TS-250M 250mm

Basic Table Saw

Code 508211

AXMINSTER

SERIES

Hobby

Hole assembly instructions including leg

stand extension table and sliding table kits

508213

Leg Stand

508214

Sliding Table Kit

508212

R/H Extension Table

717540

Table Saw and Accessories

Product Kit Codes

717540: TS-250M Table Saw and Accessories

508211: TS-250M Basic Saw

508213: TS-250M Leg Stand

508212: TS-250M R/H Extension Table Kit

508214: TS-250M Sliding Table Kit

508211

Basic Saw

Index of Contents

2

Declaration of Conformity

Copied from CE Certificate

The undersigned, Huibo Wang

Authorised by Laizhou Chunlin Machinery Co., Ltd

No. 269 Baoshi Road Wenfeng Street Laizhou City,

Shandong 261400 P.R. China.

Model Number MJ10-SB250

Circular Saw Bench

Manufactured by Laizhou Chunlin Machinery Co., Ltd.

is in compliance with the standards determined in

the following Council Directive.

EN 55014-1:2006+A1+A2

EN 61000-3-2 : 2006+A1+A2

EN 61000-3-3 : 2008

EN 55014-2 : 1997+A1+A2

Warning

The symbols below advise that you follow

the correct safety procedures when using

this machine.

Fully read manual

and safety instructions

before use

Eye protection

should be worn

Ear protection

should be worn

HAZARD

Motor gets hot

Dust mask

should be worn

Index of Contents 02

Declaration of Conformity 02

What’s Included 03-04

Optional Accessories 05-06

General Instructions for 230V Machines 07-08

Specific Instructions/Precaution for the Saw Table 08

Specification 09

Assembly 09-10-11-12-13-14-15-16-17-18

Illustration and Parts Description 19-20-21

Setup and Adjustments 22-23-24

Operating Instructions 25-26

Changing the Saw Blade 26-27

Parts Breakdow/List 28-29-30-31

Wiring Diagram 31

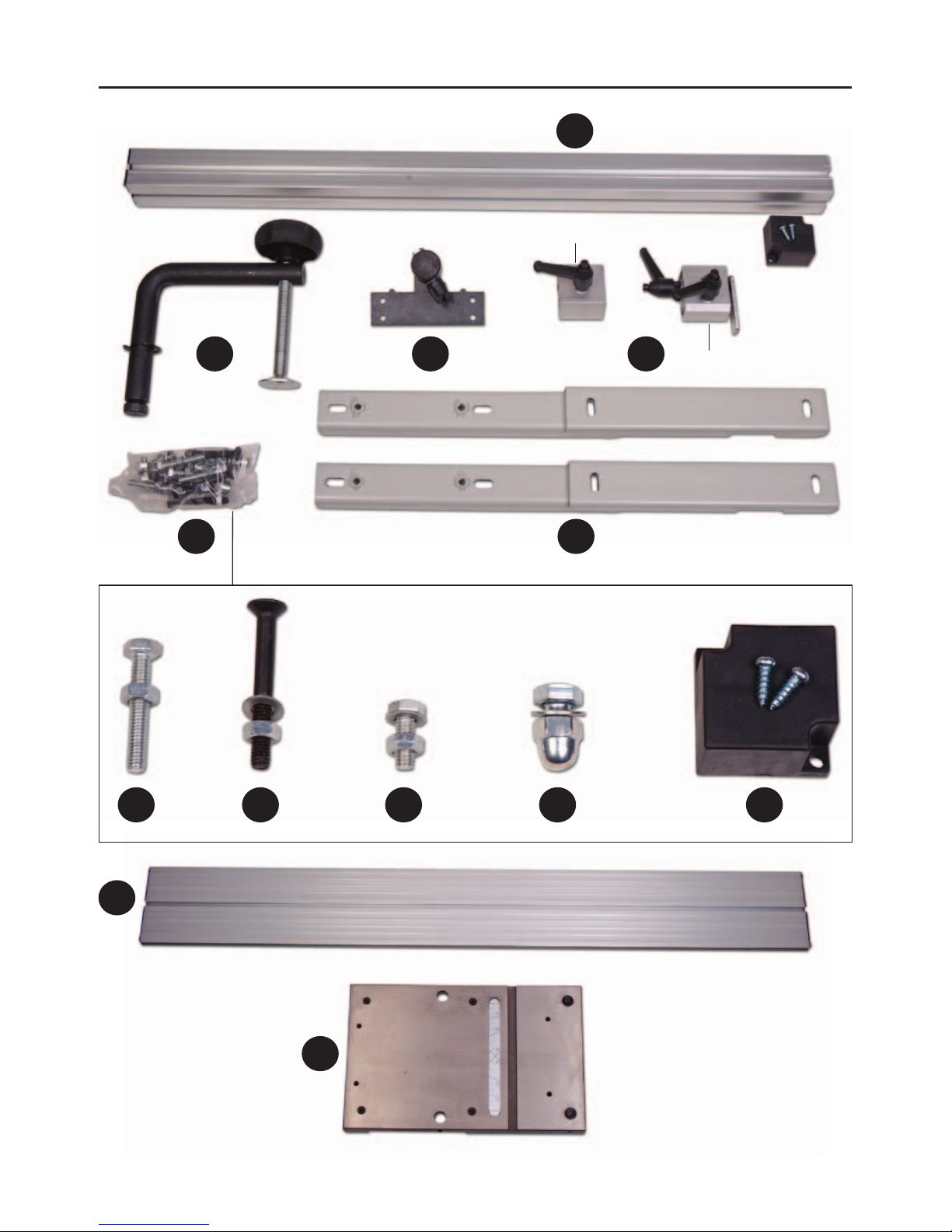

What’s Included

3

Quantity Item Part Model Number

MJ10-SB250

(Basic Table Saw Assembly) (Kit Code: 508211)

