Page 1

1

Service Manual

Plus

MICROSPEED

Mcs-Plus-gb Ver.21/02/2002

The MICROSPEED PLUS series of amplifiers are marked CE

because they conform to European Directives for

Electromagnetic Compatibility and Low Voltage.

This manual describes the mechanical and electrical

characteristics of the Microspeed Plus servoamplifier series.

It is important that the installation procedures are only

performed by qualified personnel in accordance with local

safety guidelines.

Whoever installs the equipment must follow all of the

technical instructions printed in this manual.

For more information, please contact AXOR's technical

department.

All rights reserved. Reproduction in whole or in part is prohibited without prior

written consent of the copyright owner. All specifications are subject to change

without prior written consent of the copyright owner. All specifications are subject

to change without prior notification.

Page 2

2

Service Manual

Plus

MICROSPEED

Index

Indice

1) Description

1.0 Security Standards ......................................................... 4-5

1.1 Introduction and Options ..............................................6-7

1.2 Technical Data ................................................................... 8

1.3 Microspeed Plus Description ......................................... 9

1.4 Drive Dimensions .......................................................10-11

1.5 Drive Label Description ................................................. 12

1.6 Connections...................................................................... 13

1.7 Signal Inputs and Outputs ........................................14-17

1.8 Power Supply Inputs and Outputs................................ 17

2) Indicator LEDs and Regulations

2.0 Potentiameter Adjustments ....................................... 18-19

2.1 Protections ........................................................................ 20

2.2 Indicator LEDs ................................................................. 21

3) Installation

3.0 Installation Notes ............................................................. 22

3.1 Ventilation .....................................................................22-23

3.2 Power Supply Construction and Rating .................24-28

3.3 Multiple Microspeed Connections .............................. 29

3.4 Ground and Shield Connections .............................30-31

3.5 Istructions for EMC Requirements .........................32-35

3.6 Example of Microspeed Plus Connections................ 36

3.7 Speed Reference ............................................................. 37

3.8 Current Reference........................................................... 38

3.9 Current Output Limitation .........................................39-40

3.10 Limit Switch Input +/-................................................... 41

3.11 Power Connections ....................................................... 42

Page 3

3

Service Manual

Plus

MICROSPEED

4) Start up procedures

4.0 Preliminary Checks......................................................... 43

4.1 Starting Procedures ...................................................43-44

5) Adjustments

5.0 Personalization and Settings ......................................... 45

5.1 Adjustments on Personalization Base ..................... 46-47

5.2 Solder Bridges ............................................................48-49

5.3 Speed Adjustments with D.T. Feedback ..................... 50

5.4 Speed Adjustments with Armature Feedback ......51-52

5.5 Speed Balance Adjustments (Offset)........................... 52

5.6 Nominal and Peak Current Adjustments .................... 53

5.7 Ramp Time Adjustments ................................................ 54

5.8 Dynamic Constant Adjustments...............................55-56

6) Troubleshooting

7.0 Troubleshooting ............................................................... 57

7) Option

7.1 Option Encoder .......................................................... 58-61

7.2 Option PWM+DIR......................................................62-63

Conformity Declaration ........................................................ 64

Index

Page 4

4

Service Manual

Plus

MICROSPEED

Danger Sign

This symbol is used where security directives should

be adhered to, where substantial risks are involved, and

where life endangerement or injury could occur.

Installers must scrupulously adhere to

prescribed directives and must communicate

them to the users.

W arning of Current being present

This symbol warns the user/installer to pay particular

attention to the presence of dangerous voltage (up to

270Vdc).

It's recommended to always remove drive from the

power supply net before working on the drive.

Warning

This symbol is present in all particularly important

points.

It's used where the intent is to highlight useful

considerations, prescriptions, indications, and the

correct execution procedures of every type of

intervention and prevention of damaging both systems

and drives.

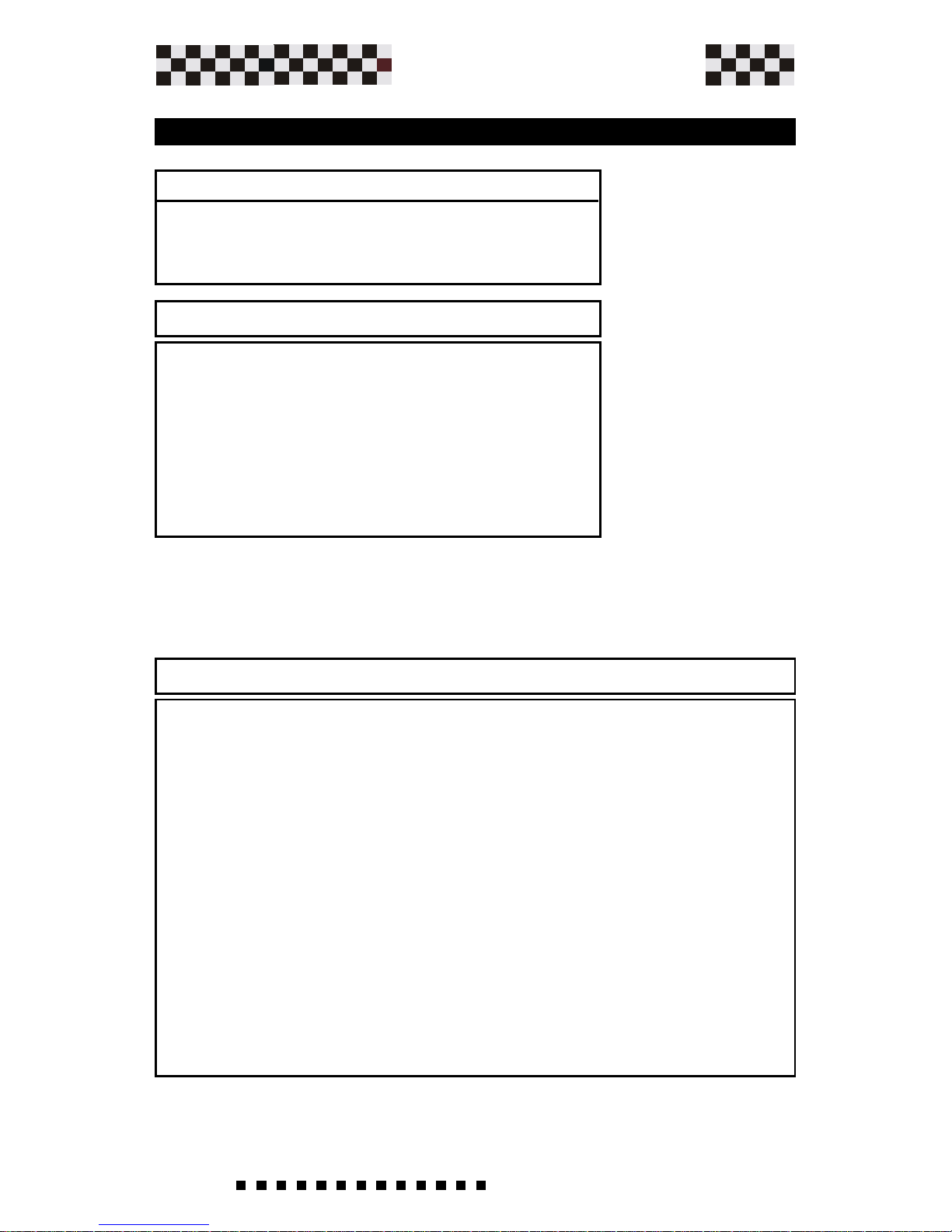

General Security Directives

Along with what is prescribed in the manual, pay

attention to the security directives for prevention

of accidents and risks.

Always remove the power supply (disable) from both

the system and the drive prior to any type of intervention

on electric or mechanical parts.

1.0 Security standards

General Description

Page 5

5

Service Manual

Plus

MICROSPEED

The Microspeed Plus must only be installed by trained, qualified

and authorized personnel.

Any intervention or modifications effected on Microspeed Plus,

and their components or accessories, constitutes loss of

guarantee.

Isolate the drive from the power supply net before removing it

(by removing fuses or turning off the principal power switch).

The drive is equipped with electronic protections that disactivate

it in case of abnormalities, therefore the motor becomes

uncontrolled; this could cause the stoppage or idle motor ( for a

period determined by the type of system used).

In some cases the drive could restart automatically when the

reason for blockage is corrected.

In this case, some systems could be damaged or destroyed

endangering the welfare of personnel.

In this case the user must remove the drives' and systmes' power

supply so that the motor cannot automatically restart or prevent

such an event in the controller's program.

The Microspeed Plus terminals must always be grounded as per

the instructions in this manual.

General Description

Page 6

6

Service Manual

Plus

MICROSPEED

Capitolo 1

1.1 Introduction

General Description

The Microspeed Plus Servo Amplifier is a compact full DC four

quadrant drive. The (MOSFET)output power stage is controlled

by a 22 Khz PWM (Pulse With Modulation)signal that allows it t

drive small to medium sized brushless servo motors (up to 6Nm)

where high dynamic performance and precise speed is required.

The Microspeed only requires a single power supply to operate

and develops all needed voltages on board to make power supply

design easy and convenient.The input voltage is from 20 to 270

Vdc max "See Tecnical Data". (Chapter 3 describes how to design

a proper supply.)

Closing the velocity feedback loop to motor may be done in

several different ways to accommodate most applications. Three

types of velocity feedback are available with these drives. Refer

to Chapter 5 for the setup procedures that will effect your

application.

Feedback Types:

-Tachogenerator

-Armature.

-Encoder (Option)

-Pwm+Direction (Option)

Two inputs are present for the disabling of clockwise and counterclockwise motor rotation (+LM SW,-LM SW).

The possibility to completely adjust the Dynamic Constant exists

by inserting new values "as opposed to the standard mounted

values".

The insertion of various prearranged operational drive values

are easily realized by opening and closing solder points. The

intervention of drive protections are all visible with LEDs on the

front of the drive.

The nominal current, as well as peak current is adjusted through

resistance on the base.

The operating temperature is from 0 to +40 °C (32° to 104°F).

In accordance with the current size and model, supplemental

ventilation can be requested.

Page 7

7

Service Manual

Plus

MICROSPEED

Characteristic and Options

The speed feedback present on the Microspeed Plus are

highlighted.

Speed Feedback from Tachogenerator

Speed Feedback from Armature

Speed Feedback from Encoder

External Power Supply + Brake for plus .60

External Power Supply + Brake for plus .140

External Power Supply + Brake for plus .200

=Standard.

=Standard on sizes 14/28 ,20/40.

=Optional

General Description

Current Reference (torque mode)

Pwm+Dir command

Version with Booster

Limit switch

Page 8

8

Service Manual

Plus

MICROSPEED

1.2 Technical Data

MICROSPEED PLUS VOLTAGE

22Khz

32°-104°F (0°+40°C)

12°-158°F (-10°+70°C)

+/-5uV Degree F

+/-10Vdc

+/-7Vdc = (PK. curr.)

+5/+12Vdc ( 220 mA Max)

+/-10Vdc ( 4mA Max.)

250Khz Max.

2.5Khz

26.45 oz (750 gr.)

44.1 oz (1250 gr.)

10/95% non-condensing

--PWM frequency

--Operating Temperature

--Storage Temperature

--Drift

--Analog inputs

--Current Monitor (Imot)

--Encoder and Hall Signal

Power Supply (+V Optional)

--Auxiliary power supply

--Encoder Max.Freq. (Optional)

-- Band Width

--Weight Microb plus

--Weight Microb plus w/booster

--Humidity

TECHNICAL DATA CHARACTERISTICS

Size I nom. (A) I peak(A)

MICROSPEED PLUS CURRENT SIZES

1/2 +/-1 +/-2

2.5/5 +/- 2.5 +/- 5

6/12 +/- 8 +/- 16

10/20 +/- 10 +/- 20

14/28** +/- 14 +/- 28

20/40** +/- 20 +/- 40

* Minimum and maximum voltage. Tipical voltage are: 60Vdc,

140Vdc and 200Vdc.

Note a) The Microspeed plus 60 is produced only in sizes 14/28 e

20/40.

General Description

Microspeed 60 20 - 80 Vdc* Note a)

