SIEG SC6 Variable

Speed Lathe

Axminster Tool Centre,

Unit 10 Weycroft Avenue, Axminster, Devon EX13 5PH

www.axminster.co.uk

951542 Mill Attachment for

the SC6 Lathe.

(Manual See Pages 31-50)

2

3

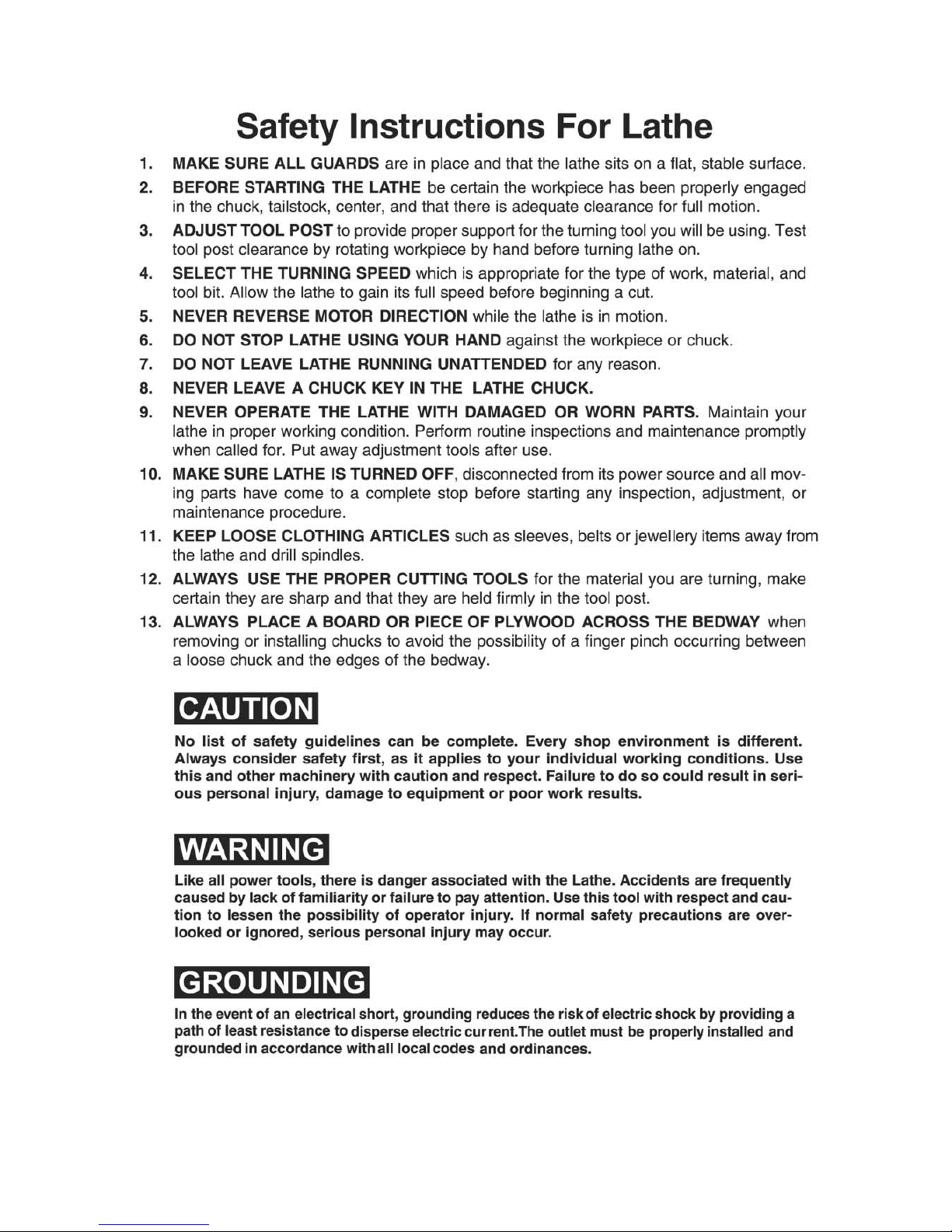

Lathe Accessory's

A) 1 No. Tailstock Centre

B) 1 No. Headstock Dead Centre

C) 3 No. External Jaws

D) 1 No. ‘C’ Spanner

E) 1 No. Spanner for Change Wheel

F) 1 No. Leadscrew Reversing Sprocket

(Extra fixed-shaft gear)

