation, recording, and all other

processing except drawing is executed. Also, a snapshot can be

taken during a pause by clicking the DISP key.

Display off Turns the LCD display off. Press any key to turn the display on

again.

4-frame split screen Displays the screen split into four sections.

Expansion/

compression

<Touch operation in a 4-frame split scre en display>

The display type and group can be selected in each frame by touching the DISP button. For details see

5.5. Also, operations on each fra m e can be executed by clicking the group selection button and marker

button for the frame.

Trends can be displayed with the time axis compressed (same size

to 1/60).

23

Page 32

5.4.2 Touch Operations in Setting Screens

On the MENU and HOME set t ings screens, settings can be changed most easily by touch. To enter a

value for any item, touch the but t on w it h t he ▼ ma r k .

To return to the previous screen, click the [Bac k] but ton.

On screens with a scroll bar, information can be scrolled by touching and moving the scrol l bar. Als o,

screens can be scrolled one at a t ime by touching above or below the scroll knob.

Note

• Do not rub or press a knife or other sharp object on the touch panel.

• Avoid storage or use in atmospheres subject to water, organic solvents and acid, or where the touch panel

• Avoid use in locations exposed to direct sunlight.

• Wipe off dirt from the touch panel using a soft, dry cloth or a cloth moistened with a neutral detergent or

Cautions When Us ing the Touch Panel

may come into contact these liquids.

alcohol. If chemicals come into contact with the touch panel, wipe off immediately.

• Condensation is a natural phenomenon and can occur inside the touch panel. If the touch

panel is brought close to room temperature, condensation will disappear naturally. However,

use of the touch panel with condensation inside should be avoided, since it can cause a

malfunction.

Scroll button

Scroll knob

Scroll bar

24

Page 33

5.4.3 Handwritten Input on Trend Screens

On the real trend screen and historical trend screen, handwritten notations can be freely made by

touching the display and d rawing your finger along it.

To write with your finger, touch

When handwritten in put is enabled,

If [Pen] is touched again, drawn details are fixed and saved, handwritten in put is turned off, and from then

on regular touch operation is possible. Drawn content that was saved can be read again into internal

memory, CD card and USB memory. (See "7.10 CF Card/USB Memory Screen.")

(Delete operation)

Toggles handwritten

input on/off.

once to enable the function.

is displayed in yellow as shown below.

Handwritten input

example

Sets line thickness

and color.

Erases drawn

content.

If

If the drawn content is con t inuous, all of it will be deleted in a single operation. However, if it is not

continuous, only the previ ously drawn locus will be deleted. Further touches of the but t on will delete loci in

the order of input, starting fro m the most recent locus.

Note: Once content is saved by touching the [Pen] button, it cannot be deleted with [ Undo].

is touched while writing on the touch screen, the previously draw n cont ent is deleted.

25

Page 34

(Setting operation)

The thickness and color of handw rit t en input can be be changed by touching

10 line thicknes ses

are available.

16 line colors are

available.

Supplementary Explanation

The number of handwritten points is obtained by periodically sensing and sampling coordinate

data when the touch panel is touched. T he m aximum number of points that can b e input is 8,000.

When the number of drawn points exceeds this limit, the oldest points are erased.

It is difficult to dist inguish v isually how m any points ha ve been inp ut. However, since the num ber

of points is sam pled peri odicall y, writing slowly with the pen will res ult in m ore p oints being used;

and alternativel y, writing quickly will result in fewer poin ts being use d.

The thickness of the loc us, and the size and color of the font bear no relation to the num ber of

points consumed.

The reference figure below shows the number of handwritten points recognized by internal

processing on the recorder.

Number of Handwritten Points

3 points used for

1 touch

.

← Fine Thick →

Example of use

Quickly drawn:

approx. 8

points used

Slowly drawn:

approx. 80

points used

26

Page 35

5.4.4 Automatic Scrolling on the Historical Trend Screen

Section 5.4.2 dealt with touch operations on screens with a scroll bar. On the historical trend screen

(see 7.6, “Historical Trend Screen”) and the dual trend screen (7.7, “Dual Trend Screen”), on which

recorded data can be played back , the scroll bar can be made to move automatically by swiping the

screen as if to move it to see the latest part of the graph.