Microspeed 140 40 - 180 Vdc*

Microspeed 200 60 - 270 Vdc*

Page 9

9

Service Manual

Plus

MICROSPEED

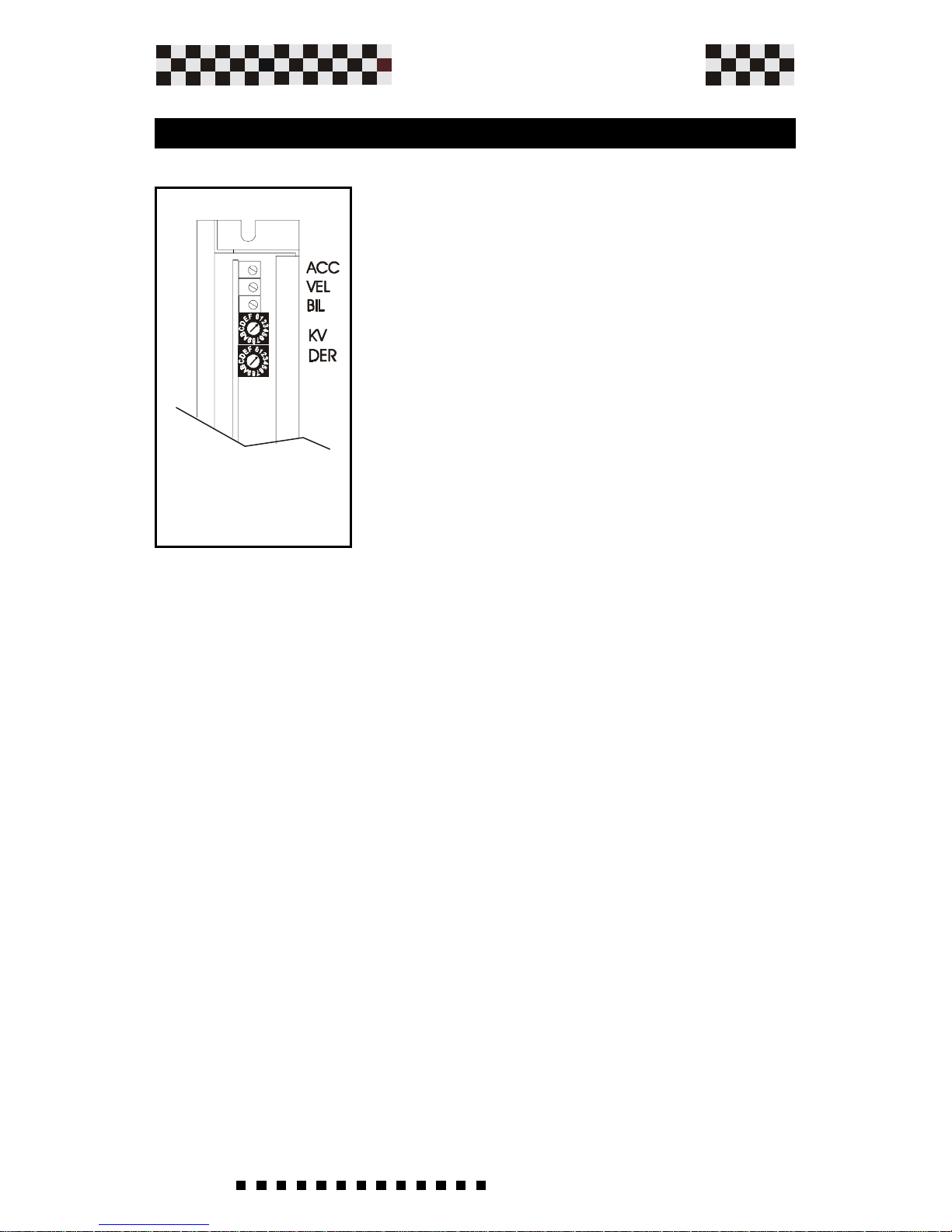

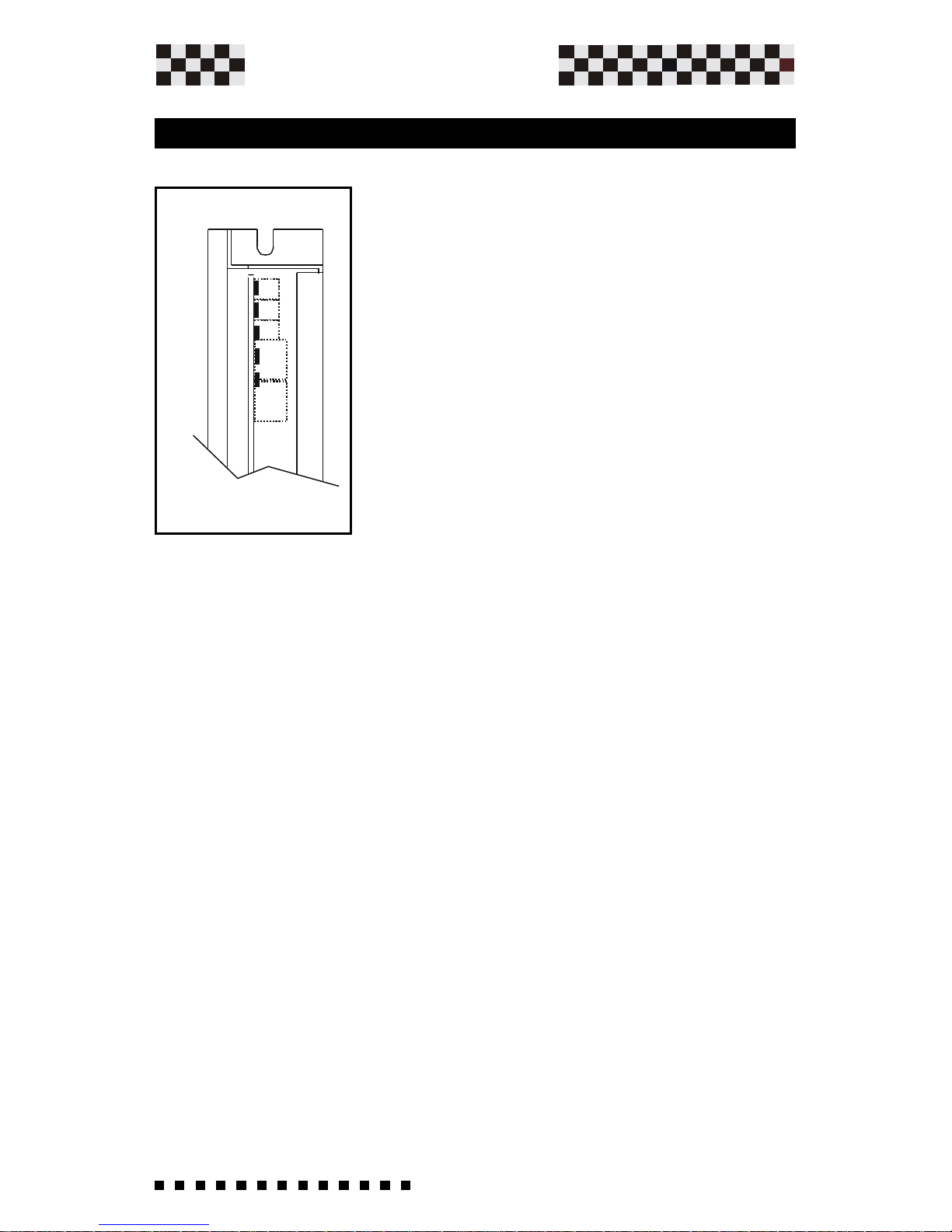

1.3 Microspeed Plus Description

General Description

1 Calibration Area

2 Calibration Potentiometers

3 Hexadecimal Rotating Switch

4 10 poles 5.08 Phoenix Signal Terminals.

5 10 poles 5.08 Extractable Phoenix Terminals.

6 6 poles 3.81 Phoenix Signal Terminals.

7 6 poles 3.81 Extractable Phoenix Terminals.

8 Power Terminals AUGAT

9 Product Cover

10 Fixing screws

11 Serial Number

12 Product ID Label

13 Tacho Test point (Tachometric signal)

The power connector "AUGAT 6PCR-05" is used

on sizes 10/20-14/28 e 20/40A.

Power terminals "Phoenix GMSTB2,5/5-G" 7,62

for Microb sizes 1/2 2,5/5 6/12 .

Page 10

10

Service Manual

Plus

MICROSPEED

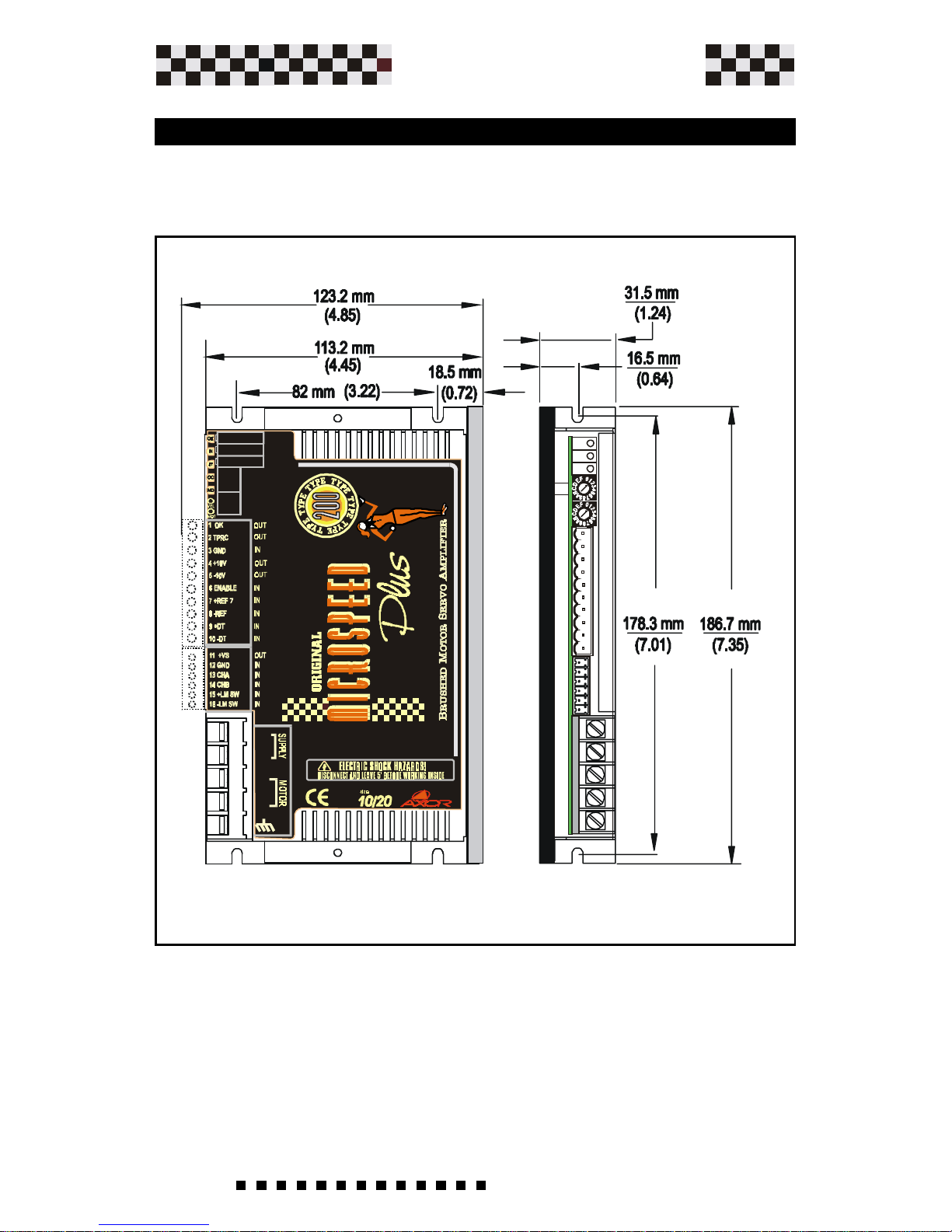

MICROSPEED PLUS

KV

DER

BIL

VEL

ACC

+M-M-AT

+AT

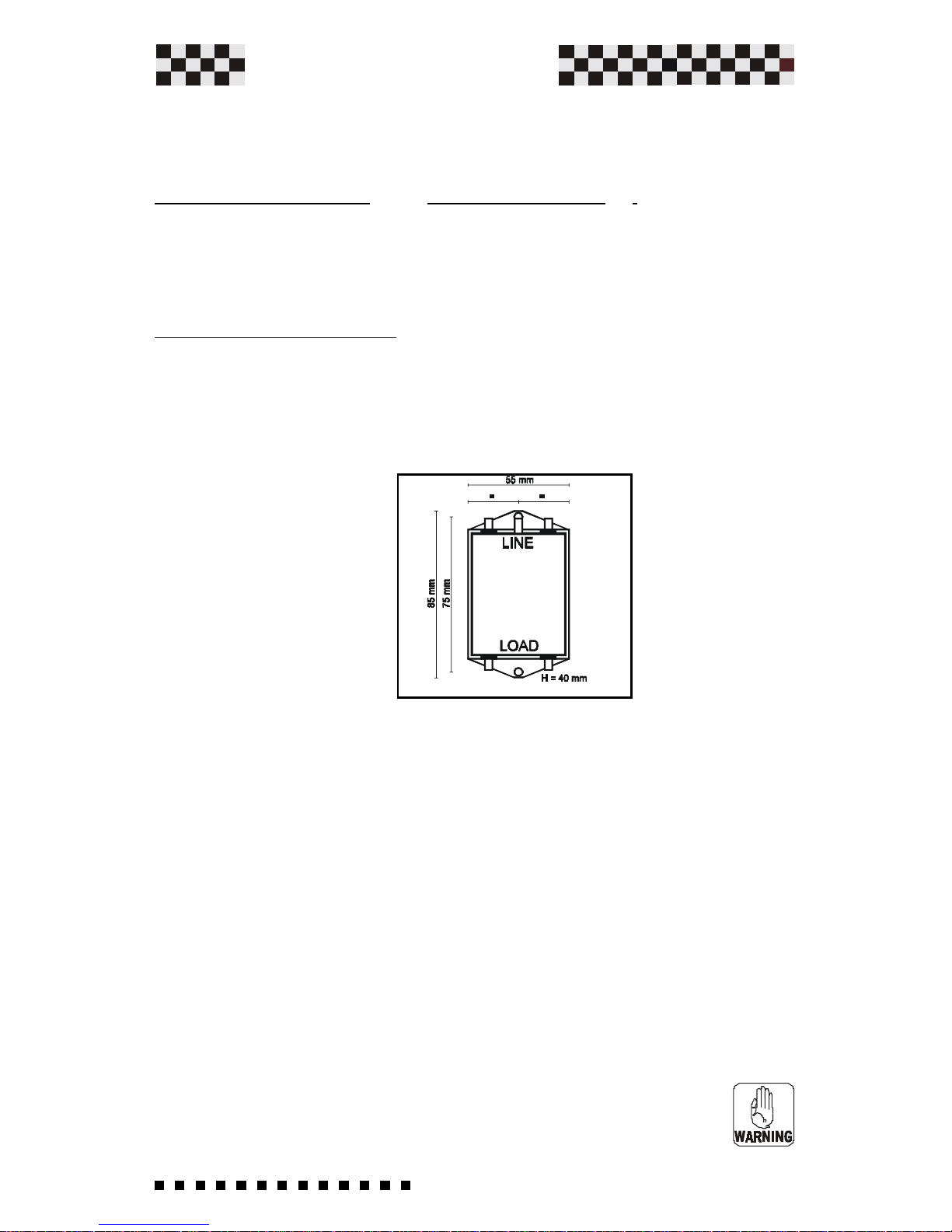

1.4 Drive Dimensions

NOTE: Dimensions mm ( INCHES)

General Description

Page 11

11

Service Manual

Plus

MICROSPEED

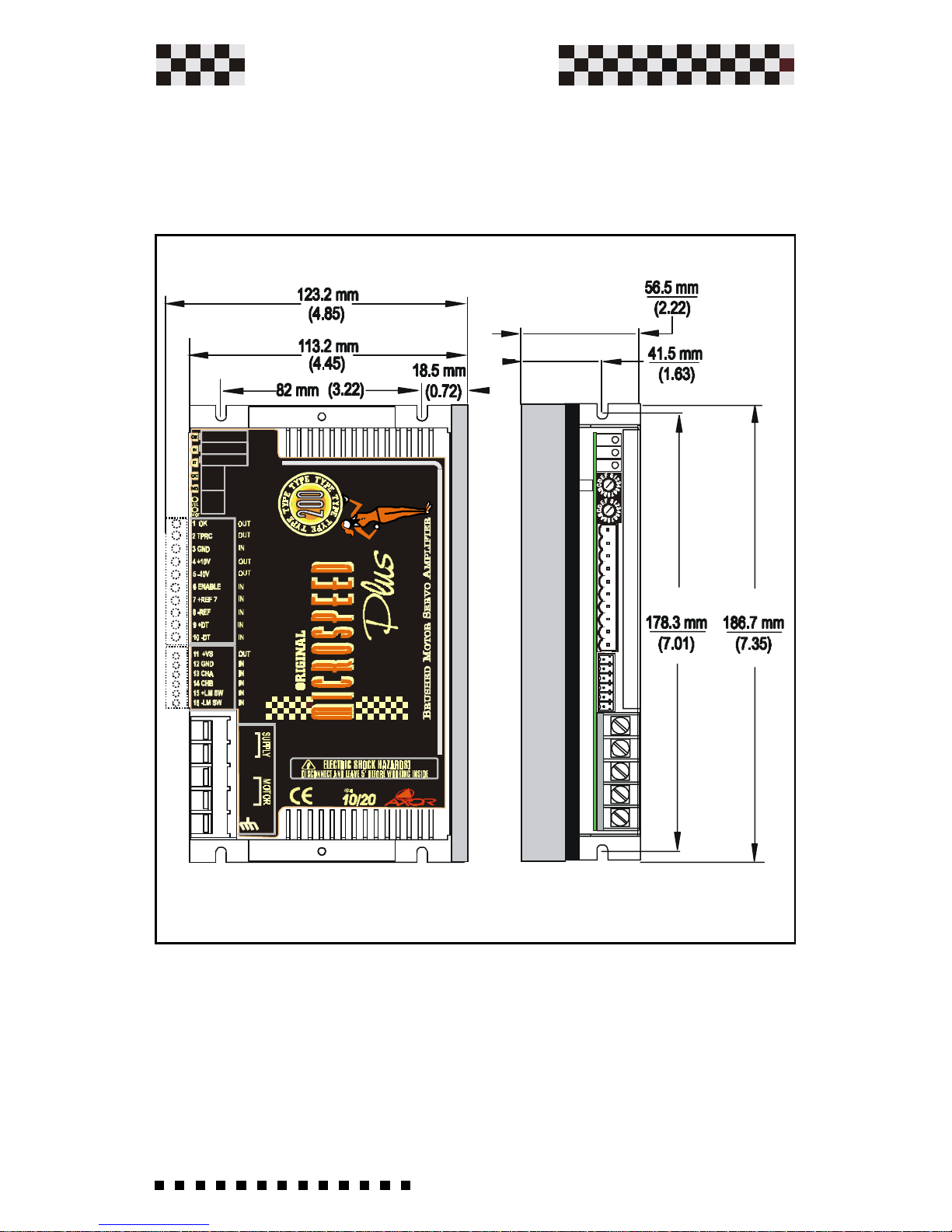

MICROSPEED PLUS WITH BOOSTER

KV

DER

BIL

VEL

ACC

+M-M-AT

+AT

General Description

NOTE: Dimensions mm ( INCHES)

