AXMINSTER

Hobby

SERIES

MB1931(TP2000)

Benchtop Thicknesser

Code 104279

Original Instructions

AT&M: 23/04/2018

BOOK REF : 104860

Index of Contents

Declaration of Conformity 02

What’s Included 03-04

General Instructions for 230V Machines 04

Specific Instructions for Thicknessing Machines 05

Specification 05

Assembly 06-07

Illustration & Parts Description 08-09-10-11

Setup & Adjustment 12-13

Operating Instructions 14

Changing the Blades 15-16-17

Maintenance 18-19

Troubeshooting 20

Exploded Diagrams/Lists 21-22-23

Wiring Diagram 23

CE Certificate 24-25

Notes 26-27

EU Declaration of Conformity

Cert No: MB1931(TP2000)

Axminster Tools & Machinery Ltd

Axminster Devon

EX13 5PH UK

axminster.co.uk

declares that the machinery described:-

Type Thicknesser

Model MB1931

Signed

Andrew Parkhouse

Operations Director

Da te: 06/06/2016

EU Declaration of Conformity

This machine complies with the following directives:

2006/42/EC

EN 55014-1: 2006/A2:2011

EN 55014-2: 1997/A2: 2008

EN 61000-3-2: 2014

and conforms to the machinery example for which the

EC Type-Examination Certificate No S50328303 001, BM50328304 001, E8A 16 06 41469 839

has been issued by TÜV Rheinland (China) Ltd. (Member of TÜV Rheinland Group)

at: Unit 707, AVIC Bldg., No. 10B, Central Road, East 3rd Ring Road,

Chaoyang District, Beijing, 100022, P.R. China

and complies with the relevant essential health and safety requirements.

EN 61000-3-11: 2000

EN 61029-1: 2009+A11

61029-2-3: 2011

AfPS GS 2014: 01

The symbols below advise the correct safety procedures when using this machine.

Fully read manual

and safety instructions

before use

Ear protection

should be worn

Eye protection

should be worn

2

Dust mask

should be worn

HAZARD

What’s Included

Quantity Item Part Model Number

1 Benchtop Thicknesser A MB1931( TP2000)

4 Rubber Feet B

1 Rise & Fall Operating Handle

with M6 Hex Screw and Spring Washer C

1 Blade Setting Gauge D

1 8-10mm Spanner E

1 4-5mm Hex Key F

4 M8 x 45mm Nex Bolts to secure thicknesser to workbench G

A

B

C

3

What’s Included

G

D

F

General Instructions for 230V Machines

The following will enable you to observe good working

practices, keep yourself and fellow workers safe and maintain

your tools and equipment in good working order.

WARNING!! KEEP TOOLS AND EQUIPMENT

OUT OF REACH OF YOUNG CHILDREN

KEEP WORK AREA AS UNCLUTTERED AS IS PRACTICAL.

UNDER NO CIRCUMSTANCES SHOULD CHILDREN BE

ALLOWED IN WORK AREAS.

Mains Powered Tools

• Tools are supplied with an attached 13 Amp plug.

• Inspect the cable and plug to ensure that neither are

damaged. Repair if necessary by a suitably qualified person.

• Do not use when or where it is liable to get wet.

Workplace

• Do not use 230V a.c. powered tools anywhere

within a site area that is flooded.

• Keep machine clean.

• Leave machine unplugged until work is about to commence.

• Always disconnect by pulling on the plug body

and not the cable.

• Carry out a final check e.g. check the cutting tool

• Ensure you are comfortable before you start work,

• Wear appropriate safety clothing, goggles, gloves,

• If you have long hair wear a hair net or helmet to prevent it

• Consideration should be given to the removal of rings and

• Consideration should also be given to non-slip footwear etc.

• If another person is to use the machine, ensure they are

• Do not use the machine if you are tired or distracted.

• Do not use this machine within the designated safety areas

• Check cutters are correct type and size, are undamaged

• OBSERVE…. make sure you know what is happening

E

is securely tightened in the machine and the correct

speed and function set.

balanced, not reaching etc.

masks etc. Wear ear defenders at all times.

being caught up in the rotating parts of the machine.

wristwatches.

suitably qualified to use it.

of flammable liquid stores or in areas where there may be

volatile gases.

and are kept clean and sharp, this will maintain their

operating performance and lessen the loading on the

machine.

around you and USE YOUR COMMON SENSE.

4

Specific Instructions for Thicknessing Machines

When machining, long pieces of timber tend to be unstable.

Bolting the machine to a bench increases stability. It is also

advisable to use two outfeed roller stands. However you have

mounted your machine ensure it is secure before you

commence work.