1 No Basic Table Saw A

1 No Saw Guard with Flexible Hose B

1 No Dust Extraction Moulding

with four Phillips Screws C

1 No Mitre Fence Assembly D

1 No (Short) Rip Fence and Clamping Assembly E

1 No (Short) Fence Rail with Scale F

1 No Bag Containing G

2 No Screwdrivers G1

1No Hose Clip G2

2 No 10-12mm Spanners

1 No 13-15mm Spanner G3

1 No 17-19mm Spanner

1 No 3mm and 4mm Hex Keys G4

1 No Push Stick G5

2 No Operating Wheel Handles G6

(Optional Stand Assembly) (Kit Code: 508213)

4 No Leg A” Frames H

4 No Long Struts I

4No Short Struts J

4 No Rubber Feet K

1 No Bag Containing L

32 No M8x16mm Coach Bolts with Nuts L1

4 No M8x16mm Bolts with Large Washer and Nut L2

(Optional R/H Extension Table Assembly) (Kit Code: 508212)

1 No Extension Table M

2 No (Long) Front and Rear Fence and Table

Extension Rail arms N

1 No Bag Containing O

6 No M6x25mm Panhead Phillips Screws O1

6 No M6x25mm Panhead Phillips Screws with Square Nuts O2

6 No M6x16mm Panhead Phillips Screws with Square Nuts O3

3 No M6x16mm Bolt Washer and Nut O4

1 No 30mm Hose Support Bracket P

1 No (Long) Rip Fence Assembly Q

(Optional Sliding Table Assembly) (Kit Code: 508214)

1 No Angle Fence R

1 No Angle Fence End Block with two Phillips screws R1

1 No Work Clamp Assembly S

1 No Flip Over Stop T

1 No Work Clamp and Connecting Blocks U

2 No Sliding Carriage Support Arms V

1 No Bag Containing W

4 No M6x35mm Bolt and nut W1

4 No M6x45mm Countersunk Head and Washer/Nut W2

4 No M6x16mm Bolt and Washer/Nut W3

2 No M8x10mm Bolt and Domed Nut (Carriage Arm Stop) W4

1 No Carriage Arm X

1 No Sliding Carriage Table Y

What’s Included

4

A

B

C

D

F

G

G2

G1

G3

G4

G6

E

G5

Having unpacked your saw and its accessories please dispose of any unwanted packaging

properly. The packaging is biodegradable.

Basic Table Saw (Code: 508211)

M

P

O

Q

N

O1 O2 O3 O4

Optional Accessories

H

I

J

K

L

L1 L2

Stand Assembly (Kit code: 508213)

R/H Extension Table Assembly (Kit code: 508212)

5

66

Optional Accessories

R

S U

VW

W1 W2 W3 W4 R1

X

Y

T

Work clamp block

Connecting block

Sliding Table Assembly (Kit code: 508214)

7

General Instructions for 230V Machines

7

Good Working Practices/Safety

Primary Precautions

Work Place/Environment

The following suggestions will enable you to observe

good working practices, keep yourself and fellow

workers safe and maintain your tools and equipment

in good working order.

WARNING! KEEP TOOLS AND

EQUIPMENT OUT OF THE

REACH OF YOUNG CHILDREN

UNDER NO CIRCUMSTANCES

SHOULD CHILDREN BE ALLOWED

IN WORK AREAS.

These machine are supplied with a moulded 13

Amp. Plug and 3 core power cable. Before using the

machine inspect the cable and the plug to make sure

that neither are damaged. If any damage is visible

have the tool inspected/repaired by a suitably

qualified person. If it is necessary to replace the plug,

it is preferable to use an ‘unbreakable’ type that will

resist damage on site. Only use a 13 Amp plug and

make sure the cable clamp is tightened securely. Fuse

as required. If extension leads are to be used, carry

out the same safety checks on them and ensure that

they are correctly rated to safely supply the current

that is required for your machine.

Make sure when the machine is placed that it

sits firmly on the floor, that it does not rock and is

sufficiently clear of adjacent obstacles so that cutting

operations will not be impeded. Check you have

adequate clearance both in front of and behind the

machine when cutting long stuff. If you are liable to

be processing unwieldy or awkward work pieces, it is

suggested that you consider fastening the machine

down to the floor.

The machine is not designed for sub-aqua operation,

do not use when or where it is liable to get wet. If the

machine is set up in the open, and it starts to rain

(unusual though this would be in U.K.), cover it up or

move it into the dry. If the machine has got wet; dry

it off as soon as possible with a cloth or paper towel.

Do not use 230V a.c. powered machines anywhere

within a site area that is flooded or puddled and do

not trail extension cables across wet areas. Keep the

machines clean; it will enable you to more easily see

any damage that may have occurred. Clean the

machine with a damp soapy cloth if needs be, do

not use any solvents or cleaners, as these may cause

damage to any plastic parts or to the electrical

components. Keep the work area as uncluttered as is

practical, this includes personnel as well as material.

It is good practice to leave the machine unplugged

until work is about to commence, also make sure

to unplug the machine when it is not in use or

unattended. Always disconnect by pulling on the

plug body and not the cable. Once you are ready to

commence work, remove all tools used in the setting

operations (if any) and place safely out of the way.

Re-connect the machine.

Carry out a final “tightness” check e.g. guide fence,

table tilt, etc., check that the ‘cutting path’ (in this

case the path that the work piece will travel) is

unobstructed.

Make sure you are comfortable before you start

work; balanced, not reaching etc.

If the work you are carrying out is liable to

generate flying grit, dust or chips wear the

appropriate safety clothing, goggles, gloves, masks

etc. If the work operation appears to be excessively

noisy, wear ear-defenders. If you wear your hair in a

long style, wearing a cap, safety helmet, hair net, even

a sweatband, will minimise the possibility of your hair

being caught up in the rotating parts of the tool.