G) 1 No. Chuck Key

H) Set of Spanners 19,14,10,7mm

I) Set of Allen Keys

Gears

J) 1 No. 30 Teeth

K) 1 No. 40 Teeth

L) 2 No. 42 Teeth

M) 1 No. 50 Teeth

N) 1 No. 52 Teeth

O) 1 No. 60 Teeth

P) 1 No. 66 Teeth

Q) 1 No. 70 Teeth

R) 1 No. 75 Teeth

S) 1 No. 80 Teeth

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

4

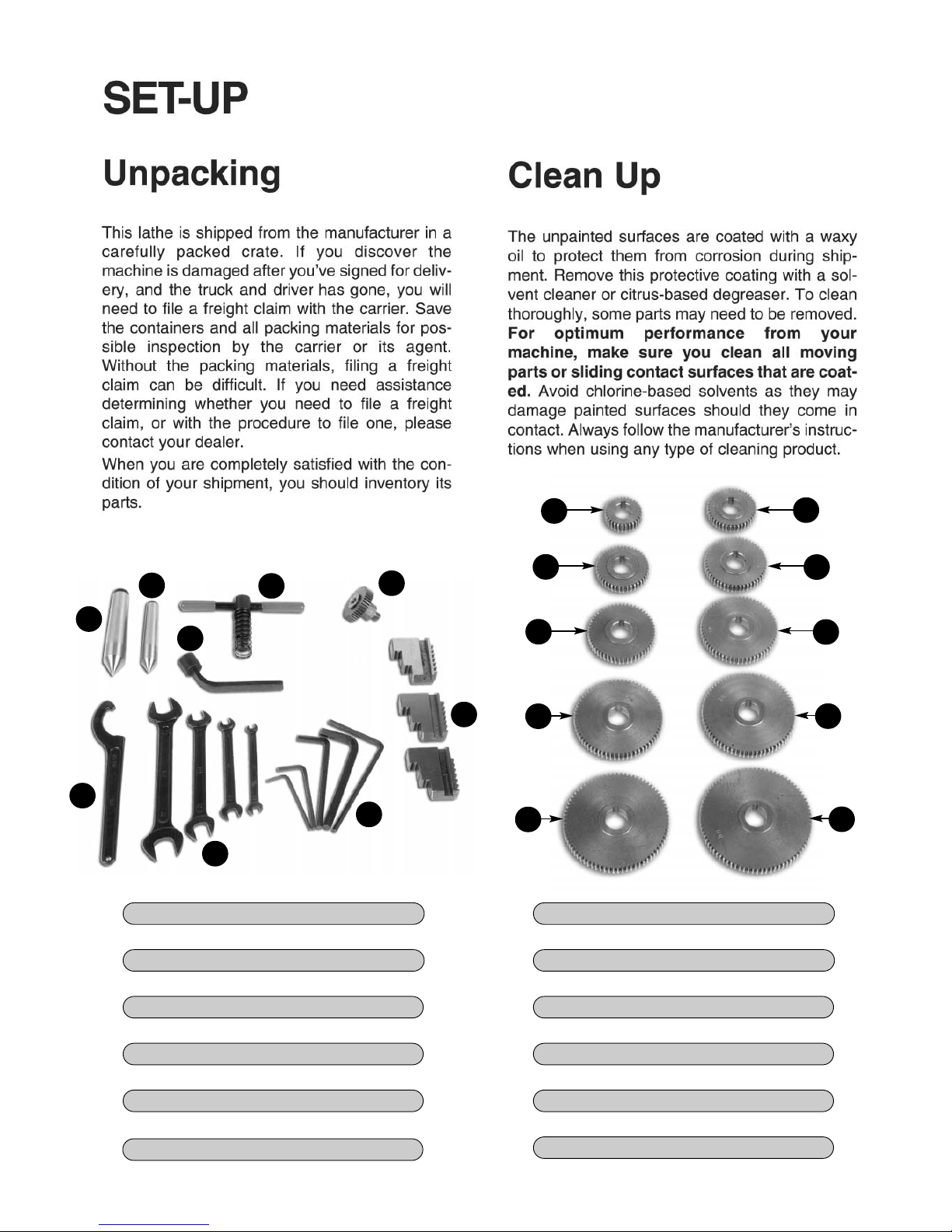

IDENTIFICATION OF SC6 VARIABLE

SPEED LATHE

1. Thread Pitch Gearing & Speed Charts

2. Speed Up Button

3. Machine ID/Safety Label

4. Emergency Stop Switch

5. Lathe Power Indicator Light

6. Selector Switch

7. Headstock Eyeshield

8. Lathe Chuck

9. Carriage Feed Handwheel

10. Cross Slide Handwheel

11. Automatic Carriage Feed Lever

12. Compound Slide

13. Tool Post

14. Tool Post Lock Handle

15. Compound Slide Handwheel

16. Tailstock Centre

17. Tailstock Clamp Bolt

18. Tailstock Axis Alignment Indicator

19. Tailstock Barrel Handwheel

20. Tailstock Centre Lock

21. Start Button

22. Digital Readout Speed Display (RPM)

23. Forward Button

24. Speed Down Button

25. Reverse Button

26. Stop Button

27. Lathe Bed

28. Fuse

1

22

3

2

21

26

27

28

4

5

6

7

8

9

23

10

11

12

13

14

15

18

16

20

17

24

25

19

Code: 210172

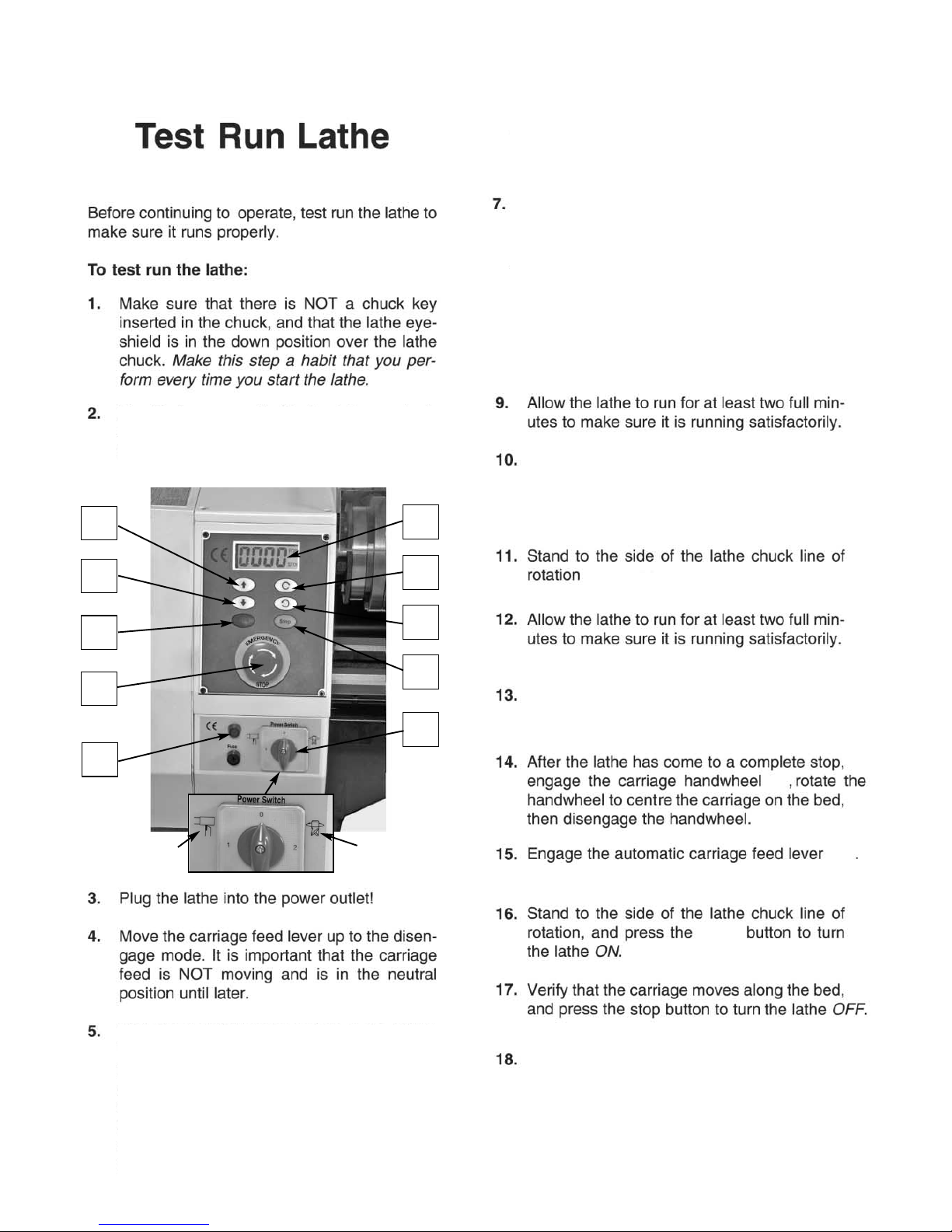

INITIAL START SC6

Release the Emergency Stop Button (4) by

turning the knob head to right, the Digital

Readout Speed Display (22) wlll come on.

Press the start button (21), the spindle will be

forward turning; the speed is 100r/min. Press

the reverse button (25) to turn the spindle in

the oppsite direction.

Press the Speed Up Button (2) to increase the

spindle speed or the Speed Down Button (24)

to decrease it.

