Code 105104

AC250CM 250mm

DeLuxe Combination

Machine

Original Instructions

AT&M: 22/06/2018

BOOK REF: 105171

Index of Contents

EU Declaration of Conformity 02

What’s Included 03

General Instructions for 230V Machines 04

Specific Safety Precautions 05-06-07

Specification 07

Assembly Instructions 08-09-10-11-12-13-14-15

Positioning the Machine 15-16

Machine Dimensions 16-17

Illustration and Parts Description 18-19-20-21-22-23-24-25

Setting Up the Machine 26-27-28

Operating Instructions 28-29-30-31-32-33-34-35

Routine Maintenance 35

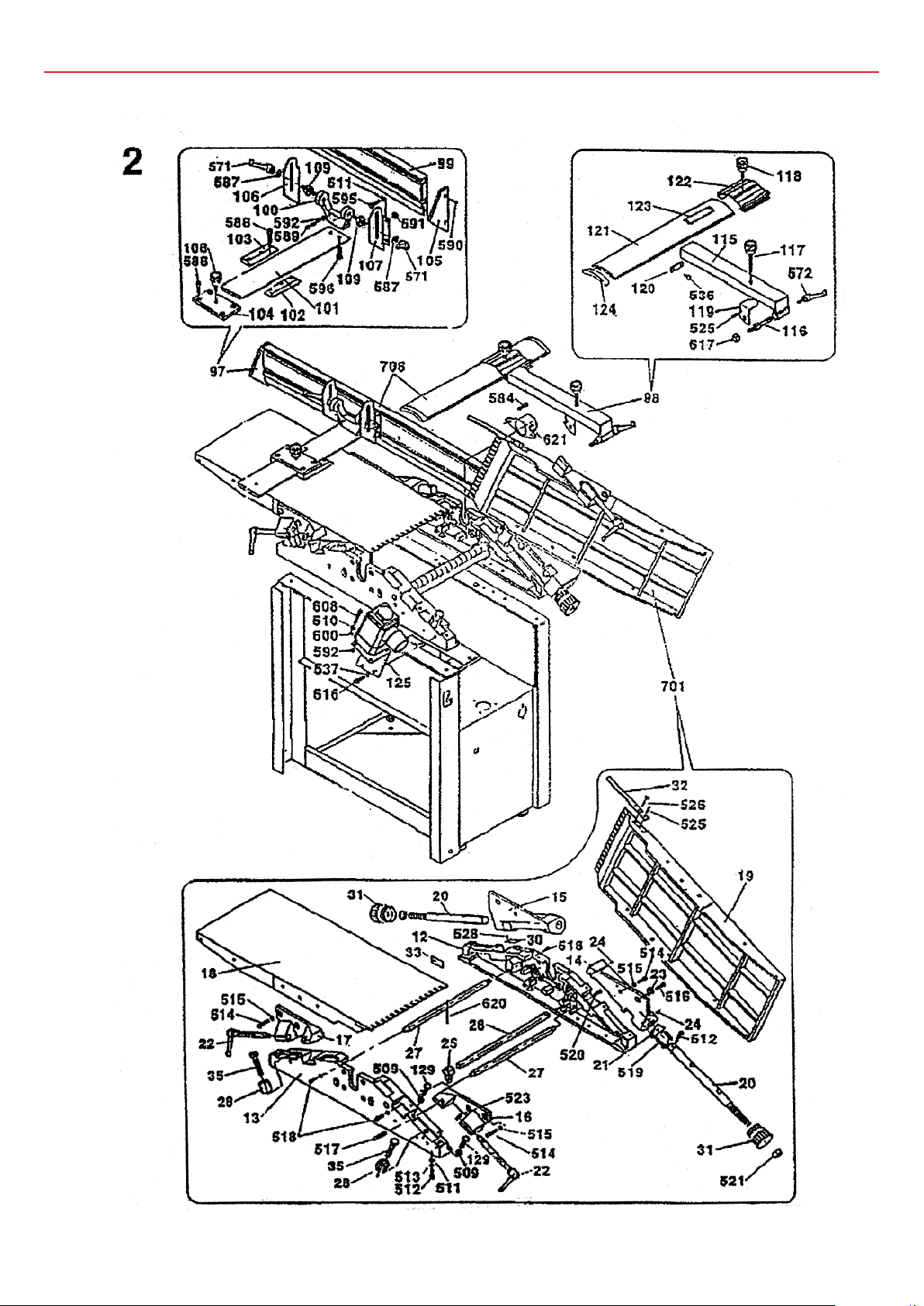

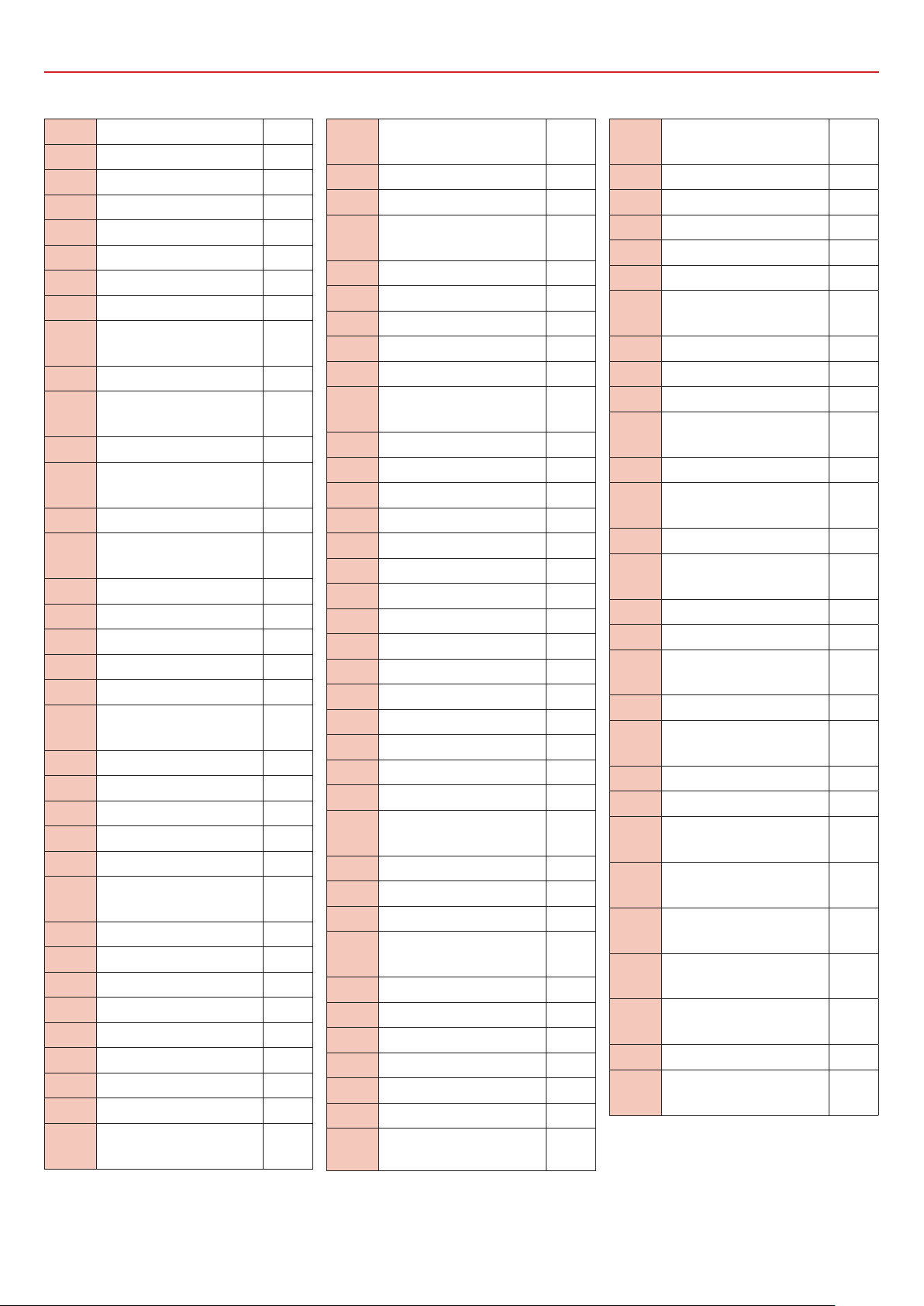

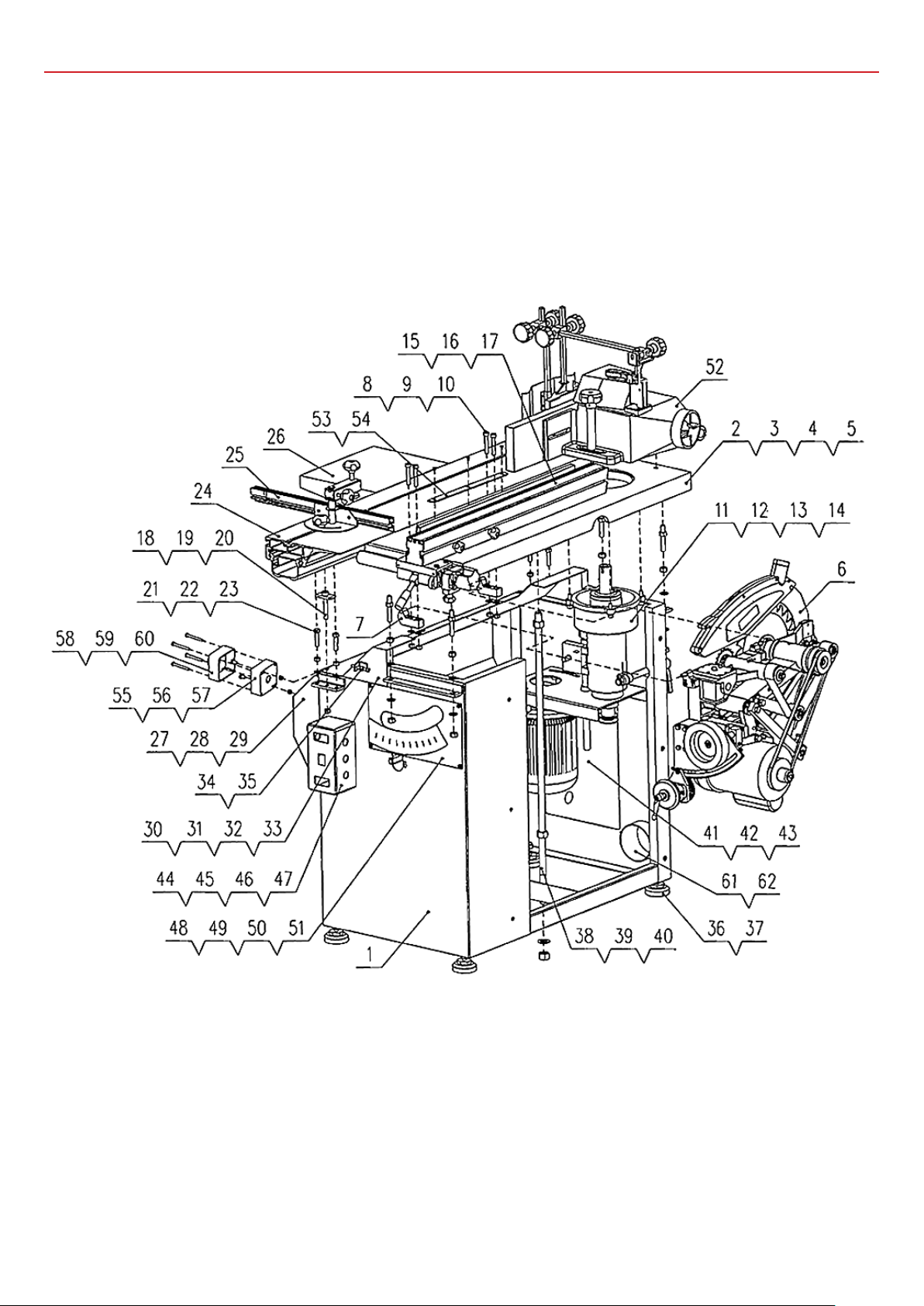

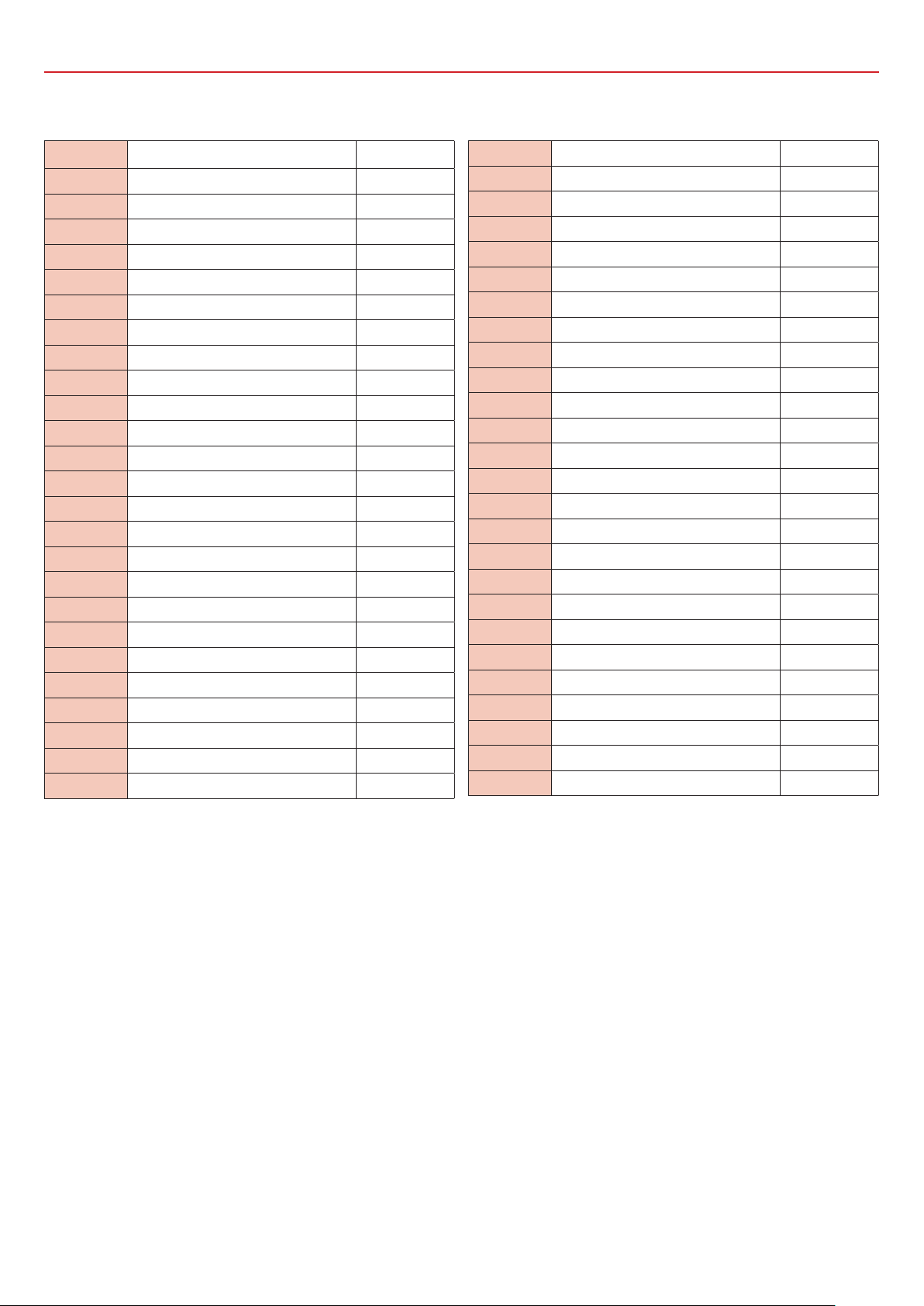

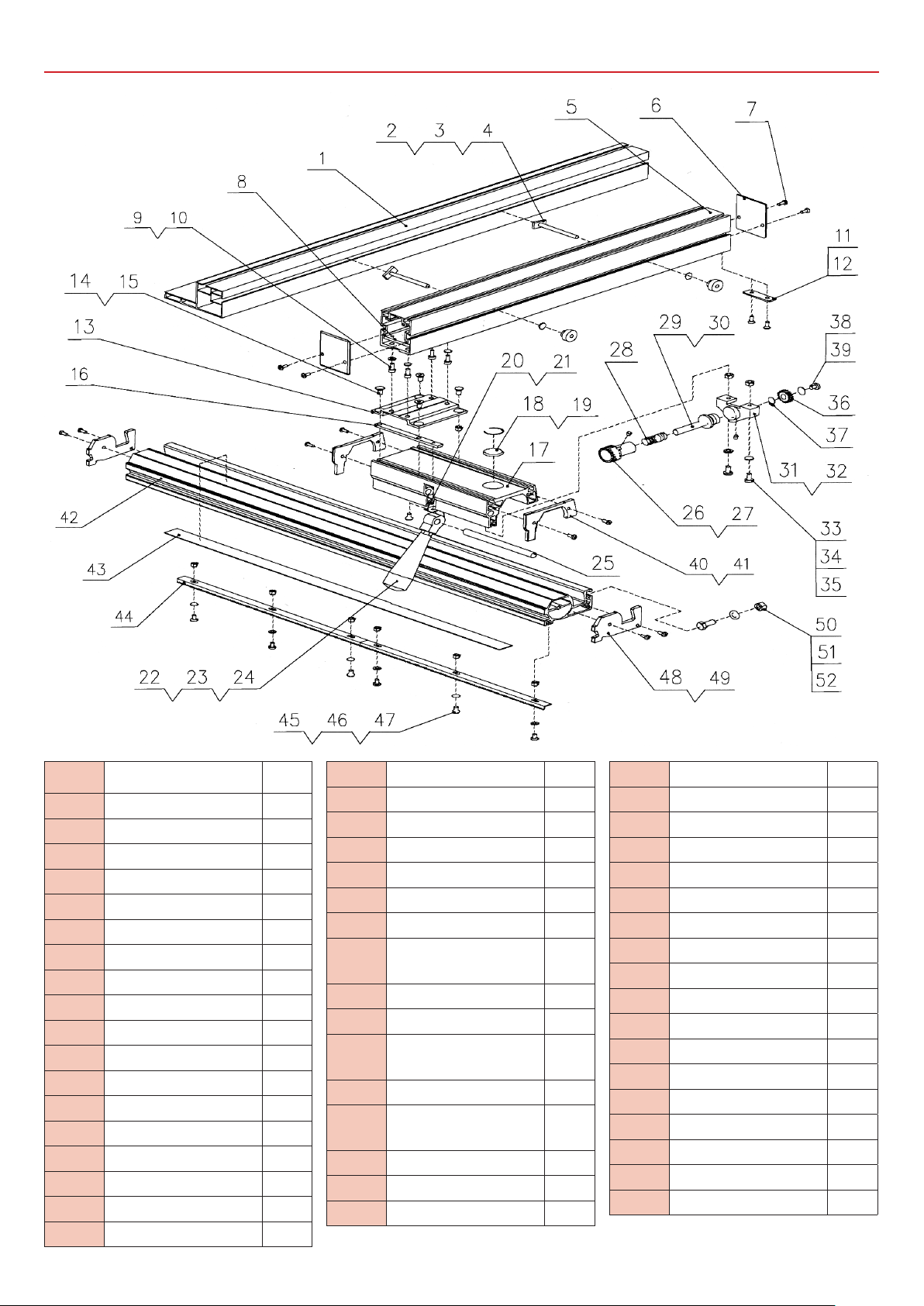

Exploded Diagrams/Lists 36-37-38-39-40-41-42-43-44-45-46-47-48-49-50-51-52-53

Wiring Diagram 54

Cutter Block Accessories 55

EU Declaration of Conformity

Cert No: ML353G

Axminster Tools & Machinery Ltd

Axminster Devon

EX13 5PH UK

axminster.co.uk

declares that the machinery described:-

Type Combination Machine

Model AC250CM

Signed

Andrew Parkhouse

Operations Director

Da te: 16/07/2015

The symbols below advise the correct safety procedures when using this machine.

EU Declaration of Conformity

This machine complies with the following directives:

2006/95/EC

2004/108/EC

EN 5514-1: 2006+A1

EN 61000-3-2: 2006+A1+A2

EN 61000-3-11: 2000

conforms to the machinery example for which the

EC Type-Examination Certificate No BM50314354, AN50176407, AN50217062

has been issued by Laizhou Planet Machinery Co., Ltd

at: Yutai West Street, Laizhou, Shandong 261400 China

and complies with the relevant essential health and safety requirements.