Page 12

12

Service Manual

Plus

MICROSPEED

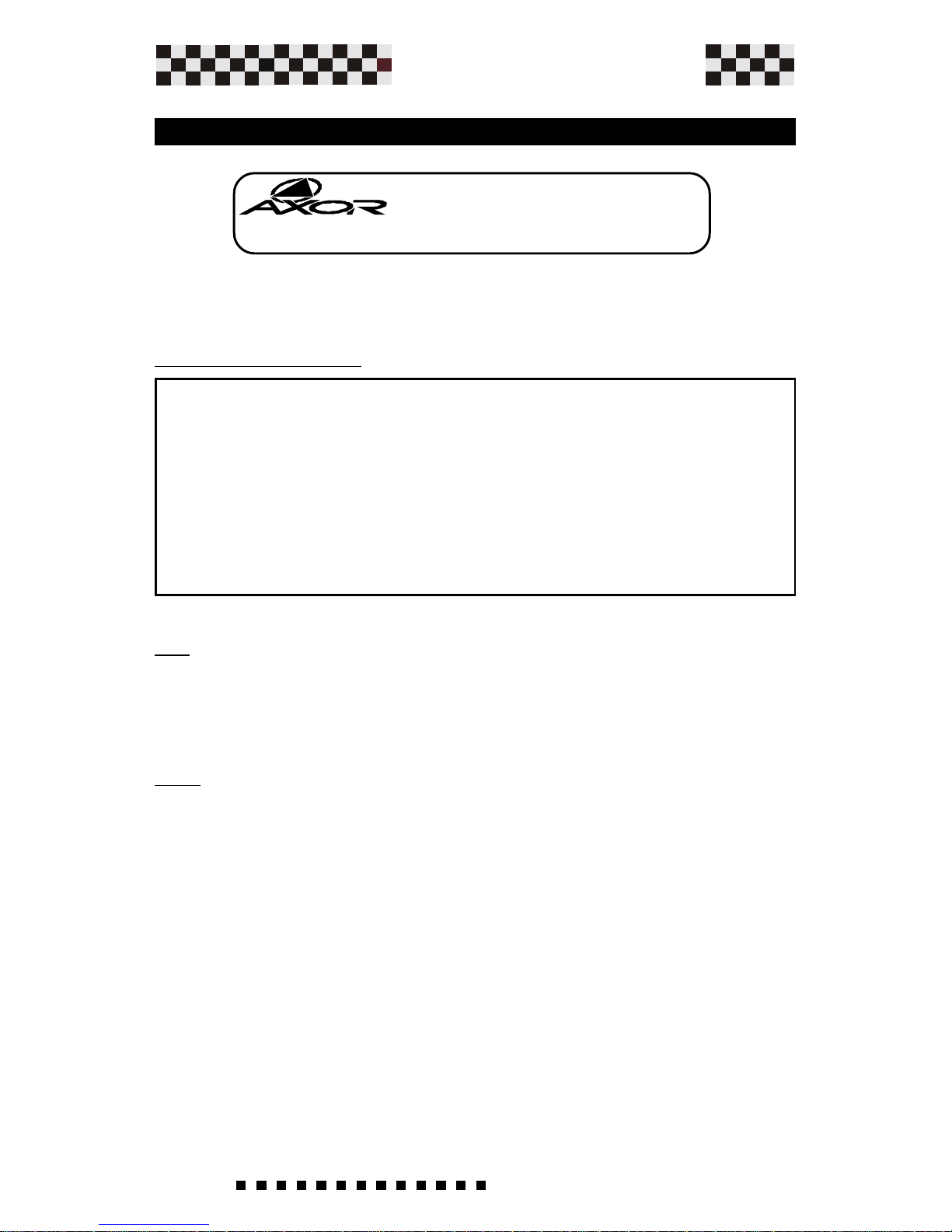

The Product Label is on all MICROSPEED PLUSDrives. The Label

printed above is a typical example. To identify the various options see

below: Product type and Identification:

ADJ is the identification of specific adjustments on the product for

specific motors. If the product is furnished Standard, the ADJ will show

the disbursed current.

ORD is AXOR's internal order number which relates to product

distribution. Always quote this number when asking for technical

assistance.

1.5 Drive Label Description (example)

General Description

Name: MCS PLUS

Model: 060-140-200

Size: 01/02- 2.5/5 -06/12 -10/20 -14/28 -20/40

Heatsink: N=Normal, B=Booster

Protection: S=Standard, T= Tropicalized

1000: Axor identification number

Feedback: T0= Tachogenerator, A0=Armature, E0=Encoder

Control mode: RD= Rifferential mode, I0= Demand current, PD=Pwm+Dir

ORDERING CODE

MCS PLUS-140-5/10-N-S-1000-T0-RD

ADJ 5/10A RA

Date 27/01/01 Ord. 365 /2001

Page 13

13

Service Manual

Plus

MICROSPEED

1.6 Connections

General Description

Page 14

14

Service Manual

Plus

MICROSPEED

2 TPRC(IN)

1 OK(OUT)

The following is the Signal Connector Description.

(10 Poles 5.08 Phoenix signal Terminals)

.

1.7 Signal inputs and outputs

General Description

Drive OK, Open Collector output 50mA Max. (Normally closed,

opens when in protection mode)

This signal can be used in 3 distinct modes:

A) Motor Current Limit Mode:

Soldering point S8 open S9 closed.

Applying a signal between zero and +10V you receive the

current limitation output from zero to max. drive size.

Ex:

Mcs Plus10/20A.......+5V limits the current to +/-10A.

Mcs Plus 14/28A.....+3.2V limits the current to +/-9A.

Note: The drive velocity loop remains active.

V ing=10 x I required

I peak

B) Motor Current Limit Mode:

S8 closed S9 open.

A motor current Limit mode connect an external resistor to

GND (pin 4) reduces the maximun current. Connect a 1/4W o

1/8W resistor between the TPRC and GND terminals.

A 47Kohm resistor reduces the current by 50%.

Note: The drive velocity loop remains active.

Page 15

15

Service Manual

Plus

MICROSPEED

3 GND

5 -10V(OUT)

6 ENABLE(IN)

4 +10V(OUT)

9 +DT(IN)

8 -REF(IN)

7 +REF(IN)

General Description

C) Current Reference (Torque Input):

S8 open S9 closed.

Range: +/- 10V, which corresponds to the drives peak current

output.

In this mode the velocity loop is automatically disabled .

Continued

Drive Common Ground. Corisponds to power supply's negative -AT input.

Power Supply +10Vdc 4mA Max.

Power Supply -10Vdc 4mA Max.

Drive Enable. Range +8Vdc to +24Vdc.

Reference Positive differential input. (Velocity command)

Reference Negative differential input. (Velocity command)

PositiveTacho input + (Connect to internal GND)

Negative Tacho input -

10 -DT(IN)

Page 16

16

Service Manual

Plus

MICROSPEED

15 +LM SW (IN)

12 GND

14 CHB(IN) (Optional)

13 CHA(IN) (Optional)

11 +V(OUT) Power supply encoder (Optional)

Note: The inputs 11-12-13-14, are enabled if the

Encoder Option is present.

General Description

Drive Common Ground. Corisponds to power supply's negative -AT input.

Encoder input Channel A

High logic level from +3,2V to +24Vdc.

Low logic level <1,5V.

+5Vdc 250mA Max.=(Solder bridge S13 closed).

+12Vdc 250mA Max.=(Solder bridge S13 open).

Encoder input Channel B

High logic level from +3,2V to +24Vdc.

Low logic level <1,5V.

Logic input that , disable with positive rotation (CW) of

motor.(Motor limit).

Such a function is enabled, by open soldering point S10 and

connecting a positive Voltage (between +5Vdc e +24Vdc)on

said input. When the voltage on said input is absent, motor

rotation blockage intervenes in a clockwise sense. See

Chapter 3.10

1.7a Signal inputs and outputs (6 poles)

Page 17

17

Service Manual

Plus

MICROSPEED

16 -LM SW (IN)

General Description

Logic input that , disable with positive rotation (CW) of

motor.(Motor limit).

Such a function is enabled, by open soldering point S10 and

connecting a positive Voltage (between +5Vdc e +24Vdc)on

said input. When the current on said input is absent, motor

rotation blockage intervenes in a counter-clockwise sense.

See Chapter 3.10

+AT (Input).

Positive continuous power supply.

+M (Output).

Motor connection +

GROUND(IN/OUT).

Ground drive

-M (Output).

Motor connection -

Negative Continuous power supply.

Common Zero Signal GND

-AT (Input).

1.8 Power Supply Inputs and Outputs

Page 18

18

Service Manual

Plus

MICROSPEED

2.0 Potentiometer Adjustments

Adjustments

ACC

The solder bridges S2-S4 select the acc/

dec function (ramp). With this

potentiometer we can adjust the slope of

the acceleration and deceleration ramps.

Turning the potentiometer clockwise

(cw) increases the ramp time from 0,1

to 1 Sec (with 10 V reference).

VEL

Motor speed adjustment.Use this potentiometer to adjust the

maximum motor speed. Turn clockwise (cw) to increase the

motor speed and counter-clockwise (ccw) to reduce the motor

speed. The range of the adjustment is +/-20%.Note:

Potentiometer is disabled in torque mode.

BIL

Offset adjustment. Adjust this potentiometer to cancel any

motor speed when the Ref. input is 0 Vdc.

(Max ref. compensation +/- 200mV).

KV

Gain potentiometer.Use this potentiometer to increase or

decrease the dynamic behavior of the motor

With a clockwise turn (cw)we increase the gain of the PI

speed stage, therefore, improving the response.

Note: Potentiometer is disabled in torque mode.

It is also possible to increase or

decrease the pre-set max acc/dec ramp

time by opening solder bridge S3 and

inserting resistance RAMP.

(See chapter RAMP TIME ADJUSTMENT)

Page 19

19

Service Manual

Plus

MICROSPEED

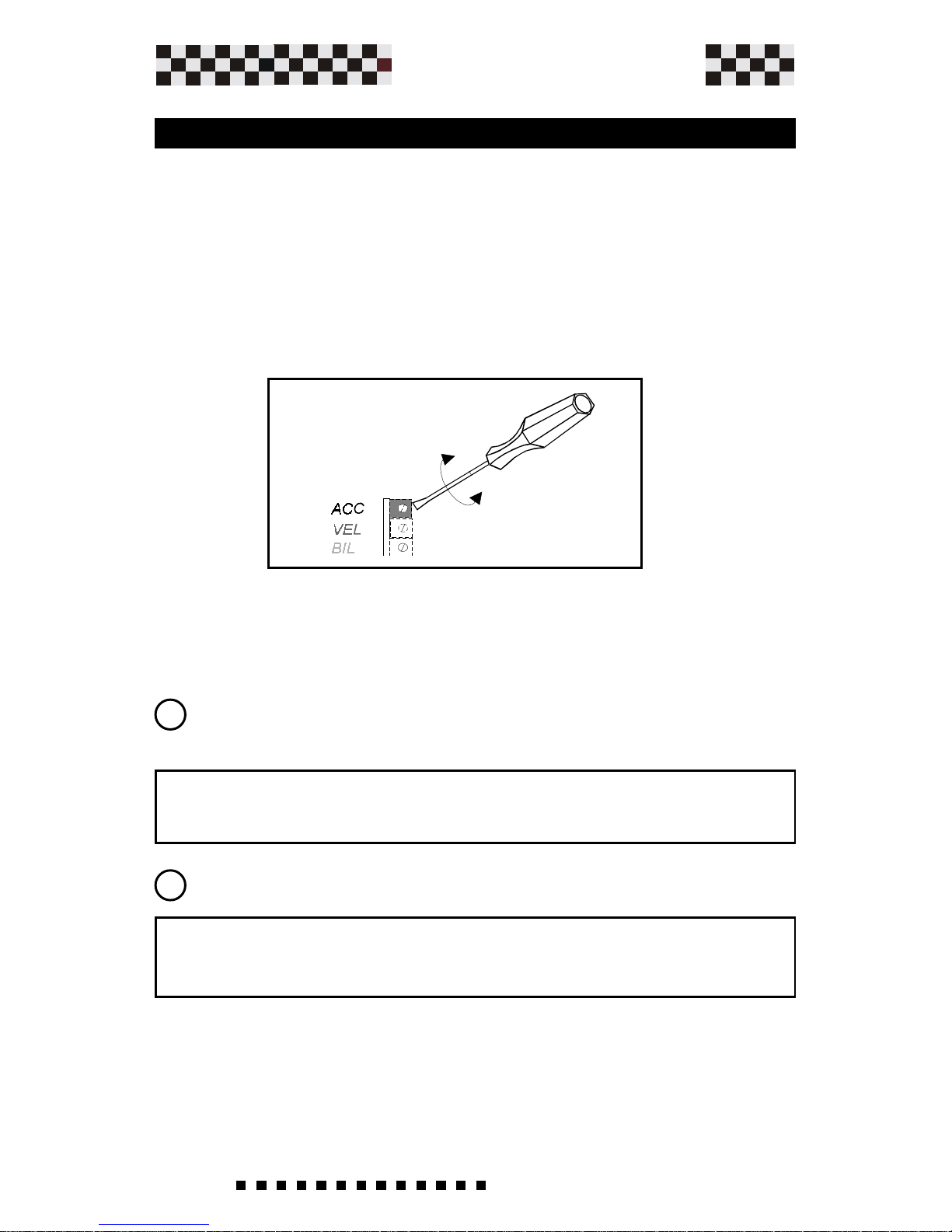

DER

Derivative potentiometer. Turning this potentiometer clockwise

decreases motor overshoot.

Note: Potentiometer is disabled in torque mode.

Continued

Adjustments

NOTE:

On the Microspeed Plus the KV and DER

functions are constituted by Hexadecimal

rotating switch indentified with numbers from 0

to F.

With 0 you have the minimun function attainable,

and with F you receive the maximum.

WARNING: Increase the gain of KV and DER

in the progressive mode using the various

intermediate positions 1-2-3-4 etc.

Therefore, "turning counter-clockwise from

position 0 to position F" the motor could begin

vibrating.

Page 20

20

Service Manual

Plus

MICROSPEED

Microspeed 60 20 Min 80 Max

Microspeed 140 40 Min 180 Max

Microspeed 200 57 Min 270 Max

MICROSPEED PLUS VOLTAGE Vdc

2.1 Protections

The MICROSPEED PLUS is equipped with protection circuits

to safeguard both the motor and the drive, in case of faults

malfunctions.

