A.Y. McDonald Natural Gas User Manual

WITHOUT YOU

THERE IS NO US.

Natural Gas

Product Catalog

April 2019

Table of Contents

Page

General Information

General Information .................................................................... 2-8

Freight Program ..............................................................................3

Trade Customs ................................................................................4

Traceability......................................................................................6

Natural Gas Ball Style

Natural Gas Ball Style ............................................................... 9-11

Features ........................................................................................10

860 / 8276 Series ..........................................................................11

Natural Gas Plug Style

Natural Gas Plug Style ............................................................ 13-18

Re-Lubrication Tool .......................................................................14

Natural Gas Meter Plug Valve Features .........................................15

559 Series .....................................................................................16

560 Series .....................................................................................17

6276 Series ...................................................................................18

Page

Natural Gas Cast Iron Meter Bars

Natural Gas Cast Iron Meter Bars............................................ 39-81

Pressure Tap Locations..................................................................40

Outlet Options ...............................................................................41

6600 Series ............................................................................. 42-43

6610 Series ............................................................................. 44-45

6640 Series ............................................................................. 46-47

6604 Series ............................................................................. 48-49

6614 Series ............................................................................. 50-51

6644 Series ............................................................................. 52-53

6684 Series ............................................................................. 54-55

6560 Series ............................................................................. 56-57

6570 Series ............................................................................. 58-59

6569 Series ............................................................................. 60-61

6660 Series ............................................................................. 62-63

6670 Series ............................................................................. 64-65

6620 Series ............................................................................. 66-67

6624 Series ............................................................................. 68-69

6564 Series ............................................................................. 70-71

6814 Series ............................................................................. 72-73

6918 Series ............................................................................. 74-75

6722 / 6722L Series ................................................................ 76-77

6762 Series ............................................................................. 78-79

6712 / 6712L Series ................................................................ 80-81

Natural Gas Bypass Ball Valves

Natural Gas Bypass Ball Valves .............................................. 19-34

Meter Valve Tap Features ........................................................ 20-21

835 Series ............................................................................... 22-23

837 Series ............................................................................... 24-25

855 Series ............................................................................... 26-27

857 Series ............................................................................... 28-29

875 Series ............................................................................... 30-31

877 Series ............................................................................... 32-33

861 / 8277 Series ..........................................................................34

Natural Gas Portable Bypass Kits

Natural Gas Portable Bypass Kits............................................ 35-38

Portable Bypass Kits Features .......................................................36

Add On Parts .................................................................................37

Replacement Parts ........................................................................38

Natural Gas Bypass Meter Bars

Natural Gas Bypass Meter Bars............................................... 83-91

6410 Series ............................................................................. 84-85

6480 Series ............................................................................. 86-87

6312 Series ............................................................................. 88-89

6282 Series ............................................................................. 90-91

Natural Gas Accessories

Natural Gas Accessories.......................................................... 93-97

Meter Nuts.....................................................................................94

Meter Plugs ...................................................................................94

Gaskets for Swivels .......................................................................94

Meter Adapters-Zinc......................................................................94

Non-Insulated Swivels-Black / Galvanized ....................................95

Insulated Swivels-Zinc ..................................................................95

6300 3 Part Union-Female ............................................................96

6301 3 Part Union-Female ............................................................96

6310 3 Part Union-Male ................................................................96

6311 3 Part Union-Male ................................................................96

Union Nuts-Female........................................................................97

Union Nuts-Male ...........................................................................97

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

2

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-194-19

General Information

Freight Program

I. PRODUCT GROUP QUALIFICATION LEVELS

Freight will be prepaid and allowed by Seller on orders that meet or exceed the following net prices or unit qualiers (net prices reect list prices

less applicable discounts):

1. High Pressure Gas (may be combined with plumbing Valves) ............................................................................................ $2,500 Net

2. Water Service Products (may be combined with Curb Boxes, Pumps, Pump Accessories, Plumbing Valves,

Frames & Covers, HPG, and Yoke Boxes) ............................................................................................................................$6,000 Net

3. Pumps ...................................................................................................................................................................................12+ units

4. Plumbing Products (may be combined with Pump Accessories) .......................................................................................... $1,300 Net

5. Tanks ................................................................................... 24+ units (may be 24 units in combination with Jets and Submersibles)

6. Pit Setters . . . 15” diameter – 144 units

18” diameter – 96 units

21” diameter – 72 units

24” diameter – 48 units

30” and 36” diameter – 24 units

General Information

II. ADDITIONS

Once an order qualies for freight in any product group, other products on your order ride free (excluding Tanks and Pit Setters). However, additions

to freight allowed orders will NOT be allowed once the original order is on board or a partial shipment has been made against the original order.

Freight qualiers are subject to change without notice.

Dimensions and weights are reference only and are subject to change.

3

General Information

Trade Customs

CONTROLLING PROVISIONS: These terms and conditions supersede all previous terms and

conditions and shall control any sale by A.Y. McDonald Mfg. Co. (“Seller”). No alteration or

waiver of these terms and conditions shall be valid unless specically accepted in writing

by an authorized representative of Seller.

PRICES: Billing prices are those in effect at the time the order is shipped. All prices are

subject to change without notice. Possession of a price sheet shall not be construed as an

offer to sell. Seller reserves the right to reject any order.

TERMS: 2% 10th Prox., Net 25th (A 2% cash discount can be taken on the 10th of the

month following the shipment. The month is dened as the 26th through the 25th. For

General Information

General Information

example, a February 25th invoice is due 2% on March 10th, a February 26th invoice is due

2% April 10th, and all invoices are due net the 11th and considered past due on the 26th

of the month). Without open credit terms, payment may be required prior to shipping. A 2%

monthly service charge (or the maximum amount permitted by law) may be applied to the

balance of any past-due invoice. Buyer shall pay any necessary collection fees, including

reasonable attorney fees.

TAXES: Any sales tax, use tax, manufacturer tax, duty, or other cost imposed by any government

entity shall, at Seller’s option, be added to the purchase price and payable by buyer. Buyer

must certify any tax exemption and agree to indemnify Seller against any tax imposed

contrary to such certication.

FREIGHT: All prices are F.O.B. Seller’s factory, with full freight allowed within the contiguous

United States and Canada on the orders that qualify pursuant to the Freight Program

schedule. Seller reserves the right to select the carrier and route of shipment and to ship

at the most economical rate. All extra charges for special handling or delivery services

will be paid for by the buyer. Terms for shipment outside the contiguous United States and

Canada shall be established on a case-by-case basis.

THIS LIMITED WARRANTY EXTENDS ONLY TO BUYERS WHO PURCHASE SELLER'S PRODUCT(S)

DIRECTLY FROM SELLER ("ORIGINAL PURCHASERS"), INCLUDING DISTRIBUTORS,

WHOLESALERS, UTILITIES, AND CONTRACTORS. THIS LIMITED WARRANTY IS NOT ASSIGNABLE

OR OTHERWISE TRANSFERABLE BY THE ORIGINAL PURCHASER TO ANY OTHER PARTY. SELLER

EXTENDS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

TO "CONSUMERS," AS THAT TERM IS DEFINED IN THE MAGNUSON-MOSS WARRANTY ACT

(15 U.S.C. SECTIONS 2301 ET SEQ.) AND THE REGULATIONS PROMULGATED THEREUNDER.

IN NO EVENT SHALL THE DURATION OF ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE BE LONGER THAN THE NINETY (90) DAY PERIOD

PRESCRIBED HEREIN.

This Limited Warranty shall not apply to product failure or defect: due to a defect in the

design, engineering, or installation of any water, gas, or other system; where the product has

been modied without the prior written authority of Seller; caused by the failure to install

or use the product in conformity with any instructions or specications provided by Seller;

caused by the improper installation, use, application, maintenance, repair, transportation,

handling, or storage of the product; caused by the fault or negligence of anyone other than

Seller or any other act or event beyond the control of Seller. Seller makes no warranties as

to any products or product parts or components that are not manufactured by Seller. The

limitations of liability contained in this Limited Warranty shall be effective without regard to

Seller's performance or failure or delay of performance under any other term or condition of

any trade customs, warranty, or other agreement. No employee, representative, or agent of

Seller, nor any other person, has authority to assume or incur on behalf of Seller any liability,

obligation, or responsibility in place of or in addition to this Limited Warranty."

CLAIMS: Inspect all shipments immediately upon receipt, examining products for damage

and verifying quantity. Any claim of damage, shortage, or non-conformance must be made

in writing within 5 business days of receipt of goods (any claim of damage or shortage must

be noted on the Freight Carrier’s signed delivery receipt).

“LIMITED WARRANTY Subject to the limitations stated herein, A.Y. McDonald Mfg. Co.

("Seller") warrants that high pressure gas products manufactured by Seller shall be free

from defects in material and workmanship and shall perform the services for which they

are intended when properly installed, under normal use, and under ordinary conditions, for

a period of ninety (90) days from the date of shipment from Seller's factory. This Limited

Warranty does not cover or apply to water service products, plumbing products, or pumps

or pump accessories manufactured by Seller. Buyer must notify Seller in writing of a

potentially defective product as soon as possible and not later than ninety (90) days from

the date of shipment from Seller's factory. Upon receipt of such notice, Seller shall, at its

option and at its expense, examine such product at Seller's factory or such other location as

Seller shall determine. Should Seller agree to a return of the product, buyer shall follow in

every respect the packaging and transportation instructions provided by Seller. In no case

shall a product be returned without rst obtaining the permission of Seller. If a product is

proven to the satisfaction of Seller to be defective, then Seller shall, at its option and at its

expense, repair or replace such product or reimburse buyer for the price paid by buyer for

such product. The cost of shipping to buyer a repaired or replaced product shall be paid by

Seller on the same shipping terms as the original shipment of such product to buyer. Except

as stated herein, buyer shall assume all responsibility and expense for any dismantling,

removal, reinstallation, and shipping in connection with this Limited Warranty, and no

claims will be allowed for labor, shipping, materials, or other costs incident to the repair,

replacement, or return of a product.

THIS LIMITED WARRANTY IS THE ONLY WARRANTY PROVIDED BY SELLER AND IS MADE IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

SELLER'S LIABILITY IS LIMITED TO REPAIR, REPLACEMENT, OR REIMBURSEMENT AS

PROVIDED ABOVE, AND IN NO EVENT SHALL SELLER'S LIABILITY EXCEED THE PURCHASE

PRICE OF THE PRODUCT(S) INVOLVED. THIS LIMITED WARRANTY PROVIDES THE EXCLUSIVE

REMEDY AGAINST SELLER FOR CLAIMS RELATING TO PRODUCTS, WHETHER IN CONTRACT,

IN TORT (INCLUDING NEGLIGENCE), OR UNDER ANY OTHER LEGAL THEORY, AND WHETHER

ARISING OUT OF WARRANTIES, REPRESENTATIONS, INSTRUCTIONS, OR DEFECTS FROM

ANY CAUSE. IN NO EVENT SHALL SELLER BE LIABLE FOR OR OBLIGATED TO PAY ANY

CONSEQUENTIAL, INCIDENTAL, SPECIAL, INDIRECT, OR PUNITIVE DAMAGES OF ANY KIND.

ORDERS: Seller is not responsible for and shall not be held liable for damages resulting from

delays or failures in shipment, nor shall Seller be liable for any delay or failure to provide

goods where occasioned by any force majeure event, including without limitation: strikes

and other labor disputes; res; acts of God; oods, snowstorms, tornados, and other storms;

unusually severe inclement weather conditions; fuel, energy, carrier, or material shortages or

embargoes; war; terrorism; civil disturbances; acts of civil or military authority; court order

or decree; partial or complete destruction of factory or other facility; acts of buyer; inability

to obtain or retain fuel, energy, carriers, materials, facilities, or labor without litigation or

the payment of penalties or unreasonable prices or the acceptance of unreasonable terms

and conditions; and any other cause beyond Seller’s control.

RETURNS: Goods cannot be returned without the prior written approval of Seller. Return

freight must be prepaid by buyer. After inspecting the returned goods, Seller may impose

upon buyer: (1) a handling and restocking charge equal to a minimum of 25% of the invoiced

cost of the returned goods; and, in addition thereto, (2) any costs required to put the goods

in like-new condition. All credit memos are subject to cash discount terms as dened in

our standard terms.

CANCELLATION: The contract resulting from Seller’s acceptance of Buyer’s order cannot be

cancelled, terminated, or modied by Buyer, in whole or in part, except upon Seller’s prior

written approval.

NON-STOCK PRODUCTS: Non-stock products (i.e., customized or non-standard products) may

require a minimum order and buyer should make prior inquiry to Seller. Once production has

begun, orders for non-stock products cannot be cancelled without the prior written approval

of Seller. Seller will not accept the return of non-stock products.

CONSTRUCTION: All sales, contracts, and offers to buy or sell, all rights, remedies and duties

of all persons, and the construction and effect of all provisions hereof, shall be governed by

and construed according to the laws of the State of Iowa.

WARNING: It is unlawful in CALIFORNIA & VERMONT (effective 1/1/2010); MARYLAND (effective 1/1/2012); LOUISIANA (effective 1/1/2013) and the UNITED STATES OF

AMERICA (effective 1/4/2014) to use any product in the installation or repair of any public water system or any plumbing in a facility or system that provides water for human

consumption if the wetted surface area of the product has a weighted average lead content greater than 0.25%. This prohibition does not extend to service saddles used in

California, Louisiana or under USA Public Law 111-380. WARNING: This product can expose you to chemicals including lead, which is known to the State of CALIFORNIA

to cause cancer and birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov.