Likewise, consideration should be given to the

removal of rings and wristwatches, if these are liable

to be a ‘snag’ hazard. Consideration should also be

given to nonslip footwear, etc.

Do not work with cutting tools of any description

if you are tired, your attention is wandering or you

are being subjected to distraction. A deep cut, a lost

fingertip or worse; is not worth it!

Do not use this machine within the designated safety

areas of flammable liquid stores or in areas where

there may be volatile gases. There are very expensive,

very specialised machines for working in these areas,

THIS IS NOT ONE OF THEM.

General Instructions for 230V Machines

8

Check that blades are the correct type and size, are

undamaged and are kept clean and sharp, this will

maintain their operating performance and lessen the

loading on the machine.

Above all, OBSERVE…. make sure you know what is

happening around you and USE YOUR COMMON

SENSE.

Specific Instructions/Precaution for the Saw Table

Make sure the saw blade is the correct type for the

job in hand. Do not force the saw, if the saw begins

to ‘stall’ you are ‘forcing the cut’ or over working the

saw.

Ensure that the saw blade is clean and sharp.

Resin build up on the blades will increase the friction

of the saw passing through the timber, and cause

over heating of the blade, blunt teeth will work

harder tearing the fibre of the timber as opposed to

shearing it, also with subsequent overheating. Both

faults unnecessarily load the machine beyond

normal usage, and shorten its longevity.

Do not use blades that are deformed in any way.

Do not remove the blade guard. The design of the

riving knife on the machine will not allow for slotting

or ‘blind’ grooving, so there is no reason to remove

the guard.

Do not remove the riving knife.

Do not use any blades that cut a smaller kerf than

the riving knife thickness. Make sure the riving knife

is correctly adjusted to the blade and is securely

fastened. If the table insert becomes damaged or

broken, and will not support the timber ‘up close’ to

the blade, replace it.

Do not start the saw with the work piece touching

the blade.

Do not commence sawing until the blade

has run up to full speed.

After switching off, never try to slow the saw down

more quickly by applying side pressure (with a piece

of wood?) to the blade. Apply the old joiner’s adage

of never getting hands within one handbreadth of

the blade. Leave the machine disconnected from the

mains supply until you are about to commence work.

Always disconnect the machine if you are leaving it

unattended.

Never leave the vicinity of the machine

unless the blade has come to a complete stop.

Do not attempt to carry out any maintenance,

corrective work, setting up etc., unless the machine

is disconnected from the mains supply. If any tools

have been used during setting up procedures, make

sure they are removed from the machine and stowed

safely away.

Do not attempt to carry out cross cutting operations

‘freehand’, always use the mitre fence for small

stuff and the sliding carriage for larger work pieces.

Unless you are an experienced machine operator, do

not attempt to ‘rip’ freehand, always use the guiding

facility of the rip fence.

It is perfectly acceptable to support guide and feed

the timber with your hands whilst ripping stuff of

some length, however, as you approach the blade

ensure that the push stick is to hand, and you use it.

Remember the emphasis of the ‘push’ should be

between the blade and the fence and close to the

fence. Use your free hand to support and guide the

material on the offside of the saw blade and at least

100mm away from it. If the timber does not extend

to at least 100mm to the offside of the saw blade,

the material possibly? does not need guiding or

supporting.

Check (especially on site), that there are no foreign

objects e.g. old nails, screws, small stones etc

embedded in the material you are about to cut. If

necessary take a wire brush to the timber before

working.

Specification

9

Code 508211

Model TS-250M Basic

Rating Hobby

Power 1.5kW 230V 1ph

Blade Dia/Bore 250mm/30mm

Blade Tilt 0° to 45°

Max Depth of Cut @ 45˚ 60mm

Max Depth of Cut @ 90˚ 80mm

Max Width of Cut with Fence 160mm standard, 760mm with R/H Table Kit

Table Size 635 x 430mm

Table Height 360mm

Dust Extraction Outlet 100mm

Min Extraction Airflow Required 750m³/hr

Overall L x W x H 660 x 480 x 400mm

Weight 80kg

Assembly

Locate and identify the four leg “A” frames (H), the

long struts (I) and the short struts (J) for the stand,

and the packet containing 32 M8 x 16mm coach

bolts, washers and nuts,(L1).

Using the M8 x 10mm coach bolts, nuts and

washers bolt together two ‘A’ frames using two

legs (H) one long strut (I) in the middle and one

short strut (J) at the top. ‘finger tighten’ the nuts

only at this time, see fig 1.

When the two ‘A’ frames have been assembled,

select one, turn it upside down on a flat surface

and loosely bolt the ‘short struts’ (J) and long struts

(I) in place, see fig 2. Attach the other “A’ frame

and loosely tighten.

When all the components are

assembled, turn the stand over

and place the four rubber

feet (K) to the ends of the ‘A’

frames. (See fig 3) Upright the

frame and stand on the floor,

see fig 4.

NOTE: GO ROUND THE

FRAME AND FINGER

TIGHTEN THE NUTS AT

THIS POINT!

Optional Stand Assembly (Kit Code 508213)

Fig 01

Fig 02

Fig 04

Fig 03

I

J

I

K

J

H

L1

Assembly

10

Mounting the Saw Bench to the Stand

1). With assistance, place the Saw

Bench (A) onto the stand. Align the four

mounting holes at the base of the Saw

Bench with the four mounting holes at

each corner of the stand. Using four M8

x 16mm hex bolts, large washers & nuts (L2) secure

the Saw Bench to the stand, see figs 05-06-07.

Fig 05

Fig 06-07

L2

2). Now tighten all the nuts on the stand assembly.

Optional Sliding Carriage Table (Kit Code 508214)

1). Position one carriage support arm (V) to the

underside of the cast iron saw bench (A), line up

the clearance holes (a) in the support arm with the

pre-drilled holes in the table, using four M6 x 45mm

countersink heads and nuts, (W2) secure the support

arm to the table using a 4mm Hex key (G4), see figs

08-09-10. Repeat for the remaining arm.