All faults are indicated by LEDs on the front of the drive. (See

the next page).

The two types of interventions are Reversible and Irreversible.

----Reversible Protection Intervention:

The drive is automatically reset/restarted when the cause of

intervention has been corrected.

-Over Current limitation

-Over/under voltage input

----Irreversible Protection Intervention:

The drive is not reset/restarted. The power supply must be

removed and the cause of intervention eliminated, then the power

supply can be replaced. *Note: A mininum amount of time must

pass in order to ensure that the drive is completely off prior to

replacing the power supply.

-Short circuit

-Over temperature

-Missing or reversal tachogenerator/Encoder

Adjustments

Page 21

21

Service Manual

Plus

MICROSPEED

OKINSTOCMD

Adjustments

2.2 L.E.D. indicators

-OK (GREEN) Normally ON.

This

indicator shows that the drive is

operating correctly. If this LED is Off, it

is indicating at least one fault has been

activated. The faults that affect this LED

are:

--Over/Under input voltage.

--Over temperature, Over 104°F (40°C).

--Short Circuit, Outputs shorted to each

other or to ground.--Missing

Tachogenerator or Encoder

- IN (RED) Normally OFF.

This indicator is lit if the drive is in Over current mode.

- ST (RED) Normally OFF.

This indicator is lit when the

drives internal temperature reaches the max.value. Remove

power and wait for the drive to cool before re-applying power.

If operating temperatures are close to the Max operating temperature of the drive, a fan, heat sink or air conditioner may be

needed to remedy the problem.

- OC (RED) Normally OFF.

This indicator is lit if there is a

short circuit between the motor leads and/or ground. Remove

power and examine the motor connecting leads for shorts

before re-powering the drive.

- MD (RED) Normally OFF.

This indicator is lit for a loss of

tachogenerator/Encoder signal, or tachogenerator/Encoder

signal reverse.

FiveLEDs are located just in front of the

potentiometers and show the current state of the drive.

Page 22

22

Service Manual

Plus

MICROSPEED

3.1 Ventilation

TheMicrospeed plus must be affixed vertically on the bottom to

guarantee efficient cooling. The drives working temperature

must be between +0° C and +40° C. Supplementary ventilation

may be requested in accordance to size. See the table below.

3.0 Installation Notes

The Microspeed Plus is predisposed for mounting inside a box.

The mounting hole measurements can be found in chapter 1.4

"Drive Dimensions". The Microspeed Plus must be fixed vertically

on the bottom of the box to guarantee efficient cooling by the

drive itself. The positioning inside the box must satisfy the

following dispositions:

• For best results from drive guarantee that inside the

electrical box a temperature between 0°C and +40°C with

humidity between 10% and 95% without condensation..

• Keep the drive from excessive mechanical vibrations in

the electrical box.

• During installation, insure avoiding any kind of metallic

residue from falling inside of the Microspeed Plus.

• Maintain a distance of 80mm from the heat source.

• The electrical box must have a predisposition for oppor-

tune air filtering holes or passageways.

Installation

Model 1/2 2.5/5 6/12 10/20 14/28 20/40

60 n.a n.a n.a n.a NV NV

140 N N N N NV NV

200 N N N NV NV BV

Page 23

23

Service Manual

Plus

MICROSPEED

MicroPower Plus Power Supply (optional)

Combination table of dissipators present on Microspeed Plus.

n.a = Unavailable size with Microspeed Plus.(Available with Microspeed Case

PM1)

N = Microspeed Plus with normal radiator (See Chapter 1.5)

B = Microspeed Plus with added radiator Booster (See

Chapter 1.4)

NV = Microspeed Plus + supplementary ventilation.

BV = Microspeed Plus with added radiator Booster + supplementary

ventilation.

Installation

Page 24

24

Service Manual

Plus

MICROSPEED

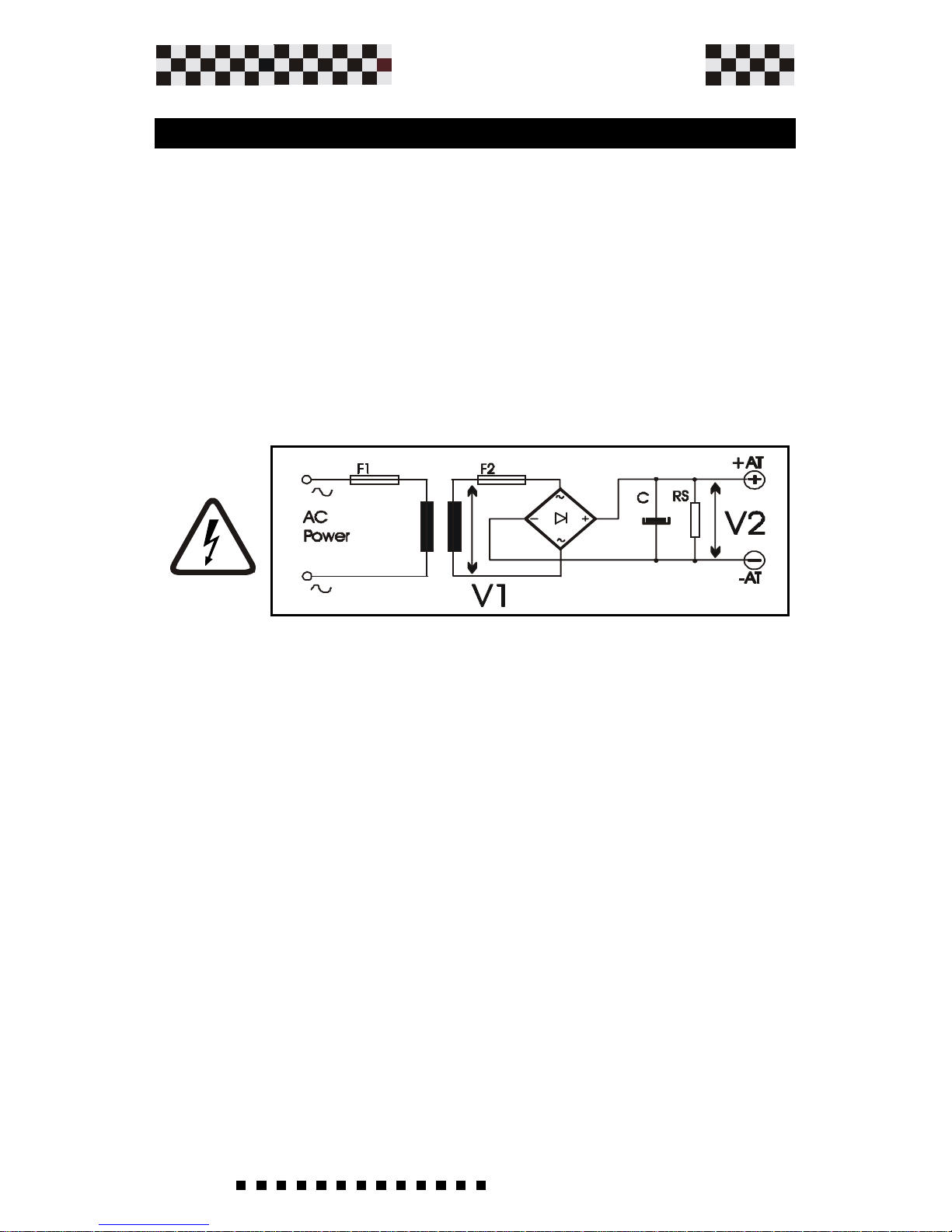

3.2 Power Supply Construction and Rating

Installation

W ARNING:Use only Un-regulated power supplies with the

Microspeed Plus Drive.The power supply is used to

absorb the motor's BEMF. Als, with this scheme, no

braking resistor are needed.

The MicrospeedPlus was designed to generate all required

supply voltages in the Drive, so only a simple single voltage power

supply is needed. Use the schematic and formulas provided

below to design a supply that will be trouble-free and handle the

power needed by the drive.

Transformer:

A single ground is used in the drive that is

connected to -AT, so DO NOT USE AN AUTO

TRANSFORMER. Use a standard heavy duty power transformer

without center taps on the secondary as shown in the schematic

above. The VA rating should be 10% greater than the power

needed by the system to insure cool operation. DO NOT

CONNECT ANY TRANSFORMER PRIMARY, OR

SECONDARY SIGNALS T O GROUND.

Keep the +AT and -AT wires, between the power supply and the

Microspeed Plus, as short as possible.

Page 25

25

Service Manual

Plus

MICROSPEED

Installation

Where:

VM= E+(R x Im)............ motor voltage

E = Ke *n°/1000............ FCEM motor (Vdc)

Im = I motor (A)

Ri = Winding resistance (Ohm)

Ke =Voltage constant (V/kRPM)

n° = MAX speed (RPM)

V1(Dc) = VMotor

0,9x1.36

Voltage

:The primary voltage depends on what is available

locally for a single phase. The secondary voltage is

calculated from the motors voltage at the required operating

speed.

The secondary voltage V1 is:

Page 26

26

Service Manual

Plus

MICROSPEED

The transformer's nominal power is calculated based upon

the sum of power from the single motors driven.

Or Better:

Note: In multi-axis applications, the transformer's power can

be downgraded by 30%.

••

••

• POWER: If the power of a transformer exceeds a

determined value, the inserted straightening point

could be damaged in the enabling phase, due to

overcurrent from the capacitors.

•max. power per trasformer is 7KVA;

Where:

Pn Motor = nominal power each motor.

n = max. speed of motor in RPM.

Cn = nominal torque of motor in (Nm).

Pn Motor = n x Cn

9,55

C (uF) = P (VA) transformer x 1000

V2

Power Transformer:

Capacitor filter:

In regards to the capacitor filter we suggest a working voltage

of:

--100 Vdc for Microspeed plus 60

--200 Vdc for Microspeed plus 140

--300 Vdc for Microspeed plus 200

It's capacitor value is derived using the following formula:

P(VA)=Power absorbed motor 1+Power

absorbed motor2+etc......

Installation

Page 27

27

Service Manual

Plus

MICROSPEED

RS (Ohm) = 20.000.000

C (uF)

P (W) = V2

2

RS

Installation

Where V2 = DC voltage present on capacitor without load. Such

a capacitor is used to filter the straightened voltage from the

power supply and to recover energy during the motor's braking

phase.

Where: RS is the resistor value in Ohm

P is the power of said resistor in Watt

Discharge resistor

The bleeder resistor is used to drain the charge from the filter

capacitor when power is removed from the supply. This helps

in bringing the supply voltage down quickly. This resistor is

mounted directly across the filter capacitor. To calculate the

correct value and wattage use the formula below.

Page 28

28

Service Manual

Plus

MICROSPEED

F 1 = (VA) trasformer x 1,1

Vac (primary) ac

F2 X MCS 2,5/5 =3,16A

X MCS 5/10 =5A

X MCS 8/16 =10A

X MCS 10/20 =16A

X MCS 14/28 =20A

X MCS 20/40 =25A

Installation

Fuses are required on both the primary and secondary of the

transformer to protect against harm to the system and the

transformer itself. They need to be of the slow blow type to

handle current in-rush at power-up. Locate the primary fuse

(F1) on the hot leg of the AC input power and the secondary

fuse (F2) on the + side of the secondary output, before the

rectifier. Use the formula below to calculate the correct values

for both fuses.

Where:

Fuses

A separate fuse F2 is required for each drive in a multi-axis

system.

Page 29

29

Service Manual

Plus

MICROSPEED

3.3 Multiple Connections

Installation

Incorrect

Wiring

Technique

Use This

In case of connecting more than one axle to a single supply,

always connect each drive DIRECTL Y to the supply and keep

the wires as short as possible, twist the + and - leads together

as twisted pairs. (try not to exceed 1,5 feet (1m) in length.

Page 30

30

Service Manual

Plus

MICROSPEED

3.4 Ground and Shield Connections

Installation

Page 31

31

Service Manual

Plus

MICROSPEED

Description:

It is important that the drive's ground connections are as short as

possible and no longer than 8 inches (20 cm). The figure shows

the connection using terminals fixed to the drive's base (bottom).

This connection also reduces disturbances in the net.

The Motor ground cable has to be external (not inserted in a

multipolar cable) with minimun section 1.5 mmq (0,059 square

inch).

Drive power and signal cables must be shielded. The cable

shields must be connected to the body of the motor.

Shelded cable is not required for the motor power cable, the +M

and -M cables should be twisted together.

On the follwoing page you'll find additional installation instructions

in respect to EMC requirements.

Installation

Page 32

32

Service Manual

Plus

MICROSPEED

3.5 Instructions for EMC Requirements

Installation

The regulated standard in accordance with conformity of

electromagnetic is summarized in Regulation CEI EN 61800 (complete).

Microspeed Plus conformity is assured only if it is installed

following the precise assembly criteria expressed below. The

fundamental assembly characteristics are summarized bolow:

--1) Use of appropriate network to filter the line (transformer input),

from disturbances conducted or produced by the drive.

A series of filters released by AXOR are available for this purpose.

--2) Use of shielded cables, both for power connection (to the

transformer and the motor), and for signal connection (also to the

controller).

--3)Using the division of cables technique. Separate power cables

from signal cables.

--4) The correct ground connection of predisposed parts.

Of all of the mentioned system, the use of network filters is without

a doubt fundamental in soppressing disturbances.

Axor, after tests, has recognized some good solutions, about its

products.

Concerning equipment where are mounted other sources, Axor

cant evaluate the global equipment. In the following page, are

reported some foundamental configurations, with the suggested

filters.

We did an agreement with Schaffner and Timonta products. The

market offers other product with the same characteristics, but not

yet checked from Axor.

When other products will be checked and approved, it will be

notified.

Follow reported an example about the noise level with and without

filter as explained in the following pages.

Network Filters

Page 33

33

Service Manual

Plus

MICROSPEED

Continued

Installation

The recommended filters for the product lines in some of the main

configurations are shown in the table on page 34-35. These filters

are produced by SCHAFFNER and TIMONTA.

Other products with the same characteristics may be sufficient,

but have not been tested or evaluated by AXOR.

In choosing the filter, we also considered the current absorption

of its connecting devices. AXOR recommends connecting the filter

before the power supply transformer. This method, besides

offering better disturbance soppression result, also allows for the

use of filters capable of supporting a lot less current, consequetly

they're cheaper (takes advantage of the transformer's ratio).

Follow the formula below for the filter dimensions to be used with

the Microspeed Plus.

I(A) = P tot

1.73 x V primary

Where:

I=is the nominal current in Amperes for the necessary filter.

Vprimary= is the voltage of Transformer.

Ptot=is the motor's max. power absorption in watts(VA)

Ptot=VA=Motor power1+motor power 2+...ect.

Instructions for EMC requirements (continued)

Page 34

34

Service Manual

Plus

MICROSPEED

For filter connection (divert to building ground the unwanted frequency)

considering such devices can produce small leakage current towards

building ground (this current amounts to "some" of milliamperes). For

these precautionary reasons, it is necessary to connect the filter to

building ground prior to connecting the power supply.

Regarding current leakage, remember that it must be considered when

sizing differential devices, thus avoiding undesired interventions. The

precise data relative to our filters can be found below.

Installation

Mechanical and Electrical Characteristics

Below is a table showing the electrical characteristics of our

recommended filters. Pay particular attention to leakage, differential

adjustements, and nominal current in accordance with operational temperature.