EN 5514-2: 1997+A1+A2

06/42/EC - Annex I/05.2006

EN 60204-1: 2006+A1+AC

EN 940: 2006+A1

Fully read manual

and safety instructions

before use

Ear protection

should be worn

Eye protection

should be worn

2

Dust mask

should be worn

HAZARD

What’s Included

Model Number: AC250CM

Panel Saw:

1 250mm DeLuxe Combination Machine

1 Rip Fence Assembly

1 250mm Saw Blade

1 Saw Guard

1 Flexible rubber Hose with Support Rod

1 Adjustable Work Clamp Assembly

1 Depth Stop Bracket

1 Sliding Table Guide Rail

2 Sliding Table Guide Rail Stops

1 Sliding Table Extension

1 Sliding Table Extension Support Casting

1 Sliding Table Extension Fence (with Adjustable Depth Stop)

Spindle Moulder:

1 Spindle Moulder Guard Assembly (Fully Assembled):

Planer/Thicknesser: Tools:

1 Planer Fence 1 Blade Setting Tool

1 Planer Fence Mounting Base 1 12mm Hex Key

1 Fence Securing Bracket 1 10mm Hex Key

1 Overhand Planer Guard Mounting Bracket 1 8mm Hex Key

1 Overhand Planer Guard 1 6mm Hex Key

1 Overhand Planer Guard Locking Plate 1 5mm Hex Key

1 Spring Metal Plate 1 4mm Hex Key

2 M10 Washers 1 3mm Hex Key

2 M10 Lever Handle Bolts 1 7/5.5mm Spanner

2 M6 x 12mm Cap Head Bolts 1 8/10mm Spanner

2 M6 Eye Bolts (for lifting) 1 13/16mm Spanner

1 36/41mm Spanner

1 16mm Socket Spanner

1 Tommy Bar

Wheel Mobility Kit:

1 Mobility Operating Handle

2 Adjustable Wheel Carriages

1 Lifting Bracket

10 M8 Cap Head Bolts and Washers

1 Manual

3

General Instructions for 230V Machines

The following will enable you to observe good working

practices, keep yourself and fellow workers safe and

maintain your tools and equipment in good working

order.