In response to this, the trend screen moves automatically, and automatic scrolling continues until the

screen is touched again. The same operation is possible on historical trends read from either internal

memory or external memory.

Automatic scrolling is possible also while the cursor is display ed. The cursor position tracks as required.

1. Swipe

2. Bar flows

automatically.

27

Page 36

5.5 Operations in 4-Frame Split Screen Display

The screen of the recorder can be split into four sections for displaying inf ormation simultaneously on

four separate screens. However, on a split screen display, the selectable display type is limited. Only

trend time charts, numeric displays and bar graphs c an be selected.

<How to switch from 1-screen display to 4-frame split displ ay>

• Select "4 scre ens" from the DISP menu.

• Touch the

4-frame split screen display can be selected by either of the above methods.

<How to switch from 4-frame s pl it screen display to 1-screen display>

• Touch inside the frame to be expanded.

• Touch the DISP button of the frame to be exp anded, and select "1 screen."

• Click the DISP key to set to the frame selection mode*, click the direction key to select the frame

to expand, and clic k the E NT ER key.

1-screen display can be sele ct ed by any of the above methods.

(*Frame selection mode)

In the 4-frame split screen display, the frame selection mode is entered by clicking the DISP key. In this

mode, the selected frame can be moved using the direction keys, and the following key operations are

possible.

ENTER Displays t he current ly selected frame as a single screen.

DISP Displays the DISP menu for the currently selected frame. The content

ESC Cancels frame selection mode.

In frame selection mode, t he currently selected frame is enclosed by a blue frame.

Currently

selected frame

icon at the bottom right.

selected in this DISP men u is used in the currently selected frame.

28

Page 37

Chapter 6. SWITCHING SCREENS

When the power is turned on, initialization takes about 10 to 30

seconds, and then an operation screen is displayed. With the factory

(Initialization

screens)

Approximately

10 to 30

Switch between different types of operation screen with the DISP menu.

(1) Press [DISP] key to display the DISP menu.

(2) Use the [arrow] keys to highlight y our sel ect ion, and then press [ENTER] key. The selected

When “Auto switching” is select ed (checked off), the display automatically swit ches between groups at

a fixed interval.

seconds

screen is displayed.

x “Select display” selects the operation screen type (real time trend, numeric display, etc.).

x “Select group” selects the group to be dis played.

settings, the operation screen that is displayed is the real-time trend

screen. However, generally when the power is turned on, the operation

screen that was being viewed when the power was turned off is

displayed.

To set parameters, push the [HOME] key or [MENU]

key from an operation screen, and the display switches

to one of the settings screens.

Open the key cover

(During key operation)

Switching to a settings screen

HOME

MENU

Switching Between Operation Screens

29

Page 38

Home screen

On the Home screen it is easy to configure the same settings on all channels. The settings

available on the Home screen are restricted, however, and settings cannot be changed on the

Home screen while recording is in progress. Also, changing the recording cycle is possible for group

1 only.

MENU screen

Configuration is do ne mainly on the MENU screen. All items can be set here. Even if recording is in

progress, all settings can be di splayed, although some settings cannot be cha nged. These settings

are displayed in gray.

30

Page 39

Chapter 7. OPERATION SCREENS

7.1. Common Key Functions

7.1.1. Use of the keys

START

STOP

DISP

With touch operation, [Operation] → [Start recording]. O r, touch the disk icon.

Starts data recording. The data for any group which has been set to be recorded is

stored in the internal memory. Any group for which recording conditions have not been

set remains in standby state, and recording begins when conditions are set. Any group

for which recording conditions have not been set is in standby state. Files are

automatically saved to the CF card at fixed intervals and when they are complete.

With touch operation, [Operation] → [Stop recording] . O r, touch the disk icon.

Stops data recording for all groups. Files being written are completed and are stored

on the CF card.

