Code 508334

Code 508336

AT&M: 16/12/2014

REF: 508470

CT-90H

Code 508334

CT-90HB

Code 508336

CT-90H & CT-90HB

Extractors

Index of Contents

2

Declaration of Conformity

Copied from CE Certificate

The undersigned, George N. Sifonios

Manufactured by META INTERNATIONAL CO., LTD.

No. 38-46, Ya Tan Rd., TaYa Hsiang. Taichung Hsien,

Taiwan, R.O.C.,

Model Number CT-90 (Dust Collector)

Manufactured by META INTERNATIONAL CO., LTD. is

in compliance with the standards determined in the

following Council Directive.

Machinery Directive: 2006/42/EC

Applicable Standards: EN ISO 121001:2003+A1:2009,

EN ISO 12100-2:2003+A1:2009

Warning

The symbols below advise that you follow

the correct safety procedures when using

this machine.

Fully read manual

and safety instructions

before use

Eye protection

should be worn

Ear protection

should be worn

HAZARD

Motor gets hot

Dust mask

should be worn

Index of Contents 02

Declaration of Conformity 03

What’s Included 030-04-05-06

General Instruction for 230V Machines 07

Specific Safety for Dust Extractors 07-08

Specification 08

Assembly 08-09-10-11-12-13

Illustration and Parts Description 14-15-16-17

Operating Instruction 18

Ducting System 19

Maintenance 19

Weekly LEV System Maintenance Log 20-21

LEV Testing 22

Extraction Accessories 23

Exploded Diagram/Parts List 23-24-25-26-27

Wiring Diagram 28

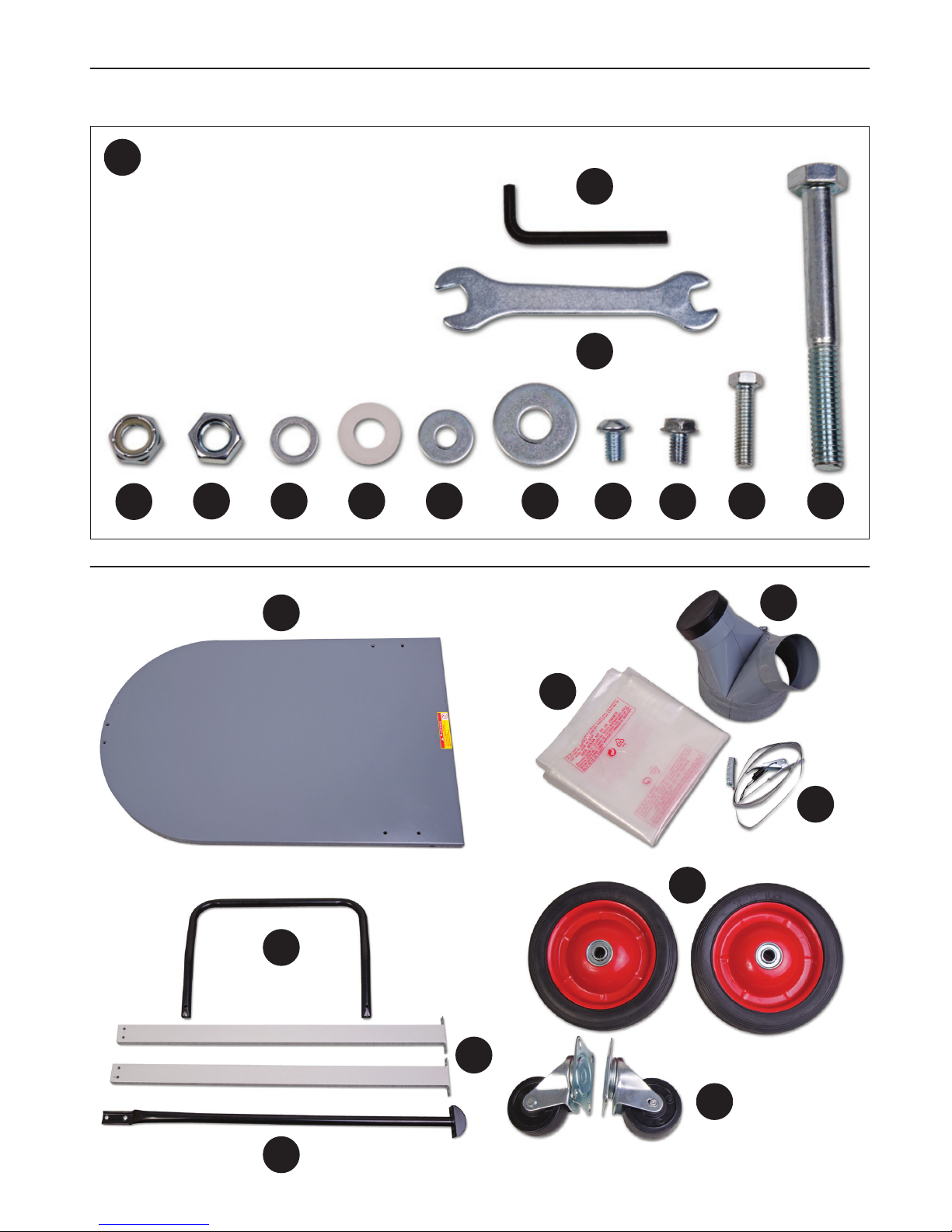

What’s Included

3

Quantity Item Part

508334

1 No Base 1

1 No Tube Support Bar 2

2 No Upright Supports 3

1 No Tube Handle 4

1 No Filter Dust Bag 5

1 No Filter Assembly 6

2 No Foam Seal Bands 7

2 No Filter and Bag Retaining Belts 8

1 No Shaker Paddle Operating Handle 9

2 No Wheels 10

2 No Castor Wheels 11

Extractor Fixings 12

1 No 5mm Hex Key a

1 No 10-12mm Spanner b

2 No 1/2" Lock Nut c

2 No 1/2" Nuts d

2 No Thin Washers e

2 No Nylon Washers f

2 No Medium Washers g

2 No Large Washers h

8 No 5/16" UNC Domed Cap head Bolts i

12 No 5/16" UNC Hex Bolts (Short) j

2 No 5/16" UNC Hex Bolts (Long) k

2 No 1/2" Large Hex Bolts l

1 No Extractor Assembly 13

Quantity Item Part

508336

1 No Base 14

1 No Tube Handle 15

1 No Upright Support 16

1 No Tube Support Bar 17

1 No Inlet Manifold 18

1 No Filter Dust Bag 19

1 No Filter Bag Retaining Belt 20

2 No Wheels 21

2 No Castor Wheels 22

1 No Shaker Paddle Operating Handle 23

1 No Filter Retaining Belt 24

2 No Foam Seal Bands 25

1 No Filter Assembly 26

Extractor Fixings 27

1 No 5mm Hex Key a

1 No 10-12mm Spanner b

2 No 1/2” Lock Nut c

2 No Nylon Washers d

2 No Thin Washers e

2 No Medium Washers f

2 No Large Washers g

1 No Small Phillips Screw No: 10 ANC h

20 No 5/16" UNC Hex Bolts (Short) i

2 No 5/16” UNC Hex Bolts (Long) j

2 No 1/2” Large Hex Bolts k

1 No Extractor Assembly 28

Model Number CT-90H Model Number CT-90HB

Please read the Instruction Manual prior to using your new machine. As well as the operating procedures for

your new machine, there are numerous hints and tips to help you to use the machine safely and to maintain

its efficiency and prolong its life. There is also a detailed description of the parts of your Extractor, which

will enable you to become familiar with terminology we will use in this manual. Keep this Instruction Manual

readily accessible for any others who may also be required to use the machine.

What’s Included

4

CT-90H Extractor

1

6

7

8

9

10

11 12

2

3

4

5

What’s Included

5

CT-90H Extractor

CT-90HB Extractor

12

a

b

c

d e f g h i

j

k l

14

15