If the lathe over-loads, for example, cutting too

much, just turn off the power by pressing the

stop button (26) then switch it on again, by

pressing the Start Button (21) and increasing

the spindle speed as required.

Familiarise yourself with the lathe controls

shown in the figure below. Make sure the

Emergency Stop Button (4) is pushed down

before continuing.

Turn the switch (6) to the left for the lathe

function. The power indicator (5) will light up.

NOTE if it does not light up, unplug the lathe

and check the fuse on the lathe and then the

plug. Call our technical sales department on

0330 100 0299 if you are still having problems.

2

24

21

4

5

22

23

25

26

6

6.

8.

, then refer to step (6 & 7).

Start

(9)

(11)

Mill Symbol

Lathe Symbol

Press the Emergency Stop Button (4) to stop

the lathe instantly, the Digital Readout Speed

Display (22) will go off. NOTE: If you lift up

the eyeshield (7) it will also stop the lathe.

If you have mounted the C6 Mill attachment

(Part No: 600870) to the lathe, turn the

selector switch (6) to the right to transfer

power to the mill. NOTE: The lathe power

indicator (5) will go out.

Press the Stop Button (26) to stop the lathe

spindle.

5

6

FWD/REV Buttons

Fuse

Digital Readout

Speed Display

Selector Switch

Start Button

Stop Button

Variable Speed

Controls

Power Indicator

LED

Emergency Stop

Button

OPERATIONS

7

8

9

10

11

12

13

14

15

Daily and Periodic Maintenance

Daily Pre-use

1. Using an oil can with a narrow nozzle, oil all the oil points on the machine, incl.

A) Saddle (4), B) tailstock (2), C) traverse slide (1), D) compound slide (2), E) leadscrew gearbox (2), and F)

leadscrew end bearing (1).

2. Move the traverse and compound slides to give access to their drive shaft threads and

lightly coat with oil, work the oil up the threads to lubricate the thread followers.

3. Spray-oil the slides and the lathe bed, exercise the saddle and the slides to spread the oil

to all surfaces, both hidden and visible.

4. Spray up under the rack cover to lubricate the rack. (G)

5. Apply oil to the change gears and their axle mountings. (H)

Daily after-use

1. Clean all swarf and chips away from the machine bed, slide surfaces, and the tool post.

2. Exercise the slides and ensure no swarf etc., is lodged in the drive shaft tunnels.

3. If you have been using ʻsudsʼ make sure the machine is thoroughly dried off. Clear the suds

tray of all swarf and chips, especially around the drain.

4. Check the tool, ensure it is usable the next time, if not re-sharpen or replace the tool tip.

5. Lightly oil spray all the machine beds and surfaces, and the tailstock barrel.

6. Clean and lightly oil any tools you may have been using (centres, drill chucks, spanners

chuck keys etc, and put them away.

7. Switch off the power supply. Disconnect the plug.

8. Cover the machine over with a dust cloth.

Your C6B bench lathe is a precision tool. In order to maintain this precision and prolong its useful

life, it is advised that you follow the recommended daily and periodic maintenance tables printed below.

16

A

G

H

1

2

3

4

5

B

C

D

E

F

Oil

Weekly

a) Check the belt tension.

b) Check the tautness of the slides.

c) Check the level of the suds reservoir. (if you are using suds).

Accessories

May we recommend the following products for use with your SC6

Grease - Rocol Saphire 2 (Part number: 810129).

Lubricant - Rocol Slideway lubricant spray (Part Number: 810141).

Cutting Fluid - Rocol Multisol Cutting Fluid (Part Number: 810140).

There are numerous accessories listed for the machine listed in the Axminster catalogue in section 2 .

LATHE MAINTENANCE

LATHE MAINTENANCE (OIL LUBRICATION POINTS)

1. Fixed Shaft Gear

2. Synchronised Counter Pulley

3. Upper Adjustable Shaft

4. Lower Adjustable Shaft

5. Pivot Shaft

Change Gear

LATHE MAINTENANCE

17

18

19

20

21

22

SC6 WIRE DIAGRAM

23

24

25

26

27

28

29

30

SIEG SC6 Mill

Attachment

The undersigned, Galen Chen authorised

by Shanghai SIEG Machinery Co., Ltd.

No.555 Caofeng Rd., South to No. 17 Bridge of Caoan Rd.,

Shanghai. P.R.China

declares that this product:

SX2

manufactured by Shanghai SIEG Machinery Co. is in

compliance with the following standards or

standardisation documents in accordance with Council

Directives

EN13128: 2001+A1: 2006 + A2: 2009/AC: 2010

EN61029-1: 2009+A11: 2010

Machinery Directive 2006/42/EC

WHATʼS IN THE BOX

Quantity Item Model Number

1 No. Mill with Chuck and M12 Draw Bar fitted SX2

Box containing:1 No. Set of Allen Keys

1 No. Chuck Key

1 No. ‘C’ Spanner

2 No. ‘T’ Slot Keepers

2 No. Steel Pins

1 No. Tommy Bar

1 No. Oiling Bottle

1 No. 36mm Spanner

1 No. 19mm Spanner

1 No. 10mm Spanner

DECLARATION OF CONFORMITY

32

1 No. Mill Support Casting

1 No. Tilt Housing Casting

1 No. 36mm Nut

3 No. M8x30 Caphead bolts

and washers

4 No. M8x35 Caphead bolts

and washers

1 No. Mill/Drill Table

1 No. M10 Drawbar

1 No. 3/8" Drawbar

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

(I)

(J)

A

B

C

D

E

F

G

H

I

J

WHAT’S IN THE BOX

Please read the Instruction Manual prior to using your new machine; as well as the

installation procedure, there are daily and periodic maintenance recommendations to

help you keep your machine on top line and prolong its life. Keep this Instruction Manual

readily accessible for any others who may also be required to use the machine.

Having unpacked your machine and its accessories, please check the contents against the

equipment list "What’s in the box", if there are any discrepancies, please contact Axminster Tool

Centre using the procedures laid down in the catalogue. Please dispose of the packaging

responsibly, much of the material is bio-degradable. The machine and its accessories will arrive

coated with heavy corrosion preventative grease. This will need to be cleaned from the

machine, its components and accessories prior to it being set up and commissioned. Use coal

oil, paraffin or a proprietary degreaser to remove the barrier grease. Be warned, it will stain if

you splash it on clothing etc., wear overalls, coverall et al., rubber gloves are also a good idea,

as is eye protection if your cleaning process tends to be a little bit enthusiastic. After cleaning,

lightly coat the exposed metal surfaces of the machine with a thin layer of light machine oil.

N.B If you used paraffin/kerosene make sure you apply this thin film sooner rather than later.

!