With touch operation, touch the [DISP] button.

Displays the DISP menu

Menu item Operation

.

Select display Selects the operation screen type.

Select group Selects a group for display.

Auto switching Enables or disables automatic switching betw een groups and

channels. Switching is enabled when checked. The auto matic

switching cycle can be set between 1 and 60 seconds (MENU

screen > Display settings > Commo n parameters > Screen auto

switch period). If the automatic switching time is set to zero,

automatic switching does not operate.

Snapshot Saves a copy of the screen to the SNAPSHOT folder on the CF

card.

Stops refreshing of screens other than the status bar. Pressing

any key refreshes the display. During a pause, all processes

Pause

Display OFF Turns off the LCD display . The display turns on again if any key

4-split screen Displays the screen split into four sections.

Expansion/compression Trends can be displayed with the time axis compressed. (same

other than drawing, such as data recording and data storage,

are executed. Snapshots also are executed during a pause by

pressing the [DISP] key.

is pressed.

size to 1/60)

31

Page 40

HOME

MENU

ENTER

ESC

With touch operation, [Operation] → [HOME setting].

Displays the HOME screen.

With touch operation, [Operation] → [MENU].

Displays the MENU screen.

With touch operation, differs according the screen.

On many screens, displays a menu. Menu contents differ depending on the screen.

With touch operation, [Back] b utton (in the settings screen)

Returns to the previous screen (except when the present screen is the real-time trend,

bar graph, or numerical display screen).

32

Page 41

When trends are displayed vertically, the up and down keys switch the displayed

group and the left and right keys switch the displayed channels.

When trends are displayed horizontally, the left and right keys switch the displayed

group and the up and down keys switch the displayed channels.

With touch operation, N/A

33

Page 42

7.1.2. Displayed data

Readings and messages displayed on screens

Data or message Description

(Numeric value) Numeric values are displayed based on the scale settings for each channel. The

number of digits after t he decimal point is determined by the maximum and

minimum values of the scale.

If the numeric value is in exponential format, it is shown in the format “1.2E+ 3. ” In

such a case, display of up to 2 digits after the decimal point can be set, but

possibly only 1 digit wil l b e shown, depending on the screen.

BURN Burnout, open circuit.

OVER A signal exceeding the measurable upper limit (upper limit + 5 % of the ran ge) was

input. Or, the calculated result exceeds the value tha t can be indicated.*

UNDER A signal falling be low t he me asurable lower limit (lower limit - 5 % of range) was

input. Or, the calculated result falls below the smallest value that can be indicated.*

CAL ER Calculation error. The equation is not correct. Or, an error (BURN, OVER, UNDER,

or CAL ER) occurred o n the channel used for the equat i on.

RJ ERR Abnormal conditions were detected. Thi s message is displayed when an input

circuit is open, or when the dev ice f or ref erence junction compensation is

damaged.

*The ranges that can be indicated for ca lculated results are as foll ows:

Standard format: ±30000, excluding the decimal point. For example: -30.000 t o + 30.000.

Exponential format : 1.00E-15 to 9.99E+15

The numeric data displayed is current (at 0.5 second intervals) irrespective of the recording cycle,

etc., except for historical data displayed as part of historical trends or dual trends. To slow down

the updating speed, change the numeric value display update interval (see 11.3.4).

34

Page 43

7.2. Status Bar Information

The status bar is always at the top of the screen. It shows information such as the status of the

recorder. If a schedule is set (see 11.7), the background color of the status bar is gray for periods

other than the scheduled period.

Currently sele cted

screen type

Group name, etc. is displayed at the bar below.

AUTO display is not available. (See 5.4.1.)

Disk icon showing

recording status etc.*

Alternately display s t he recording interval

and the approximate remaining recordable

period of the currently displayed group.

Alarm icon**

Current time

35

Page 44

The Disk Icon

• The recording state of the currently display ed group is indicated by an arrow state.

Arrow State

Flowing up Recording is in progres s.

Flashing The START key was clicked, but the recorder is in a recording standby

state since recording cond it io ns have not been met.

