Page 1

Philippe Starck Two-Handle Tub Filler

Rough-In 10452181 Installation

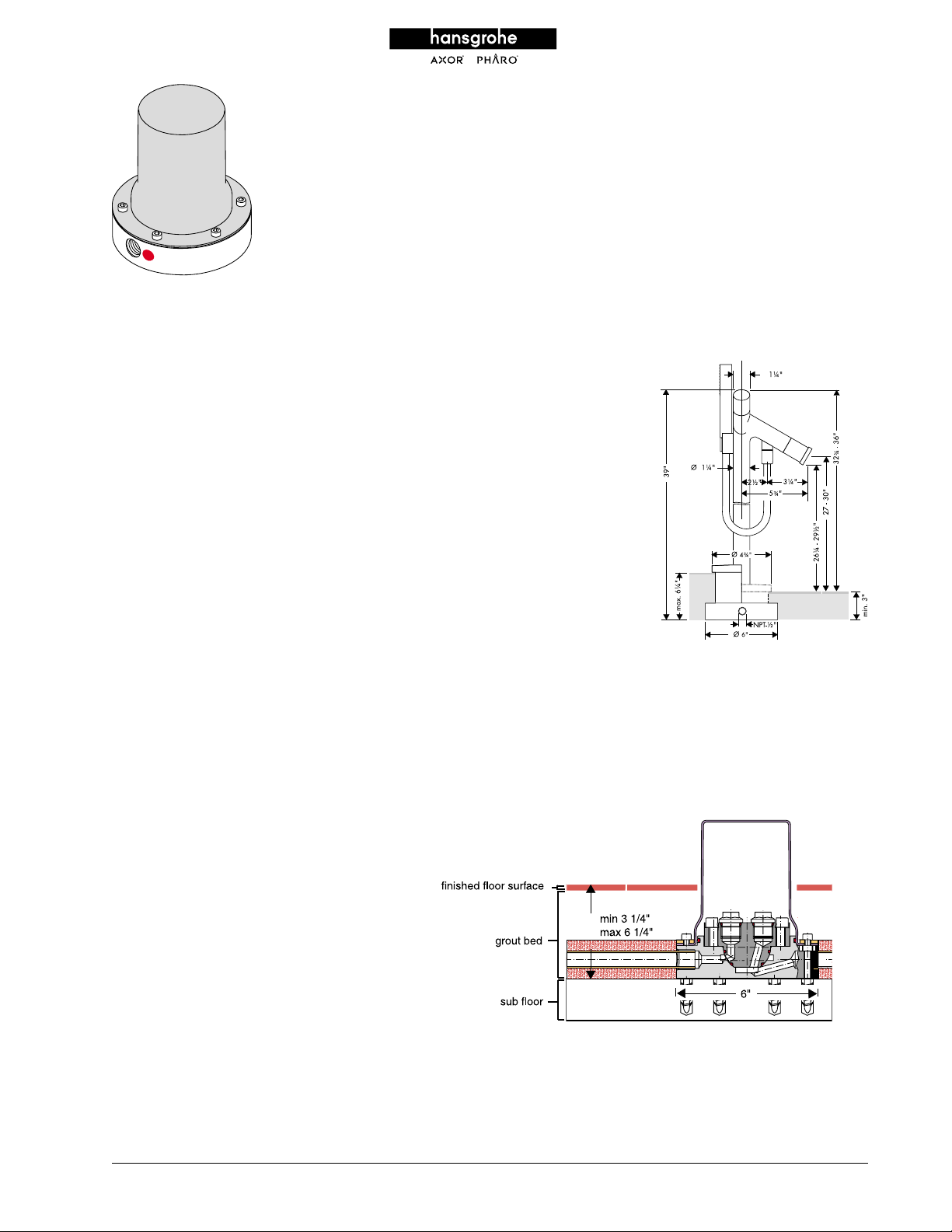

Installation Considerations:

The 10458XX1 two-handle tub filler is designed to be installed with bathrooms

that will be fitted with water impervious flooring such as tile, marble, or

decorative stone.

A remote pressure balance valve, 13418181, is available for those areas that

require scald guard valves on tub fittings that include hand showers. It is

installed to the hot and cold water supplies within 6 of the tub filler.

The 10452181 rough-in kit may be secured directly to concrete sub-flooring

using the supplied anchors. A three-inch minimum*, six-inch maximum* grout

bed must be laid over the completed rough-in assembly.

*THESE MINIMUM-MAXIMUM MEASURE-

MENTS ARE FOR THE GROUT BED ONLY.