WARNING!! KEEP TOOLS AND EQUIPMENT

OUT OF REACH OF YOUNG CHILDREN

KEEP WORK AREA AS UNCLUTTERED AS IS

PRACTICAL. UNDER NO CIRCUMSTANCES SHOULD

CHILDREN BE ALLOWED IN WORK AREAS.

Mains Powered Tools

• Tools are supplied with an attached 16 Amp plug.

• Inspect the cable and plug to ensuree that neither are

damaged. Repair if necessary by a suitably qualified

person.

• Do not use when or where it is liable to get wet.

Workplace

• Do not use 230V a.c. powered tools anywhere

within a site area that is flooded.

• Keep machine clean.

• Leave machine unplugged until work is about to

commence.

• Always disconnect by pulling on the plug body and not

the cable.

• Carry out a final check e.g. check the cutting tool

is securely tightened in the machine and the correct

speed and function set.

• Ensure you are comfortable before you start work,

balanced, not reaching etc.

• Wear appropriate safety clothing, goggles, gloves,

masks etc. Wear ear defenders at all times.

• If you have long hair wear a hair net or helmet to

prevent it

being caught up in the rotating parts of the machine.

• Consideration should be given to the removal of rings

and wristwatches.

• Consideration should also be given to non-slip footwear

etc.

• If another person is to use the machine, ensure they are

suitably qualified to use it.

• Do not use the machine if you are tired or distracted

• Do not use this machine within the designated safety

areas

of flammable liquid stores or in areas where there may

be volatile gases.

• Check cutters are correct type and size, are undamaged

and are kept clean and sharp, this will maintain their

operating performance and lessen the loading on the

machine.

•

OBSERVE….

around you and

make sure you know what is happening

USE YOUR COMMON SENSE.

4

Panel Saw

Specific Safety Precautions

Make sure the saw blade is the correct type for the job in

hand.

Do not force the saw, if the saw begins to ‘stall’ you are

‘forcing the cut’ or over working the saw. Ensure that the

saw blade is clean and sharp. Resin build up on the blades

will increase the friction of the saw passing through the

timber, and cause over heating of the blade, blunt teeth

will work harder tearing the fibre of the timber as

opposed to shearing it, also with subsequent overheating.

Both faults unnecessarily load the machine beyond

normal usage, and shorten its longevity.

Do not use blades that are deformed in any way.

Do not remove the blade guard. The design of the riving

knife on the machine will not allow for slotting or ‘blind’

grooving, so there is no reason to remove the guard. There

is adequate clearance under the guard for the capacity of

the machine (75mm).

Do not remove the riving knife.

Do not use any blades that cut a smaller kerf than the

riving knife thickness. Make sure the riving knife is

correctly adjusted to the blade and is securely fastened.

If the table insert becomes damaged or broken, and will

not support the timber ‘up close’ to the blade, replace it.

Do not start the saw with the work piece touching the

blade.

Do not commence sawing until the blade has run up to

full speed. After switching off, never try to slow the saw

down more quickly by applying side pressure (with a

piece of wood?) to the blade. Apply the old joiner’s adage

of never getting hands within one handbreadth of the

blade. Leave the machine disconnected from the mains

supply until you are about to commence work.

Always disconnect the machine if you are leaving it

unattended.

Never leave the vicinity of the machine unless the blade

has come to a complete stop.

Do not attempt to carry out any maintenance, corrective

work, setting up etc., unless the machine is disconnected

from the mains supply. If any tools have been used during

setting up procedures, make sure they are removed from

the machine and stowed safely away.

Do not attempt to carry out cross cutting operations

‘freehand’, always use the mitre fence for small material

and the sliding carriage for larger work pieces. Unless you

are an experienced machine operator, do not attempt to

‘rip’ freehand, always use the guiding facility of the rip

fence. It is perfectly acceptable to support, guide, and feed

the timber with your hands whilst ripping stuff of some

length, however, as you approach the blade ensure that

the push stick is to hand, and you use it.

Remember the emphasis of the ‘push’ should be between

the blade and the fence and close to the fence. Use your

free hand to support and guide the material on the

offside of the saw blade and at least 100mm away from

it. If the timber does not extend to at least 100mm to the

offside of the saw blade, the material possibly does not

need guiding or supporting.

Check (especially on site), that there are no foreign

objects e.g. old nails, screws, small stones etc embedded

in the material you are about to cut. If necessary take a

wire brush to the timber before working.

If you are being assisted whilst using the saw (by a ‘take

off’ or ‘support’ number?), remember there is only one

sawyer at a machine, and they stand in front of it. The

assistant does not push, pull, guide etc., unless specifically

asked or instructed to do so by the sawyer.

Spindle Moulder

Authorised Use

This machine is designed for shaping wood and wood

derived materials.

Machining of other materials is not permitted and may be

carried out in specific cases only after consulting with the

manufacturer.

The proper use also includes compliance with the

operating and maintenance instructions given in this

manual.

The machine must be operated only by persons familiar

with its operation and maintenance and who are familiar

with its hazards.

The required minimum age must be observed. The

machine must only be used in a technically perfect

condition. When working on the machine, all safety

mechanisms and covers must be in operation.

5

Continues Over....

Specific Safety Precautions

In addition to the safety requirements contained in these

Operating Instructions and your country’s applicable

regulations, you should observe the generally recognized

technical rules concerning the operation of woodworking

machines.

Any other use exceeds authorisation.

In the event of unauthorised use of the machine, the

manufacturer renounces all liability and the responsibility

is transferred exclusively to the operator.

General Safety Notes

Woodworking machines can be dangerous if not used

properly. Therefore the appropriate general technical

rules as well as the following notes must be observed.

Read and understand the entire instruction manual

before attempting assembly or

operation.

Keep these Operating Instructions close by the machine,

protected from dirt and humidity, and pass them over to

the new owner if you part with the tool.

Planer/Thicknesser

Most machines currently are well interlocked to ensure

that the machine must be in the correct configuration to

perform one task or the other. Make yourself familiar with

these configurations and do not try to use the machine

in a half and half state, or rig the interlocks to enable you

to do so. These machines are designed for cutting timber

only. They will, but are not designed to, cut timber

derivatives or composites. Glue lines in plywood, block

board etc, will ‘notch’ the blades. The bonding agent in

chipboard is likewise detrimental to the health of your

planer knifes. It is best to leave them alone. If you have

to machine composites, work out the costs of tungsten,

against HSS (plus the sharpening costs), and proceed

accordingly. On larger machines it is common practice to

leave a portion of the blade (usually the offside 30 mm) to

be used on ‘aggressive’ materials.

Overhand Planing

Make sure during overhand planing operations, that the

fence is set to the required angle, is securely fastened and

locked in position. Ensure the planer block guarding is in

position and secured.

No changes to the machine may be made.

Daily inspect the function and existence of the safety

appliances before you start the machine.

Remove all loose clothing and enclose long hair.

Before operating the machine, remove tie, rings, watches,

other jewellery, and roll up sleeves above the elbows.

Wear safety shoes; never wear leisure shoes or sandals.

Always wear the approved working outfit.

Do not wear gloves while operating the machine.

For the safe handling of cutting tools wear work gloves.

Control the stopping time of the machine, it may not

exceed 10 seconds.

Remove cut and jammed work pieces only when the

machine is at a complete standstill and motor is turned

off.

Install the machine so that there is sufficient space for safe

operation and work piece handling.

Keep work area well lit.

Disengage the autofeed for the thicknesser. Ensure both

tables are correctly seated and locked down. Ensure the

dust extraction hood is in place and is not blocked. Fit

dust extraction.

Check the sharpness of planer knifes, check for ‘nicks’ and

‘notches’, if there are damaged sections on the blades, try

to plane in the ‘clear’ areas.

Especially when planing material down to ‘thin’

dimensions, maintain pressure on the ‘front’ of the

material i.e., that portion of the stuff that has passed

over the block, but use a push stick or a pusher shoe to

clear the end of the stuff over the block.

Thicknessing

When thicknessing, remove the fence. Lower the

thicknessing table slightly.

Unlock and swing both tables ‘up and out of the way’,

taking care not to foul the overhand guard/arm assembly,

which will probably swing free.

Turn the dust extraction hood up and over the block.

Connect the dust extraction. Ensure the hose will not foul

the wood when being passed through the machine.

6

Specific Safety Precautions

Check the height of the thicknessing table.

Engage the autofeed mechanism.

Periodically, clean any excess build up of resin from the

thicknessing table, and apply any proprietary brand of

lubricating agent.

NOTE, Consideration should be given to the type of

finish you will be applying to the wood when you

select your cleaning/lubrication agent. Some

compounds won’t mix. i.e. PTFE and Acrylic.

Specification

Code 105104

Model AC250CM

Power 3,000W (Saw) 2,000W ( Planer) 3,000W (Spindle) 230V

Number of Motors 3

Blade Speed 4,050rpm

Blade Tilt 0 - 45°

Blade Dia/Bore 250mm x 30mm

Table Size 1,200 x 840mm (Saw) 250 x 1,050mm (Planer) 250 x 600mm (Thicknesser)

Max Ripping Width 460mm

Max Depth of Cut @ 45˚ 45mm

Max Depth of Cut @ 90˚ 65mm

Max Planing Width 250mm

Sliding Table Size 1,200 x 120mm

Cutterblock Speed 4,000rpm

Cutterblock Diameter 75mm

Knives HSS x 3

Feed Speed 8m/min

Max Thicknesser Capacity 180mm

Spindle Speed 3,500, 5,500, & 7,500rpm

Spindle Diameter 30mm

Spindle Travel 130mm

Max Tooling Diameter Above Table 140mm

Dust Extraction Outlet 100mm x 3

Weight 370kg

7

Assembly Instructions

PLEASE NOTE: Some of this assembly

procedure is best accomplished by two

persons. Although the tasks are not impossible,

some of the items are heavy and awkward, and

a mishandling error could cause injury. Please think about

what you are doing, your capabilities and your personal

safety.