16

18

20

19

21

22

17

Continues Over....

What’s Included

6

CT-90HB Extractor

23

26

27 a

b

c d e f g

h

i j

k

24

25

General Instruction for 230V Machines

7

These machines are supplied with a moulded 16 Amp

plug and 3 core power cable. Before using the machine,

inspect the cable and the plug to make sure that neither

are damaged. If any damage is visible, have the damaged

item inspected/repaired by a suitably qualified person.

If it is necessary to replace the plug, it is preferable to

use an ‘unbreakable’ type that will most resist damage.

Only use a 16 Amp plug, and make sure the cable clamp

is tightened securely. Fuse as required. If extension leads

are to be used, carry out the same safety checks on them,

and ensure that they are correctly rated to safely supply

the current that is required for your machine. Remember,

most machines or tools have handles or holding

positions, the power cable is not one of them.

Good Working Practices/Safety

Mains Powered Tools and Machines

Primary Precautions

Workplace/Environment

The following suggestions will enable you to observe

good working practices, keep yourself and fellow

workers safe and maintain your tools and equipment in

good working order.

WARNING!! KEEP TOOLS AND EQUIPMENT OUT

OF THE REACH OF YOUNG CHILDREN

KEEP THE WORK AREA AS UNCLUTTERED AS

IS PRACTICAL, THIS INCLUDES PERSONNEL

AS WELL AS MATERIAL. UNDER NO

CIRCUMSTANCES SHOULD

CHILDREN BE ALLOWED IN WORK AREAS.

The machine is not designed for use outside. Keep the

machine clean; it will enable you to more easily see any

damage that may have occurred. Clean the machine with

a damp soapy cloth if needs be, do not use any solvents

or cleaners, as these may cause damage to any plastic

parts or to the electrical components. It is good practice

to leave the machine unplugged until work is about

to commence, also make sure to unplug the machine

when it is not in use, or unattended. To avoid inadvertent

‘start up’, if your machine is not fitted with a NVR system,

ensure the switch is always returned to the OFF position.

Once you are ready to commence work, remove any

tools, objects or items that could inadvertently get

‘sucked up’ by the machine and place safely out of the

way. Re-connect the machine, ensuring the power cable

is not ‘snagged’ or routed where it could be tripped over

as you move about the workshop; it is not too close to

an unguarded heat source, or is laid over or around a

sharp edge. If the work you are carrying out is liable to

generate flying grit, dust or chips, wear the appropriate

safety clothing, goggles, gloves, masks etc. If the work

operation appears to be excessively noisy, wear

ear-defenders. If you wear your hair in a long style,

wearing a cap, safety helmet, hairnet, even a sweatband,

will minimise the possibility of your hair being caught

up in the rotating parts of the machine, likewise,

consideration should be given to the removal of rings

and wristwatches if these are liable to be a ‘snag’ hazard.

Consideration should also be given to non-slip footwear,

etc.

Do not use this machine if you are tired, your attention is

wandering or you are being subjected to distraction.

Do not use this machine within the designated safety

areas of flammable liquid stores or in areas where there

may be volatile gases. There are very expensive, very

specialised machines for working in these areas. Above

all, OBSERVE…. make sure you know what is happening

around you, and USE YOUR COMMON SENSE.

