AT508WL

Woodturning Lathe

Code 102265

Original Instructions

AT&M: 04/07/2019

BOOK REF : 103273

Index of Contents

EU Declaration of Conformity 02

What’s Included 03-04

General Instructions for 230V Machines 05

Specific Safety Instructions for Woodturning Lathes 06

Specification 06

Assembly 08-09-10-11

Illustration and Parts Description 12-13-14-15

Operating Instructions

Rotating the Headstock 1

Removing the Faceplate 17

Live Centre Nose Cone 17

Indexing Facility 18

Removing the Drive Centre 19

Changing the Belt Speed 19

Alignment Centre 20

Digital Display 1.5V SR44 Battery 20

Maintenance 21

Exploded Diagram/Parts List 22-23-24-25-26-27

Wiring Diagram 28

CE Certificate 29-30

Notes 31

EU Declaration of Conformity

Cert No: KC-INV

Axminster Tools & Machinery Ltd

Axminster Devon

EX13 5PH UK

axminster.co.uk

declares that the machinery described:-

Type Woodturning Lathe

Model AT508WL

Signed

Andrew Parkhouse

Operations Director

Da te: 5/12/2014

The symbols below advise the correct safety procedures when using this machine.

EU Declaration of Conformity

This machine complies with the following directives:

2006/42/EC

2004/108/EC

EN 61000-6-2:2005

EN 61000-6-4: 2007+A1:2011

and conforms to the machinery example for which the

EC Type-Examination Certificate No RA/2014/80020C, RD/2014/C0010C

has been issued by KINGCRAFT MACHINERY COMPANY LIMITED.

at: No. 26, Gong Yeh 12rd., Dah Li District, Taichung City, Taiwan

and complies with the relevant essential health and safety requirements.

EN ISO 1200: 2010

EN 60204-1: 2006+AC:2010

Fully read manual

and safety instructions

before use

Ear protection

should be worn

Eye protection

should be worn

2

Dust mask

should be worn

HAZARD

What’s Included

Quantity Item Part Model Number

1 Variable Speed Wood Lathe A AT508WL

1 Tool Rest Extension Post B

1 Spanner C

1 Live Centre Push Rod D

1 Push Rod E

1 Tool Rest (Small) F

1 Tailstock Live Centre G

1 Alignment Centre 2MT H

1 4 Prong Drive Centre 2MT I

1 Face Plate J

1 Tool Rest (Large) K

4 Adjustable Feet L

2 Lathe Stands M

1 Lathe Extension Bed N

1 Motor Handle O

1 Spindle Locking Pin (with Magnetic Base) P

Fixing Q

A

3

Continues Over....

What’s Included

P

O

K

F

E

C

B

D

G

H

J

I

Q

M

N

4

L

General Instructions for 230V Machines

The following will enable you to observe good working

practices, keep yourself and fellow workers safe and maintain

your tools and equipment in good working order.

WARNING!! KEEP TOOLS AND EQUIPMENT

OUT OF REACH OF YOUNG CHILDREN

KEEP WORK AREA AS UNCLUTTERED AS IS

PRACTICAL. UNDER NO CIRCUMSTANCES

SHOULD CHILDREN BE ALLOWED IN WORK

AREAS.

Mains Powered Tools

• Tools are supplied with an attached 13 Amp plug.

• Inspect the cable and plug to ensuree that neither are

damaged. Repair if necessary by a suitably qualified person.

• Do not use when or where it is liable to get wet.

Workplace

• Do not use 230V a.c. powered tools anywhere

within a site area that is flooded.

• Keep machine clean.

• Leave machine unplugged until work is about to commence.

• Always disconnect by pulling on the plug body and not the

cable.

• Carry out a final check e.g. check the cutting tool

is securely tightened in the machine and the correct

speed and function set.

• Ensure you are comfortable before you start work,

balanced, not reaching etc.

• Wear appropriate safety clothing, goggles, gloves,

masks etc. Wear ear defenders at all times.

• If you have long hair wear a hair net or helmet to prevent it

being caught up in the rotating parts of the machine.

• Consideration should be given to the removal of rings and

wristwatches.

• Consideration should also be given to non-slip footwear etc.

• If another person is to use the machine, ensure they are

suitably qualified to use it.

• Do not use the machine if you are tired or distracted

• Do not use this machine within the designated safety areas

of flammable liquid stores or in areas where there may be

volatile gases.