THESE MEASUREMENTS ASSUME 1/4TILE

BE LAID OVER THE GROUT BED. FOR

WILL

THICKER THAN 1/4, SUBTRACT ANY

TILES

THICKNESS

THICKNESS

USED, THE MINIMUM GROUT BED THICKNESS

IS

WOULD

WOULD

SUBFLOOR

THICKNESS

OVER 1/4 FROM THE GROUT BED

. FOR EXAMPLE, IF 1/2 THICK TILE

BE 2 3/4 AND THE MAXIMUM

BE 5 3/4. MEASURING FROM THE

UP, THE MINIMUM OVERALL FLOOR

IS 3 1/4 AND THE MAXIMUM IS 6

1/4. SPECIAL CONSIDERATION WILL BE

NECESSARY

PORTION

ALLOW

MENTS

DURING THE FLOOR FRAMING

OF THE CONSTRUCTION PROCESS TO

FOR THESE FLOOR THICKNESS REQUIRE-

55

Installation

Page 2

Installation Instructions

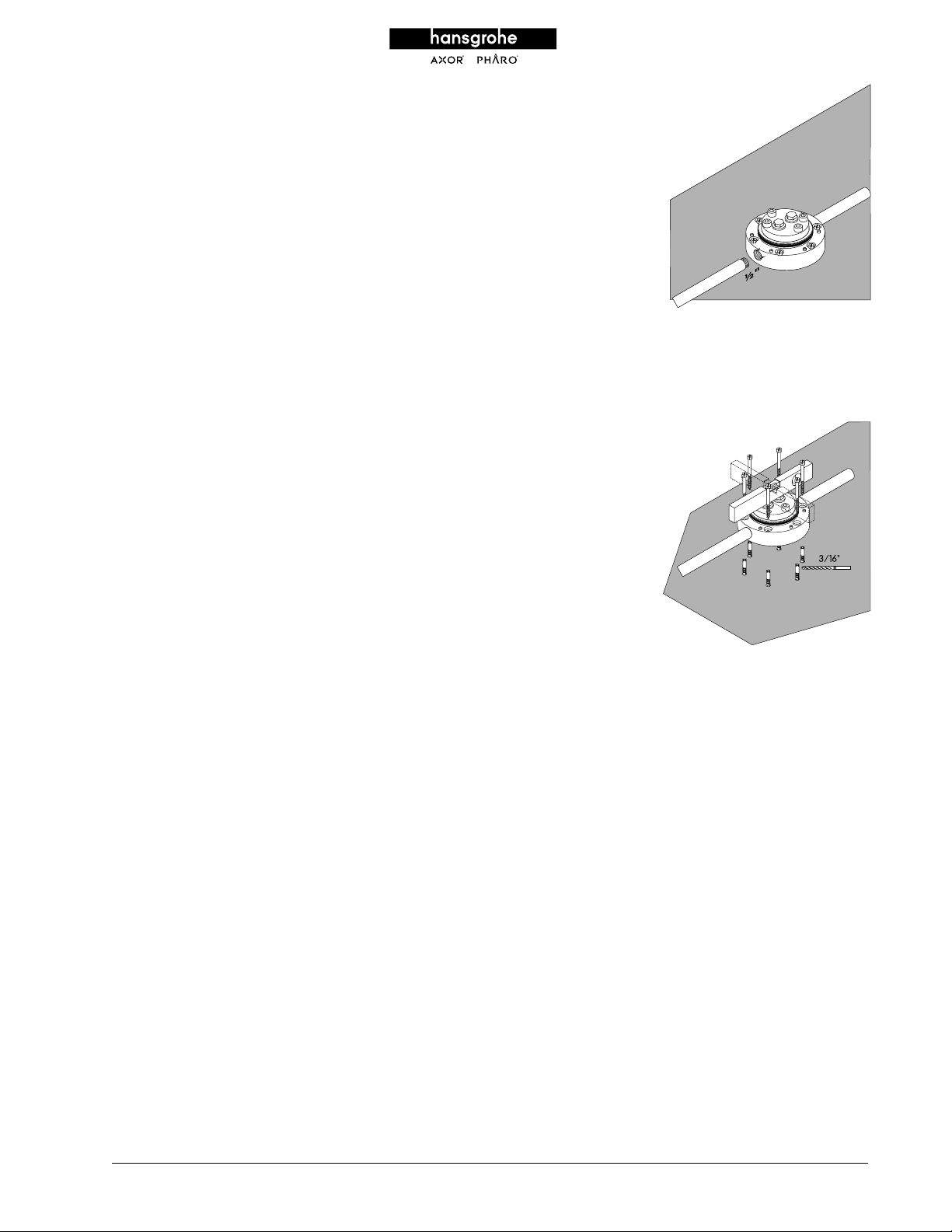

• Apply plumbers thread sealing tape on two six-inch brass threaded pipe

nipples (not supplied) and tighten them into the brass rough-in flange.