Specific Safety for Dust

Extractors

Do not use this machine as a vacuum cleaner, try to keep

the waste medium to wood by products.

Do not uplift workshop floor debris (stones, nails, screws,

paper etc., etc). Be aware that wood dust is an explosive

medium.

Do not allow any ‘naked light’ source to occur anywhere

near the machine. This includes cigarettes, matches, etc,

and do not place the machine near any unprotected

light bulbs, that could possibly get broken.

The suction force is generated by a high speed fan unit.

This has the potential to amputate fingers, grab loose

clothing (ties etc.,) and ‘bat’ large chips etc, at high

speeds. Keep all guarding in place, and if access to the

fan becomes necessary (due to blockage etc.,)

Disconnect the machine from the mains supply and

ensure the fan has come to a complete stop before

putting your hands anywhere near to it.

If you are not using ‘clear’ extraction hose, periodically

remove the hose to check that the inlet to the machine

is not getting restricted. ( The safety guard grill of the

inlet duct can be particularly irksome in this way, as long

strand shavings etc., can wrap around the grill fret.)

Keep the particle filter clean. The machine relies on its

ability to ‘blow’ air through the filter, to generate good

Specific Safety for Dust Extractors

8

suction. If the particle filter starts to clog, this reduces the

air flow and hence the machine becomes less efficient.

The particle filter can be cleaned, by using an ‘M’ class

vacuum cleaner, clean the inside of the filter.

Be aware that in dry air periods or areas, the movement

of the air through the machine can generate static

electric fields. These are not normally a problem as the

machine is bonded together via its construction and

the whole is earthed back through the electrical supply;

problems can occur with isolated items, such as stands

or hosing that are insulated from the ground (standing

on rubber feet?, suspended in the air etc).

If possible, try to connect everything together electrically,

to eliminate static shocks.

(Use the integral metal coil in flexible plastic hosing to

connect units together).

Try to route the power cable and the hosing away from

busy walkways.

Do not allow the inlet to become ‘dead ended’, or block

or restrict the outlet, this puts undue strain on the motor

and can lead to overheating.

NOTE: DO NOT FIT PLASTIC WASTE BAGS TO THIS MACHINE!

