A.Y. McDonald DuraMAC E Installation Manual

TM

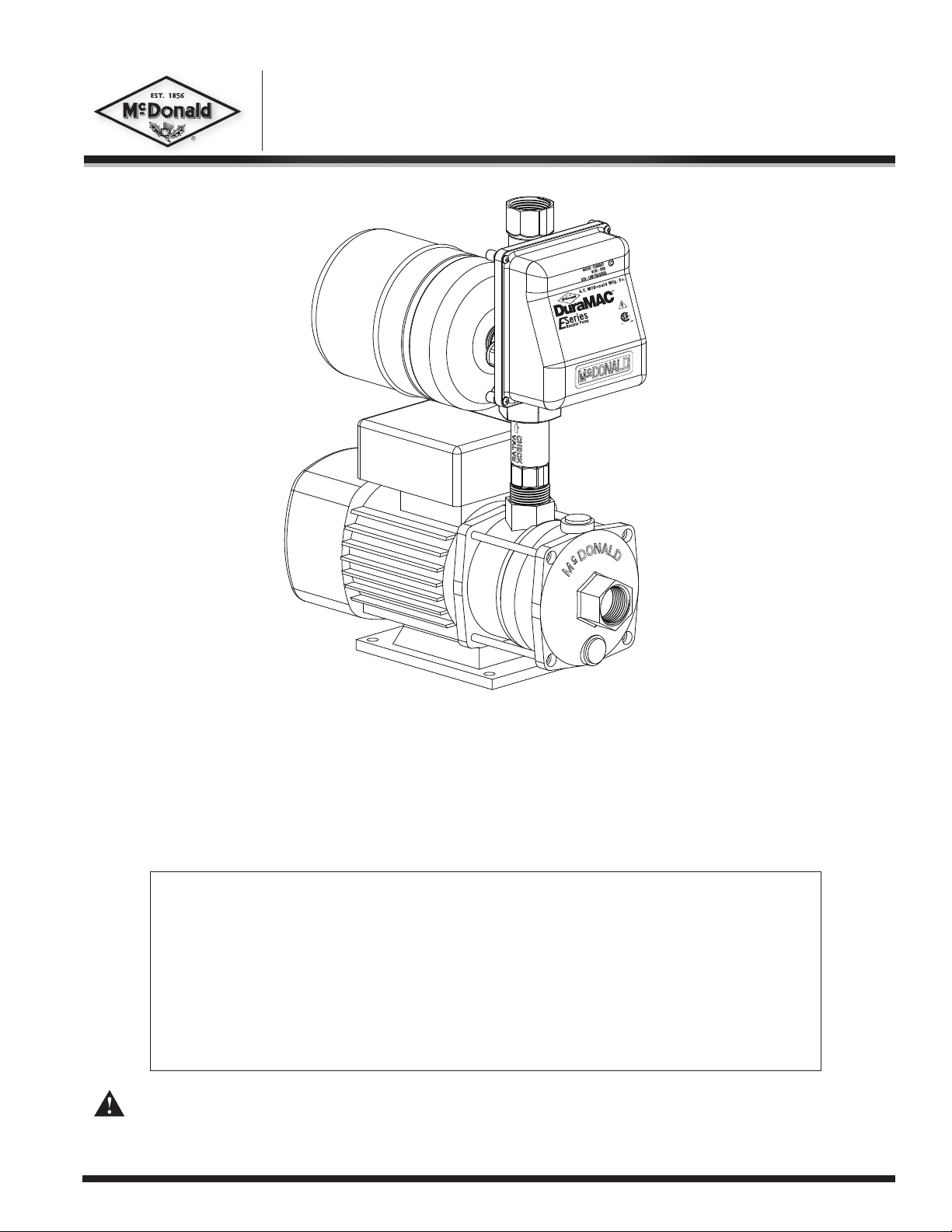

E-Series DuraMAC

Residential

Water Pressure Booster System

Y

B

D

N

A

T

S

-

N

N

E

U

E

R

R

-

G

E

U

L

B

E

R

U

S

S

E

R

P

W

O

L

-

D

E

R

TM

E-Series PUMP CONTROL

5300PC DuraMAC

1

120VAC 60HZ 10 FLA 60 LRA

O

S

P

PUMP STARTS ON PRESSURE OR FLOW

O

T

S

P

M

U

P

D

L

A

N

O

D

C

M

Y

A

.

W

W

W

1

A

M

E

N

Y

L

N

O

W

E

S

O

U

L

R

F

O

O

D

OW

N

I

L

N

M

O

C

.

Installation Instructions

The E-Series DuraMAC™ Water Pressure Booster System is designed for residential and small commercial boosting applications.