• Check cutters are correct type and size, are undamaged

and are kept clean and sharp, this will maintain their

operating performance and lessen the loading on the

machine.

• OBSERVE…. make sure you know what is happening

around you and USE YOUR COMMON SENSE.

5

Specific Safety Instructions for Wood turning Lathes

1. Do not use ‘split’ work pieces.

2. Always start at the lowest speed when starting a new task.

3. Check that the tool rest is at or slightly below the centre line

of the work piece.

4. Check the work piece is securely mounted in the lathe before

switching on the power.

5. Rotate the work piece by hand, to check that it is centralised,

clear of the tool rest, not ‘split’ or has loose knots.

6. Where lathes have the facility to be reversed; check the

machine is rotating in the correct

direction.

7. If your lathe has the facility to run in reverse, you must ensure

Specification

that the mounting accessories (chucks, faceplates etc.,) can

be ‘locked’ onto the lathe mandrel, and in the case of chucks,

have some form of security device to prevent them ‘unwinding’

during reverse operation.

8. Make sure your tools are stored/racked away from the

turning area of the lathe. Do not reach over a rotating work

piece at any time.

9. Do not ‘dig in’ or try to take too large a cut.

10. Do not leave the lathe running unattended; or leave the

machine until everything is stopped.

11. Some turning tools may have specific sharpening angles

that have been determined by the manufacturers; when

re-sharpening, adhere to these angles to maximise the finish

of your work.

Code 102265

Model AT508WL

Rating Trade

Power 2.2kW 230V 1ph

Speed 60-1,200, 100-2,200, 140-3,700 rpm

Spindle Taper MT2

Spindle Thread M33 x 3.5mm

Taper Tailstock MT2

Distance Between Centres 762mm + 500mm with extension bed (depending on the centres fitted)

Max Diameter over Bed 508mm

Tool Rest Stem Diameter 30mm

Overall L x W x H 1,800 (plus 500mm with Bed Extension) x 600 (plus 330mm with Side Extension) x 1,230mm

Weight 280kg

6

Assembly

Important Notes

Please take some time to read the section entitled ‘Illustration

and Description’ to identify the various parts of your machine

so that you are familiar with the terminology we will use to

enable you to set up and operate your table lathe safely and

correctly.

The lathe and its accessories will arrive coated with corrosion

preventative grease. This will need to be cleaned from the

lathe, its components and accessories prior to it being set up.

Wearing overalls and rubber gloves is advisable, as is eye

protection. After cleaning, lightly coat the machine with a

thin layer of light wax.

UNPACK YOUR NEW LATHE AND RECYCLE

THE PACKAGING RESPONSIBLY. THE CARDBOARD PACKAGING IS BIODEGRADABLE.

WARNING: THE WOOD LATHE IS A HEAVY

MACHINE, IT IS ADVISABLE TO USE A LIFTING

DEVICE SUCH AS A HOIST, SCISSOR LIFT OR

SEEK HELP WHEN ASSEMBLING THE LATHE.

2. Carefully remove the headstock, tailstock and tool rest banjo

and place safely aside, see fig 06-07-08.

NOTE: Before you remove the headstock assembly, first

remove the Electronic inverter control box from the pallet

by removing the two securing screws and place safely aside,

see fig 05.

3. Using a lifting device or seek help, lift the lathe bed from the

pallet onto a work bench in rediness to mount the leg stands

(M).

Control box unit

Phillips screws

Fig 05

Fig 06-07-08

WARNNING! WE RECOMMEND YOU REMOVE

THE HEADSTOCK, TOOL REST AND TAILSTOCK

FROM THE LATHE BED BEFORE LIFTING THE

LATHE ASSEMBLY OFF THE PALLET

PLEASE NOTE: The Trade Lathe comes 90%

pre-assembled. In order to reduce the footprint of the

machine for packaging, several items are dismounted from

the machine and need to be re-affixed. Please check all the

boxes, packets etc. to make sure that all the parts have

been accounted for.

1. Remove the headstock and tailstock stop pins to the ends of

the lathe bed and place safely aside, see fig 01-02.

Fig 01-02

Tailstock

Banjo

Stop Pin

7

Headstock

Continues Over....

Assembly

Stand Assembly

1. Locate the two lathe stands (M) and the four adjustable feet

(L). Screw the threaded feet into the pre-drilled holes to the

base of the stands, see fig 09.