Code 508334

Model CT-90H

Rating Trade

Power 0.75kW 230V 1ph

Air Flow 850 m³/h at 100mm

Noise Level 65dB

Particle Size 1 micron

Hose Diameter 100mm

Bag Capacity 60 litre

Overall L x W x H 720 x 660 x 1460mm

Weight 32kg

Code 508336

Model CT-90HB

Rating Trade

Power 1.5kW 230V 1ph

Air Flow 2,250 m³/hr at 175mm,

1,200 m³/hr at 100mm

Noise Level 70dB

Particle Size 1 micron

Hose Diameter 1 x 175mm, 2 x 100mm

Bag Capacity 170 litre

Overall L x W x H 1000 x 800 x 1,900mm

Weight 67kg

Specification

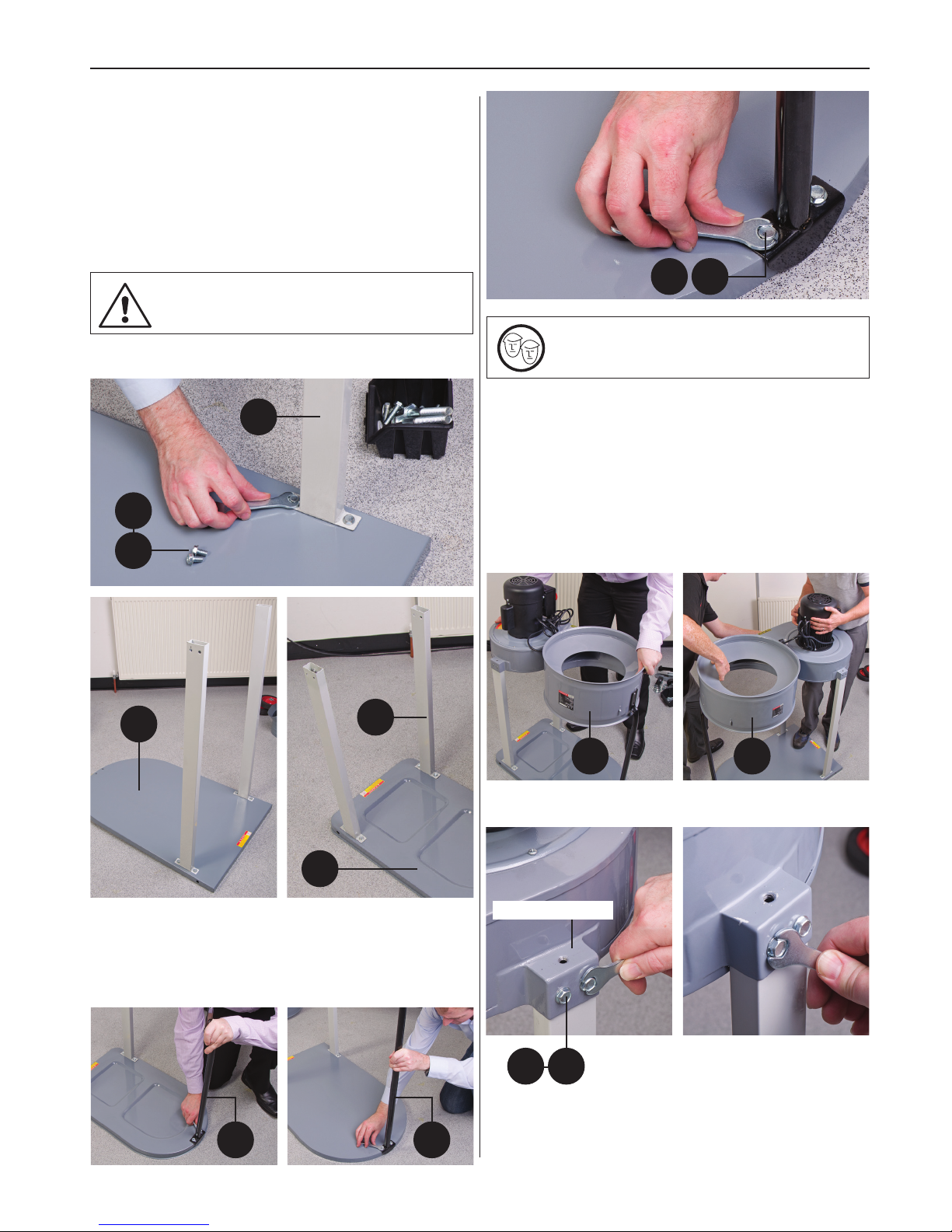

Please read through the section entitled Parts Identification and Description, this will enable you to more readily

identify those parts of the cyclone extractor.

Please note: some of this assembly procedure is best accomplished by two persons. Although

the tasks are not impossible, some of the items are heavy and awkward, and a mishandling

error could cause injury. Please think about what you are doing, your capabilities and your

personal safety. We have added the ‘two person symbol’ to any operation that we recommend

should be a two person task.

Unpack all the boxes and check all the components listed in the “What’s Included” section. If any parts or components

are missing, please contact our Customer Services Department using the procedures and telephone numbers listed

in our catalogue.

Please note: on occasions the packing list is not strictly adhered to. Please check all the boxes, packets

etc. to make sure that all the parts have been accounted for.

PLEASE RECYCLE ANY UNWANTED PACKAGING RESPONSIBLY!

Assembly

Assembly

9

Having unpacked the boxes, put all components where

they are readily to hand.

1. Locate the base (1-14), twelve UNC short bolts

(12j - 27i) and upright supports (3-16). Place one of the

supports (3-16) on to base and line up the pre-drilled

holes with the ones to the side of the base, lightly secure

in place with two UNC bolts, see fig 01-02-03. Repeat for

the remain support.

Fig 01-02-03

14

1

16

3

NOTE: MAKE SURE THE TWO HOLES TO THE TOP

OF THE SUPPORTS FACE OUTWARDS!

2. Locate the tube support bar (2-17), line up the two

holes with the holes to the front of base (1-14) and

lightly secure using two UNC short bolts, see fig 04-05-06.

27i

12j

Fig 04-05-06

172

3. Locate the extractor assembly (13-28), lower the

assembly down and insert the two upright supports

into the extractors mounting brackets to either side of

the assembly, see fig 07-08-09.

4. Line up the holes and secure in place using four UNC

short bolts (12j-27i) and the supplied spanner, 09-10.

NOTE: YOU WILL REQUIRE ASSISTANCE FOR THE

NEXT STEP!

Fig 07-08

Fig 09-10

12j 27i

12j 27i

13 28

Mounting bracket

Continues Over....

Assembly

10

5. Locate a further two UNC short bolts and secure the

front support bar (2-17) to the extractor assembly (13-28),

see fig 11-12.

Fig 11-12

6. Locate the tube handle (4-15), medium washers

(12g- 27f) and 5/16" UNC Hex bolts (long) (12k-27j).

7. Place a washer over the bolts, line up the holes in

the tube handle with the threaded holes on top of the

mounting brackets, inset the bolts and secure the handle

to the extractor assembly with the supplied spanner,

see fig 13-14.

Fig 13-14

12g

12k

27f

27j

4

15

8. Lower the assembly down to the floor, note you may

require assistance as the motor assembly is heavy.

Wheels/ Castor Wheels

Locate the following: wheels (10-21), castor wheels

(11-22), 5/16” UNC domed cap head bolts (12i) , eight

5/16” UNC Hex bolt (27i), 1/2” nuts (12c & d), (27c), nylon

washers (12f & 27d), thin washers (12e & 27e), large

washers (12h & 27g) and large 1/2" Hex bolts (12l & 27k).

1. Put to hand the castor wheels, line up the holes in the

brackets with the pre-drilled holes to the extractor’s base

and secure with domed bolts (12i) for (CT-90H) and Hex

bolts (27i) for (CT-90HB), see fig 15-16.

Fig 15-16

12i

27i

11

22

17

2

2. Place a large washer over the 1/2" hex bolts (12l & 27k)

and slide the bolt through the centre hole to the front

NOTE: USE THE HANDLE, 4-15 TO LOWER THE

EXTRACTOR TO THE FLOOR.

Fig 17

12h

12l

27g

27k

Assembly

11

of one of the wheels, see fig 17. Turn the wheel over and

place a nylon washer then a thin washer down over the

thread of the Hex bolt, see fig 18.

3. Lower the wheel assembly down and slot the hex bolt

through the pre-drilled holes to the side of the extractor’s

base, see fig 19.

Fig 18

Fig 19-20

CT-90H Extractor Only

CT-90H Extractor Only

Before sliding the Hex bolt down through the

second hole, screw on an 1/2" Hex nut (12d) onto

the thread, see fig 20.

