Page 1

USER’S MANUAL

AXOPAR 28 OPEN / OC / T-TOP

Page 2

Page 3

FOREWORD ..................................................................................... 2

INTRODUCTION ............................................................................... 4

Symbols used ................................................................................... 4

Identification .................................................................................... 5

Manufacturer’s plate ......................................................................... 5

General layout Cabin ........................................................................ 6

Work decks and swim ladders Cabin ................................................ 7

General layout AC ........................................................................... 8

Work decks and swim ladders AC .................................................... 9

Technical data ................................................................................ 10

Declaration of conformity .............................................................. 11

Toilet-, black water- and grey water systems ................................... 12

Electrical system ............................................................................. 14

Bilge pump system ......................................................................... 16

Deck and security equipment ......................................................... 17

Fire control and fuel-,

cooling-, and gas systems .............................................................. 18

LPG equipment .............................................................................. 20

Installation of LPG equipment ........................................................ 21

Steering system .............................................................................. 22

Environment .................................................................................. 23

CONTENTS

HANDLING OF THE BOAT ............................................................... 24

Starting the engine ........................................................................ 24

Before weighing anchor ................................................................. 24

Leaving the jetty ............................................................................ 25

Stability and buoyancy ................................................................... 25

Driving the boat ............................................................................. 25

Dead man’s switch ......................................................................... 26

Driving at high speed ..................................................................... 26

Using the trim tabs ........................................................................ 27

Driving in rough seas ..................................................................... 28

Manoeuvring in narrow channels ................................................... 28

Docking ......................................................................................... 28

Before anchoring ........................................................................... 29

Anchoring, mooring and towing .................................................... 29

AFTER RUNNING THE ENGINE(S) .................................................... 30

Maintenance .................................................................................. 30

Wooden interior ............................................................................ 30

Cover ............................................................................................. 31

Preventing frost damage ................................................................ 31

Lifting and transporting ................................................................. 32

Actions before winter storage ......................................................... 33

Action before launching ................................................................. 33

APPENDIXES ................................................................................. 34

1

Page 4

In this user’s manual you will find important information that will help

you handle and maintain your boat in a safe and easy manner. Furthermore, the manual contains detailed information about the boat and

the systems installed, and general information about handling and taking care of your boat.

We advise you to read the manual carefully and familiarise yourself with

your boat before you start to use it. Naturally this owner’s manual is not

a substitute for boating safety skills or good seamanship. If this is your

first boat or if this boat type is new to you, we ask for your own comfort and safety that you ensure you can handle the boat before you set

out for the first time. Your boat dealer, local boat clubs and national

motorboat or yacht federations will gladly inform you about local sea

schools or recommend approved instructors.

You should ensure that the anticipated wind and wave conditions correspond to the design category of your boat, and that you and your

crew are able to handle the craft in these conditions. Design category

C corresponds to wind and wave conditions that can vary from storm

to strong winds. Category C also indicates a risk of exceptional swell

and gust. Even if your boat is designed for such conditions, they are still

very dangerous. Only a capable, fit and trained crew, using a well main-

Congratulations on your new Axopar boat! We thank you for

choosing this boat and wish you safe and enjoyable moments out

on the waters.

FOREWORD

tained craft, can satisfactorily operate in such conditions.

This owner’s manual is not a detailed maintenance or troubleshooting

guide. If problems occur, you should contact the boat manufacturer or

their representative. When you are in need of maintenance or repair

and alteration work, you should always turn to competent and trained

workshops. Changes that can affect the boat’s security features must be

assessed, carried out and documented by competent professionals. The

boat manufacturer cannot be held responsible for unauthorised modifications. Every change to the boat’s centre of gravity (from highly mounted heavy equipment or a new engine type etc.) will significantly affect

the stability, trim and performance of the boat.

The boat owner must take local and international regulations into consideration concerning the boat crew, equipment and handling of the

boat. In some countries, a driving licence or a separate authorization is

required for driving the boat and in some countries special regulations

might also be in force.

Always maintain your craft properly and make allowance for the deterioration that will occur over time and as a result of heavy use or misuse

of the craft. Any craft, no matter how strong it may be, can be severe-

2

Page 5

ly damaged if not used properly. Inappropriate use of this boat i.e. use

which is not compatible with safe boating, is not allowed. It is always

important to adjust the speed and direction of the craft to the sea conditions and your own boating experience.

If your boat is fitted with a life raft, carefully read its operating manual. On-board, the craft should have the appropriate safety equipment

according to the type of craft, weather conditions, etc. This equipment

is compulsory in some countries. The crew should be familiar with the

use of all safety equipment and the most important actions in different

emergency situations (man overboard recovery, towing, etc.). Sailing

schools and clubs regularly organize rescue drills.

The equipment in your boat may differ from the equipment used in the

pictures and illustrations in this manual. The reason for this might be

e.g. due to any optional equipment you have chosen or modifications

that have been adapted since this manual was made. In such cases we

recommend that you contact your local dealer for additional information regarding the equipment in question.

Keep this manual in a safe place and pass it on to the new owner if

you sell your boat. If the manual is mislaid or destroyed, a copy can be

ordered from your dealer. The warranty on the engine, as well as option-

al equipment such as trim tabs, bow thrusters, navigation equipment

and other equipment fitted afterwards, is on the individual supplier’s

conditions. The warranties for this equipment and the suppliers’ contact

information are enclosed. Concerning all other warranty claims, please

contact you Axopar dealer mentioned on the cover page.

See the purchase agreement/order for the scope of your purchase. In

case something does not work satisfactorily with your boat or its equipment, you can check the service documents for possible service and

repair measures. In the event of uncertainty, you should always contact your dealer.

Please note that your boat is a recreational craft, thus not suitable for

professional use.

Specifications, illustrations and examples and related constructional data

in this publication are not binding. We reserve the rights for changes.

3

Page 6

INTRODUCTION

SYMBOLS USED IN THIS MANUAL:

The purpose of the owner’s manual is not to be a complete service guide or repair handbook, but to guide the owner into the

characteristics of his/her new boat and to handle it in a proper way.

CE-CATEGORY – C

This boat belongs to category C. The CE-categories means that boats in

each category must be designed and constructed to withstand the following parameters in respect of stability, buoyancy, and other relevant

essential requirements stated. One requirement is that the boats must

be easy to manoeuvre.

A. Ocean

These boats are designed for extended voyages, where conditions experienced may exceed wind force 8 Beaufort Scale and include significant

wave heights of at least 4 metres. Under such conditions these boats

must be largely self-sufficient.

B. Offshore

These boats are designed for offshore voyages, where conditions up to

and including wind force 8 Beaufort Scale and significant wave heights

up to and including 4 metres may be experienced.

C. Inshore

These boats are designed for voyages in coastal waters, large bays, estuaries, lakes and rivers, where conditions up to and including wind force

6 Beaufort Scale and significant wave heights up to and including 2 m

may be experienced.

DANGER!

Maximum caution should be observed to prevent fatal injury or

permanent harm.

WARNING!

Denotes that an extreme inherent hazard exists which very likely could

result in death or serious injury if proper precautions are not taken.

CAUTION!

Take precautions to prevent injury and/or damage to the boat and its

components.

4

Page 7

IDENTIFICATION

Each boat is supplied with a unique identification code, containing the

data described below. The identification code comprises 14 characters

plus a hyphen. The height of the code text is 6 mm and it is applied to

the starboard side of the stern. The identification code reads as follows:

FI – AXOC8001E414

FI Country of manufacture

- Hyphen

AXO Manufacturer: ___________

C8 Boat model

001 Boat number

E Month of manufacture: A = January, B = February, etc..

