Page 1

WE MAKE

WATER WORK

Pump Catalog

January 2019

Page 2

A.Y. McDonald Mfg. Co.

2

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 3

MISSION STATEMENT

The mission of A.Y. McDonald Mfg. Co. in the words of our founder is

“To make good products and to sell them honestly.”

We, the stockholders and employees, accomplish this by extending the McDonald family culture

through excellent customer service and by focusing on our customers’ needs.

WHO’S THE BOSS?

Here’s a question I’ll bet you could ask a thousand working people and never get the right answer. The

question is:

There’s only one boss, and whether a person shines shoes for a living or heads up the largest corporation

in the world, the boss remains the same.

The customer is the person who pays everyone’s salary and who decides whether a business is going to

succeed or fail. The customer doesn’t care if a business has been around a hundred years. The minute

it starts treating them badly, the customer will put it out of business.

This boss, the customer, has bought and will buy everything you have or will ever have. The customer has

bought all of your clothes, your home, your car, your children’s education, and your vacation. They pay all

of your bills and they pay them in exact proportion to the way you treat them.

The man who works deep inside a big plant on an assembly line might think he’s working for the company

that writes his pay check, but he is not. He’s working for the person who buys the product at the end

of the line, the customer. In fact, this customer can re everyone in the company from the president on

down. And they can do it by simply spending their money someplace else. This is one of the reasons why

taking pride in the work we do is so important to us personally. Doing an exceptionally good job will not

only bring joy and satisfaction, it will help get more customers, keep the ones we’ve got, and ensure that

we continue to get a pay check from our bosses.

“Who’s The Boss?”

It’s The Customer!

Some of the largest companies that had ourishing businesses a few

years ago are no longer in existence. They couldn’t - or didn’t - satisfy the

customer. They forgot who the boss really was!

At A.Y. McDonald we remind ourselves every day that the customer is

the boss. It’s one of our core values and the reason we provide the

best customer service in the business.

3

Page 4

Table of Contents

Table of Contents

Page

Pump Basics

General Information .................................................................. 7-22

Submersible Pumps

Submersible Pumps .............................................................. 23-106

21000 Series ........................................................................... 24-37

22000 Series ........................................................................... 38-52

23000 Series ........................................................................... 53-65

24000 Series (5 - 25 GPM) ...................................................... 66-79

24000 Series (35 - 80 GPM) .................................................... 80-91

26000 Series - All Stainless Steel ......................................... 92-105

Bottom Suction Pump..................................................................106

4” Motors, Controls & Accessories

4” Motors & Controls ........................................................... 107-118

4” A.Y. McDonald Submersible Motors ................................. 108-115

A.Y. McDonald Control Boxes ...............................................116-117

Starter Kits & Pumptec................................................................118

Submersible Pump Accessories

Pump Accessories ............................................................... 119-124

Pressure Master

Pressure Master .................................................................. 125-144

Monodrive............................................................................ 128-131

SubDrive 15 / 75 ................................................................. 132-134

SubDrive 20 / 100 ............................................................... 135-137

Subdrive 30 / 150................................................................ 138-140

SubDrive 50 / 300 ............................................................... 141-143

SubDrive UT2W ............................................................................144

Page

6” , 8”, & 10” Motors & Controls

Motors & Controls................................................................ 167-182

6”, 8”, & 10” Submersible Motors & Technical Information

Control Panels & Deluxe Control Boxes ........................................181

Starter Kits ..................................................................................182

.. 168-180

Pressure Tanks

Pressure Tanks .................................................................... 183-190

How to .........................................................................................184

Tank Sizing ..................................................................................185

Features & Benets .....................................................................186

Water Well Tanks .........................................................................187

Expansion Tanks - Potable Water ................................................188

Expansion Tanks - Hydronic.........................................................189

Jet Pumps

Jet Pumps............................................................................ 191-212

Installations ................................................................................192

Features & Motors .......................................................................193

8100 Series ......................................................................... 194-195

8200 Series ......................................................................... 196-197

8300 Series - E-Series......................................................... 198-199

8500 Series ......................................................................... 200-201

8600 Series ......................................................................... 202-203

1000 Series ......................................................................... 204-205

1500 Series ......................................................................... 206-207

Nema & Square Flange Motors ............................................ 208-209

Jet Ejectors & Adapters - Flanges........................................ 210-211

Jet Pump Accessories ..................................................................212

6”, 8”, & 10” Pump Ends

6”, 8”, & 10” Pump Ends .................................................... 145-166

How to Order................................................................................147

90 GPM................................................................................ 149-150

150 GPM.............................................................................. 151-152

230 GPM.............................................................................. 152-153

300 GPM.............................................................................. 154-155

400 GPM.............................................................................. 156-157

500 GPM.............................................................................. 158-159

650 GPM.............................................................................. 160-161

800 GPM.............................................................................. 162-163

1100 GPM............................................................................ 164-165

4

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

DuraMACTM Booster Pumps

TM

DuraMAC

How to Order - Residential / Light Commercial ...........................216

How It Works - Residential / Light Commercial ...........................217

E-Series Booster Pump ........................................................ 218-219

Residential Booster ............................................................. 220-221

Light Commercial & Irrigation ............................................. 222-223

Dual Mode Modular ............................................................. 224-225

Dual Mode Simplex .............................................................. 226-227

Dual Mode Duplex................................................................ 228-229

How to Order - Vertical Multistage Variable Speed Systems ........230

How It Works - Vertical Multistage Variable Speed Systems ........231

Vertical Multistage Variable Speed - Simplex ...................... 232-233

Vertical Multistage Variable Speed - Duplex ........................ 234-235

Vertical Multistage Variable Speed - Triplex ........................ 236-237

Technical Information & Performance Curves .....................238-245

Booster Pumps ................................................... 213-246

1-19

Page 5

Page

Irrigation & Booster Pumps

Page

Pump Repair Parts

Pit Setters

Irrigation & Booster Pumps ................................................. 247-260

Superbooster ....................................................................... 248-251

92000 & 93000 Series - Workhorse ..................................... 252-253

84000 Series ....................................................................... 254-255

1500XSW Series ..........................................................................256

8600SW Series ............................................................................257

E-Series 89000 Series ......................................................... 258-259

Sump, Sewage, & Efuent Pumps

Sump, Sewage, & Efuent Pumps ....................................... 261-292

How to Order................................................................................263

Utility Pumps...............................................................................264

Sump Pumps ....................................................................... 265-277

Efuent Pumps.................................................................... 278-281

Sewage Pumps .................................................................... 282-284

Sewage Packages................................................................ 285-289

Sump Pump Backup ....................................................................290

Guardian .....................................................................................291

Sump, Sewage, & Efuent Accessories........................................292

Wastewater Pumps

Wastewater Pumps .............................................................. 293-316

Efuent Pumps.................................................................... 296-299

Thermoplastic - Efuent...................................................... 300-303

Sewage Ejector Pumps ........................................................ 304-309

Grinder Pumps .................................................................... 310-313

Pumpmaster & Alarms ........................................................ 314-315

Basin, Check Valves, & Grinder Accessories ................................316

Pump Repair Parts .............................................................. 347-362

Motor Control Components ..........................................................348

Handymac ...................................................................................349

8100 / 8200 Series ......................................................................350

E-Series 8300..............................................................................351

8500 / 8600 Series ......................................................................351

1000 / 1500 Series .............................................................. 352-353

92000 / 93000 Series ..................................................................354

87000 Series ...............................................................................355

84000 Series ...............................................................................356

88000 Series ...............................................................................357

E-Series 89000............................................................................358

Guardian .....................................................................................359

TM

DuraMAC

Booster Pumps Repair Parts............................... 360-362

Troubleshooting

Troubleshooting ................................................................... 363-371

Submersible Pumps ............................................................ 364-367

Jet Pumps............................................................................ 368-371

Dewatering Pumps

Dewatering Pumps .............................................................. 317-346

How to Order (Trash Pumps) ........................................................319

Mini Mac ............................................................................. 320-321

Handymac ...................................................................................322

Submersible Pumps ....................................................................323

SludgeMaster ...................................................................... 324-325

Cast Iron Sewage ................................................................ 326-327

2” General Purpose ............................................................. 328-329

2” High Pressure ................................................................. 330-331

2” & 3” Self-Priming Trash Pumps......................................332-333

3” & 4” Trash Pump ............................................................ 334-337

6” Trash Pump ....................................................................338-339

Dredging Pump ................................................................... 340-341

Diaphragm Pump ................................................................ 342-343

Fire Pump ............................................................................ 344-345

5

Page 6

6

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 7

Pump Basics

Pump

Basics

Pump Catalog -

MORE THAN A BRAND. WE’RE A FAMILY.

January 2019

Page 8

Pump Basics

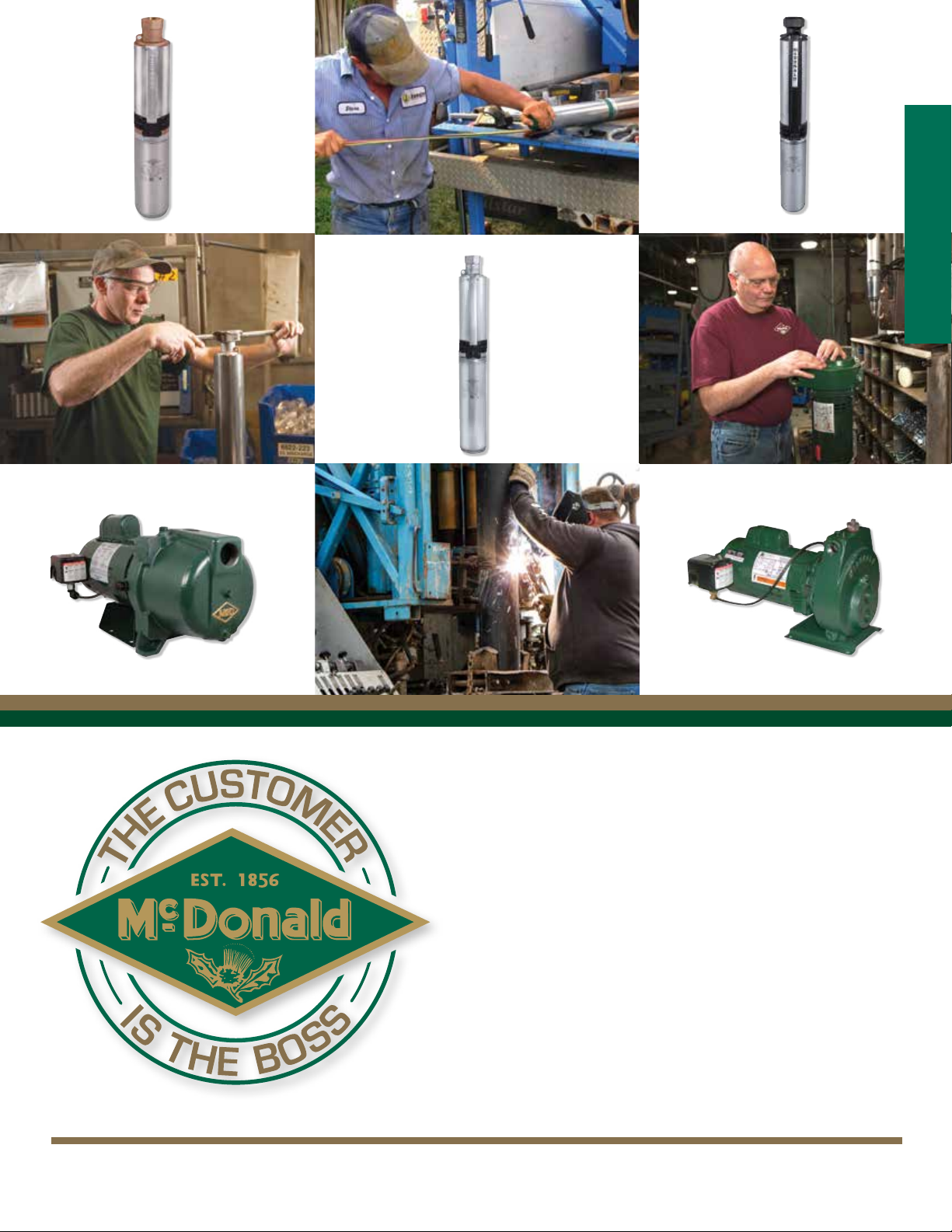

How a Centrifugal Pump Works

A centrifugal pump is a very simple design. The only moving part is an impeller attached to a shaft that is

driven by the motor. The two main parts of the pump are the impeller and diffuser. The impeller can be made

of bronze, stainless steel, cast iron, polycarbonate, and a variety of other materials. A diffuser or volute

houses the impeller and captures the water off the impeller.

Water enters the eye of the impeller and is thrown out by centrifugal force. As water leaves the eye of the

impeller, a low pressure area is created, causing more liquid to ow toward the inlet because of atmospheric

Pump Basics

pressure and centrifugal force. Velocity is developed as the liquid ows through the impeller while it is

turning at high speeds on the shaft. The liquid velocity is collected by the diffuser or volute and converted

to pressure by specially designed passageways that direct the ow to discharge into the piping system, or

on to another impeller stage for further increasing of pressure.

Diffuser

The head or pressure that a pump will develop is in direct relation to the impeller diameter, the number of

impellers, the eye or inlet opening size, and how much velocity is developed from the speed of the shaft

rotation. Capacity is determined by the exit width of the impeller. All of these factors affect the horsepower size of the motor to be used; as the more water

to be pumped or pressure to be developed, the more energy is needed.

A centrifugal pump is not positive acting. As the depth to water increases, it pumps less and less water. Also, when it pumps against increasing pressure

it pumps less water. For these reasons it is important to select a centrifugal pump that is designed to do a particular pumping job. For higher pressures

or greater lifts, two or more impellers are commonly used; or a jet ejector is added to assist the impellers in raising the pressure.

Impeller

Which Pump Do I Need?

The two most popular types of pumps used for private well systems or low ow irrigation applications are jet pumps and submersible pumps.

Submersible Pump End

Jet Pump

Impeller /

Diffuser Stack

Diffuser

Suction

Nozzle

Venturi

Impeller

8

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 9

Pump Basics

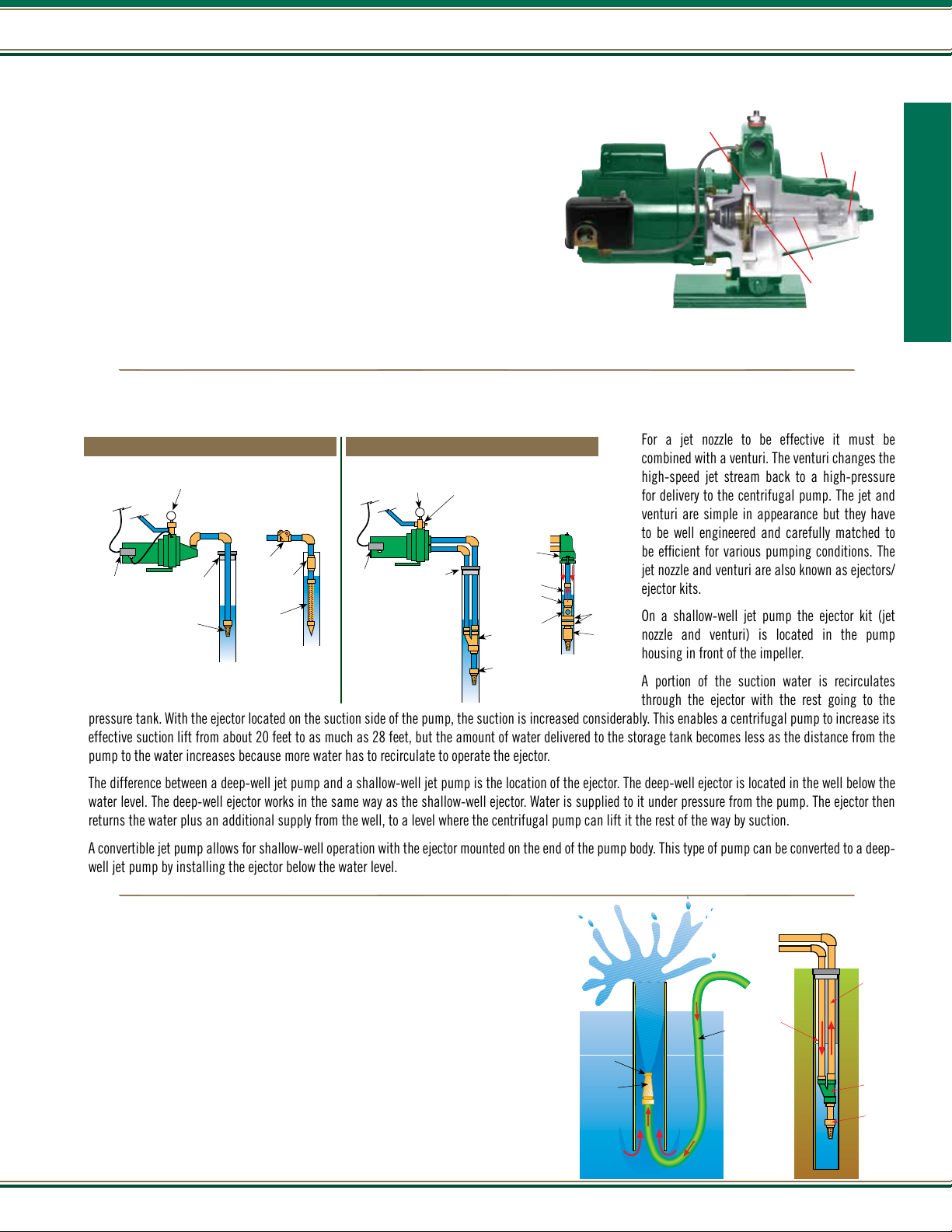

For a jet nozzle to be effective it must be

combined with a venturi. The venturi changes the

high-speed jet stream back to a high-pressure

for delivery to the centrifugal pump. The jet and

venturi are simple in appearance but they have

to be well engineered and carefully matched to

be efcient for various pumping conditions. The

jet nozzle and venturi are also known as ejectors/

ejector kits.