The pump starts with water ow or pressure drop and stops on low ow.

A constant speed, totally enclosed fan-cooled motor drives the E-Series DuraMAC™ booster pump with single phase power. It tells you it

is working properly by illuminating a single status light.

ATTENTION!

Important information for installers of this equipment!

This equipment is intended for installation by technically qualied personnel. Failure to install it in compliance with

national and local electrical codes and with motor suppliers recommendations, may result in electrical shock or re hazard,

unsatisfactory performance, and equipment failure.

WARNING!

Serious or fatal electrical shock may result from failure to connect the motor, control enclosures, metal plumbing, and all other

metal near the motor or cable, to the power supply ground terminal using wire no smaller than motor cable wires. To reduce

risk of electrical shock, disconnect power before working on or around the water system.

WARNING: It is unlawful in CALIFORNIA & VERMONT (effective 1/1/2010); MARYLAND (effective 1/1/2012); LOUISIANA (effective 1/1/2013) and the UNITED

STATES OF AMERICA (effective 1/4/2014) to use any product in the installation or repair of any public water system or any plumbing in a facility or system

that provides water for human consumption if the wetted surface area of the product has a weighted average lead content greater than 0.25%. This prohibition does

not extend to service saddles used in California, Louisiana or under USA Public Law 111-380.

3210-602 8/18

800.292.2737 | FAX 800.832.9296 | pumps@aymcdonald.com | ayboosters.com

1

TABLE OF CONTENTS

SECTION 1 ELECTRICAL INSTALLATION .............................................................................. 2

SECTION 2 INSTALLATION & LOCATION .......................................................................... 2-3

SECTION 3 PUMP ASSEMBLY ............................................................................................. 4

SECTION 4 PIPING ......................................................................................................... 5-7

SECTION 5 PUMP CONTROL ..............................................................................................8

SECTION 6 ALTERNATE CONTROL METHODS ...................................................................... 9

SECTION 7 TROUBLESHOOTING ................................................................................. 10-11

Before installation, read the following instructions carefully. Each E-Series DuraMAC™ pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

1. GROUNDING & ELECTRICAL INSTALLATION

The pump and control is supplied with a 3-conductor grounding cord. Connect the control only to a properly grounded,

dedicated GFCI protected circuit. Do not lift the pump by the electrical cord.

Follow local and national plumbing, building and electrical codes when installing the pump. Maintain this pump in compliance with the

National Electrical Code (NEC) or the Canadian Electrical Code (CEC) and with all local codes and ordinances that apply. Consult your

local building inspector for local code information.

Use copper conductors only and be certain wire and fuses of the correct size are installed.

DO NOT GROUND TO GAS OR FUEL LINES

2. INSTALLATION & LOCATION

The pump should be installed in a dry, accessible area protected from freezing temperatures. Proper ventilation must be provided for

proper cooling of the electrical equipment.

Follow local plumbing codes. In some cases a dual check valve, reduced pressure zone device, or other equipment may be

required.

If your new boosted pressure is greater than 80 PSI*, you must install a pressure reducing valve before your pump. Consult local

plumbing codes and pressure ratings on your water appliances.

A pressure relief valve or expansion tank is recommended downstream of device if thermal expansion conditions are possible.

*See table on Page 3 for maximum incoming pressure.