Fig 08

Fig 09-10

a

W2

V

Pre-drilled holes

2). Place an M6x16mm Hex bolt (W3) in each of the

four clearance holes on both support arms (V) and

loosely screw on an M6 nut and washer, see fig 11.

3). Locate the four M6x30mm Hex Bolts (W1) and

lightly screw each bolt into the threaded holes to

the underside of the carriage arm (X), see fig 12.

V

Assembly

11

Fig 11

Fig 12

NOTE: Only screw on the bolts just enough so they

are just below the surface of the threaded nut, see

fig 11.

4). Line up the Hex bolts (W3) with the ‘T’ slots in the

carriage arm (X) and slide on the carriage arm, see

fig 13.

Fig 13

w3

w3

w1

Threaded nuts

‘T’ Slot

V

X

5). Locate the sliding carriage table (Y) and slide it

onto the carriage arm (X), see fig 14.

Make sure the wheels on carriage table engages

correctly onto the carriage arm rails, see fig 15.

Fig 14-15

Carriage arm rail

Y

6). Slide the carriage table (Y ) to one end of the saw

table (A), place a Level across both tables and adjust

the M6 Hex bolts (W1) until the sliding carriage table

(Y) is level with the table saw table (A), see fig 16.

Repeat for the opposite side. When both tables are

level tighten the four M6 Hex nuts (W3) to secure the

sliding arm (X) in position.

Fig 16

Continues Over...

Assembly

12

7). Locate the two carriage arm stops (W4), loosen

the domed nuts and slide the bolt heads into each

end of the carriage arms ‘T’ slot. Tighten the nuts to

lock the stop in place, see fig 17.

Fig 17

W4

Angle Fence

1). Put to hand the work clamp block (U), and slide it

into the T-slot on the angle fence (R). Locate the

connecting block (U) and slide it onto the angle fence

as before, see figs 18-19. Slide the T-bolt on the base

of the connecting block (U) into the T-slot on the

sliding carriage table (Y ), see figs 20-21. Locate the

plastic block and Phillips screws (R1), secure it to the

end of the angle fence (R), see fig 22.

Fig 18-19

R

U

U

Work clamp block

Connecting block

Fig 20-21

Fig 22

The picture above shows the angle fence (R)

removed from the carriage table for clarity.

Y

‘T’ Slot

‘T’ Bolt

‘T’ Bolt

Connecting block

R1

2). Locate the work clamp (S), slot the work clamp

into the 20mm hole in the work clamp block (U),

secure in position with the lift and shift handle, see

fig 23. To set the angle fence at 90˚, push the angle

fence (R) up against the stop, see fig 24.

3). Make sure the plastic block on the end is just

missing the blade. Using a 90˚ square check that

the blade is at 90˚ to the angle fence (R), see fig 25.

When correct tighten the lift and shift handle on the

Lift and shift handle

Assembly

13

Fig 23

S

U

Lift and shift handle

Fig 24

Angle fence stop

connecting block (U), see fig 21. If the angle fence (R)

is not set to 90˚, undo the grub screw to the side of

the sliding carriage table (Y ), using a flat screwdriver

turn the eccentric bush until the angle is correct, see

figs 26-27.

4).To set the angle fence (R) to angles between 45˚

and 90˚ loosen the three lift and shift handles on

the connecting and work clamp blocks (U) and set

the fence to the required angle on the scale on the

Fig 25

Fig 26-27

Grub locking screw

Eccentric bush

carriage table (Y ), see figs 28-29. Tighten the three

lift & shift handles to lock the angle fence in position.

Note: The fence can also be used at the rear of the

sliding carriage table if you prefer to push the

timber against the fence.

Fig 28-29

Continues Over...

Carriage table scale

90˚ Square

Assembly

14

5). Locate the flip over stop (T) and slide it into the

T-slot on top of the angle fence (R), see fig 30. Tighten

the butterfly knob.

Fig 30

Locate the Mite fence assembly (D) and slide it into

one of the saw tables “T” slots, see fig 31.

Mitre Fence

Fig 31

T

R

D

Operating Wheel Handles

Locate the two operating wheel handles (G6) and,

using the supplied 3mm Hex key (G4), secure one to

the height mechanism shaft to the front of the saw

by undoing the grub screw on the operating wheel

handle (G6) and sliding it onto the shaft, making sure

the grub screw is in line with machined slot (a), in the

shaft. Retighten the grub screw. Repeat for the tilt

mechanism to the right hand side of the saw, see figs

32-33.

Fig 32-33

G6

a

Tilt mechanism shaft

Height mechanism shaft

Saw Guard

Fig 34

Threaded pin

Lift and shift handle

Find the saw guard (B), remove the flexible hose,

remove the lift and shift handle and threaded pin

from the guard and place safely aside. Slot the saw

guard over the riving knife and line up the pre-drilled

holes, replace the threaded pin and handle then

lightly tighten (DO NOT OVERTIGHTEN), see fig 34.

Assembly

15

Optional Extension Table (Kit Code 508212)

1). Put to hand six M6 x 25mm Phillip head screws

with square nuts (O2), remove the nuts and place

the screws into the three holes to the front and rear

of the main saw table (A). Replace the nuts. (Note:

Leave a gap between the base of the table and

nut), see figs 35-36.

NOTE: KIT CODE 508211 COMES WITH

THE FENCE SUPPORTING ARM ONLY

AND DOES NOT INCLUDE THE REAR

SUPPORTING ARM!

Fig 35-36

2). Locate the two extension rail support arms (N).