Unpack all the boxes and check all the components

against the “What’s in the Boxes’ List. If any parts or

components are missing, please contact our customer

services department using the procedures and telephone

numbers listed in our catalogue, and you will be dealt

with quickly and efficiently.

PLEASE NOTE: that, on occasion, the packing list is not

strictly adhered to, please check all the boxes, packets etc,

to make sure that all the parts have been accounted for.

Having unpacked the boxes, (please dispose of any

unwanted packaging responsibly), put the parts and

components whereby they are readily to hand. Break

down the main box by knocking the sides away (be

careful of exposed nails etc.), but leave the machine

sitting on its pallet. Remove the protective grease film

that is coating all the unpainted parts of the machine.

Use a proprietary de-greasing agent or paraffin.

Unfortunately, this cleaning process is always a bit ‘mucky’

especially if you tackle the job with a high level of

enthusiasm. You are advised to wear overalls or coveralls

etc., during the process. After cleaning, especially if you

used paraffin, lightly coat the exposed metal surfaces to

prevent any rusting.

Note: The AWC4 Combination Machine comes 95%

assembled, in order to reduce the footprint of the

machine for packaging, several items are dismounted

from the machine and need to be re-affixed.

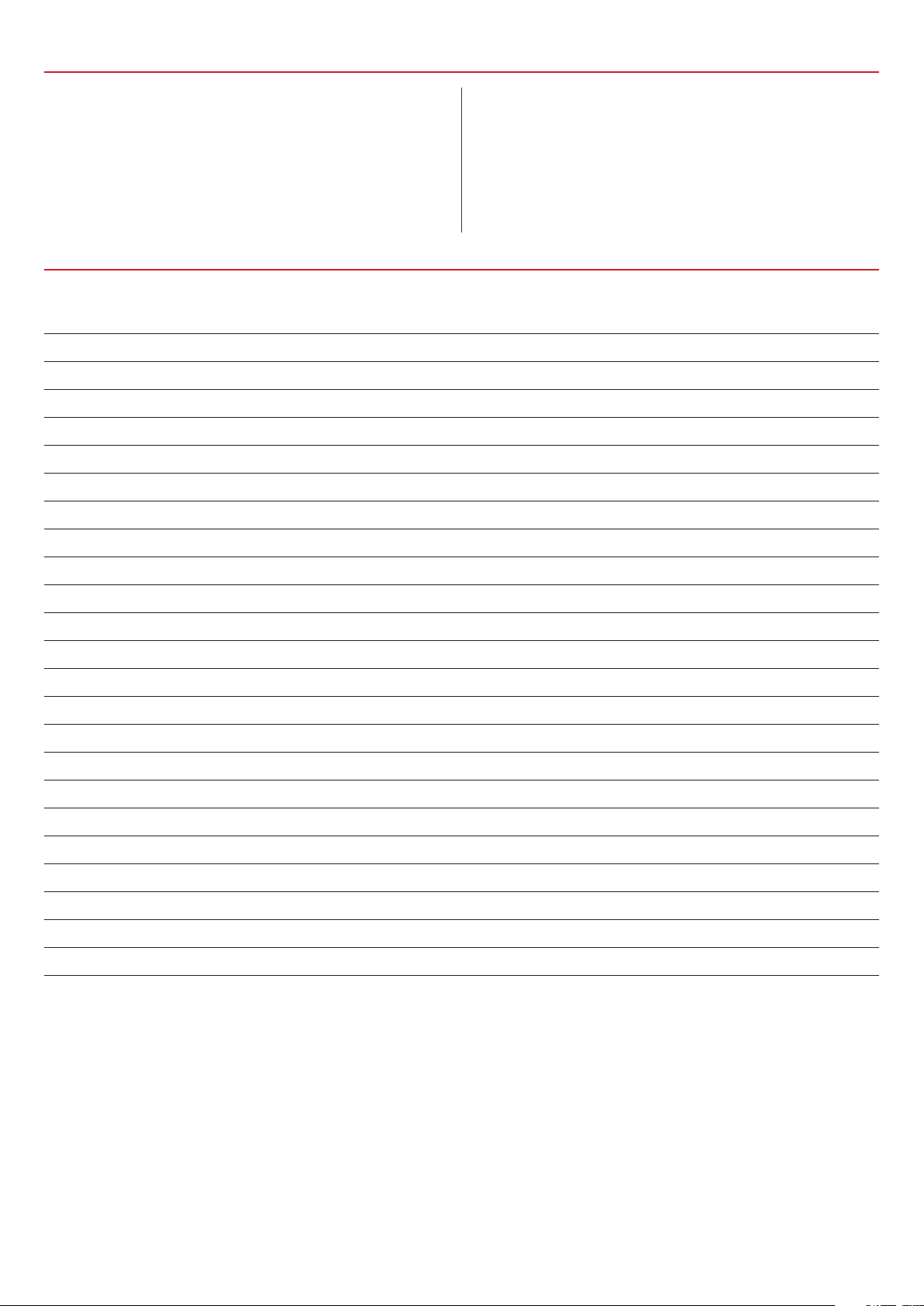

Fig 01

M6 Caphead screw/nut

5mm Hex key

Extension Table

1). Locate the table extension guide rail and two square

inserts and butterfly screws. Insert the butterfly screws

through the pre-drilled holes in the angle brackets, screw

on the square inserts and slot them into the ‘T’ slots on

the extension rail see fig 2. Position the extension rail so

it’s over hanging more to the right of the machine and

tighten the butterfly screws to clamp the extension rail in

position, see fig 3.

Fig 02-03

WHEN YOU FIRST RECEIVE YOU COMBINATION

MACHINE IF YOU INTEND TO USE THE SPINDLE

MOULDER FIRST PLEASE GO TO PAGES 12-13

FOR ASSEMBLY INSTRUCTION.

Panel Saw

Fitting the Saw Guard

Locate the saw guard and M6 caphead screw and M6 nut

and attach it to the riving knife using a 5mm hex key, see

fig 1.

Butterfly screw

Square insert

8

2) Locate the steel pin plate (A) , line up the pins with the

elongated slots in the extension table (B) and lower the

plate into the table, see fig 4. Locate the two lift and shift

Assembly Instructions

MAKE SURE THE SUPPORT CASTING WHEEL

RUNS SMOOTHLY ALONG THE EXTENSION RAIL!

Fig 04

A

B

Lift and shift handle

handles and slot them through the two pre-drilled holes

in the extension table (B) and screw them into the

threaded holes in the steel pin plate (A). NOTE: Make

sure to leave sufficient clearance between the steel

plate and the table frame for the next step.

3) Position the extension table (B) against the sliding

table assembly. Line up the steel pin plate (A) with the ‘T’

slot to the end of the sliding table and slide on the extension table (B), see fig 05.

4) Position the extension table so it’s roughly centred to

the sliding table and tighten the two lift and shift handles

to lock the asssembly in position, see fig 6.

5) On top of the extension table there are two adjustment

caphead screws, using a straight edge adjust the screws

until both sliding and extension tables are level.

Fig 07-08

Straight edge

Caphead screw

Fig 05

Fig 06

B

Caphead screw

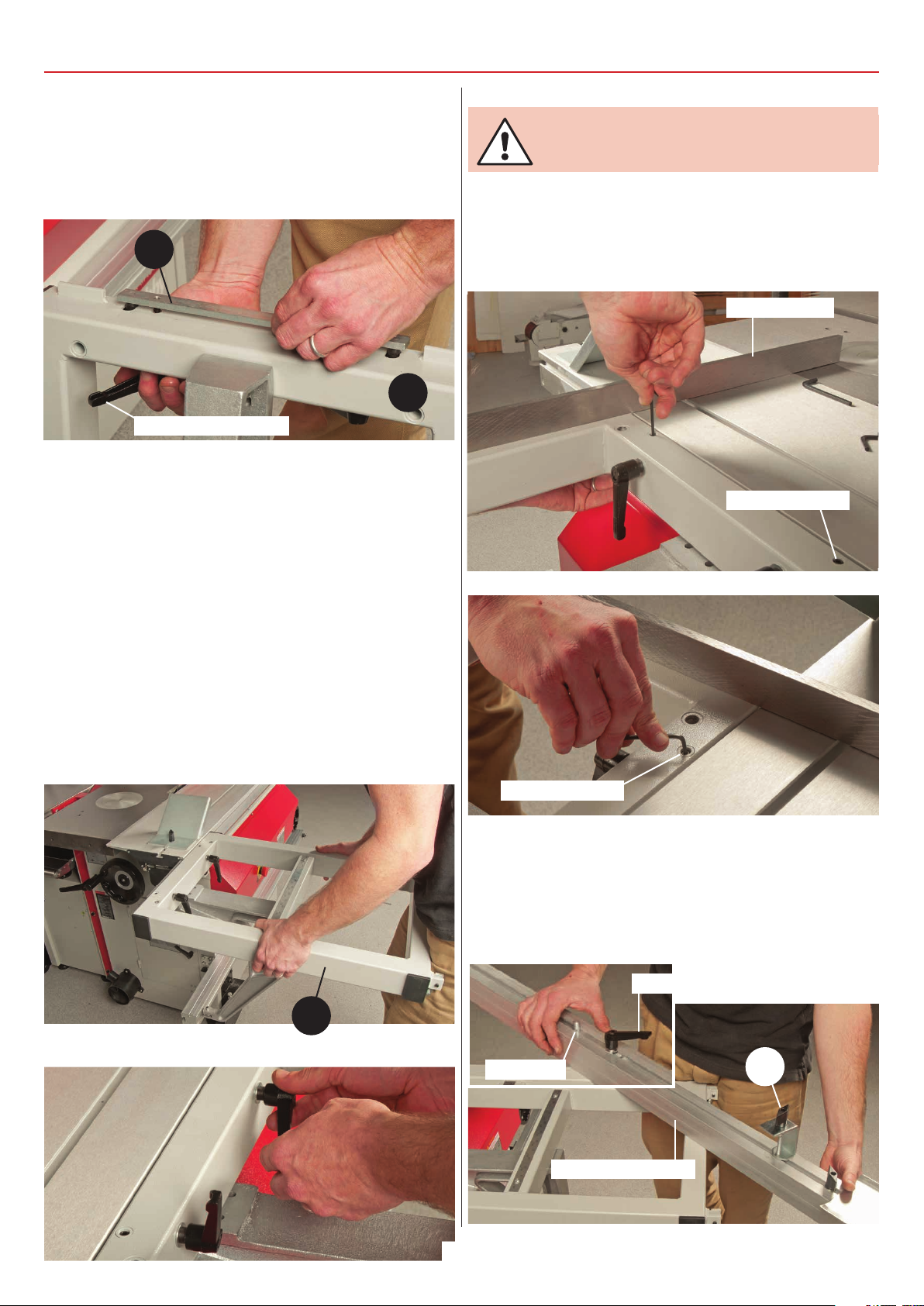

Sliding Table Fence

Locate the sliding table fence, loosen the angle bracket

clamp by undoing the butterfly knob (A), loosen the steel

pin by releasing the clamping handle beneath the fence,

see fig 9. Line up and push the steel pin into one of the

Steel pin

Clamping handle

A

Sliding table fence

Fig 09

9

Continues Over....