2

800.292.2737 | FAX 800.832.9296 | pumps@aymcdonald.com | ayboosters.com

8/18 3210-602

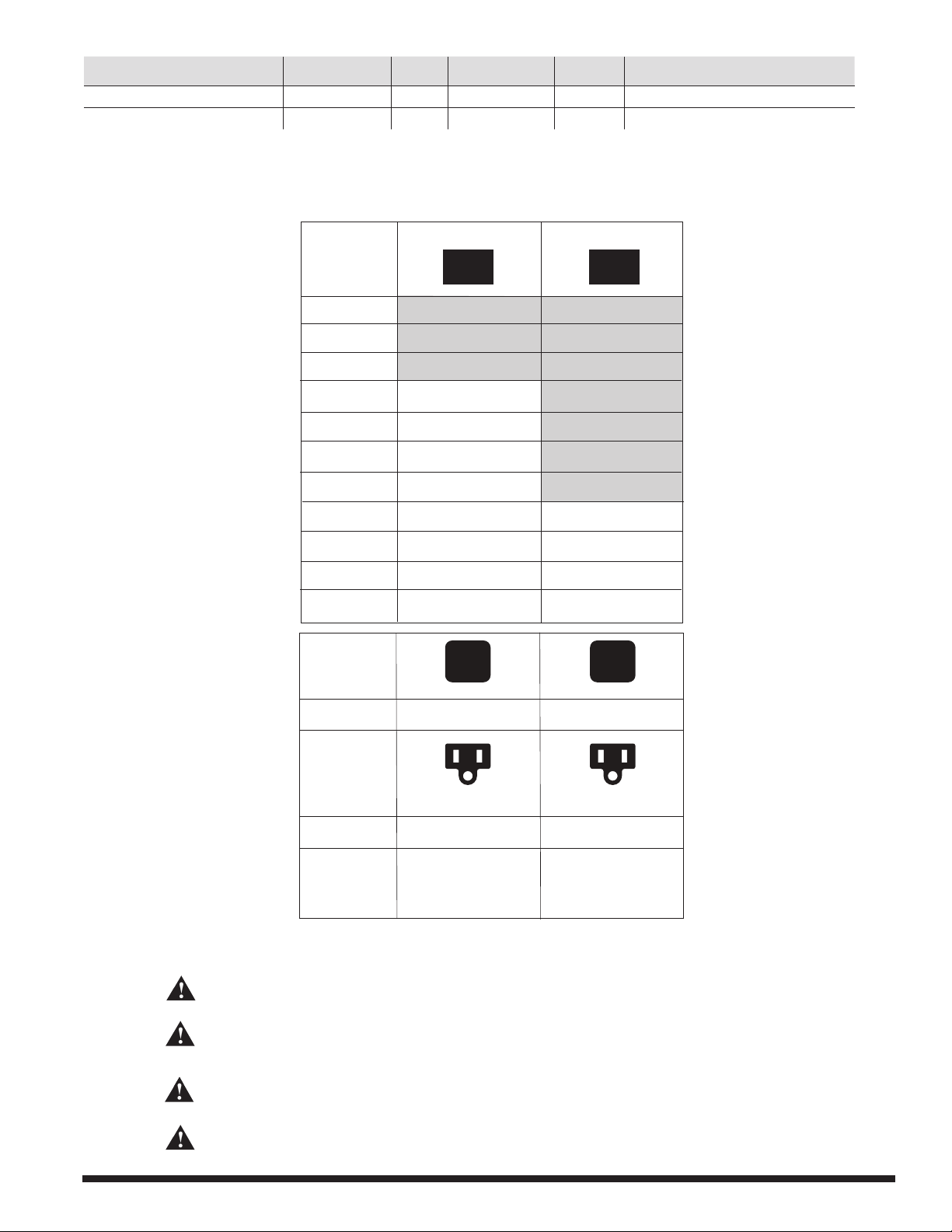

E-Series DuraMAC™ Model Pump Boost Amps Voltage Power *Maximum incoming pressure

18035R020PC1 35 PSI 5.5 120 - 60 Hz ½ HP 45 PSI

18052R020PC1 52 PSI 7.0 120 - 60 Hz ¾ HP 28 PSI

Total static pressure E-Series DuraMAC™ pump

Incoming 18035R020PC1 18052R020PC1

Pressure

(PSI)

+35 +52

60

55 90

50 85

45 80

40 75

35 70 87

30 65 82

25 60 77

20 55 72

15 50 67

10 45 62

Pump

Boost

Model #

+

35

PSI

BOOST

18035R020PC1 18052R020PC1

CONTACT FACTORY

+

PSI

BOOST

52

3210-602 8/18

Cord

Connection

120V 120V

Power

1/2 HP

3/4 HP

Max

Incoming

45 psi

28 psi

Pressure

Do not spray water on or near the electric motor or control.

Pump only water with this pump. Do not pump ammable liquids or chemicals. Do not use the pump near

gas pilot lights or where chemical or gas fumes are present.

Use of an electric pump with liquids other than water or in an atmosphere containing chemical or gas fumes

may ignite those liquids or gases and cause injury or death due to an explosion and/or re.

Always install near a oor drain where leakage will not cause damage to homes or property.