4

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

General Information

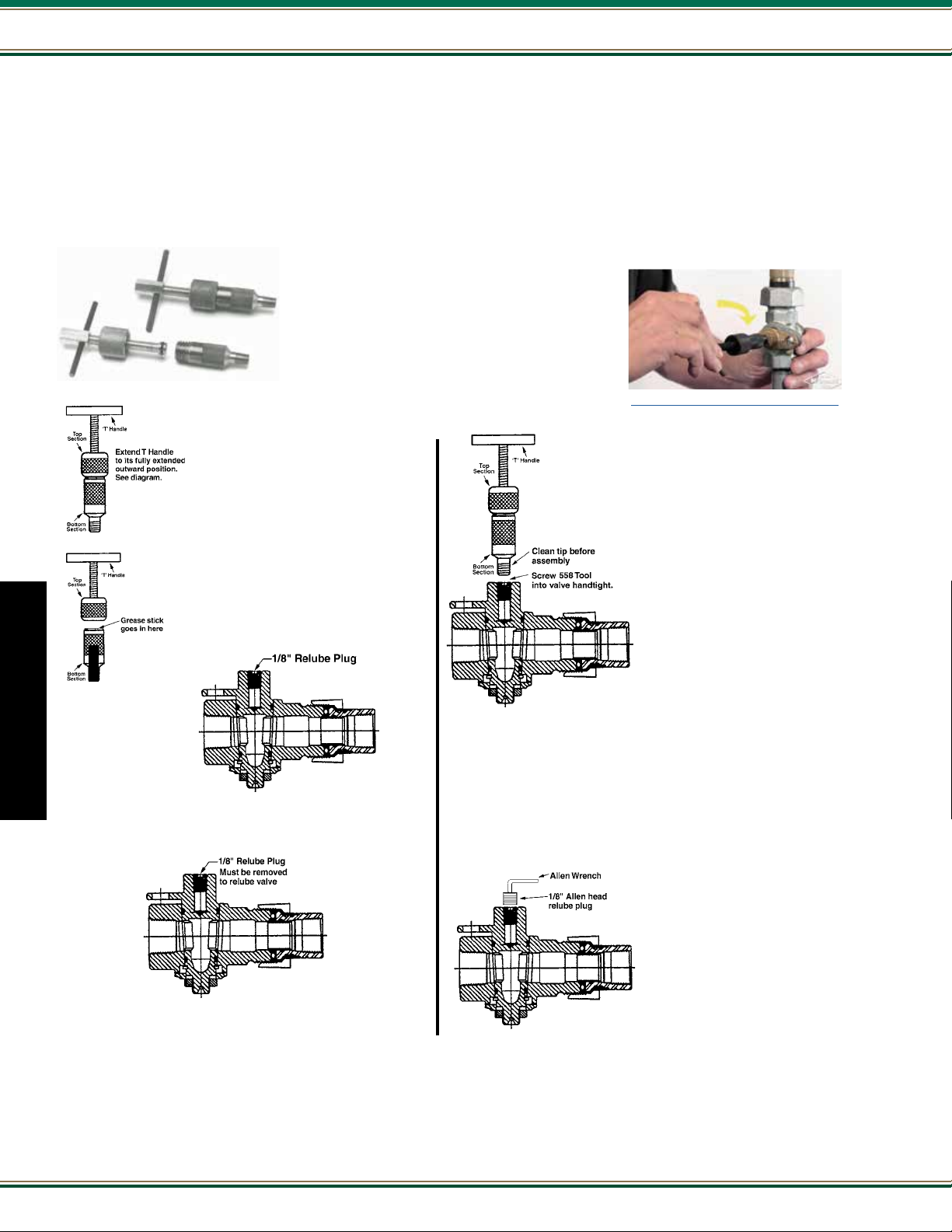

YOU SPOKE AND WE LISTENED.

METER SET ASSEMBLY SAFETY, TESTING, TECHNOLOGY, INNOVATION, CUSTOMER SERVICE.

A.Y. McDonald has been assembling for a long time but we are doing it for the first time ever as a full Meter Set Assembly.

Our Meter Set Assemblies combine safety, testing, technology, innovation, and customer service in a single solution. With 163

years of expertise and knowledge to rely on, you won’t be disappointed with the result!

General Information

At A.Y. McDonald, you aren’t just getting a product; you are getting an innovative

solution, access to educational opportunities, and the ability to be treated like

family. The customer is the boss and we aim to break the mold on how we reach

customer satisfaction. Because in the end, without you, there would be no us.

sales@aymcdonald.com I 800.292.2737 I aymcdonald.com

5

General Information

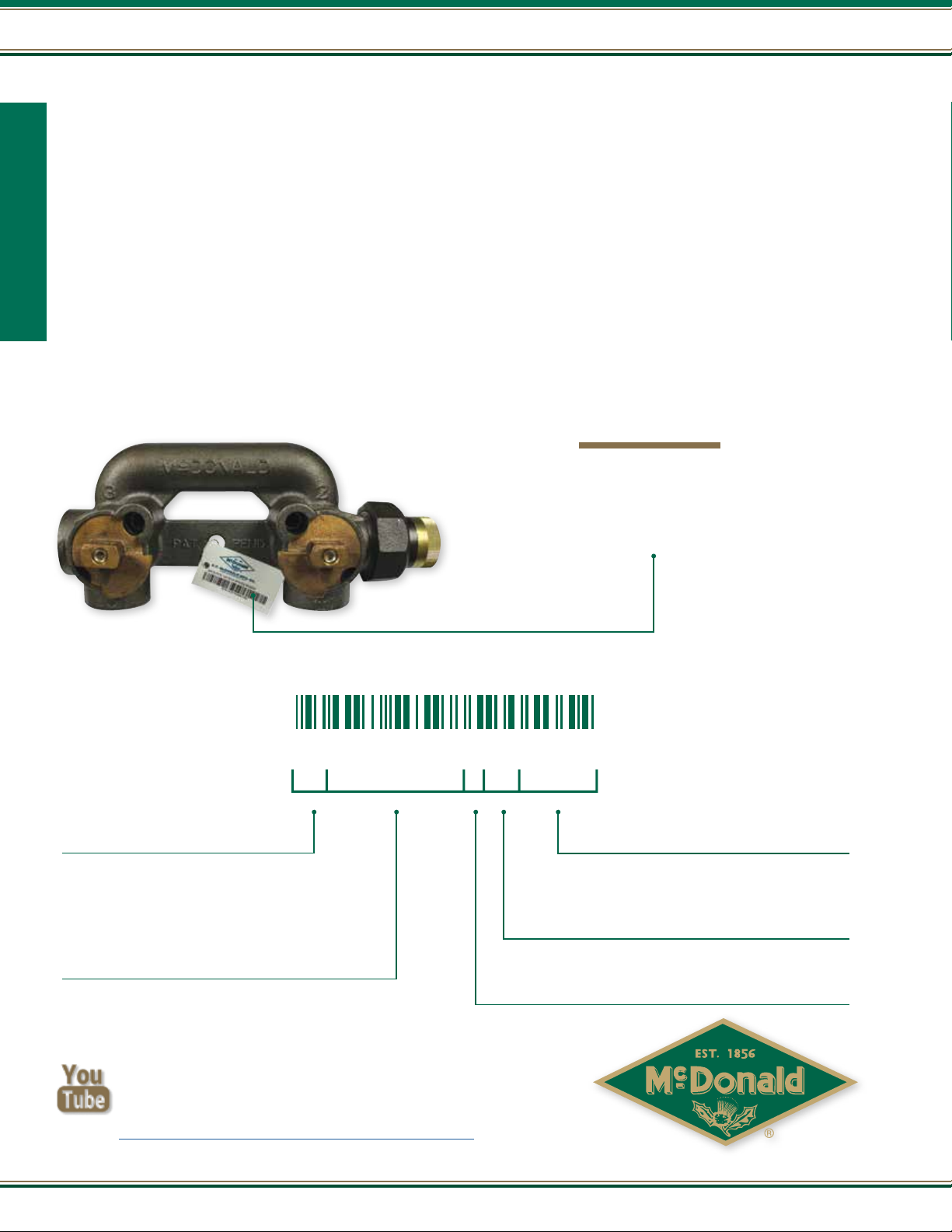

WELCOME TO

THE STANDARD OF SAFETY.

A.Y. McDonald designs and manufactures our natural gas products to comply with several industry standards – ASME, ANSI, and ASTM. But as

of May 1, 2015, we took this a step further by starting to mark A.Y. McDonald natural gas products with a new barcode that was developed in the

new ASTM F-2897-14 standard. As a real game changer, A.Y. McDonald is one step ahead when it comes to our commitment to gas safety and

accountability through the use of traceability tags!

New times, new technology Making accountability easy

General Information

Thanks to traceability, city streets and backyards can be a whole lot

safer. With innovation and organization at its core, the ASTM F-289714 standard determines the information gas distribution products are

marked with. In the event of an accident caused by a gas leak, gas

utilities can access this information to locate other potentially faulty

products. Through inspections and necessary replacements, we can

prevent future accidents.

To make this standard of traceability convenient for you, A.Y.

McDonald has made TRACE TAGS standard on each and every

gas valve and meter bar we manufacture. These products

come complete with a barcode detailing the type of material

the product is made from; component details; and the date an

A.Y. McDonald employee in Elizabethton, Tennessee, Albia or

Dubuque, Iowa, machined, assembled and tested the product.

EVERY PART. COMPLETELY ACCOUNTED FOR.

AY1vVV7PMOM4c7U0

Component Manufacturer

— Manufactured by A.Y. McDonald Mfg. Co.

Lot Code & Date Code

— Built in Albia & Dubuque, Iowa or Elizabethton, Tennessee

— Item Number

— Item Description

— Job Number (what cell it was built on, when

it was built and who was working on the cell)

— Date it was built

All gas valves and meter bars you purchase

from A.Y. McDonald will include a TRACE TAG.

Once the tag is scanned for installation, enjoy

the peace of mind of being forward thinking.

Connection Type and Size

— Inlet/Outlet Size

Component Type

— Plug Valve

— Ball Valve

— Meter Bar

Material

— Cast Iron

— Brass

Learn more about making your community safer

with TRACE TAGS by visiting our YouTube channel.

https://www.youtube.com/watch?v=URHP-QPr7BQ

More than a brand. We’re a family.

6

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

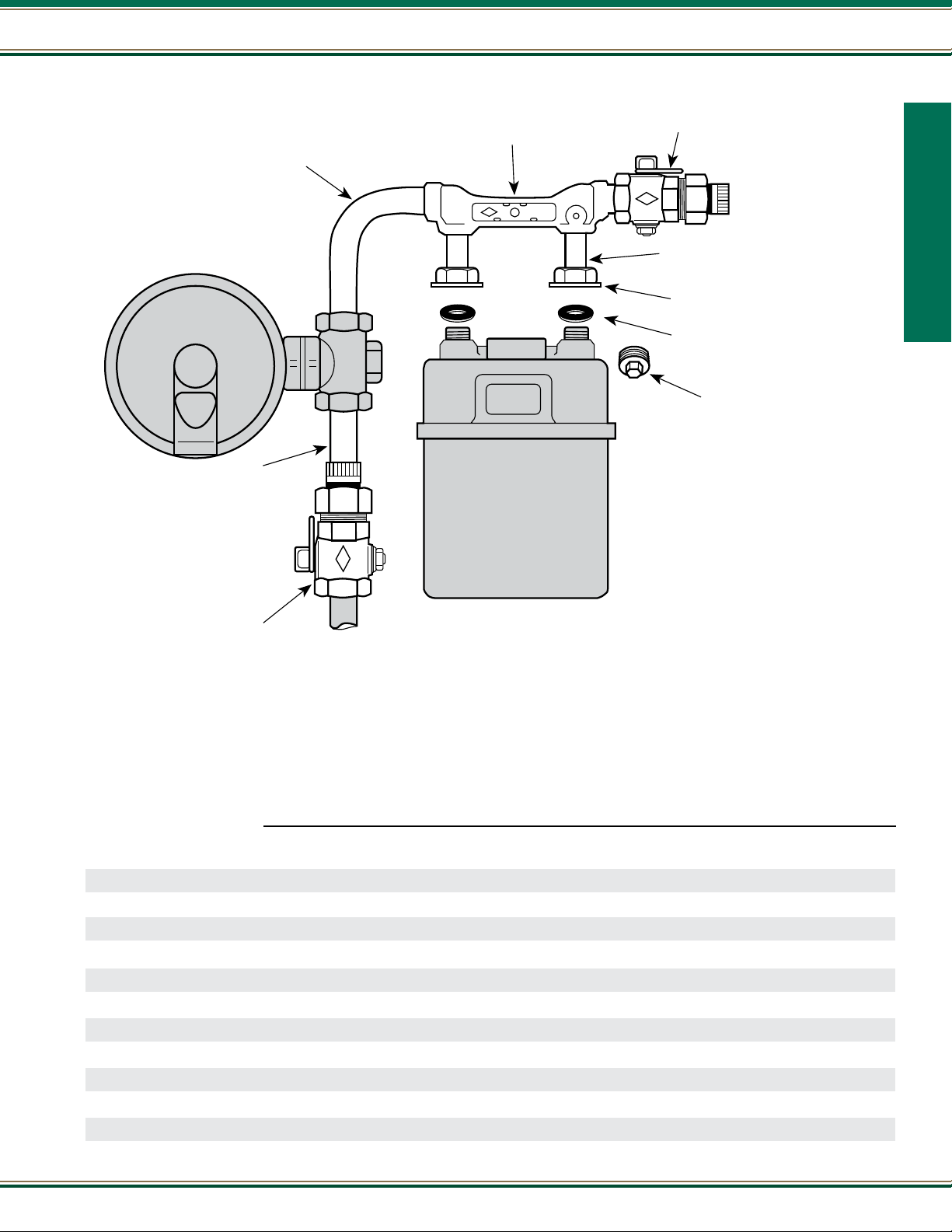

General Information

Meter Bar

Nipple

Nipple

Integral Union

Outlet Valve

Riser Valve

Meter Nut Plug

Meter Swivel Gasket

Meter Nut

Meter Swivel

General Information

A.Y. McDonald Mfg. Co. is known in the gas industry for its wide variety of house piping valves and gas meter valves. Serving the

needs of gas utilities is our number one priority. The items indicated above are the products we currently offer, produced at our state-ofthe-art manufacturing facilities.