Note: Check there are no foreign objects e.g. old nails,

screws, small stones etc embedded in the material you

are about to machine.

WARNING!! DO NOT CARRY OUT ANY

CLEANING OR MAINTENANCE WITH THE

MACHINE CONNECTED TO THE MAINS SUPPLY!

THIS THICKNESSER IS FOR

MACHINING TIMBER ONLY!

1. Check knives are clean and sharp.

2. Check thicknessing table is clear of debris before

commencing work.

3. Check there is no excess build up of resin etc.,

on the thicknessing bed.

4. Check feed rollers are clean and unclogged.

5. Check the guards are in place and secure

before using the machine.

6. Do not stand directly in line with the infeed or the

outfeed of the machine especially when starting up.

7. Do not force the timber through the machine, it has

its own feed rollers and will feed itself at the correct rate.

8. The machine is designed for PLANING TIMBER ONLY.

9. Do not put man-made materials through this machine.

10. Remove loose knots from timber before planing.

11. Always allow machine to run up to full speed before

introducing the timber.

12. If your machine is fitted with ‘pass over rollers’

make sure that they are rotating freely.

Specification

Code 104279

Model MB1931(TP2000)

Power 1.8 kW

Feed Speed 7 m/min

Cutterblock Speed 9,000rpm

Cutterblock Diameter 48mm

Max Thicknesser Capacity 153mm

Max Planing Width 318mm

Max Depth of Cut Thicknesser 2.5mm

Noise Level dB (A) (Sound Pressure Level) LpA: 99.6dB (A)

(Sound Power Level) LwA: 112.6dB (A)

(Uncertainty) K: 3.0dB (A)

Knives HSS (Resharpenable) x 2

Min Extraction Airflow Required 390 m³/hr

Dust Extraction Outlet 50mm

Overall L x W x H 560 x 360 x 580mm

Weight 30 kg

5

Assembly

Fitting Rubber Feet Rise & Fall Operating Handle

1

2

1

C

B

2

4

33

4

6

Workbench Assembly

Assembly

1

3

5

G

2

4

Place a washer to each corner as shown

Mark the four holes with an pencil;