800.292.2737 | FAX 800.832.9296 | pumps@aymcdonald.com | ayboosters.com

3

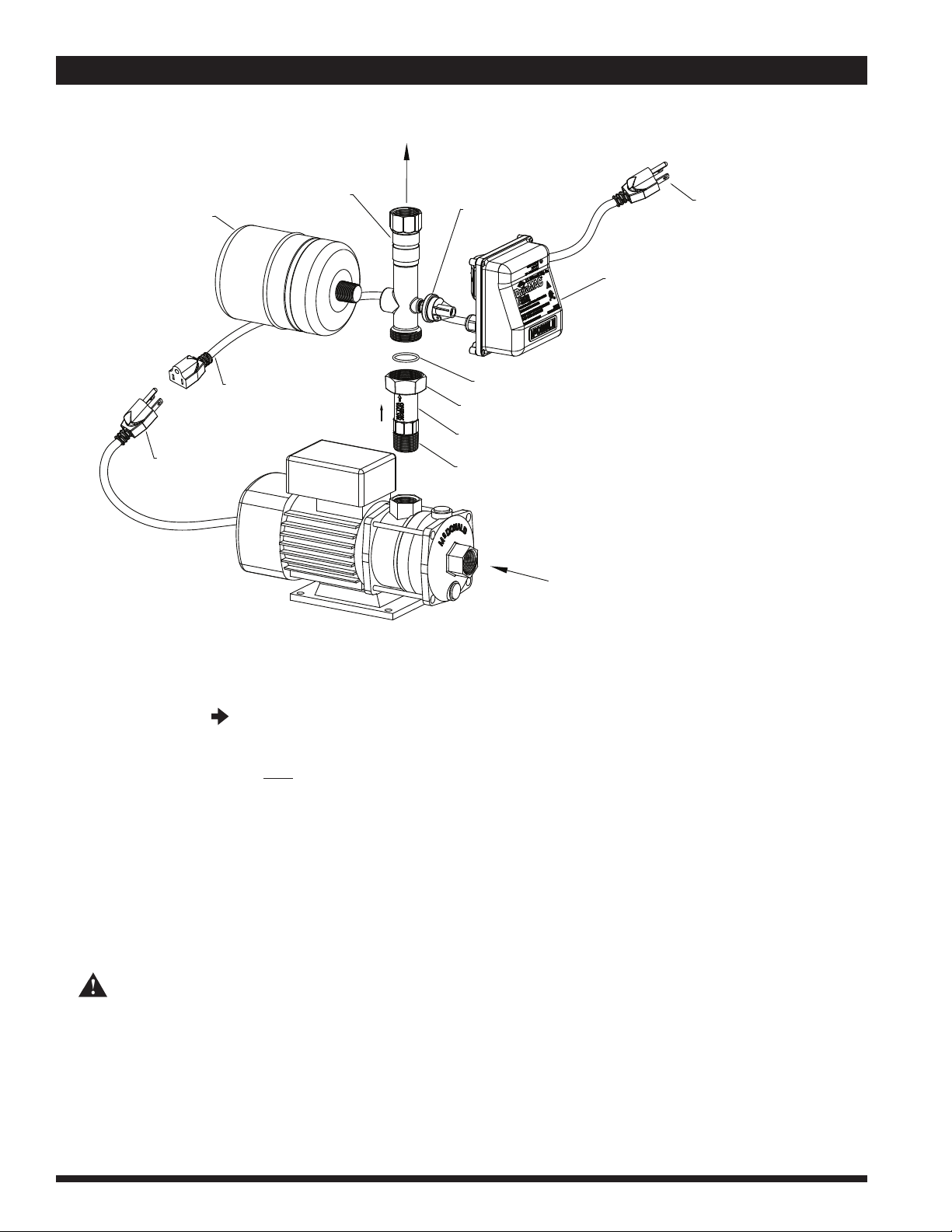

3. PUMP ASSEMBLY

OUTLET

TANK

PUMP

CORD

CONTROL CROSS

CONTROL

CORD

FLOW

PRESSURE SWITCH

O-RING

UNION NUT

CHECKVALVE

TAILPIECE

MUST CONNECT TO A

GFCI PROTECTED CIRCUIT

15300 PC1 CONTROL

INLET

1. Make sure arrow on tailpiece check valve is in the direction of ow. Push inside the check valve to make sure poppet can

move. If the check valve is installed in the wrong direction water will not leave the pump.

2. Apply pipe sealant on the male threads of tailpiece with check valve. Install into outlet of pump. DO NOT apply any pipe

sealant on pump threads.

3. Make sure the union nut is over the tailpiece before threading into pump.

4. O-ring should be installed in groove on top of tailpiece with check valve. Then tighten union nut to control cross.

5. Apply pipe sealant on tank threads and install into control cross port labeled “Tank”. Only tighten with a wrench on the ats

of the tank. The 1/2 gallon tank included is required for this product to work properly. The air pressure of the tank must be

set at 28 PSI. This is 2 PSI less than the start pressure of the pump.

6. Plug the pump cable into the control cord. Do not plug the control into wall yet.

Plugging in the control prior to making plumbing connections and priming the pump will cause the pump to run dry and

void warranty.

7. Rotate control so front panel is visible when installed.

8. Mount the pump base rmly and follow piping instructions on next page.

4

800.292.2737 | FAX 800.832.9296 | pumps@aymcdonald.com | ayboosters.com

8/18 3210-602

Loading...

Loading...