On a shallow-well jet pump the ejector kit (jet

nozzle and venturi) is located in the pump

housing in front of the impeller.

A portion of the suction water is recirculates

through the ejector with the rest going to the

pressure tank. With the ejector located on the suction side of the pump, the suction is increased considerably. This enables a centrifugal pump to increase its

effective suction lift from about 20 feet to as much as 28 feet, but the amount of water delivered to the storage tank becomes less as the distance from the

pump to the water increases because more water has to recirculate to operate the ejector.

The difference between a deep-well jet pump and a shallow-well jet pump is the location of the ejector. The deep-well ejector is located in the well below the

water level. The deep-well ejector works in the same way as the shallow-well ejector. Water is supplied to it under pressure from the pump. The ejector then

returns the water plus an additional supply from the well, to a level where the centrifugal pump can lift it the rest of the way by suction.

A convertible jet pump allows for shallow-well operation with the ejector mounted on the end of the pump body. This type of pump can be converted to a deep-

well jet pump by installing the ejector below the water level.

Jet

Nozzle

Water

Under

Pressure

Jet Ejector

Drive

Pipe

Return Pipe

Foot Valve

Jet Pumps

A deep well ejector is of particular value when you have a water level that is gradually

lowering. The proper jet package will be required to work efciently.

Diffuser

Suction

Nozzle

Because jet pumps are centrifugal pumps, the air handling characteristics are such

that the pump should be started with the pump and piping connections to the water

supply completely lled with water.

With a shallow-well jet pump, the ejector is mounted close to the pump impeller. With a

deep well jet pump, the ejector is usually mounted just above the water level in the well,

or else submerged below water level.

Venturi

Impeller

Centrifugal pumps, both the shallow-well and deep well types have little or no ability to pump air. When starting, the pump and suction line needs to have

all of the air removed. An air leak in the suction line will cause the pump to quit pumping. This is or sometimes referred to as “losing its prime”.

Typical Jet Pump Installation

Deep Well

TWO PIPE SYSTEM

Pressure

Regulator

Well

Seal

Jet

Ejector

Foot

Valve

SINGLE PIPE SYSTEM

Reducing

Nipple

Turned

Coupling

Packer

Ejector

Cup

Leathers

Foot Valve

To safety

switch or

circuit

breaker panel

Pressure

Switch

Shallow Well

Pressure

Gauge

Well

Seal

Foot

Valve

Check

Valve

Well

Point

Vertical

Check

Valve

To safety

switch or

circuit

breaker panel

Pressure

Switch

Pump Basics

How a Jet Provides

Pumping Action

Water is supplied to the Jet ejector under pressure. Water surrounding the jet stream is

lifted and carried up the pipe as a result of the jet action.

When a jet is used with a centrifugal pump a portion of the water delivered by the pump

is returned to the jet ejector to operate It. The jet lifts water from the well to a level where

the centrifugal pump can nish lifting It by suction.

9

Page 10

Pump Basics

Submersible Pumps

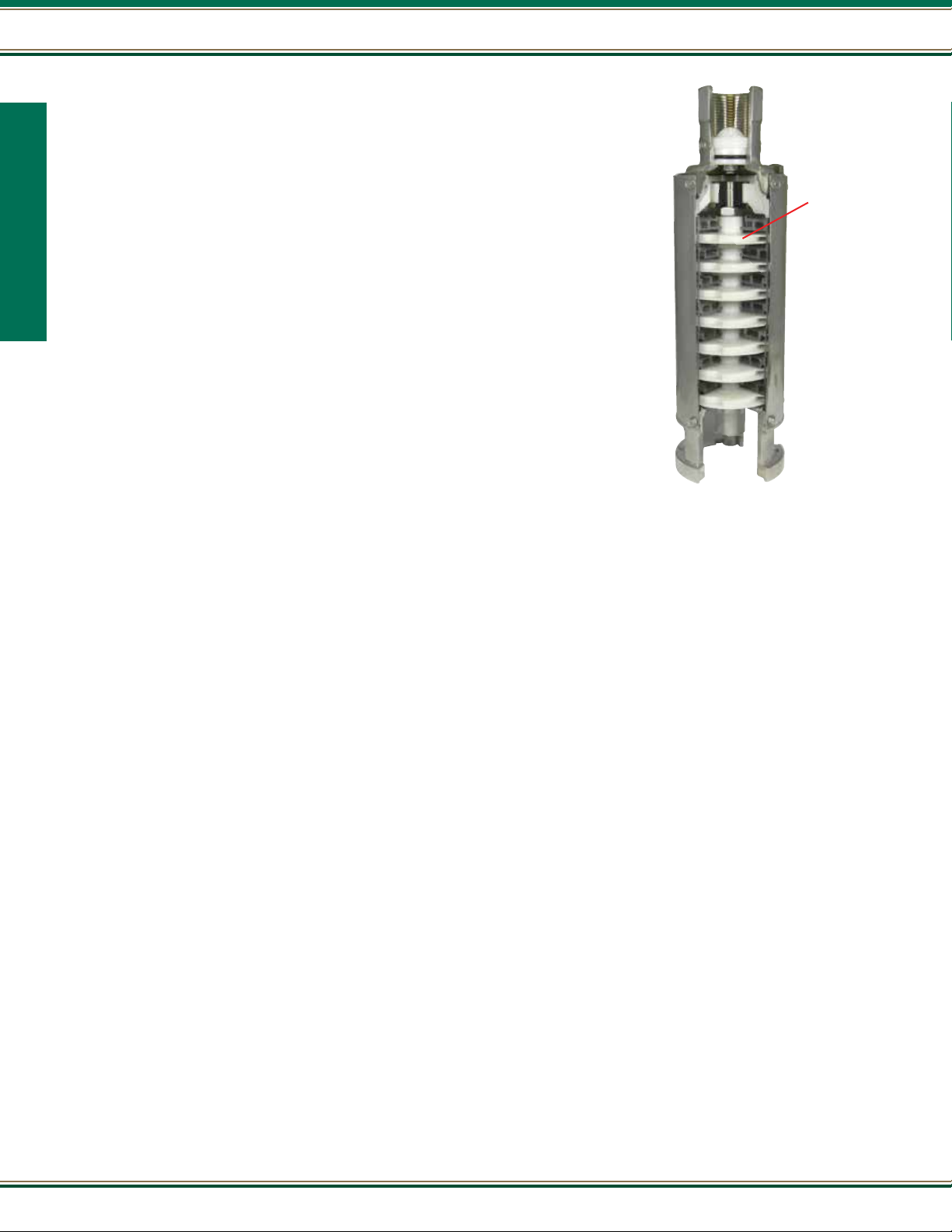

The submersible pump is a centrifugal pump. Because all stages of the pump end (wet end) and the motor are

joined and submerged in the water, it has a great advantage over other centrifugal pumps. There is no need to

recirculate or generate drive water as there is with jet pumps, therefore, most of its energy goes toward “pushing”

the water rather than ghting gravity and atmospheric pressure to draw water.

Virtually all submersibles are “multi-stage” pumps. All of the impellers of the multi-stage submersible pump are

Pump Basics

mounted on a single shaft and all rotate at the same speed. Each impeller passes the water to the eye of the next

impeller through a diffuser. The diffuser is shaped to slow down the ow of water and convert velocity to pressure.

Each impeller and matching diffuser is called a stage. As many stages are used as necessary to push the water

out of the well at the required system pressure and capacity. Each time water is pumped from one impeller to the

next, its pressure is increased.

The pump and motor assembly are lowered into the well by connecting piping to a position below the water level. In

this way the pump is always lled with water (primed) and ready to pump. Because the motor and pump are under

water they operate more quietly than above ground installations and pump freezing is not a concern.

A.Y. McDonald can stack as many impellers as needed; however, the horsepower of the motor is limited. For instance,

numerous pumps have 1/2 HP ratings - pumps that are capable of pumping different ows at different pumping

levels; they will, however, always be limited to 1/2 HP. Another way to look at it is that a pump will always operate somewhere along its design curve.

Impeller /

Diffuser Stack

To get more ow, the exit width of the impeller is increased and there will then be less pressure (or head) that the pump will develop because there will be

less impellers on a given HP size pump. Remember, the pump will always trade-off one for the other depending on the demand of the system. If the system

demands more than a particular pump can produce, it will be necessary to go up in horsepower; thereby, allowing more impellers to be stacked or to go to a

different design pump with wider impellers.

10

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 11

Pump Curves

1000

900

800

700

600

500

400

300

200

100

CAPACITY IN U.S. GALLONS PER MINUTE

TOTAL DYNAMIC HEAD IN FEET

0 4 8 12 16 20 24 28 32 36 40 44 48

1000

900

800

700

600

500

400

300

200

100

CAPACITY IN U.S. GALLONS PER MINUTE

TOTAL DYNAMIC HEAD IN FEET

0 4 8 12 16 20 24 28 32 36 40 44 48

H - C

1000

900

800

700

600

500

400

300

200

100

CAPACITY IN U.S. GALLONS PER MINUTE

TOTAL DYNAMIC HEAD IN FEET

0 4 8 12 16 20 24 28 32 36 40 44 48

1000

900

800

700

600

500

400

300

200

100

5

H

P

-

2

8

S

t

a

g

e

s

3

H

P

-

1

9

S

t

a

g

e

s

2

H

P

-

1

4

S

t

a

g

e

s

1

1

/

2

H

P

-

1

1

S

t

a

g

e

s

1

H

P

-

8

S

t

a

g

e

s

CAPACITY IN U.S. GALLONS PER MINUTE

TOTAL DYNAMIC HEAD IN FEET

0 4 8 12 16 20 24 28 32 36 40 44 48

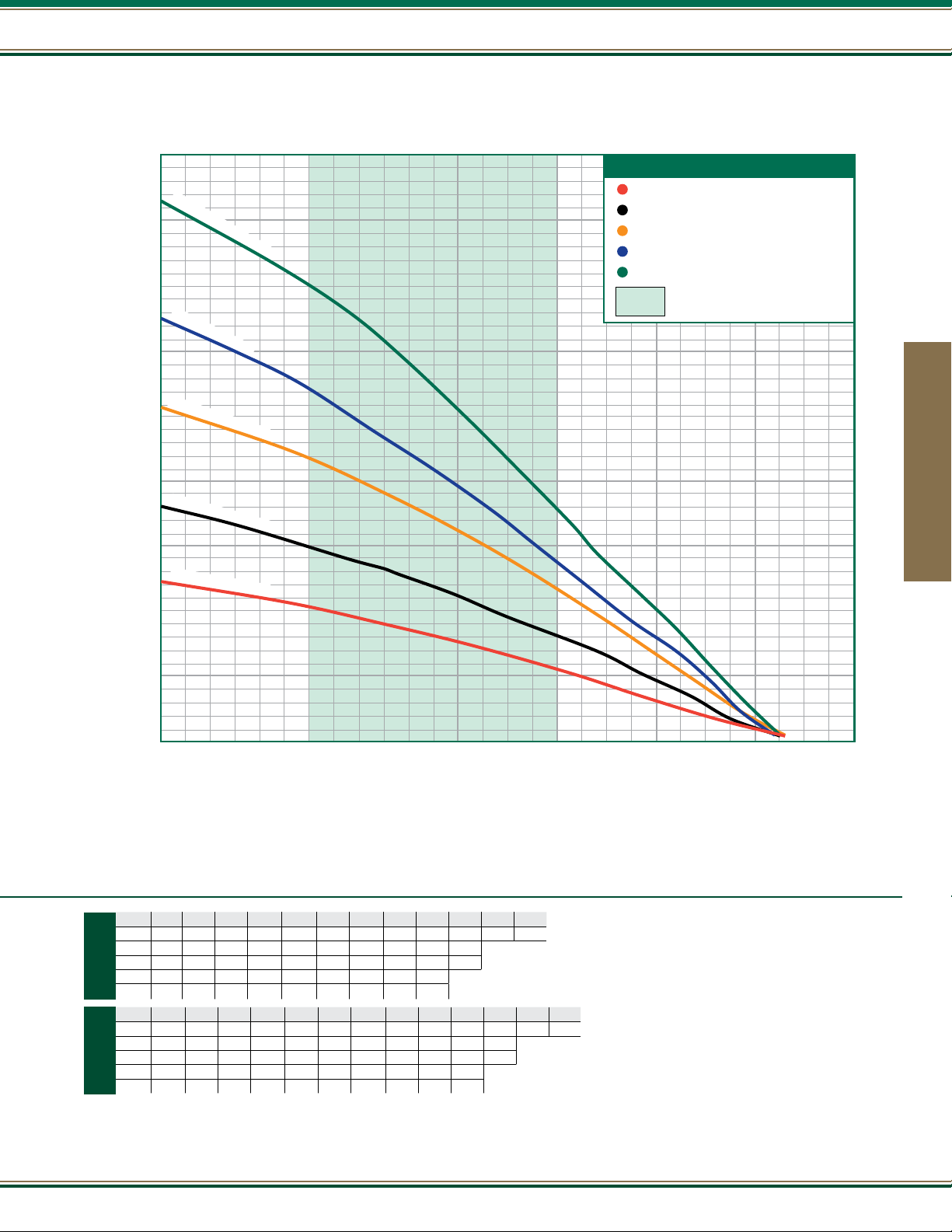

Pump Basics

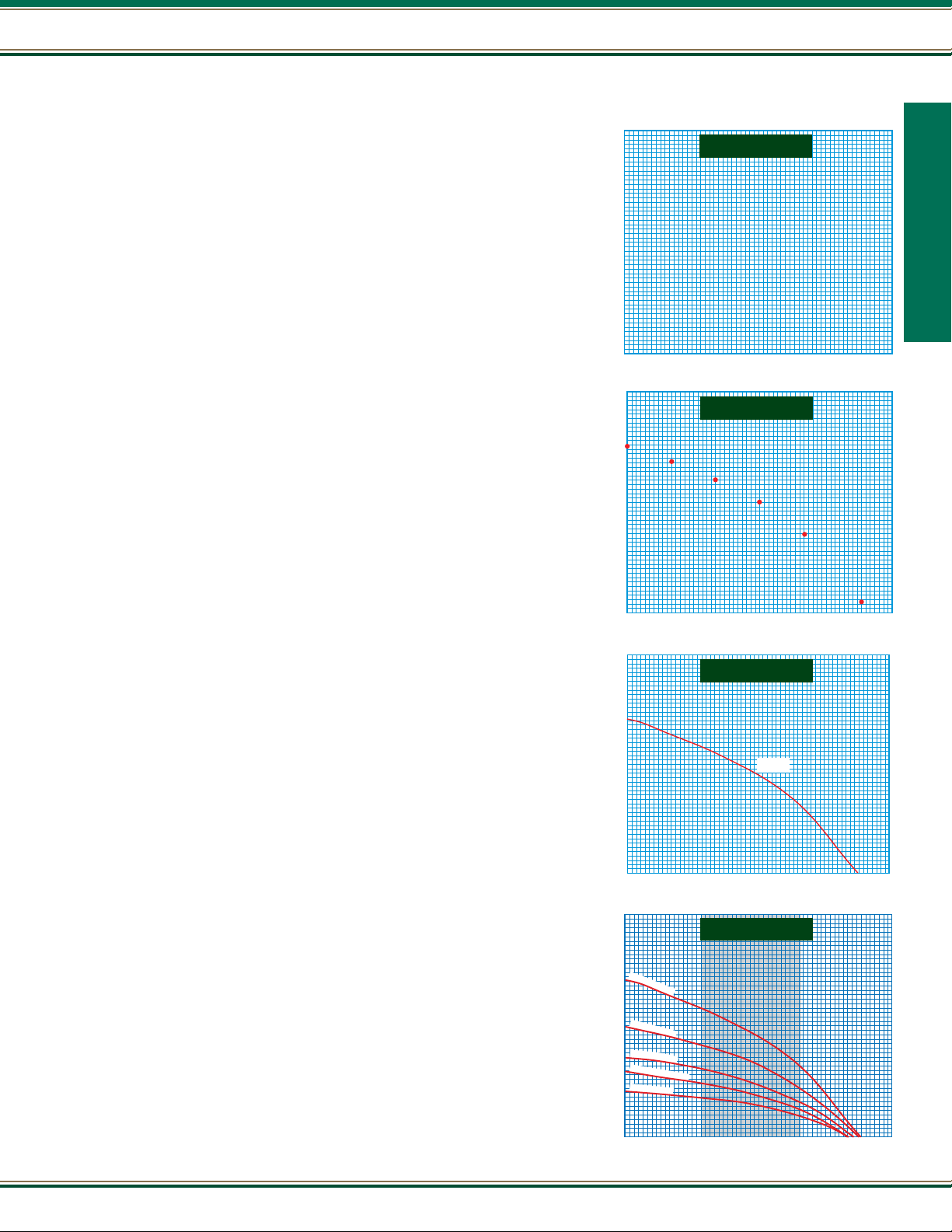

A pump curve is a curved line drawn over a grid of vertical and horizontal lines. The curved line