Fig 09

M

L

2. Place the leg stands on their feet, locate the eight M10 bolts,

spring washer/washers, see fig 10. Place a washer/spring washer

over each bolt, using a lifting device or get assistance lift the

lathe bed up about 700mm from the floor. Line up the four

machined holes two each end of the lathe bed with the holes

in the leg stands (M) and secure in place with the four M10

bolts. Using a 17mm socket or spanner securely tighten, see figs

11-12-13.

Fig 10

M10 Bolt

Fig 11-12-13

700mm

3. Before replacing the headstock banjo/tool rest and

tailstock to the lathe bed, remove the oil residue from all

machined surfaces, see fig 14-15.

Fig 14-15

8

4. Make sure the lathe bed is thoroughly cleaned then replace

the headstock banjo/tool rest and tailstock, replace the stop

pinsto either end of the lathe bed, see fig 16-17-18-19.

Fig 16-17-18-19

Assembly

Hex screw

Hex key

Electronic Inverter Control Box

Locate the inverter control box and two Hex screws. Position

the control box up inside the leg stand (M) and line up the

threaded holes in the mounting bracket with the top two holes

inside the leg stand assembly. Using a Hex key insert the two

Hex screws through the leg stand casting and into the control

box mounting bracket, see fig 20-21-22.

Fig 20-21-22

Mounting bracket

Inverter control box

Main Control Box

The main control box has a magnetic base enabling it to be

positioned anywhere on the lathe, see fig 23.

9

Continues Over....

Fig 23

Assembly

Lathe Bed Extension

The extension bed (N) will increase the capacity of your lathe in three

ways. The lathe can be used with the main bed either way around, this is

because the extension bed (N) can be mounted either on the end of the

main bed to extend the distance between centres, on the leg stand (M)

to create a bigger turning diameter, or on a mounting plate machined

onto the side of the main bed. This allows bowl turning with the

headstock rotated to suit.

Setup 1 ( to increase distance between centres)

Locate the four cap head bolts/spring/washers and the bed extension

(N). Remove the stop pin from one side of the lathe bed and place safely

aside. Place a sping/washer over each cap head bolt, with help align the

for holes in the bed extension (N) with four threaded holes to the end of

the lathe bed. Insert the bolts through the castings and just nip up the

bolts. Manoeuvre the tailstock over the two beds and lock in place. (this

aligns the two beds) Now tighten all four cap head bolt to secure the

extension in place. Replace the stop pin in the extension bed (N), see fig

24-25.

Fig 24-25

Stop pin

Height mounting plates

Fig 27-28

Cap head bolt

Threaded holes

N

Setup 2 ( mounted to leg stand)

1. The extension bed can be mounted to the leg stand (M) in

two set heights for the required piece being turned, see fig 26.

Align the holes in the extension bed with the thread holes to

one of the set height mounting plates and secure with the four

cap head bolts, see fig 27-28.

3. Loosen tool rest extension clamp and insert one of the two

tool rests (F) or (K) and secure in position.

4. Remove the tailstock assembly and place safely aside, lift up

the headstock locking handle and slide the headstock assembly

until it’s up against the edge of the lathe bed and lock in place.

Insert the stop pin in the lathe bed and extension bed, see fig

29.

Fig 29

2. Slide the banjo assembly into the extension bed. Loosen the

tool rest clamping handle, locate the tool rest extension post (B)

and insert it into the banjo and tight the clamping handle.

10

Assembly

Setup 3 ( mounted to side of the lathe bed)

The extension bed can be mounting to one side of the lathe

bed, this feature allows you to use the headstock at a set angle

for turning bowls and gives the user more flexibility.

Position the extension bed so the holes line up with the ones

on the mounting plate and secure in place as described on the

previous setups, see fig 30-31-32.

Fig 30-31-32

Mounting plate

2. Insert drive centre Morse taper (G) into the headstock

spindle and repeat the process for the live centre (I) into the

tailstock barrel. Make sure firmly home, see fig 37-38.

Fig 34

Fig 35-36-37-38

Drive Centre & Live Centre

1. Locate both live and drive centres (I and G). Locate the

spindle locking pin (P), rotate the spindle until the machined

hole on the shaft lines up with the spindle collar access hole.

Insert the locking pin to lock the spindle and undo the two

locking grub screws on either side of the boss, see fig 33. Place

the supplied spanner (C) over the boss and remove the face

plate, place safely aside, see fig 34. Clean all traces of oil and

greese from the drive/tailstock spindle barrels and live/drive

centres/morse tapers, see fig 35-36.