Remove the plastic cover to the left hand side of the

support arm with the scale, see fig 37. Line up the ‘T”

slot to the end of the rail arm and slot it over the M6

nuts, see fig 38. Push the extension rail so it is flush

with the end of saw table (A) and lightly secure the

extension support arm using a Phillips screwdriver,

see fig 39. Replace the plastic cover you removed

earlier, see fig 40. Repeat for the other extension

support arm.

Fig 37-38

Fig 39-40

O2

A

N

Plastic cover

‘T’ Slot

Continues Over...

N

Plastic cover

Assembly

16

3). Put to hand six M6 x 16mm Phillip head screws

with square nuts (O3), remove the nuts and place

safely aside. Slot the screws into each of the 6 holes

on the extention table lip (M), replace the square

nuts, see figs 41-42. (Note: Leave a gap between

the base of the extension table lip and nut)

Fig 41-42

O3

M

M6x16mm Phillips screw

4). Remove the plastic covers from the ends of the

two extension table support arms (N), see fig 43.

Offer up the M6 nuts to the support arms T-slots

and slide on the extension table (M) into the support

arms (N). Push the extension table (M) until it is flush

up against the saw table (A), place six Phillips screws

(O1) into the captive nut locations, place a level

between both tables, adjust the screws (O1) until

both tables are level. Tighten the six M6 Phillips

screws (O3) to clamp the extension table to the

supporting arms (N). Replace the plastic covers you

removed earlier, see figs 44-45-46-47.

Fig 44

Fig 45

Fig 43

Fig 46

Fig 47

‘T’ Slot

Captive nut

M

O1

O1

Plastic cover

03

Assembly

17

Rip Fence

NOTE: THIS ASSEMBLY

OLNY APPLIES IF YOU HAVE

PURCHASED KIT CODE: 508212

1). Remove the fence clamp assembly from the rip

fence (E) by lossening the clamping bolt to the base

of the asssebly. using a 10mm socket/spanner. Locate

the rip fence (Q), slot the steel square clamp into the

T-slot to the end of the rip fence and tighten the bolt,

see figs 48-49.

Fig 48-49

Steel square clamp

10mm socket/spanner

Clamping bolt

Q

2). Lower the fence assemby so the clamp assembly

slots over the fence extention table support arm (N).

Clamp the fence assembly in position by turning the

lift and shift handle clockwise, see figs 50-51.

Note: Lubricate the Fence supporting arm (N) and

the underside of the clamp assembly so the rip

fence assembly runs smoothly back and forth.

Fig 50-51

Clamp asssembly

Q

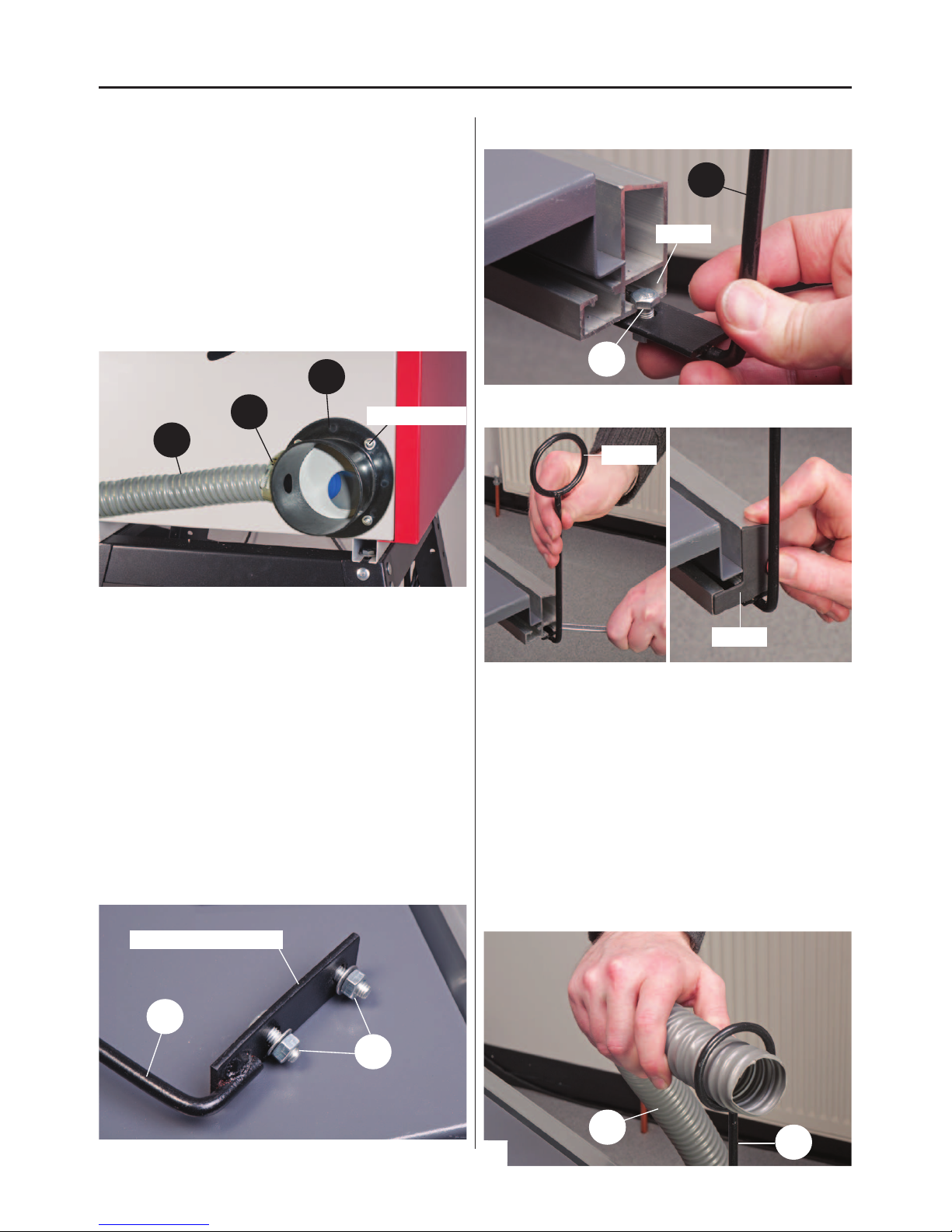

Dust Extraction

1). Locate 30mm hoses (B), hose clips (G2), 100mm

dust extraction moulding with four Phillips screws

and washers (C).