SPECIFICATIONS

Code 951542

Motor 230V a.c. 50 Hz. 220V d.c. 350W

Quill Travel 30mm

Spindle Speeds Low Gear 0-1100rpm (variable) High Gear 0-2500 rpm (variable)

Spindle Taper No. 3 MT

Draw Bar Threads M10,3/8"

Drilling Capacity 13mm

End Mill Capacity 16mm

Face Mill Capacity 30mm

Weight 35kg

DEFINITIONS

‘X’ Axis. This is the axis described by the work table as it is moved side to side.

Normally, movement that moves the tool to the right in the workpiece is

referred to as +ve ‘X’, and movement that moves the tool to the left in the

workpiece is referred to as –ve ‘X’. Where the initial position of the tooling

and the worktable is designated 0,0. (Horizontal plane only).

‘Y’ Axis. This is the axis described by the work table as it is moved from front to

back. (Traverse) Normally movement that moves the tool to the front in

the workpiece is referred to as-ve ‘Y’, and movement that moves the tool

to the rear in the workpiece is referred to as+ve ‘Y’. Where the initial

position of the tooling and the worktable is designated 0,0.(Horizontal

plane only).

‘Z’ Axis This is the axis described by the worktable in the vertical plane.

(Not possible with this machine). However, to establish a point in space,

the co-ordinates can be transferred to the ‘tip’ of the tooling, whereby, if

we assume that the tool and the worktable in their initial positions, where

designated 0,0,0, (Horizontal and vertical planes) any point above the tool

tip is referred to as +ve ‘Z’, and any point below the tool tip is referred to

as -ve ‘Z’

33

34

INITIAL ASSEMBLY - REMOVING THE SPLASH GUARD

1) Remove the four Phillip screws and pull out the electrical back plate to the rear of the lathe and lay the

circuit board to one side. (See fig 1 & 2 )

(NOTE. Be careful when lifting out the electrical circuit board as it contains delicate components)

2) Locate a 5mm allen key and 10mm spanner, remove the two caphead bolts and nuts that secures one side

of the splash guard to the headstock. ( See fig 3 & 4)

!

DISCONNECT THE LATHE FROM THE MAINS SUPPLY

Remove the four Phillip screws

and lift out the electrical panel

Electrical

back plate

Electrical

circuit

board

Headstock

Fig 2

Fig 3

Fig 4

Fig 1

Remove the two caphead bolts and nuts that secures one

side of the splash guard to the headstock

Two caphead bolts

Two 10mm nuts

Step 1

Step 2

A

A

B

B

C

D

INITIAL ASSEMBLY - REMOVING THE SPLASH GUARD

INITIAL ASSEMBLY - MOUNTING THE MILL

3) Loosen the two bolts and washers which clamps the opposite

end of the splash guard to the side of the lathe bed, below the tailstock.

(See fig 5)

4) Remove the splash guard and place safely aside.

Fig 5

WARNING

!

When mounting the Mill to the Lathe, we strongly advise you get

the assistance of another person because of the weight of the

machine.

Remove the four grub screws to

the side of the lathe bed and

place safely aside.

Locate the angle support casting and four

M8x35 caphead bolts and washers. Secure

the angle support to the side of the lathe

bed. DO NOT OVERTIGHTEN

35

Grub screws

A

B

C

D

Tip the lathe forward and have your assistant

thread the support leg up into the angle support

casting. Adjust the support leg until it makes

contact with the surface of your bench or stand,

tighten the lock nut to lock the leg in position.

Locate the tilt housing casting and three M8x30

caphead bolts and washers. Offer up the pre-drilled

holes with the holes in the support casting and

secure in place using the M8 bolts and washers.

Lift the mill assembly and slide it over the tilt

housing shaft until it is flush against the tilt

housing. Locate the 36mm nut and spanner and

lock the mill assembly in position.

DO NOT OVER TIGHTEN

Insert the Mill’s power plug into the socket

in the rear of the lathe as shown.

INITIAL ASSEMBLY - FITTING THE MILL

B

C

D

Step 3

Step 4

Step 5

Step 6

WARNING

HEAVY

TWO MAN

ASSEMBLY

!

Make sure that everything is secure then replace the splash guard as described on pages 34-35.

36

Mill power plug

Leg lock nut

Lathe socket

37

INITIAL TESTING

Please read the section entitled Identification and Parts description so that you may more

easily identify the parts to which reference is made in the text.

Testing

When the Mill is mounted to your satisfaction, proceed as follows:-

a) Close the chuck jaws

b) Check the millhead is ‘locked’ in position on the column.

c) Check that all loose items are removed from the worktable.

d) Set the worktable approximately mid-positioned under the chuck jaws.

e) Check the speed control is switched OFF (fully anti-clockwise).

f) Rotate the Lathe/Mill selector switch on the lathe’s control panel to the milling position.

g) Select L (Low) on the gear box.

h) Connect the machine to the mains supply, open the switch shroud and press the on button (Green), check

the green power light comes on, lower the lid of the switch shroud (Do Not Close).

i) Turn the Speed Control Switch On (Clicks On).

j) Check the Amber LED (Fault Light) is illuminated and the green light is illuminated.

k) Turn the Speed Control to Off (Clicks Off ), the Amber LED is now Off and the Green light stays on.

l) Turn the Speed Control Switch On and advance until the Chuck starts to rotate.

m) While it’s running press the Emergency Stop button, check the machine stops, check that the green light

and the Amber LED is on. Disengage the Emergency Stop button by opening the switch shroud, turn the

Speed Control Switch to Off ( All lights are off).

n) Press the on button, turn the Speed Control On and advance until the chuck starts to rotate.

o) Over a period of approximately 5 minutes advance the speed in stages to maximum, run at maximum for at

least 2 minutes, check that there is nothing untoward, (no excessive vibration, speed progression is smooth

etc.). Stop the spindle and change the gear selector to H (High), carry out the previous check.

p) If all the above checks are correct, stop the spindle, (turn the speed control to zero and press the Off button

(Red). Push the Tri-lever feed handle in (if necessary ‘joggle’ the feed to enable the gears to mesh), exercise the

quill up and down, check the movement is smooth and precise.

q) With the Tri-lever engaged, raise and lower the quill using the fine feed control. Check the movement is

smooth and precise, there are no hard spots and the feed doesn’t bind up. Disengage the tri-lever by pulling

the assembly back.

r) Ensure the head lock clamp is loosened and exercise the rise and fall, driving the head up and down the

tool post. Check the movement is smooth and tight. Leave the head fairly well down the tool post for the next

check.

s) Loosen the 36mm tilt clamp bolt, to the rear of the tool post and tilt the tool post to the left or right, clamp

the tool post in an arbitrary position and tighten the bolt. Check that the tool post remains locked in place.

t) If all the above checks are correct, your mill is now ready for use.

!