represents the performance of a given pump. The vertical and horizontal grid lines represent units

of measure to display that performance.

Let’s think of a well full of water. We want to use the water in a home. The home is at a higher level

than the water in the well. Since gravity won’t allow water to ow uphill, we use a pump. A pump

is a machine used to move a volume of water a given distance. This volume is measured over a

period of time expressed in gallons per minute (GPM) or gallons per hour (GPH).

The pump develops energy called discharge pressure or total dynamic head. This discharge

pressure is expressed in units of measure called pounds per square inch (psi) or feet of head (ft).

NOTE: 1 psi will push a column of water up a pipe a distance of 2.31 feet. When measuring

a pump’s performance, we can use a curve to determine which pump is best to meet our

requirements.

Figure 1 is a grid with the unit of measure in feet on the left hand side. We start with 0 at the

bottom. The numbers printed as you go up the vertical axis relate to the ability of the pump to

produce pressure expressed in feet. Always determine the value of each grid line. Sometimes the

measure will say feet head, which is what most engineers call it.

With the pump running a reading was taken from the gauge in psi and converted to feet

(1 psi = 2.31 feet).

We show another unit of measure in gallons per minute across the bottom. You start with 0 on

the left. The numbers printed as you go to the right relate to the ability of the pump to produce

ow of water expressed as capacity—in gallons per minute (GPM). Again, always determine the

value of each grid line.

FIGURE 1

Pump Basics

FIGURE 2

To establish a pump curve we run the pump using a gauge, valve, and owmeter on the discharge

pipe. We rst run the pump with the valve closed and read the gauge. This gives us the pump’s

capability at 0 capacity and maximum head in feet.

Figure 2 - We mark the grid point 1. Next we open the valve to 8 GPM ow, and read the gauge.

We again mark this point on the grid 2. We continue this process until we have

marked all the points on the grid.

Figure 3 - We now connect all the points. This curved line is called a head/capacity curve.

Head (H) is expressed in feet and capacity (C) is expressed in gallons per minute (GPM).

The pump will always run somewhere on the curve.

When the total dynamic head (TDH) is known, read vertically up the left hand side of the curve to

that requirement, for example, 300 feet. Then read horizontally to a point on a curve that connects

to the capacity needed, for example 26 GPM. It is then determined that a 3 HP 19 stage pump is

needed.

There are many different type curves shown in our catalog. Figure 4 is a composite performance

curve (more than one pump) for the submersible. There is a separate curve for each horsepower

size. Let’s compare two sizes:

1. First look at the 1 HP, 8 stages (impellers and diffusers). At 20 GPM capacity this model will

make 160 feet.

2. Now look at the 5 HP, 28 stages. At 20 GPM capacity this model will make 500 feet.

When you add impellers, the pump makes more pressure (expressed in feet). This allows the pump

to go deeper in a well, but also takes more horsepower.

FIGURE 3

FIGURE 4

11

Page 12

Pump Basics

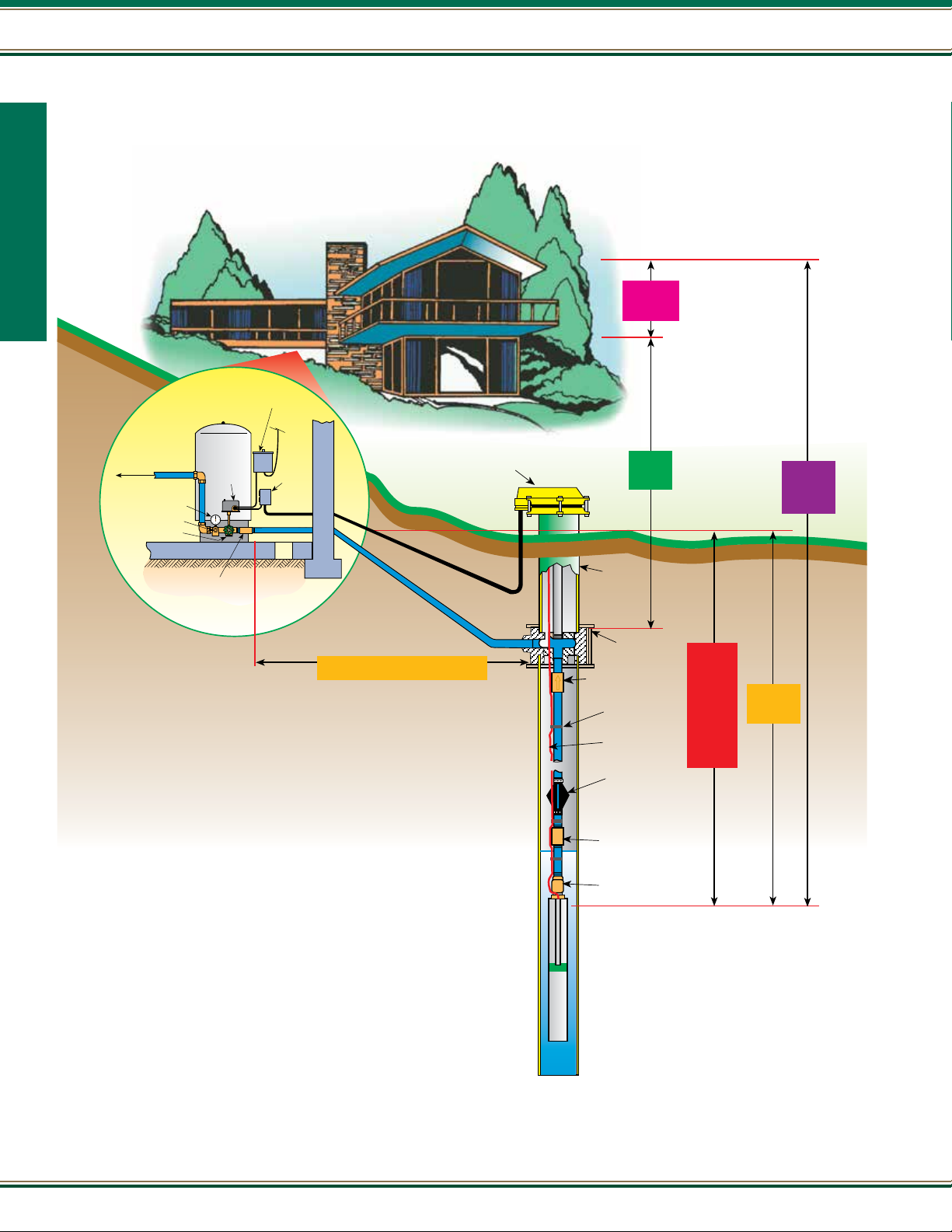

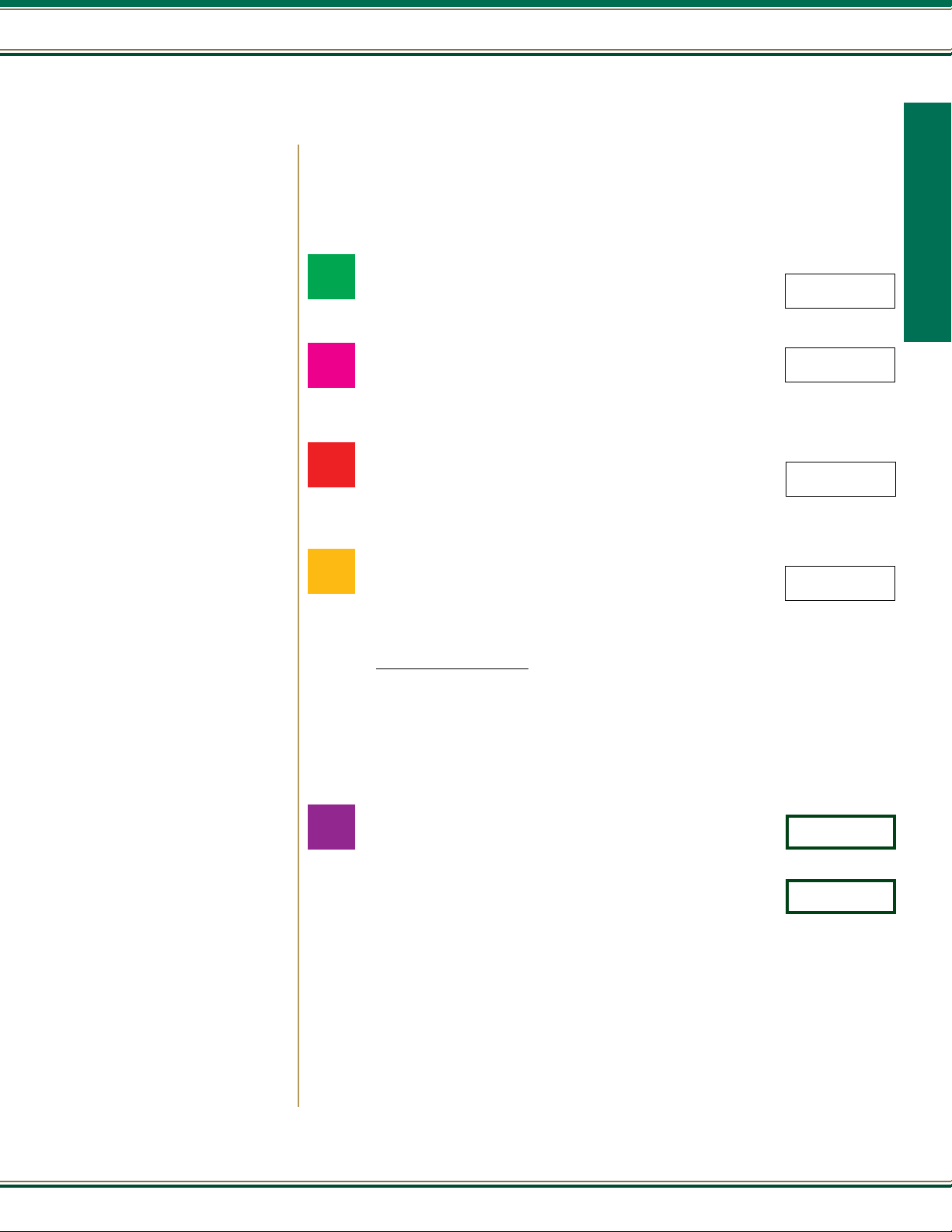

Typical Submersible Installation

Pump Basics

Disconnect

Switch/Circuit

Breaker

PRESSURE

TANK

TO HOUSE SERVICE

Pressure Relief Valve

Drain Valve

Pressure

Gauge

Pressure

Switch

Control

Box

Well Cap

2

Service

Pressure

1

Vertical

Lift

5

Total

Dynamic

Head

Check Valve

(Where local codes allow)

Horizontal & Vertical PIpe Run

All Pipe from pump to tank

Well

Casing

Pitless

Adapter

Check Valve

Tape Cable

to Pipe

Submersible

Cable

Torque Arrester

Coupling

Check Valve

3

Pumping

Level

Consists of:

Static or

Standing

Water

Level

Draw

Down

4

Friction

Loss

12

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 13

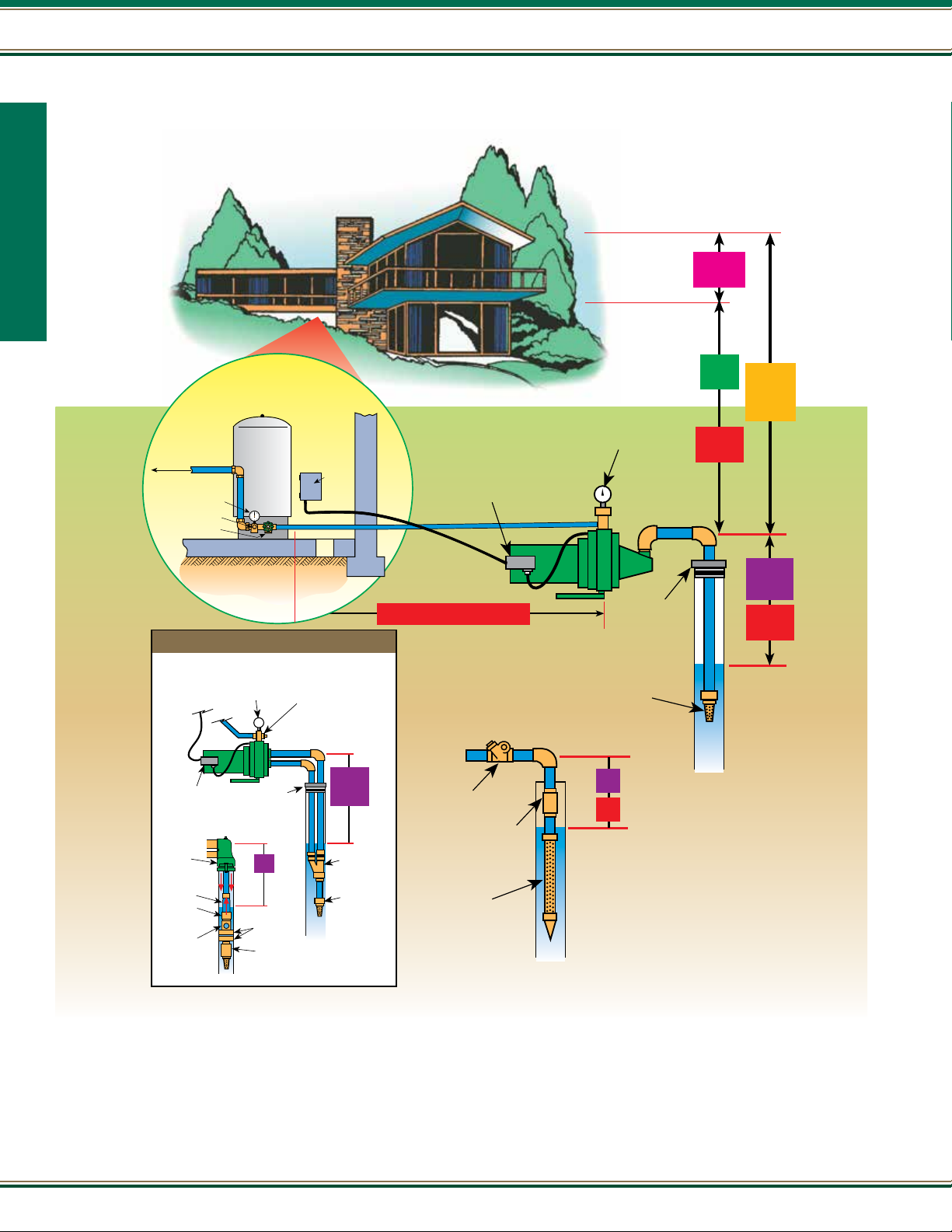

Pump Sizing - Submersible Pumps

MORE ABOUT...