4 Year of manufacture

14 Model year

MANUFACTURER’S PLATE

The cooperation with VTT (Technical Research Centre of Finland) means

that VTT as an external and independent organisation has inspected

that the boat fulfils the Recreational Craft Directive and related standards requirements. The manufacturer’s plate is always fitted close to the

steering position in the boat. The manufacturer’s plate gives the following information:

BOAT TYPE Boat model

DESIGN CATEGORY Boat class. See additional information in the

chapter CE-category.

MAX. NO Maximum number of persons on board

MAX. LOAD Buoyancy. Total weight of persons including

personal luggage (excluding tank contents).

ID OF NOTIFIED

AUTHORITY

VTT

A comprehensive explanation of the information given on the plate is

presented in each chapter respectively in this manual.

(Load and max. engine power)

CAUTION!

The liquids in the built-in tanks are not included in the max. load shown

on the Manufacturer’s plate.

WARNING!

You must not exceed the max. number of persons of the boat. Regarding the number of persons you must also always take into consideration

that the total weight of the persons on board and their personal luggage

must never exceed the max. load of the boat. When out on the water,

always use the seats intended for passengers.

5

Page 8

GENERAL LAYOUT OPEN

1

2

8

1

6

5

5

13

13

11

11

9

9

3

17

2

23

18

20

22 21

4

7

14 15

12

10

10

8 16

19

6

Page 9

WORK DECKS AND SWIM LADDERS OPEN 01 Swim ladders 02 Trailer eyelet Work deck Attaching points

01 Mast light

02 Running lights 112.5° red

112.5° green output 10W

03 Dry powder extinguisher 2kg output

13A89BC

04 Fuel tank

05 Bilge pump

06 Manual bilge pump

07 Service hatch for fuel tank

08 Breather valve for fuel tank

09 Deck drain flaps

10 Cockpit drain

11 Cockpit drain cocks

12 Fuel inlet pipe

13 Fuel filter / - water separator

14 Septic tank

15 Water tank

16 Flushing water cock for toilet

17 Septic tank cock

18 Service hatch for bow thruster

19 Septic tank deck drain

20 Inlet pipe for water tank

21 Breather valve for water tank

22 Breather valve for septic tank

23 Liquefied petroleum gas container

7

Page 10

GENERAL LAYOUT OC / T-TTOP

1

2

8

1

6

5

5

14

13

11

11

9

9

3

17

2

23

18

20

22 21

4

7

14 15

12

10

10

8 16

19

8

Page 11

WORK DECKS AND SWIM LADDERS OC / T-TOP 01 Swim ladders 02 Trailer eyelet Work deck Attaching points

01 Mast light

02 Running lights 112.5° red

112.5° green output 10W

03 Dry powder extinguisher 2kg output

13A89BC

04 Fuel tank

05 Bilge pump

06 Manual bilge pump

07 Service hatch for fuel tank

08 Breather valve for fuel tank

09 Deck drain flaps

10 Cockpit drain

11 Cockpit drain cocks

12 Fuel inlet pipe

13 Fuel filter / - water separator

14 Septic tank

15 Water tank

16 Flushing water cock for toilet

17 Septic tank cock

18 Service hatch for bow thruster

19 Septic tank deck drain

20 Inlet pipe for water tank

21 Breather valve for water tank

22 Breather valve for septic tank

23 Liquefied petroleum gas container

1

2

9

Page 12

TECHNICAL DATA

BOAT M ODE L ..................................................................... AXOPAR 28 OP EN / OC / T-TOP

DESIGN C ATEGORY ..................................................................................... C (INSHORE)

LENGTH ......................................................................................................... LH 9, 01 M

BEAM ............................................................................................................ BH 2,81 M

MAX . RECOMMENDE D NUMBER OF P ERSONS ............. 8 (DEFAU LT WEIGHT OF O NE ADULT

........................................................................................ 75KG, A CHI LD 37,5 KG)

MAX . RECOMMENDE D ENGINE PO WER .................................... (SI NGLE) 221 K W / 300 HP

............................................................................. ( TWIN) 2 X 111 KW / 2 X 150 HP

MAX RE COMMENDED W EIGHT OF ENG INES ................... ( SINGLE) 313 KG, ( TWIN) 52 2 KG

BOAT HULL W EIGHT (EXCLU DING ENGI NES) ........................................................ 16 50 KG

WEIGH T OF UNLOADE D BOAT

WITH M AX. WEI GHT OUTBOA RD ENGIN ES ......................................................... 2 250 KG

MAX . RECOMMENDE D LOAD ............................................................................... 9 00 KG

BOAT WEIGH T AT MAX. LOAD ........................................................................... 3150 KG

OF WHICH:

TOTAL WEIGH T OF ALL PERS ONS ......................................................................... 6 00 KG

PERSONAL LUGGAGE ............................................................................................ 50 KG

AMOU NT OF FRESH WATER ......................................................................... 39 KG (3 9 L)

AMOU NT OF BLACK WATER ........................................................................... 45 KG (45 L)

AMOU NT OF FUEL ..................................................................................... 192 KG (2 60 L)

TRAI LER WEIGH T ................................................... 2470 KG KG (NOT INCLUDI NG WEIGH T

............................................................................. OF CREW, P ERSONA L LUGGAGE

........................................................................................................ OR SEWAG E)

TOTAL WEIGH T OF FUEL, WATER

AND OTH ER LIQUID S ............................................................................................ 261 KG

DRAUG HT AT MAX. LOAD ( EXCLUDING E NGINE) ................................................. 0,45 M

HEIGH T MEASURE D FROM WATERLIN E AT LIGHT LOAD ....................... OPEN / OC 2,0 5 M

............................................................................... ( WITH TARGA A RCH 2,85 M)

.................................................................................................... T-TOP 2 ,95 M

Assessment of the stability of the boat has been done at max. load

conditions. The maximum recommended load contains only the weight

components mentioned above.

CAUTION!

The specified tank capacity is not necessarily fully available, depending

on the trim and load on board. The tank should always be kept at least

20% full.

WARNING!

When loading the craft, never exceed the maximum recommended load

of the boat. Always load the craft carefully and always distribute loads

appropriately to maintain design trim. Avoid placing heavy equipment

or material high up in the boat. Overloading the boat can damage the

engine, even when shut off.

10

Page 13

GELCOAT / PAINT

HULL ................................................................. Ashland Max Guard

DECK .................................................................. Ashland Max Guard

SWITCH PAN EL MODULE.................................................................. Nextel

TANK CAPACITY

FUEL TANK ........................................................................................ 2 60 L

FRE SH WATE R TANK ............................................................................. 45 L

HOLDING TANK .................................................................................... 42 L

ELECTRICAL SYSTEM 12V

STARTER BATTERY ............................................................................. 105A

SERVICE BATTERY .............................................................................. 105A

ELECTRICAL SYSTEM 230V

FREQUENCY

BATTERY CHA RGER ......................................................................... 12 A H

SHOREPOWER CONNECTOR .........................................................................