Hidden The START key has not been clicked. (stopped by STOP key)

• The state of the CF card is indicated by background color.

Background

color

Gray Normal

Yellow The amount of space left on the CF card is 10% or less. (When the

Red There is no space left on the CF card. (W hen the overwrite mode (13.11.4)

• When “x” is displayed on t he di sk mark, this indicates that the CF card is not inserted.

• The round mark at the top right of the icon indicates the access state on the CF card. When this

mark is red, do not remove the CF card. Doing so might damage or destroy the data. Before

removing the CF card, make sure that the round mark is gray.

Color State

Gray The CF card is not being accessed.

Yellow Data will be written to the CF card within about 5 seconds.

Red The CF card is being accessed.

When “USB memory” is selected at “External Memory Selection” (see 13.11.17), “USB” is displayed

on the icon. In this case, data is saved to the connected USB memory. For details on USB memory,

see “15. Recording Data to USB Memory.”

State

overwrite mode (13.11.4) is set , t he display does not turn yellow.)

is set, the display does not t urn red. )

When an alarm occurs, the alarm icon is shown in t he status bar. The alarm icon staus is turned by the

alarm status and the alarm acknowledgment status. To clear the alarm icon display, alarm

acknowledge operation in the ENTER m enu of the operation screen is required or the alarm icon m ust

be touched.

Alarm status Alarm acknowledgment (ACK) status Icon status

No alarms — Not shown

Recent alarm Not acknowledged yet Interior blinking

Recent alarm Acknowledged Lit

Old alarm Not ac knowledged yet Blinking

Old alarm Acknow l edged Not shown

**The Alarm Icon

36

Page 45

7.3. Real-time Trend Screen

A

}

The data trends can be viewed as on an analog recorder. Up to 4 scale bars can be displayed. A “pen”

for each channel is positioned on the scale bars according to the display position setting for the

channel. If the same display position is set for multiple channels, the scale numbers on the scale bar

apply to the channel with the lowest channel number. Pens and trends of the other channels on the

scale bar are displayed in the correct relative position, taking the scale bar width as 100% of the

each channel’s range.

The data reading for a

channel with an active

alarm is shown in red.

Scale bars

nnotation

made with

marker

function

The ENTER menu

Expansion/

compression

With touch operation, the same items as i n the DISP menu are avai lable.

Trends can be displayed with compression of the time axis. (Same magnification to

1/60)

Special functions of keys (see 7.1 above for other functions)

SCROLL

MARKER

With touch operation, [Hist] button

Displays the historical trend (or dual trend) screen. The same can be done by

selecting historical trend (or dual trend) in the DISP menu. SCROLL displays

the type of screen (historical/dual) that was last selected from the DISP menu.

With touch operation, [Ma r ker] button

The marker dialog box for adding an annotation

is displayed. The marker cannot be used if

recording is stopped. Either input a text or

select a text already input (using the MENU

settings) and add the text to the trend screen by

pressing [ENTER] key. If “Input Text” is

selected, the character input screen is displayed.

Display options for

this section are: dat a

display (with or

without a tag), bar

graph, and no display.

37

Page 46

7.4. Bar Graph Screen

On this screen, bar graphs display the readings for each channel in real time, for easy visual

evaluation. The scales and length of the bars are determined by the display scale of the channel with

the lowest channel number in the group.

The ENTER menu

Not available

Special functions of keys (see 7.1 above for other functions)

None.

Display options for this

section are: data display

}

(with or without a tag), and

no display.

7.5. Numeric Display Screen

Data readings for each channel and alarm status are displayed. Depending on the number of

numeric data display frames and the number of registered groups, the data for 1, 2, 3, 4, 6, 8, 9, 10,

12, 24, 36, 48 or 56 channels is displayed.

The data reading for a

channel with an active

alarm is shown in red.

The ENTER menu

Not available

Special functions of keys (see 7.1 above for other functions)

Not available

38

Page 47

7.6. Historical Trend Screen

play

Previously recorded data can be played back in trend format. If “Historical trend” is selected from

the DISP menu (or if [SCROLL] key is pressed while the real-time trend screen is displayed),

internal memory is displayed.