Assembly Instructions

two pre-drilled holes on top of the extension table, see

fig 10. Lift-up the 90˚ stop located to the corners of the

extension table, push the fence up against the 90˚ stop,

see fig 11 and clamp the angle bracket (A) to the table’s

steel girder by tightening the butterfly knob, see fig 12.

Re-tighten clamping handle to lock the fence in position,

see fig 10.

Fig 10

Clamping handle

Steel pin

Pre-drilled hole

Fig 11-12

Fig 13

Butterfly nut

Steel square clamp

Work Clamp

Locate the work clamp assembly, loosen the clamping

ring, slot the clamp assembly into the sliding table’s ‘T’

slot and tighten the ring to clamp the assembly in place.,

see fig 14.

90˚ Stop

A

Butterfly

Workstop Plate

Fit the workstop plate by loosening the butterfly nut,

insert the steel square clamp into the ‘T’ slot on the sliding

table and re-tighten the butterfly nut, see fig 13.

Fig 14

Clamping ring

Dust Extraction Hose

Locate the ‘Y’ rod which will support the flexible hose

and screw the threaded end into one of the pre-drilled

holes on top of the planer/thicknesser chassis, see fig 15.

Attach one end of the hose to the moulded outlet in the

saw guard, (make sure it is a snug fit) see fig 16. Attach

the other end to the dust

extraction outlet, see fig

17. Lower the hose into

the ‘Y’ support rod to raise

the hose clear of the work

table, see fig 18.

Fig 15

10

Assembly Instructions

Fig16

Fig 17

Flexible hose

Flexible hose

Fig 19

End cover

Fig 20-21

C

M8X50 Bolt

Dust extraction outlet

Fig 18

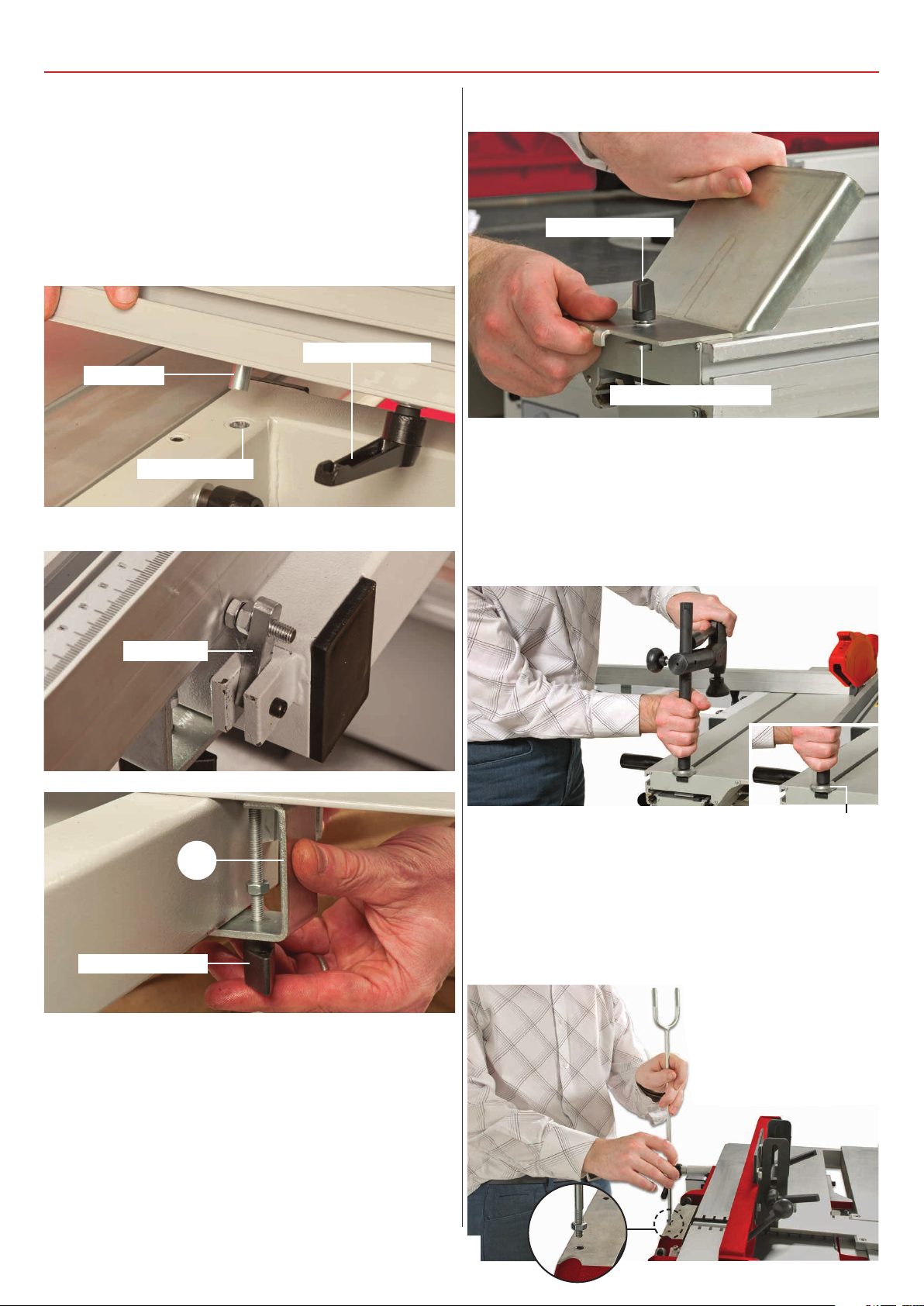

Rip Fence Assembly

Locate the rip fence (A), rip fence extension (B) with ‘T’

bolts, washers and clamping knobs, fence guide rail (C)

and two M8 x 50 bolts and nuts.

1) Insert the two M8 bolts into the pre-drilled holes to the

side of the main saw table and loosely screw on the nuts.

‘T’ Slot

4) Replace the cover to the end of the guide rail (C)

and secure with the Phillips screws you removed earlier.

Position the rail so it lines up with the edge of the saw

table and only finger tighten the nuts at this point,

see fig 22.

Fig 22

C

2) Remove the cover to the end of the fence guide rail (C)

by removing the two Phillips screws, place safely aside,

see fig 19.

3) Line up the first bolt head with the ‘T’ slot in the fence

guide rail and slide on the rail, repeat for the remaining

bolt, see figs 20-21.

11

Continues Over....

Assembly Instructions

5) Locate the rip fence (A) and lower the clamp assembly

over the guide rail (C), see fig 23.

Fig 23- 24

‘T’ Slot

A

Mounting Bracket

6) Locate the micro adjuster assembly (D) and remove

the mounting bracket by removing the two Phillips

screws, place safely aside. Remove the end cover from

the fence clamp assembly (A) and place aside. Insert the

mounting bracket into the ‘T’ slot to the side of the fence

casting assembly, see fig 24. Line up the pre-drilled holes

in the micro adjuster with the holes in the mounting

bracket, making sure the pinion engages into the rack

beneath the fence guide rail (C), secure the micro

adjuster with the two Phillips screws you removed

earlier, see figs 25-26.

Rip-Fence Extension

1) Locate the rip fence extension (B) and the two ‘T’ bolts,

washers and clamping knobs. Slide the ‘T’ bolts into the ‘T’

slot to the end of the fence extension casting, see fig 27.

2) Line up the ‘T’ bolt threads and insert them through

the two pre-drilled holes to the side of the rip fence, push

the fence extension up against the fence and secure in

place with the two clamping knobs and washers, see figs

28-29.

Fig 27

‘T’ bolt

B

Fig 28-29

Fig 25

Fig 26

Rack

D

B

A

D

Pinion

12

Clamping knob

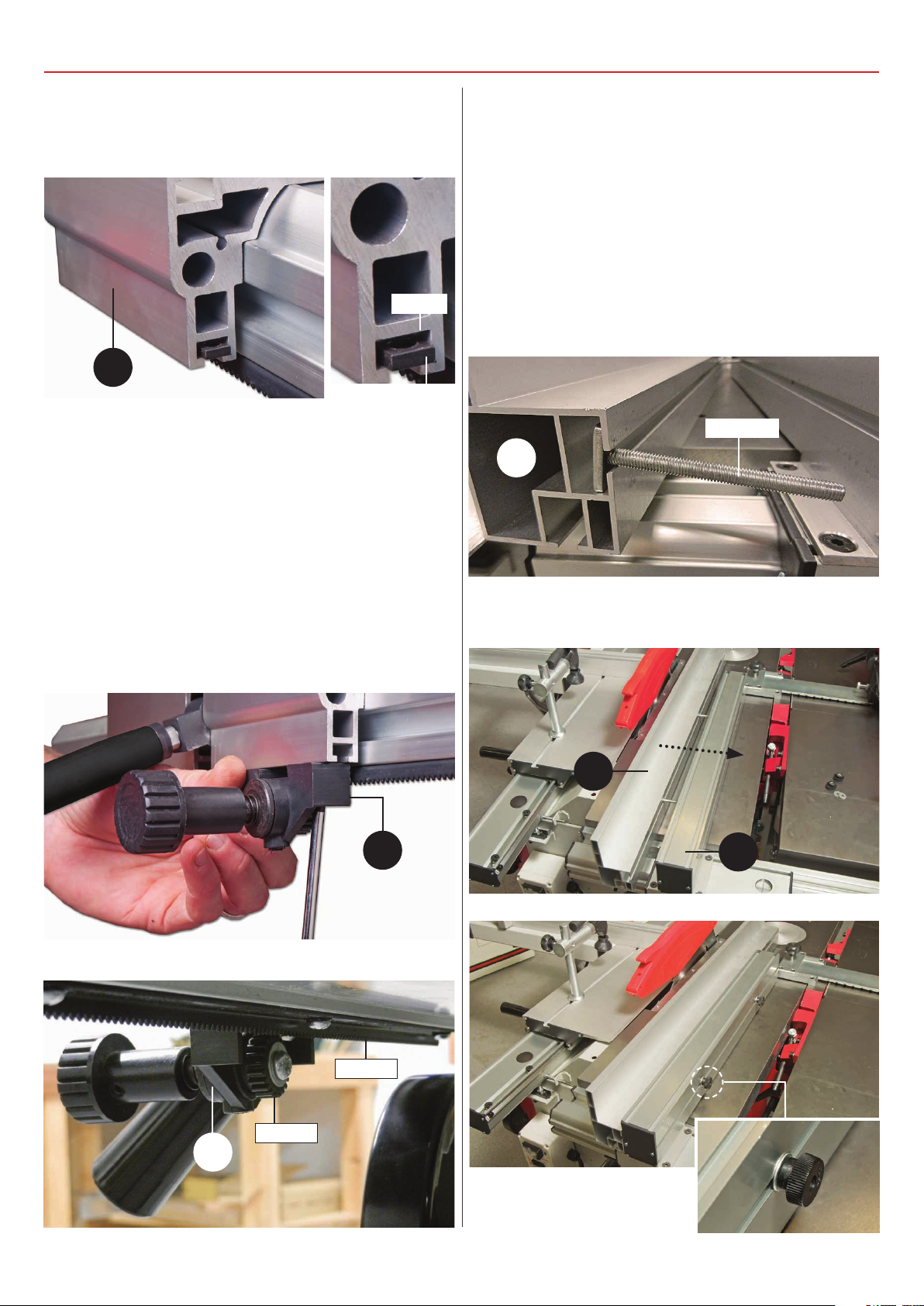

Assembly Instructions

3) Raise the saw blade to it’s highest point and slide the

fence assembly (A) up against the blade and adjust the

fence guide rail (C) until the pointer reads ‘0’on the scale

then tighten the two nuts beneath the arm rail to secure

the assembly, see fig 30.