VERTICAL LIFT/ ELEVATION

The vertical distance between the well

head and the level at the point of use.

It must be added to the TOTAL DYNAMIC

HEAD if the inlet is lower than the outlet and subtracted if the inlet is higher.

As a rule of good installation practice,

however, pipes should slope continuously

upward from the inlet to the outlet to prevent entrapment of air.

SERVICE PRESSURE

The range of pressure in the pressure

tank during the pumping cycle.

Determining Total Dynamic Head

Vertical Lift / Elevation

The vertical distance in feet from the pitless adapter to the top of

1

the pressure tank

Service Pressure

The average (pump shut-off) pressure switch setting x 2.31'.

2

Example for a 30/50 switch: 40 x 2.31' = 92.4 feet

Pump Basics

Well Size

(inside diameter in inches)

__________

HEAD

+

Convert PSI to feet

(X 2.31)

Pump Basics

PUMPING LEVEL

The lowest water level reached during

pumping operation. (Static level – drawdown)

STATIC OR STANDING WATER LEVEL

The undisturbed level of water in the well

before pumping. Not as important as

pumping level.

DRAWDOWN

The distance that the water level in the

well is lowered by pumping. It is the difference between the STATIC WATER LEVEL

and the PUMPING LEVEL.

FRICTION LOSS

The loss of pressure or head due to the

resistance to ow in the pipe and ttings. Friction loss is inuenced by pipe

size and uid velocity, and is usually ex-

pressed in feet of head.

HORIZONTAL RUN

The horizontal distance between the

point where uid enters a pipe and the

point at which it leaves.

TOTAL DYNAMIC HEAD or TDH

TDH and capacity required determines

pump size. The total pressure or head

the pump must develop is the sum of the

VERTICAL LIFT/ELEVATION, THE SERVICE

PRESSURE, PUMPING LEVEL, and THE

FRICTION LOSS. All of these measurements must be expressed in the same

units, usually feet of head or pressure

(PSI), before adding them together.

Pumping Level

The vertical distance in feet from the pitless adapter or well seal

3

to the water drawdown level in the well that yields the ow rate

required by the pump

+

+

Friction Loss

Water owing through piping will lose head depending on the size,

4

type and length of piping, number of ttings, and ow rate. Example:

Pumping 20 GPM through 500 ft. of 1 1/4" plastic pipe with three

elbows will cause a friction loss equal to:

500 ft. + 21 ft. (elbow loss)

100 ft.

Feet of Pipe _______________ Diameter of Pipe ______________

Type of Pipe __________________________________________

See Friction Loss Charts on Page 16

Total Dynamic Head

5

After determining TDH, match this number with capacity required

on pump curves of specic pumps in this catalog to select the

correct pump.

Gallons Per Minute (or Hour) Needed

Determining Flow Rate

Although methods will vary, in general, the Water Systems Council bases pump ow selection for a residential

system on total gallon usage during a seven minute peak demand period. This can be supplemented by using

a properly sized pressure tank.

Farms, irrigation, and lawn sprinklers demand more water.

X 6.00 ft (loss per 100') = 31.26 ft.

=

Ft.

13

Page 14

Pump Basics

Typical Jet Pump Installation

SHALLOW WATER

Pump Basics

TO HOUSE SERVICE

Pressure Relief Valve

Drain Valve

To safety

switch or

circuit breaker

panel

Pressure

Gauge

PRESSURE

TANK

Deep Well

TWO PIPE SYSTEM

Pressure

Gauge

Pressure

Regulator

Safety

Switch

Circuit

Breaker

Pressure Switch

Horizontal & Vertical Pipe Run

All pipe from pump to tank

Pressure Gauge

Foot

Valve

Well

Seal

2

Service

Pressure

1

Vertical

Lift

3

Friction

Loss

4

Total

Discharge

Head

(Pressure)

5

Pumping

Level

3

Friction

Loss

14

Pressure

Switch

SINGLE PIPE SYSTEM

Casing

Adapter

Reducing

Nipple

Turned

Coupling

Packer

Ejector

Well

Seal

5

Cup Leathers

Foot Valve

5

Pumping

Level

Jet Ejector

Foot Valve

Horizontal

Check Valve

Well Point

(if used)

Vertical

Check Valve

5

3

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 15

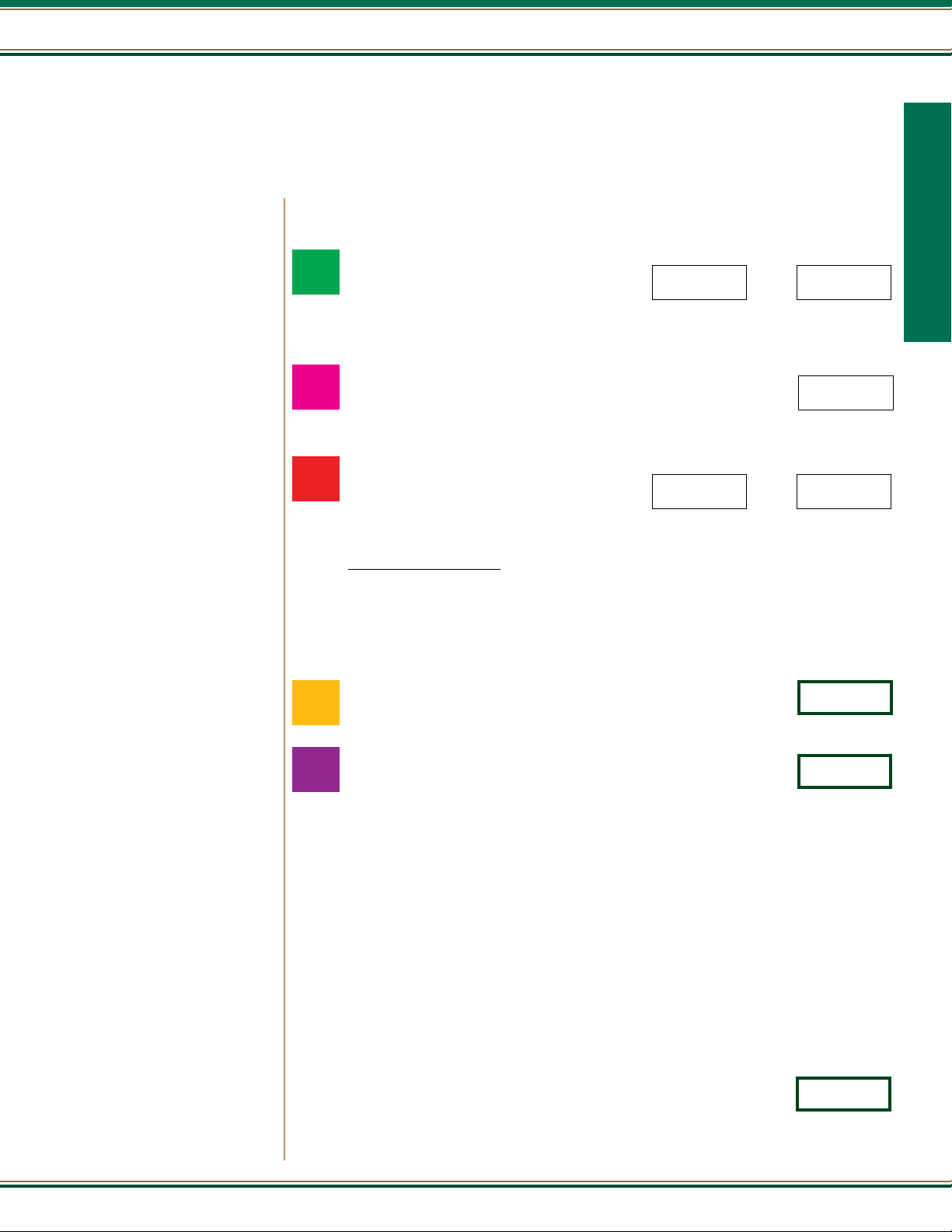

Pump Basics

Aboveground Pumps

The difference between submersible pump and surface pump sizing is that surface pumps, including jet pumps, show performance in “charted” form

versus “curves” for submersibles. Except for the “pumping level” (which is shown in feet in the charts) all other head/lift requirements should be

converted to PSIG for surface pump sizing. (Feet X .433 = PSIG (Pounds per Square Inch Gauge).

MORE ABOUT...

VERTICAL LIFT/ ELEVATION

The vertical distance between the

well head and the level at the point

of use. It must be ADDED to the

Total Dynamic/Total Discharge Head

if the inlet is lower than the outlet

and SUBTRACTED if the inlet is

higher. As a rule of good installation

practice, however, pipes should slope

continuously upward from the inlet to

the outlet to prevent entrapment of

air.

SERVICE PRESSURE

The range of pressure in the pressure tank

during the pumping cycle.

FRICTION LOSS

The loss of pressure or head due to

the resistance to ow in the pipe and

ttings. Friction loss is inuenced

by pipe size and uid velocity, and is

usually expressed in feet of head.

HORIZONTAL RUN

The horizontal distance between the

point where uid enters a pipe and the

point at which it leaves.

Vertical Lift / Elevation

1

The vertical distance in feet from the location of the pump

to the point of highest delivery (e.g. from a pump house

near the well to the second oor of a two story house)

Service Pressure

The average pressure switch setting.

2

Example 20/40 switch (1/2 HP) = 30 PSIG average (3/4 HP and larger pumps

have 30/50 switch settings) = 40 PSIG average

Friction Loss

3

Water owing through piping will lose head depending on the

size, type and length of piping, number of ttings, and ow

rate. Example: Pumping 10 GPM through 100 ft. of 1" plastic

pipe with 3 elbows will cause a friction loss equal to:

100 ft. + 18 ft. (elbow loss)

100 ft.

Feet of Pipe ___________ Diameter of Pipe __________

Type of Pipe __________________________________

See Friction Loss Charts on Page 16

X 6.31 ft (loss per 100') = 7.44' X .433 = 3.2 PSIG

X .433

X .433

Well Size

(inside diameter

in inches)

_________

PSIGFeet

+

PSIG

+

PSIGFeet

=

Pump Basics

TOTAL DYNAMIC/TOTAL

DISCHARGE HEAD or TDH

TDH and capacity required

determines pump size. The total

pressure or head the pump must

develop is the sum of Vertical Lift/

Elevation, The Service Pressure,

and The Friction Loss. All of these

measurements must be expressed in

the same units, usually feet of head

or pressure (PSI), before adding them

together. For aboveground pumps,

distance to water in feet are shown in

the respective charts.

PUMPING LEVEL

The lowest water level reached during

pumping operation. (Static level minus

drawdown)

STATIC OR STANDING WATER LEVEL

The undisturbed level of water in the

well before pumping. Not as important

as pumping level.

DRAWDOWN

The distance that the water level in the

well is lowered by pumping. It is the

difference between the STATIC WATER

LEVEL and the PUMPING LEVEL.

Total Dynamic/Discharge Head • 1 + 2 + 3 =

4

Pumping Level/Depth to Water

5

The vertical distance in feet from the pump to the water level including

draw down level - if any. In Shallow Well systems, referred to as suction

lift/head and is limited to 20 or 25 feet at sea level (deduct 1’ suction

capability for each 1000’ above sea level).

Note: Friction losses (3) in the suction piping must be added to the

pumping level for total suction lift.

Deep Well jet pump charts include the friction losses in the vertical piping

only. See page 15 if long horizontal, offset piping cannot be avoided.

No need to

convert-

Charts are

in feet

If 25' or less,

use shallow

well charts

If more than 25'

use deep

well charts

Determining Flow Rate

Although methods will vary, in general, the Water Systems Council bases pump ow selection for a

residential system on total gallon usage during a seven minute peak demand period. This can be

supplemented by using a properly sized pressure tank.

Farms, irrigation, and lawn sprinklers demand more water.

Gallons Per Minute (or hour) Needed

See Page 20 for water demands

After determining TDH and ow requirements in GPM / GPH, match these numbers

with surface pump charts in sections 3 and 4.

PSIG

Ft.

15

Page 16

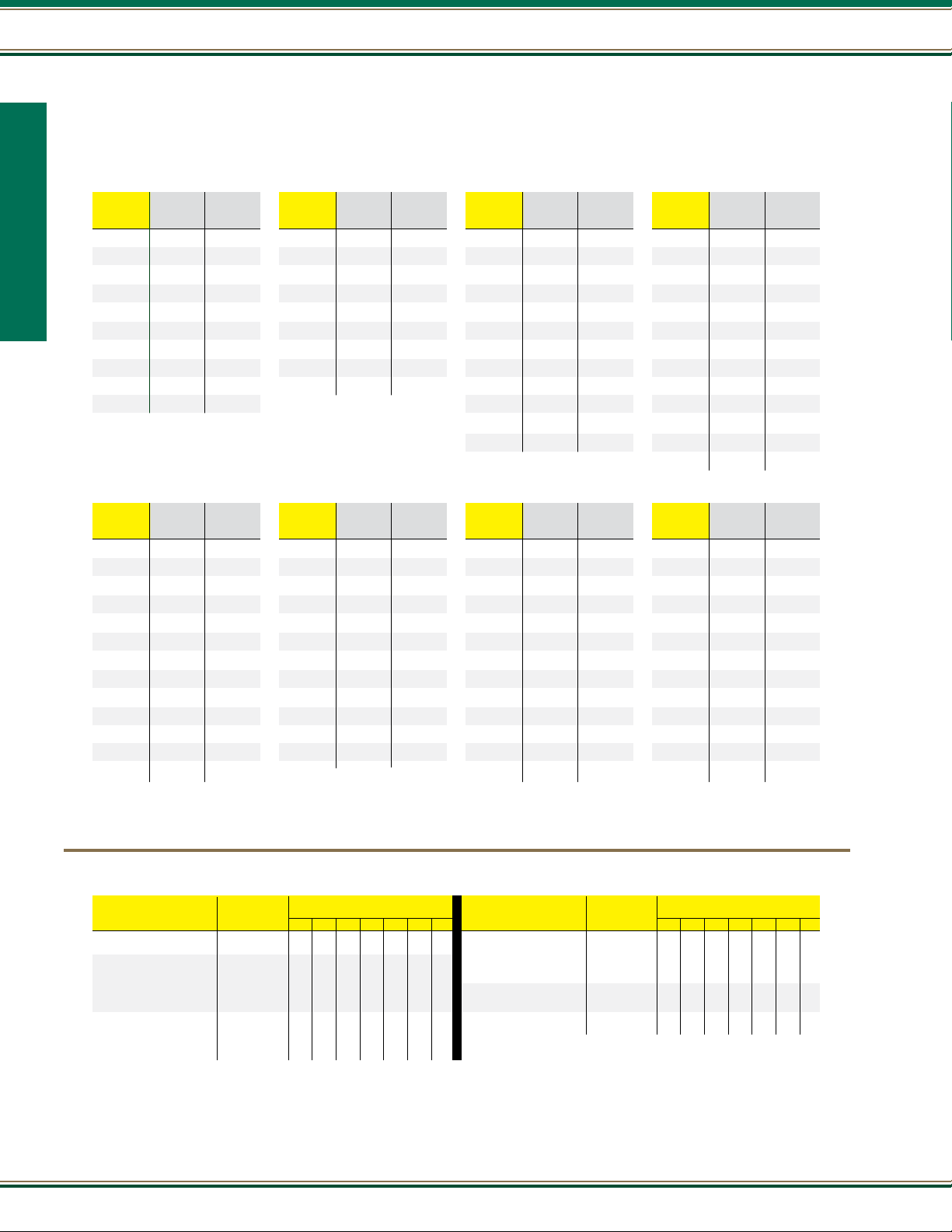

Pump Basics

Friction Loss - Charts

LOSS OF HEAD IN FEET, DUE TO FRICTION PER 100 FEET OF PIPE

3/4” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID .824” ID .824”