38

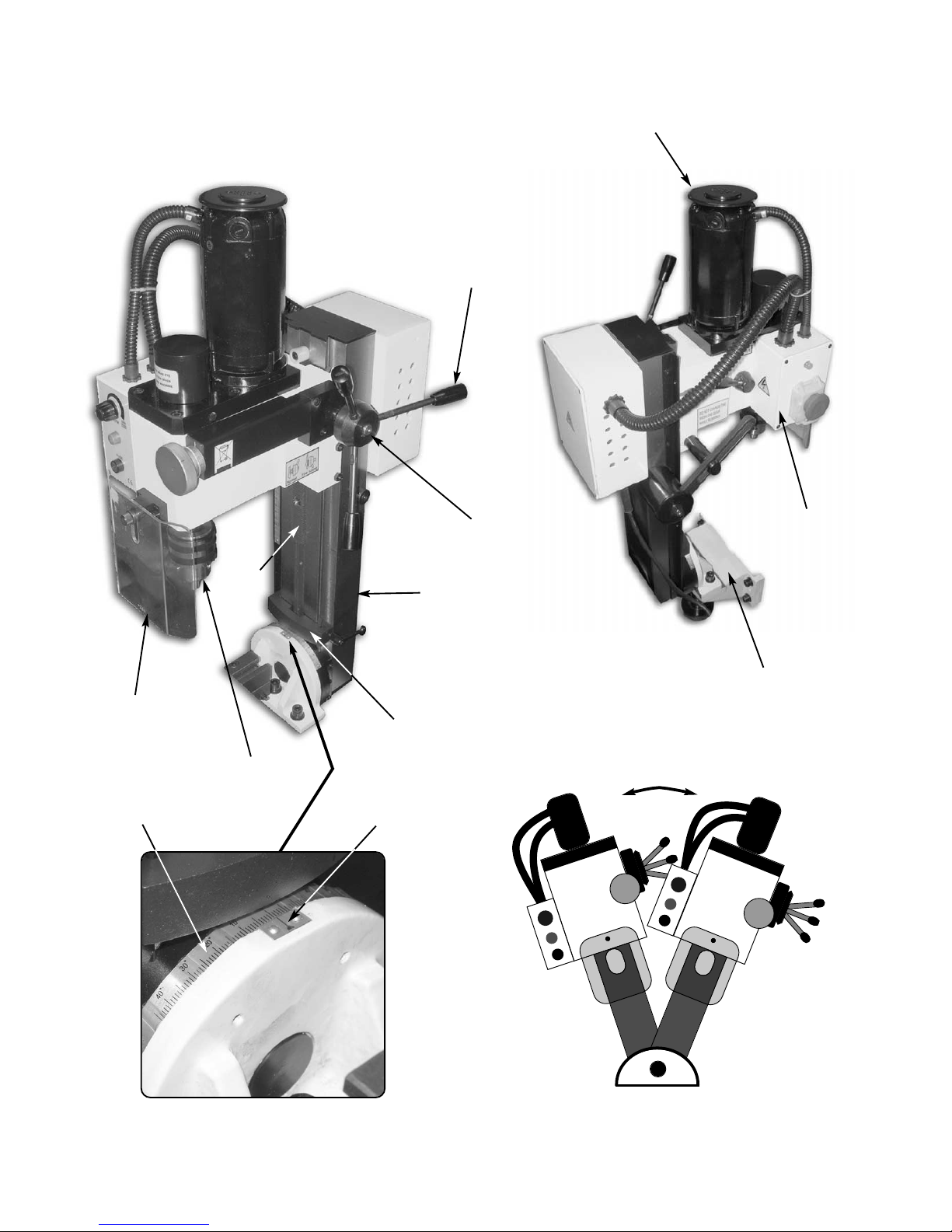

PARTS IDENTIFICATION AND DESCRIPTION

Please take some time to identify the various parts of your machine so that you are familiar

with the terminology we will use to enable you to set up and operate your Mill safely and

correctly.

Main tool post This is the column of the mill, it is an 65 x 50 bar with a dovetail

slide machined on the front onto which the milling head is

mounted, the lower part there is a pre-drilled hole which slides over

the tilt housing shaft and secured in place by a 36mm nut. On the left

side of the post a scale, graduated in mm’s, is mounted to read against

a pointer mounted on the head casting.

Rise and fall Rise and fall, there is a dovetail slide machined on each side of the the

mechanism headbox support column which mounts a through shaft. A pinion gear

is mounted on the shaft inside the headbox that meshes with a rack on

the support column, driving the pinion shaft will cause the headbox to

rise and fall up and down the headbox support column. The part of the

shaft protruding from the headbox has a hole through it to mount the

tri-lever feed assembly.

Tilt housing The tilt housing is mounted to the base casting using 3 M8x30 caphead

bolts and washers. The tool post is mated to the housing and clamped

by a 36mm nut. The main tool post can tilt 45˚ from the vertical either

left or right. There is a pointer and a scale mounted on the housing to

give an indication of the amount of tilt that has been applied.

Milling head This is the ‘milling machine’ and the descriptions of its

various parts and components are detailed as follows:-

Milling head The main casting to which all the components are attached. The

casting head has a dovetail housing machined at the rear, which allows

the casting to be fitted to the Main Tool Post. The left side of the

dovetail slide is fitted with a gybe strip to maintain the fit.

Head clamp Located to the right side of the main tool post above the gybe strip

adjusters and locknuts is a handled bolt that clamps the gybe strip

against the slide to effect a locking action for the rise and fall of the

head.

Motor and The motor and gearbox assembly are mounted above the main

gearbox head casting at the top of the arbor sleeve. The motor drive is

geared through to the spindle with an intermediate 2:1 gearbox.

Gear change The gear change lever allows the selection of the high or low ratio

lever of the gear train. The speed of the spindle is then governed by the

speed control on the motor panel. (You may have to ‘joggle’ the

chuck/tool to aid the meshing action).

Motor A 220V d.c. motor rated at 350W.

39

MACHINE ILLUSTRATION OF THE MILL

Rise and fall Tri-lever feed

Main tool post

Guard

Depth stop

Rack

Feed handle

Chuck

Scale

Pointer

Angle support casting

Control unit

Motor

0-45˚tilt either

direction

Tilt housing assembly

Tri-Lever feed Three levered handle that is used to drive the quill (and hence the

chuck or the tool) up and down. The boss of the handle is fitted to the

end of a ‘splined’ gear shaft. This ‘splined’ gear is, in turn, engaged in

the rack cut into the quill body. The other end of the ‘splined’ shaft is

engaged in a contra-wound spring, this provides counter balance to the

weight of the quill, arbor, chuck and drill, giving a more controlled ‘feel’

during drilling operations. It also retracts the quill when drilling is

completed.

Fine feed The fine feed assembly floats around the splined gear shaft that

assembly drives the quill up and down. When the action of the fine feed

mechanism is required; pushing the tri-lever feed handle in ‘engages’

the knob of the fine feed control meshes the gearing (you may have to

‘joggle’ the feed handle to aid the meshing action) between the splined

shaft and the fine feed control shaft; this enables the spindle to be

driven by the fine feed control wheel with greater precision. Behind the

boss of the fine feed control wheel handle is a graduated ring (thimble)

so that the movement of the quill can be measured. The thimble is

held to the drive shaft by friction, and can be pre-positioned to

establish a predetermined start or stop dimension.