Fig 30

Blade

A

Mount the overhand plane guard arm onto the side of

the out feed table that corresponds to your preferred

handing, then fit the overhand cutter block guard. In the

accessories packet there is a small spring metal plate,

this fits into the overhand guard clamping assembly to

spread the load of the guard clamp onto the guard. It also

prevents the bolt scoring the upper surface of the guard,

fasten in position using the guard lock,see fig 33-34.

Fig 32

Fence support bracket

Planer fence base

Clamp

Clamping handles

Scale

Pointer

Planer/Thicknesser

Locate the fence mounting bracket and fix to the

machine casting as shown in fig 31, using 2 No. M6 x

12mm caphead bolts, depending on your preferred

handing. Introduce the planer fence base into the

bracket; so that the planer fence base slides into the

fence mounting bracket; then secure; position the fence

approximately mid-table, see fig 32.

Fig 31

Fig 33-34

Plane guard arm

Guard arm clamp handle

Cutter block guard

Guard clamp

Mounting bracket

Caphead bolt

13

Spring metal plate

Continues Over....

Assembly Instructions

Spindle Moulder

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

NOTE: IN ORDER TO INSTALL THE SPINDLE

MOULDER ASSEMBLY THE FOLLOWING

COMPONENTS NEED TO BE REMOVED.

1) Remove the panel saw rip fence by lifting the locking

lever up and lifting the fence away from the guide rail,

place safely aside.

2) Disconnect the dust extraction hose from the saw

guard, remove the guard and place safely aside then

lower the saw beneath the table.

4) Remove the planer/thicknesser fence assembly by

undoing the two M6 caphead bolts on the mounting

bracket and placing the fence assembly safely aside.

2) Lift the spindle guard assembly onto the work table,

manoeuvre the assembly over the pre-drilled holes in the

table. Insert threaded clamping handles through the

elongated slots and align the two pre-drilled threaded

holes on either side of circular ring, see fig 38.

3) Loosely screw the guard assembly down onto the table,

see fig 39-40.

Fig 38-39-40

5) Remove the workstop plate.

The spindle moulder guarding comes fully assembled

but is not yet mounted to the work table, see instructions

below for mounting the spindle moulder assembly.

1) Remove the circular rings from the work table and

place aside, see fig 35-36-37.

Fig 35-36-37

Pre-drilled holes

Elongated slot

Spindle guard assembly

14

Threaded clamping handle

Assembly Instructions

Positioning the Machine

4) Place a 90˚degrees square against the fence and adjust

the assembly until the fence is perpendicular to the table,

tighten the clamping handles to lock the guard in place,

see fig 40.

Fig 40

Square

Wheel Mobility Kit

The wheel mobility kit enables the combination machine

to be moved easily to a new location. The kit comprises of

two adjustable wheel carriages (A) that bolts to each side

of the machine, a mobility operating handle (B) and lifting

bracket (C). Follow the instruction below to assemble the

kit.

1) Put to hand eight M8 cap head bolts and washers and

the two wheel carriages (A). Line up the four holes in one

of the wheel carriages mounting brackets with the four

threaded holes to one side of the machine and secure

using the M8 cap head bolts and washers, see figs 41.

Tighten using the supplied Hex key. Repeat for the

remaining wheel bracket.

Fence

Fig 42-43

M8 Cap head bolts

C

Lifting point hole

Ascertain the orientation of the machine and move it to

its desired position in the workshop. Ensure that the

machine is positioned to allow sufficient clearance all

round to cater for the maximum length of timber you

wish to machine. The machine should be positioned on a

flat level surface.

Fig 41

M8 Cap head bolt

Raise and

lowing bolt

Pivot bolt

A

Locking nut

2) Locate the lifting bracket (C) and two M8 cap head

bolts and washer. Line up the two pre-drilled holes in

the bracket with the threaded holes to the base of the

machine and secure in place with the M8 cap heads, see

figs 42-43.

Manoeuvring the Machine

1) Turn the “raise and lowing bolts” on the wheel

carriages clockwise until the rear feet are lifted away from

the floor then nip up the locking nut to secure the setting.

2) Locate the mobility operating handle (B), insert the

handles lifting bar into the hole in the lifting bracket (C),

see fig 44 and push down the handle to raise the machine.

Fig 44

Handle lifting bar

B

15

Continues Over....

Positioning the Machine

3) Manoeuvre the machine to the

chosen location making sure there is

sufficient space all round, then carefully

lower the machine down, see fig 45.

4) With the machine in position lower

the rear feet by loosening the two

“raise and lowering bolts”, on the

wheel carriages (A), fig 41.