2). Place one of the hose clips over one end of the

30mm hose and fit the hose over the table saws dust

extraction outlet and nip tight, see fig 52.

Fig 52

DO NOT OVERTIGHTEN as the guard is only plastic!

Continues Over...

B

G2

Assembly

18

3). Line up the holes in the extraction moulding (C),

with the threaded holes to the rear of the saw table

(A) and secure in place with the Phillips screw and

washers, see fig 53.

4). Slide the remaining hose clip over one end of

the 30mm hose and fit the hose over the table saws

30mm dust extraction moulding outlet and nip tight,

see fig 53.

Fig 53

C

B

G2

Phillips screws

Code 508212 Only

5). Locate 30mm hose support bracket (P) and two

M6x16 Hex bolts, washers and nuts (O4). Remove the

plastic cover from the end of the rear extension table

support arm (N) and place safely aside. Remove the

nuts and washers from the Hex bolts, introduce the

bolts through the pre-drilled holes in the support

bracket plate (P) and replace the washers and nuts,

see fig 54.

NOTE: Leave a gap between the Hex bolt head

and support bracket plate for the next step.

Fig 55

Fig 54

Fig 56-57

O4

P

Support bracket plate

6). Turn the bracket support (P) so the ring is facing

upwards, line up the two Hex bolts (O4) with the

‘T’ slot and slide the support bracket assembly on.

Leave sufficant space to replace the plastic cover.

Tighten the Hex nuts to sercure the assembly,

see figs 55-56. Replace the cover to the end of the

support arm, see fig 57.

7). Slot the flexible hose (B) through support ring (P),

see fig 58 and secure it to the extraction moulding

(C) as described in step 3.

Fig 58

P

O4

‘T’ slot

Ring

Cover

B

P

Illustration and Parts Description

19

Part Description Part Description

A Basic Table Saw M Extension Table

B Saw Guard with Flexible Hose N Long Fence and Table Extension Rail Arms

C 50-100mm Dust Extraction Moulding (see page 20) P 30mm Hose Support Bracket

D Mitre Fence (see page 20) Q Long Rip Fence Assembly

E Short Rip Fence and Clamping Assembly (not shown) R Angle Fence (see page 20)

F Short Fence Rail with Scale (not shown) S Work Clamp Assembly

G6 Operation Wheel Handles T Flip Over Stop

H Leg ‘A’ Frames U Work Clamp and Connecting Blocks

I Long Struts V Sliding Carriage Support Arms (see page 20)

J Short Struts W4 Carriage Arm Stop

K Rubber Feet X Carriage Arm

L1 M8x16mm Coach Bolt Y Sliding Carriage Table

A

B

E

F

Basic Table Saw Kit Code 508211TS-250M Table Saw Kit Code 717540

G6

H

I

J

K

L1

M

N

P

Q

S

T

U

W4

Continues Over...

Illustration and Parts Description

20

C

D R

V

X

Y

Work clamp block (A) and connecting block (B) Flip over stop assembly

A

B

Clamp

B

M

N

Illustration and Parts Description

21

Tilt scale pointer and adjusting screw

Carriage table scale for measuring set angles

Rise and fall operating handle and the

clamping handle for the tilt mechanisum

Tilt operating handle

Mitre fence assembly NVR ON/OFF switch with emergency stop shroud

Clamping knob

Pointer

Pointer

Adjusting screw

Scale

Scale

Scale

Tilt mechanisum clamp

OFF

Shroud

ON

Setup and Adjustments

The Riving Knife

1). Raise the saw blade to its highest point and

remove the saw blade guard, see fig 34 on page 14.

2). Remove the four Hex screws and place carefully

aside, remove the table insert, see fig 59. Using the

spanner provided loosen the riving knife and adjust

until the tip of the riving knife is no more than 8mm

away from the saw blade and re-tighten, see fig 60.

NOTE: Check that the riving knife is parallel to the

saw blade by placing the fence up against them.

(See fig 61).

Fig 59

Fig 60-61

Adjusting the Rip Fence to the Blade

The fence assembly must be parallel to the saw

blade for producing accurate cuts.

1). Loosen the fence clamping handle and slide the

fence assembly up against the saw blade and check

it reads “ZERO” on the fence rail (F) or on the table

extension support arm (N), see fig 62.

NOTE: If the fence assembly does not line up

correctly with the “ZERO” marker on the scale

you will need to adjust the fence rails (F-N) until

correct.

Fig 62

NOTE: Use the ‘T’ slot to the right side of the saw

blade as a reference to check the fence is parallel,

see figs 63-64. Regularly check the fence is

parallel to ensure a perfect cut.

Fig 63-64

22

Table insert

Riving knife

ZERO marker

Tables ‘T’ slot

R

8mm

8mm

Setup and Adjustments

23

4). The rip fence (E-Q) can be repositioned to face

the opposite direction for guiding thin timber pieces

through.

5). Loosen the square clamp bolt beneath the clamp

assembly (E-Q), see figs 48-49 on page 17, turn the

fence around so the large surface of the fence is

pointing away from the blade, re-attach the fence

clamp assembly. The two illustrations below, figs 6566, shows the fence in both positions.

Fig 65-66

The small surface of the fence is for

guiding thin timber through.

The small surface of the fence is for

guiding thick timber through.

E Q

Adjusting the Cutting Height

Adjust the blade height with the hand wheel (G6), see

fig 67, so that the blade teeth are protruding through

the work piece.