1.5 1.13 .61

Pump Basics

2.0 1.93 1.04

2.5 2.91 1.57

3.0 4.08 2.21

3.5 5.42 2.93

4.0 6.94 3.74

4.5 8.63 4.66

5.0 10.50 5.66

6.0 -- 7.95

7.0 -- 10.60

2” Pipe 2 1/2” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 2.067” ID 2.067”

10 .431 .233

15 .916 .495

20 1.55 .839

25 2.35 1.27

30 3.29 1.78

35 4.37 2.36

40 5.60 3.03

45 6.96 3.76

50 8.46 4.57

55 10.10 5.46

60 11.90 6.44

70 -- 8.53

80 -- 10.90

1” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 1.049” ID 1.049”

2 .595 .322

3 1.26 .680

4 2.14 1.15

5 3.42 1.75

6 4.54 2.45

8 7.73 4.16

10 11.7 6.31

12 -- 8.85

14 -- 11.8

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 2.469” ID 2.469”

20 .654 .353

30 1.39 .750

40 2.36 1.27

50 3.56 1.92

60 4.99 2.69

70 6.64 3.58

80 8.50 4.59

90 10.60 5.72

100 -- 6.90

110 -- 8.25

120 -- 9.71

130 -- 11.30

1 1/4” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 1.380” ID 1.380”

4 .564 .304

5 .853 .460

6 1.20 .649

7 1.59 .860

8 2.04 1.10

10 3.08 1.67

12 4.31 2.33

14 5.73 3.10

16 7.34 3.96

18 9.13 4.93

20 11.10 6.00

25 -- 9.06

1 1/2” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 1.61” ID 1.61”

4 .267 .144

6 .565 .305

8 .962 .520

10 1.45 .785

12 2.04 1.10

14 2.71 1.46

16 3.47 1.87

18 4.31 2.33

20 5.24 2.83

25 7.90 4.26

30 11.1 6.0

35 -- 7.94

40 -- 10.20

3” Pipe 4” Pipe

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 3.0” ID 3.068”

20 .149 .129

30 .316 .267

40 .541 .449

50 .825 .676

60 1.17 .912

70 1.57 1.22

80 2.03 1.56

90 2.55 1.95

100 3.12 2.37

110 3.75 2.84

120 4.45 3.35

130 5.19 3.90

140 6.00 4.50

FLOW STEEL PLASTIC

US GAL C-100 C-140

MIN ID 4.0” ID 4.026”

20 .038 .035

30 .076 .072

40 .128 .120

50 .194 .179

60 .273 .250

70 .365 .330

80 .470 .422

90 .588 .523

100 .719 .613

110 .862 .732

120 1.02 .861

130 1.19 1.00

140 1.37 1.15

16

Example:

10 GPM with 1’ plastic pipe has 6.31’ of loss per 100 ft. - if your run is 50 ft., multiply by .5, if 250 ft. multiply by 2.5, etc.

Loss through ttings in terms of equivalent lengths of pipe

PIPE & FTG.

TYPE FITTING MATERIAL.

& APPLICATION (Note 1)

1/2 3/4 1 1

Insert coupling Plastic 3 3 3 3 3 3 3

Threaded adapter

Plastic or copper Copper 1 1 1 1 1 1 1

to thread Plastic 3 3 3 3 3 3 3

Steel 2 3 3 4 4 5 6

90° standard elbow Copper 2 3 3 4 4 5 6

Plastic 4 5 6 7 8 9 10

Note 1: Loss gures are based on equivalent lengths of indicated pipe material

Note 2: Loss gures are for screwed valves and are based on equivalent lengths of steel pipe

Note 3: Loss gures for copper lines are approximately 10% higher than shown for plastic

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

EQUIVALENT LENGTH OF PIPE

NOMINAL SIZE FITTING & PIPE

1

⁄4 11⁄2 2 21⁄

PIPE & FTG.

TYPE FITTING MATERIAL.

& APPLICATION (Note 1)

1/2 3/4 1 1

2

Steel 4 5 6 8 9 11 14

Standard tee Copper 4 5 6 8 9 11 14

Flow through side Plastic 7 8 9 12 13 17 20

Gate valve Note 2 2 3 4 5 6 7 8

Swing check valve Note 2 4 5 7 9 11 13 16

EQUIVALENT LENGTH OF PIPE

NOMINAL SIZE FITTING & PIPE

1

⁄4 11⁄2 2 21⁄

2

1-19

Page 17

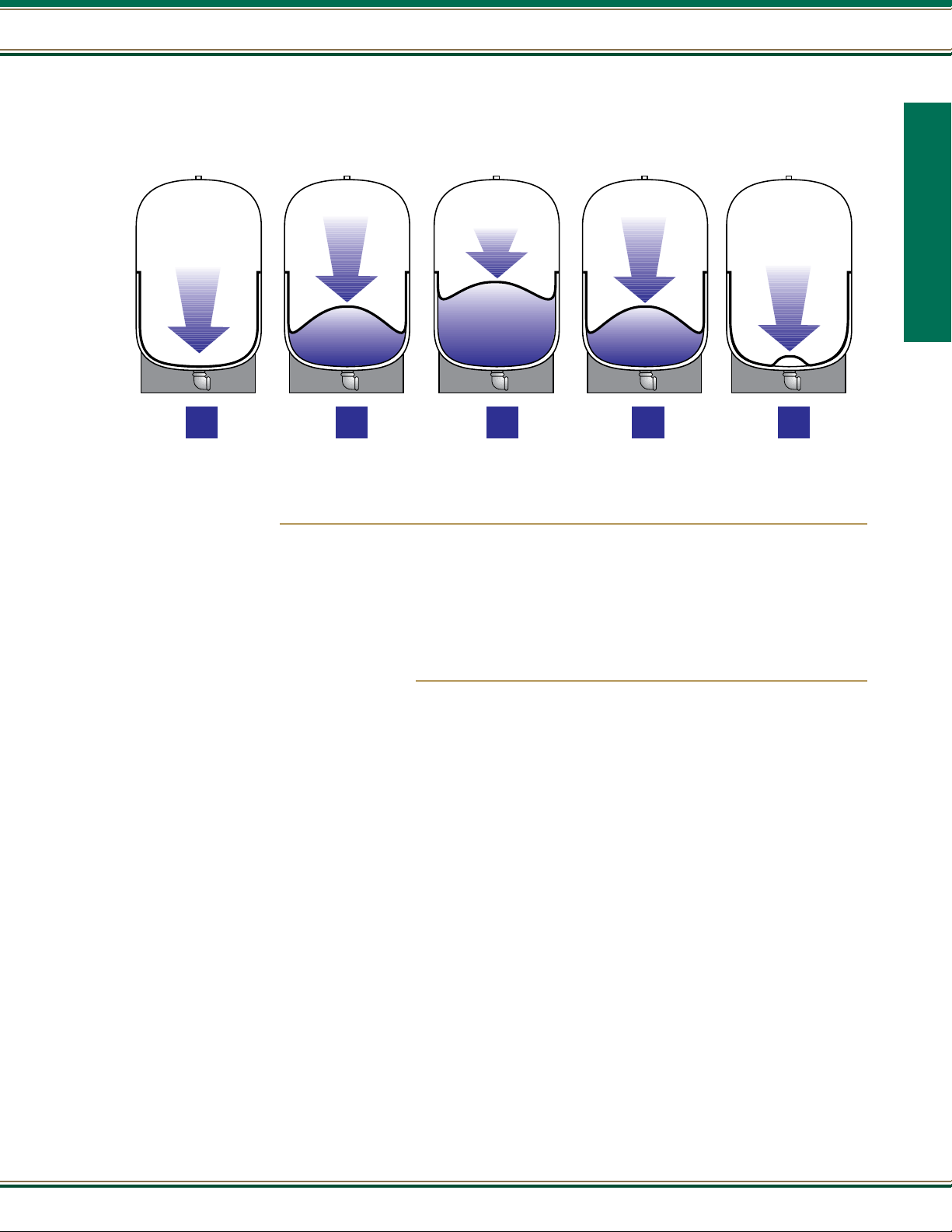

Pressure Tank - Sizing

Precharge Air

Pressure

Air Pressure

Increasing

Pressure

Switch Cut-Out

Pressure

Air Pressure

Decreasing

Pressure

Switch Cut-In

Pressure

Tank empty

Pump comes

on and cycle

begins

1

Tank is filling

2

Tank is full

Pump turns off

3

Water is

being used

4

Tank is nearly

empty and pump

comes on to

repeat cycle

5

TANK OPERATIONS

Pump Basics

Pump Basics

Why do I need a tank?

There are four main reasons to include a tank in your system:

1. To protect and extend the life of the pump by reducing the number of cycles.

2. To provide storage of water under pressure for delivery between cycles.

3. To have reserve capacity for periods of peak demand.

4. To reduce system maintenance.

How do I choose a tank for my system?

Choosing the proper tank for your pumping system will greatly reduce the risk of premature pump failure. Most manufacturers recommend a

minimum run time of one minute in order to protect the pump and the pump motor. The larger the tank the longer the running time and fewer

pump cycles will result in longer pump life. One HP and larger pumps require longer run times.

To determine the proper size of tank, there are three factors to consider:

1. Pump ow rate in gallons per minute

2. Desired run time of the pump

3. Cut-in and cut-out psi of the pressure switch

From these factors you can determine the tank drawdown with the following equation:

Pump ow rate X run time = tank drawdown capacity required.

Tank drawdown capacity is the minimum amount of water stored and/or delivered by the pressure tank between pump shut-off and pump re-start.

This should not be confused with “tank volume.” For example, a pre-charged tank with a tank volume of 20 gallons has only ve to seven gallons

drawdown capacity depending on the cut-in / cut-out (on/off) setting of the pressure switch.

Pumps with ow rates (capacities) up to 10 GPM should have a tank with a minimum of one gallon drawdown capacity for each GPM delivered by

the pump. Example: 10 GPM pump = 10 gallon “drawdown”.

Pump ow rates from 11 to 20 GPM should have tank drawdowns approximately 1.5 times the GPM rating.

For example, 20 GPM X 1.5 = 30 gallon “drawdown”.

Pump ow rates above 20 GPM should have tank drawdowns approximately two times the GPM rating and multiple tanks should be considered.

(CHECK YOUR TANK MANUFACTURER’S CHARTS FOR TANK DRAWDOWN RATING.)

17

Page 18

Pump Basics

Technical Data - Glossary

ACIDITY - A condition of water when the pH is below 7. See pH.

ALKALINITY - A condition of water when the pH is above 7. See pH.

AQUIFER - A water-saturated geologic unit or system that yields water to wells or springs at a sufcient rate that the wells or springs can serve as practical sources

of water.

Pump Basics

ARTESIAN WELL (owing and non-owing) - Well in which the water rises above the surface of the water in the aquifer after drilling is completed. It is a owing

artesian well if the water rises above the surface of the earth.

CENTRIFUGAL - Consists of a fan-shaped impeller rotating in a circular housing, pushing liquid towards a discharge opening. Simple design, only wearing parts are

the shaft seal and bearings (if so equipped). Usually used where a ow of liquid at relatively low pressure is desired. Not self-priming unless provided with a priming

reservoir or foot valve: works best with the liquid source higher than the pump (ooded suction/gravity feed). As the discharge pressure (head) increases, ow and driven

power requirements decrease. Maximum ow and motor loading occur at minimum head.

CHECK VALVE - Allows liquid to ow in one direction only. Generally used in suction and discharge line to prevent reverse ow.

CISTERN - A non-pressurized tank (usually underground) for storing water.

COAGULATION - The chemically combining of small particles suspended in water.

CONTAMINATED WATER - Water that contains a disease causing or toxic substances.

DEEP WELL - Use a pump (submersible or deep well jet) to force water upward from a pumping element below the well water level. Not restricted by suction lift

limitations.

DRAWDOWN - The vertical distance the water level drops in a well pumped at a given rate.

DYNAMIC HEAD - Vertical distances (in feet) when the pump is running/producing water.

FLOODED SUCTION - Liquid source is higher than pump and liquid ows to pump by gravity (Preferable for centrifugal pump installations).

FLOW - The measure of the liquid volume capacity of a pump. Given in Gallons Per Hour (GPH) or Gallons Per Minute (GPM), as well as Cubic Meters Per Hour (CMPH),

and Liters Per Minute (LPM).

FOOT VALVE - A type of check valve with a built-in strainer. Used at point of liquid intake to retain liquid in the system, preventing loss of prime when liquid source

is lower than pump.

FRICTION LOSS - The loss of pressure or head due to the resistance to ow in the pipe and ttings. Friction loss is inuenced by pipe size and uid velocity, and is

usually expressed in feet of head.

GRAINS PER GALLON - The weight of a substance, in grains, in a gallon. Commonly, grains of minerals per gallon of water as a measure of water hardness.

1 gpg = 17.1 mgl.

GROUND WATER - Water that has ltered down to a saturated geologic formation beneath the earth’s surface.

HARDNESS MINERALS - Minerals dissolved in water that increase the scaling properties and decrease cleansing action - usually calcium, iron, and magnesium.

HEAD - Another measure of pressure, expressed in feet. Indicates the height of a column of water being lifted by the pump neglecting friction losses in piping.

INCRUSTATION - A mineral scale chemically or physically deposited on wetted surfaces, such as well screens, gravel packs, and in tea kettles.

INTERMEDIATE STORAGE - A holding tank included in a water system when the water source does not supply the peak use rate.

JET PUMP - A pump combining two pumping principles - centrifugal operation and ejection. Can be used in shallow or deep wells.

MILLIGRAMS PER LITER (mg/l) - The weight of a substance, in milligrams in a liter. 1 mg/l = 1 oz. per 7500 gallons. It is equivalent to 1 ppm.

See Parts per Million.

NEUTRALITY - A condition of water when the pH is at 7. See pH.

18

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 19

Technical Data - Glossary

Pump Basics

OXIDATION - A chemical reaction between a substance and oxygen.

PALATABLE WATER - Water of acceptable taste. May also include non-offensive appearance and odor.

PARTS PER MILLION, ppm - A measure of concentration; one unit of weight or volume of one material dispersed in one million units of another; e.g., chlorine

in water, carbon monoxide in air. Equivalents to indicate small size of this unit: 1 ppm = 1 oz. per 7500 gallons; 1 kernel of corn in 13 bushels 1/4 sq. in. in an acre.

PEAK USE RATE - The ow rate necessary to meet the expected maximum water demand in the system.

pH - A measure of the acidity or alkalinity of water. Below 7 is acid, above 7 is alkaline.

POLLUTED WATER - Water containing a natural or man-made impurity.

POTABLE WATER - Water safe for drinking.

PRESSURE - The force exerted on the walls of a container (tank pipe, etc.) by the liquid. Measured in pounds per square inch (PSI).

PRIME - A charge of liquid required to begin pumping action of centrifugal pumps when liquid source is lower than pump. May be held in pump by a foot valve on the

intake line or a valve or chamber within the pump.

RELIEF VALVE - Usually used at the discharge of a pump. An adjustable, spring-loaded valve opens, or relieves pressure when a pre-set pressure is reached. Used

to prevent excessive pressure and pump or motor damage if discharge line is closed off.

SHALLOW WELL - Use a pump located above ground to lift water out of the ground through a suction pipe. Limit is a lift of 33.9 feet at sea level.

SOFTENING - The process of removing hardness caused by calcium and magnesium minerals.

SPRING - A place on the earth’s surface where ground water emerges naturally.

STATIC HEAD - Vertical Distance (in feet) from pump to point of discharge when the pump is not running.

Pump Basics

STRAINERS - A device installed in the inlet of a pump to prevent foreign particles from damaging the internal parts.

SUBMERGENCE / SETTING - The vertical distance between PUMPING LEVEL and the bottom of the pump or jet assembly. Submergence must be sufcient to insure

that the suction opening of the pump or jet assembly is always covered with water, while maintaining enough clearance from the bottom of the well to keep it out of

sediment (at least 10 foot clearance is recommended). Could be useful when guring friction loss.

SUBMERSIBLE - A pump which is designed to operate totally submersed in the uid which is being pumped. With water-proof electrical connections, using a motor

which is cooled by the liquid.

SUMP - A well or pit in which liquids collect below oor level.

SURGING - Forcing water back and forth rapidly and with more than normal force in a well or other part of the water system.