Fig 45

Machine Dimensions

2200mm

1600mm

16

Sliding Table

Machine Foot Print

2020mm

Sliding Table

17

1920mm

Illustration and Parts Description

Spindle Moulder Set Up

Panel Saw Set Up

18

Planer Set Up

Illustration and Parts Description

Thicknesser Set Up

19

Illustration and Parts Description

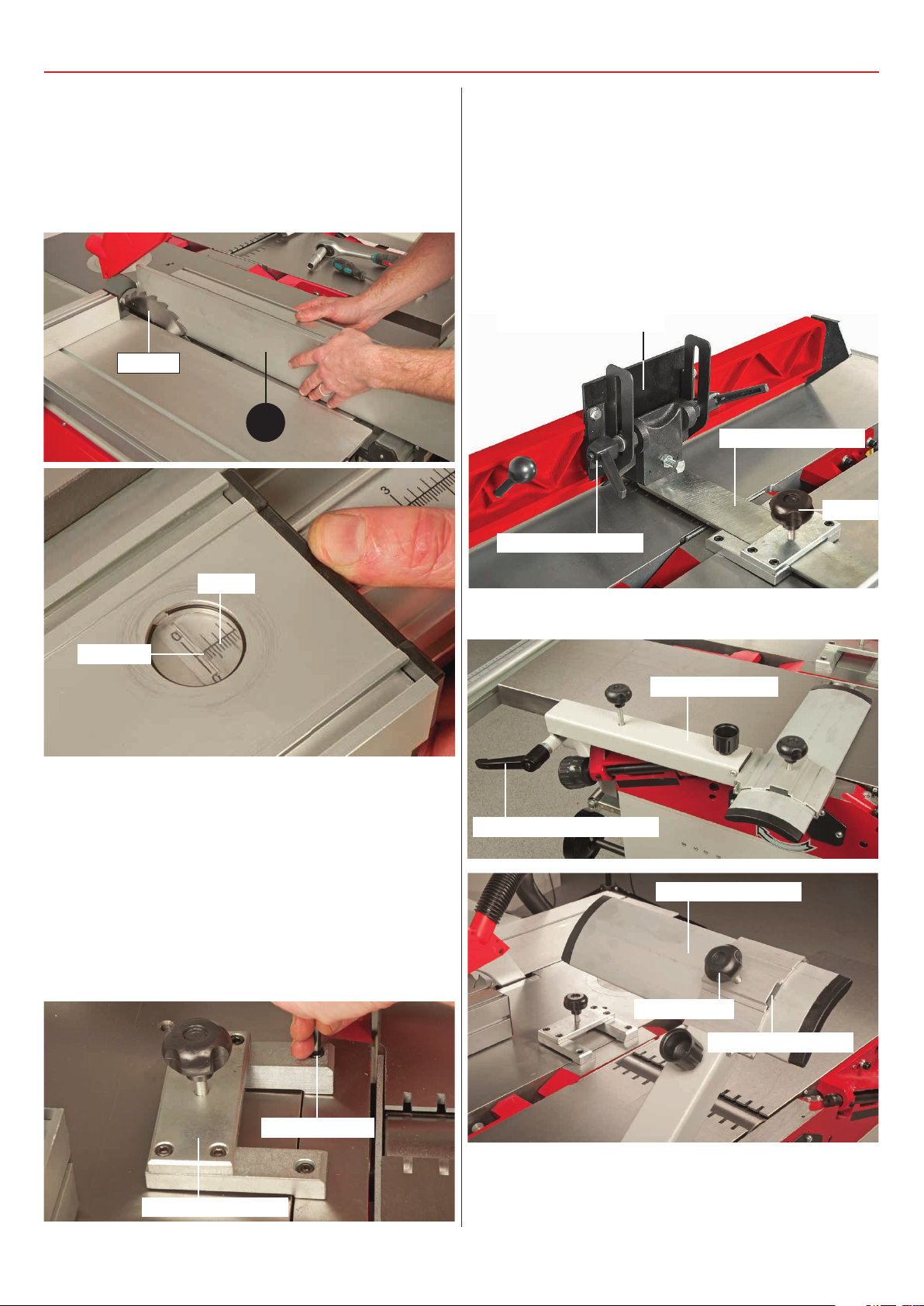

Table extension fence

Guide rail

‘Y’ support rod

Sliding table

Flexible hose

Saw guard

Saw table

Rip fence

3 Way control

switch assembly

Spindle moulder assembly

Distance stop

Table extension

Tilt control hand wheelMain emergency stop

Planer out feed table

Fence assemblySaw table

Panel saw rise and fall

control handle wheel

Telescopic extension

Carriage wheel assembly

Table extension support

20

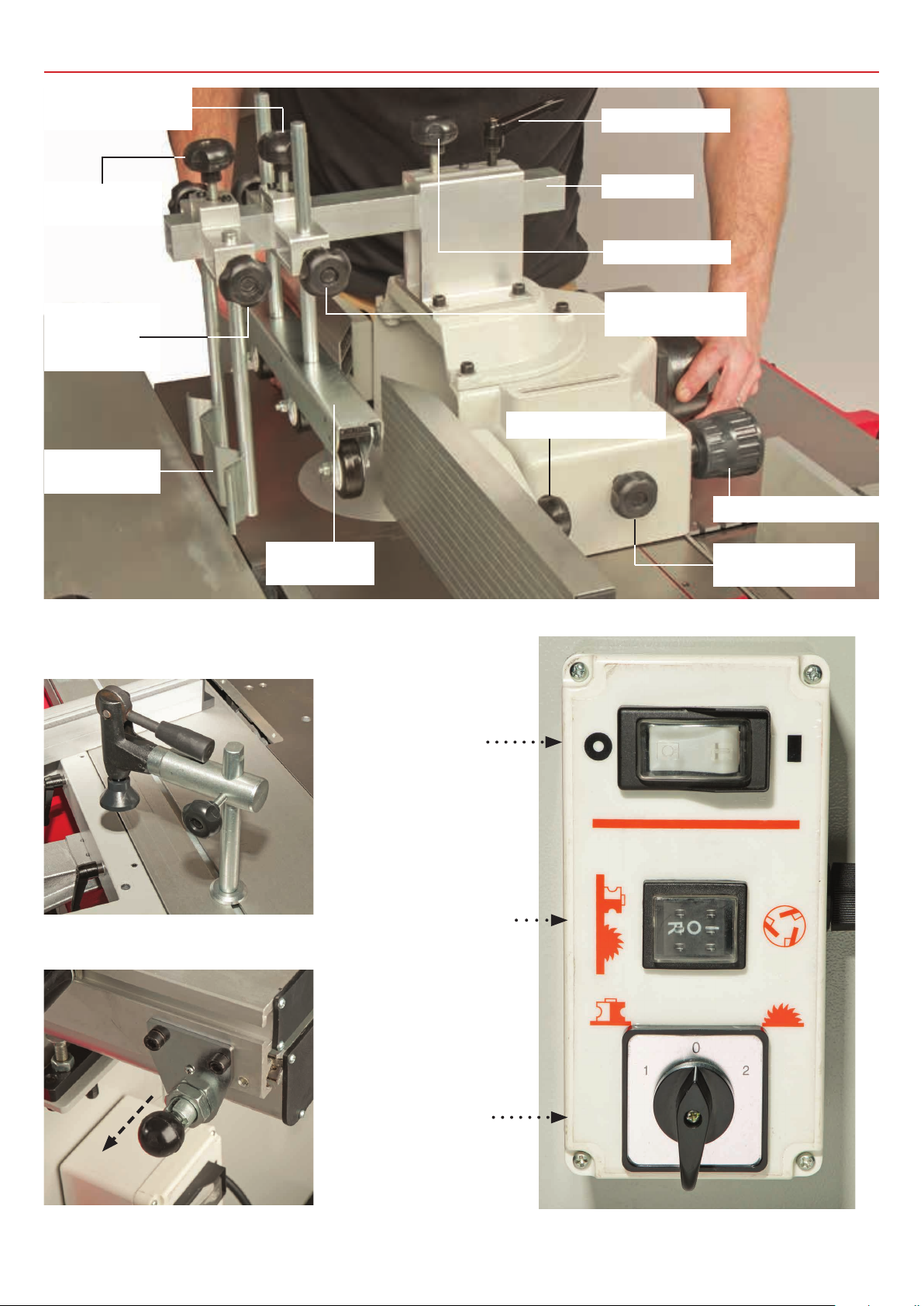

Guide rail stop

Guide roller height

clamping knob

Illustration and Parts Description

Guide arm clamp

Anti-kickback

clamping knob

Anti-kickback

height

clamping knob

Anti-kickback

assembly

Guide roller

assembly

Guide arm

Clamping knob

Guide roller height

clamping knob

Fence adjusting knob

Fence advancing knob

Fence advancing

clamping knob

Work clamp

NVR On/Off switch

‘O’ for OFF

‘I’ for ON

Power selector switch

‘R’ for Spindle Moulder/

Panel Saw, ‘I’ for Planer

Thicknesser

Selector switch

‘0’ No Function

‘1’ Spindle Moulder

‘2’ panel Saw

Sliding table locking knob

21

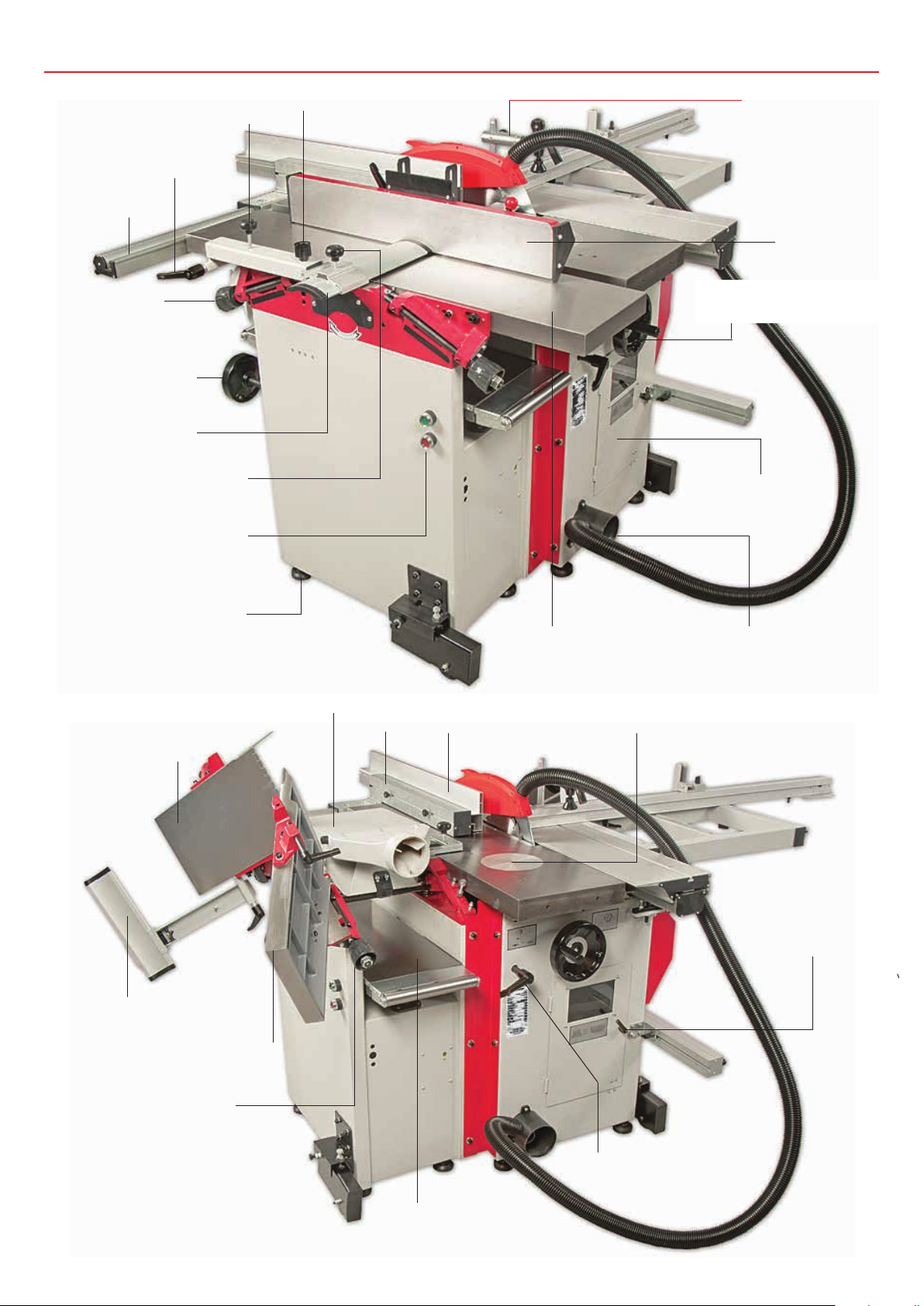

Illustration and Parts Description

Height adjuster knob

Mounting arm lock

Fence rail

Out feed table

adjuster

Thicknessing table

rise and fall control

Cutter block guard

Cutter block guard clamp

ON/OFF Switch Planer/

Thicknesser

Cutter block guard adjuster

Work clamp

Fence

Spindle moulder rise/fall

control handle wheel

Spindle moulder

access door

Out feed table

Cutter block guard

Foot

Dust extraction

In feed table

Rip-Fence

Planer in feed table Dust extraction outlet

Fence extension Spindle moulder circular rings

Spindle moulder

access door lock

In feed table adjuster

Spindle height lock

Thicknesser table

22

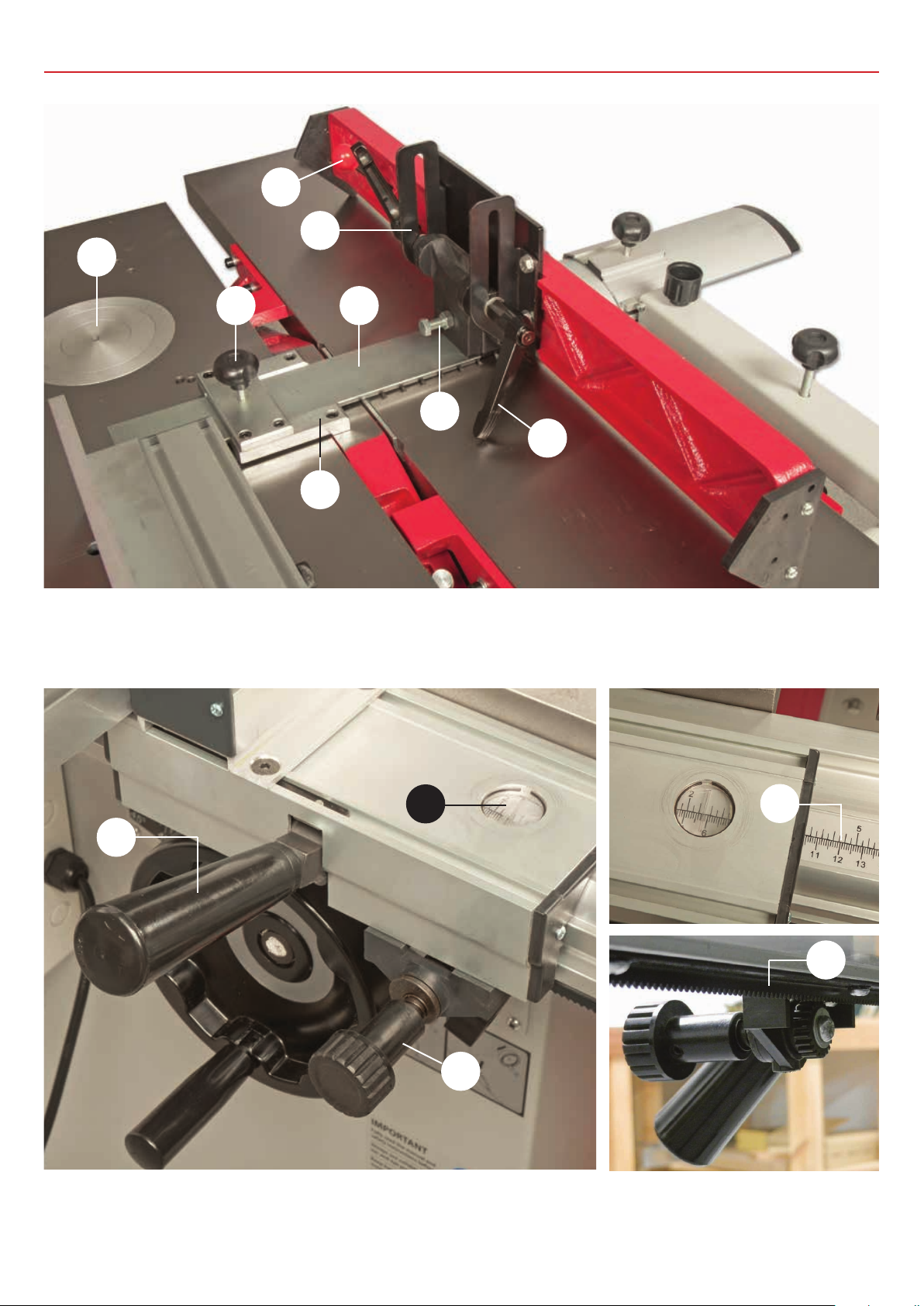

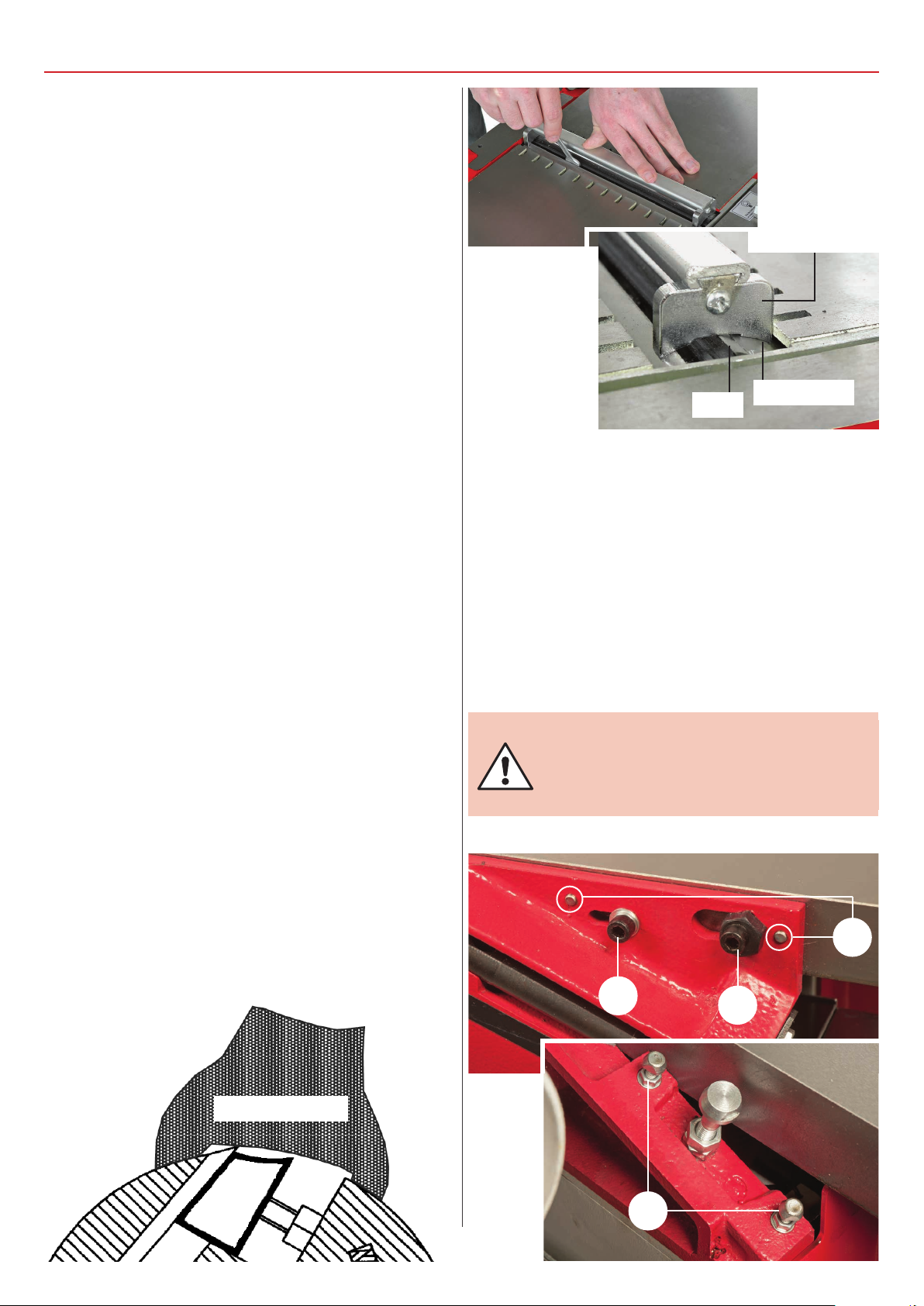

A

B

Feed scale overhand (A)

Pointer (B)

Illustration and Parts Description

A

B

Cam lock (A), Table height