Fig 67

G6

Adjusting the Pivot

Release the locking handle (A), see fig 67-68 the saw

can be angled up to a maximum of 45˚ by turning

the hand wheel (G6), see figs 68-69.

Fig 68

Fig 69

G6

A

G6

Continues Over...

Lock

Setup and Adjustments

24

If the blade is not cutting 100% true, the blade is out

of alignment. Follow the instructions below on how

to set the blade to the table.

1). Remove the blade guard and table insert,

see fig 70.

2). Loosen the four Hex screws (A), see figs 70-71.

3). Place a steel rule up-against one end of the blade

and take a measurement to the ‘T’ slots edge, see fig

72.

Fig 70-71

Table insert

A

A

A

Fig 72

Fig 73

Fig 74-75

Table ‘T’ slot

Steel rule

Blade rail

Blade assembly

B

4). Place the rule to the opposite end of the blade

and take a further reading, see fig 73.

6). If there is any deviations between the

measurements,adjust the blade assembly by

moving each end on it’s rails (B) (beneath the table),

see figs 74-75, until both ends of the blade are the

same distance away from the ‘T’ slot edge.

7). Tighten the four Hex scews (A).

8). Replace the blade guard and table insert.

Setting the Blade Alignment

Operating Instructions

25

CONNECT THE SAW TO THE

MAINS SUPPLY!

NOTE: BEFORE USING YOUR

SAW, GO ROUNDAND MAKE

SURE EVERYTHING IS SECURE,

FASTENED DOWN, THAT ALL

TOOLS ARE CLEARED AWAY

FROM THE WORK AREA!

CHECK: THE BLADE FOR

SHARPNESS,MISSINGTEETH,

RESINBUILDUP ECT., CLEAN

IF NECESSARY. CHECK THE

BLADE IS SECURELY CLAMPED

IN PLACE (I.E. NOT LOOSE)!

Give the machine a ‘quick’ burst check ( i.e. quick

ON-OFF) to ensure everything is O.K. If everything is

satisfactory, the table saw is ready for use.

WARNING! KEEP TOOLS AND

EQUIPMENT OUT OF THE

REACH OF YOUNG CHILDREN!

UNDER NO CIRCUMSTANCES

SHOULD CHILDREN BE ALLOWED

IN THE WORK AREAS!

CONNECT A DUST EXTRACTON

MACHINE TO THE DUST

EXTRACTION OUTLET ON YOUR

TABLE SAW!

Feeding the Work by Hand

Start up the saw, wait until it has reached full speed

and slowly feed the timber through using both

handles, (making sure to keep your hands well clear

of the blade and using a push stick for small pieces),

until the timber is behind the riving knife. Switch off

the saw, wait until the blade has come to a complete

stop and remove the timber, see fi gs 76-77.

Fig 76

Fig 77

NOTE: Secure larger pieces of timber to the table

by using the clamp assembly (S), see page 23.

Cutting Narrow Pieces

Use the small fl at surface of the fence (E-Q) to cut thin

timber narrower that 120mm, see fi g 65. Use a push

stick.

The Mitre Fence

The mitre fence (D) can be mounted on either side

of the saw blade in the two ‘T’ slots, pre machined

into the saw table, see fi g 78. The mitre fence can be

angled from 90˚ to 45˚ degrees , see fi g 79-80.

Continues Over...

D

‘T’ Slot

Operating Instructions

26

Fig 80

LOCK THE MITRE

FENCE AND HOLD

THE WORK FIRMLY

Fig 79

THE BLADE IS SET

AT AN ANGLE

LESS THAN 90˚

DEGREES FOR

BEVEL CUTS

HOLD THE

WORK FIRMLY

BLADE GUARD

Changing the Saw Blade

1). Raise the saw blade to its highest point, remove

the saw blade guard, remove the four Hex screws

that secure the table insert, place carefully aside and

remove the table insert, see fig 81. Using the spanner

provided, put the spanner onto the flats on the bolt

and place a peace of timber up against the saw blade

to stop it from moving, see fig 82.

3). Check the new blade for damage, missing teeth,

sharpness etc. Fit the new blade, ensure that the

teeth are pointing towards the front of the machine.

Put the sawplate washer onto the shaft and twist on

the saw bolt. Spin the bolt up finger tight and check

the saw is correctly seated.

4). Place the piece of timber against the blade as

before and tighten up the saw bolt, check the riving

knife is aligned with the saw blade, and correctly

positioned. Replace the table insert and secure with

the four Hex screws. Replace the saw blade guard.

When everything is satisfactory, turn the saw blade

once by hand to check it doesn’t foul anywhere.

5). Reconnect the machine to the mains supply. Give

the machine a ‘quick’ burst check (i.e. quick ON-OFF)

to ensure everything is O.K. If everything is

satisfactory, continue to use the machine.

Fig 81

Fig 82

Hex screw

Table insert height shims

Saw bolt

Spanner

NOTE: BE CAREFUL NOT TO DISTURB

THE SHIMS BENEATH THE TABLE

INSERT IF FITTED AS THE SHIMS ARE

SET SO THE TABLE INSERT IS LEVEL

WITH THE TABLE SURFACE!

2). Slacken off the saw bolt (remember right hand

thread). Remove the saw nut, then remove the

sawplate washer and the saw blade, see figs 83-84.

It would be a good time to give the interior of the

machine, the dust extraction channels, etc. a

thorough clean.

Changing the Saw Blade

6). Check the old blade for sharpness, missing teeth, resin build up, etc., clean if necessary and send for

refurbishment/resharpening if required. If the blade is not to be re-sharpened, clean and pack away in its

storage case.

Fig 83

Maintenance

Fig 84

Sawplate washer

Sawplate washer

1). Keep the saw as clean and free from saw dust

build up as is practical. Periodically, remove the saw

gullet and vacuum out and clean out the saw box

and the extraction housing. Remove any resin build

up in the saw box, using a proprietary resin cleaner.