Traditionally a strong competitor in the industry, A.Y. McDonald Mfg. Co. continues to practice its founder's philosophy:

“WE WILL MAKE GOOD PRODUCTS AND SELL THEM HONESTLY”

Material Specications

BODY/END PIECE - Cast Iron per ASTM A 126 Class B

PLUG - Cast Brass - ASTM B 584/Alloy 83600 or Alloy 84400

BRASS BALL - CDA 36000

CAP (Ball Valve) - Diecast Zinc / Alloy #7

BRASS NUTS & WASHERS (Plug Valve) - ASTM B 584/Alloy B83600 or Alloy 84400 or MPIF Std. 35 Code CZ 3002

O-RINGS/TORQUE SEALS - Buna-N (Nitrile) or Neoprene rubber

PORT SEALS (Ball Valve) - PTFE

INSULATED UNION TAILPIECES - Super tough nylon 66 insulation

UNION TAILPIECES - Zinc plated yellow dichromate nished steel

STEM (Ball Valve) - Copper Alloy - CA 36000

UNION NUT - Malleable Iron per ASTM A197 or Ductile Iron per ASTM A536

SWIVEL / SWIVEL NUT - Malleable Iron per ADTM A47 or Ductile Iron per ASTM A536

7

General Information

YOU CAN’T SPELL

SAFETY WITHOUT A.Y.

General Information

SAFETY NO ROOM FOR MISTAKES. BALL VALVES.

As a solution that can make life for you and your customers’ that much

easier, A.Y. McDonald’s Gas Ball Valve is a pretty big deal. After all, we

proudly place our name on each and every A.Y. McDonald gas valve in the

hopes that when you recognize it, you will think if safety, dependability,

and a long-lasting product.

At A.Y. McDonald, you aren’t just getting a product; you are getting an innovative

solution, access to educational opportunities, and the ability to be treated like

family. The customer is the boss and we aim to break the mold on how we reach

customer satisfaction. Because in the end, without you, there would be no us.

sales@aymcdonald.com I 800.292.2737 I aymcdonald.com

8

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

General Information

General Information

Ball Style

Natural Gas

Ball Style

MORE THAN A BRAND. WE’RE A FAMILY.

9

Natural Gas Ball Valves

Natural Gas Meter Ball Valves

175 PSIG BALL STYLE METER VALVES

Precision machined and offers bubble tight leak protection both open and closed. Ball Valves offer the added feature of lower and more

closely controlled operating torques for the life of the valve. The brass ball rides between two PTFE port seals that require no lubrication. The

stem has a double o-ring seal and cannot be removed from the valve. The body and endpiece threads are pinned to prevent disassembly

without damaging the valve. No eld adjustment or maintenance of this valve is needed.

All connections with pipe threads require use of thread sealant at installation. (PTFE tape is not recommended, see instruction sheet.)

Additional Features:

- A.Y. McDonald’s Iron Body, Brass Ball Valve is designed and tested to comply with ANSI/ASME B16.33 American National

Standard for “Manually Operated Metallic Gas Valves for use in Gas Piping Systems up to 175 PSIG.”

- Soft seat design does not rely on grease to prevent leakage to the atmosphere or through the valve seats. Sealing capability is

maintained even after many cycles.

- Tamper-resistant (Tamperproof) design makes the A.Y. McDonald Ball Valve virtually impossible to disassemble without

making the valve unusable, i.e. pinned end piece requires excessive force to remove and valve cannot be reassembled if

forcefully disassembled. The valve utilizes an internally loaded operating stem. The external cap is secured with a tamper-

resistant stainless steel screw.

Ball Style

- Breaking torques are closely controlled in excess of what can be turned “by hand” and yet low enough to ensure easy turning

with a small wrench. Easy turning remains for normal life of valve.

o

rotation provides complete shut-off from the open position. Valve can be rotated full 360o.

- A 90

- Pressure may be applied in either direction as A.Y. McDonald's Ball Valve is a non-directional valve.

- Traditional lockwing design easily accommodates standard Barrel-Locks or padlocks.

- Full Port openings accommodate the best known stop changers and yet provide less ow restriction than non-circular

openings or valves with reduced ports.

- Ball valve design isolates operating cap/stem seals and main shell from internal line pressure when the valve is in the normal

used, full open position. Sealing against external leakage during this normal service is thereby doubly-provided and the stem

seals do provide the necessary external leak protection during cycling.

- In the normal open position, the sealing surface of A.Y. McDonald’s Brass Ball is isolated from the probable contaminants by

the port seals. This results in a more reliable shut off over the life of the valve.

- In addition to an o-ring, metal-to-metal positive seating of the end piece limits the squeeze on port seals, and serves

as back-up seal if necessary.

- No eld adjustment or maintenance required.

- Each valve is pressure tested in both directions electronically.

o

- Temperature Range: –20

- Available in FNPT x FNPT (860) or FNPT x Insulated union (8276).

to +150oF.

Note: These valves are intended for use with natural, manufactured and L.P. gas only.