Instructions for EMC requirements (continued)

Below is a table showing the electrical characteristics of our

recommended filters. Pay particular attention to leakage, differential

adjustements, and nominal current in accordance with operational temperature.

Type Current Leakage Curr. Power loss Weight

(A) (mA) W Lb.

SCHAFFNER FN355 3(40°C) 0.07 (400V 50Hz) 1.5 0.55

SCHAFFNER FN2070 3(40°C) 0.4 (250V 50/60Hz) 0.55

TIMONTA FMW4 4(40°C) <0.5 (400V 50/60Hz) 1 0.6

TIMONTA FSS2 3(40°C) <0.5 (250V 50/60Hz) 0.6

TIMONTA FSS2 6(40°C) <3 (250V 50/60Hz) 0.6

The TIMONTA FMW65-4: 3 PHASE Series filters are furnished with Faston connectors for both input and output.

Max. voltage : 440Vac

Max. current : 4A @ 40°C

The SCHAFFNER FN355-3: 3 PHASE Series filters are furnished with Faston connectors for both input and output.

Max. voltage : 420Vac

Max. current : 3A @ 40°C

Working temperature: -25° +85°C

Page 35

35

Service Manual

Plus

MICROSPEED

Installation

NOTE:

--The filter must be placed before the trasformer.

--All connections of the Net filters must be shielded and shouldn't be

longer that the length shown in the scheme.

--The cable shield must cover the entire length of the wire and be as

close as possible to the connection terminals.

--Always use shieded cable (twisted) to connect the motor and the

drive.

--Avoid passing signal and power cables through the same channels.

--It is very important that the panel where the filters are mounted is

connected to ground.

--Power and Command/Signal condotors should not be placed in the

same channels (keep separate). Avoid twisting, crossing, etc. If

crossing is inevitable, try to cross at a 90 degree angle. Where

possible use metallic channels connected to ground.

Instructions for EMC requirements (continued)

Mechanical dimension

The TIMONTA FSS2-65-3 TIMONTA FSS2-65-6 : Single

PHASE Series filters are furnished with Fast-on connectors for both input and

output.

Max. voltage : 250Vac

Max. current : 3A @ 40°C, Max. current : 6A @ 40°C

The SCHAFFNER FN2070-3: Single PHASE Series filters are furnished with

Fast-on connectors for both input and output.

Max. voltage : 250Vac

Max. current : 3A @ 40°C

Working temperature: -25° +85°C

Page 36

36

Service Manual

Plus

MICROSPEED

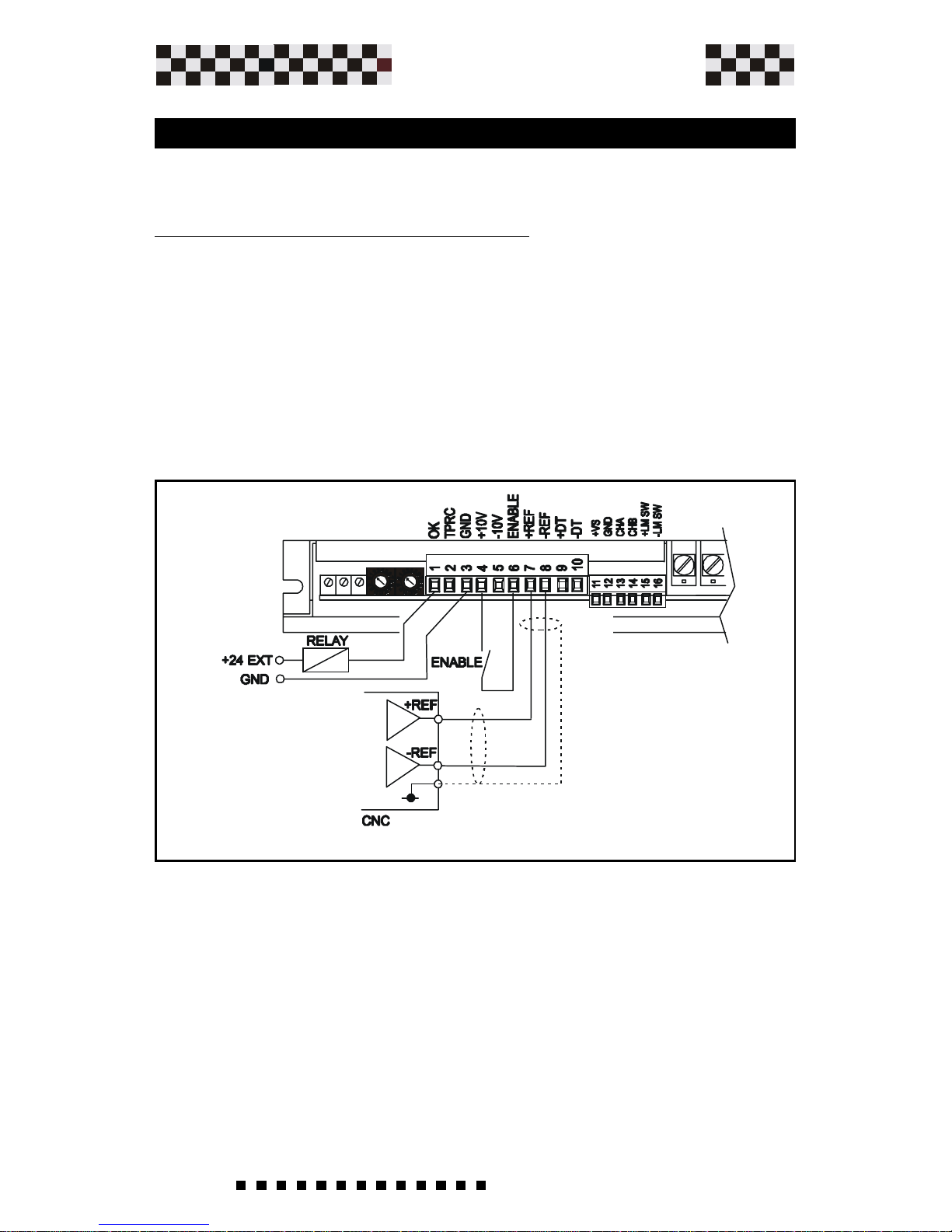

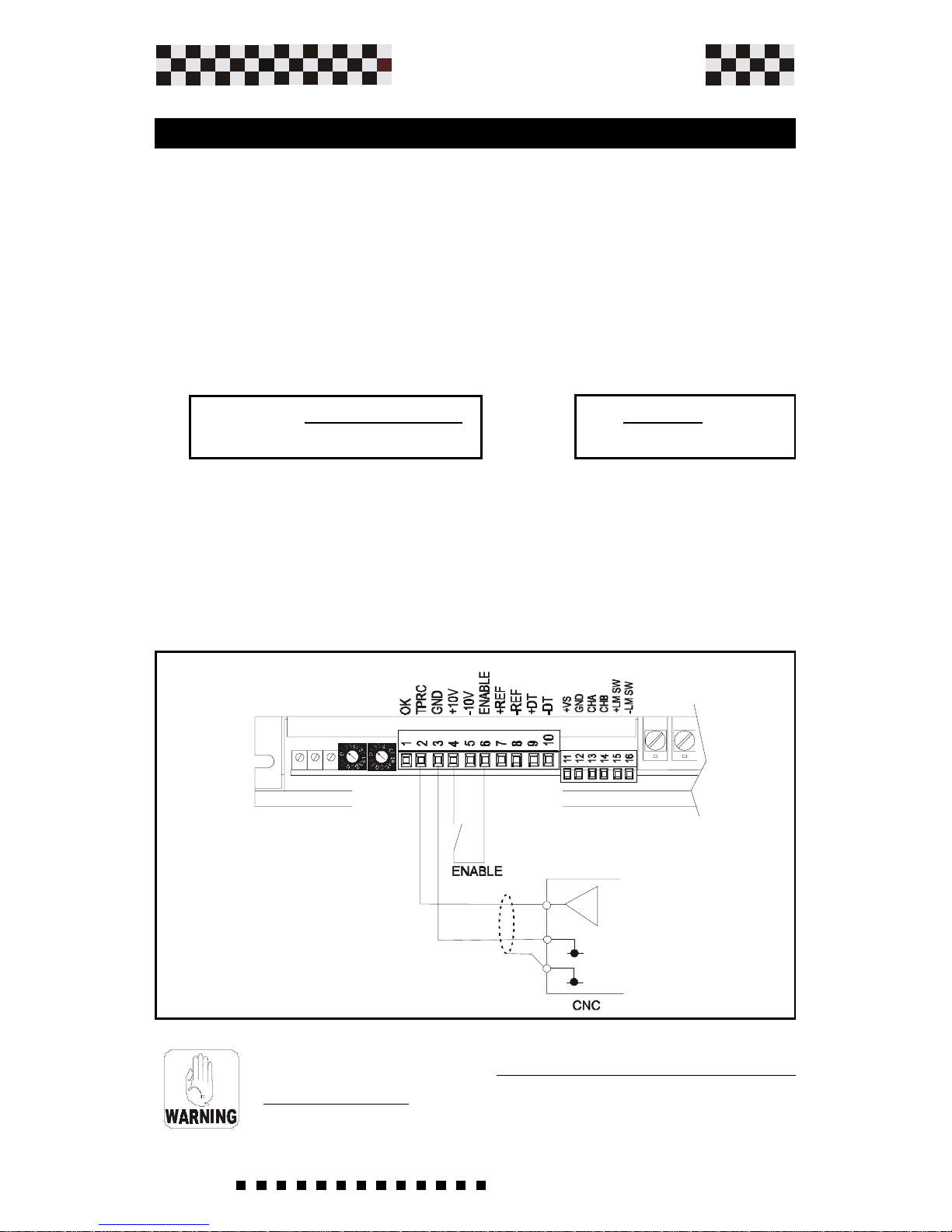

The following diagram shows an application utilizing a

differential reference from a C.N.C.

The drive is enabled using the Auxiliary power supply +10V

(Connector 4). It is possible to use an external power supply

for this function (24Vdc). Remember to also connect the GND

of the power supply to Connector 3.

3.6 Examples of Microspeed Plus Connections

On connector 1 "OK" an external relay coil was connected.

This output has a rating of 50mA Max.

Do Not connect a supply exceeding 24Vdc. Connect the

Power Supply GND externally using connector 3

.

Installation

Page 37

37

Service Manual

Plus

MICROSPEED

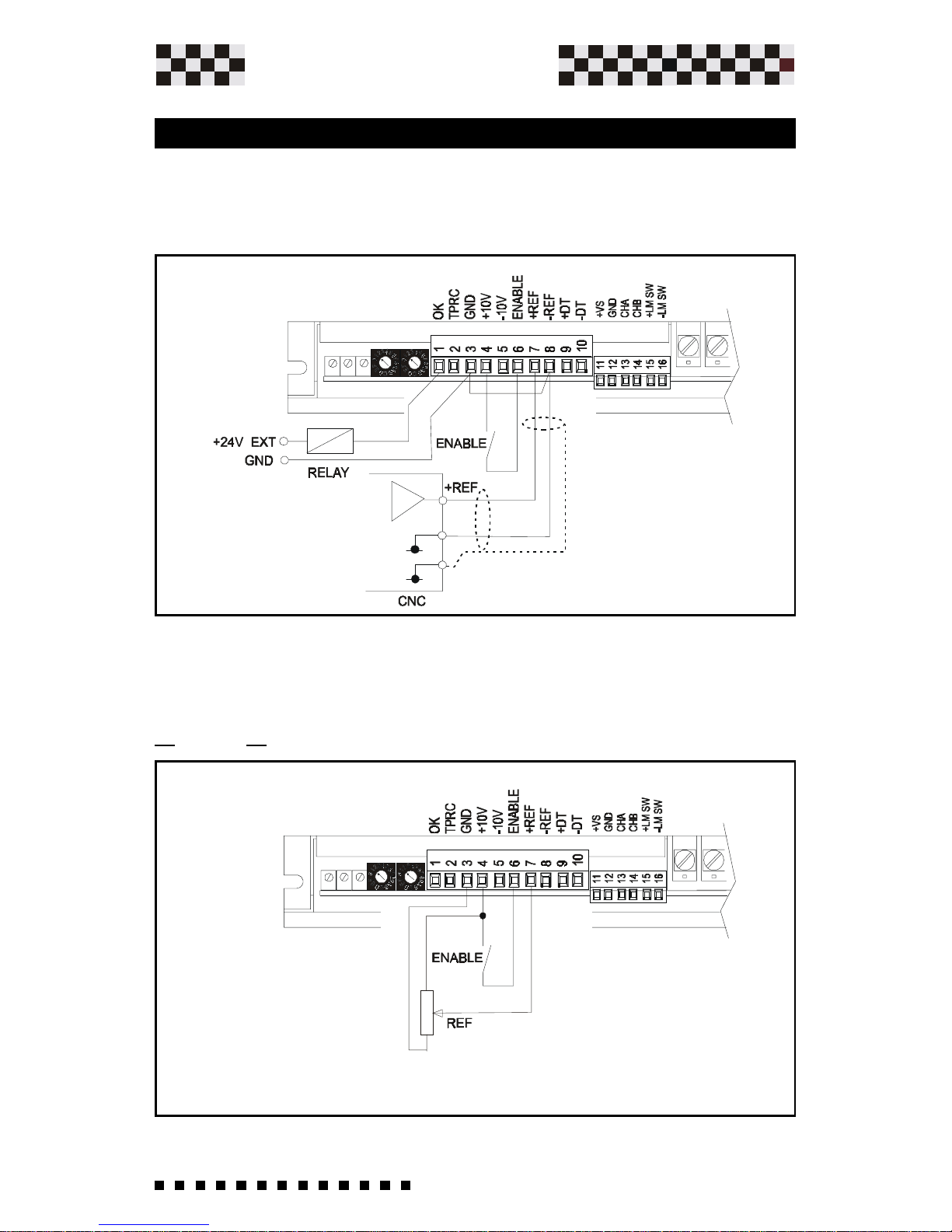

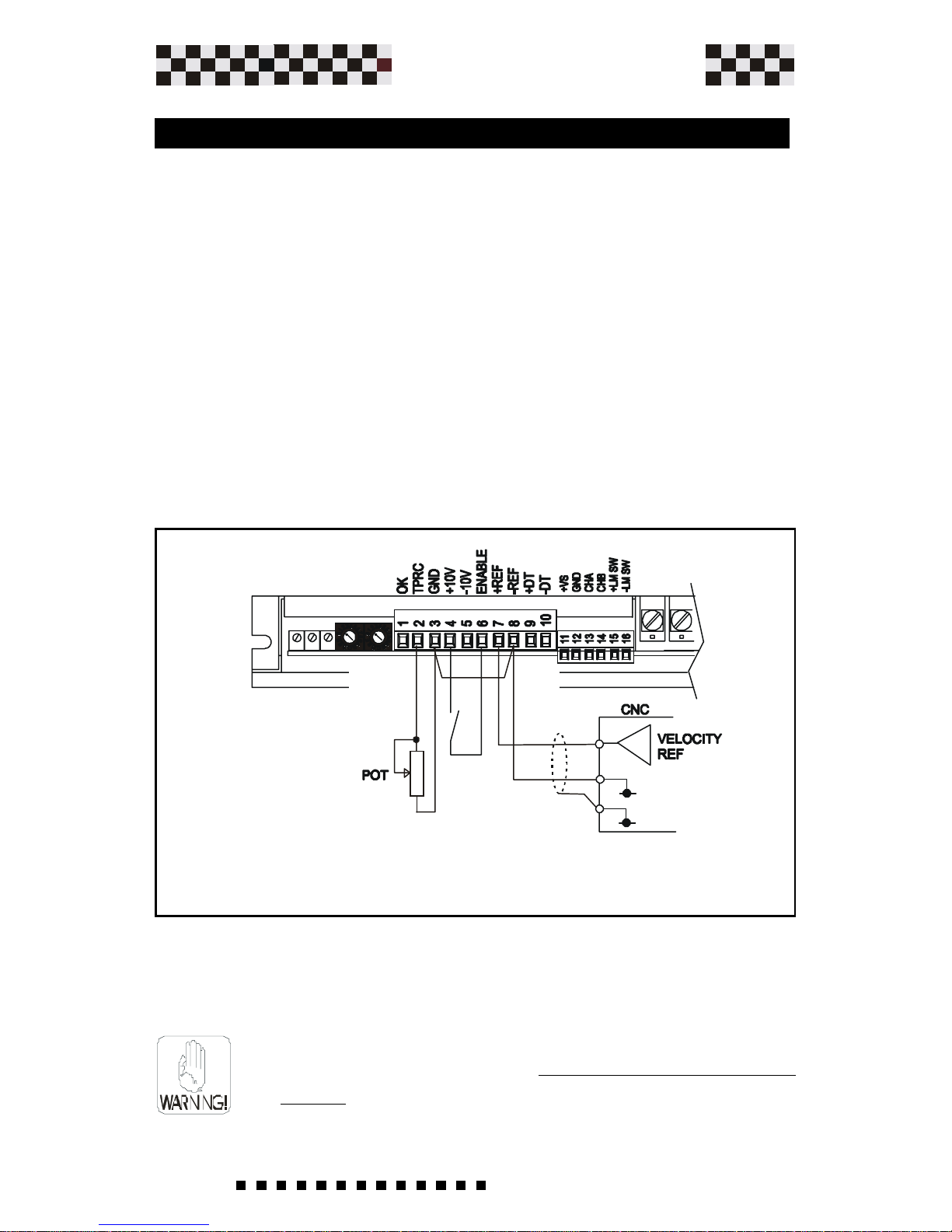

Installation

The following figure shows an application with speed reference

connections using an internal MICROSPEED PLUS power supply.