2). Clean the threaded drive shafts of the rise and fall

and tilt mechanisms. At the same time check the belt

drive, i.e. the belt is not ‘glazing’ with resin build up,

likewise with the pulley wheels. Check the belt

tension. If the belt is becoming slack, loosen the

motor hold down bolts and drive the motor

backward with its adjusting bolt.

3). Check the saw blade regularly for chipped,

missing, damaged teeth etc. and remove any resin

build up from the blade, riving knife etc.

4). If you have finished using the saw bench, clean

above and below the work table and using a damp

cloth wipe the saw bench over. If the saw bench is

not going to be used for a period of time, smear a

light coat of oil over the work table and place a dust

sheet over the saw bench.

27

Parts Breakdown/List

28

Parts Breakdown/List

29

Part No Description Q’TY

1 Set screw 1

2 Shaft 1

3 Hand wheel 1

4 Pin 1

5 Sharp 1

6 Pin 1

7 Screw 1

8 Motor 1

9 C-Spring 1

10 Motor guidance plate 1

11 Arbor 1

12 Washer 3

13 Set screw 3

14 Set screw 2

15 Washer 1

16 Long plate 1

17 Washer 1

18 Nut 2

19 Motor pulley 1

20 Extractor connecting piece 1

21 Washer 1

22 Set screw 1

23 Riving Knife (Splitting wedge) 1

24 Flange 1

25 Washer 1

26 Set screw 1

27 Washer 2

28 Set screw 2

29 Holding plate A 1

30 Riving Knife (Splitting wedge) 1

31 Holding plate B 1

32 Poly-V belt HR410 1

33 Spindle pulley 1

34 Washer 5 2

35 Ball bearing 1

36 Ball bearing 1

37 C-Spring 1

38 Shaft 1

39 Flat head screw M5 1

40 Press block 1

41 Supporting plate 1

42 Washer 2

43 Nut 2

44 Washer 1

45 nut 2

46 Washer 6 1

47 T-nut M6 2

48 Sawing base 1

49 Pin 1

50 Set screw 1

51 washer 6 1

52 Connecting plate 1

53 Lock bolt M5 1

54 Screw 1

55 Screw 1

56 Hand wheel 1

57 Screw M20 2

58 Nut M20 1

59 Threaded shaft 1

60 Plate 1

61 Clamp 2

62 Dust extraction pipe 1

63 Base 1

64 Switch Box 1

65 Switch 1

66 Clamp for cord 1

67 Set screw 4

68 Power Cord 1

69 Washer 1

Parts Breakdown/List

30

Parts Breakdown/List

31

70 Arbor 1

71 Plate 2

72 Supporting rear 2

73 Washer 2

74 Nut M20 1

75 Table 1

76 Cover 1

77 Screw 6

78 Screw 4

79 Pin 1

80 Scale 1

81 Lock handle 1

82 Stop ruler 1

83 Plate 1

84 Guide 1

85 Lock handle 1

86 Scale 1

87 Guide 2

88 Bolt 1

89 Tap screw 4 x12 1

90 Flat head screw M4 x 8 6

91 Right protection plate 1

92 Flat head screw M4 x 8 1

93 Safety screen (right) 1

94 Left protection plate 1

95 Tap screw 4 x 24 2

96 Lock bolt 1

97 Washer 5 1

98 Screw M5 x 12 4

99 Washer5 4

100 Dust cover 1

Wiring Diagram

Axminster Tools & Machinery Ltd

Weycroft Avenue, Axminster, Devon EX13 5PH

axminster.co.uk

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling.

Help to protect the environment, take the packaging to the local recycling centre and place into

the appropriate recycling bin.

Do not dispose of electric tools together with household waste material. In observance of

European Directive 2002/96/EC on waste electrical and electronic equipment and its

implementation in accordance with national law, electric tools that have reached the end of their

life must be collected separately and returned to an environmentally compatible recycling facility.

Only for EU countries

The Axminster guarantee is available on

Hobby, Trade, Industrial, Engineer, Air Tool & Axcnc Technology Series machines

It’s probably the most comprehensive FREE guarantee ever- buy with confidence from Axminster!

So sure are we of the quality, we cover all parts and labour free of charge for three years!

• Look for the icon and put your trust in Axminster

• No registration necessary - just keep your proof of purchase

• Optional Service Plan for Industrial Series machinery

Great value & easy-to-use,

perfect for use at home

Solid, reliable machines

designed for daily use

Top performers with class leading features and

build quality for use in busy workshops

Quality, precision machines

for the workshop or education

Precision CNC machines for

industry and education

Small machines for the home

engineer

Compressors and tools for home or

workshop use; durable and great value

Free Three Year Guarantee on Axminster Hobby, Trade and Industrial Series

woodworking and engineering machines, Axminster Air compressors and Air

Tools, and bench top grinders - no registration necessary just proof of purchase.

We will repair or replace at our discretion and will collect only from a UK

mainland address, irrespective of the original delivery address.

The Guarantee assumes that you have bought the correct machine for the

required operation, in accordance with our guidelines; have operated and

maintained it in accordance with the instruction manual; and that all cutting

machines will be used with a blade which is sharp and serviceable at all times.

It does not cover consumable items purchased with the original product,

including original blades or abrasives.

Normal wear and tear; misuse, abuse and neglect are excluded and the machine

should not have been modified in any way. Please do not attempt to service the

product without first contacting us; we are happy to guide you but failure to do

so may invalidate the guarantee.

The Guarantee is transferable from owner to owner in the first three years but

you must have original proof of purchase. Should we need to replace a machine

in the first three years the guarantee will still continue to be effective from the

original purchase date.

Full Terms and Conditions can be found at axminster.co.uk/terms

This guarantee does not affect your statutory rights.

For more information visit axminster.co.uk/3years

Loading...

Loading...