Data for

the cursor

position is

dis

Marker

function

annotation

Cursor

line

{

ed.

The ENTER menu

When a file has been selected

from the “Internal memory”

screen, “CF card” screen or

“USB memory” screen, the data

of the target file is displayed.

The scales, trends and pens

conform to the current settings

for the real-time trend screen.

Expansion/compression

(With touch operation)

The same items as in the DISP menu are available.

Trends can be displayed with compression of the time axis. (Same

magnification t o 1/60)

Special functions of keys (for functions see too 7.1 below)

When the trends are displayed vertically, the up and down keys switch the

displayed group and the left and right keys switch the displayed channels.

When the trends are displayed horizontally, the left and right keys switch the

displayed group and the up and down keys switch the displayed channels.

SCROLL

CURSOR

MARKER

Pressing this key activates scroll mode, which is indicated by a yellow frame

around the indicator line on the scroll bar. In scroll mode, the arrow keys scroll

the trends screen by screen. When SCROLL is pressed again, scroll mode turns

OFF and the arrow keys scroll the trends a pixel at a time.

With touch operation, select display channel → channel selection button on left

and right of data display area

Cursor movement → Tou ch t rend.

Scroll → Operate scroll bar.

Pressing this key activates cursor mode, in which a cursor line is displayed in

yellow. When an arrow key is pressed, the cursor line moves without scrolling the

trends, and the data for the cursor position is displayed on the upper display in

numerical format (or as a bar graph).

With touch operation, [Ma r ker] button

The marker dialog box is displayed. Select a text

already entered (in the MENU settings) and insert it

at the cursor position by pressing [ENTER]. Or,

select “Input Text.” The character input screen is

displayed and a new text can be input.

39

Page 48

With touch operation, touch the H, L icons on status

HOME

bar

If the data format set for the displayed file is

maximum/minimum, the numeric value display (or

bar graphs) show maximum and minimum values.

The status bar will indicate either H (= high or

max.) or L (= low or min.). Other functions of the

[HOME] key are the same as elsewhere.

40

Page 49

7.7. Dual Trend Screen

The screen is split into upper and lower

parts to display both real-time trends

and historical trends, allowing them to

be easily compared. The numerical data

section is also split, and shows both

current readings and the readings for

the cursor position in the historical

trends. The trend format, pen positions,

etc. are the same as on the real-time

trend screen.

However, if the recorder is set to display multiple scales, only 1 scale is displayed, and no

numeric values are displayed on the scale. Otherwise the operation of this screen is the same as

for the historical trend screen.

The ENTER menu

With touch operation, the same items as in the DISP menu are available.

Expansion/compression

Trends can be displayed with compression of the time axis. (Same

magnification t o 1/60)

Special functions of keys (see 7.1 above for other functions)

Same as for historical trends (see 7. 6).

Upper row:

}

current data

readings

Lower row: data

for the cursor

position in the

historical trends

7.8. Alarm Display Screen

Alarms that have occurred are listed. Activation

(alarm occurrence) date and time, cancellation

date and time (when applicable), channel number

or tag, and alarm types are displayed in reverse

chronological order (latest on top). All alarms that

have occurred are displayed, without regard to

groups. The maximum number of alarms in the

list is 1000. When the number of alarms exceeds

1000, the oldest alarm information is overwritten.

The ENTER menu

The trend display for the selected row at the date and time of the alarm will appear. If

Trend

display

recording was not in progress when the alarm occurred or if the file cannot be found, the

trend will not be shown. The internal memory is searched for the file first, and then the CF

card is searched.

The selected row is highl ighted in yellow.

41

Page 50

Special functions of keys (see 7.1 above for other functions)

Up and down arrows move the yellow highlighting up and down.

Left and right arrows are not used.

SCROLL

With touch operation, operate the scroll bar.

Operation is the same as on the historical trends screen. See 7.6 above.