The speed potentiometer must have an included value between

>10 and <47Kohm.

The following diagram shows an application using speed

reference connections in the Common Mode.

3.7 Common Mode Reference

Page 38

38

Service Manual

Plus

MICROSPEED

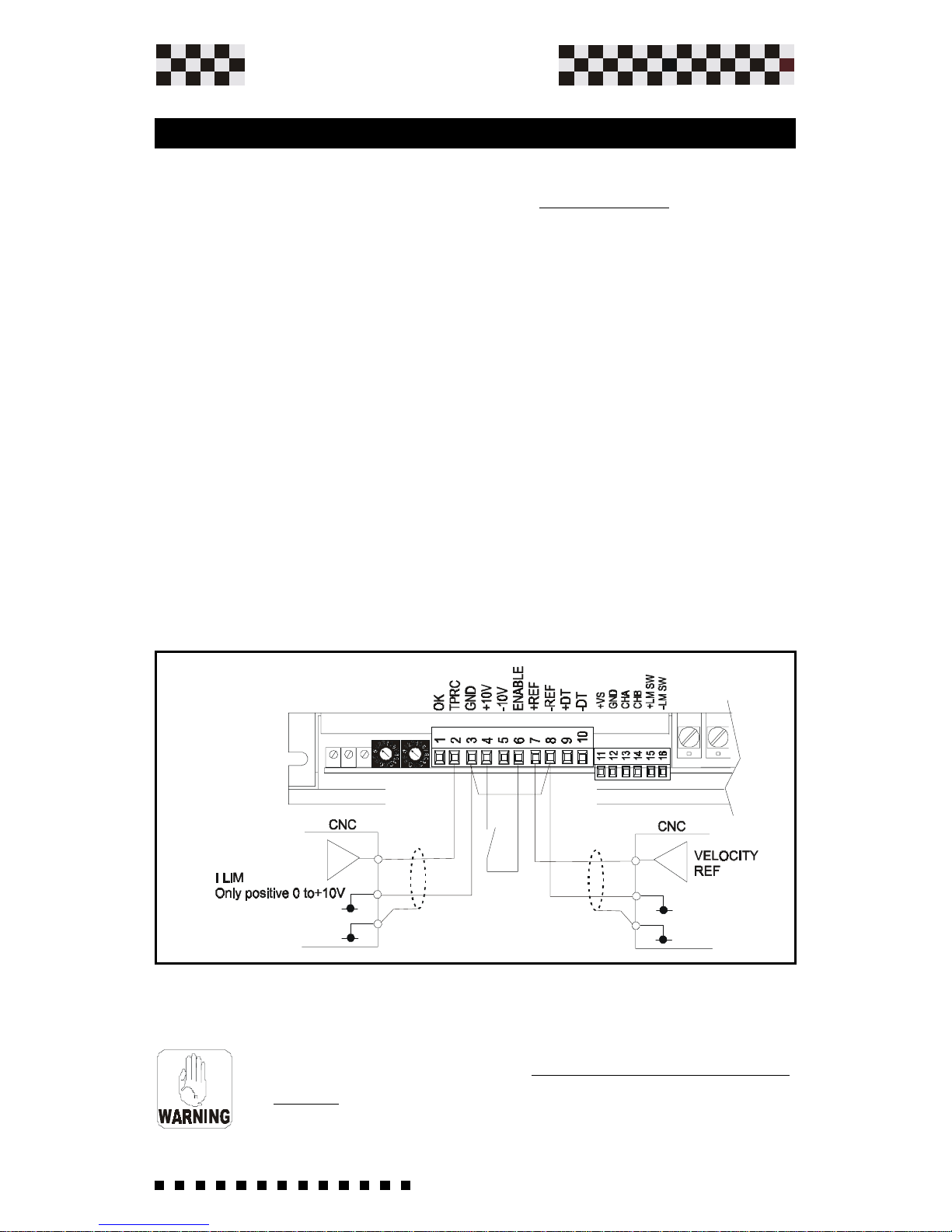

With a voltage output (ex. from a CNC) you can command the

drive in torque mode. Applying a signal of +/- 10V at TPRC, the

MICROSPEED PLUS to supply positive or negative peak current.

For this configuration soldering point S8 is closed , S9 and S12

is open.

The formula to determine the value of Ving to apply in TPRC in

order to obtain requested current is the following:

Other examples:

Mcs Plus10/20A.......+5V gives current of -10A.

...... - 5V gives current of +10A.

Mcs Plus14/28A.....+3.2V gives current of -9A.

..... - 3.2V gives current of +9A.

3.8 Current Reference (Torque Mode)

Ex: 10 x 9 = 3,2V

28

Ving =10 x I request

I pk MCS

In this case the loop of internal velocity automatically

excludes itself .

Installation

Page 39

39

Service Manual

Plus

MICROSPEED

3.9 Current Output Limitation

With a voltage output (ex. from a CNC) only positive between 0V

and +10Vdc, you have a limitation of output current (from zero to

max. size) drive's.

For this configuration the soldering point S8 is open, S9 closed.

The speed ring remains active and uses the input reference

signal.

Example:

Mcs Plus 10/20A.......+5V limits the current to +/-10A.

Mcs Plus 14/28A.....+3.2V limits the current to +/-9A.

The current polarity functions as speed ring output.

In this case the loop of internal velocity remains

active.

Installation

Page 40

40

Service Manual

Plus

MICROSPEED

Installation

By connecting a resistance load at TPRC (ex. a potentiometer),

you'll obtain the limitation current output.

For this configuration soldering point S8 is closed , S9 is open.

Connect a resistence of 1/4W - 1/8W between the TPRC

terminal and the GND terminal, or a potentiometer connected

as in figure 5.

With external Resistance of 47K you limit the current at 50% of

I Max. of size.

Example:

Mcs Plus 10/20A.......47Kohm limits the current to +/-10A

The potentiometer of the output

current limitation 470K-1M Ohm.

In this case the loop of internal velocity remains

active.

3.9a Current Output Limitation

(continued)

Page 41

41

Service Manual

Plus

MICROSPEED

10

10

Installation

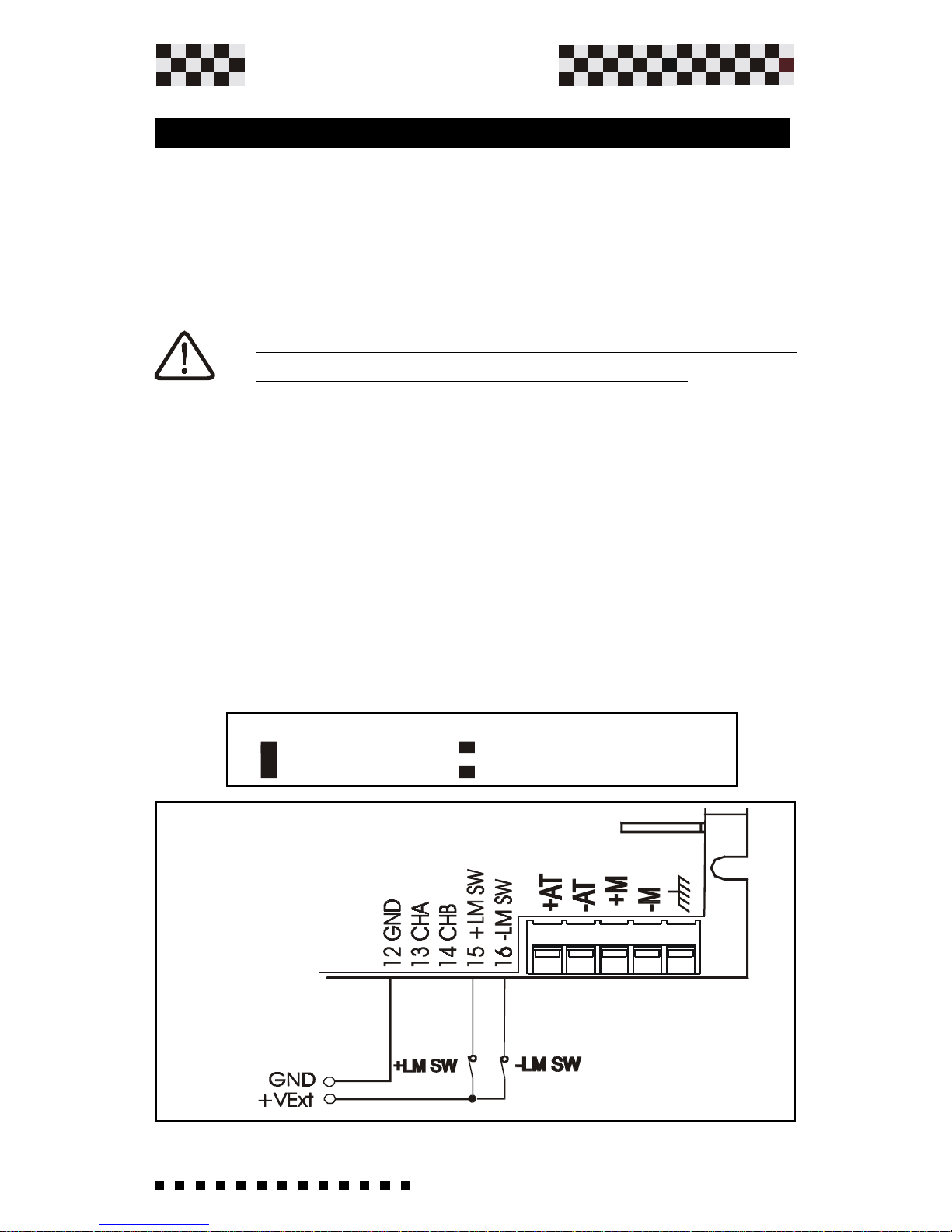

It's possible to enable clockwise (CW) and counter-clockwise

(CCW) motor rotation by connecting the +LM SW and -LM

SW inputs.

They may be used to block motor rotation when the machines

overflow contact is intercepted.

Note - When one of these said contacts is intercepted

the motor stops with the required inertia.

The Enable input in regards to this input always has priority.

To enable such a function, you must:

-- Open soldering point S10

-- Open soldering point S12 ( disable a internal allarm for

missing tachogenerator or encoder).

-- Then connect on said input a positive voltage (between

+5Vdc and + 24Vdc) coming from -for example two N.C.

contacts. You may connect an external supply "combining

negative" as well as from one of the supplies furnished on the

Microspeed Plus. Function: At opening one of the following

contacts you enable the motor rotation in the corresponding

direction.

3.10 Limit Switch Input +/-

=NOT ENABLE =+/- LIMIT SW. ENABLE

Page 42

42

Service Manual

Plus

MICROSPEED

Power cable specification is recommended as follows:

1.5 square mm up to 6/12

2.5 square mm up to 10/20

The +M and -M drive outputs can be connected directly to the

motor terminals.

The minimum motor inductance value is 0.5 mH. In the case of

motors driven with armature inductance lower than 0.5 mH, it is

necessary to use a chokes connected in series with the motor.

3.11 Power Connections

Installation

Page 43

43

Service Manual

Plus

MICROSPEED

4.1 Starting Procedures

Two ways to place the Microspeed Plus into function:

• If the drive has already been pre-adjusted for its motor and

has accompanying connection sheet, proceed with chapter on

"Starting procedures".

• If the drive hasn't been pre-adjusted for its motor, first consult

the chapter on "Personalization and Settings" and Chapter 5.0

4.0 Preliminary Checks

The standard drive is furnished with the following

characteristics:

• Nominal and Peak current of drive corresponds to the drive

size; "RIN and RIP resitors are not mounted".

Ex.: Microspeed Plus 140 10/20A ; 20A peak for 2 seconds, 10A

upon return.

• Encoder speed adjustment for 3000 rpm at 10V ref. with

encoder of 1000 Imp/rev. "RDT resistor = 22Kohm".

• KV and DER positions are "1".

How to proceed

What to check

Verify that all signal and power connection terminals are

accurately closed/tightened and execute a visual check of the

drive's cabling.

Start up procedures

• Remove load from motor shaft and be prepared to quickly

shut off power supply if required. (Warning: keep motor well

fixed to the ground/floor or attached to a mechanical support).

• Insert the fuses in series with alternating power or insert

the corresponding thermal magnet, insuring the available

power value by measuring with a tester.

Page 44

44

Service Manual

Plus

MICROSPEED

• Powering up the drive.

Under normal conditions the green L.E.D. comes on after

approx. 1 second.

Prepare to power up the drive by first insuring that the

reference signal is zero =0V.

ATTENTION: If possible, in the case of piloting motor with a

C.N.C. controller, make sure the manual reference with the

calculated error corrections of the same are not inserted.

(Space ring not inserted).

• Power up the Enable input. (It's a good application norm

to always supply the Enable command after the powering up

the drive).

• Furnish the reference signal.

Increase the speed reference signal up to minimum value

(approx. 1V) and observe the motors sense of rotation. If the

motor rotates contrary to what you require, shutdown and invert

the +REF and -REF,

• Reconnect the motor's shaft to the load and insert the

space ring of eventual controller. If at this point you still have

the same results as those verified before insertion and the

controller doesn't show errors, the system is regulated

correctly.

• Now execute standard working cycles verifying that no

protections intervene.

