900118,810165

SSBP 305mm &

RTC7030 750mm

Sheet Metal Workers

Axminster Reference No: RTC7030 (810165)

Axminster Reference No: SSBP (900118)

User Manual

WHITE

AXMINSTER

W

www.axminster.co.uk

SSBP (900118)

RTC7030

(810165)

WHITE

AXMINSTER

W

Index of Contents...

Page No.

01

Safety Protection Symbols

SAFETY!!

!

The symbols shown on the cover of this

manual advise that you wear the correct

safety protection when using this machine.

E

y

e

P

r

o

t

e

c

t

i

o

n

S

a

f

e

t

y

H

e

l

m

e

t

P

r

o

t

e

c

t

i

v

e

G

l

o

v

e

s

S

a

f

e

t

y

F

o

o

t

w

e

a

r

R

e

s

p

i

r

a

t

o

r

S

a

f

e

t

y

V

i

s

o

r

R

e

a

d

M

a

n

u

a

l

T

w

o

M

a

n

A

s

s

e

m

b

l

y

E

a

r

D

e

f

e

n

d

e

r

s

D

u

s

t

M

a

s

k

Index of Contents...........................................................................................................................01

Declaration of Conformity

………….………........……..…………............................................... 01

What’s in the Box………….………........……..…………................................................................. 02

General Safety Instructions............................................................................................03

Specific Safety Instructions............................................................................................03

Specifications

….………........……..…………............................................................................... 04

Assembly Instructions

….………........……..………….................................................................04