DECLARATION OF CONFORMITY AND ESSENTIAL SECURITY

REQUIREMENTS

Basic data EN ISO 8666:2002

2.1 Hull identification ISO 10087:2006

2.2 Manufacturer’s plate RCD annex I, 2.2

2.5 Owner’s manual EN ISO 10240:2004

Layout and equipment

2.3 Preventing falling overboard EN ISO 15085:2003/A1:2009

3.7 Life raft stowage RSG Guidelines

3.8 Escape EN ISO 9094-1:2003

3.9 Anchoring and towing EN ISO 15084:2003

5.7 Running lights 1972 COLREG

5.8 Emissions control EN ISO 8099:2000

Installations

5.1 Engines and engine spaces -

5.2 Fuel system EN ISO 10088:2013, EN ISO 11105:1997,

EN ISO 21487:2012

5.3 Electrical system EN ISO 10133:2012, ISO 28846:1993/A1:2000

5.4 Steering system EN ISO 10592:1995/A1:2000

5.5 Gas systems -

5.6 Fire protection EN ISO 9094-1:2003

Dimensioning

3.1 Structure RSG Guidelines ISO 12215-5:2008, ISO 12215-6:2008

Hydrostatics

3.2 Stability and freeboard EN ISO 12217:2013

3.3 Buoyancy and floatation EN ISO 12217:2013

3.6 Manufacturer’s maximum recommended load

EN ISO 14946:2001/AC 2005

3.4 Openings in hull, deck and superstructure EN ISO 9093-1:1997,

EN ISO 12216:2002

3.5 Flooding EN ISO 11812:2001, EN ISO 15083:2003,

ISO 8849:2003

Handling characteristics

4 Handling characteristics EN ISO 11592-2 WD 2013-11-20,

EN ISO 8665:2006

2.4 Visibility from the steering position EN ISO 11591:2011

Exhaust emissions of engines Noise emissions -

11

Page 14

01 Septic tank

02 Septic tank cock

03 Septic tank drain pipe

04 Breather valve for septic tank

05 Flushing water cock for toilet

06 Water tank

07 Inlet pipe for water tank

08 Breather valve for water tank

TOILET-, BLACK WATER- AND GREY WATER SYSTEMS OPEN / OC / T-TOP

2

4 8

7

3

5

1

6

12

Page 15

TOILET

Clean the toilet with a mild cleaner. Do not ever use cleaning agents or

deodorants which contain pine oil, formaldehyde or chlorine nor corrosive or petroleum based agents. These can damage plastic and rubber

parts in the toilet. Lubricate the pump shaft with Vaseline to increase

the service life of the seal. Flush the toilet system thoroughly with fresh

water when the boat is not in use. Never put any other objects but toilet

paper in the toilet. Under no circumstances is it allowed to flush paper

towels, fabric or rubber products, hard objects, oil products or solvents

into the toilet. In order to avoid various damages, you must also not

pour hotter than lukewarm water into the toilet.

Holding tank

Avoid environmental pollution! The black water tank is fitted with a

deck outlet pump using an international standard type connection.

Using the pump, the black water can be emptied to permanent septic

tanks ashore. These facilities must always be used. In areas where there

are no permanent septic tanks, you should do as follows:

Open the sealed sea valve. If possible empty the tank daily and always

in deep waters far from the shore. The location of the pump is indicated on the construction drawing. CAUTION! The shut-off valve must be

closed after the evacuation. Do not allow the tank to become full. This

can lead to paper becoming compacted in the bottom of the tank, making it more difficult to empty. See the cleaning instructions in the chapter Winter storage.

Spring preparation of the toilet

01 Lubricate the pump cylinder with Vaseline.

02 Flush the system with fresh water.

03 Connect the hoses and open both valves.

04 Check the connections thoroughly for leaks.

Winter lay-up

CAUTION!

Before the boat is laid-up for winter storage, the whole system must

be cleaned and flushed through while the boat is still in the water. The

whole system must be thoroughly drained of water when the boat is

lifted out of the water. This measure prevents frost damage, bacteria

growth and smells.

We do not recommend the use of antifreeze, since it is impossible to

guarantee that it reaches all parts of the system..

13

Page 16

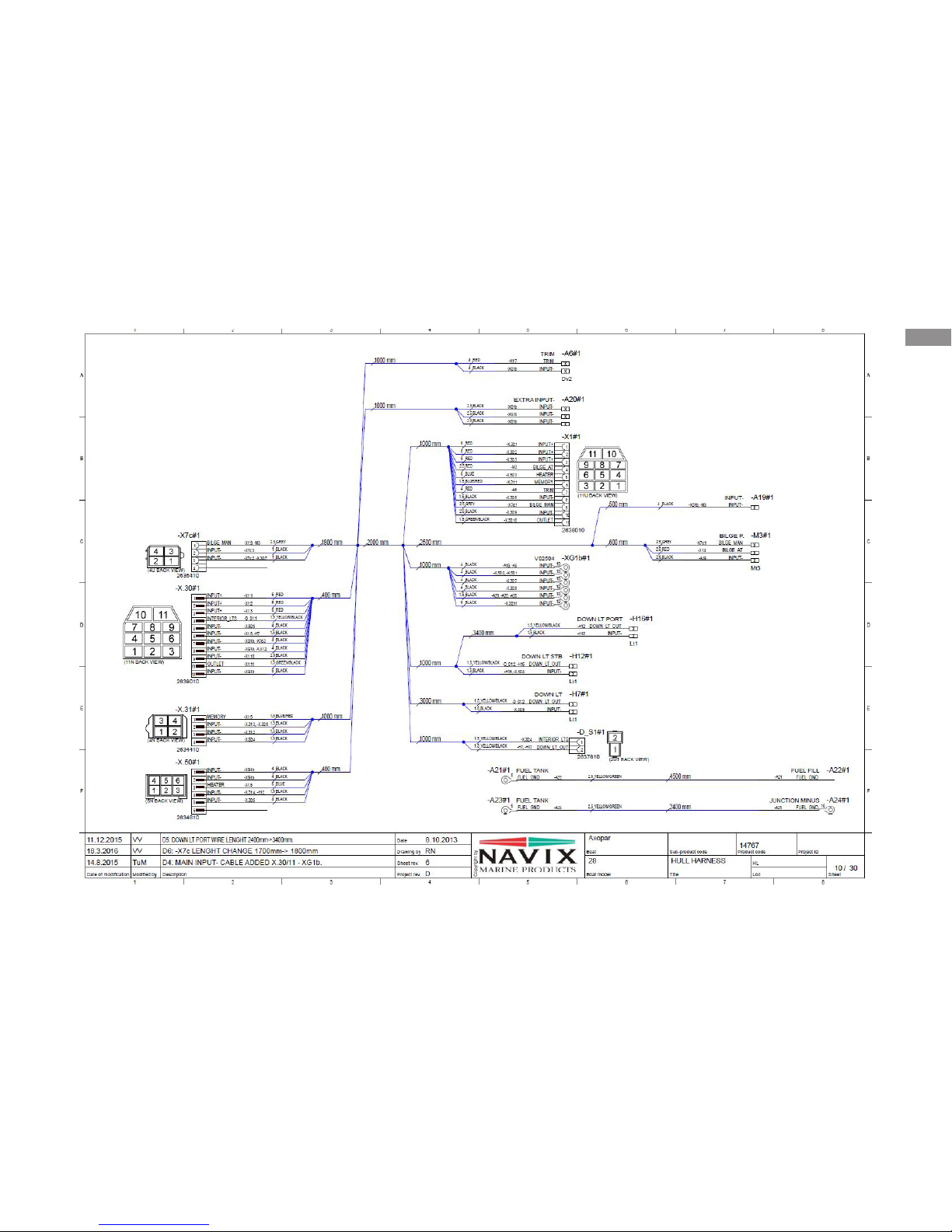

ELECTRICAL SYSTEM OPEN / OC / T-TOP

01 Battery compartment

02 Main switch

03 Bilge pump

04 Mast light, white 360°

05 Running lights

06 Switch panel

07 Power outlet 12v. max 10A

08 Fuse box

09 Windscreen wiper

Your boat is equipped with so-called automatic fuses that pop out when

they go off. Before activating them again, you should check for possible reasons why the fuse went off. To activate, press the fuse back into

position.

WARNING! Do not:

•

• carry out electrical installations when the power is switched on

• modify the boat’s electrical system or diagrams; service and

maintenance must be carried out by a qualified electrician

• modify the nominal rated amperage of the overvoltage protector

• install or replace electrical equipment with components that cause

the circuit’s nominal rated amperage to be exceeded

• leave the boat unattended with the electrical system switched on,

except for the automatic bilge pump or alarm system

High voltage system 230V with shore power connection (optional

equipment). The high voltage system comprises the following parts: 230

V 16 A earth fault breaker, 230 V power outlet in the toilet and cockpit, 1 shore power cable.