Start up procedures

Page 45

45

Service Manual

Plus

MICROSPEED

Adjustments

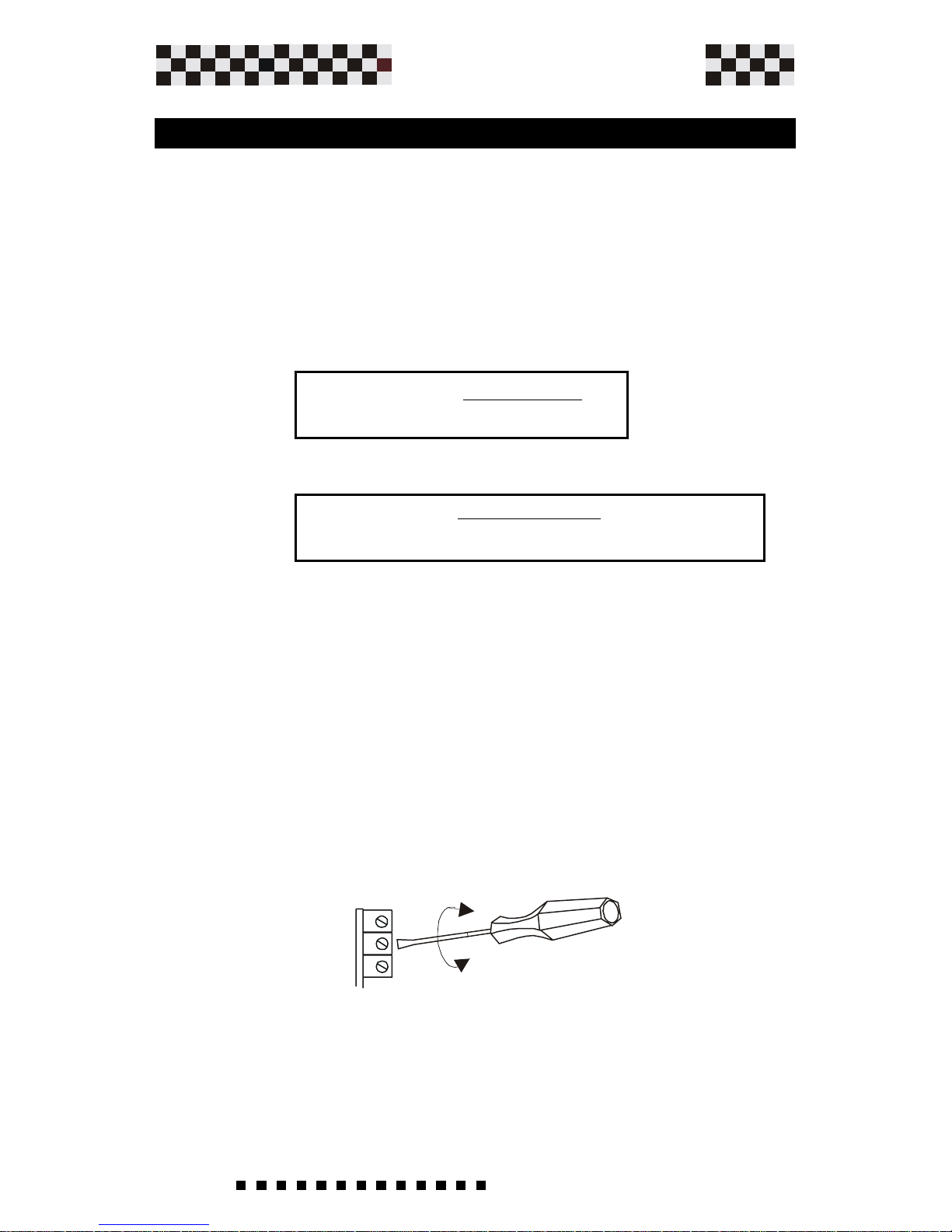

5.0 Personalizazion and Settings

Soldering points

Personalization base

adjustments

If the drive isnt adjusted with the proper servomotor, follow these

procedures. If changes need to made to the internal drive setting

powering, please wait at least 10 seconds after the power has

been removed and the OK LED is off.

All of the personalizations are located inside of the MICROSPEED

PLUS. To gain access to the adjustment pads and the solder

bridges, unscrew (A) , and remove the cover (B). (See figure

above).

A

A

B

Page 46

46

Service Manual

Plus

MICROSPEED

RENC

GAIN

RIP

RKV

RCA

RDT

RIN

RA

RAMP

5.1 Adjustement components

Droop compensation for internal motor resistance

(RI);Chapter 5.4 .

Nominal drive current resistor; Chapter 5.6

Armature Feedback resistor. It permit adaptament

at the costant motor tension. (See chapter 5.4)

Peak drive current resistor ; Chapter 5.6

Changes static gain in the velocity loop. Open

Solder bridge S6 and insert R GAIN if a change is

required. Consult factory for the correct value.

Resistor value that form the proportional/integral

network of the velocity Loop gain.

Standard values are 100 Kohm, there are disabled

by opening Solder bridge S5.

Adjustments

If we insert this resistance, we adapt KE

tachogenerator costant with input amplifier costant.

If the KE costant is small, we can bridge this

resistance (See chapter 5.3)

It gives ACC/DEC time. (See chapter 5.7)

If we insert this resistance, we adapt Impuls

Encoder costant with input amplifier costant. (Optional See chapter 7.1)

Page 47

47

Service Manual

Plus

MICROSPEED

CKV

CDER

Derivative constant capacitor, increases the velocity

loop derivative constant.

Capacitor value that form the proportional/integral

network of the velocity Loop gain.

Standard values is 47nF, there are disabled by

opening Solder bridge S5.

Adjustments

Adjustement components

(Continued)

Page 48

48

Service Manual

Plus

MICROSPEED

S1 Normally open.If Closed, when the IN protection is lit the green

OK LED goes off and is unable to allow the Drive OK LED to come

on.

S2- S4 Normally open. (See Chapter 5.7 Ramp time adjustment).

S3 Normally closed. (See Chapter 5.7 Ramp time adjustment).

S5 Normally closed. If Open , install components for the Dynamic

velocity costant CKV and RKV. (Standard constant RKV=100Kohm

, CKV= 47nF).Consult factory for proper use.

S6 Normally closed. If Open - you must insert theNew GAIN

resistor. (Static Gain). Standard value= 22ohm

S7 Normally open.If closed enables Armature Feedback. See

chapter 5.4

5.2 Solder Bridges

Adjustments

17 Solder Bridges located on the left hand side of the drive are

used to change internal and external functions on the Microspeed

Plus. Below are the descriptions of each solder bridge functions.

Verify the corresponding solder bridge closings required by the

drive.

This Drive is factory set with the following solder bridge

configuration.

1234567891011121314151617

Page 49

49

Service Manual

Plus

MICROSPEED

S8 Normally open. (See chapter 3.8, 3.9, 3.9a)

S9 Normally closed. (See chapter 3.8, 3.9, 3.9a)

S10 Normally closed. (If open predisposes input function

+/-LM SW). Chapter 3.10

S1 1 Normally open.If closed enables Encoder Feedback. See

chapter 7.1

S12 Normally closed. If open you disable a internal allarm for

missing tachogenerator or Encoder.

S13 Normally closed. (Power supply on terminal +Vs=5Vdc.

If open configure +V=+12Vdc).

Only for Optional Encoder.

S14 -S15 Normally open.If closed you insert for each encoder

input a pull-up resistor of 3.3 Kohm to internal +14V.

Only for Optional Encoder.

S16- S17 Normally open.If closed you insert for PWM and

DIR input a pull-up resistor of 3.3 Kohm to internal +14V.

Note: Closed only for Pwm+Dir Optional.

Adjustments

NOTE: Further along in the manual all desired speed feedback are

highlighted the soldering points to close.

Page 50

50

Service Manual

Plus

MICROSPEED

RDT

(Kohm)

= Kdt x n x 9,7 _

8

1000 x Vref

RDT

(Kohm)

= 10 x 3000 x 9,7 _

8=21.8 Kohm

1000 x 10

The drives are provided with the RDT resistance mounted on

board.The drive is adjusted for 3000 rpm with a tachometer costant

10v/1000 rpm referred to 10V reference.

If you desire to change this resistor, just open the cover of the

drive, then change the value of the resistor.

To calculate it,please use the following equation:

Example: KDT=10, n=3000, Vref=10

Where:

Rdt is the value expressed in Kohm with a power rating of 1/8 or

1/4w.

Kdt is the tachogenerator costant

n° is the max speed express ed in RPM.

Vref is the max voltage reference expressed in Volts.

When the RDT resistor is mounted adjust the fine speed by using

the VEL potentiometer located in front of the drive.

Clockwise...............Increases the speed.

CounterClockwise..Decreases the speed.

The range adjustments are +/- 20 %.

5.3 Speed adjustment with tacho feedback

Adjustments

VEL

BIL

ACC

Page 51

51

Service Manual

Plus

MICROSPEED

RA

(k ohm)

= 166 x Vref

E - 1,4 Vref

RA

(k ohm)

= 159 x Vref

E - 3,3 Vref

RA

(k ohm)

= 158 x Vref

E - 5 Vref

Adjustments

5.4 Speed adjustment with Armature feedback

Armature feedback mode may be used as speed feedback

when a tachogenerator is not fitted to the motor.

Speed control is then less precise(the regulation range is 1/

20, and below this value the torque is reduced).

This funciton will be enabled by solder bridge S7 Closed, S12

open, and mounting in the socket RA and RCA resistors.

RA resistor It will be mounted on the personalization zone to

adapt the system to the voltage motor costant.

To calculate it use this equation:

RA

(kohm)

= 166 x 10

= 36 Kohm

60 - 1,4 x10

E = 3000 x 20

=

60

1000

WHERE:

E

=

n x Ke

1000

Ke= Servomotor BEMF at 1000 rpm

Vref= Max voltage reference.

n= max speed express in rpm.

Use the nearest commercial value, 33 Kohm.

Example:Servomotor with Ke=20 n=3000 RPM Vref=10 For MCS

Plus 60.

MCS PLUS 60

MCS PLUS 140

MCS PLUS 200

CONTINUE

Page 52

52

Service Manual

Plus

MICROSPEED

RCA

(k ohm)

= 0,5 x n Ke

Vref Ipk Ri

RCA resistor It will be mounted on the socket , to compensate for the voltage drop due to the motors internal resistance.

To calculate it,use this equation:

Use a resistor of 200 Kohm or the higher value.

RCA

(kohm)

= 0,5 x 4000 x 50

=200 Kohm

10 x 20 x 2.5

Example: Drive 10/20 A , Ri=2.5 ohm

If,after this procedure the motor is unstable increase the value by

using the next (higher) commercial value avalaible.

WHERE:

n= max. speed expressed in rpm.

Ri=Total motor resistance with brushes.

Ipk =Peak current, (size)of the drive.

Ke=Sevomotor BEMF at 1000 rpm.

Vref= Max voltage reference.

Adjustments

5.4 Speed adjustment with Armature feedback

5.5 Adjusting Speed Balance (Offset)

The Microspeed Plus is provided with a BIL potentiometer

that allows the motor to be adjusted to zero speed when 0.0

Vdc is applied to the +REF. Re-adjust the Bil trimmer to correct

eventual system offset. (You may compensate +/- 200mV from

reference input). With the reference input at Zero turn the BIL

potentiometer until the motor stops moving.

VEL

BIL

ACC

Page 53

53

Service Manual

Plus

MICROSPEED

Adjustments

5.6 Nominal and Peak Current Adjustment

Peak Current

Note * = No resistor mounted.

Nominal Current

Note * = No resistor mounted.

The Microspeed Plus is pre-set to the nominal current rating

of the drive, if a lower current is needed to match the motor

used, refer to the chart below and select the correct resistor

value to be fitted as RIN. Use the table below to select the

correct value.

To reduce the value of the peak motor current , its necessary

to mount RIP on the header located inside of the drive.Use

the table below to select the correct value.

eulaVNIR

mhoKni

* 33 22 51 01 8,6 7,4 3,3 2,2 5,1 1

2/1SCM

1 69,0 29,0 68,0 87,0 17,0 36,0 55,0 64,0 93,0 23,0

5/5,2SCM

5,1 4,2 3,2 1,2 9,1 7,1 5,1 3,1 2,1 1 8,0

21/6SCM

6 8,5 5,5 2,5 7,4 3,4 8,3 3,3 7,2 3,2 2

02/01SCM

01 6,9 2,9 6,8 8,7 1,7 3,6 5,5 6,4 9,3 2,3

82/41SCM

41 7,31 31 2,21 2,11 01 9,8 7,7 5,6 4,5 5,4

04/02SCM

02 2,91 4,81 2,71 6,51 2,41 6,21 11 2,9 8,7 4,6

eulaVPIR

mhoKni

* 86 74 33 22 51 21 01 2,8 8,6 6,5

2/1SCM

2 9,1 8,1 7,1 6,1 5,1 4,1 3,1 2,1 1,1 1

5/5,2SCM

5 8,4 6,4 4,4 4 7,3 4,3 2,3 3 7,2 5,2

21/6SCM

21 5,11 1,11 6,01 8,9 9,8 3,8 7,7 2,7 6,6 6

02/01SCM

02 3,91 6,81 7,71 3,61 8,41 8,31 9,21 21 11 01

82/41SCM

82 72 62 52 32 7,02 3,91 81 7,61 4,51 41

04/02SCM

04 6,83 2,73 4,53 6,23 6,92 6,72 8,52 3,42 22 02

Page 54

54

Service Manual

Plus

MICROSPEED

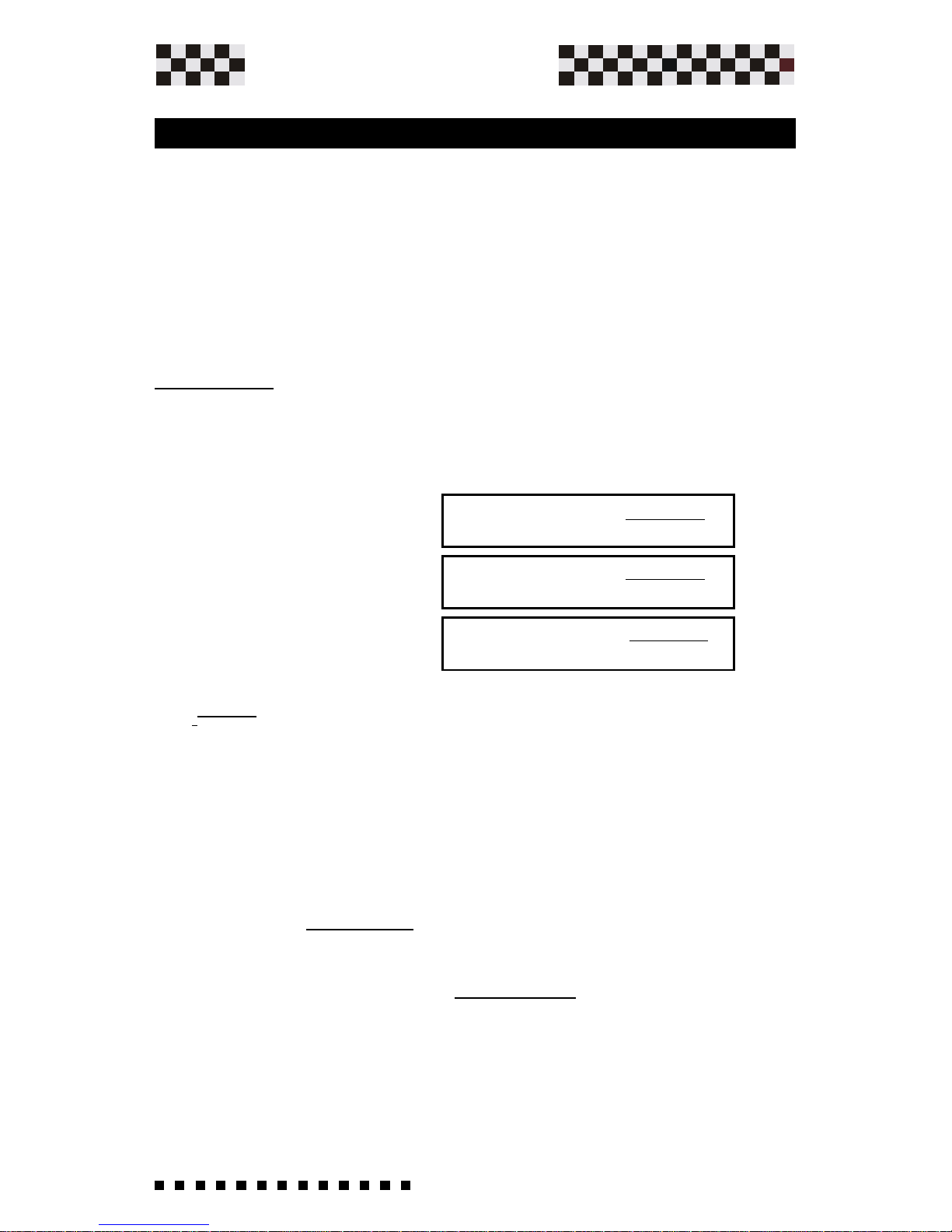

S3 S2 S4

Closed Open Open

Closed Closed Closed

Open Closed Closed

FUNCTION

Ramp Disabled

Ramp Enabled

Ramp Enabled

RANGE

0 Sec.

0,1 - 1sec

by RAMP

NOTE

Standard

adj by ACC

adj by ACC

1

Res. RAMP 680K 820K 1MOHM

TIME 0,2-2,6 Sec. 0,3-3,2 Sec. 0,4-3,9Sec

2

This function is enabled by solder bridges S2, S4 (closed).