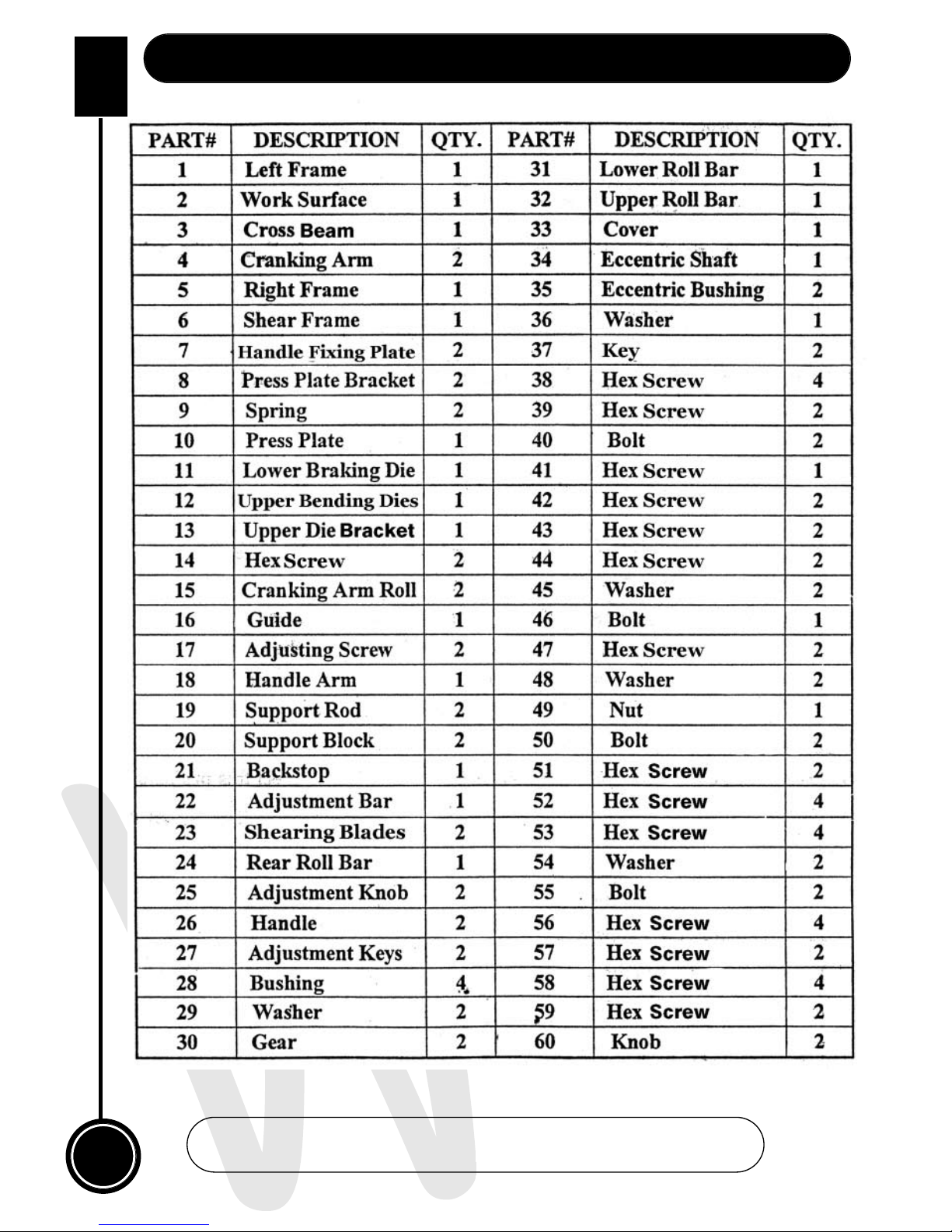

Illustration & Parts Description.................................................................................................05-06

Operating Instructions

………........……..…………..................................................... 07-08-09-10

Adjustments to the Sheet Metal Worker........................................................................................11

Maintenance...................................................................................................................................12

Parts List.........................................................................................................................................13

Parts Breakdown............................................................................................................................14

PLEASE NOTE: THE IMAGES IN THIS MANUAL SHOW THE SSBP

SHEET METAL WORKER, THE RTC7030 IS EXACTLY THE SAME

BUT ON A LARGER SCALE.

!

KEEP HANDS AWAY

FROM ROLLERS!

!

!

KEEP HANDS AWAY

FROM DIE PRESS!

Die

HEAVY

kg

THE MACHINE IS A HEAVY

PIECE OF EQUIPMENT. YOU

ARE ADVISED TO SEEK

HELP BEFORE YOU

ATTEMPT TO LIFT

OR MOVE THIS MACHINE.

WARNING!

WHITE

AXMINSTER

W

02

Whats in the Box...

Model Number: SSBP

1 off: (A) 305mm Sheet Metal Worker

2 off: (B) Support Rods

1 off: (C) Backstop Bar

2 off: (D) Support Blocks

2 off: (E) Support Locking Knobs

1 off: Instruction Manual

1 off: Guarantee Card

Model Number: RTC7030

1 off: (A) 750mm Sheet Metal Worker

2 off: (B) Support Rods

1 off: (C) Backstop Bar

2 off: (D) Support Blocks

2 off: (E) Support Locking Knobs

1 off: Instruction Manual

1 off: Guarantee Card

A

B

C

D

E

A

Fig 1

03

WHITE

AXMINSTER

W

General Safety Instructions...

www.axminster.co.uk

Good Working Practices/Safety

The following suggestions will enable you to observe good working

practices, keep yourself and fellow workers safe and maintain your tools and

equipment in good working order.

• Mount the machine on a flat level bench or surface. Secure the machine to the surface where

applicable.

• Always use machines in an uncluttered area. To reduce the risk of accidents, avoid leaving

materials or other items within the working area and allow clear access to all machine parts

and controls.

• Clean machines by wiping with a oily rag. Do not use solvents or cleaners that may

cause damage to painted/coated surfaces.

• When storing or leaving the machine for any length of time, spray bare metal surfaces

with a protective spray to minimise surface corrosion.

• Before using the machine, ensure that all locking-nuts, chucks etc, are tightened and

secure. Check that all loose keys, spanners etc. have been removed.

• Always ensure that long hair is tied back or retained by a band, hat or safety helmet. Remove all

loose jewellery to prevent it from catching in rotating machinery.

• Always check that the correct machining or cutting speed has been selected.

• Do not operate machine when tired or under the influence of alcohol, drugs or certain medicines.

• WHEN USING THE MACHINE ALWAYS WEAR THE APPROPRIATE EYE PROTECTION, EAR

DEFENDERS AND DUST OR FUME INHALATION PROTECTION.

WARNING!!

!

KEEP TOOLS AND EQUIPMENT OUT

OF THE REACH OF YOUNG CHILDREN

Specific Safety Instructions...

• Ensure that the machine is bolted firmly to a workbench before starting work.

• Keep fingers away from the rollers, the bending dies and the shearing blades.

• Do not wear loose clothing which might get drawn into the machine.

• Keep the top cover closed when the rollers are not in use.

!

WHITE

AXMINSTER

W

04

Specifications...