TOTAL HEAD - The sum of discharge head suction lift and friction losses.

VISCOSITY - The thickness of a liquid, or its ability to ow. Temperature must be stated when specifying viscosity, since most liquids ow more easily as they get

warmer. The more viscous the liquid the slower the pump speed required.

WATER TABLE WELL - A well where the water level is at the surface of the aquifer.

WATER TREATMENT - A process to improve the quality of water.

WATER WELL - A man-made hole in the earth from which ground water is removed.

WELL DEVELOPMENT - A process to increase or maintain the yield of a well.

19

Page 20

Pump Basics

Technical Data

MEASUREMENT CONVERSION FACTORS (APPROXIMATE)

Metric x Conversion Factor = Customary Customary x Conversion Factor = Metric

LENGTH

mm millimeter ............................. 0.04 inches in

cm centimeters ............................. 0.4 inches in

m meters ..................................... 3.3 feet ft

Pump Basics

m meters ..................................... 1.1 yards yd

km kilometers ............................... 0.6 miles mi

AREA

2

square centimeters ............... 0.16 square inches in

cm

m2 square meters ......................... 1.2 square yards yd

km2 square kilometers ................... 0.4 square miles mi

ha hectares (10.000 m2) ............. 2.5 acres

LENGTH

in inches ................................... 2.54 centimeters cm

ft feet ....................................... 30.5 centimeters cm

yd yards ....................................... 0.9 meters m

mi miles ....................................... 1.6 kilometers km

AREA

2

square inches ......................... 6.5 square centimeters cm

in

2

ft2 square feet ............................ 0.09 square meters m

2

yd2 square yards ........................... 0.8 square meters m

2

mi2 square miles ........................... 2.6 square kilometers km

a acres ....................................... 0.4 hectares ha

2

2

2

2

MASS (weight)

g grams ................................. 0.035 ounces oz

kg kilograms ................................ 2.2 pounds Ib

t tonnes(1000kg) ....................... 1.1 shorttons

VOLUME

ml milliliters .............................. 0.03 uid ounces n oz

l liters ....................................... 2.1 pints pt

l liters ..................................... 1.06 quarts qt

l liters ..................................... 0.26 gallons gal

3

cubic meters ......................... 35.3 cubicfeet tt

m

m3 cubic meters ........................... 1.3 cubic yards yd

m3 cubic meters ....................... 264.2 gallons gal.

FORCE/AREA

kPa kilo paschals ....................... .145 pound force/in

bar bar ........................................ 14.5 pound force/in

Average water requirements for general service

around the home and farm

Each person, per day for all purposes ............................................100 gal.

Each horse, dry cow or beef animal ..................................................12 gal.

Each milking cow .............................................................................35 gal.

Each hog per day................................................................................4 gal.

Each sheep per day ............................................................................2 gal.

For 100 chickens per day....................................................................4 gal.

2

psi

2

psi

MASS (weight)

oz ounces ..................................... 28 grams 9

Ib pounds .................................. 0.45 kilograms kg

short tons (2000 Ib) ................ 0.9 tonnes t

VOLUME

tsp teaspoons .................................. 5 milliliters ml

tbsp tablespoons ............................. 15 milliliters ml

oz uid ounces .............................30 milliliters ml

c cups ...................................... 0.24 liters

3

pt pints ..................................... 0.47 liters

3

qt quarts ................................... 0.95 liters

gal gallons .................................... 3.8 liters

3

cubic feet .............................. 0.03 cubic meters m

ft

yd3 cubic yards ........................... 0.76 cubic meters m

gal gallons .................................

FORCE/AREA

psi pound force/in

psi pound force/in

To sprinkle 1/4" of water on each

1000 sq. ft. of lawn ............................................................... 160 gal.

Dishwasher .................................................................10-20 gal. @ 2 GPM

Washer .................................................................up to 50 gal. @ 4-6 GPM

Regeneration of water softener .............................................up to 150 gal.

Average ow rate requirements by various xtures

GPM = GaI. per minute • GPH = Gal. per hour

2

...................... 6.89 kilo paschals kPa

2

...................... .069 bar bar

.0038

cubic meters m

3

3

3

20

Average amount of water required by various

home and yard xtures

Drinking fountain .............................................................. 50-100 gal./day

Each shower ................................................................25-60 gal. @ 5 GPM

To ll bathtub ...................................................................................35 gal.

To ush toilet..................................................................................3-7 gal.

To ll lavatory ................................................................................. 1-2 gal.

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

Shower .......................................................................................... 3-5 GPM

Bathtub ......................................................................................... 3-5 GPM

Toilet .................................................................................................4 GPM

Lavatory ............................................................................................4 GPM

Kitchen sink ......................................................................................5 GPM

1/2" hose & nozzle.............................................................................3 GPM

3/4" Hose & nozzle ............................................................................6 GPM

Lawn sprinkler............................................................................... 3-7 GPM

1-19

Page 21

Technical Data

70

60

50

40

30

20

10

0

170

160

150

140

130

120

11 0

100

90

80

70

60

50

40

30

20

10

0

HEAD OF WATER IN FEET

PRESSURE IN POUNDS PER SQUARE INCH

Jet Setting

Tail Pipe-35' long

Maximum Possible

Drawdown

Standing Level

Pump Capacity

100% at rated GPM

10 ft. suction lift - 80% rated GPM

15 ft. suction lift - 70% rated GPM

20 ft. suction lift - 57% rated GPM

25 ft. suction lift - 40% rated GPM

28 ft. suction lift - 25% rated GPM

29 ft. suction lift - 17% rated GPM

CENTRIFUGAL PUMPS | FORMULAS | CONVERSION FACTORS

Pump Basics

Pipe velocity (ft. per second) = =

Velocity head (feet) =

Water horsepower =

Brake horsepower (pump) =

Efciency (pump) = =

Brake horsepower (motor) =

Pressure (lbs. per sq. in.) = =

Head feet =

.408 x GPM

–––––––––––––

(pipe diameter)

(pipe velocity ft. per second)

––––––––––––––––––––––

GPM x head in ft. x specic gravity

––––––––––––––––––––––––––––

GPM x head in ft. x specic gravity

––––––––––––––––––––––––––––

GPM x head in ft. x specic gravity

––––––––––––––––––––––––––––

Watts input x motor efciency

––––––––––––––––––––––––

Head ft. x specic gravity

–––––––––––––––––––––

2

64.4

3960

3960 x pump efciency

3960 x BHP

746

2.31'

Lbs. per sq. in. x 2.31'

–––––––––––––––––

Specic gravity

.321 x GPM

––––––––––

pipe area

2

Head ft. x

specic gravity x

.433

Lbs. per square in. = Head in ft. x .433 • Head in ft. = lbs. per sq. in. x 2.31'

WHP

––––

BHP

Pump Basics

Offset Jet Pump - Pipe Friction

When the jet pump is offset horizontally from the well site, add the following distances to the vertical lift to approximate capacity to be received.

Friction loss in feet per 100 feet offset • Friction loss is to be added to vertical lift

JET SIZE HP 1

1/3 12 8 6 4

1/2 18 12 8 6 3 2

3/4 30 22 16 11 6 4

1 30 25 16 9 6

1 1/2 13 8 5 3

2 20 13 7 5

3 13 9 6 4

Example: Vertical distance to water is 60 feet, but a 100 feet horizontal / offset (run of piping) is required. A 3/4

HP jet pump is used so the capacity should be taken from the “80' depth to water” performance.

For example: 60 feet to water + 22 feet friction loss (with 1 1/4 x 1 1/4 two pipe system) = 82 feet, which is

approximately 80 feet.

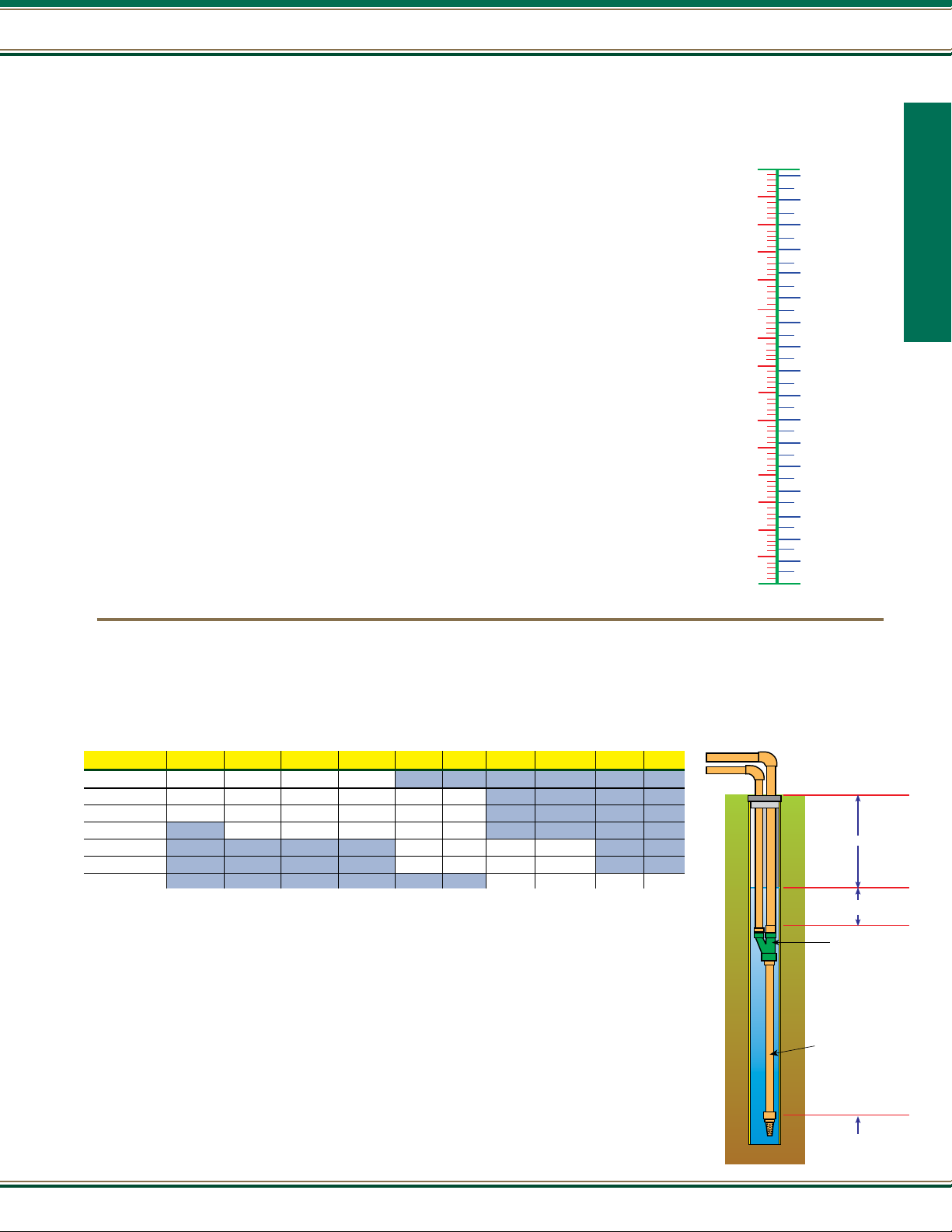

Installation of a Long Tail Pipe on Deep Well Jet Pumps

The pumping capacity of a deep well jet pump can be reduced to equalize with the well ow by installing a 35

foot tail pipe below the jet assembly.

With a tail pipe, pump delivery remains at 100% of capacity down to the ejector level. If water level falls below

that, ow decreases in proportion to drawdown as shown by gures. When delivery equals well inow, the water

level remains constant until the pump shuts off. The pump will not lose prime with this tail pipe arrangement.

1

⁄4 x 1 11⁄4 x 11⁄4 11⁄2 x 11⁄4 11⁄2 x 11⁄2 2 x 11⁄2 2 x 2 21⁄

x 2 21⁄2 x 21⁄2 3 x 21⁄2 3 x 3

2

21

Page 22

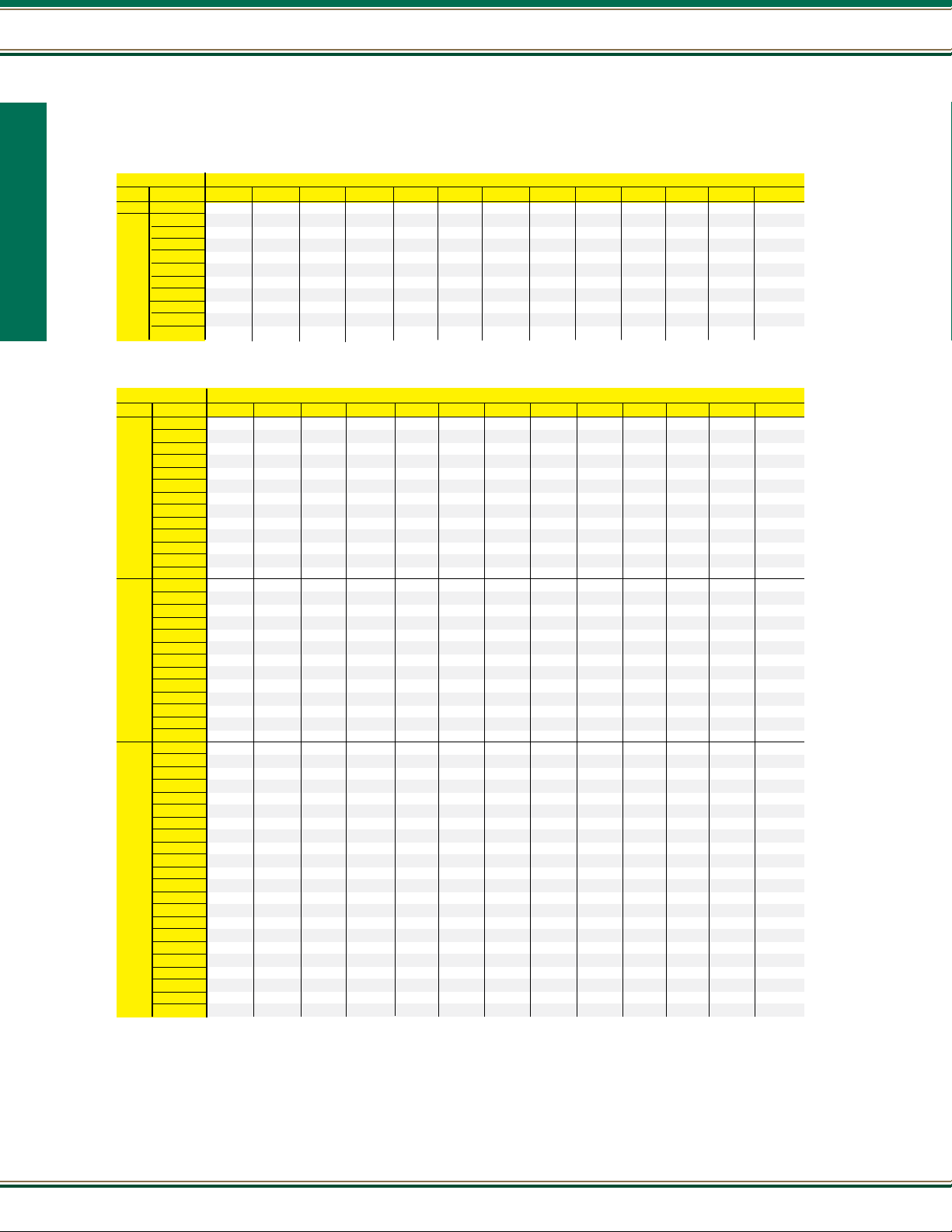

Pump Basics

Drop Cable Selection Chart

Single-Phase, Two or Three Wire Cable, 60 HZ (Service Entrance to motor)

Motor Rating Copper Wire Size

Volts HP KW 14 12 10 8 6 4 3 2 1 0 00 000 0000

115 1/2 .37 100 160 250 390 620 960 1190 1460 1780 2160 2630 3140 3770

1/2 .37 400 650 1020 1610 2510 3880 4810 5880 7170 8720

3/4 .55 300 480 760 1200 1870 2890 3580 4370 5330 6470 7870

1 .75 250 400 630 990 1540 2380 2960 3610 4410 5360 6520

Pump Basics

230 1.5 1.1 190 310 480 770 1200 1870 2320 2850 3500 4280 5240

2 1.5 150 250 390 620 970 1530 1910 2360 2930 3620 4480

3 2.2 120* 190 300 470 750 1190 1490 1850 2320 2890 3610

5 3.7 0 0 180* 280 450 710 890 1110 1390 1740 2170 2680

7.5 5.5 0 0 0 200* 310 490 610 750 930 1140 1410 1720

10 7.5 0 0 0 0 250* 390 490 600 750 930 1160 1430 1760

15 11 0 0 0 0 170* 270* 340 430 530 660 820 1020 1260

1 foot - .3048 meter

Three-Phase, Three Wire Cable, 60 HZ 200 and 300 volts (Service Entrance to motor)