Quill hold pocket The size of the machine precludes any ‘fancy’ locking mechanism for

the quill. There is a blind pocket on the spindle that accepts the tommy

bar supplied in the tool kit, to enable the spindle to be held in position

whilst the draw bar is loosened.

Draw bar cover A moulded plastic cover that clips into the top of the Motor Gearbox

assembly, to afford protection from the rotating top of the draw bar,

when the quill is at the top of its travel.

Draw bar This is a metal rod, threaded at one end and with an 19mm

(unseen) squared shank and flange machined on the other. It is fitted through

the spindle mandrel to hold the fitted tool/tooling hard into the No. 3 MT

taper of the spindle shaft.

Motor control Power On LED

panel Green LED that indicates that power is available to the motor. i.e.

mains is applied, fuse is intact and the Emergency stop switch is

not activated.

Fault LED

(marked UN-NORMAL)

Amber LED that indicates that there is a fault or an incorrect

control sequence. i.e. the chuck guard interlock has been activated

or the speed control is activated. The Motor will not run if the fault LED

is illuminated. If the safety interlock is activated, the safety interlock will

remain in force until the interlock is reset and the start sequence

re-initiated.

Fuse Cap

Access cap for the 20mm fuse cartridge (1 Amp 250V) Speed Control

Knob Round raised ridge knob connected to the circuit that controls the

spindle speed (0-1100 rpm or 0-2500 depending upon the gearbox

selection).

40

PARTS IDENTIFICATION AND DESCRIPTION

41

MACHINE ILLUSTRATION OF THE MILL

Fault LED

Fuse cap

Pointer

Scale

High ratio

Low ratio

Power LED

ON/Off switch & shroud

Speed control knob

Emergency stop

Gear change lever

42

MACHINE ILLUSTRATION OF THE MILL

Draw bar cover

Circuit control box

Motor

Head clamp

Top of draw bar

Fine feed thimble

Fine feed control

Quill hold pocket

To engage the fine feed control push the tri-lever assembly

in until it meshes with the bevel gear. Pulling the tri-lever

back will disen gage the fine feed control.

Spindle

NORMAL

FINE FEED

43

GENERAL OPERATING INSTRUCTIONS

SETTING AND ADJUSTMENTS

GERERAL SAFETY POINTS

Warning. Do not operate the mill in any function unless the head clamping lever is

tightened.

TOOL CHANGING

Note. The taper socket in the spindle mandrel does not have a ‘drive flat’ and all tooling,

including the drill chuck is secured and driven by the taper lock and the draw bar.

Make sure the power is switched off or better still remove the power from the machine.

Locate and put to hand the 19mm A/F spanner and the tommy bar. Remove the Draw Bar Cover.

Hold the quill immovable by inserting the tommy bar into the quill hold pocket and loosen the

draw bar. Unscrew two or three turns and then strike sharply with a hammer (preferably a copper

face, to prevent the head of the draw bar peining over) this will break the lock between the tool

and the spindle tapers .

Unscrew the draw bar from the tool. Ensure the tool is supported, i.e. will not fall onto the

workpiece/table et al. When it is free put the tool carefully aside, remove the draw bar, check the

thread, check the taper and the thread of the new tool are clean and undamaged, introduce the

new tool into the taper, re-insert the draw bar and screw into the top of the tool.

Screw in the draw bar finger tight. Hold the quill immovable and tighten with the spanner. DO NOT

OVERTIGHTEN. Replace the draw bar cover.

Remove all tooling and reconnect the machine. Ensure the tool path is clear, switch on, and check

that the tool is correctly seated, is running true etc. If all is O.K, proceed.

!

Milling (all cases) Ensure the workpiece is securely clamped to the table.

Along the longitudinal Ensure that the quill is locked in position before

Axis (X) milling is commenced. Ensure the traverse slide lock

is tightened.

Along the Traverse Axis (Y) Ensure that the quill is locked in position before milling is

commenced. Ensure the worktable lock is tightened.

Milling or Drilling Vertically Ensure the traverse slide and the worktable locks are

(Z) tightened.

Milling head adjustment

The Milling Head is mounted over a dovetail section. In order to maintain the ‘tightness’ of the fit;

between the sloping surface of the component and its mating surface, on the right hand side, a

gybe strip has been inserted. To adjust the gybe strip, use the supplied allen key and spanner,

release the lock nuts and screw the gybe strip grubscrews clockwise to compensate for any slackness or anti-clockwise to loosen the movement. Check, using the rise and fall drive feed handles,

that the head moves smoothly, If not, repeat the adjustments until the movement is smooth and

tight over the whole of the travel.