drill a 9mm hole to each corner

G

6

Locate the four M8 Hex bolts (G) and insert down through

each hole. Using four M8 washers nuts, secure in place

7

Illustration & Parts Description

NVR Switch shroud

Thicknessing head

Rise & Fall handle

Motor brush

Extension table Roller Width guide

Pointer

Scale

Extension table levelling bolt

8

A

Illustration & Parts Description

C

B

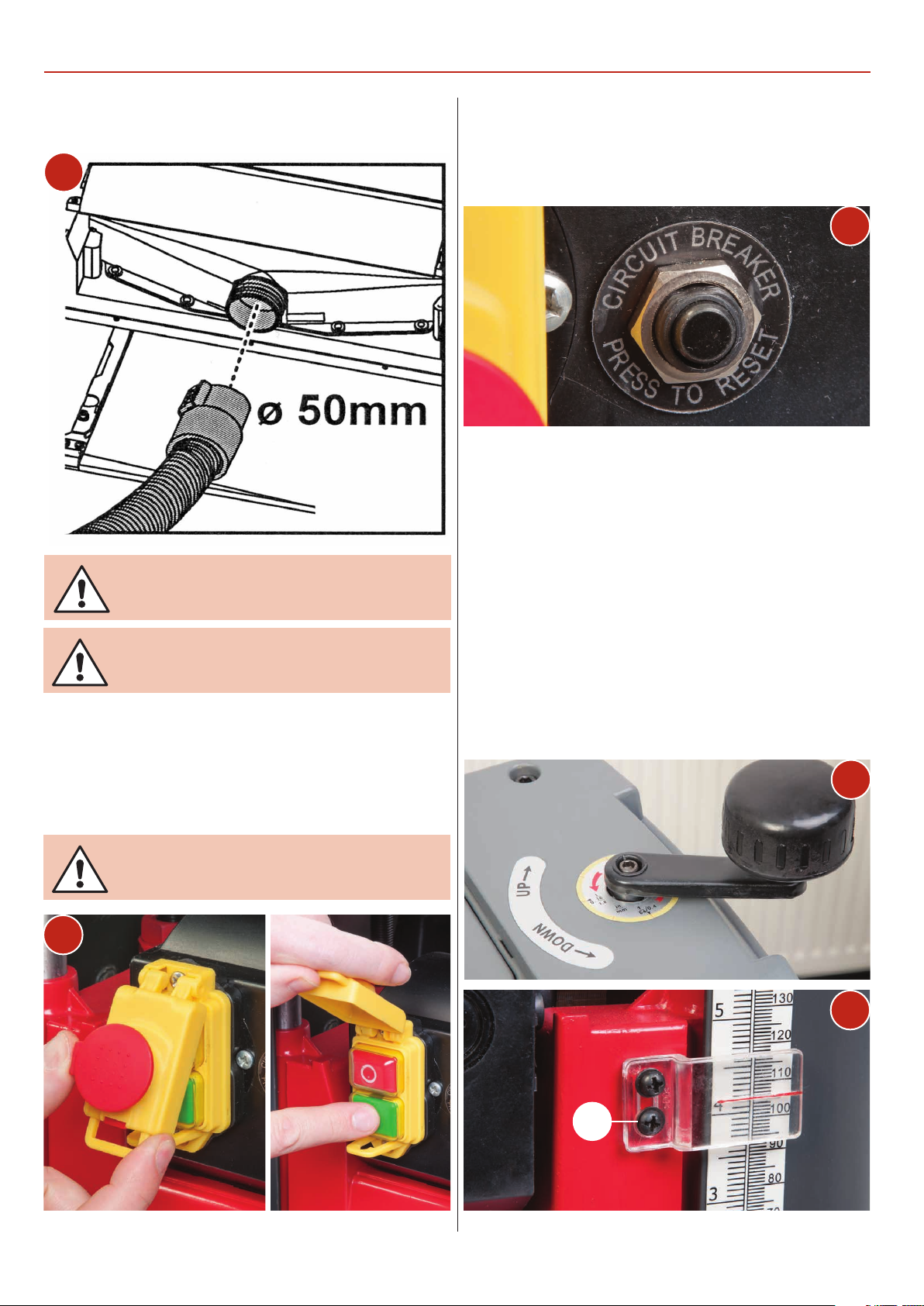

NVR switch emergency stop (A),

Circuit breaker ‘RESET’ switch (B), On/Off buttons (C)

A

Cutter block (A), Anti-kickback fingers (B), Feed rollers (C)

B

Thicknessing head rise & fall control handle

C

9

Thicknessing scaleTool compartment

Illustration & Parts Description

Cutter block cover Motor & gearbox

Motor brush

Dust extraction

Threaded shaft

Thicknessing bed

318mm

10

A

Illustration & Parts Description

C

B

Cutter block (A), Blade holder (B), Blade (C), Square nut (D)

E F

Width guides (E-F)keep the timber within the boundaries of the cutter block

D

G

Cutter block cover with a 50mm duct extraction outlet (G) Folding infeed outfeed

extension tables

11

Setup & Adjustment

Levelling Extension Tables

Wind the thicknessing head up and place a straight edge across

the extension tables. Adjust the two stop bolts (A) below the

table until level is correct.

1

B

Loosen nut

5

2

3

A

Adjust stop bolt

6

7

4

8

A

B

Table stop bolt (A) and locking nut (B)

12

Setup & Adjustment

Setting Cutter Head to Thicknessing Bed

Plane a piece of timber and measure the thickness after

the cut. If the thicknesses are different on both sides of

the work piece, follow the instructions below:

Use a piece of hardwood to make a tool gauge block

(Illustrations 1-2).

1

4

5

Gauge block

2

Make the following adjustments:

6

7

Cutter head adjusting nut

3

Adjust the height nuts on either side to suit the gauge block

then tighten when level. Reassemble the thicknesser and

remove gauge block.

13

Continues over...

Operating Instructions

Connect the thicknesser to a dust extractor with an air volume

of 700m3/hr.

1

CONNECT THE THICKNESSER TO THE MAINS

SUPPLY!

CLEAR ALL TOOLS AWAY FROM THE WORK

AREA!

Lift up the emergency stop shroud and press the GREEN ‘ON’

button (2). Let the thicknesser reach full speed and feed a piece

of timber through from the infeed table. Wait until the timber

has passed through then switch off the machine by pressing

the RED ‘OFF’ button and wait until the machine comes to a

complete stop.

Circuit Breaker ‘RESET’ Switch

The thicknesser has an overload switch (3). If an overload

occurs, the switch will pop out. Wait several minutes before

pressing in the switch to reset the machine.

3

Depth of Cut Scale

It is important that the depth of cut scale reads accurately.

Adjust as follows.

• Turn the rise & fall handle (4) to the required depth.

NOTE: one revolution of the handle equals 1.6mm of depth.

• Switch ‘ON’ the thicknesser and wait until it reaches full speed.

• Feed a piece of timber through.

• Switch ‘OFF’ and wait until it comes to a complete stop.