42

Page 51

7.9. Internal Memory Screen

This screen lists the files contained in the

recorder’s internal memory. The start date

and time, the end date and time (the last

moment of recording) and the number of

records (data count) are displayed. Files are

displayed in chronological order (latest on

top). All files in the selected group only are

displayed.

The ENTER menu

With touch operation, the ENTER menu is displayed by touching a row in the list.

Trend display The trends recorded in the file of the selected row will appear.

Special functions of keys (see 7.1 above for other functions)

The selected row is

highlighted in yellow

Up and down arrows move the yellow highlighting up and down.

Left and right arrows are not used.

SCROLL

With touch operation, operate the scroll bar.

Operation is the same as on the historical trends screen. See 7.6 above.

43

Page 52

About internal memory

The ARF200 writes all data to internal memory as a file. The recorded data is copied to the CF

card at a preset interval and when rec ordi ng i n a f il e is complete.

• File size. When data reaches the maximum file size in internal memory, the file is completed.

File sizes can be calcul at ed by the following formula:

File size = Data size x number of channels x number of record ings

Data size is norm ally 4 bytes in binary expressi on and 6 bytes when the data format is

“max/min”.

When recording ends when recording conditions are not established, the STOP key is

Limitations on internal memory

pressed or the power is turned off before the maximum file size is reached, recording is

concluded at that time.

Number of

Groups Used

Max. File Size

(KB)

Number of

Recordings

When 12 Points

Are Used

(4-byte data)

1 3904 83280

2 1920 40960

3 1216 25940

4 896 19110

5 704 15010

6 576 12280

Note)

If a file is saved in CSV format, the numbers of records listed above will be the approximate

number of lines. For example, if 12 inputs are used by 3 groups, the number of lines per file is

approximately 25,940.

If the number of lines is limited by the spreadsheet software, etc., change the number of

records (the number of lines) by resetting the recording cycle, referring to “Setting file size” in

11.5, “File settings.”

• Number of files. The maximum number of files that can be saved in the internal memory is

250. For files per group, divide 250 by the number of groups and round down.

• Total capacity for files. The total file size that can be saved in the internal memory can be

computed by: 64 KB × (125 ÷ (Number of groups) – 2). If the data exceeds this size, files will

be deleted, starting with the oldest.

44

Page 53

7.10. CF Card/USB Memory Screen

This screen shows a list of files stored on the

CF card or the USB memory for the group

identified in the status bar. The screen

displays the start date and time, the end date

and time (or the time of the latest recording,

if recording is in progress), and the number of

records (data count). Files are displayed in

reverse chronological order (the latest on top).

All files in the selected group only are

displayed.

If data is stored in binary format, the number

of records is displayed in the Data count

column. If data is stored in CSV format,

instead of the number of records, “(Text)” is

displayed in the column.

The ENTER menu

With touch operation, the ENTER menu is displayed by touching a row in the list.

Trend display

Delete

FTP transfer

For binary files, the trends recorded in the file referred to by the selected row

will be displayed.

Deletes the file in the selected row. However, deletion is not possible while

recording is in progress.

Send the file in the selected row to the FTP server. See 11.10.4, “FTP client

configuration.”

Special functions of keys (see 7.1 above for other functions)

The selected row is highl ighted in yellow.

Up and down arrows move the yellow highlighting up and down.

Left and right arrows are not used.

SCROLL

With touch operation, operate the scroll bar.

Operation is the same as on the historical trends screen. See 7.6 above.

45

Page 54

7.11. Marker Screen

Shows a list of annotations recorded on the

trends with the marker function. The date

and time and the annotation are displayed in

chronological order (latest on top). Only

annotations in the selected group are

displayed.

A maximum of 200 annotations can be

recorded. If the number of annotations

exceeds 200, the oldest annotation is

overwritten.

The ENTER menu

Trend

display

Delete

Delete all

Special functions of keys (see 7.1 above for other functions)

The trend at the position of the marker for the selected row will be displayed,

unless the file cannot be found.

Deletes the marker on the selected row. However, markers cannot be

deleted from a complete d file on the CF card.