Hot and cold connections will be made to these nipples.

• If the water connections are to be made below the floor, elbows can be

fitted to the brass nipples and turned down through the floor. The water

piping can be routed alternately along the surface of the sub-flooring if

desired.

• Note: It is important to have at least six inches of hot and cold piping

on top of the sub-flooring as it lends stability to the tub filler when

embedded in the grout floor. Strap all support piping to the sub-flooring.

• Remove and set aside the six hex-head screws securing the black plastic

plaster guard from the brass rough-in flange. Position the brass rough-in

flange in the desired location of the two-handle tub mixer. Orient the

two water inlets to allow convenient connection to the hot and cold

supplies. Using the rough-in flange as a template, mark the six screw

holes using a 3/16 drill bit. Secure the rough-in flange to the floor

using the supplied lag screws.

• IMPORTANT: Make sure to keep the brass rough-in flange

level in all planes.

• The brass rough-in flange can also be through-bolted to the wood sub-

flooring, if desired (hardware not included).

• The same procedure is used for a concrete sub-floor, with the exception

that an eight-millimeter masonry drill bit is used for the screw holes. The

plastic masonry anchors (supplied) are inserted into the six screw holes

and the rough-in flange is secured to the concrete sub-floor using the

supplied screws. Once again, the flange must be level in all

planes, and grout and tile built up to the same dimensions over the

completed rough in, just as in a wood sub floor installation.

56

Installation

Page 3

• Make all water connections. Remove the two nylon plugs from the top of

the white nylon test cover on the brass rough-in flange, and screw hose

bibbs into the threaded openings. Pressurize the piping system and check

for leaks. Attach a hose to the hose bibbs and thoroughly flush the hot

and cold piping of all debris.

• Depressurize and drain the piping system. Remove the hose bibbs and

reinstall the nylon plugs into the top of the white nylon test cover. Repressurize the system and check all connections for leaks.

• Reinstall the black plastic plaster guard onto the brass rough-in flange

using the hex-head screws.

• Finish flooring can now be completed. The outside surface of the finished

floor MUST fall somewhere between the minimum and maximum

markings on the shield. Rough-in is now complete.

57

Installation

Page 4

Philippe Starck Two-Handle Tub Filler

Trim Kit 10458XX1 Installation

Installation Considerations

Rough-in 10452181 must be installed, and the finished

floor must be complete before installing this trim kit.

Installation Instructions

• Cut off the black plastic plaster guard 3/8 above the finished

floor. Depressurize and drain down the piping system.

• Remove the four hex-head screws that secure the white nylon test

cover to the brass rough-in flange. Put the screws in a safe

place - they will be re-used. Lift the test cover off. The test

cover may be discarded. Make sure not to allow any debris to

fall onto the brass rough-in flange.

• Carefully lower the two-handle tub filler onto the brass rough-in

flange and gently twist it to firmly seat the o-ring seals into their

receiver in the brass flange. Make sure the tub filler is plumb in

the vertical plane. After making sure the tub filler spout is oriented

in the desired direction, tighten the six hex-head screws (supplied)

to secure the tub filler to the rough-in flange. All screws should be

hand tightened, and then tightened one turn at a time beginning

with one screw and then tightening the screw on the opposite side

an equal amount. Follow this procedure until all screws are firmly

and equally tightened.

• Re-check the vertical plumb of the tub filler.

58

Installation

Page 5

• Connect the handshower head and hose to the tub

filler using the supplied rubber gaskets. Turn on the

water supply and check for leaks.

• Seal the juncture of the plaster guard and the finished

floor with a compatible, non-staining waterproof

sealant.

• After ensuring that the two-handle tub filler installation

is performing properly, lower the decorative floor

flange to the finished floor.

User Instructions

The right handle controls the cold water, the left handle

controls the hot water.

When the unit is first turned on, water will come from the

spout. Pull on the end of the spout to divert to the

handshower. When the water is turned off, the unit will

automatically reset to the spout. NOTE: DO NOT DIVERT

TO THE HANDSHOWER UNLESS IT IS POSITIONED OVER THE TUB.

WATER

To remove the handhshower from the holder, pull up until

the hose nut clears the holder, then pull out. Reverse the

process to put the handshower back into the holder.

The handshower uses the RubitTM cleaning system. To

dislodge any scale deposits from the spray channels, turn

the water on lightly and rub the spray channels gently

with your finger or a sponge.

59

Installation

Loading...

Loading...