10

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

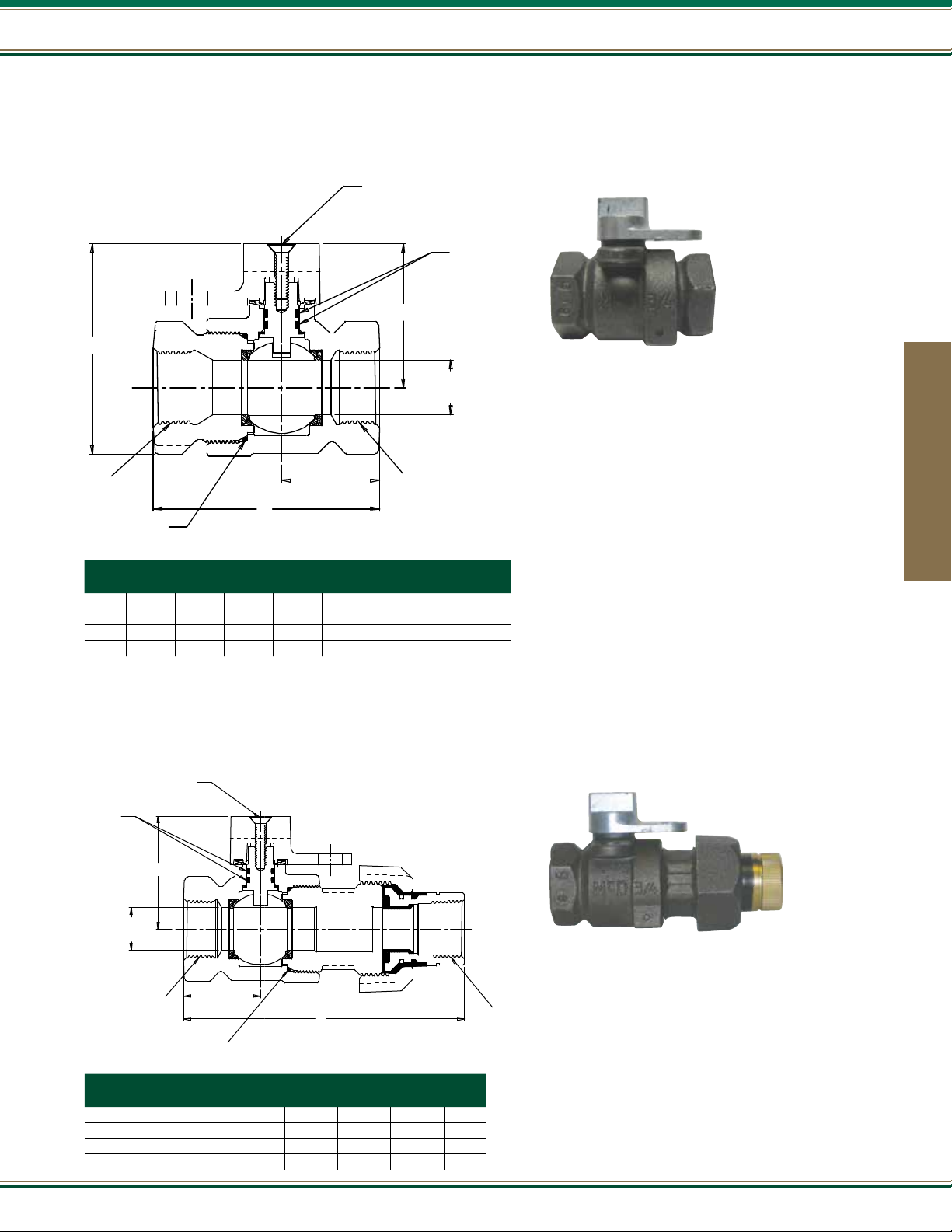

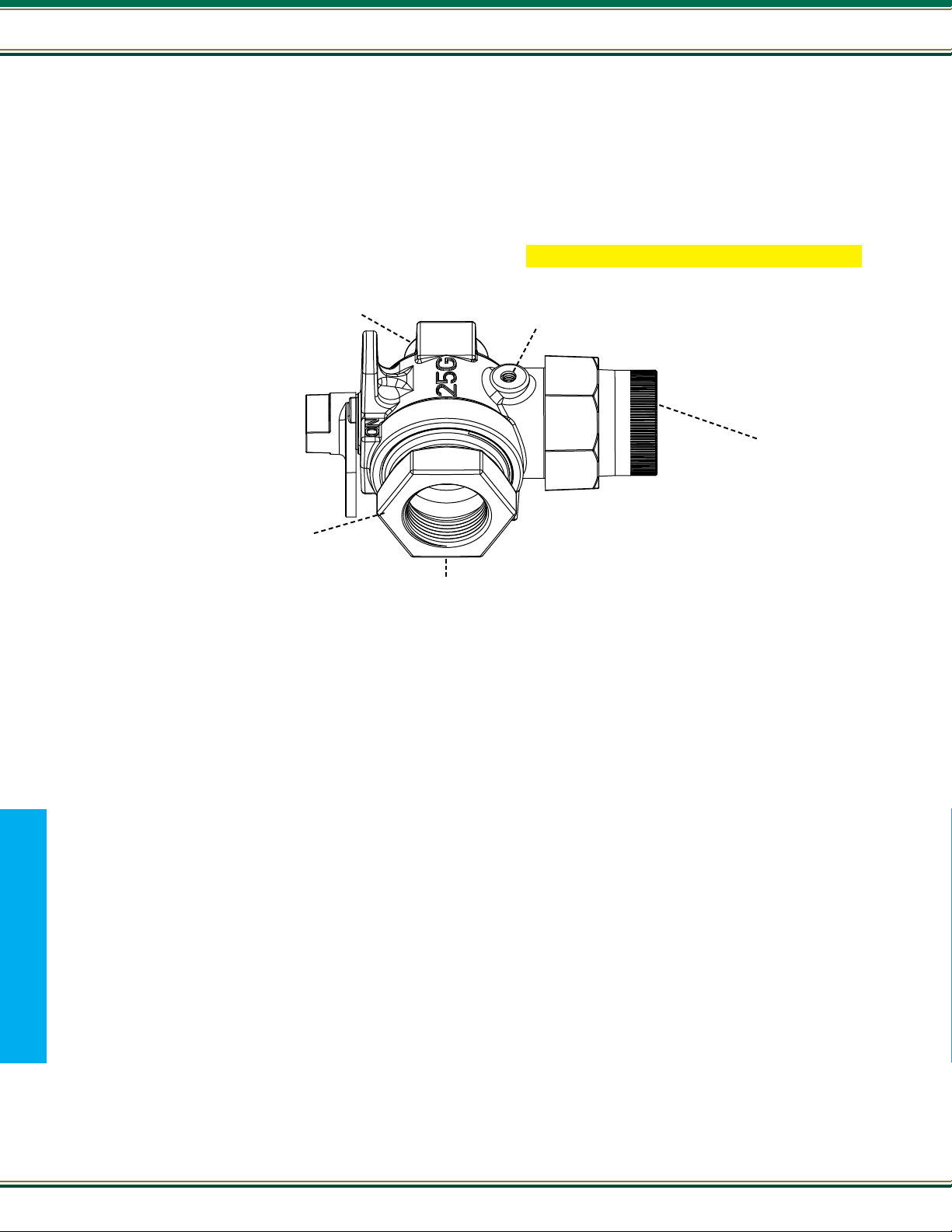

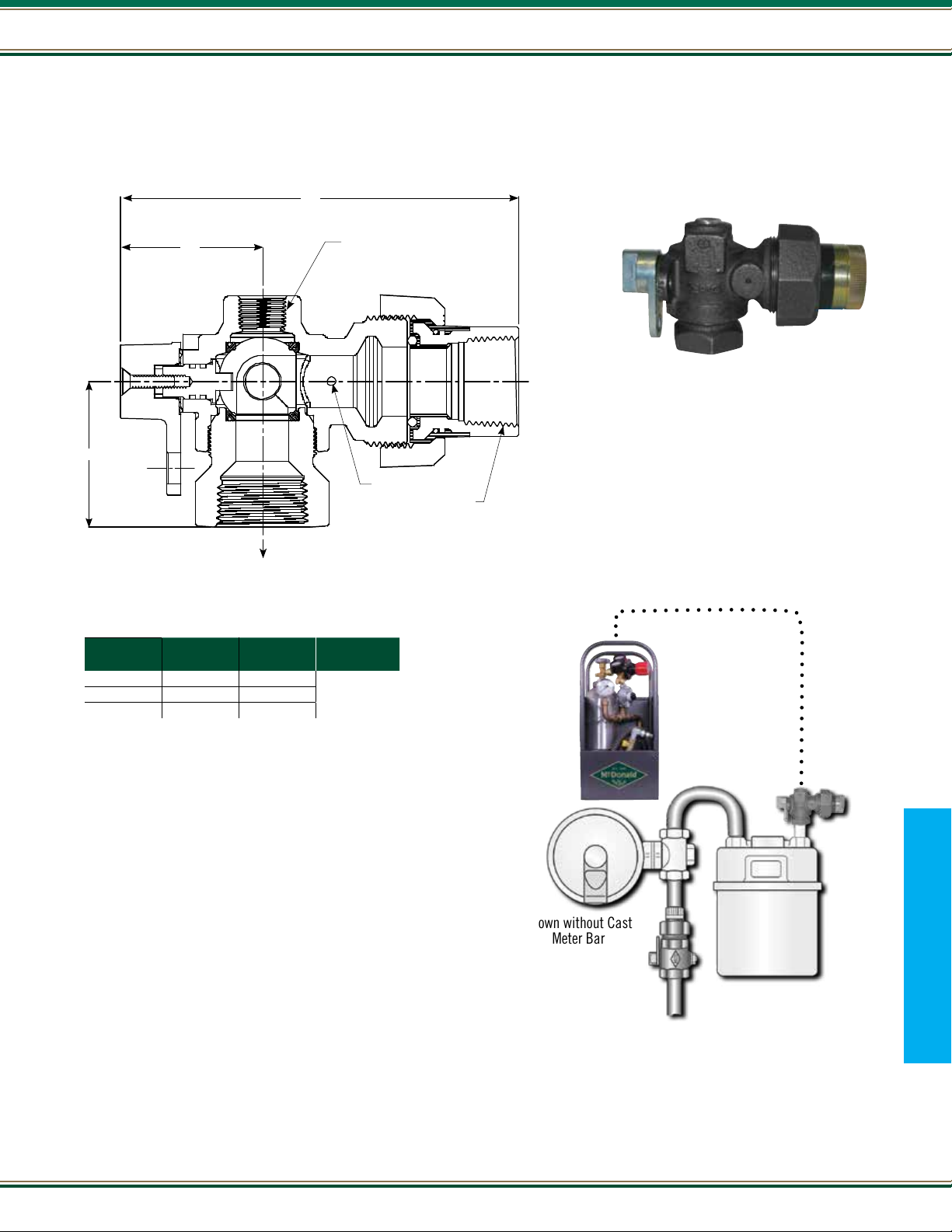

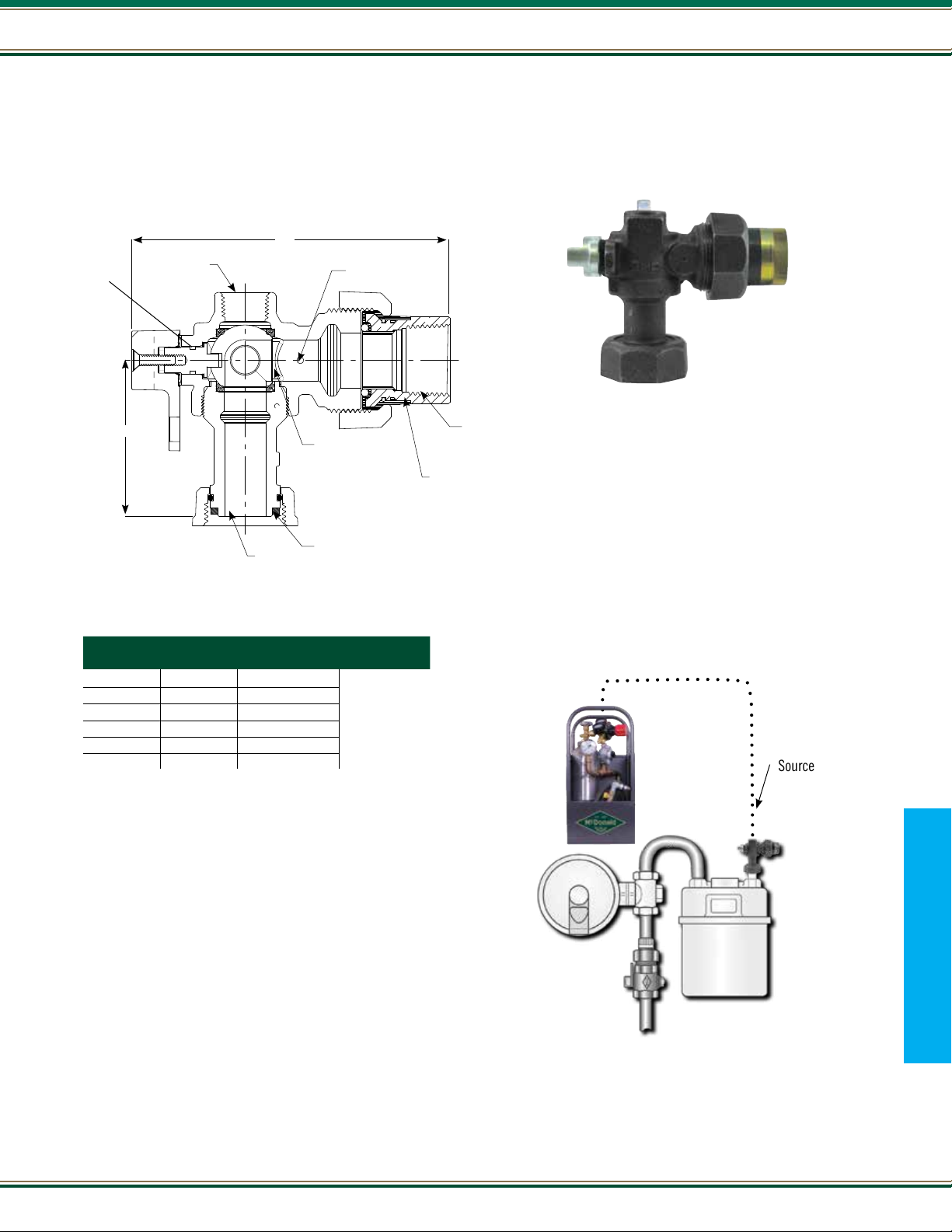

Natural Gas Ball Valves - 860 Series

TAMPERPROOF, 175 PSIG, FLAT HEAD, BRASS BALL, LOCKWING

These valves are designed for use with natural, manufactured and L.P. gas only.

TAMPERPROOF

SCREW

O-RINGS

D

C

FNPT x FNPT

E

Natural Gas Ball Valves

(black iron shown)

COATINGS AVAILABLE

860B Black Iron

F

A

O-RINGS

B

G

860G Zinc Coated w/Clear Chromate Finish Iron

860PNT Paint Coated

860N Zinc & Painted

DIMENSIONS

Size A B C D E F G Weight

3/4”

1”

1 1/4”

2”

3 1/8” 1 3/8”

3 9/15” 1 11/16”

4 3/8” 1 7/8”

5 7/16” 2 7/16”

2 13/16” 1 13/16” 3/4” 3/4” 3/4” 1.8

3 1/8” 2” 1” 1” 1” 2.5

3 15/16” 2 1/2” 1 1/4” 1 1/4” 1 1/4” 4.5

5 1/16” 3” 2” 2” 2” 8.3

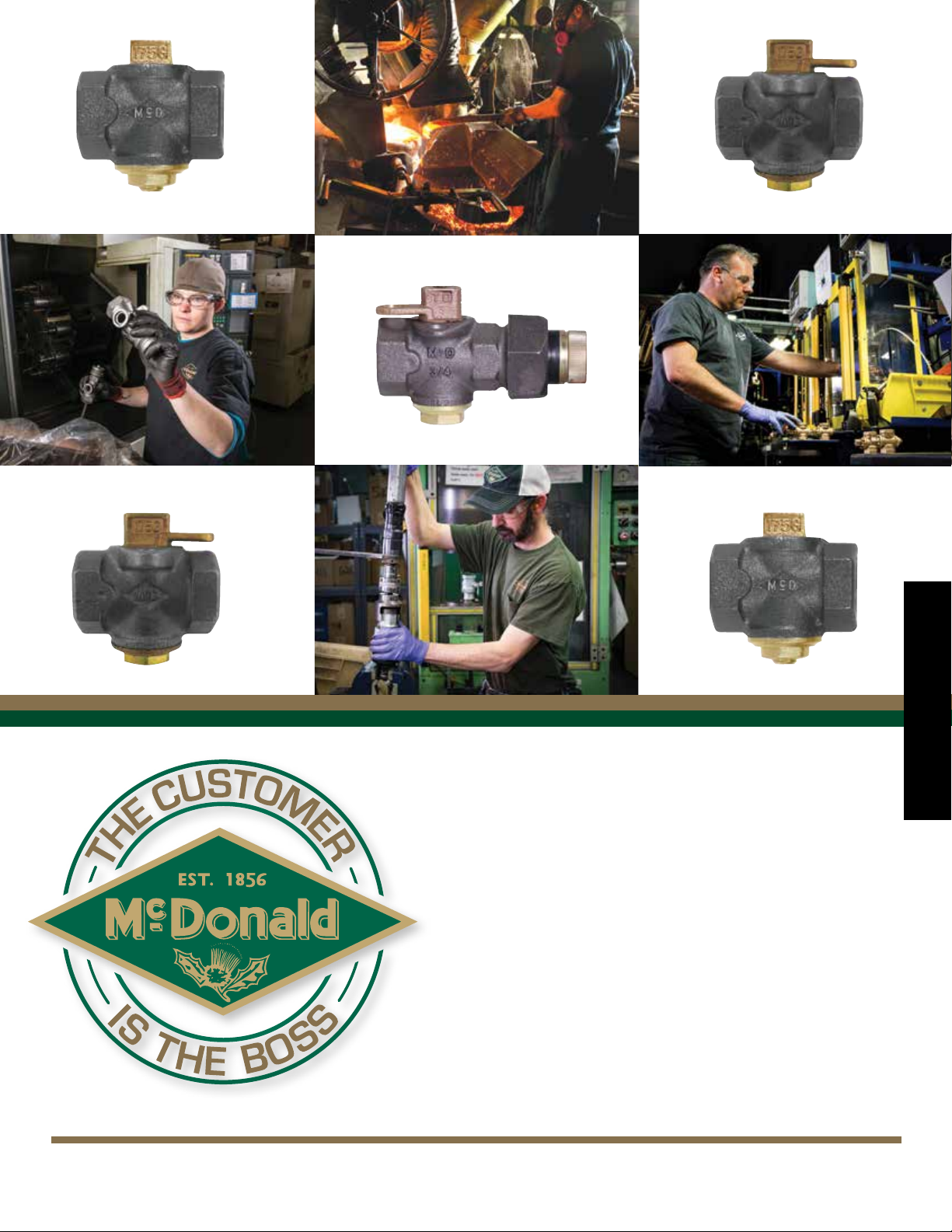

Natural Gas Ball Valves - 8276 Series

TAMPERPROOF, 175 PSIG, FLAT HEAD, BRASS BALL, LOCKWING

These valves are designed for use with natural, manufactured and L.P. gas only.

TAMPERPROOF

SCREW

O-RINGS

Ball Style

C

D

F B

A

O-RING

DIMENSIONS

Size A B C D E F Weight

3/4”

1”

1 1/4”

2”

5” 1 3/8”

5 13/16” 1 11/16”

7” 1 7/8”

6 15/16” 2 7/16”

1 13/16” 3/4” 3/4” 3/4” 2.5

2” 1” 1” 1” 3.4

2 1/2” 1 1/4” 1 1/4” 1 1/4” 5.7

3” 2” 2” 2” 12.5

(black iron shown)

FNPT x Insulated Union with FNPT Tailpiece (o-ring only)

COATINGS AVAILABLE

E

8276B Black Iron

8276G Zinc Coated w/Clear Chromate Finish Iron

8276PNT Paint Coated

8276N Zinc & Painted

11

Natural Gas Ball Valves

TURN TO US FOR YOUR VALVES.

NATURAL GAS PLUG VALVES

There’s no room for mistakes in the natural gas industry. As a concept

that never goes out of style, safety is at the core of the creation for A.Y.

McDonald’s Gas Plug Valves. Trust in a company that has seen success

for 163 years – and many more to come!

Ball Style

12

At A.Y. McDonald, you aren’t just getting a product; you are getting an innovative

solution, access to educational opportunities, and the ability to be treated like

family. The customer is the boss and we aim to break the mold on how we reach

customer satisfaction. Because in the end, without you, there would be no us.

sales@aymcdonald.com I 800.292.2737 I aymcdonald.com

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Natural Gas Ball Valves

Ball Style

Natural Gas

Plug Style

Plug Style

MORE THAN A BRAND. WE’RE A FAMILY.