The shore power system should be checked at least bi-annually. Always

disconnect the shore power cable when the system is not in use. Metal

casings of installed electrical equipment must always be connected to

earth in the boat’s electrical system. Use electrical equipment equipped

with earth protection only.

1

1

6

5

9

9

3

2

4

7

8

14

Page 17

WARNING!

Do not touch an energised high voltage system

Do not modify the shore power cable connectors, only use compatible

connectors

DANGER!

• The bleed hoses must be connected after battery replacement or

service. When replacing batteries, marine batteries capable of being

connected to the bleed hoses must be used. The battery isolating

switches are located in the main switch panel. The batteries are

charged when the engines are running, or they can be charged with a

battery charger or other extra equipment.

• Try to minimize the risk of electric shock, short circuit and fire.

• Do not allow the shore power cable to hang in the water. If it does, a

hazardous electric field could be created in the water.

• Switch off the shore power switch before connecting and

disconnecting the cable. Connect the shore power cable to the boat

before connecting it ashore.

• Disconnect the shore power cable ashore before disconnecting it from

the boat. Close the hatch to the shore power socket on the boat.

• Never modify the connections on the shore power cable. Use

compatible connectors only.

• If the earth fault breaker is tripped, disconnect the shore power cable

immediately. In such a case contact a qualified electrician for repairs

before the system is used again.

Low voltage system

The boat’s 12 V low voltage system is fed by the service batteries. The

batteries can be disconnected from all circuits using the main power

switches in the electrical panel. With the main power switches on, power is conducted to the electrical panel and distributed throughout the

boat. The switches for controlling the different functions of the boat are

located on a control panel.

Charging the batteries

Remember that the batteries discharge an explosive oxy-hydrogen gas

at a voltage of 14.4 volts. The voltage of a normal battery in unloaded status is 12.3-12.7 V. During charging, the voltage increases and the

charging regulator stops the charging process automatically at a pre-set

level. The voltage measurement should be taken at the battery terminals, not the alternator, to achieve the correct result.

Charging status

The best method for determining charging status is to measure the specific gravity of the battery acid. This is done using a hydrometer (acid

measurer). Normal specific gravity for a fully charged battery at 20 °C

is 1.26-1.28g/cm³. Note that the specific gravity varies with temperature. Batteries from different manufacturers can have a different specific gravity. Ask your dealer for the correct information. If the specific

gravity varies from cell to cell, then the battery is not in good condition,

and should be replaced. For winter storage, the batteries can be left on

board only if they are fully charged. A partially discharged battery can

freeze and crack. Always disconnect the cable terminals from the battery to avoid oxidation.

Cleaning the batteries

The top of the batteries should be cleaned regularly to avoid current

leakage between the cells. If the battery is located in a separate area,

it is normally sufficient to clean it in the spring and autumn. Make sure

that the air holes in the cell plugs are open so that gas can be vented.

15

Page 18

The terminals and cable terminals must be lubricated to prevent deposits and corrosion.

Electrolyte level in cells

Do not use matches, a cigarette lighter or other form of naked flame

when checking the electrolyte level, because the battery gives off explosive gas.

The electrolyte level in the batteries must be checked at regular intervals. The electrolyte level must be approx. 10 mm above the plates. If

the level is too low, top up with distilled water.

BILGE PUMP SYSTEM

CAUTION!

Avoid pollution! The purpose of the boat’s electrical bilge pumps is to

minimize the risk of accidental discharge of oil polluted water. The boat

owner should check the bilge water regularly for contaminants such as

oil, diesel, glycol etc.

The bilge pump system comprises several different pumps that cover all

areas of the boat.

Your boat has electrical as well as manual bilge pumps. There is also a

sign in the boat indicating the draining area of each pump respectively.

The manual bilge pump is operated with the handle next to the pump,

located in a storage compartment on the aft deck.

The electrical pumps are submersible. One is located in the area before

the toilet (models Open and TT) and the other in front of the engine

compartment in the bilge. The bilge water level should always be kept

at a minimum.

The pumping capacity of the automatic bilge pump is 41 litres per minute. The pumping capacity of the manual bilge pump is 33 litres per

minute. The automatic bilge pump has an alarm sound which is activated when the pump starts.

DANGER!

Check the functionality of the bilge pumps regularly. Remove any waste

from the intakes.

The combined capacity of the bilge pump system is not designed to

pump out the boat in the event of hull damage. The pumps are con

stantly activated and pump out the boat as required. The pumps can also

be started manually from the boat’s main control panel.

CAUTION!

The pumps must not be run dry for any length of time.

16

Page 19

DECK AND SECURITY EQUIPMENT

01 Swim ladders

02 Electrical bilge pump 41l /min

03 Manual bilge pump 33l /min

Location of fire extinguisher OPEN

Location of fire extinguisher OC / T-TOP

Seating

EMERGENCY EXITS

Get to know where the emergency exits are

by studying the illustrations above. All emergency exits are marked with a white arrow on

a green background.

DANGER!

The loading hatch on the aft deck must always

be kept closed during driving. Do not keep the

hatch open when the engines are running, due

to the risk of carbon monoxide poisoning.

1

3

LIFERAFT

2

2

1

3

LIFERAFT

2

2

OPEN

OC / T-TOP

17

Page 20

FIRE CONTROL, FUEL-, AND LPG SYSTEM

FIRE CONTROL

This boat is fitted with hand-held fire extinguishers with the following

output and location. Keep the bilge clean and check regularly for fueland gas fumes or fuel leaks. Do not hang curtains or other fabrics near

or above the LPG cooker or other equipment with naked flames.

The fire extinguisher must have a fire rating of at least 8A 68B. The fire

extinguisher’s total fire rating must be at least 8A / 68B and for an individual extinguisher at least 5A / 34B. Check the correct location of the

extinguishers from the diagram on page 19.

The fire blanket should be kept beside the driver’s seat.

CAUTION!

Never:

• Block evacuation routes and emergency exits.

• Block access to safety equipment such as fuel valves or main power

switches.

• Block access to fire extinguishers, visible or concealed.

• Leave the boat unattended when the cooker or heater is switched on.

• Modify the boat’s systems (especially electrical, fuel or gas systems).

• Refuel or replace gas containers when the engines are running.

• Smoke when handling fuel or gas.

It is the boat owner’s/user’s responsibility to ensure that:

• the fire extinguishing equipment is checked regularly at the intervals

specified for the equipment.

• equipment with passed expiry dates is replaced immediately with

equivalent or better equipment.

• the crew and guests are advised of the location and instructions for

fire control equipment, and the location of evacuation routes and

emergency exits.

• the fire control equipment is accessible at all times.

18

Page 21

Action in the event of fire in the engine compartment

• Stop the engine.

• If possible, steer the boat up against the wind.

• All passengers on board must put their life jackets on.

• If necessary, evacuate the passengers.

• If necessary, call for sea rescue.

• Shut off fuel, LPG and main power switches.

• Wait until fully certain that the fire has been extinguished before

opening the engine hatches. Carefully open the engine hatch and

be prepared to use the handheld fire extinguisher if necessary for

post-fire extinguishing.

• Put out possible smouldering fires with water.

Action after the fire has been extinguished

• Open doors and windows for better ventilation.

• Make sure that the fire extinguishing equipment is refilled or

replaced after use.

FUEL SYSTEM

The boat is fitted with a separate fixed fuel system and extra fuel filter on the suction line. The extra fuel filter is a water separating type.

Try to prevent damages on the fuel lines.