Tighten the Hex nut (12d) up against the angled

bracket, see image above.

4. Locate the 1/2" locking nuts (12c & 27c) and screw it

onto the thread, see fig 21 then tighten using two

spanners or open-ended sockets, see fig 22.

Fig 21-22

5. Repeat steps 2-4 for the remaining wheel assembly,

see fig 23-24. Stand the extractor upright.

12f

12e

27d

27e

12d

Fig 23-24

Continues Over....

Assembly

12

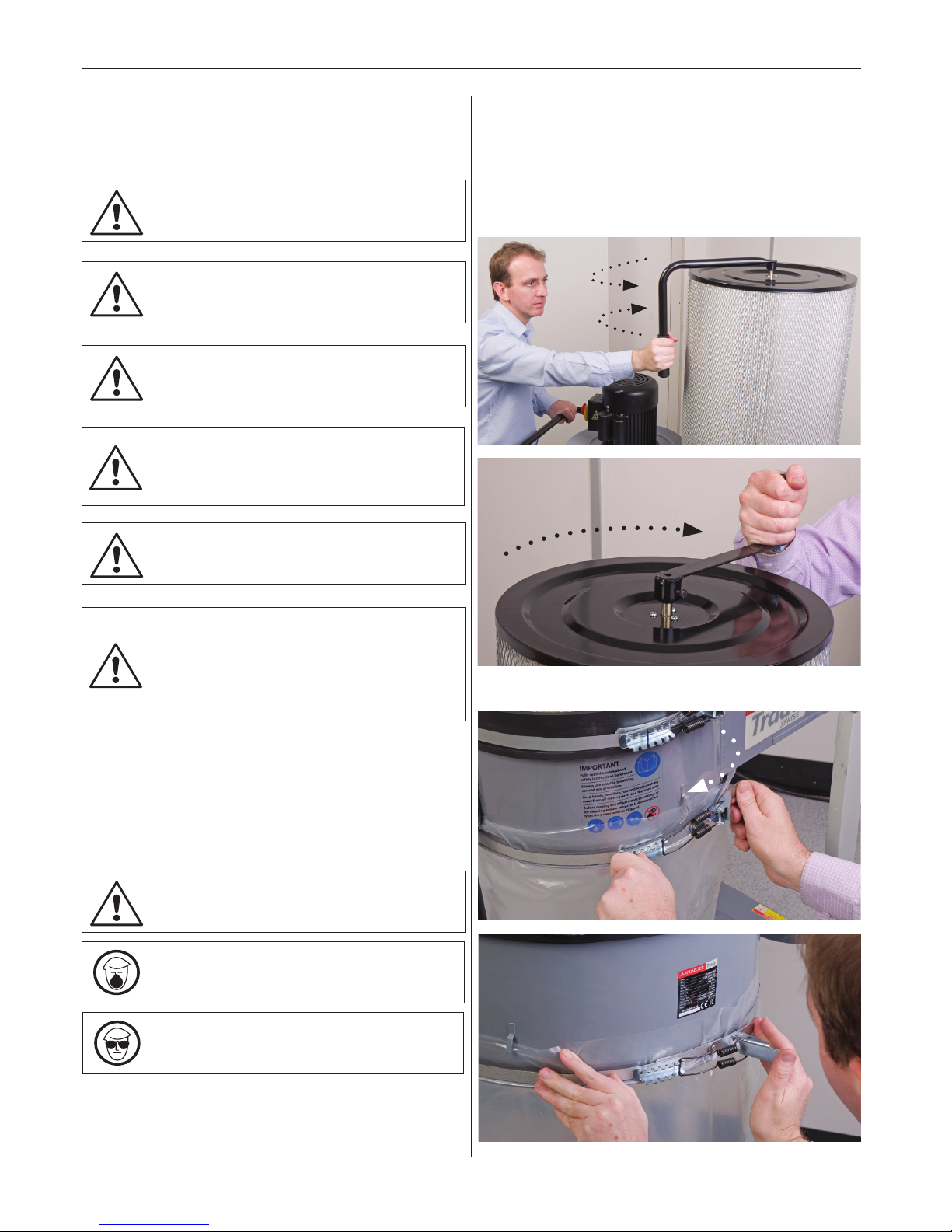

Extractor Filter

1. Locate the filter assembly ( 6-26) filter retaining belts

(8-24) and foam seal bands (7-25).

2. Put to hand the wide foam seal band, peal back the

paper backing, position the end of band up against the

underside of the upper lip on the extractor housing and

firmly press down to secure in place. Carefully peal back

the backing guiding the seal band round the extractor

until it overlaps, use a knife to cut off any excess, see fig

25-26-27.

Fig 25-6-26-27

3. Go round pressing down the band to make sure it’s

stuck firmly down. Locate the filter assembly (6-26), lower

the filter down over the extractor opening until it’s firmly

down, see 28.

4. Straighten the filter retaining belt (8-24), position the

belt around the base of the filter and latch it down to

hold and to seal the filter assembly, see fig 29-30.

Fig 28

Fig 29-30

5. Locate the remaining foam seal band, peal back the

paper backing, position the end of band up against the

edge of the lower lip of the extractor housing pressing

firmily down, see fig 31.

6. Work the band around the extractor as before, find the

dust bag (5-19) and the remaining retaining belt. Open

up the dust bag and place it up and over the lower

extractor housing, see fig 32.

7 25

Paper backing

Upper lip

6

26

24

8

Assembly

13

Fig 32

7. Hook the bag onto the steel hooks around the

extractor housing to temporary hold the bag in place,

see fig 33.