• Compare the measurement on the timber with the reading on

the scale. (5) If the reading is different, adjust the scales pointer

by loosening the two screws (A).

• Feed another piece of timber through to check the depth of

cut and make further adjustments if necessary.

4

2

NEVER PLANE MORE THAN 3MM IN ONE PASS!

NEVER PLANE A BOARD UNDER 127MM IN

LENGTH!

5

A

14

Changing the Blades

1

2

DISCONNECT THE MACHINE FROM THE MAINS

SUPPLY BEFORE CONTINUING!

E

Loosen

6

7

3

4

8

Remove assembly

9

Clean cutter block

5

15

10

Continues over...

Changing the Blades

B

A

C

D

E

Cutter Block Assembly

Blade Setting Gauge A

Blade B

Blade Holder C

Spring D

Clamping Square Nut E

16

Changing the Blades

11

12

CAUTION!! THE BLADES ARE SHARP!

Blade

Slot

Pin

15

16

13

14

Tighten

D

17

E

18

17

19

Blade

Maintenance

Changing the Motor Brushes

DISCONNECT THE MACHINE FROM THE

MAINS SUPPLY BEFORE CONTINUING!

Check the carbon brushes every three months. Replace if worn.

Take careful note of the orientation of the

brushes when you remove them, remember

that they have bedded themselves to the

profile of the commutator in that position.

If you fit them reversed they may not be in

exactly the same position, which can cause

excessive sparking and heat until they have

re-bedded themselves.

1

4

5

2

3

6

7

18

8

Checking the Condition of Drive Belt Checking the Condition of Drive Chain

Maintenance

• Visually inspect the drive belt for damage or slackness every

month.

1

2

• Once a month, check the chain drive has not become too

slack or the teeth on the sprockets too worn. Check the chain

has not become clogged.

1

3

4

2

3

• Clean the chains, remove build-up of dust or wood shavings

and apply a light coat of greese over the chains.

• Remove the build-up of sawdust and debris around the

machine.

• Replace guard covers.

19

Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

Grain is fussy 1. Planing wood with high

moisture content

2. Blades are dull

Grain is torn 1. The cut is too heavy

2. Blades are cutting against the grain

3. Blades are dull

Grain is rough/raised 1. Blades are dull

2. Cut is too heavy

3. Moisture content is too high

4. Cutter head bearings are damaged

Uneven depth of cut

from side to side

Board thickness does

not match depth of

cut scale

Chain is jumping 1. Sprockets are misaligned

1. Blade projection is not uniform

2. Cutter head is not levelled

to planer bed

1. Depth of cut scale is incorrect 1. Adjust the depth of cut scale

2. Sprockets are worn

1. Dry the wood

2. Sharpen the blades

1. Review proper depth of cut

2. Feed the workpiece with the grain,

or turn workpiece around

3. Sharpen the blades

1. Sharpen the blades

2. Review proper depth of cut

3. Dry the wood

4. Replace the bearings

1. Adjust the blade projection

2. Level the cutter head to table

1. Align the sprockets

2. Replace the sprockets

Machine will not

start/restart

Circuit tripping

resulting in motor

stoppage

Poor feeding

of timber

Workpiece is jammed 1. Inadequate blade setting height 1. Set the blade to the correct height

1. Tool is not plugged in

2. Motor failure

3. Wire is loose

4. Overload reset has failed

5. Motor starter failure

1. Extension cord is too long or too thin

2. Blades are too dull

3. Low voltage running

1. Planer table is dirty

2. Feed roller is damaged

3. Sprocket is damaged

4. Gear box malfunctions

1. Check the power source

2. Check the motor

3. Check the motor by a qualified electrician

4. Allow machine to cool down and restart

5. Check the motor by a qualified electrician

1. Use a shorter or thicker extension cord

2. Sharpen or replace the blades

3. Check the voltage

1. Clean off the pitch and residue,

and lubricate the planer table

2. Replace the feed roller

3. Replace the sprocket

4. Check the gear box

20

Exploded Diagrams/Lists

Continues over...