Fig 33

Grub screw

P

I

G

11

Illustration and Parts Description

Motor locking handle

Motor handle

Four prong

drive centre

Tailstock

Tailstock

barrel lock

Tool rest

Tool rest lock

Setup 1

Headstock locking handle

Control box with

magnetic base

Lathe bed

Electronic inverter control box

Flexible control box cord

Headstock

Banjo lock handle

Stand

Adjustable foot

Digital readout

Live centre

Tailstock wheel

Headstock pivot lock

Pull the pivot lock back

enabling you to rotate

the headstock

Setup 2

Mounting plate

12

Tailstock locking leverExtension bed

Illustration and Parts Description

B

A

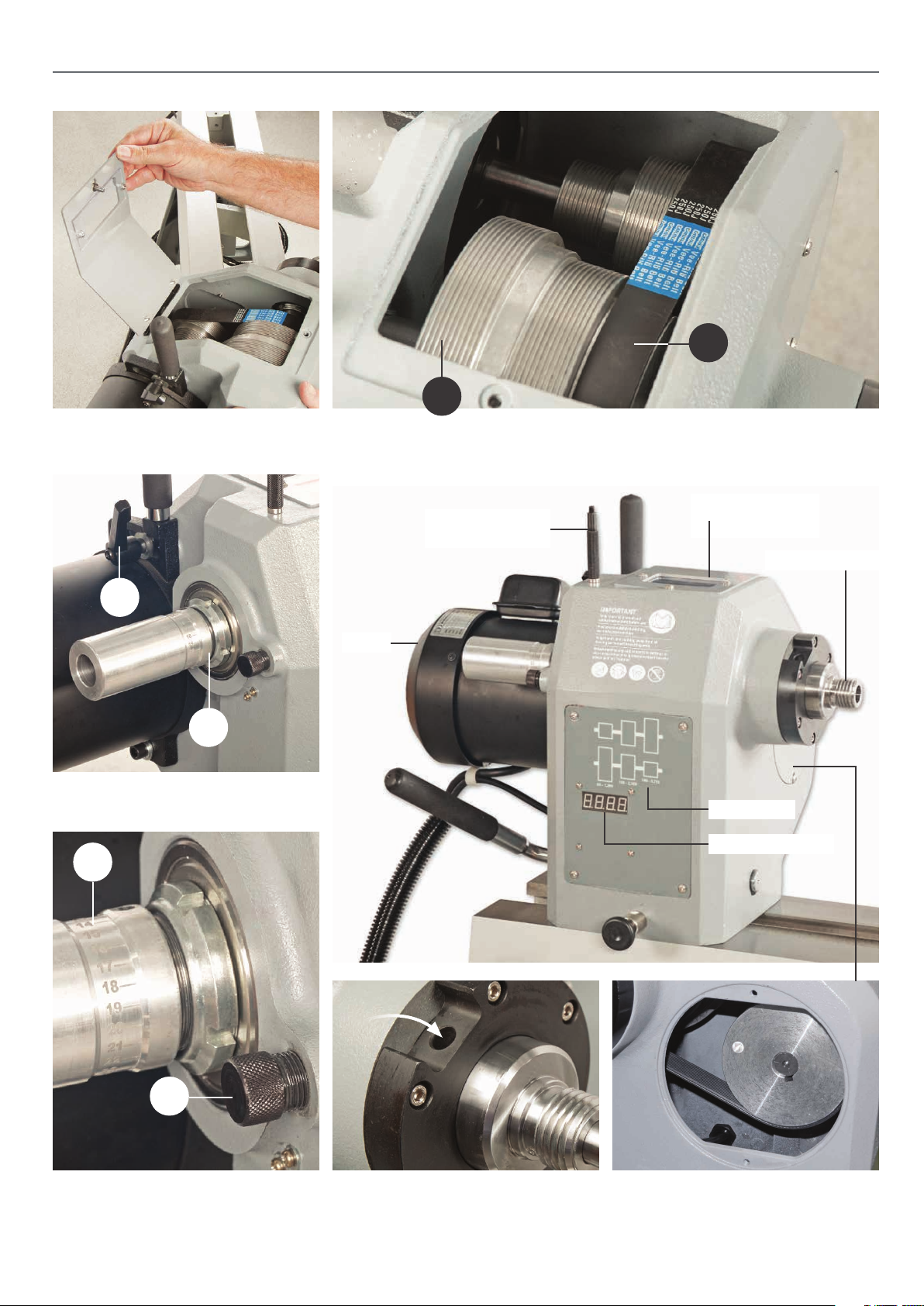

Motor pulley access panel Motor and spindle pulleys (A), Drive belt (B)