8. Locate the retaining belt, rap the belt around the bag

making sure the belt is positioned on top foam seal band

then latch it down to hold and to seal the bag against the

extractor, see fig 34-35.

Fig 33-34-35

Shaker Paddle Operating Handle

1. Locate the shaker paddle (9-23), insert the handle

mounting over the paddle drive shaft making sure the

clamping bolt is positioned over the machined face then

tighten the bolt using the supplied spanner to secure the

handle, see fig 36-37-38.

Fig 36-37-38

Inlet Manifold (CT-90HB Extractor Only)

Locate the inlet manifold (18) and the small Phillips screw

(27h). Insert the manifold over the extractors inlet and

line up the threaded hole in the inlet with cutout slot in

the manifold, see fig 39. Secure the manifold in place with

the Phillips screw, see fig 40.

Fig 39-40

5

19

Fig 31

Bag hook

9

23

18

27h

Illustration and Parts Description

14

CT-90H

Filter

Shaker paddle operating handle

Tube handle

Motor assembly

Upright supports

Wheels

Base

Filter dust bag

Tube support bar

Bag retaining belt

Filter retaining belt

Extractor assembly

NVR switch assembly

Illustration and Parts Description

15

NVR switch assembly with (O)

indicating (OFF) and (I)

indicating (ON).

Shaker paddle assembly

For emergencies “SLAP” the shroud

down to “STOP” the machine.

Dust extraction outlet

Filter and dust bag and retaining steel beltsMotor vents

OFF

ON

Illustration and Parts Description

16

Filter

Shaker paddle operating handle

Tube handle

Motor assembly

Upright supports

Wheels

Base

Filter dust bag

Bag retaining belt

Filter retaining belt

Extractor assembly

NVR switch assembly

CT-90HB

Illustration and Parts Description

17

NVR switch assembly with (O)

indicating (OFF) and (I)

indicating (ON).

Filter retaining steel belt clip

For emergencies “SLAP” the shroud

down to “STOP” the machine.

Bag hook to hold the dust bag in place when fitting the retaining steel belt

Inlet moulding with lid

Shaker paddle assembly, rotate the handle to operate the paddles with-in the filter assembly

OFF

ON

Operating Instructions

18

CONNECT THE POWER SUPPLY TO THE MAINS

AND SWITCH ON!

DISCONNECT THE POWER SUPPLY FROM THE

MAINS!

DISCONNECT THE POWER SUPPLY FROM THE

MAINS!

WAIT UNTIL IT’S UP TO FULL SPEED AND CHECK FOR

SIGNS OF VIBRATION, IF ALL IS WELL SWITCH OFF

AND WAIT UNTIL THE EXTRACTOR HAS COME TO A

COMPLETE STOP.

IF THE EXTRACTOR FAILS TO START UP OR ANY

OTHER STRANGE NOISES APART FROM VIBRATION

SOUNDS, CONTACT THE “TECHNICAL SALES” FOR

SUPPORT.

Phone: 03332 406406

Email: technical@axminster.co.uk

Testing the Extractor

WARNING!! MAKE SURE CHILDREN ARE

KEPT AWAY FROM THE EXTRACTOR WHILE IN

OPERATION.

NOTE: ALWAYS TURN ON/OFF THE EXTRACTOR

BY THE NVR CONTROL SWITCH NOT THE MAINS

SWITCH!

Connect the extraction hose/s to the adaptor outlet.

After a period of time dust, sawdust and shavings can

build-up causing blockages and reduced suction

performance. Carry out the following checks to keep

your extractor working at peak performance.

• Check the lter for signs of buildup of sawdust and

move the shaker paddle handle back and forth to

remove any built up dust and debris from inside,

see fig 41-42. Then clean the outside with a vacuum

cleaner.

Reduced Suction Performance

Fig 41-42

Fig 43-44

• Check the hoses for blockages

• Check the dust bag and empty if full, see g 43-44.

WARNING! ALWAYS WEAR A DUST MASK

WARNING! ALWAYS WEAR EYE PROTECTION

Ducting System

19

WARNING! ALWAYS WEAR A DUST MASK

WARNING! ALWAYS WEAR EYE PROTECTION

Daily

• Empty the collection bag before it overfl ows, wear a

dust mask whilst removing and emptying the bag.

Weekly

• Check the inlet and outlet duct and remove any

accumulated sawdust.

•Check the inlet hoses for splits and cracks, repair as

necessary.

• Check the dust collection bag for wear and tear,

especially around the neck of the retaining belt. If wear

or fraying is occurring, replace the bag.

• Check the motor for dust, sawdust, shavings etc, build

up. If this has occurred, clean with a vacuum cleaner, see

fi g 45.

• Move the shaker paddle handle back and forth to

remove any built up dust and debris from inside the fi lter.

Monthly

• Remove the fi lter securing belt and remove the fi lter

assembly, see fi g 46 using an ‘M’ class vacuum cleaner,

clean inside the fi lter.

Basic Maintenance

Fig 45

Fig 46

Clean the motor housing vents

Maintenance

Many manufacturers will state the volume of air required for each machine in their manual. If

not, note the size of the extraction port and use the chart below

Basic design

• Keep it simple, don’t over complicate the system.

• Keep it straight, ducting runs should all be straight with as few bends as possible.

• Keep transfer duct as big as required by the extractor, this should get larger towards the

extractor.

• Keep fl exible duct to a minimum. If the machine cannot be connected to the system by

solid ducting only then should fl exible ducting be used for the fi nal connection.