21

Exploded Diagrams/Lists

No. DESCRIPTION QTY

1 CONNECTING PLATE 4

2 NUT 4

3 WASHER 4

4 SCREW 8

5 PLUNGER 4

6 PIPE 2

7 TABLE 2

8 NUT 2

9 WASHER 4

10 WASHER 20

11 PRESSING PLATE 2

12 FIXED SPINDLE 1

13 REATAINING PART 54

14 RETAINING WASHER 53

15 PROTECTION GUARD 1

16

17

18 SCREW 6

19

20

21 FEET 4

22 SCREW 8

23 BOLT 4

24 WASHER 4

25 LINE PRESSING CARD 1

26 WASHER 4

27 SHAFT RING 4

28 BEVEL GEAR 4

29 GUIDE PILLAR 4

30 GUIDE PLATE 2

31

32 LEAD SCREW 1

33 FLAT KEY 4

34 PRESSING PLATE 2

35 BASE 1

36 SIDE PLATE 2

37 SCALE 1

38

39 SCREW 3

40 SPRING WASHER 22

41 SCREW 33

42

43 LEAF SPRING 4

44 BARREL 1

45 NUT 2

46 LIMIT SLEEVE 4

47 WORK TABLE 1

48 PLANER CUTTER 2

49 PRESSING PLATE 2

50 COMPRESSION SCREW 14

51 BEARING 1

52 CHECK RING 1

53 FLAT KEY 1

54 DRIVEN WHEEL 1

55 NUT 1

56 BELT 1

57 CHIP SHIELDS 1

58 SCREW 2

59 BODY 1

60 CLAMP 1

61 POINTER 1

62 SCREW 4

63 FLAT WASHER 13

64 BELT WHEEL 1

65 MOTOR 1

66 LIMIT PIN 2

67 CHAIN WHEEL 4

68 WASHER 3

69 SPRING WASHER 6

70 SCREW 3

71 HANDLE 1

72 COVER 1

73 ROTATION MARK 1

74 SCREW 2

75 TOOL CABINET 1

76 TOOL CABINET COVER 1

77 SCREW 6

78 COVER 1

79 CHAIN 2

80 CHAIN SHILED 1

81 LOCKNUT 2

82 BUSH 3

83 BUSH 1

84 CHECK RING 1

85

86 BEARING 1

87 SPRING 3

88 BEARING 4

89 BEARING PRESSING

PLATE

90

91 PRESSURE SPRING 1

92 COMPRESSION ROLLER 2

93 CUTTER 1

94 BARREL 1

95 LEAD SCREW 1

96 TRANSFER BAR 1

97 OIL BEARING 2

98 BAFFLE 1

99 SCREW 6

100

101 SPRING 1

102 BRUSH HOLDER 2

103 SCREW 2

104 MOTOR SHELL 1

105 STATOR 1

106 WIND SHIELD 1

107 BEARING 1

108 SCREW 2

109 ROTOR 1

110 BEARING 1

111 REDUCTION BOX

COVER

112 OIL BEARING 2

113 GEAR 1

114 SWITCH 1

115 AXIS 1

116 PLUG CORD 1

117 PROTECTING BUSH 1

4

1

22

Exploded Diagrams/Lists

118 LINE PRESSING CARD 1

119 SCREW 4

120 AXIS 1

121 FLAT KEY 1

122 GEAR 1

123 OIL BEARING 2

124 LOCATING BUSH 2

125 WASHER 3

126 SCREW 1

127 SCREW 3

128 MOTOR SHAFT 1

129 FLAT KEY 1

Wiring Diagram

130 BEARING 1

131 MOTOR LABEL 1

132 BRUSH 2

133 BRUSH CAP 2

134 CHECK RING 1

135 GEAR 1

136 BEARING 1

137 REDUCTION BOX 1

138 FOAM PAD 1

139 SHIELD 1

140 OVERLOAD

PROTECTOR

141 INSERT 4

142 SCREW 2

143 HOUSING 1

144 NUT 1

145 SWITCH DEAD PLATE 1

146 SCREW 1

147 SPRING WASHER 1

148 WRENCH 4 1

149 WRENCH 5 1

150 FELLER BLOCK 1

151 8-10 SPANNER 1

1

152 SCREW 4

153 CHARGING ARM 1

154 SPRING 4

155 CAPACITOR 1

156 PANEL 1

157 SCREW 1

158 SCREW COLLAR 2

159 JOINING CHAIN 1

160

161 SCALE 1

162 NUT 4

163 SCREW 4

23

CE Certificate

24

CE Certificate

25

Notes

26

Notes

27

The Axminster guarantee is available on

Craft, Trade, Engineer, Air Tools & CNC Technology Series machines

Buy with confidence from Axminster!

So sure are we of the quality, we cover all parts and labour free of charge for three years!

For more information visit axminster.co.uk/3years

The packaging is suitable for recycling.

Please dispose of it in a responsible manner.

EU Countries Only

Do not dispose of electric tools together with household waste material.

By law they must be collected and recycled separately.

Axminster Tools & Machinery Ltd

Axminster Devon EX13 5PH

axminster.co.uk

Loading...

Loading...