B

Indexing assembly (A)

Motor locking handle (B)

A

A

Motor

Spindle locking pin

with magnetic base

Pulley access panel

with window

M33 Spindle thread

Speed chart

Spindle speed LED

B

Indexing ring with 24 positions

at 10˚ segments (A), Indexing locking pin (B)

Spindle collar access hole to use in conjunc-

tion with the spindle pin (P) to lock the spin-

dle when removing the face plate

13

Removing the side access plate from

the headstock allows you easier access

when changing the belt

Illustration and Parts Description

A

B

The control box has a magnetic base enabling it to be positioned anywhere on the lathe.

(Green button) to turn ON and (Red button) to switch OFF

Electronic inverter control box Turn the switch to (O) thus

isolating the lathes power

Forward and Reverse switch, (A), Speed

Control Knob (B), enables you to increase

or decrease the speed of the spindle

Turn the switch to the (I) position to put

power to the main control box

Tailstock barrel locking handle

Battery compartment

• The tailstock has an integrated digital display for accurate

measuring. Wind the tailstock wheel and read the digital display until

required length is reached. Press the mm/inch ‘BLUE’ button to change

display from metric to Imperial. Press the ‘YELLOW’ button reset the

display to ‘ZERO’ and press the ‘RED’ button to power off the unit.

14

• The digital display has a cover to protect the unit whilst the lathe is

in operation and to prevent the display being accidently reset.

• The digital display is powered by an 1.5V SR44 battery

Setup 3

Illustration and Parts Description

Setup 4

B

A

Four prong drive with a 2MT shaft (A) and Tailstock live centre with a 2MT tshaft (B)

15

Operating Instructions

Rotating the Headstock

The headstock can be swivelled a full 360˚ degrees with indexing stops

every 45˚ degrees. To rotate the headstock lift up the Headstock locking

lever (a) and pull the headstock pivot lock (b) out, see fig 39-40. Swivel

the headstock around, you will here a click as the head engages in the

first index stop at 45˚, see fig 41. Pull out pivot lock again, continue

round until the desired angle is reached. Press down the headstock

locking lever to lock the head in position, see fig 42-43-44-45.

Fig 39-40-41-42-43-44-45

a

b

45˚

The headstock can swivel through 360˚ with indexing stops every 45˚

16

Removing the Faceplate

1. Locate the spindle locking pin (P), rotate the spindle until

the machined hole on the shaft lines up with the spindle collar

access hole. Insert the locking pin to lock the spindle, undo the

two locking grub screws on either side of the boss, see 46-47.

Fig 46-47

Spindle collar

P

Operating Instructions

Fig 48

C

Live Centre Nose Cone

The live centre features a removable front nose cone revealing

a small centring pin for turning small work. Removing the pin

allows you to use the hollow live ring centre for holding your

work piece such as bowls.

1. To remove the front nose cone locate the live centre push

rod (D), rotate the cone until you can see daylight through

the machined hole on the main body. Insert the rod through

the hole thus locking the spindle, see fig 49.

2. Rotate the nose cone to remove it from the main body

and place safely aside, see fig 50.

Fig 49-50

Face plate

Grub screw

Hex key

Nose cone

D

Machined hole

D

2. Place the supplied spanner (C) over the boss and remove the

face plate, place safely aside, see fig 48.

17

Continues Over....

Operating Instructions

3. To remove the centring pin, insert the live centre push rod (D)

through the shaft and place the centre pin safely aside, see fig

51-52.

Fig 51-52

D

Centre pin

Fig 54-55

Indexing Facility

DISCONNECT THE LATHE FROM THE

MAINS SUPPLY!

The Indexing ring is situated to the left side of the headstock

which incorporates 24 positions at (10˚) segments. To the side

of index ring is the index locking pin to lock the spindle in

position. The indexing facility is useful for fluted columns, clock

faces and accurate hole positioning, see fig 53.

Fig 53

Indexing ring

10˚ Segments

Fig 56-57

Note: Fig 56 shows the index number set to position 5

and Fig 57 shows the index number set to position 23.

Index lock pin

Line up the measurement you require on the index ring on

the headstock and screw in the index locking pin to lock the

spindle in position, see fig 54-55.