Axminster No. SSBP RTC7030

900118 810165

Shearing Capacity:

Bending Capacity:

Rolling Capacity:

Width of Bending Fingers:

Diameter of Rolls:

Overall L x W x H:

Weight:

Steel 0.5mm, Aluminium 1.5mm

Steel 0.5mm, Aluminium 1.5mm

Steel 1.0mm, Aluminium 1.5mm

25, 50, 75 & 102mm

38mm

380 x 420 x 300mm

46kg

Steel 0.8mm, Aluminium 1.5mm

Steel 0.8mm, Aluminium 1.5mm

Steel 1.0mm, Aluminium 1.5mm

25, 51, 75, 152, 203 & 254mm

38mm

1,020 x 410 x 510mm

130kg

Assembly Instructions ...

The bender comes secured to the base of the crate with four bolts; these bolts can be used

for mounting the bender to the workbench for safe and convenient operation.

The operating handle can be mounted on either side of the machine. To re-position the

handle remove the handle securing plate (see fig 2 & 2a), transfer the handle to the other

side and replace both retaining plates.

Handle

5mm Hexagon key

Grease nipple

Handle securing plate

Handle locking knob

Hex bolt

Fig 2

Fig 2a

05

WHITE

AXMINSTER

W

Illustration & Parts Description...

Cover

Lower roller

Roller clearance adjusting keys

Handle arm

Handle

Handle locking

knob

Lower bending die

Right frame

casting

Cranking arm

Pressure plate

Work surface

Guide block

Upper roller

Upper bending die

Left frame

casting

Fig 3

Roller cover

WHITE

AXMINSTER

W

06

Illustration & Parts Description...

FREEPHONE 0800 371822

Lower roller

adjusting knobs

Cross beam

Back stop

Back stop

support block

Back stop

support rods

Cranking arm

Adjustment bar

Adjustment

bolt

Fig 4

Upper roller

Lower roller

WHITE

AXMINSTER

W

Operating Instructions...

The basic operation of the machine is as follows. The operating handle is attached to a

shaft which serves two functions; firstly it drives the three rollers which carry out the rolling

operation and secondly, with the aid of eccentrics, mounted at the two ends, it raises and

lowers the lower cross bar of the machine. Mounted on the top of this cross bar are the

female bending dies whilst the lower edge carries the upper shear blade. The male bending

dies are fixed to the static cross beam and the lower shear blade is fixed to the table on

which the work is supported. Thus, as the handle is operated, the rolls rotate to form

cylindrical items whilst the main beam goes up and down to either form bends between the

two dies or to shear material between the moving and fixed blades.

Shearing

Shearing can be carried out either by positioning the material between the blades by eye

using a line marked on the sheet or by using the adjustable backstop for more precise

results.

To fit the backstop assembly, screw the two rods into the rear of the static cross beam

(see fig 5), fit the two blocks to the backstop bar with two hex screws (see fig 6) and slide

the bar onto the two rods (see fig 7). The two clamping screws are used to secure the

backstop in the required position on the two rods. Please note that the flange of the

backstop bar should be positioned downwards.

If a precise 90 deg angle is required, the guide block can be fitted to the right hand side of

the table using hex screws. (see fig 8). The guide block should be set square to the lower

blade using an engineer’s square.

To carry out the shearing operation, raise the cross beam to its highest position, slide the

material in between the blades, position it correctly either with the marked line or up against

the back stop and rotate the operating handle to make the cut.

NOTE: If you find that the rollers are not rotating all the way round while sheet

bending, it’s because the pressure plate that clamps the material during

shearing, binds up on it’s springs & the handle can not be turned completely

over. If this accrues, remove the pressure plate.

Bending

As with the shearing operation, bending can either be carried out by lining up the work by

eye or by positioning it with the help of the backstop. If the backstop is to be used it should

be positioned in the upper holes (see fig 7) and the backstop bar reversed so that the

flange is upwards.

Having positioned the workpiece correctly between the bending dies, rotate the handle to

bring the dies together to form the bend. The angle of the bend, up to a maximum of 90

deg., is controlled by limiting the travel of the upper die. If repetition work is to be carried

out then the bend angle can be set by adjusting the height of the cross beam using

adjusting screws shown (see fig 9b).

If it is required to bend only part of the workpiece, as shown in fig. 9, then the appropriate

sections of the upper die can be removed by undoing the hex bolts (see Fig. 9a). When

forming this type of bend it will be necessary to notch the corner as shown in figs 10 & 10a

to achieve the required result.

!

07

WHITE

AXMINSTER

W

Operating Instructions...