See the engine’s instruction manual for care and maintenance of the

engine’s fuel system.

Do not smoke or handle open flames when refuelling.

Remember that it is not allowed to store fuel in spaces not specifically

designed for it. Since there is no ventilated storage space on this boat,

possible spare fuel cans must be stored on deck.

Management

When refuelling a boat with composite decks, (Esthec or FlexiTeek) the

deck should be wetted down with water before refuelling. This ensures

that any fuel spillage will float on the water and won’t penetrate the

decking material.

Water reaching the engine’s injection system can cause rapid corrosion

damage to the precision components in the injection pump components. For this reason, it is vital to check the extra fuel filter regularly for water. Every so often, drain a small quantity of fuel into a suitable container (avoid fuel spillage) and check that there is no condensation water. If there is water in the filter, continue to drain until only

clean fuel appears.

The fuel system on the engine is sensitive to air bubbles in the fuel.

Always fill the tanks well before they are completely empty. If the system has been run dry, it must be bled before the engine can be started

again. See the engine manufacturer’s instruction manual before bleeding the fuel system.

19

Page 22

THE LPG EQUIPMENT

DANGER!

Your Axopar boat has LPG equipment fitted as optional equipment for

the LPG cooker. The system is tested and approved before delivery.

The equipment is fitted with one shutoff valve (connected to the cooker)

and a pressure reduction valve. The space where the gas container is

installed is vented to the outside of the hull.

Before igniting your LPG cooker, make sure that the driver’s seat is com

-

pletely turned in the forward position and is not too close to the cooker.

WARNING!

Never use an open flame when detecting leaks.

Appliances which burn fuel consume oxygen in the cabin and discharge

combustion products into the boat. Ventilation is essential when using

appliances. Open vents as indicated, when using gas appliances. Never

use the cooker or oven for heating the boat. Never cover ventilation

openings. (The boat owner should keep information about locations of

ventilation openings and types in every space where a gas appliance is

installed.)

WARNING!

Never leave the boat unattended when LPG appliances are in use.

Do not smoke or use open flames when a gas container is being

replaced.

• Before opening the valve to the gas container, make sure that the

appliance valves are properly closed

• If an LPG cooker is installed:

• Fire blanket: The fire blanket must be stored in the correct position

CAUTION!

Do not use solutions that contain ammonia.

An LPG container must only be kept in a space designed for it..

Lighting the LPG cooker

01 Open both shut-off valves. Each burner has an ignition cut-out

which cuts the gas supply when the flame is out..

02 Press in the knob for the required burner and turn to max. position

while holding the lighter beside the burner. Keep the knob pressed

in for about 20 seconds after the burner lights. If it is released sooner, the burner may go out. The reason for the burner going out is

that the ignition cut-out might not be hot enough. If the burner does not light, it may be because a valve is closed, the knob is

incorrectly set or the gas container is empty.

20

Page 23

THE LPG INSTALLATION

Valves

Close the valves on the supply pipes and the container valve when no

appliance is in use. Close the valves before refuelling and immediately in

an emergency. Check that the appliance valves are closed before opening the container valve.

Keep the valves of empty cylinders closed and disconnected. Fit the

protective covers, caps or plugs. Store spare or empty containers on

an open deck or in drained areas designed for the purpose. The regulating valve does not last forever. It contains a thin rubber diaphragm

which eventually dries out or swells up. If the diaphragm breaks, gas

can escape from the cylinder with full pressure into the system, and thus

causing a fire. We recommend that the valve is replaced every 10 years.

Inspections

Regularly test the LPG system for leaks by brushing soapy water or a

detergent solution which does not contain ammonia. Check all connections for leakages. If a leakage is detected, close the container valve

and repair the system before using it again. Repairs must be carried out

by a qualified gas fitter.

Ventilation

Appliances which burn fuel consume oxygen and discharge combustion

products into the boat. Good ventilation is essential when an appliance

is in use. Never use the LPG cooker for heating the boat. Never cover

ventilation openings.

Note

• Make sure that you always have free and rapid access to the LPG

system.

• The ambient temperature for LPG systems is –20 - +60°C.

• Do not use areas intended for LPG containers for storing other

equipment.

• Never leave the boat unattended when LPG appliances are in use.

• Do not smoke or use open flames when a container is being

replaced.

• Hoses and pipes in the system must be inspected regularly,

• at least annually. They must be replaced if there is any deterioration

or damage. LPG hoses should be replaced every second year outside

the cabin, and every 3 to 5 years inside.

• Check flue ducts at least once a year. They must be replaced if there

is any deterioration or damage.

• Connection gaskets for the regulating valve must always be checked

when containers are replaced and replaced annually.

21

Page 24

01 Steering with tilt function

02 Control device BB

03 Control device SB

04 Ignition key BB

05 Ignition key SB

06 Emergency stop

07 iPad holder

08 12v DC power outlet

09 Trim tab switch

10 Bow thruster

a) Navigation lights

b) Anchor light

c) Interior lights

d) Deck lights

e) AUX

f) Signal horn

g) Windshield wiper BB

h) Windshield wiper SB

i) Bilge pump

j) AUX

STEERING SYSTEM CABIN / ACSTEERING SYSTEM OPEN / OC / T-TOP

g

j i f h

a c

d

e

b

1

9

3 2

6 5

4

7

10

8

22

Page 25

STEERING SYSTEM

Checking and topping up oil

The safety of the boat depends on effective steering, so the oil level in

the pump should be checked before casting off.

Hydraulic oil is added to the steering system via the filling plug in the

steering wheel pump. The oil level must be approx. 10 mm below the

filler hole. Read the manufacturers manual for oil recommendation for

the steering system. (For steering systems provided by engine manufacturer read the engine manufacturers instructions).

Maintenance of the steering

Check couplings, mountings and bearings.

For maintenance of the steering system: See the manufacturer’s instruction manual.

ENVIRONMENT

CAUTION!

•

When handling environmentally hazardous substances such as fuel, oils,

solvents, grease, bottom coats etc. you should consider the following

matters:

• Always read the instructions for each product carefully and handle

the product with care. Make sure that used packaging, cans and

similar items are discarded in designated collection points. If you are

in any doubt whether the product is hazardous or not, contact the

supplier or vendor of the product.

• The backwash from boats wears down the shoreline and creates

problems for other boats near you. Always adjust your speed to the

situation and the surroundings to avoid unnecessary backwash.

• Always drive your boat at the most economical engine revs possible

in the prevailing conditions to avoid unnecessary emissions and noise.

• Make sure that the engine is properly maintained at regular intervals

so that noise and emission levels are minimised. Read the engine

manufacturers manual carefully.

• As a boat owner you should be aware of local environmental laws,

and respect codes of good practice.

• Never empty the septic tanks or black water tank into waters.

• Familiarise yourself with the international regulations on the

prevention of marine pollution (MARPOL) and comply with these

regulations as far as possible.

23

Page 26

OPER ATION

STARTING THE ENGINE

DANGER!

Risk of carbon monoxide poisoning. It is important to be aware of the

risks with engine exhausts. Under certain conditions (e.g. turbulence

or disadvantageous wind conditions), exhaust can enter the boat. If

this happens you should avoid idling the engines. Should these prob

lems occur under way, do not open hatches and ventilators, as this can

worsen the problems. Instead, a solution to the problem might be to

change the boat’s speed or weight distribution for example.

Read the engine manufacturer’s manual.

01 Set the engine lever in neutral.

02 Turn the ignition on and check the fuel level.

03 Start the engine by turning the ignition key.

04 Check that the gauges for oil pressure and volt meter show nor-

mal values.

05 Run the engine to operating temperature at idling speed. Never

rev up a cold engine.

For further information, read the engine manufacturer’s manual.