18

Removing the Drive Centre

To remove the drive centre from the spindle, locate the push

rod (E), insert it through the index ring assembly and push the

drive centre out, see fig 58.

Fig 58

Drive centre

Operating Instructions

Fig 61-62

E

Changing the Belt Speed

NOTE: THE LOWEST SPEED PULLEY COMBINATION

IS FURTHEST FROM THE FACEPLATE. THE SMALLEST

MOTOR PULLEY DAMETER TO LARGEST SPINDLE

PULLEY DIAMETER, SEE CHART ON THE HEADSTOCK

DISCONNECT THE LATHE FROM THE

MAINS SUPPLY BEFORE CHANGING

THE BELT!

1. Open up the pulley access panel on top of the headstock

by removing the Hex screw, see fig 59-60. Slacken the belt by

loosening the motor locking handle (a), move the motor

until the belt is slack enough to be reposition, see fig 61-62.

Fig 59-60

a

2. Reposition the belt, making sure the groves in the belt slot

into the groves in the pulleys. Pull/push the motor assembly

until the belt is under tension, retighten the motor locking

handle (a), see fig 63-64.

Motor handle

Fig 63-64

Push the motor back and tighten

locking handle

19

Operating Instructions

Alignment Centre

The alignment centre (H) is a simple tool as it has a

double-ended taper that can be used on any woodturning

lathe with a sliding or rotating headstock that has a 2MT

spindle and tailstock fittings. Simple to use, just insert the tool

firmly into the headstock spindle taper as you would a drive

centre, loosen the headstock clamp, bring the tailstock up to

the other tapered end and insert into the tailstock barrel. Lock

the tailstock to the bed, then tighten the tool into place by

using the tailstock barrel hand wheel, but not too much! Lock

the headstock onto the bed. Your two tapers are now aligned

as near as they can be on a woodturning lathe. Slide the tailstock back and remove the tool from the headstock spindle

taper, see fig 65-66.

Fig 65-66

Headstock Tailstock

I

O

Alignment tool

I

O

H

Alignment tool

I

O

Clamp headstock Clamp Tailstock

Remove tool

I

O

Turn wheel

to tighten tool

(Not to tight)

Unlock Tailstock

Digital Display 1.5V SR44 Battery

If the digital display starts to ‘FLASH’ the battery will need to

be replaced. Follow the instruction below:

1. To change the battery on the tailstocks digital display,

open the displays protective cover and slide the battery cover

to the right. Remove the discarged battery and recycle it at a

environmentally compatible recycling facility.

2. Insert a new 1.5V battery into the compartment, positive

side facing down. Replace the battery cover.

20

Battery cover

Fig 67

DISCONNECT THE LATHE FROM THE

MAINS SUPPLY!

Daily After Use

• Clean wood shavings away from the lathe bed and tool rest.

• Smear a light coat of wax, ‘Axminster Machine Wax’, code

101582’ , see fig 68, over the lathe bed to allow the banjo and

tailstock to run more smoothly over the bed and to prevent

corrosion.

Maintenance

Fig 68-69

• Spray ‘Axcaliber Dry Lubricant’, code 503468, over the tailstock

barrel/live centre and headstock spindle/chuck after use, see fig

69.

Monthly

• Check the tension of the belt and adjust, (See pages 19 for

Changing the Belt Speed).

WARNING!! ALWAYS WEAR EYE

PROTECTION WHEN USING AN AIR LINE.

• Check any build up of wood shaving on the motor

and spindle pulleys and clean if necessarily.

• Also blow out the motor air vents, see fig 70.

NOTE: IF THE LATHE IS NOT GOING TO BE

USED FOR A PERIOD OF TIME, APPLY A

LIGHT COAT OF ‘LIBERON LUBRICATING

WAX’ OVER THE BED AND PLACE A DUST

SHEET OVER THE LATHE.