Deletes all markers. However, markers cannot be deleted from a completed

file on the CF card.

The selected row is

highlighted in yellow.

Up and down arrows move the yellow highlighting up and down.

Left and right arrows are not used.

SCROLL

With touch operation, operate the scroll bar.

Operation is the same as on the historical trends screen. See 7.6 above.

46

Page 55

Chapter 8. INITIA L SETTINGS

When the power is turned on with the default factory settings or when the settings are initialized, the initial

settings screen will appear. Set parameters for the following, at a minimum:

・Language

・Power frequency (50/60 Hz)

・Usage group count

・Clock

・Input

・Display

・File

You can exit without changing anything. In that case, the paperless recorder operates with the

default factory settings.

Press [ENTER] key when the above message is displayed. The message disappears and the

settings can be changed.

1) L anguage

Move the focus to “Language” with the arrow keys and press [ENTER]. A pull-down menu is

displayed. Select English or Japanese and press ENTER to finalize the choice.

47

Page 56

2) Power frequency

The sub-screen is displayed by touching the ▼ button for the 50Hz/60Hz item.

The selected item is displayed by touching the item to set from 50Hz or 60Hz in the sub-screen. Before

setting this, check the frequency of the power supply you are using.

3) Usage group count

The sub-screen is displayed by touching the ▼ button for the Usage group count item.

• The usage group count can be set between 1 to 6.

• The smaller a usage group count is set, the longer the time that internal memory can be recorded

becomes. (See “7.9 Internal Memory Screen.”)

48

Page 57

4) Clock settings

The clock setting screen below is displayed by touching the [Set] button at the Clock settings item.

For detailed setting instructions, refer to “11.11.1. Clock”. (Page 101)

5) Input settings

The input setting screen below is displayed by touching the [Set] button at Input settings item.

For detailed settings instructions, refer to “11.2 Input settings”. (Page 59)

49

Page 58

6) Display settings

The display setting screen below is displayed by touching the [Set] button at Display settings item.

For detailed setting instructions, refer to “11.3.1. Channel parameters”. (Page 68)

7) File settings

The file setting screen below is displayed by touching the [Set] button at File settings item.

For detailed setting instructions, refer to “11.5. File settings screen”. (Page 81)

50

Page 59

p

t

)

g

s

k

)

Chapter 9. MENU STRUCTURE

g

g

Operation

screen

HOME settin

screen (page 37)

MENU settin

screen (page 40)

Input parameter settings (page 37)

Recording interval settings (page 37)

Specification confirmation (page 39)

Input operation settings (page 44)

Display settings (page 52)

Alarm settings (page 60) Detail settings

File settings (page 63)

Totalizer reset settings (page 67)

Instrument specifications display

List

Channel parameters

Group parameters

Group parameter2

(Version 2.00 and later )

Common parameters

LCD settings

ON/OFF settings

Detail settings

Detail settings

Setting of display

Setting of group

Detail settings

Parameter settings

of o

eration screen

Detail settings

Detail settings

Schedule settings (page 69)

Marker text settings (page 70)

Memory operation (page 71)

Network setting (page 72)

Detail settings

Detail settings

Write settings to external memory

Read settings from external memory

Initializing the settings

Write internal memory to external

Copy CF data to USB memory

Clearing the internal memory data

CS card formatting

USB memory formatting

Ethernet settings

DNS settings

Web server settin

(Version 2.00 and later )

FTP client settings

(Version 2.00 and later )

FTP server settings

SNTP settings

(Version 2.00 and later

E-MAIL settings

Save settings

Reading the settings

OK/cacel settings

OK/cacel settings

OK/cacel settings

OK/cacel settings

OK/cacel settings

OK/cacel settings

Detail settings

Detail settings

Detail settings

Detail settings

Detail settings

Detail settings

Forward address

Transmission

conditions selection

送信 CH

Detail settings

Detail settings

Detail settings

Detail settings

System setting

(page 82)

Clock settings

Key loc

Password settings

Host communications

Slave communications (displayed