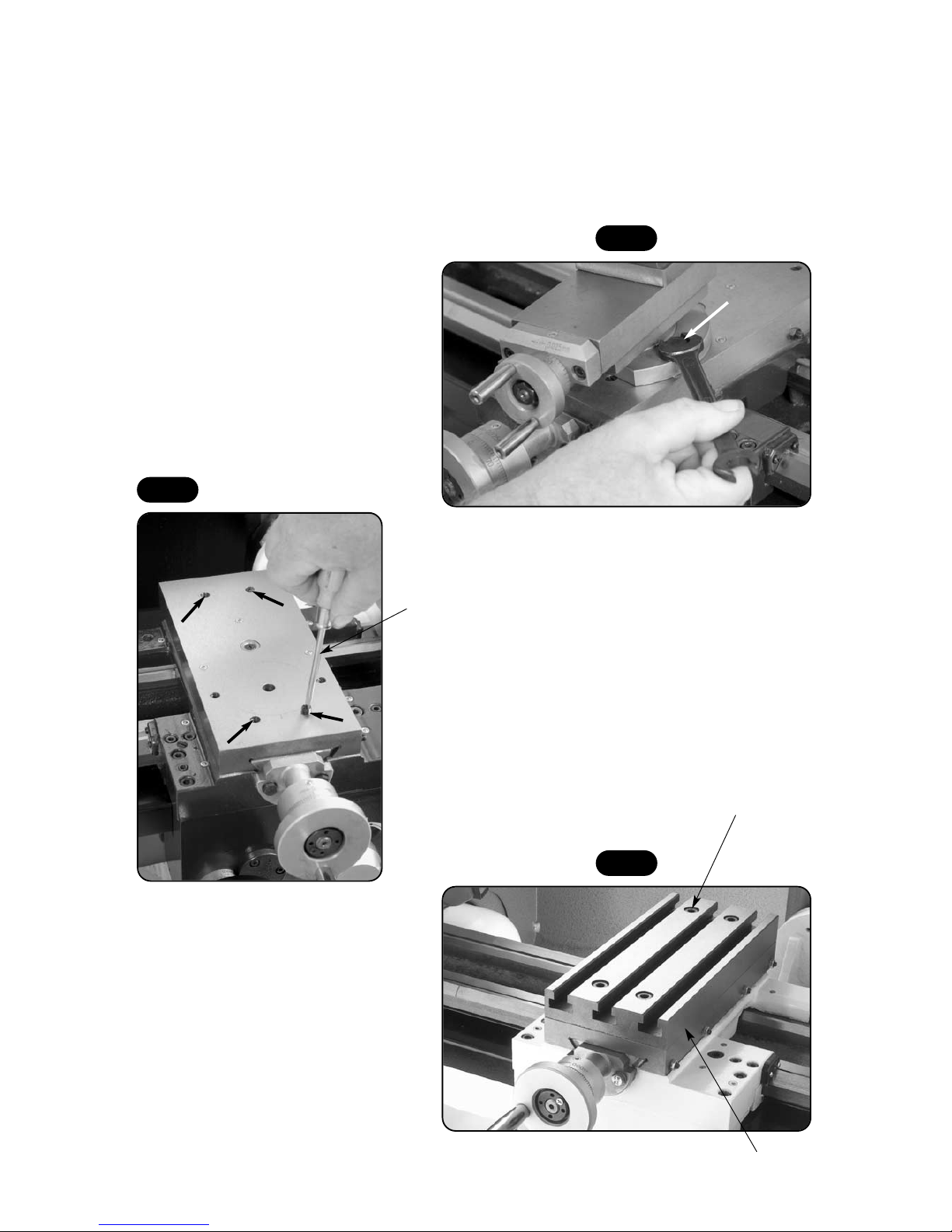

MILL TABLE ASSEMBLY

44

The Mill/Drill includes a milling table as an accessory. To install the milling table the compound

slide must be removed from the cross slide from the lathe bed. Once installed, the milling table can

move back and forth with the cross slide. Follow the instruction below to install table.

1) Using a 12mm spanner remove the two

bolts that secure the compound slide to

the cross slide, remove the compound slide

and place safely aside. (See fig A)

3) Locate the milling table and the

supplied caphead bolts. Lower the

table onto the cross slide, line up the

holes and insert and secure the table

using a 6mm allen key. (See fig C)

2) Using a Phillips screwdriver remove the four grub screws

from the cross slide and place safely aside. (See fig B)

Fig A

Fig B

Fig C

Remove the two bolts using a 12mm spanner, remove

the compound slide from the cross slide.

Phillips screwdriver

Caphead bolt

Milling table

45

MAINTENANCE

Your Mill is a precision tool. In order to maintain this precision and prolong its useful life, it is

advised that you follow the recommended daily and periodic maintenance tables printed

below.

Daily and Periodic Maintenance

Daily

1. Carry out a visual inspection. Repair any damage immediately. Minor damage to the beds

should be taken out with an oilstone.

2. Move the worktable and the traverse feed back and forth by hand, check that the movement

is smooth.

3. Spread a light film of oil over the worktable and the traverse slide bed.

4. Oil the end bearings of the drive shafts. Squirt oil onto the slide faces of mating components.

5. Exercise the components to ensure the oil is spread over both visible and obscure surfaces.

Daily after-use

1. Clean all swarf and chips away from the machine bed, slide surfaces, and the tool post.

2. Exercise the slides and ensure no swarf etc., is lodged in the drive shaft tunnels.

If you have been using a coolant make sure the machine is thoroughly dried off.

3. Check the tool, ensure it is usable the next time, if not re-sharpen or replace the tool tip.

4. Lightly oil spray all the machine beds and surfaces.

5. Clean and lightly oil any tools you may have been using (drill chucks, spanners, chuck keys

etc), and put them away.

6. Switch off the power supply. Disconnect the plug.

7. Cover the machine over with a dust cloth.

Weekly

1. Move the traverse slide fully back to give access to the tunnel, blow out to make sure all

swarf is cleared away and heavily spray oil the tunnel, exercise the slide to work the oil into

the drive thread and to lubricate the dog.

2. Spray oil the slide and the worktable bed, exercise the worktable to spread the oil to all

surfaces, both hidden and visible.

3. Spray oil the underside of the machine onto the drive screws, exercise to ensure the

oil is coating all components.

4. Clean and spray oil the rise and fall drive screw, exercise to ensure all parts are coated.

5. Check the movement of the worktable, the traverse slide and the head, check they are

smooth and ‘tight’, if necessary reset the gybe strips until the movements are smooth and

tight.

6. Wipe the quill outer sleeve clean and lightly oil, exercise the quill to spread the oil in

the sleeve bushes.

Monthly

a) Give the motor a good ‘blow through’ to remove any dust, dirt etc,

b) Check all the interlocks function correctly.

Accessories

There are numerous accessories for the machine listed in the Axminster catalogue.

Some are illustrated at the rear of this manual. (See page 47)

MAINTENANCE OILING POINTS

46

Oil

OIL

47

MILL ACCESSORIES

Clamping kit

Part No: (100033)

#2MT 6mm collet

Part No: (100023)

#2MT 10mm collet

Part No: (100024)

Quick vice 50mm

Part No: (100022)

Part No: (100034)

610184 Slot Drill 3mm

610185 Slot Drill 4mm

610186 Slot Drill 6mm

610187 Slot Drill 8mm

610181 Slot Drill 10mm

Code Description

Metric Screwed Shank Two Flute Slot Drills.

Axminster HSS

Slot Drills

610170 Bull Nose Slot Drill 3mm

610171 Bull Nose Slot Drill 4mm

610172 Bull Nose Slot Drill 6mm

610173 Bull Nose Slot Drill 8mm

610168 Bull Nose Slot Drill 10mm

Code Description

Metric Screwed Shank Two Flute Bull Nose Slot Drills

Axminster Bull Nose Slot Drills

Rotary Milling Vice

for Micro Mill 55mm

Axminster Micro

Mill Collets

Micro Mill Clamping Kit

50mm Release Vise

610177 3mm End Mill

610178 4mm End Mill

610179 6mm End Mill

610180 8mm End Mill

610174 10mm End Mill

Code Description

Metric Screwed Shank Three Flute End Mills.