Motor Rating Copper Wire Size (1)

Volts HP KW 14 12 10 8 6 4 3 2 1 0 00 000 0000

1/2 .37 710 1140 1800 2840 4420

3/4 .55 510 810 1280 2030 3160

200V 1 .75 430 690 1080 1710 2670 4140 5140

60 Hz 1.5 1.1 310 500 790 1260 1960 3050 3780

2 1.5 240 390 610 970 1520 2360 2940 3610 4430 5420

Three 3 2.2 180 290 470 740 1160 1810 2250 2760 3390 4130

Phase 5 3.7 110* 170 280 440 690 1080 1350 1660 2040 2490 3050 3670 4440

7.5 5.5 0 0 200 310 490 770 960 1180 1450 1770 2170 2600 3150

Three 10 7.5 0 0 0 230* 370 570 720 880 1090 1330 1640 1970 2390

Wire 15 11 0 0 0 160* 250* 390 490 600 740 910 1110 1340 1630

20 15 0 0 0 0 190* 300* 380 460 570 700 860 1050 1270

25 18.5 0 0 0 0 0 240* 300* 370* 460 570 700 840 1030

30 22 0 0 0 0 0 0 250* 310* 380* 470 580 700 850

1/2 .37 930 1490 2350 3700 5760 8910

3/4 .55 670 1080 1700 2580 4190 6490 8060 9860

230V 1 .75 560 910 1430 2260 3520 5460 6780 8290

60 Hz 1.5 1.1 420 670 1060 1670 2610 4050 5030 6160 7530 9170

2 1.5 320 510 810 1280 2010 3130 3890 4770 5860 7170 8780

Three 3 2.2 240 390 620 990 1540 2400 2980 3660 4480 5470 6690 8020 9680

Phase 5 3.7 140* 230 370 590 920 1430 1790 2190 2690 3290 4030 4850 5870

7.5 5.5 0 160* 260 420 650 1020 1270 1560 1920 2340 2870 3440 4160

Three 10 7.5 0 0 190* 310 490 760 950 1170 1440 1760 2160 2610 3160

Wire 15 11 0 0 0 210* 330 520 650 800 980 1200 1470 1780 2150

20 15 0 0 0 0 250* 400 500 610 760 930 1140 1380 1680

25 18.5 0 0 0 0 0 320* 400 500 610 750 920 1120 1360

30 22 0 0 0 0 0 260* 330* 410* 510 620 760 930 1130

1/2 .37 3770 6020 9460

3/4 .55 2730 4350 6850

1 .75 2300 3670 5770 9070

1.5 1.1 1700 2710 4270 6730

2 1.5 1300 2070 3270 5150 8050

460v 3 2.2 1000 1600 2520 3970 6200

60 Hz 5 3.7 590 950 1500 2360 3700 5750

7.5 5.5 420 680 1070 1690 2640 4100 5100 6260 7680

Three 10 7.5 310 500 790 1250 1960 3050 3800 4680 5750 7050

Phase 15 11 0 340* 540 850 1340 2090 2600 3200 3930 4810 5900 7110

20 15 0 0 410* 650 1030 1610 2000 2470 3040 3730 4580 5530

Three 25 18.5 0 0 0 530* 830 1300 1620 1990 2450 3010 3700 4470 5430

Wire 30 22 0 0 0 430* 680 1070 1330 1640 2030 2490 3060 3700 4500

40 30 0 0 0 0 500* 790 980 1210 1490 1830 2250 2710 3290

50 37 0 0 0 0 0 640* 800 980 1210 1480 1810 2190 2650

60 45 0 0 0 0 0 540* 670* 830* 1020 1250 1540 1850 2240

75 55 0 0 0 0 0 0 0 680* 840* 1030 1260 1520 1850

100 75 0 0 0 0 0 0 0 0 620* 760* 940* 1130 1380

125 90 0 0 0 0 0 0 0 0 0 0 740* 890* 1000*

150 110 0 0 0 0 0 0 0 0 0 0 0 760* 920*

175 130 0 0 0 0 0 0 0 0 0 0 0 0 810*

200 150 0 0 0 0 0 0 0 0 0 0 0 0 0

Lengths marked * meet the U.S. National Electrical Code ampacity only for individual conductor 75°C cable. Only the lengths without

cable. Local code requirements may vary.

meet the code for jacketed 75°C

*

CAUTION!! Use of wire sizes smaller than determined above will void warranty, since low starting voltage and early failure of the unit will result. Larger wire sizes (smaller

numbers) may always be used to improve economy of operation.

(1) If aluminum conductor is used, multiply above lengths by 0.61. Maximum allowable length of aluminum wire is considerably shorter than copper wire of same size.

22

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 23

Pump Basics

Pump Basics

Submersible Pumps

Submersible

Pumps

Pump Catalog -

MORE THAN A BRAND. WE’RE A FAMILY.

January 2019

23

Page 24

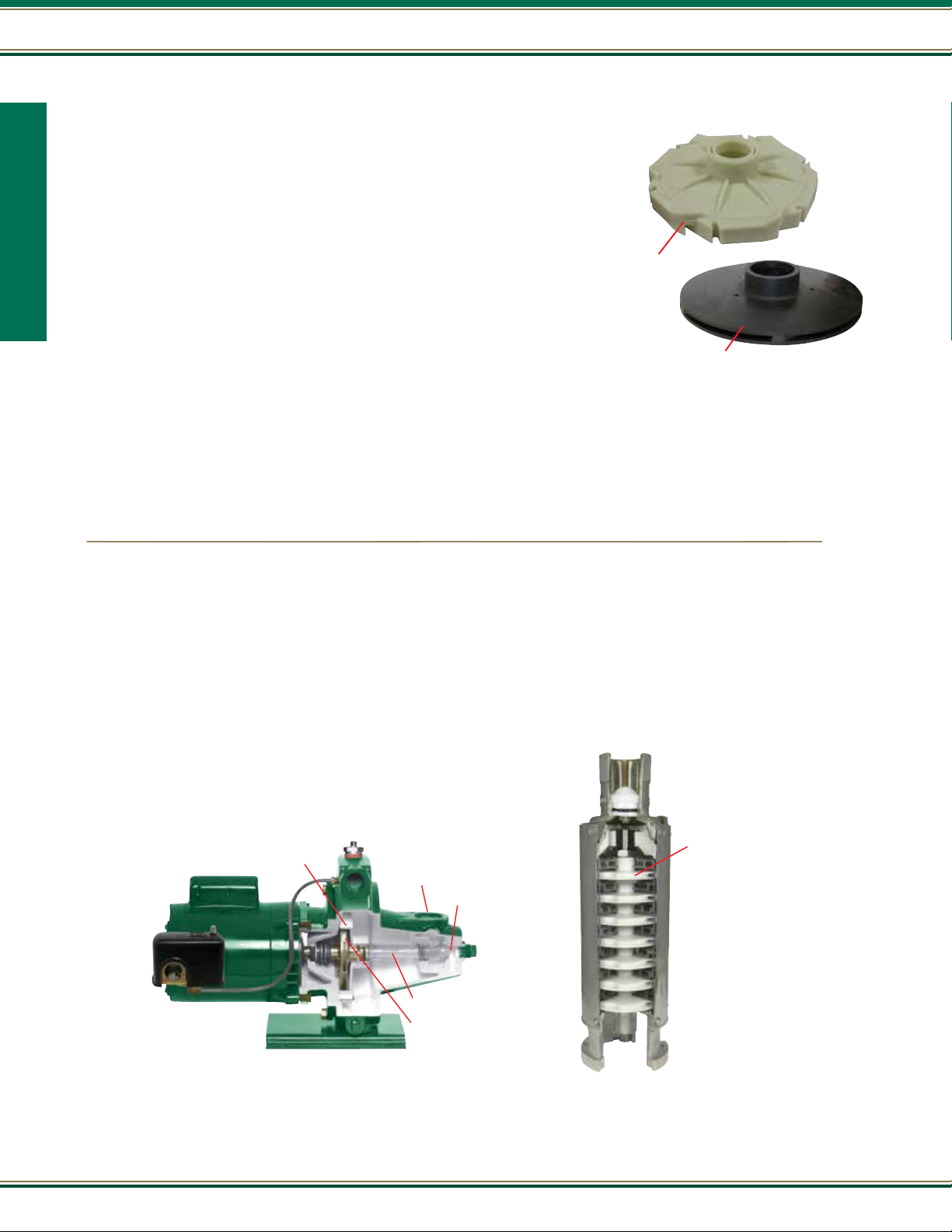

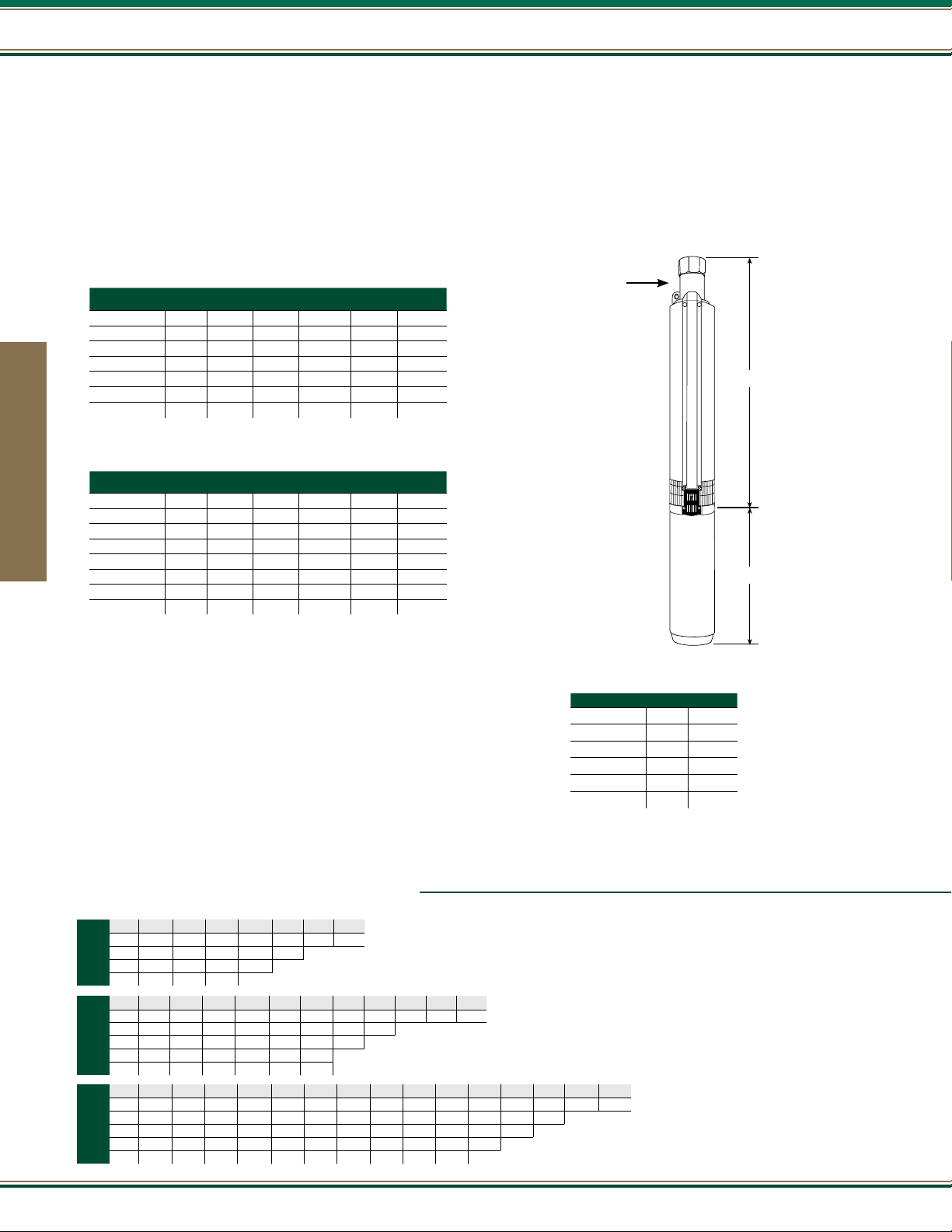

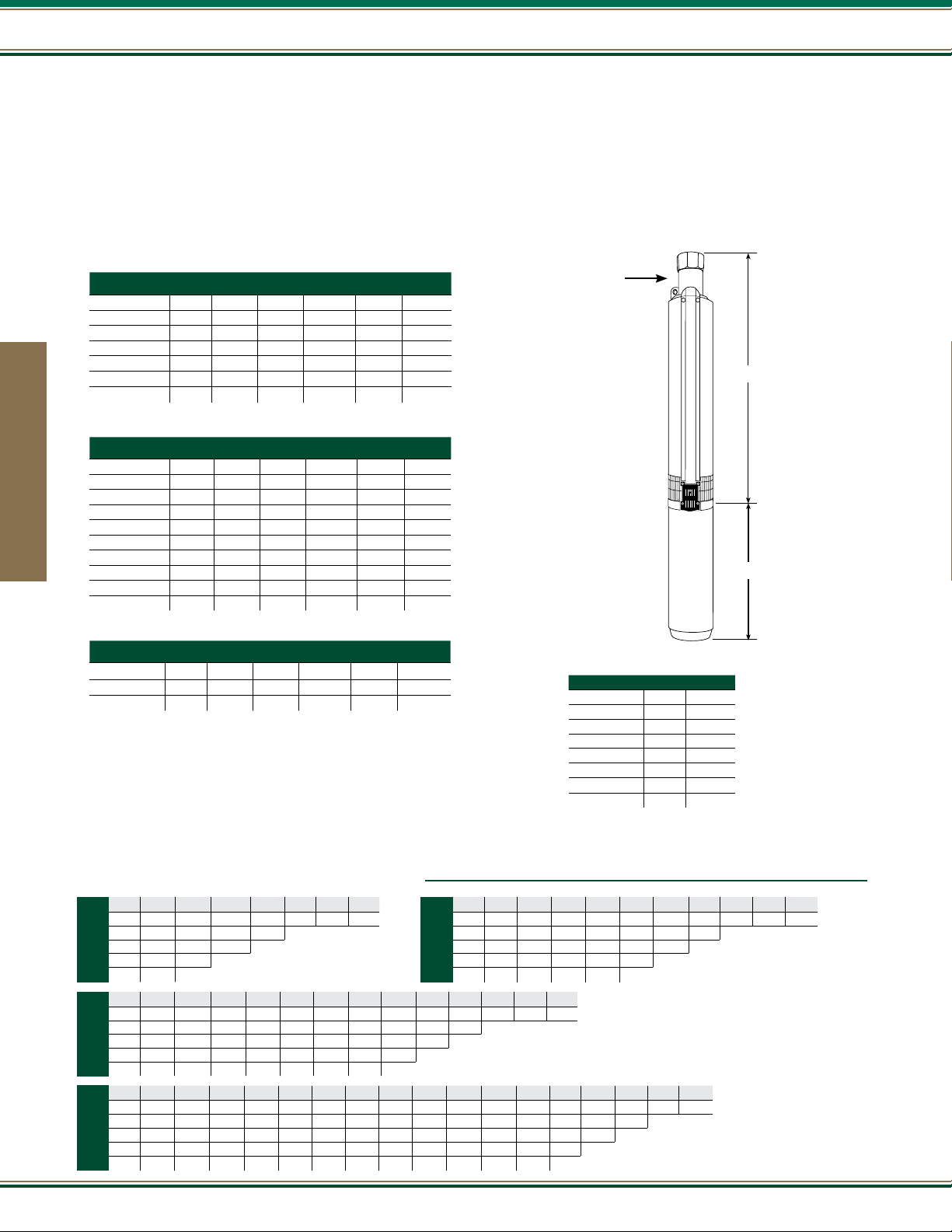

21000 Series

21000 Series

A.Y. McDonald offers a full line of four inch submersibles ranging from 1/3 through 5 horsepower, with ow

rates ranging from 5 to 25 GPM. Our 21000 submersibles offer peak capacity performance in 5, 7, 10, 15,

20, and 25 GPM models.