It allows adjustment of the ramp slope during both acceleration and

deceleration.

Adjusting the ACC potentiomenter, located in front of the drive,

clockwise (cw) increases the ramp time between 0,1 and 1S (It for

a 10V reference). (See figure below)

5.7 Ramp time Adjustment

Adjustments

It is also possible to modify the range of the ramp by opening

solder bridge S3 and mounting a resistor (RAMP) with the values

shown in the table 2) below.

Page 55

55

Service Manual

Plus

MICROSPEED

Adjustments

Usually, these settings are made by the factory and

do not need to be changed.

Only re-tuning by KV and DER potentiometer is

required.

If high inertia loads are present (ratio 3:1 between load and

motor), it is necessary to set the proportional gain KV

potentiometer and the derivative gain DER potentiometer.

The adjustment procedure must take place with the load

connected to the motor.

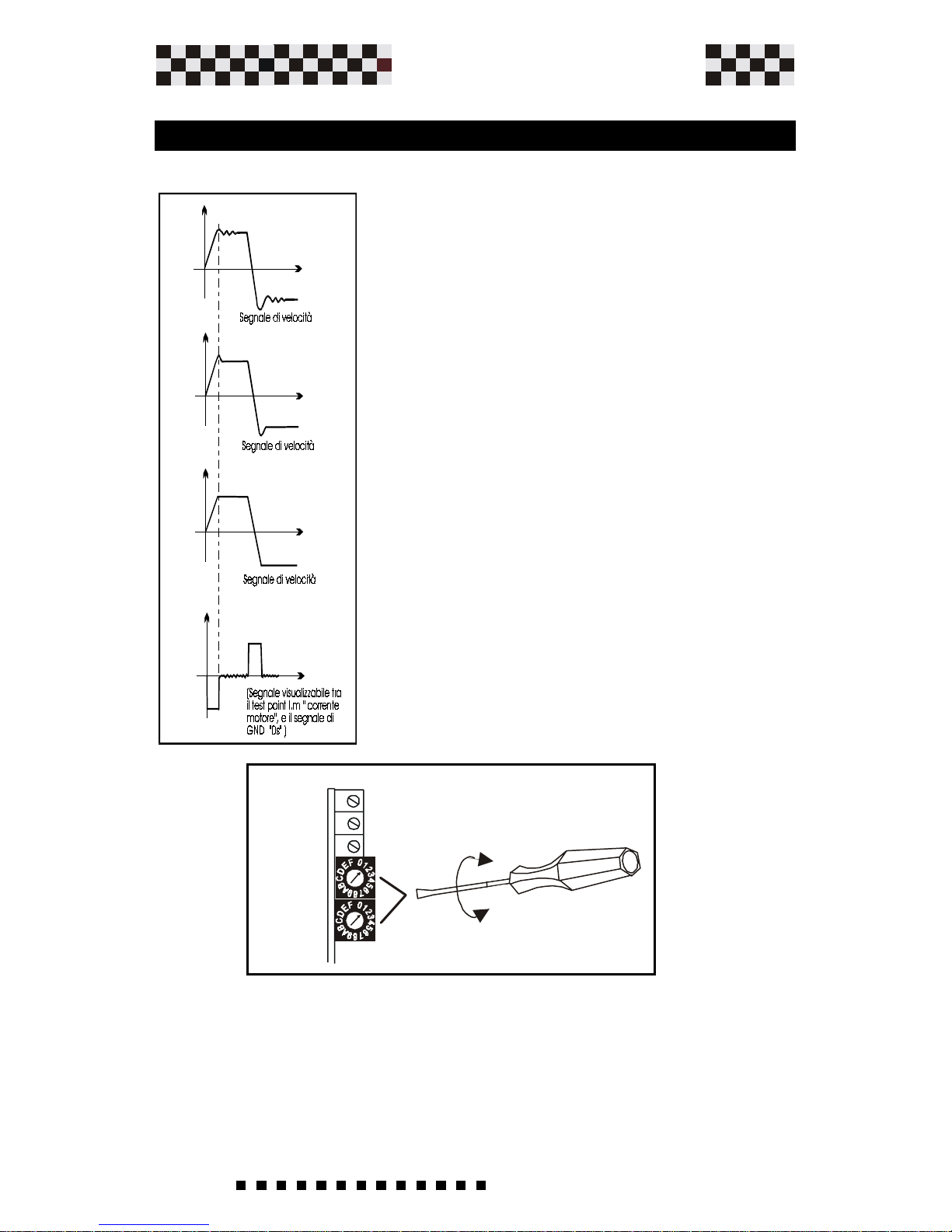

Connect a square wave (0,5 hz, +/-1V) function generator to

the input speed reference terminals.

Connect the "channel A" probe of the memory oscilloscope

to the test point TEST1. (The ground of the probe must be

connected to the GND of the drive).

Adjust the DER and KV potentiometers.

Be sure that the loads motion doesnt create a safety risk.

Apply power to the drive and start it.

The load will begin to move alternatively; if possible increase

the generator amplitude to +/-2V.

Check the signals in the oscilloscope; the waveforms should

be as shown on the next page.

5.8 Dynamic Constant Adjustments

dinamiche

Page 56

56

Service Manual

Plus

MICROSPEED

Increase the gain by turning clockwise

(cw) using "KV potentiometer" until

achieving a situation as shown on the left.

Insufficient proportional gain.

To reduce the overshoot adjust

clockwise (cw) using "Der

potentiometer" until achieving a situation

as shown on the left.

Caution: Do not set KV too high : it can

cause unnecessary motor heating

caused from ocsillating currents in the

motor.

It's possible to increase the velocity loop derivative constant

by inserting a capacitor CDER on the personalization

adjustment.

Adjustments

5.8 Dynamic Constant Adjustments

(Continue)

VEL

BIL

ACC

KV

DER

Page 57

57

Service Manual

Plus

MICROSPEED

6.0 Troubleshooting

Troubleshooting

1) When power is on -the green OK LED doesn't come on.

-Check the voltage between +AT and -AT with a multimeter

2) With the green OK LED on the motor doesn't run when

the drive is enabled.

- Check input signal (Enable-reference)

3) When the drive is enabled the green OK LED goes off and

the red O.C. LED comes on.

- Short circuit between motor terminals or motor winding is

connected to ground. Switch off and measure with tester.

4) During motor deceleration phase the green OK LED

blinks.

-You've exceeded max. consented voltage. Verify filter capacity

value. (See Power Supply chapter).

5) During operation the motor stops and the S.T. LED

comes on.

-Drive operating temp. is too high (more than 40°C). Ventilation

missing (where required).

6) At Startup or Enabling the DT Led comes on.

-Missing Tachogenerator Signals or reversal.

-Missing Encoder Signal or reversal.

Page 58

58

Service Manual

Plus

MICROSPEED

7.1 Encoder Feedback

(option)

Options

The encoder feedback is an option of the MICROSPEED PLUS

drive.

This allows you to adjust the motor speed,using a signal coming

from an encoder with two channels.

This solution saves the use of a tachogenerator,using the same signal

requested for the position control.

The performance of the drive at low speeds are improved with the

high encoder resolution. It is reccomended that you use an encoder

with resolution of at least 500 imp/rev. An auxiliary power supply

+5 V or + 12 V is avalaible to supply the encoder.

Dont exceed the load declared.

If the encoders absorption is unknown,please check it by a

milliamperometer connected in series to +Vs.

If the value is higher, please use an external power supply.

Encoder inputs Push-Pull ,Line-driver, Open-C.

Power supply levels From 0V to 5 min. 0V to 24V max.

Max. frequency 250 Khz

Encoder power supply S13 Close Vs=+5V Max 220 mA

S13 Open Vs=+12V Max.220 mA

Operating temperature 0 - 40 C°

Tecnical specification

Code Description Pin out

11(+Vs) Encoder power supply +5 /12V Output

12(GND) GND Power supply Input/Output

13(CHA) Input channel A encoder Input

14(CHB) Input channel B encoder Input

Terminals description

Code Description Standard

S11 Encoder Feedback Enable Close

S13 Chose Power Supply Close

S13 Insert internal res. pull-up (Inp.CHA) Open

S14 Insert internal res. pull-up (Inp.CHB) Open

Solder bridge description

Page 59

59

Service Manual

Plus

MICROSPEED

Encoder Connections

Options

The following diagram shows typical connections between the

drive and a brushed motor.

The Encoder power comes from the (+V), connector 11.

Page 60

60

Service Manual

Plus

MICROSPEED

Option

Encoder Connection from External Power Supply

The figure below shows a self-powered MICROSPEED PLUS

with the Encoder signalS are powered externally. The Ground

of the external power supply must be connected to the drives

GND pin 12.

Page 61

61

Service Manual

Plus

MICROSPEED

Option

Speed Adjustment with Encoder Feedback

Where: Fenc=the rate factor

PPR= encoder pulses per revolution (line count)

RPM=Motor Velocity Max.

Calculate RENC:

RENC=680000

Fenc.

The resistor RENC determine what is the max. speed of the motor

at 10V of reference. The result of RENC is in Kohm.

The Microspped Plus needs to be set up for the motor and Encoder

used to ensure proper operation and speed control.

Use the following formula to determine the correct resistor value to place

in RENC. The value placed in RENC is application dependent. Determine

what the max. speed of the motor will be and find out what the line count

(PPR) of the encoder is before using the formula. This is a two-part formula, the first part gives a factor based on rate, the second part

determines the resistor value. Keep in mind when selecting the encoders

line count that the Maximum encoder input frequency to the Microspeed

Plus is 250Khz. Find the rate factor:

Fenc=PPR x RPM

60

Example: 1000 PPR Encoder

3000 RPM Motor Velocity Max.

RENC=680000=13.6Kohm

50000

Fenc=1000 x 3000=50000

60

You will adapt to the nearest commercial value: 15 or 12Kohm value in 1/8

or1/4W.

Once the resistor RENC is inserted, proceed with final speed

adjustment.

Operate using trimmer VEL on the front of the drive.

Clockwise Rotation.....................Speed increases

Counter Clockwise Rotation.........Speed decreases

The Range of regulation is +/- 20%.

Page 62

62

Service Manual

Plus

MICROSPEED

Option

7.2 Command with PWM + Direction (Option)

It is possible to run the Microspeed Plus using digital PWM

commands. (Frequency signal in PWM plus direction signal

DIR) (see figure ).

Such logic signals must be furnished to the Microspeed Plus

by a controller which must be able to elaborate the motor's speed

ring and possibly the positioning ring.

(The signals high logic level PWM and DIR must be between

+5Vdc and 24Vdc max.).The Microspeed comes predisposed

to function with supported logic signals, also highlighted in

the figure below.. The range of PWM frequency is 10 to 20Khz.

Page 63

63

Service Manual

Plus

MICROSPEED

Option

--With High PWM logic signal and any DIR logic value you have

zero output voltage between +M and -M. (Motor output

terminal).

--With logic signa PWM = H and DIR = L you receive

clockwise motor rotation.

--With logic signal PWM = H and DIR = H you receive counterclockwise motor rotation.

NOTE:

--The motor wiring must be connected correctly. (Consult the

connections diagram furnished with the motor).

For additional information contact AXOR.

Signal Connector Description.

1 Drive OK, Open Collector output 50mA Max. (Normally

closed, opens when in protection mode).

3 and12 GND Common zero signal

4 Auxiliary output voltage +10V, 4mA.

5 Auxiliary output voltage -10V, 4mA.

6 Enable (+10/30 Volt drive enabled)

7 PWM input Frequency

8 DIR input Direction

Note: -The other pins connector are N.C

-For the leds indicator, in this option,see Chapter 2.2

-The only active adjustemente in this option are RIN and

RIP.

-If closed S16 or S17 you insert for PWM and DIR input a

pull-up resistor of 3.3 Kohm to internal +14V.

Page 64

64

Service Manual

Plus

MICROSPEED

CE CONFORMITY DECLARATION

The manufacturer: AXOR Industries

Address: Via Cà Sordis 6/g, 36054 Montebello

Vicentino (VI) ITALY

DECLARE under their own responsability that the following line

of products:

series MICROSPEED PLUS with the relative options and accessories

installed in accordance with the operating instructions furnished

by the manufacturer, conform to the provisions of the following

directives, including the latest modifications and all relative

national issued legislation:

Machine Directive (89/392, 91/368, 93/44, 93/68)

Electromagnetic Compatibility Directive (89/336, 92/31,

93/68)

And that · the following technical standards were

applied:

CEI EN 60204-1 Safety of machinery – Electrical

equipment of machines – Part 1: General requirements.

CEI EN 60439-1 Low-voltage switchgear and controlgear

assemblies – Part 1: Type-tested and partially typetested assemblies.

CEI EN 61800-3 Adjustable speed electrical power drive

systems – Part 3: EMC product standard including

specific test methods.

Recall: CEI EN 61000-4-2 CEI EN 60146-1-1.

CEI 28-6 Insulation co-ordination for equipment within

low-voltage systems – Part 1: Principles,

requirements

and tests.

CEI 64-8 Electrical system users of nominal voltage

not exceeding a 1000V.alternate current and a

1500V continuous current.

Montebello Vicentino, 19 Dicember 2000 Management

Loading...

Loading...