Axminster HSS End Mills

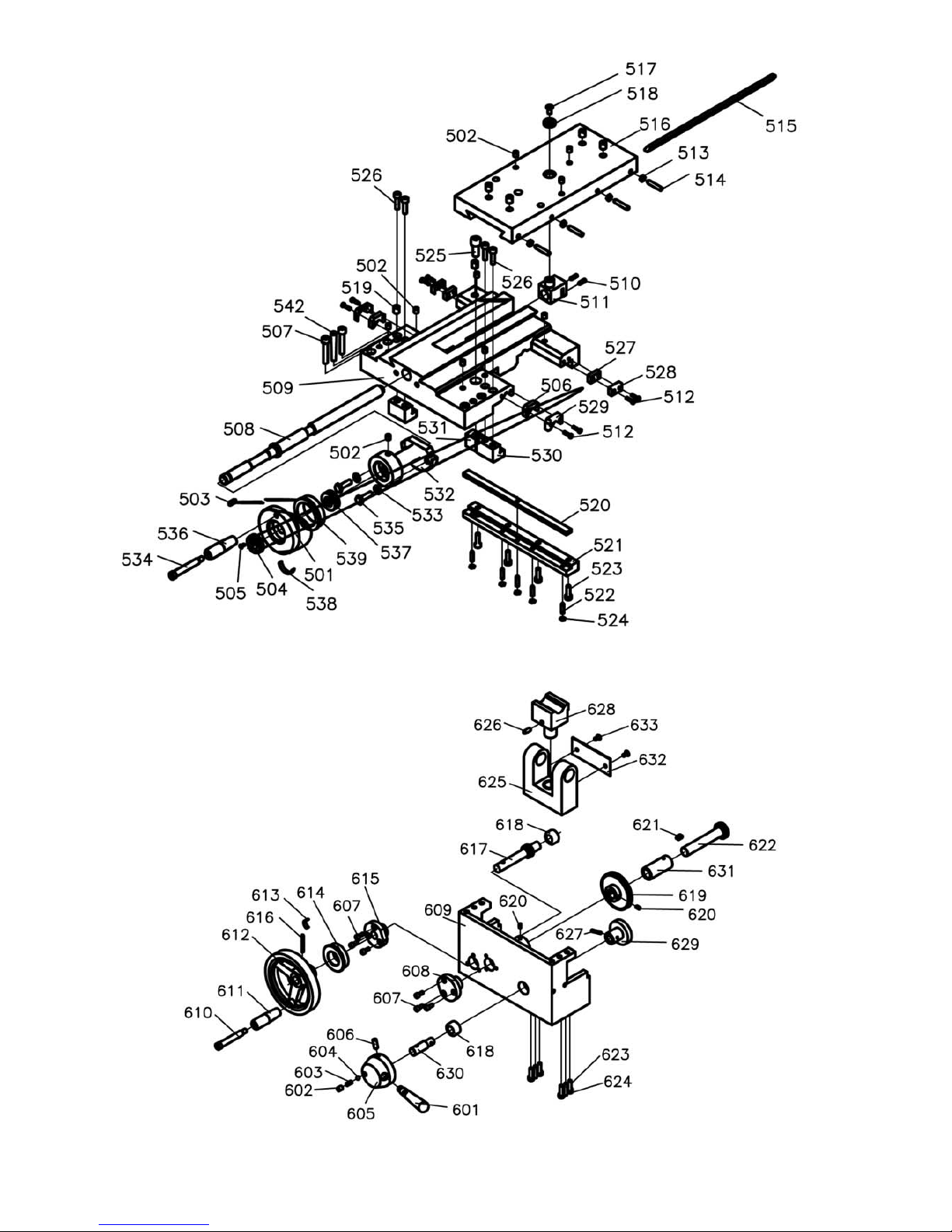

PARTS BREAKDOWN FOR THE MILL

48

PARTS BREAKDOWN FOR THE MILL

49

50

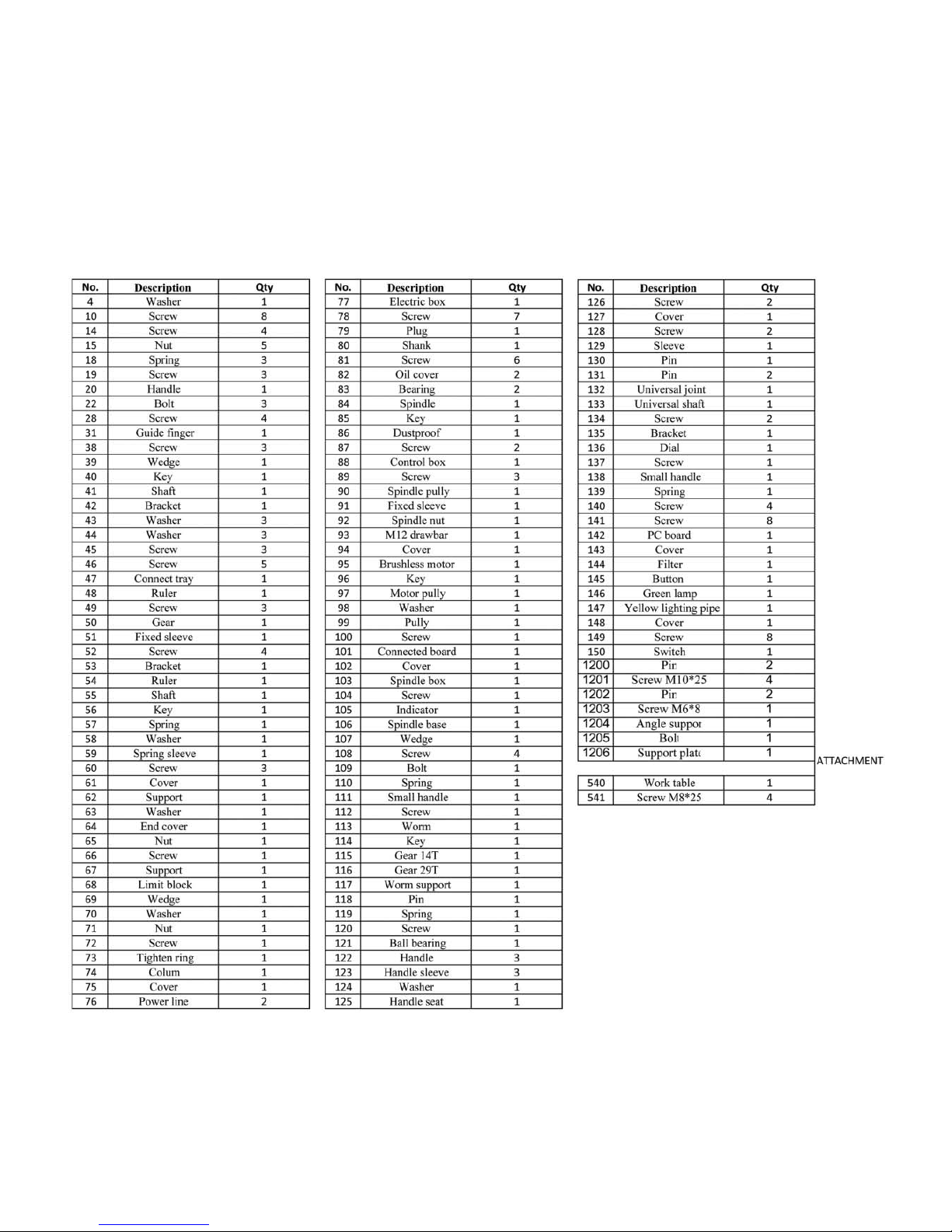

PARTS LIST FOR THE MILL

Loading...

Loading...