Rolling

Start by removing the cover which protects the rollers then lower the rear roller by

slackening off the adjustment screws. (see figs 11 & 12) (see page 10)

Insert the workpiece between the upper and lower rollers and close up the gap between the

rollers using the adjusting screws, (fig 3), until there is a very slight clearance between the

workpiece and the rollers.

Lower the bottom roller using the adjustment knobs (see fig 12) then advance the

workpiece through the rollers by rotating the operating handle until contact is made with

the rear roller. Adjust the rear roller so that the work is slightly deformed as it passes

through the rollers. Make a series of passes through the rollers, closing up the rollers each

time, until the required diameter is achieved. The amount of bend that can be achieved per

pass through the roll depends on the type and thickness of the material being formed. (see

fig 13) (see page 10)

Wire can be rolled into rings by using one of the three grooves at the end of the rollers

(see fig 14).

Alternative position for backstop bar

Shearing Illustrations

Back stop

Support block

Clamping

screw

2 hex bolts

Back stop

Fig 5

Fig 6

Fig 7

08

09

WHITE

AXMINSTER

W

Operating Instructions...

Guide block

Hex bolt

This part of the die

has been removed

Notch

corners

Bending Illustrations

Workpiece

Bolt

Hex screw

Fig 8

Fig 9

Fig 9a

Fig 10

Fig 10a

Fig 9b

!

KEEP HANDS AWAY

FROM DIE PRESS!

Die

WHITE

AXMINSTER

W

Operating Instructions...

10

Grooves for wire

and rod bending

Lower roller

Upper roller

Workpiece

Roller cover adjustment

screw, one each end of

casting

Lower roller adjustment

knobs

Rear roller

Rolling Illustrations

Fig 14 Fig 13

Fig 12

Fig 11

KEEP HANDS AWAY

FROM ROLLERS!

!

11

WHITE

AXMINSTER

W

Adjustments to the Sheet Metal Worker...

Shear bow

Over a period of time the frame which carries the lower shear blade may go out of

alignment, resulting in shear cuts which are not straight. To correct this problem, the bolt

attached to the adjusting bar should be adjusted; tightening the bolt will cause the ends of

the frame to bow outwards whilst loosening it will bring it in (see figs 15 & 16).

Shear Blade Adjustment

To check the alignment of the blades, lower the upper shear blade as far as it will go and

examine the gap between the blades. If one side of the lower shear blade is further away

from the upper blade then the work table will need to be adjusted (see fig 17).

Loosen the screws which secure the work table to the frames and adjust the screws

underneath the table until the two blades meet evenly along their length. Re-tighten the

table securing screw (see fig 17).

Bending Die Adjustment

If t

he line-up of the upper dies becomes uneven for any reason they can be re-aligned. Cut

a piece of hardwood to the same length as the dies, ensuring that opposite faces are flat

and parallel. Raise the upper dies to their highest position, place the wooden gauge on the

lower die, slacken off the clamping screws (see fig 9a) which secure the upper dies and

allow them to r

est on the timber. Check that all the dies are lying flat on the timber and then

re-tighten the bolts securely.

17mm spanner

Adjusting bar

Upper blade

Work table

Gap between

the blade and

work table

Table clamping screws

Table adjusting

screws

Fig 16 Fig 15

Fig 17

WHITE

AXMINSTER

W

12

Maintenance...

• Grease the cranking arms using the grease nipples positioned on the tops of the arm

(see figs 18 & 18a).

• Lightly grease the gears shown in fig 18b.

OIL

Fig 18

Fig 18b Fig 18a

13

WHITE

AXMINSTER

W

Parts List...

www.axminster.co.uk

WHITE

AXMINSTER

W

14

Parts Breakdown...

FREEPHONE 0800 371822

Axminster Reference No: RTC7030 (810165)

Axminster Reference No: SSBP (900118)

WHITE

AXMINSTER

W

900118,810165

www.axminster.co.uk

Axminster Devon EX13 5PH UK

FREEPHONE 0800 371822

SSBP 305mm & RTC7030 750mm Sheet Metal Workers

Please dispose of packaging for the product in a

responsible manner. It is suitable for recycling. Help to

protect the environment, take the packaging to the local

amenity tip and place into the appropriate recycling bin.

Do not dispose of electric tools together with household

waste material! In observance of European Directive

2002/96/EC on waste electrical and electronic equipment

and its implementation in accordance with national law,

electric tools that have reached the end of their life must be

collected separately and returned to an environmentally

compatible recycling facility.

Only for EU countries

Loading...

Loading...