Axminster Machine Wax

Code: 101582

Axcaliber Dry Lubricant

Code: 503468

Fig 70

Motor air vents

Liberon Lubricating Wax

Code: 600221

21

Exploded Diagram/Parts List

22

Exploded Diagram/Parts List

PART NO

AT20-A01

AT20-A02

AT20-A03

AT20-A04

AT20-A05

AT20-A06

AT20-A07

AT20-A08

AT20-A09

AT20-A10

AT20-A11

AT20-A12

AT20-A13

AT20-A14

AT20-A15

AT20-A16

AT20-A17

AT20-A18

AT20-A19

AT20-A20

AT20-A21

AT20-A22

AT20-A23

AT20-A24

AT20-A25

AT20-A26

AT20-A27

AT20-A28

AT20-A29

AT20-A30

AT20-A31

AT20-A32

AT20-A33

AT20-A34

AT20-A35

AT20-A36

AT20-A37

AT20-A38

AT20-A39

AT20-A40

AT20-A41

AT20-A42

AT20-A43

AT20-A44

AT20-A45

AT20-A46

DESCRIPTION SPECIFICATION Q’ty

FACE PLATE 6” 1

SET SCREW 1/4”x3/8” 4

SPUR CENTER MT2 1

KEY 8 8*60 1

SPINDEL M33*P3.5 1

ROUND HEAD SCREW M6*10mm 4

BEARING 6209 2

WASHER M6 5

ROUND HEAD SCREW M5x12mm 13

COVER 1

HEADSTOCK 1

LATTER NIU 1

BELT COVER 1

ROUND HEAD SCREW M6x15 1

NUT CSTW-5 1

BELT 250J-10 1

SPINDLE PULLY 1

C RING S-22 2

TAP SCREW 1/4x1/2 2

CAP SCREW M5x25 6

COVER PLATE 1

DIGITAL READOUT 230V 1

CONTROL PLATE 1

CONTROL PANEL

ACRYLIC

TAP SCREW M3*10 4

FLAT HEAD SCREW M3x10 1

POSTION SET 1

NYLO NUT M3 4

WASHER M3 8

ROUND HEAD SCREW M3*35 2

MAGNET 1

BEARING 6208 1

GUK NYLON NUT M45 1

GUK NYLON NUT M40 1

HAND WHEEL 1

CORD PROTECTOR PG11(Long-Type) 1

WAVE WASHER BWW6201 1

NYLON NUT M5 4

BOLT 1

SET SCREW M6x12 4

HEADSTOCK BASE 1

FIXING PIECE 1

NYLO NUT 3/4” 1

HEADSTOCK SHAFT 1

C-RING S-9 1

SPRING 1

1

AT20-A47

AT20-A48

AT20-A49

AT20-A50

AT20-A51

AT20-A52

AT20-A53

AT20-A54

AT20-A55

AT20-A56

AT20-A57

AT20-A58

AT20-A59

AT20-A60

AT20-A61

AT20-A62

AT20-A63

AT20-A64

AT20-A65

AT20-A66

AT20-A66-1

AT20-A66-2

AT20-A66-3

AT20-A66-4

AT20-A66-5

AT20-A66-6

AT20-A66-7

AT20-A66-8

AT20-A66-9

AT20-A66-10

AT20-A66-11

AT20-A66-12

AT20-A66-13

AT20-A66-14

AT20-A66-15

AT20-A67

AT20-A68

AT20-A69

AT20-A70

AT20-A71

AT20-A72

AT20-A73

AT20-A74

AT20-A75

AT20-A76

AT20-A77

AT20-A78

AT20-A79

LOCK PIN 1

MOTOR PULLY 1

KEY 6*6*55 1

MOTOR 230V 50HZ 1

WASHER 3/8”xψ21x2.5 2

HANDLE 3/8” 1

MOTOR LABEL 1

SPRING WASHER 3/8” 1

CAP SCREW 3/8”-16uncx1-1/4 1

CORD PROTECTOR PG13.5 1

DOUBLE CONE 1

WIRE FIXING PIECE ACC-8 4

LOCK PIN 1

TAPERED SHAFT 1

KNOB 1

FACEPLATE WRENCH 1

POWER CORD 1

POWER CORD 2 1

MOTOR WIRE 1

CONTROL BOX 1

FED/REV SWITCH 1

PROTECTOR 1

SWITCH-GREEN 1

SWITCH-RED 1

VR CONTROL 1

VR NUT 1

BOX 1

MAGNET 1

CORD PROTECTOR PG9 1

SINGLE WIRE 1

CONTROL ACRYLIC 1

WIRE 1 1

WIRE 2 1

WIRE 3 3

LABLE 1

HORSE 1

GLOVE 1

MOTOR HANDLE 1

BEARING COVER 1

TOOTH WASHER M5 1

C-RING S-40 1

PMMA PLATE 1

POWER CORD 3 1

GLOVE 1

ROUND HEAD SCREW M5x30 1

WIRE FIXING PIECE ACC-3 1

SENSOR BRACKET 1