13

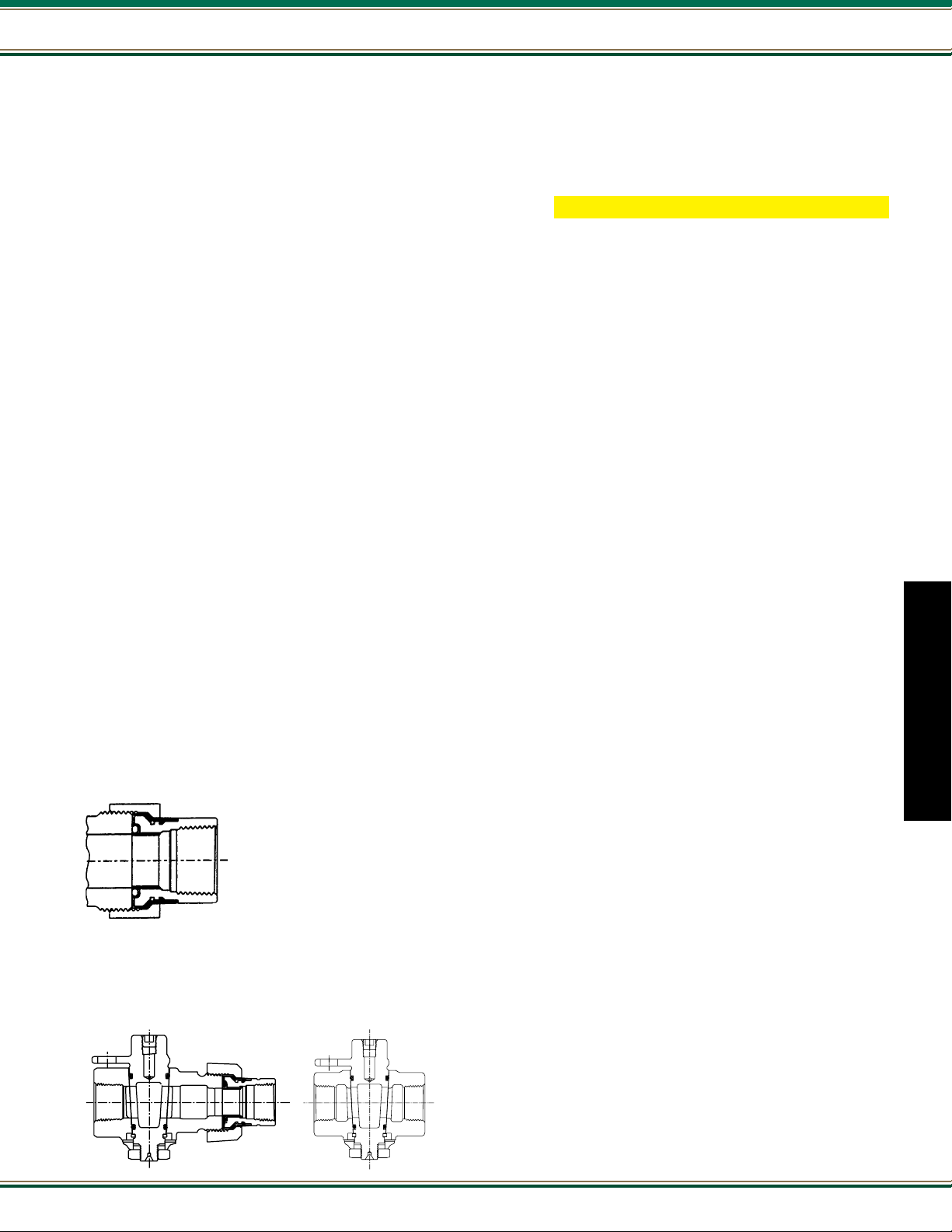

Natural Gas Plug Valves

Re-Lubrication Tool

FOR USE ON 175 PSIG RE-LUBE VALVES & WITH A.Y. MCDONALD GREASE ONLY

A.Y. McDonald Mfg. Co. model number 558 Re-Lubrication Tool is an easy and economical way to lubricate 175 PSIG gas meter valves.

The tool is machined from steel alloy for durability and has an Allen wrench mounted to the body for convenience. It can be used to re-lubricate

A.Y. McDonald valves in the full open or the full closed position when the valve is pressurized or unpressurized. It will also lubricate valves of

other manufacturers. Check with them for their recommended procedures.

Watch our Re-Lubrication Tool demonstration video

- 558 - Grease Tool

- 558GR - Grease Sticks for use with 588

Re-Lubrication tool. 24 sticks/box.

https://www.youtube.com/watch?v=RMKheuv6nPM

Turn the "T" Handle counter-clockwise

1

until the handle is fully extended outward

(see picture), this will raise plunger & O-ring

into the cap so grease may be added inside the

body (bottom section) of the tool.

Clean the nozzle tip of the "558" Re-Lubrication Tool

5

and very carefully thread it into the re-lube port in the

head of the valve plug.

Plug Style

A.Y. McDonald 175 PSIG Gas Valves may be re-lubricated in the full open

3

or the full closed position when the valve is pressurized or un-pressurized.

Unscrew the top section (with the handle)

2

from the "558" Re-Lubricating Tool, insert

a stick of A.Y. McDonald Grease (#558GR) into

the body (bottom section) of the tool, and screw

the top section back onto the bottom section

hand tight.

Full Open

Turn the "T" Handle clockwise to force

6

the lubricant into the valve, if immediate

resistance is felt, the "558" Re-lubrication

Tool may have a hardened grease deposit

in the barrel which must be removed before

proceeding to re-lube the gas valve, (remove

re-lube tool from the valve, unscrew the top

section from the bottom section of the re-lube

tool, stick a piece of wire (smaller than opening

on end of tube) through the bottom section of

the re-lube tool until the wire comes out the

opposite end) reassemble the top section to

plug re-lube port, and continue to turn the "T" Handle clockwise to force the A.Y.

McDonald Lubricant into the valve. Caution: Re-lube valve carefully to insure the

valve is not over lubricated.

Unscrew "558" Re-Lubrication Tool by turning counter-clockwise until there is

7

only a couple threads left engaged. Turn "T" Handle clockwise to add a little

more grease to ll void left in head of plug from backing off the tool, then remove tool

completely from valve (put tool back into container to avoid dirt or foreign material

from contaminating grease on tool).

the bottom section, re-connect tool to valve

After re-lubrication of the valve is

8

complete, the 1/8" Allen Head Re-Lube

Plug must securely replaced in the re-lube port

in the head of the valve plug and tightened

with an Allen Wrench to 30 in. Ibs. of torque.

Remove the 1/8" NPT Allen Head Pipe Plug from the re-lubrication port

4

in the head of the plug.

NOTE:

- A small amount of gas leakage may be observed from the re-lube port while performing this procedure, based on the amount of grease

left in the valve prior to the valve being re-lubed.

- Other commercially available re-lube tools may be used, but you must check with the factory before using.

- The eld Service Personnel, after a few trials, should be able to tell by the feel (resistance) of the handle, when the stop is lled has a

adequate amount of grease in it.

14

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Natural Gas Plug Valves

Natural Gas Meter Plug Valves

175 PSIG PLUG STYLE METER VALVES

Precision machined and offer bubble tight leak protection both open and closed. Plug Style Meter Valves can be relubricated while in

service. Special machined grooves in the plug channel provide grease to all sealing surfaces.

All connections with pipe threads require use of thread sealant at installation. (PTFE tape is not recommended, see instruction sheet.)

Iron Body Gas Plug Valves Features

- A.Y. McDonald’s Iron Body, Brass Plug Valve is designed and tested to comply with ANSI/ASME B16.33 American

National Standard for “Manually Operated Metallic Gas Valves for use in Gas Piping Systems up to 175 PSIG.”

- Pressure ratings are or 175 PSIG.

- Each valve is factory lubricated and suitable for use with natural, manufactured and LP gases.

- 175 PSIG valves can be relubricated while in service and under pressure. This renews the grease seal to a like new

condition adding to the life of the valve.

- Valves plugs are equipped with top and bottom o-rings for added security against external leakage.

- Tamper-resistant (tamperproof) design prevents disassembly with normal household tools.

- The on/off turning torques are controlled at assembly by using torque machines to set the bottom nut which is also

staked in place to maintain this torque.

- Pressure may be applied in either direction as A.Y. McDonald's Plug Valve is a non-directional valve.

o

- The 90

- Available with or without lockwing. Both models t industry-standard, separately-supplied locking devices such as the

casket, barrel lock or padlock.

- Port openings sized to accommodate the best known stop changers.

- Temperature Range: –20

- Available in FNPT x FNPT (560) or FNPT x Insulated union (6276).

- Each valve is pressure tested in both directions electronically or with air under water.

Note: These valves are intended for use with natural, manufactured and L.P. gas only.

METER VALVE OUTLET UNION STYLES

- A second O-ring is molded into the plastic to improve sealing without over tightening the union nut.

- The one piece molded insulator protects the service line and the main from stray currents.

rotation provides complete shut-off from open position. Valve can be rotated full 360o.

o

to +150oF.

Insulated Union

with O-ring seal

FNPT Outlet Threads

Plug Style

RE-LUBRICATION

15

Natural Gas Plug Valves

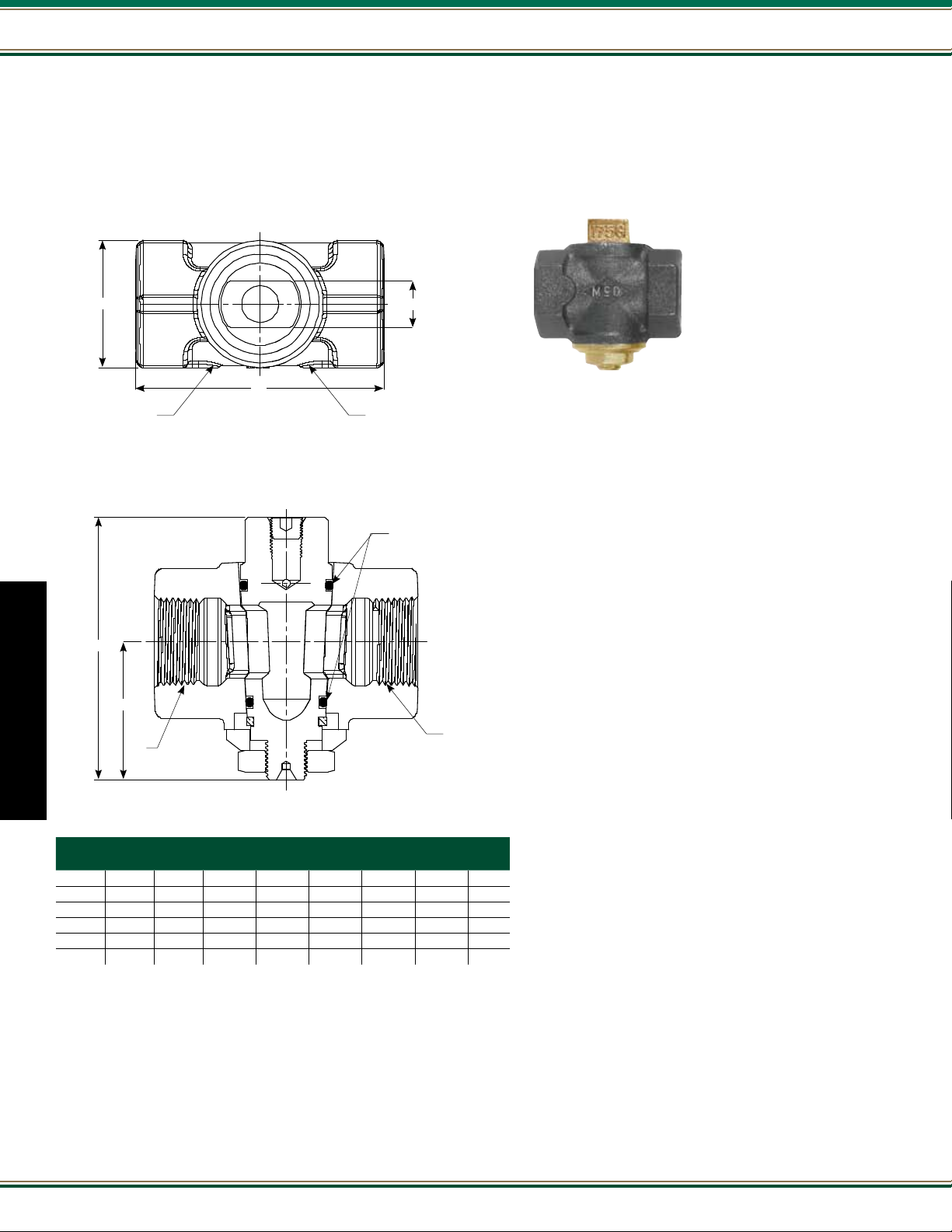

Natural Gas Plug Valves - 559 Series

TAMPERPROOF, 175 PSIG, FLAT HEAD, BRASS PLUG

These valves are designed for use with natural, manufactured and L.P. gas only. All A.Y. McDonald 175 PSIG Gas Valves may be re-lubricated

in the full open or the full closed position when the valve is pressurized or un-pressurized. Do Not Tamper with Bottom Nut

C - OPTIONAL 1/8” NPT

TEST PORT (559BC)

Plug Style

E

D

(black iron shown)

A

D - OPTIONAL 1/8” NPT

TEST PORT (559BD)

FNPT x FNPT

COATINGS AVAILABLE

559B Black Iron

NITRILE

O-RINGS

B

C

F

G

559G Zinc Coated w/Clear Chromate Finish Iron

559PNT Paint Coated

559N Zinc & Painted

559BC Black Iron w/ 1/8” Test Plug

559BD Black Iron w/ 1/8” Test Plug

Taps available on all the above product options.