BEFORE WEIGHING ANCHOR

WARNING!

• Never climb the bathing ladder when the engine is running.

• Stop the engine before inspecting the steering and propellers.

CAUTION!

• Before leaving harbour it is important to check that the boat and its

equipment are in seaworthy condition.

• All persons on board should wear an appropriate life vest when on

deck. Note that, in some countries, it is a legal requirement to wear a

life vest in accordance with national regulations at all times.

• Always listen to long-term weather forecasts when planning longer

trips.

• Always make sure there is enough fuel and freshwater in the tanks.

• Always keep the engine compartment closed when starting the

engine.

• Check that all items on board are properly stowed and adequately

secured to manage rough sea and wind conditions.

• Make sure that the bathing ladder is raised out of the water before

moving off.

• Make sure that the steering is correctly positioned before starting.

• Always brief your crew on how you plan to leave the jetty.

24

Page 27

For safe navigation under all weather conditions, proper sound signalling equipment in compliance with regulations (COLREG, 1972) must

be carried on board. Make sure that the sound signalling equipment on

your boat is compliant with these regulations.

LEAVING THE JETTY

Before casting off, consider how best to leave the jetty. What is the wind

direction? Using a bow thruster, it is easy to move the bow out and then

engage the propeller.

If your boat has two engines, it is easy to move away from the jetty by

engaging the engine nearer the jetty astern at idling speed and engaging the other engine ahead at idling speed on. The boat will swing out

from the jetty astern. As the bow will move against the jetty, it is important to fend off properly.

With only one engine this can be a little more challenging, especially if

the wind is pressing the boat firmly against the jetty. Then you have to

use a spring to get the stern out. Firmly fend off the bow from the jetty. Take a line from the bow around a bollard or cleat, so that it can be

easily let go. Engage idling speed ahead and turn the rudder so that the

stern glides out from the jetty. When the boat has reached a position,

where it can safely be reversed, release and retrieve the line, quickly centre the rudder and engage astern.

CAUTION!

Gather in all lines and fenders while you are still in sheltered water. A

rope around the propeller can disable a boat.

STABILITY AND BUOYANCY

All weight dispositions (for example installing a fishing tower, radar or

furling mast, engine replacement etc.) can have a significant impact on

the stability, trim, and performance of your boat. The bilge water level should be kept at a minimum. The stability of your boat will be compromised if any weight is placed in a high position. In stormy weather

all hatches, compartments and doors should be kept closed to minimise

the risk of flooding. The stability can be diminished when towing or lifting heavy objects using the davit or jib crane. Breaking waves represent

a serious significant danger to stability.

CAUTION!

To avoid the risk of flooding, always keep sea valves closed when not in

use. (For example the sea valve for the toilet’s flushing water).

DRIVING THE BOAT

Going out in a motor boat involves a responsibility, not just to those on

board but also to others we meet on the water. Showing consideration

for others makes boating comfortable. Everyone has the same right to

be at sea, whatever kind of craft they go afloat in.

The physical laws that apply to a boat are rather different from those

affecting a car, for example. You can influence a boat’s behaviour and

the level of comfort on board primarily by adapting the speed to the

prevailing sea conditions and by the intelligent use of the trim tabs. A

planing boat rides almost level in the water at maximum speed. As the

speed of the boat is reduced the trim angle increases and the bow rises slightly. This is normal, and is a prerequisite for good performance.

25

Page 28

DEAD MAN’S SWITCH

If your boat is equipped with a dead man’s switch, attach its lanyard

to yourself immediately after detaching the mooring lines. For more

detailed instructions, refer to the engine manual. It is very important

that the boat stops if you for some reason fall overboard or stumble on

board, particularly if you are alone. However, remember to detach the

lanyard from your wrist before docking or beaching operations to prevent the engine from stopping unintentionally.

DRIVING AT HIGH SPEED

Although the Axopar 28 boats have passed the CE requirements for

swerve tests at full speed, we do not recommend making sharp turns

at high speed. When exceeding a certain speed limit any hull construction might lose its grip. This might lead to passengers hurtling out of the

boat, especially in single engine configuration.

• The maximum rated engine power is Open / OC 205kw / 275hv,

T-Top 223kw / 300hv

• Do not use the boat if it has an engine with a higher power rating

than indicated on the capacity plate.

• Do not drive the boat at high speed if the engine’s rig angle is negative (bow down).

• Do not drive at full speed on congested waterways or if the visibility

is limited because of weather conditions or waves.

• Reduce your speed and wake as a matter of courtesy, and also for

the safety of yourself and others.

• Observe and obey speed limits and prohibitions associated with a

swell.

• Follow the rules of navigation and the requirements of COLREG

(Convention on the International Regulations for Preventing Collisions at Sea).

• Always make sure that you have the space needed for avoiding collisions and coming to a halt and for evasive manoeuvres.

• Always use a dead man’s switch if available.

• Reduce speed in high seas for increased comfort and safety.

• Learn your boat’s speed potential. Utilise this knowledge for eco-

nomical and safe cruising.

• Avoid using high speed along with large rudder movements when

going astern, because that places large strains on the rudder and

steering mechanism.

• Avoid sudden steering manoeuvres at high speeds.

• Avoid staying in the bow area when driving at high speeds.

DANGER!

A rotating propeller can be lethal for a swimmer or person who has

fallen overboard. Use the dead man’s switch and shut down the engine

when somebody climbs on board out of the water.

You should avoid sudden changes in direction of travel at high speed.

Let the boat come to a stop, and the engine rev down before shifting

between forward and reverse. Otherwise excessive strain is put on the

engine, which could cause the engine to stop. In the worst case, sea

water may enter the engine.

A right-handed propeller rotates clockwise and a left-handed propeller

anti-clockwise, seen from the stern. The rotation of the propeller is critical for steering the boat. The right handed propeller pushes the stern

of the boat to starboard when the engine is engaged ahead and to port

when it is going astern. The direction of rotation of the propeller has

a major impact on the turning radius. A right handed propeller gives a

smaller turning radius to port than to starboard. This is called the propeller’s paddlewheel effect.

Your propellers have considerable propulsion power that provides powerful acceleration. Take this into consideration to avoid dangerous situ-

26

Page 29

ations arising from this.

Take the visibility from the helming position into consideration. Among

other things the following factors can considerably reduce visibility:

• Gear trim angle

• Trim tab angle

• Load and load positioning

• Speed

• Rapid acceleration

• Changeover from displacement speed to planing

• Sea conditions

• Rain and thunderstorms

• Darkness and fog

• Inner lighting when under way in the dark

• Position of curtains

• People and equipment that can block the helmsmen’s view.

The International Regulations for Preventing Collisions at Sea (COLREG)

demand that a proper lookout is kept at all times, and the “right of

way “rule must be observed. It is essential that these rules are followed.

STAYING ON DECK

Staying on the deck is not allowed for safety reasons in speeds exceeding 30 knots. If the sun deck cushions of fore deck table are in place the

observe the maximum speed of 15 knots to avoid the cushions or table

detaching at speed or in high waves.

USING THE TRIM TABS

WARNING!

Make only small adjustments at a time. Holding down the button for the

trim tab for any length of time can result in partial loss of control of the

boat.

An Axopar boat does not need trim tabs to get up on the plane or to

give good performance. Trim tabs are, however, a very useful aid, if used

correctly. There are two situations in particular where trim tabs should

be used. These are when it is desirable to trim the bow down in a rising sea and at speeds between going up planing and cruising speed, as

well as when running with a strong beam wind.

A planing boat always leans into a strong beam wind. This reduces the

boat’s sea-keeping qualities, which is why listing to one side should be

eliminated as far as possible. Lowering the trim tab on the windward

side brings the boat back into normal attitude.