• Keep branches joining the duct to a maximum of 45° When branches join the main duct

ideally they must enter at the side or the top at an angle of a maximum of 45° towards the

direction of fl ow.

• Fit Blastgates to maximise effi ciency and balance the system.

The negative pressure inside the ducting draws air into the system. Incorrect sizing of the

duct, too many bends coupled to lots of fl exible hose induces losses into the system and in

badly designed systems this is akin to leaving the hand brake on in a vehicle.

Example: for a single machine with a 100mm port an extractor of a minimum of 700m³/hr

will be suffi cient. For multiple machines count the number of extraction ports per size,

multiply the number of each size by the volume of air required. Then add the results

per outlet size to give you a total volume of air required. This total is for all the machines

operating at the same time. You then must decide which and how many machines will be

used at the same time. Divide the total volume of air required by this number and add 500m³/

hr. Choose an extractor that gives the airfl ow required by your calculations. Look at the main

inlet size of the extractor, this is the size of the main duct to be used. In larger systems the

ducting should get larger towards the extraction unit as more machines that are in use are

added to maintain the correct air speed in the duct. This is very important; if the airfl ow is too

low a build up of dust and debris will occur and is a fi re and explosion risk. If the air speed is

high then the system will be noisy but there will be no deposits in the ducting. Always use

blastgates to close off airfl ow to machines that are not in use.

outlet size volume of air required

50 200 m³/hr

100 700 m³/hr

125 1100 m³/hr

150 1600 m³/hr

200 2800 m³/hr

Gerneral Info

Weekly LEV System Maintenance Log

20

Week

Date

Checked by

Check all ducting

for physical damage

Check inlets, clear any

obstructions if found

Check operation of all

blastgate controls

Check filter(s) for damage

and condition

Check filter shakers

(if fitted) and clean filters

Check waste collector(s)

for damage and condition

Empty waste collectors

if necessary

Comments

1

2

3

4

5

6

7

8

9

10

11

12

REMOVE AND

CLEAN FILTERS

13

14

15

16

17

18

19

20

21

22

23

24

REMOVE AND

CLEAN FILTERS

25

26

27

28

29

30

31

32

33

34

Weekly LEV System Maintenance Log

21

Week

Date

Checked by

Check all ducting

for physical damage

Check inlets, clear any

obstructions if found

Check operation of all

blastgate controls

Check filter(s) for damage

and condition

Check filter shakers

(if fitted) and clean filters

Check waste collector(s)

for damage and condition

Empty waste collectors

if necessary

Comments

35

36

REMOVE AND

CLEAN FILTERS

37

38

39

40

41

42

43

44

45

46

47

48

49

REMOVE AND

CLEAN FILTERS

50

51

52

Nearly 14 months it is now a legal requirement to have

your system tested and certified

53

54

55

56

57

58

59

60

LEV Testing

22

Why should I bother with LEV?

The law says you must control the risks from these

substances (the Control of Substances Hazardous to

Health (COSHH) Regulations). Installing LEV may help

you to do this.

For more information about other ways of eliminating or

reducing airborne contamination at work look, at HSE’s

COSHH website, hse.gov.uk/coshh.

Ref Code: HSG258

The book above provides guidance on the supply of

local exhaust ventilation (LEV) equipment. It describes

the principles and good practice of deciding on,

designing, commissioning and testing cost-effective LEV.

The guidance is written for the suppliers of LEV goods

and services, but will also be helpful for employers and

managers in medium-sized businesses, and trade union

and employee safety representatives. All of these groups

need to work together to provide, maintain and use

effective LEV and to reduce exposure from inhalation of

hazardous substances.

The book contains information about the roles and

legal responsibilities of suppliers and of their clients

as employers; competence; principles of good design

practice for effective LEV hoods and their classification;

ducts, air movers, air cleaners; and system documentation

with checking and maintenance schedules, and the

marking of defective equipment.

It also includes guidance on the specification of LEV; the

supplier’s quotation; commissioning; zone marking; the

user manual and logbook; testing and hood labels.

Health and Safety Executive

A guide to local exhaust ventilation (LEV)

For all of our accessories please see our catalogue or visit

our website at axminster.co.uk.

Contact us on:

Call: 03332 406406

Web: axminster.co.uk

Extraction Accessories

Extraction Accessories

Exploded Diagram/Parts List

23

CT-90H

Exploded Diagram/Parts List

24

CT-90HB

Exploded Diagram/Parts List

25

CT-90H

CT-90HB

No Description Q’TY

1 Motor 1

2 Motor Plate 1

3 Handle 1

4 Base 1

5 Collector Support 1

6 Canister Filter Unit 1

7 Hex Bolt 1/2” x 4” 2

8 Bearing Wheel 7” 2

9 Belt Clamp 1

10 Plastic Dust Bag 1

11 Washer 1/2” x 19 2

12 Washer 1/2” x 34 2

13 Impeller Washer 1

14 Lock Nut 1/2” 2

15 Hex Bolt 5/16” x 1/2” 20

16 Cap Screw M6 x 20 1

17 Tube Cap 2

18 Leg 2

19 Manin Housing 1

20 Plastic Washer 2

21 Round HD screw M5 x 10 12

22 Impeller 1

23 Hex Bolt 1/4” x 1” 4

24 Motor Packing 1

25 Caster 2-1/2” 2

26 Hex Bolt 5/16” x 1-1/4” 2

27 Washer 1/4” x 18 4

No Description Q’TY

1 Base 1

2 Leg 2

3 Manin Housing 1

4 Collector Support 1

5 Plastic Dust Bag 1

6 Belt Clamp 1

7 Impeller 1

8 Motor 1

9 Impeller Washer 1

10 Spring Washer 1/4” 1

11 Cap Screw M6 x 30 (LH) 1

12 Round HD Screw 3/16” x 3/8” 12

13 Hex Bolt 5/16” x 1” 4

14 Washer 5/16” x18 4

15 Handle 1

16 Tube Cap 1” 2

17 Flange Bolt 5/16” x 1/2” 18

18 Hex Bolt 5/16” x 1-1/4” 2

19 Caster 2-1/2” 2

20 Bearing Wheel 7” 2

21 Hex Bolt 1/2” x 4” 2

22 Lock Nut 1/2” 2

23 Key 1

24 Flange Nut 5/16” 4

25 Plastic Washer 1/2” 2

26 Washer 1/2 “x 19 2

27 Power Cord 1

28 Motor Packing 1

29 Washer 1/2” x 34 2

30 Inlet 7” x 4” x 4” 1

31 Inlet Cap 1

32 Round HD Screw 3/16” x 3/8” 1

33 Inlet Cover 7” 1

35 Switch 1

36 Canister Filter Unit 1

37 Hex Bolt 5/16” x 3/4” 2

Exploded Diagram/Parts List

26

CT-90H Filter Assembly CT-90HB Filter Assembly

Exploded Diagram/Parts List

27

CT-90H Filter Parts List

CT-90HB Filter Parts List

No Description Q’TY

1 Canister Filter 1

2 Spindle 1

3 Bearing Fixing Plate 2

4 Bearing 2

5 Round HD Screw M 5 x 8 6

6 Lower Fixing Plate 1

7 Fixing Plate 2

8 Round HD Screw M 5 x 15 4

9 Nut M5 4

10 Round HD Screw M6 x10 1

11 Washer 1/4” x 18 7

12 Flapper 3

13 Hex Bolt M6 x 10 6

14 Belt Clamp CK-370 1

15 Foam Strip 5 x 32 x 1200 1

16 Sponge 10 x 15 x 1200 1

17 Foam Strip 4 x 20 x1200 1

18 Handle Arm 1

19 Hex Bolt M6 x 16 1

20 Handle 1

21 Lock Nut M10 1

No Description Q’TY

1 Canister Filter 1

2 Lower Fixing Plate 1

3 Spindle 1

4 Handle 1

5 Bearing Fixing Plate 2

6 Fixing Plate 2

7 Flapper 3

8 Nut M5 4

9 Round HD Screw M6 x10 6

10 Washer 1/4” x 18 7

11 Round HD Screw M 5 x 15 4

12 Round HD Screw M 5 x 8 6

13 Hex Bolt M6 x 16 1

14 Hex Bolt M6 x 10 1

15 Foam Strip 4 x 20 x1560 1

16 Foam Strip 5 x 32 x 1560 1

17 Sponge 10 x 15 x 1560 1

18 Belt Clamp CK-500S 1

19 Bearing 2

20 Handle Sleeve 1

21 Tube Cap 1

Wiring Diagram

Axminster Tools & Machinery Ltd

Weycroft Avenue, Axminster, Devon EX13 5PH

axminster.co.uk

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to

protect the environment, take the packaging to the local recycling centre and place into the appropriate

recycling bin.

Do not dispose of electric tools together with household waste material. In observance of European

Directive 2002/96/EC on waste electrical and electronic equipment and itsimplementation in accordance

with national law, electric tools that have reached the end of their life must be collected separately and

returned to an environmentally compatible recycling facility.

Only for EU countries

Free Three Year Guarantee on Axminster Hobby, Trade and Industrial Series woodworking and

engineering machines, Axminster Air compressors and Air Tools, and bench top grinders - no

registration necessary just proof of purchase.

We will repair or replace at our discretion and will collect only from a UK mainland address,

irrespective of the original delivery address.

The Guarantee assumes that you have bought the correct machine for the required operation, in accordance with our

guidelines; have operated and maintained it in accordance with the instruction manual; and that all cutting machines

will be used with a blade which is sharp and serviceable at all times. It does not cover consumable items purchased with

the original product, including original blades or abrasives.

Normal wear and tear; misuse, abuse and neglec t are excluded and the machine should not have been modified in any

way. Please do not attempt to service the product without first contacting us; we are happy to guide you but failure to

do so may invalidate the guarantee.

The Axminster guarantee is available on

Hobby, Trade, Industrial, Engineer, Air Tools & CNC Technology Series machines

It’s probably the most comprehensive FREE guarantee ever- buy with confidence from Axminster!

So sure are we of the quality, we cover all parts and labour free of charge for three years!

• Look for the icon and put your trust in Axminster

• No registration necessary - just keep your proof of purchase

• Optional Service Plan for Industrial Series machinery

AXMINSTER

SERIES

Hobby

Great value & easy-to-use,

perfect for use at home

Quality, precision machines

for the workshop or education

Precision CNC machines for

industry and education

Solid, reliable machines

designed for daily use

Small machines for the home

engineer

Top performers with class leading features and

build quality for use in busy workshops

Compressors and tools for home or

workshop use; durable and great value

The Guarantee is transferable from owner to owner in the first three years but you must have original proof of purchase.

Should we need to replace a machine in the first three years the guarantee will still continue to be effective from the

original purchase date.

Full Terms and Conditions can be found at axminster.co.uk/terms

This guarantee does not affect your statutory rights.

For more information visit axminster.co.uk/3years

Loading...

Loading...