DIMENSIONS

Size A B C D E F G Weight

1/2” 3.14 3.16

3/4” 3.14 3.16

1” 3.36 3.53

1 1/4” 3.88 4.38

1 1/2” 4.65 4.99

2” 5.60 5.57

16

1.66

1.66

186 .59 1.94 1” 1” 2.4

2.38 .65 2.31 1 1/4” 1 1/4” 3.7

2.66 .62 2.62 1 1/2” 1 1/2” 6.1

2.96 .59 3.00 2” 2” 9.3

.59

.59

1.62 1/2” 1/2”

1.62 3/4” 3/4”

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

1.6

1.6

4-19

Natural Gas Plug Valves

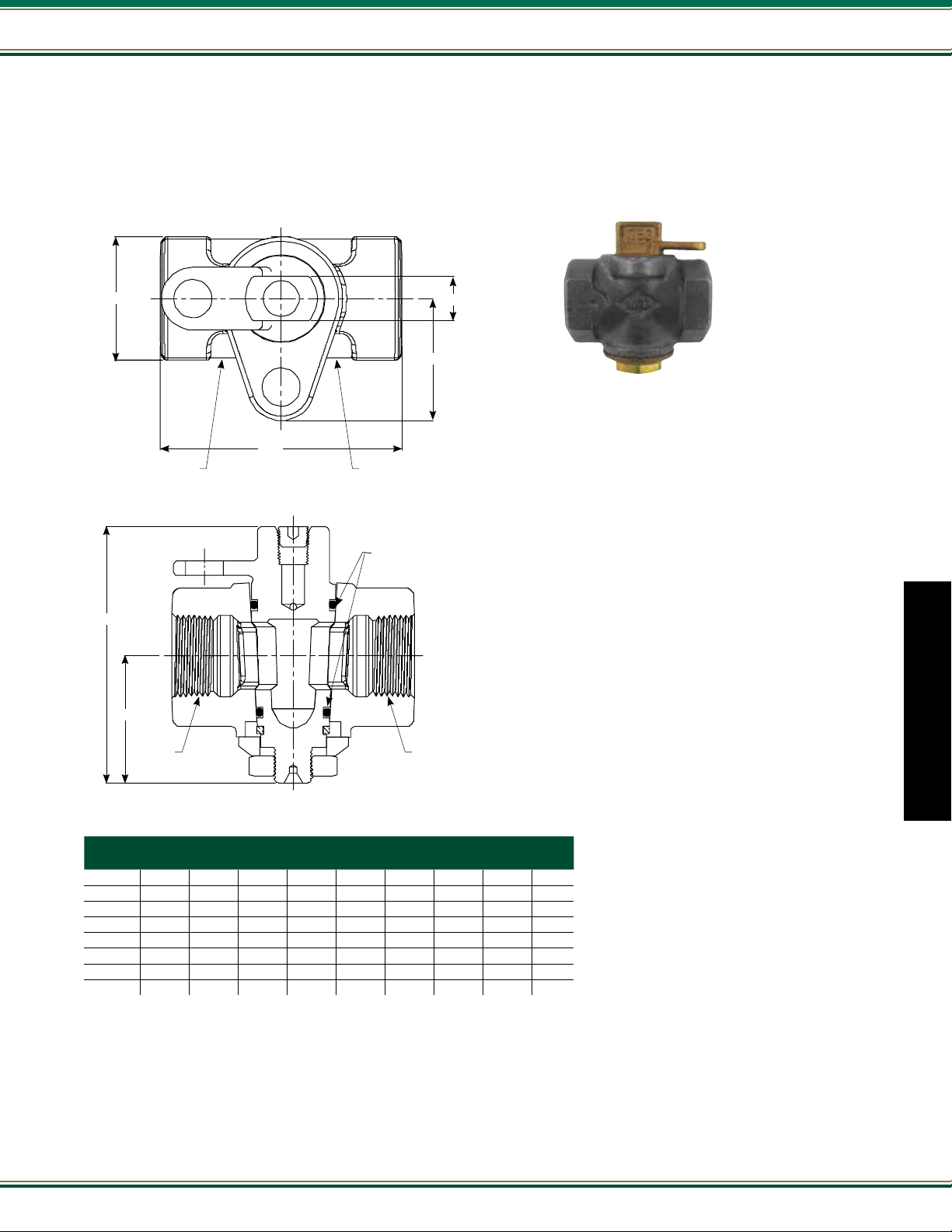

Natural Gas Plug Valves - 560 Series

TAMPERPROOF, 175 PSIG, FLAT HEAD, LOCKWING, BRASS PLUG

These valves are designed for use with natural, manufactured and L.P. gas only. All A.Y. McDonald 175 PSIG Gas Valves may be re-lubricated

in the full open or the full closed position when the valve is pressurized or un-pressurized. Do Not Tamper with Bottom Nut

F

C - OPTIONAL 1/8” NPT

TEST PORT (560BC)

B

C

B

(black iron shown)

E

FNPT x FNPT

A

D - OPTIONAL 1/8” NPT

TEST PORT (560BD)

COATINGS AVAILABLE

560B Black Iron

560G Zinc Coated w/Clear Chromate Finish Iron

560PNT Paint Coated

NITRILE

O-RINGS

560N Zinc & Painted

560BC Black Iron w/ 1/8” Test Plug

560BD Black Iron w/ 1/8” Test Plug

Taps available on all the above product options.

Plug Style

HG

DIMENSIONS

Size A B C D E F G H Weight

1/2” 3.14 3.34

1/2” x 3/4” 3.14 3.34

3/4” 3.14 3.34

3/4” x 1” 3.36 3.67

1” 3.88 4.69

1 1/4” 4.66 5.43

1 1/2” 5.60 5.82

2” 5.60 5.82

1.66 .59 1.60 1.62 1/2” 1/2” 1.8

1.66 .59 1.60 1.62 1/2” 3/4” 1.8

1.66 .59 1.60 1.62 3/4” 3/4” 1.8

1.86 .59 1.67 1.94 3/4” 1” 2.5

2.37 .65 1.94 2.31 1 1/4” 1 1/4” 2.4

2.65 .62 2.31 2.62 1 1/2” 1 1/2” 3.9

2.96 .47 2.53 3.00 2” 2” 6.9

2.96 .47 2.53 3.00 2” 2” 9.5

17

Natural Gas Plug Valves

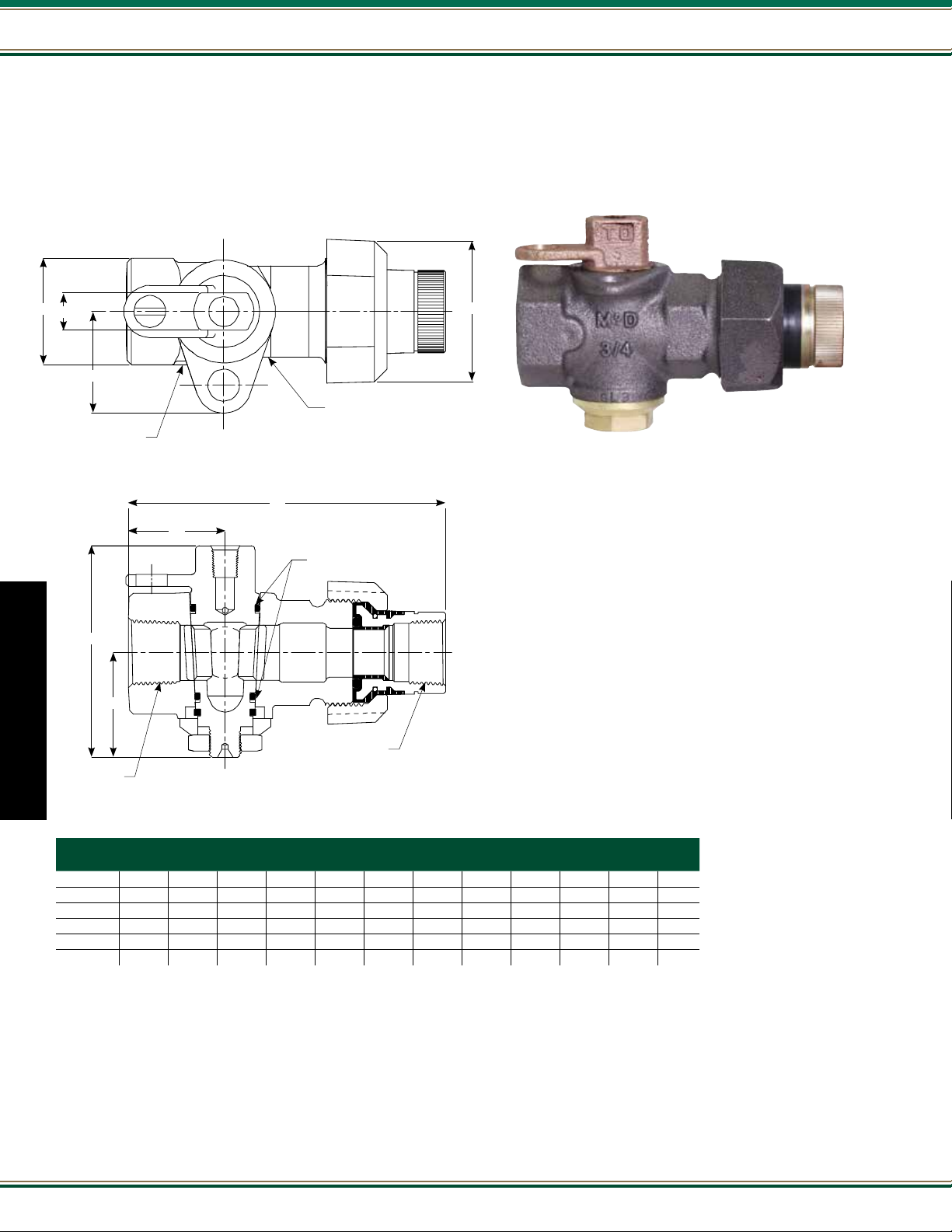

Natural Gas Plug Valves - 6276 Series

TAMPERPROOF, 175 PSIG, FLAT HEAD, LOCKWING, BRASS PLUG

These valves are designed for use with natural, manufactured and L.P. gas only. All A.Y. McDonald 175 PSIG Gas Valves may be re-lubricated

in the full open or the full closed position when the valve is pressurized or un-pressurized. All A.Y. McDonald plug style gas valves have

factory set turning torque. Do Not Tamper with Bottom Nut

G

E

C - OPTIONAL 1/8” NPT

TEST PORT (6276BC)

Plug Style

H & I

F

D - OPTIONAL 1/8” NPT

TEST PORT (6276BD)

A

B

NITRILE

O-RINGS

FNPT x Insulated Union with FNPT Tailpiece (o-ring only)

COATINGS AVAILABLE

6276B Black Iron

(black iron shown)

6276G Zinc Coated w/Clear Chromate Finish Iron

6276PNT Paint Coated

D

6276N Zinc & Painted

6276BC Black Iron w/ 1/8” Test Plug

6276BD Black Iron w/ 1/8” Test Plug

C

K

Taps available on all the above product options.

DIMENSIONS

Size A B C D E F G H I J K Weight

3/4” 5.03 1.54

1” 5.74 1.68

1” x 3/4” 6.03 2.50

1 1/4” x 3/4” 6.02 2.49

1 1/4” 6.51 2.18

2” 7.85 2.81

18

J

1.66 3.34 .59 1.60

186 3.68 .59 1.65

1.66 3.34 .59 1.59

1.66 3.34 .59 1.59

2.37 4.68 .59 1.94

2.97 5.82 .59 2.52

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

1.68 1.96

1.94 2.30

2.12 1.96

2.12 1.96

2.12 2.57

3.00 3.86

HEX 3/4” 3/4” 2.5

DCT 1” 1” 3.5

HEX 1” 3/4” 3.1

HEX 1 1/4” 3/4” 5.3

DCT 1 1/4” 1 1/4” 3.1

DCT 2” 2 12.4

4-19

Natural Gas Plug Valves

Natural Gas

Bypass

Ball Valves

Plug Style

Bypass Ball Valves

MORE THAN A BRAND. WE’RE A FAMILY.

19

Angle Ball Valves

Angle Ball Valves

5 PSIG 3/4” & 1”, 25 PSIG 1 1/4” ANGLE BALL STYLE METER VALVES

Precision machined and offer bubble tight leak protection both open and closed. Ball Valves offer the added feature of lower and more

closely controlled operating torques for the life of the valve. The brass ball rides between two PTFE port seals that require no lubrication. The

stem has a double o-ring seal and cannot be removed from the valve. The body and endpiece threads are pinned to prevent disassembly

without damaging the valve. No eld adjustment or maintenance of this valve is needed.

All connections with pipe threads require use of thread sealant at installation. (PTFE tape is not recommended, see instruction sheet.)

Position A Tap

Position B Tap

Positions B & C are possible

pressure tap locations. Please

refer to Block 5 for pressure

tap options.

Outlet

Position C Tap

Opposite position B

Inlet

INLET AND OUTLET CONNECTIONS

NPT inlet tapping provides a solid connection directly into the valve.

Outlets are available with NPT integral or union type connections.

Union connections have a at rubber gasket or an o-ring seal.

- Soft seat design does not rely on grease to prevent leakage to the atmosphere or through the valve seats. Sealing capability is

maintained even after many cycles.

- Tamper-resistant (Tamperproof) design makes the A.Y. McDonald Ball Valve virtually impossible to disassemble without making the

valve unusable, i.e. pinned end piece requires excessive force to remove and valve cannot be reassembled if forcefully disassembled.

The valve utilitizes an internally loaded operating stem. The external cap is secured with a tamper-resistant stainless steel screw.

- Breaking torques are closely controlled in excess of what can be turned “by hand” and yet low enough to ensure easy turning with a

small wrench. Easy turning remains for normal life of valve.

o

rotation from the open position places valve into bypass position.

- A 90

- In addition to an o-ring, metal-to-metal positive seating of the end piece limits the squeeze on port seals, and serves

as back-up seal if necessary.

Bypass Ball Valves

- Traditional lockwing design easily accommodates standard Barrel-Locks or padlocks.

- 1” is reducing port.

- No eld adjustment or maintenance required.

- Each valve is pressure tested in both directions electronically or with air under water.

o

- Temperature Range: –20

Note: These valves are intended for use with natural, manufactured and L.P. gas only.

to +150oF.

The union outlet is available insulated to

minimize electrolysis.