For trimming the bow down, both trim tabs are used in parallel. Begin

by retracting both trim tabs completely, then lower both of them a little at a time, so that you retain complete control over how the boat is

affected.

When running with a following sea, both trim tabs should always be fully raised. The reason for this is that boats have a tendency

to “dive” in a strong following sea, which can result in uncontrollable

slowing. Therefore you should run the boat with a high bow angle in

a following sea.

27

Page 30

DRIVING IN ROUGH SEAS

Never go out in rough seas, if you are uncertain whether the boat and

those on board can cope. Follow these simple rules:

• Be well prepared.

• Remember to secure loose equipment.

• Always have a sea-anchor and other emergency equipment easily

accessible.

• Avoid breaking seas that can appear close to land and over shallows.

• If there is significant waves, always reduce speed to guarantee the

safety of the persons on board.

• Use the trim tab to trim the bow down to reduce hull slamming in a

head sea.

In a head sea

• Adjust speed to suit the size of the waves.

• Adjust the trim angle to the size of the waves. Avoid taking seas

beam on.

In a following sea

• Remember to keep the bow high in a following sea. Avoid crash-

ing through waves, maintain low speed. If necessary, deploy the sea

anchor to reduce speed.

• Planing boats can be particularly exposed in rough following seas.

The stern of the boat rises and the rudder does not answer, so the

boat broaches while the bow cuts down into the sea.

CAUTION!

Even a non-slip moulding can be slippery to walk on when the deck is

wet.

MANOEUVRING IN NARROW CHANNELS

When manoeuvring the boat in narrow channels the engine speed

should be kept as low as possible so that manoeuvres are calm and

steady. In difficult wind and current conditions, more revs might be necessary to make full use of the power of the engine. In these conditions,

it is important that manoeuvres are made quickly and precisely to prevent the boat from drifting into trouble for example.

A good rule, before starting a manoeuvre under difficult conditions, is to

think through the different situations which could arise. Pay attention to

the wind and current conditions and decide in advance which manoeuvres you will make. It is also important to brief crew members on what

they should do in different situations.

Always keep in mind that the stability of the boat may be reduced when

towing.

DOCKING

Always brief your crew how you are planning to dock.

Fenders and at least one mooring line fore and aft must be in place

before approaching the jetty.

It is always easiest to dock against the wind. Try to hold the bow exactly into the wind and maintain sufficient speed for the boat to answer

the rudder. If the bow is blown off in one direction, back out and repeat

the manoeuvre. Bring the bow up to the jetty, and make sure you get

a line ashore quickly.

Docking with a beam wind is a little more difficult. Do not steer parallel to the jetty letting the boat blow in as there is always a risk of the

bow being blown off towards other boats or the jetty. Instead, try to

manoeuvre the boat so that the wind comes directly from astern. Then

the boat can be manoeuvred straight ahead since the wind helps hold

28

Page 31

the boat on a straight course. It is good to have someone on the foredeck that can go ashore and quickly turn the bow in the desired direction after the boat has stopped completely.

Try to always avoid sharp movements of the throttle, since idling speed

in ahead and astern is generally adequate. Sharp movements of the

throttle can lead to panic manoeuvres.

BEFORE ANCHORING

01 Check the chart to see if anchoring is permitted in the area.

02 Listen to the weather forecast for the area and take note of the

expected wind conditions.

03 Switch on the echo sounder.

04 Study the seabed conditions and make sure that there is good

holding ground.

05 Check that the safety chain has been released from the anchor.

06 Wait until you have reached the intended anchoring point before

lowering the anchor.

07 Let out the anchor line equal to at least three times the depth of

the water.

08 Put the engine in astern to check that the anchor has taken hold.

(Only when bow anchoring)

09 Note your position on the GPS. Regularly check that the boat has

not moved from its position.

10 Set the echo sounder to “Anchor Watch”

ANCHORING, MOORING AND TOWING

Fastening points are indicated in the illustration on page 30. Points (or

cleats) are located both at the stern, midship and bow. When anchoring or towing, the forward force is 28.5kN

When mooring the forward force is 23.3kN

When mooring the rearward force is 19,8kN

CAUTION!

The tensile strength of the lines or chains should normally not exceed

the strength of the fastening point in question.

When towing another boat or being towed, always drive slowly. If the

boat you are towing is of the displacement hull type, never exceed its

hull speed

Always attach the tow line so that it can be detached under load. It is

the owner’s/operator’s responsibility to ensure that mooring lines, tow

ing lines, anchor chains, anchor lines and anchors are adequate for the

vessel’s intended use.

29

Page 32

AFTER RUNNING

THE ENGINE(S)

To counteract decarburising and heat stress after the engine(s) has/have

been run, let it/them idle in neutral for a couple of minutes. This is particularly important after running at high revs.

• Stop the engine(s) by turning the ignition key to position S.

MAINTENANCE

• The boat requires a certain amount of maintenance. This is especially

relevant for external parts which are exposed to sun and salt water.

A proper maintenance of your boat comprises the following:

• Regularly wash the boat with freshwater.

• If the boat is used the whole year, the hull should be polished

approximately every fourth month.

• Polish the stainless and chromed parts with Autosol or similar

chrome polish.

• Aluminium parts are cleaned with freshwater to which soap solution

is added if necessary.

• Rinse the cover in freshwater. Allow to dry thoroughly before folding away.

• A teak deck requires maintenance. It is recommended to clean a

composite deck using a soft brush and a mild soap solution. Over

time, the teak deck takes on a satin grey appearance.

• A teak deck requires maintenance. It is recommended to clean a

composite deck using a soft brush and a mild soap solution. Over

time, the teak deck takes on a satin grey appearance.

• Avoid using aggressive cleaners.

WOODEN INTERIOR

Interior details of the boat such as locker doors and drawer fronts,

wooden strips etc. are in oiled walnut. Clean them with a damp cloth

and a little soapy water. Treat the wooden surfaces again every year to

protect the wood.

Plastic and painted surfaces are cleaned by wetting the surface evenly

with water before the actual cleaning. Regular stains are removed with

a brush and a lightly diluted cleaner. Grease is removed with a brush/

sponge and window cleaner. Clean the surface afterwards with sponge

and water. Wipe dry with a piece of cloth.

The interior fabrics are washed according to separate washing instructions (marking) or as follows: Wash in 40°C with light spin-drying and

hang to drip dry. The material may shrink slightly. If you want to avoid

this, take the fabrics to a dry cleaner.

The tracks of sliding doors and hatches shall be cleaned regularly and

lubricated if necessary. Do not lubricate sliding surfaces. Lubricate handles and locks with regular lock lubricant.

Cleaning

Let the cover soak for at least 24 hours.

The cover should be thoroughly cleaned twice a year. You should then

wash the in- and outside with a sponge or soft brush. Use mild soapy

water and plenty of water max. 30 degrees Celsius. Rinse thoroughly

with freshwater. We recommend mixing 12% vinegar in the final rinsing to neutralize the soap residues. Finally hang the cover to drip dry.

CAUTION!

Never use high pressure washers or chemical cleaners.

30

Page 33

COVER

New covers may leak initially, since the seams need to swell.

To prevent quick deterioration of the cover, it should be tightly secured

in a folded-up position to prevent flapping.

CAUTION!

Hang to dry. Never use a drying cabinet or iron to speed up drying.

Check that the cover is completely dry before stowing. A moist cover can

cause mould damage.

Winter store the cover in dry indoor conditions.

The cover must not be stored in the boat..

PREVENTING FROST DAMAGE

• The bilge pump system is fitted with a water lock on the hose.

Detach the hose and fully drain the water from the water lock and

run the pumps dry. Otherwise the pumps can freeze and break.

• Unscrew the frost plug on the underside of the shower fittings. If

there is no frost plug, unscrew the shower hose.