ROUND HEAD SCREW M3*25 2

23

Exploded Diagram/Parts List

24

Exploded Diagram/Parts List

PART NO DESCRIPTION SPECIFICATION Q’TY

AT20-B01 TOOL REST 12” 1

AT20-B02 LEVER 3/8” 1

AT20-B03 TOOLREST CARRIAGE 1

AT20-B04 C RING S-22 4

AT20-B05 BUSHING 2

AT20-B06 BOLT 1

AT20-B07 FIXING PIECE 2

AT20-B08 NYLON NUT 3/4” *10UNC 2

AT20-B09 ECCENTRIC SHAFT 1

AT20-B10 SET SCREW 5/16”X1/4” 1

AT20-B11 LIVE CETER MT2 1

AT20-B11-1 LIVE CENTER ROD 1

AT20-B12 LABEL 1

AT20-B12-1 IC BOARD 1

AT20-B13 QUILL 1

AT20-B14 DIGITAL READER 1

AT20-B15 SET SCREW M3X6 4

AT20-B16 NUT M10 1

AT20-B17 SET SCREW M10X30 1

AT20-B18 LEVER 5/16” 1

AT20-B19 CORD PROTECTOR PG13.5 2

AT20-B20 TAILSTOCK SCREW 3/4”-16UNF 1

AT20-B21 SET SCREW 5/16”*1/4” 2

AT20-B22 HANDWHEEL 1

AT20-B23 HANDLE 1

AT20-B24 NUT M5 2

AT20-B25 ECCENTRIC SHAFT 1

AT20-B26 STOP RING 1

AT20-B27 TAILSTOCK 1

AT20-B28 BOLT 1

AT20-B29 BIG ROUND HEAD

SCREW

AT20-B30 THRUST WASHER WTM-2036-015 1

AT20-B31 NAME LABEL 2

AT20-B32 STOP ROD 2

AT20-B33 BED 1

AT20-B34 INVER BOX-DOWN 1

AT20-B35 ROUND HEAD SCREW M5X12 2

AT20-B36 INVERTER 3HP 1

AT20-B37 FLAT HEAD SCREW M4X15 4

AT20-B38 INVER BOX-UP 1

AT20-B39 ON/OFF SWITCH 1

AT20-B40 LABEL 1

AT20-B41 HEX SCREW M10X50 8

AT20-B42 BREAK 1

AT20-B43 NUT M4 4

AT20-B44 CORD PROTECTOR PG9 2

AT20-B45 CORD PROTECTOR PG11 1

AT20-B46 TOOL REST 6” 1

AT20-B47 GLOVE 19*100 1

AT20-B48 GLOVE 19*140 1

AT20-B49 ROUND HEAD SCREW M6X20 2

AT20-B52 COVER-DOWN 1

AT20-B53 COVER-UP 1

AT20-B54 NUT M3 2

AT20-B55 ROUND HEAD SCREW M3X10 2

AT20-B56 ROUND HEAD SCREW M3X5 2

AT20-B57 ID LABEL 1

AT20-B58 WARNING LABEL 1

AT20-B59 NYLON NUT M3 2

M4X10 4

25

Exploded Diagram/Parts List

26

Exploded Diagram/Parts List

PART NO. DESCRIPTION SPECIFICATION Q’TY

AT20-C01 STAND 2

AT20-C02 WASHER M10 8

AT20-C03 SPRING WASHER M10 8

AT20-C04 HEX HEAD SCREW M10X40 8

AT20-C05 NUT 1/2”-12UNC 4

AT20-C06 ADJUSTABLE LEVELER 1/2”-12UNC 4

PART NO DESCRIPTION (BAT20 BE) SPECIFICATION Q’TY

1 EXTEND BED 1

2 CAP SCREW M10X45 4

3 WASHER M10 4

4 EXTEND ROD 1

5 LOCK HANDLE 3/8* 1

6 SPRING WASHER M10 4

27

Wiring Diagram

28

Notes

29

Notes

30

Notes

31

The Axminster guarantee is available on

Craft, Trade, Engineer, Air Tools & CNC Technology Series machines

Buy with confidence from Axminster!

So sure are we of the quality, we cover all parts and labour free of charge for three years!

For more information visit axminster.co.uk/3years

The packaging is suitable for recycling.

Please dispose of it in a responsible manner.

EU Countries Only

Do not dispose of electric tools together with household waste material.

By law they must be collected and recycled separately.

Axminster Tools & Machinery

Axminster Devon EX13 5PH

axminster.co.uk

Loading...

Loading...