INSULATED UNION OUTLET

20

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

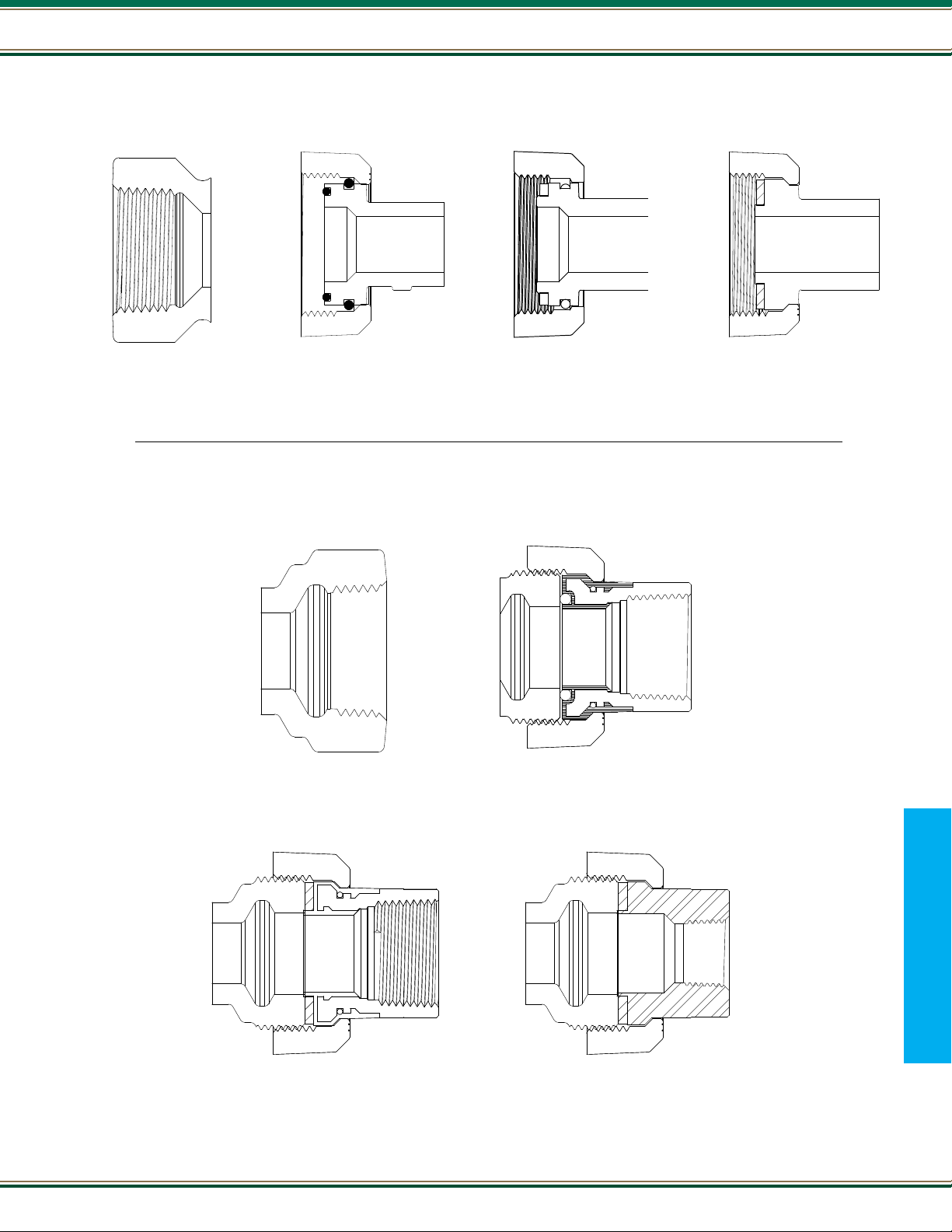

Angle Ball Valves

Inlets/Type - Block 1

Integral FNPT Meter Swivel Nut O-ring Seal Meter Swivel Nut Flat Gasket Seal Union Inlet

Outlets/Type - Block 2

Integral FNPT

Insulated Union / O-ring Seal FNPT

Bypass Ball Valves

Insulated Union / Flat Gasket Seal FNPT

Non Insulated Union / Flat Gasket FNPT

21

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 835 Series

FOR 835 SERIES OUTLET ANGLE VALVES - BALL STYLE

A.Y. McDonald Mfg. Co. Gas Meter Bars can be ordered to t your requirements. Select the features you need from list below and build

your own ordering number. Please note the difference in numbers between regular valves, and valves with built in swivels. Meter valves

with swivels have two extra blocks before the size to select the size and type of swivels.

TO ORDER:

Example: Model number 835B means:

8 3 5 B A G 3/4” x 3/4” x 1”

1 2 3 4 5

INLET PORT SIZE OUTLET

SPACE

SIZE

BLOCK 1 - INLET TYPE

83 = Integral FNPT Inlet

BLOCK 2 - OUTLET TYPE

5 = Integral FNPT

BLOCK 3 - FINISH

B = Black cast iron nish

G = Zinc plated with Clear Sealant nish

H = Zinc plated Clear Sealant & paint

P = Painted nish

BLOCK 4 - TAP(S) LOCATION

A = Pos. A (Bypass)

B = Pos. B

C = Pos. C

D = Pos. A & B (A with 3/8” recessed head)

E = Pos. A & C (C with 3/8” recessed head)

F = Pos. A & C (A with 3/8” square head)

BLOCK 5 - TAP SIZE / PLUG TYPE

A = 1/8” NPT recessed hex head plug

B = 1/8” NPT square head plug

C = 1/8” NPT - no plug

D = 1/4” NPT recessed hex head plug

E = 1/4” NPT square head plug

F = 1/4” NPT - no plug

G = 3/8” NPT recessed hex head plug

H = 3/8” NPT square head plug

J = 3/8” NPT - no plug

K = 1/8” NPT square head plug (raised bosses)

L = 1/8” NPT hex head (raised bosses)

M = 1/8” NPT hex head plug

N = 1/4” NPT square head plug in inlet and 1/8”

recessed hex head plug in outlet

Bypass Ball Valves

22

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

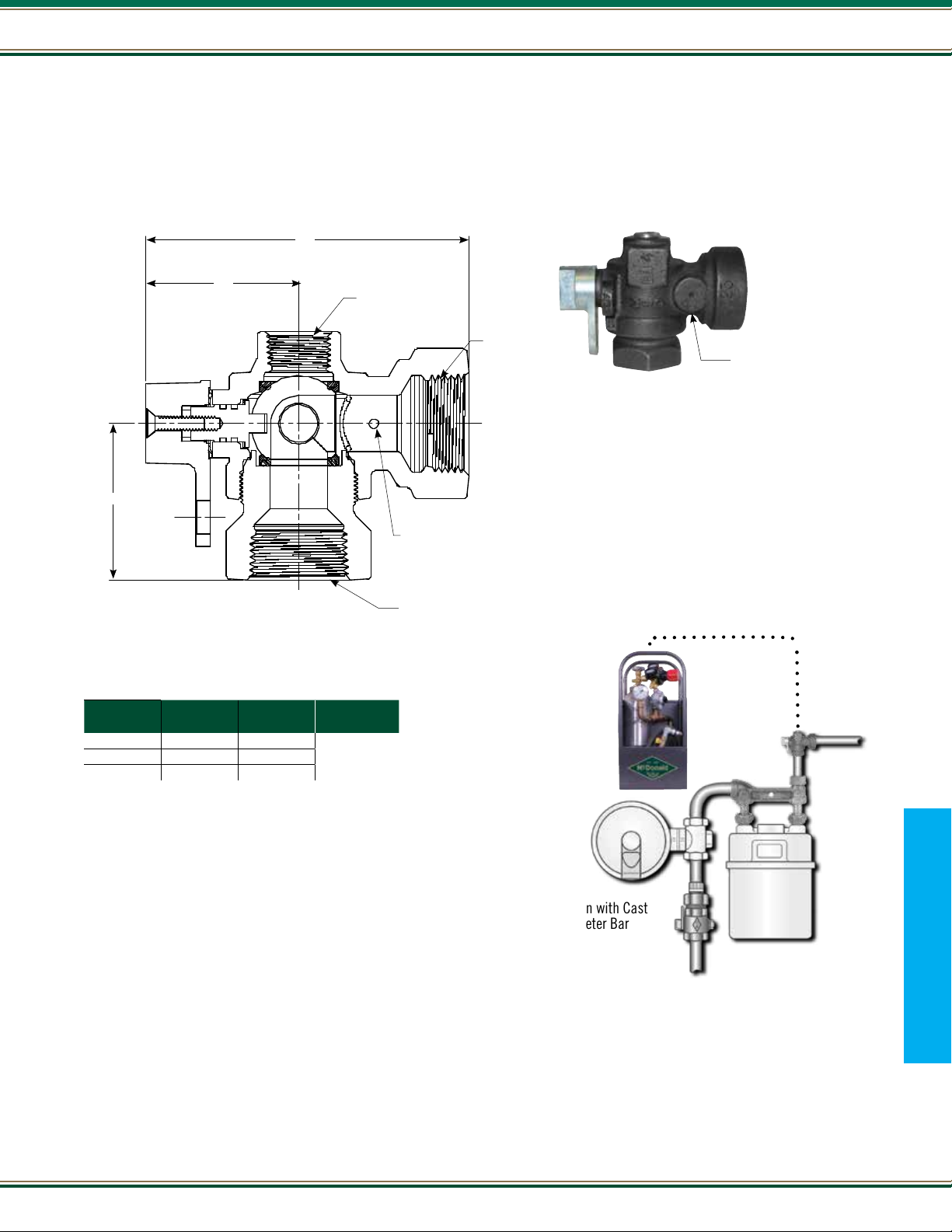

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 835 Series

TAMPERPROOF, LOCKWING, BYPASS OPTION

Can be assembled directly to the meter outlet, or used with a meter bar that provides a solid anchor to the meter set. This valve can be

produced with or without a Bypass feature. These valves are designed for use with natural, manufactured and L.P. gas only.

4.32

2.05

2.10

DIMENSIONS

FNPT

Inlet

3/4” 3/4” 3/4”

1” 1”* 1”

1 1/4” 1 1/4” 1 1/4”

Port

Size

FNPT

Outlet

3/8” FNPT - Tap A

Pressure Tap

(optional)

See Block

4 & 5

PRESSURE

TAP

FNPT INLET

FNPT

OUTLET

(black iron shown)

Tap C

INTEGRAL FNPT x INTEGRAL FNPT

COATINGS AVAILABLE

835B Black Iron

835G Zinc Coated w/Clear Sealant Finish Iron

835N Zinc Plated Clear Sealant /Painted Finish

835P Painted Finish

Taps available on all the above product options.

* 1” is reducing port

Bypass Ball Valves

Shown with Cast

Meter Bar

NOTES:

For external source of gas see Portable Bypass Kit on page 36

23

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 837 Series

FOR 837 SERIES OUTLET ANGLE VALVES - BALL STYLE

A.Y. McDonald Mfg. Co. Gas Meter Bars can be ordered to t your requirements. Select the features you need from list below and build

your own ordering number. Please note the difference in numbers between regular valves, and valves with built in swivels. Meter valves

with swivels have two extra blocks before the size to select the size and type of swivels.

TO ORDER:

Example: Model number 837B means:

INLET PORT SIZE OUTLET

8 3 7 B A G 3/4” x 3/4” x 3/4”

1 2 3 4 5

SPACE

SIZE

BLOCK 1 - INLET TYPE

83 = Integral FNPT

BLOCK 2 - OUTLET TYPE

7 = Female insulated O-ring union

8 = Female insulated at gasket

9 = Female non-insulated at gasket

BLOCK 3 - FINISH

B = Black cast iron nish

G = Zinc plated with Clear Sealant nish

H = Zinc plated Clear Sealant & paint

P = Painted nish

BLOCK 4 - TAP(S) LOCATION

A = Pos. A (Bypass)

B = Pos. B

C = Pos. C

D = Pos. A & B (A with 3/8” recessed head)

E = Pos. A & C (C with 3/8” recessed head)

F = Pos. A & C (A with 3/8” square head)

BLOCK 5 - TAP SIZE / PLUG TYPE

A = 1/8” NPT recessed hex head plug

B = 1/8” NPT square head plug

C = 1/8” NPT - no plug

D = 1/4” NPT recessed hex head plug

E = 1/4” NPT square head plug

F = 1/4” NPT - no plug

G = 3/8” NPT recessed hex head plug

H = 3/8” NPT square head plug

J = 3/8” NPT - no plug

K = 1/8” NPT square head plug (raised bosses)

L = 1/8” NPT hex head (raised bosses)