• Drain the water tank and all other components containing water in

order to avoid frost damage.

• Run the freshwater pump dry to drain out all the water.

• Make sure that no water remains in the boat under any circumstanc-

es. Leave the hatches in the cabin partially open.

31

Page 34

Lifting

Position the lifting straps as shown in the picture below. When the

straps have been attached to the lifting hook on the crane they should

be secured with lines to the bow and stern cleats to prevent the lifting

straps from sliding.

LIFTING AND TRANSPORTING OPEN / OC / T-TOP

Transporting

Always use an authorized boat transport company for transporting the

boat on land. Make sure the company has full insurance cover, in case

of any damages.

32

Page 35

ACTIONS BEFORE WINTER STORAGE

01 Wash the hull and bottom immediately after lifting the vessel out

of the water.

02 Leave all lockers, drawers, cabin and wardrobe doors ajar.

03 Wash all parts inside, also under the floorboards.

04 Carpets and cushions should preferably be stored indoors in a dry

place. If this is not possible, make sure that the cushions are dry and

position them on their side. Remove the carpets.

05 Be very thorough about having good ventilation in the boat.

06 If the batteries are being left aboard, make sure they are fully

charged, otherwise the batteries can freeze and crack.

CAUTION!

The lifting beam should be exactly the same width as the boat.

Always take great precautions near and around the boat when lifting.

Note the location of the log transducer to avoid damaging it. Protect the

hull sides well to avoid damages. The position of the slings may need to

be adjusted depending on how the boat is loaded.

ACTION BEFORE LAUNCHING

01 Remove the tarpaulin in good time before launching.

02 Wash the hull with a regular shampoo and soft brush.

03 Wax the hull if necessary. Use a standard boat wax.

04 If there are small scratches on the hull, or if some of the surface

gelcoat has lost its shine, use a rubbing compound on these areas before polishing.

05 Paint the bottom with antifouling paint.

06 If the batteries have been removed, put them back and check the

electrolyte level in the cells. Check the condition of the batteries.

07 Check all cables, clamps, engine mountings and other fastenings.

08 Check the steering before launching.

09 Check the instrumentation.

10 Close all water drain plugs.

11 Check that the seacocks are in order and tight, check for any frost

damage.

12 Check all pipes, hoses and cocks.

13 Make a note of any frost damage.

33

Page 36

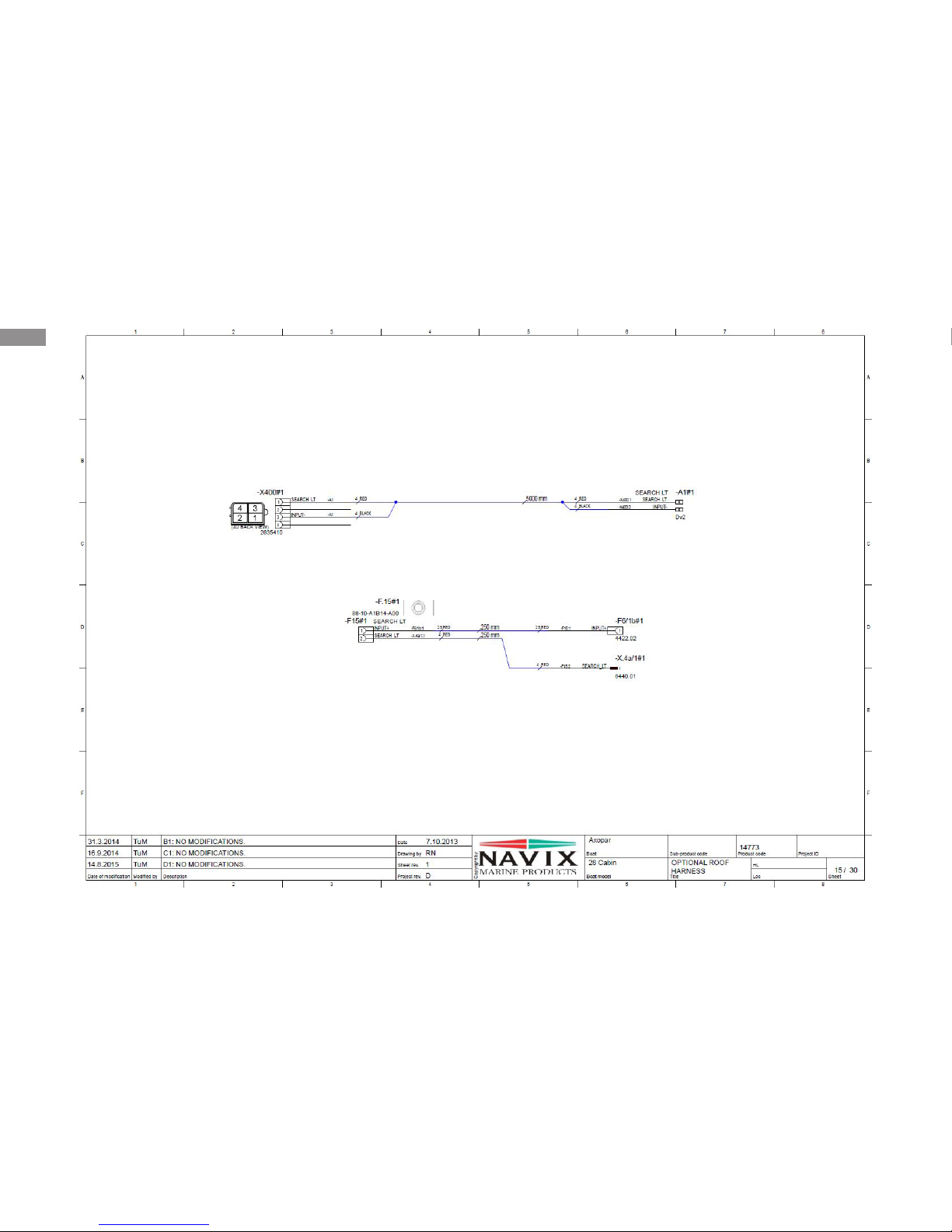

APPENDIX 1: FUSE PANEL

F1 Navigation lights

F2 Bilge pump

F3 Interior lights

F4 Windscreen wipers

F5 AUX

F6 Windscreen washer

F7 Horn

F8 12v DC power outlet

F9 Chart plotter

F10 VHF radio

F11 Heater control

F12 Deck lights

F13 Refrigerator

F14 Radio

F15 Search light

F16 Toilet light

F17 Radar

F18 Echo

F19 NMA 2000

F20 Autopilot

F21 Waste tank sensor control unit

F22-25 Spare

F26 Macerator (septic)

F27 Fresh water pump

12v DC power outlet

34

Page 37

APPENDIX 2: MAIN POWER SWITCH

A) SB engine

B) BB engine

C) Service

D) Aux

E) Bow thruster fuse

F1 Main fuse

F2 Main fuse

F3 Main fuse

F4 Automatic bilge pump

F5 Webasto heater

F6 Radio memory

F7 Trim tabs

F8 Bilge pump manual control

F9 Amplifier

A B C

E

D

35

Page 38

36

Page 39

37

Page 40

38

Page 41

39

Page 42

40

Page 43

41

Page 44

42

Page 45

43

Page 46

44

Page 47

45

Page 48

46

Page 49

47

Page 50

48

Page 51

49

Page 52

50

Page 53

51

Page 54

52

Page 55

53

Page 56

54

Page 57

55

Page 58

56

Page 59

57

Page 60

58

Page 61

59

Page 62

60

Page 63

61

Page 64

62

Page 65

63

Page 66

64

Page 67

65

Page 68

AXOPAR BOATS OY

WWW.AXOPAR.FI

WWW.FACEBOOK.COM/AXOPAR

Loading...

Loading...