Powered by NEMA approved A.Y. McDonald stainless steel motors.

The charts on the following page will assist you in choosing the pump that meets your needs.

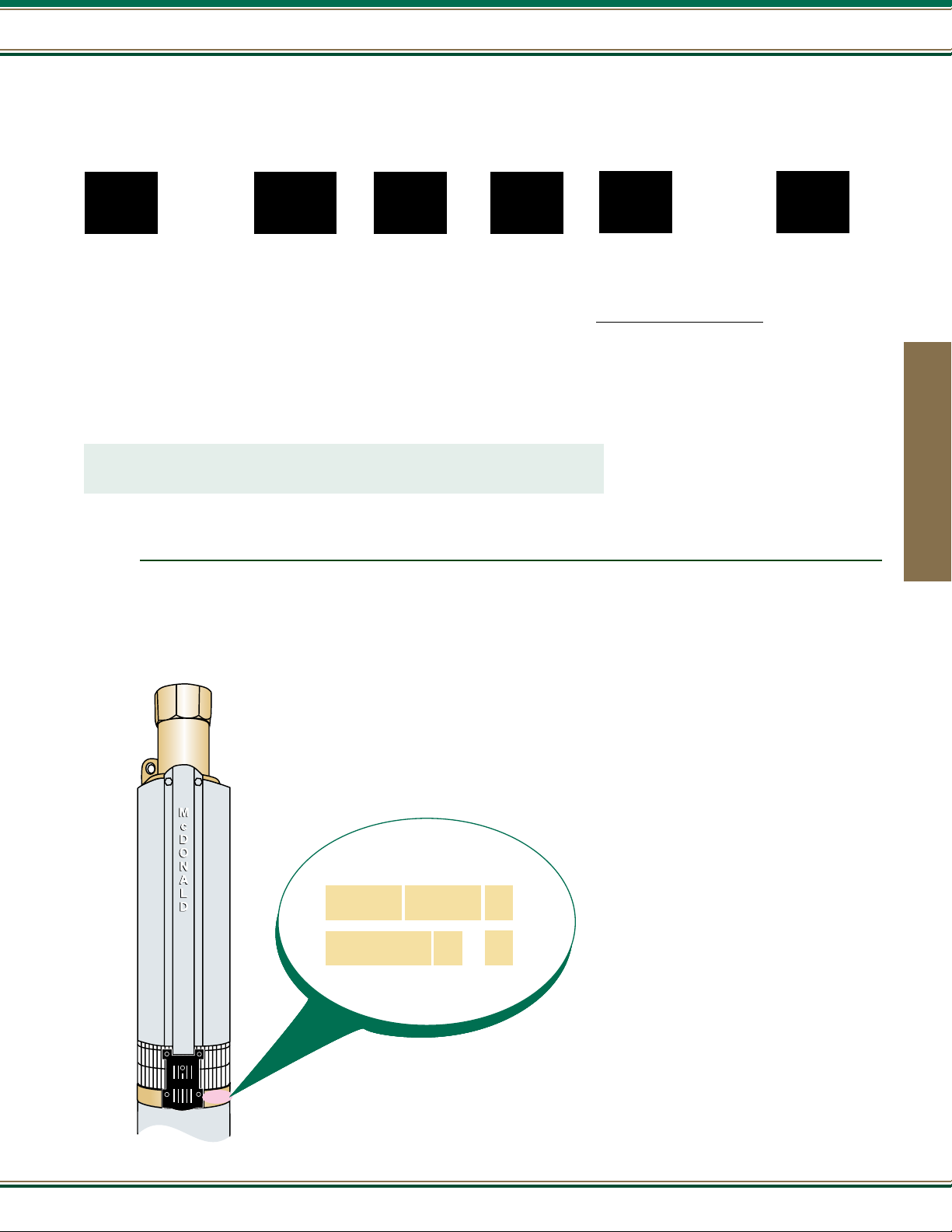

Discharge Casting

No-Lead Brass Alloy

Cable Guard

Stainless steel cable guard protects motor

leads. Angled top helps keep leads stationary

when lowering and raising submersible

pump.

Submersible Pumps

Check Valve

Acetal check valve poppet and seal housing, Buna-N

O-ring, and stainless steel washer head retention

screw. Threaded for easy installation or removal.

Working pressure of 400 PSI.

Discharge Bearing

Rubber surrounding the stainless steel

shaft provides superior wear resistance

against the harshest conditions while

maintaining shaft alignment. Self

lubricating for long life.

Diffuser

Polycarbonate durable, corrosion, and

abrasion resistant. Designed for efcient

performance and superior sand handling

capability.

Impeller

Glass Bead Acetal. This smooth and exible

material is precision

engineered for maximum performance.

- Once assembled, each

pump is individually tested to

assure performance within

design specications.

- Each pump is stamped with

the tester’s “signature” marking

to assure quality control.

- Non-corrosive in-take screen

- Cutaway illustrates features and

is not indicative of specic

model performance.

A.Y. McDonald uses it’s time proven captured

stack design. The captured stack design

incorporates sand notches into the diffusers,

which has proven, over time, to keep sand

owing thru the stack.

Polished Stainless Steel Shell

Heavy duty and threaded at both ends for

easy eld service.

Shaft

7/16” 300 series stainless steel, hex design

for positive impeller drive. Each shaft

individually measured for straightness with

strict tolerances.

Stainless steel motor coupling.

Motor Bracket

No-Lead Brass Alloy

24

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 25

How to Order 4” Submersible Pumps

Order by Model Number - Example: 21050K3A

21000 Series

21 050 K 3

Pump Model

21 - No-Lead Brass

22 - Thermoplastic

23 - Domestic Stainless Steel

24 - Stainless Steel

Model 21050K3A is a 1/2 HP, three wire, 115 volt, single phase no-lead brass

4" submersible pump, designed to pump in the 10 GPM range.

Horsepower

030 - 1/3 HP

050 - 1/2 HP

075 - 3/4 HP

100 - 1 HP

150 - 1 1/2 HP

200 - 2 HP

300 - 3 HP

500 - 5 HP

NOTES

- Standard is 230V, Single Phase, 60 HZ (no sufx letter required)

- Two-Wire Single phase models include; pump, motor, leads

- Three-Wire Single phase models include; pump, motor, leads, and control box

- Three-Wire Three phase models include; pump, motor, leads, and starter kit

- All submersible pumps include internal check valves and ground lead on motor.

Series

J Series - 5 GPM

V Series - 7 GPM

K Series - 10 GPM

L Series - 15 GPM

P Series - 20 GPM

M Series - 25 GPM

Wires

Two wire or

Three wire

A

Other Controls

Leave blank for 230V

60 HZ, Single Phase (Standard)

A - 115V Single Phase

Other Options Contact Factory

Z - 230V Three Phase

Y - 460V Three Phase

Leave blank for

Control (Standard)

LB - Less box

(Single Phase Option)

LS - Less starter

(Three Phase Option)

Submersible Pumps

Locating the code number on the pump

K18050K

230V2 X

EXAMPLE

Date Code

Motor HP

Pump

Series

K18 050 K

230V 2 X

Voltage

No. of

Power

Leads

Assembler’s

Code

A code is stamped on each A.Y. McDonald

submersible pump. Contained in this code is the

following information:

- Date of manufacture

- Motor HP

- Pump Series

- Voltage

- Number of power leads

- Assembler’s code

25

Page 26

21000 Series

M

c

D

O

N

A

L

D

A

B

J Series - 5 GPM

A.Y. McDonald offers a full line of no-lead brass submersible pumps built for years of trouble free operation, with high-efciency impellers

and diffusers. These submersibles offer peak capacity performance in 5, 7, 10, 15, 20, and 25 gallons per minute (GPM). Other features

include no-lead discharge head with a built-in check valve, and stainless steel shaft and coupling.

All J Series No-Lead Pumps come with a 1 1/4” discharge and sizes range from 1/3 to 1 1/2 horse power (HP). Two or three wire models

up to 1 1/2 horse power (HP).

Two Wire Single Phase

Model No. HP Stages Volt A B Wt.

21030J2A* 1/3 9 115 13.48" 9.53" 26

21030J2* 1/3 9 230 13.48" 9.53" 26

21050J2A 1/2 13 115 16.68" 9.53" 30

21050J2 1/2 13 230 16.68" 9.53" 30

21075J2 3/4 18 230 20.67" 10.66" 36

21100J2 1 23 230 25.93" 11.75" 41

21150J2 1 1/2 30 230 31.45" 15.12" 49

Three Wire** Single Phase

Model No. HP Stages Volt A B Wt.

Submersible Pumps

21030J3A* 1/3 9 115 13.48" 9.53" 26

21030J3* 1/3 9 230 13.48" 9.53" 26

21050J3A 1/2 13 115 16.68" 9.53" 30

21050J3 1/2 13 230 16.68" 9.53" 30

21075J3 3/4 18 230 20.67" 10.66" 36

21100J3 1 23 230 25.93" 11.75" 41

21150J3 1 1/2 30 230 31.45" 13.28" 41

Three Wire Three Phase

Model No. HP Stages Volt A B Wt.

21150J3Z 1 1/2 30 230 31.45" 11.75" 45

Pump end

discharge

1 1/4" FNPT

3 3/4" diameter

with cable guard

4” No-Lead Brass Pump Ends

Model No. HP Wt.

21030J 1/3 10

21050J 1/2 11

21075J 3/4 13

21100J 1 15

21150J 1 1/2 18

26

* All one-third horsepower pumps are furnished with one-half horsepower motors (and control boxes where applicable).

** All three wire pumps are available in three phase by selecting pump end and appropriate motor and starter kit (see pages 108-118).

Output

1/3

1/2

3/4

- in Gallons Per Minute (Depth to Water)

PSI 25’ 50’ 75’ 100’ 125’ 150’ 175’ 200’ 225’

0 11.7 10.6 9.5 8.4 7.3 6.1 4.8 3.4 1.8

30 8.6 7.5 6.4 5.1 3.8 2.2

40 7.6 6.4 5.2 3.9 2.3

HP

50 6.5 5.3 4.0 2.5

PSI 25’ 50’ 75’ 100’ 125’ 150’ 175’ 200’ 225’ 250’ 275’ 300’ 325’

0 11.9 11.2 10.5 9.8 9.1 8.4 7.6 6.8 6.0 5.0 4.1 3.0 1.8

30 10.0 9.2 8.5 7.8 7.0 6.1 5.3 4.3 3.2 2.1

40 9.3 8.6 7.8 7.0 6.2 5.3 4.4 3.3 2.2

HP

50 8.6 7.9 7.1 6.3 5.4 4.4 3.4 2.3

60 7.9 7.2 6.3 5.5 4.5 3.5 2.3

PSI 25’ 50’ 75’ 100’ 125’ 150’ 175’ 200’ 225’ 250’ 275’ 300’ 325’ 350’ 375’ 400’ 425’ 450’

0 12.2 11.7 11.2 10.7 10.2 9.7 9.2 8.7 8.1 7.6 7.1 6.5 5.9 5.3 4.7 4.0 3.3 2.6

30 10.8 10.3 9.8 9.3 8.8 8.3 7.7 7.2 6.6 6.1 5.5 4.9 4.2 3.5 2.7 1.9

40 10.3 9.8 9.3 8.8 8.3 7.8 7.2 6.7 6.1 5.5 4.9 4.3 3.6 2.8 2.0

HP

50 9.9 9.4 8.9 8.3 7.8 7.3 6.7 6.2 5.6 4.9 4.3 3.6 2.9 2.0

60 9.4 8.9 8.4 7.9 7.3 6.8 6.2 5.6 5.0 4.4 3.7 2.9 2.1

FRICTION LOSSES IN RISER PIPE

HAVE NOT BEEN CALCULATED

800.292.2737 | FAX 800.832.9296 | sales@aymcdonald.com | aymcdonald.com

1-19

Page 27

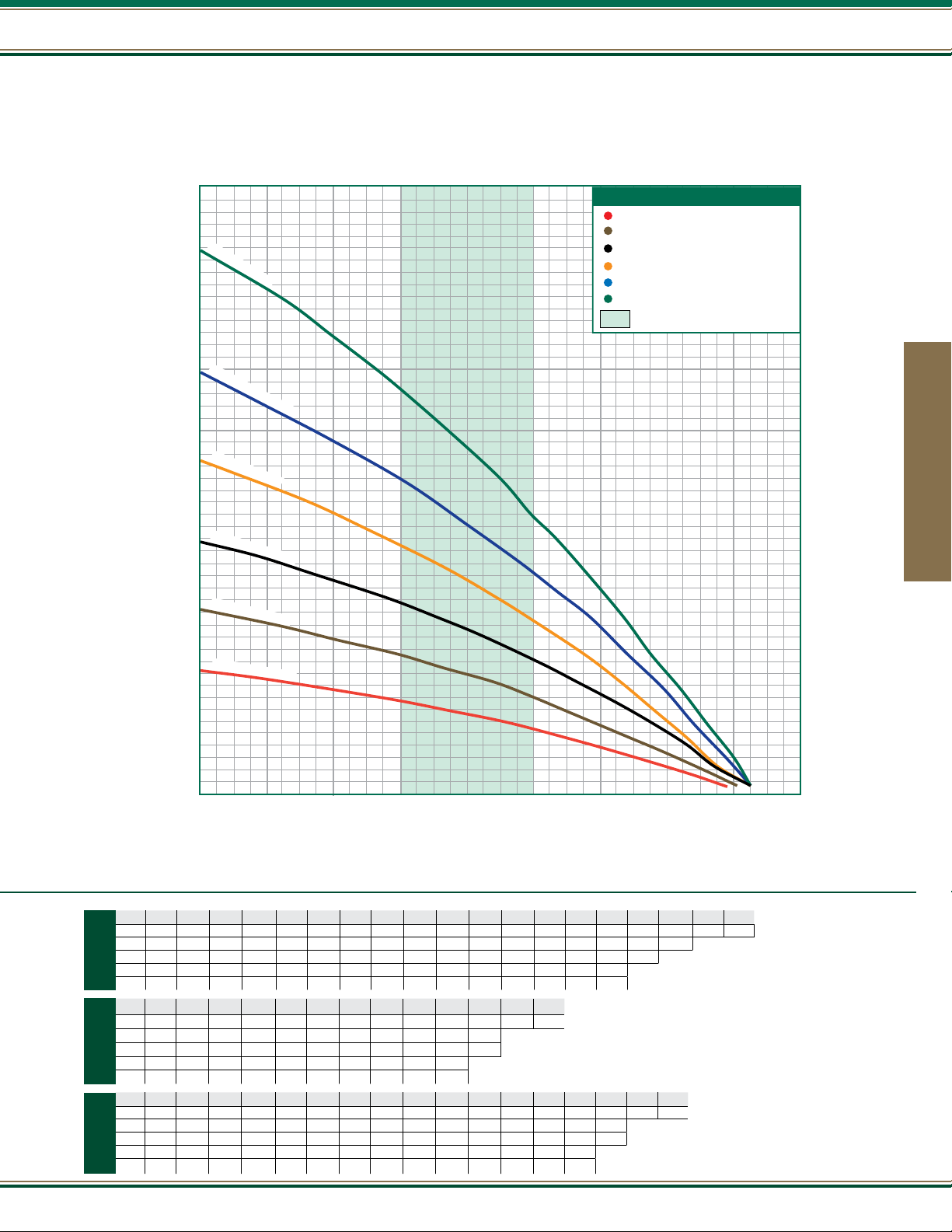

J Series - 5 GPM

21000 Series

900

1

1

/

2

H

800

700

600

500

400

TOTAL HEAD IN FEET

300

200

P

•

3

0

1

H

P

•

2

3

S

t

a

g

3

/

4

H

P

•

1

8

S

1

/

2

H

P

•

1

3

S

1

/

3

H

P

•

9

S

t

SHUTOFF HEAD

1/3 HP 245 FT. • 106 P.S.I.

1/2 HP 361 FT. • 156 P.S.I.

S

t

a

g

e

s

e

s

t

a

g

e

s

t

a

g

e

s

a

g

e

s

3/4 HP 512 FT. • 222 P.S.I.