M = 1/8” NPT hex head plug

N = 1/4” NPT square head plug in inlet and 1/8”

recessed hex head plug in outlet

Bypass Ball Valves

24

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Angle Ball Valves

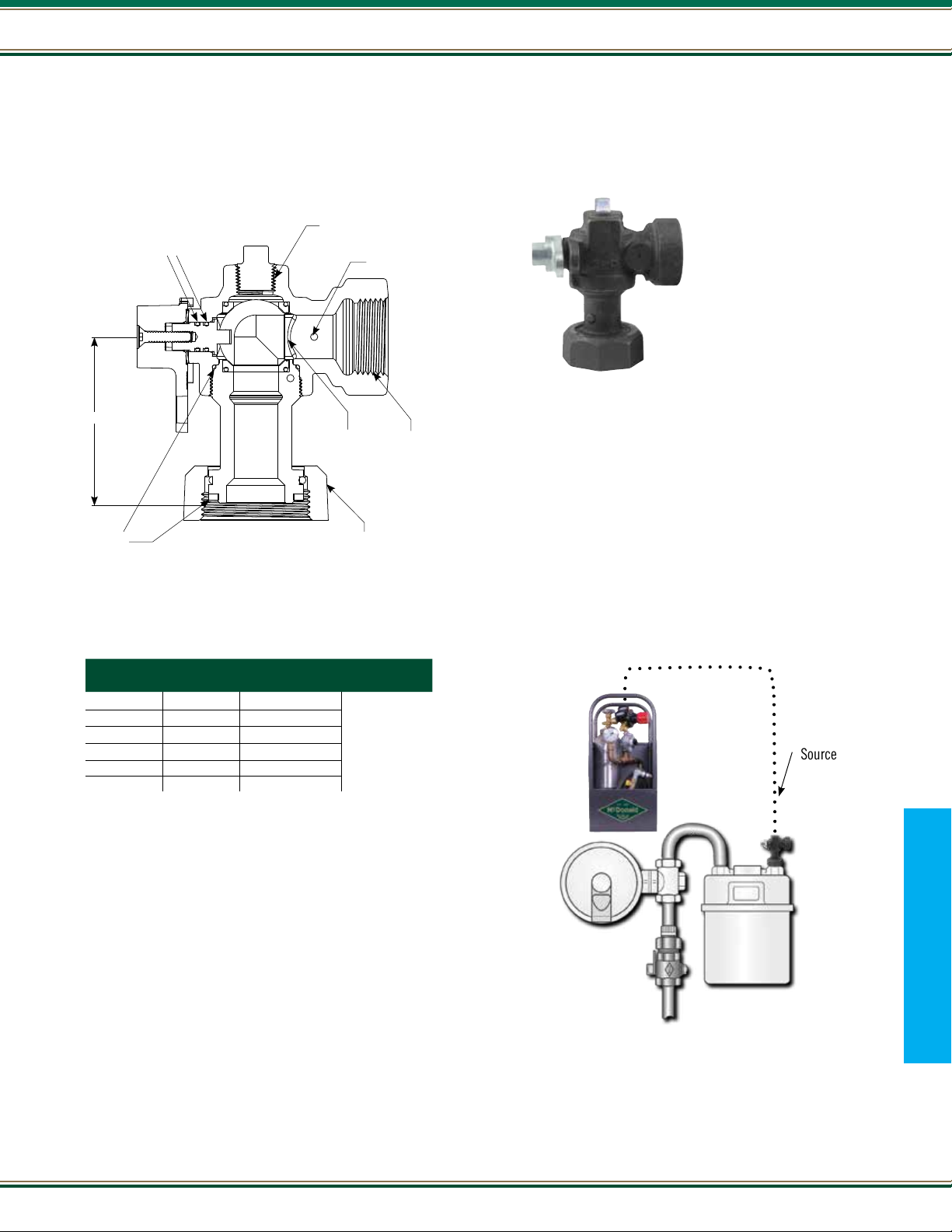

Meter Outlet / Bypass Ball Valves - 837 Series

TAMPERPROOF, LOCKWING, UNION, BYPASS OPTION

Can be assembled directly to the meter outlet, or used with a meter bar that provides a solid anchor to the meter set. This valve can be

produced with or without a Bypass feature. These valves are designed for use with natural, manufactured and L.P. gas only.

5.76

2.05

2.10

DIMENSIONS

FNPT

Inlet

3/4” 3/4” 3/4”

1” 1”* 1”

1 1/4” 1 1/4” 1 1/4”

Port

Size

FNPT INLET

FNPT

Outlet

OPTIONAL 3/8” FNPT

BYPASS TAP

PRESSURE

Pressure Tap

(optional)

See Block

4 & 5

FNPT OUTLET

(black iron shown)

Integral FNPT x Insulated Union with FNPT Tailpiece

COATINGS AVAILABLE

837B Black Iron

837G Zinc Coated w/Clear Sealant Finish Iron

837N Zinc Plated Clear Sealant /Painted Finish

837P Painted Finish

Taps available on all the above product options.

* 1” is reducing port

Bypass Ball Valves

Shown without Cast

Meter Bar

NOTES:

For external source of gas see Portable Bypass Kit on page 36

25

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 855 Series

FOR 855 SERIES OUTLET ANGLE VALVES - BALL STYLE

A.Y. McDonald Mfg. Co. Gas Meter Bars can be ordered to t your requirements. Select the features you need from list below and build

your own ordering number. Please note the difference in numbers between regular valves, and valves with built in swivels. Meter valves

with swivels have two extra blocks before the size to select the size and type of swivels.

TO ORDER:

Example: Model number 855B means:

8 5 5 B A G B - 3/4” x 3/4” 20LT

1 2 3 4 5 6 7

SPACE

SWIVEL

PORT SIZE OUTLET SIZE

SIZE

BLOCK 1 - INLET TYPE

85 = Meter Swivel Nut

BLOCK 2 - OUTLET TYPE

5 = Integral FNPT

BLOCK 3 - FINISH

B = Black cast iron nish

G = Zinc plated with Clear Sealant nish

H = Zinc plated Clear Sealant & paint

P = Painted nish

BLOCK 4 - TAP(S) LOCATION

A = Pos. A (Bypass)

B = Pos. B

C = Pos. C

D = Pos. A & B (A with 3/8” recessed head)

E = Pos. A & C (C with 3/8” recessed head)

F = Pos. A & C (A with 3/8” square head)

BLOCK 5 - TAP SIZE / PLUG TYPE

A = 1/8” NPT recessed hex head plug

B = 1/8” NPT square head plug

C = 1/8” NPT - no plug

D = 1/4” NPT recessed hex head plug

E = 1/4” NPT square head plug

F = 1/4” NPT - no plug

G = 3/8” NPT recessed hex head plug

H = 3/8” NPT square head plug

J = 3/8” NPT - no plug

K = 1/8” NPT square head plug (raised bosses)

L = 1/8” NPT hex head (raised bosses)

M = 1/8” NPT hex head plug

N = 1/4” NPT square head plug in inlet and 1/8”

recessed hex head plug in outlet

BLOCK 6 - SWIVEL SIZE / TYPE

A = 10LT - 10 Light swivel with at gasket seal

B = 20LT - 20 Light swivel with at gasket seal

C = 20LTO - 20 Light swivel with o-ring

D = 30LT - 30 Light swivel with at gasket seal

E = 30LTO - 30 Light swivel with o-ring seal

F = OEM - O-Emco swivel with at gasket seal

G = OEMO - O-Emco swivel with o-ring seal

H = 1A - #1A Sprague swivel with at gasket seal

J = 1AO - #1A Sprague swivel with o-ring seal

K = 45LT - Only at gasket

BLOCK 7 - SPECIAL

– = Standard swivels and nuts

G = Galvanized swivels and nuts

H = Galvanized nuts only

P = Zinc with yellow di-chromate plated nuts only

Q = Zinc with yellow di-chromate plated nuts only

with swivel gaskets not attached

Bypass Ball Valves

26

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 855 Series

TAMPERPROOF, LOCKWING, BYPASS OPTION

Can be assembled directly to the meter outlet, or used with a meter bar that provides a solid anchor to the meter set. This valve can be

produced with or without a Bypass feature. These valves are designed for use with natural, manufactured and L.P. gas only.

3/8” FNPT - BYPASS PORT SIZE

8.95”

NITRILE

O-RINGS

NITRILE O-RINGS

PRESSURE TAP

.75

INLET METER NUT

FNPT

OUTLET

(black iron shown)

Meter Swivel Nut x Integral FNPT

COATINGS AVAILABLE

855B Black Iron

855G Zinc Coated w/Clear Sealant Finish Iron

855N Zinc Plated Clear Sealant /Painted Finish

855P Painted Finish

Taps available on all the above product options.

DIMENSIONS

Port

Size

3/4” 3/4” or 1” * 10LT

3/4” 3/4” or 1” * 1A

3/4” 3/4” or 1” * OEM

3/4” 3/4” or 1” * 20LT

1 1/4” 1 1/4”* 30LT

1 1/4” 1 1/4” 45LT

* 1” is reducing port

FNPT

Outlet

Swivel

Size Nut

Pressure Tap

(optional)

See Block

4 & 5

Regulated

Bypass Gas

Source

Bypass Ball Valves

Shown without Cast

Meter Bar

NOTES:

For external source of gas see Portable Bypass Kit on page 36

27

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 857 Series

FOR 857 SERIES OUTLET ANGLE VALVES - BALL STYLE

A.Y. McDonald Mfg. Co. Gas Meter Bars can be ordered to t your requirements. Select the features you need from list below and build

your own ordering number. Please note the difference in numbers between regular valves, and valves with built in swivels. Meter valves

with swivels have two extra blocks before the size to select the size and type of swivels.

TO ORDER:

Example: Model number 857B means:

8 5 7 B A G A - 3/4” x 3/4” 10LT

1 2 3 4 5 6 7

SPACE

SWIVEL

PORT SIZE OUTLET SIZE

SIZE

BLOCK 1 - INLET TYPE

85 = Meter Swivel Nut

BLOCK 2 - OUTLET TYPE

7 = Female insulated O-ring union

8 = Female insulated at gasket

9 = Female non-insulated at gasket

BLOCK 3 - FINISH

B = Black cast iron nish

G = Zinc plated with Clear Sealant nish

H = Zinc plated Clear Sealant & paint

P = Painted nish

BLOCK 4 - TAP(S) LOCATION

A = Pos. A (Bypass)

B = Pos. B

C = Pos. C

D = Pos. A & B (A with 3/8” recessed head)

E = Pos. A & C (C with 3/8” recessed head)

F = Pos. A & C (A with 3/8” square head)

BLOCK 5 - TAP SIZE / PLUG TYPE

A = 1/8” NPT recessed hex head plug

B = 1/8” NPT square head plug

C = 1/8” NPT - no plug

D = 1/4” NPT recessed hex head plug

E = 1/4” NPT square head plug

F = 1/4” NPT - no plug

G = 3/8” NPT recessed hex head plug

H = 3/8” NPT square head plug

J = 3/8” NPT - no plug

K = 1/8” NPT square head plug (raised bosses)

L = 1/8” NPT hex head (raised bosses)

M = 1/8” NPT hex head plug

N = 1/4” NPT square head plug in inlet and 1/8”

recessed hex head plug in outlet

BLOCK 6 - SWIVEL SIZE / TYPE

A = 10LT - 10 Light swivel with at gasket seal

B = 20LT - 20 Light swivel with at gasket seal

C = 20LTO - 20 Light swivel with o-ring

D = 30LT - 30 Light swivel with at gasket seal

E = 30LTO - 30 Light swivel with o-ring seal

F = OEM - O-Emco swivel with at gasket seal

G = OEMO - O-Emco swivel with o-ring seal

H = 1A - #1A Sprague swivel with at gasket seal

J = 1AO - #1A Sprague swivel with o-ring seal

K = 45LT - Only at gasket

BLOCK 7 - SPECIAL

– = Standard swivels and nuts

G = Galvanized swivels and nuts

H = Galvanized nuts only

P = Zinc with yellow di-chromate plated nuts only

Q = Zinc with yellow di-chromate plated nuts only

with swivel gaskets not attached

Bypass Ball Valves

28

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 857 Series

TAMPERPROOF, LOCKWING, BYPASS OPTION, UNION

Can be assembled directly to the meter outlet, or used with a meter bar that provides a solid anchor to the meter set. This valve can be

produced with or without a Bypass feature. These valves are designed for use with natural, manufactured and L.P. gas only.

5.77

2.84

3/8” FNPT -

BYPASS PORT

SIZE

INLET

METER NUT

PRESSURE

TAP

NITRILE

O-RING

BUNA-N OR

NEOPRENE GASKET

OUTLET

INSULATED

END

FNPT

(black iron shown)

Meter Swivel Nut x Insulated Union

with FNPT Threads Tailpiece

COATINGS AVAILABLE

857B Black Iron

857G Zinc Coated w/Clear Sealant Finish Iron

857N Zinc Plated Clear Sealant /Painted Finish

857P Painted Finish

Taps available on all the above product options.

NITRILE

O-RINGS

DIMENSIONS

Port

Size

3/4” 3/4” or 1” * 10LT

3/4” 3/4” or 1” * 1A

3/4” 3/4” or 1” * OEM

3/4” 3/4” or 1” * 20LT

1 1/4” 1 1/4” 30LT

1 1/4” 1 1/4” 45LT

* 1” is reducing port

FNPT

Outlet

Swivel

Nut Size

Pressure Tap

(optional)

See Block

4 & 5

Regulated

Bypass Gas

Source

Bypass Ball Valves

Shown without Cast

Meter Bar

NOTES:

For external source of gas see Portable Bypass Kit on page 36

29

Angle Ball Valves

Meter Outlet / Bypass Ball Valves - 875 Series

FOR 875 SERIES OUTLET ANGLE VALVES - BALL STYLE

A.Y. McDonald Mfg. Co. Gas Meter Bars can be ordered to t your requirements. Select the features you need from list below and build

your own ordering number. Please note the difference in numbers between regular valves, and valves with built in swivels. Meter valves

with swivels have two extra blocks before the size to select the size and type of swivels.

TO ORDER:

Example: Model number 875B means:

8 7 5 B A G 1” x 3/4” x 1”

1 2 3 4 5

INLET PORT SIZE OUTLET

SPACE

SIZE

BLOCK 1 - INLET TYPE

87 = Female Union Inlet

BLOCK 2 - OUTLET TYPE

5 = Integral FNPT

BLOCK 3 - FINISH

B = Black cast iron nish

G = Zinc plated with Clear Sealant nish

H = Zinc plated Clear Sealant & paint

P = Painted nish

BLOCK 4 - TAP(S) LOCATION

A = Pos. A (Bypass)

B = Pos. B

C = Pos. C

D = Pos. A & B (A with 3/8” recessed head)

E = Pos. A & C (C with 3/8” recessed head)

F = Pos. A & C (A with 3/8” square head)

BLOCK 5 - TAP SIZE / PLUG TYPE

A = 1/8” NPT recessed hex head plug

B = 1/8” NPT square head plug

C = 1/8” NPT - no plug

D = 1/4” NPT recessed hex head plug

E = 1/4” NPT square head plug

F = 1/4” NPT - no plug

G = 3/8” NPT recessed hex head plug

H = 3/8” NPT square head plug

J = 3/8” NPT - no plug

K = 1/8” NPT square head plug (raised bosses)

L = 1/8” NPT hex head (raised bosses)

M = 1/8” NPT hex head plug

N = 1/4” NPT square head plug in inlet and 1/8”

recessed hex head plug in outlet

Bypass Ball Valves

30

800.292.2737 | sales@aymcdonald.com | aymcdonald.com

4-19

Loading...

Loading...