locating bolts (B) to level the table

with the cutter block blade

A

Feed table locking handle (A)

A

Sliding table height assembly (A)

A

C

B

Planer/Thicknesser ON/OFF switch (A)

Emergency stop (B), Rise/Full clamp (C)

A

Saw table height adjusters (A)

Panel saw rise and fall control

butterfly handle lock

A

Autofeed engage control (A)

Thicknesser rise and full scale

D

A

C

B

Cutter block (A), In feed roller (B),

Out feed roller (C), Anti kickback fingers (D)

B

A

C

Tilt angle scale (A), Pointer (B), Tilt handle lock (C)

23

Illustration and Parts Description

F

D

H

A

C

G

E

B

Fence securing clamp (A), Fence mounting bracket (B), Planer fence base (C),

Elongated fence support bracket (D), Fence locking handle (E),

Fence positioning knob lever (F), Fence adjusting bolt (G), Spindle moulder circular rings (H)

A

C

B

Rip fence locking handle (A), Rip fence micro adjuster (B),

Magnifying glass (C), Fence rail scale (D), Fence rail rack (E)

24

D

E

Illustration and Parts Description

A

B

Magnifying glass

C

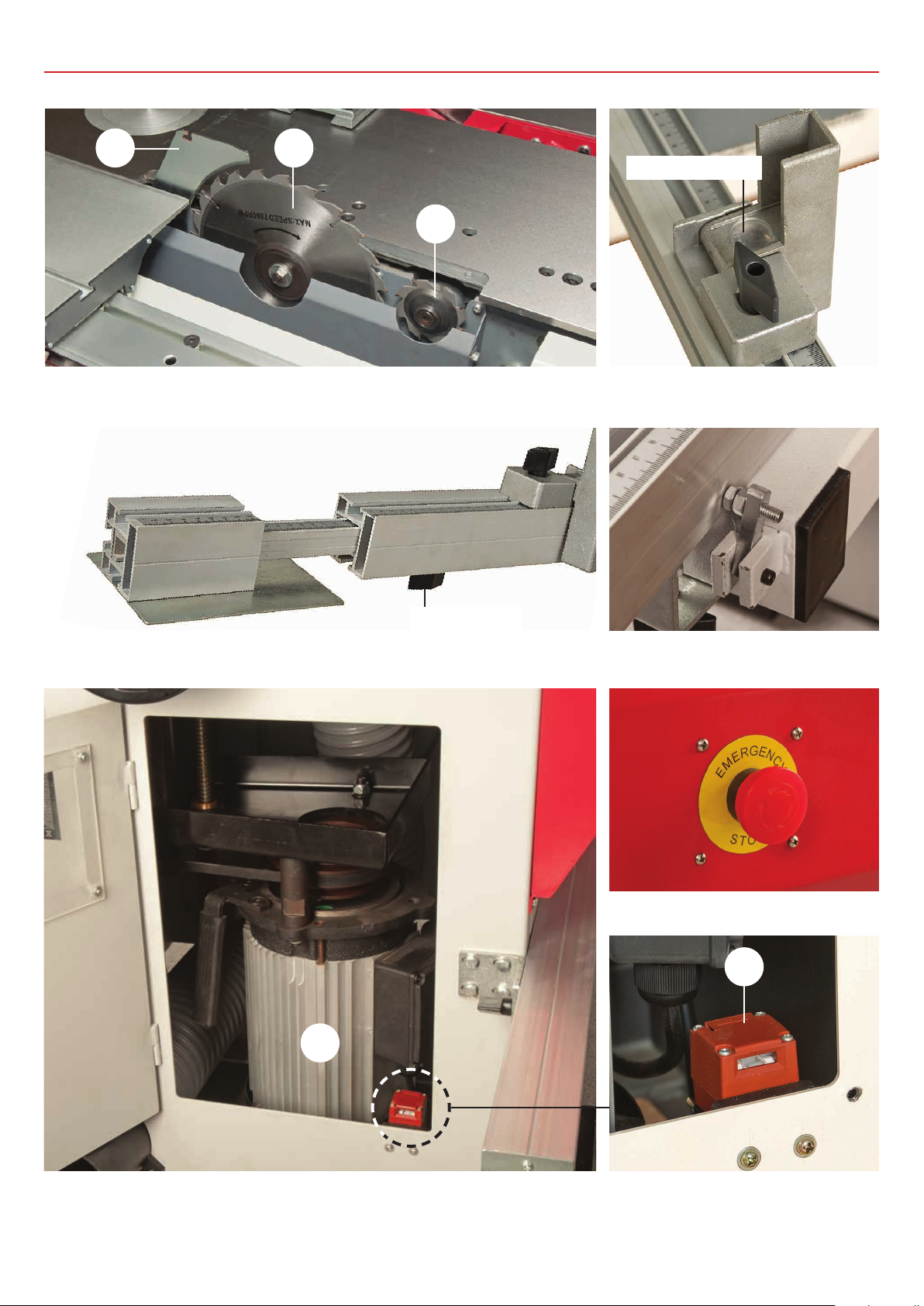

Riving knife (A), Saw blade (B), Scoring blade (C) Distance stop assembly

Butterfly clamp

Telescopic extension assembly

A

90˚ degree extension fence stop

Main emergency stop button

B

Spindle moulder motor assembly (A) and motor door micro switch (B)

25

Setting Up the Machine

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Panel Saw

the angle scale reading is correct. Set the rip fence a

predetermined distance from the saw blade and lock in

position. Check that the rip fence is held securely when it

is locked in position. If the locking appears a little ‘slack’,

adjust the position of the clamping lug at the rear of the

rip fence by tightening the nut.

Raise the blade to its maximum height, check that is

upright to the table. Slacken the angle bracket clamp by

undoing the butterfly nut (A) and the steel plate pin

assembly by loosening the clamping handle (B), see fig 46

and slide the fence up close to the saw blade. Secure the

fence again as described above.

Fig 46

B

A

Fig 47

Nut/bolt

not, adjust the 90˚ extension fence stop nut/bolt until the

fence is square to the blade.

Loosen the butterfly nut (A) and handle (B) as described

above, slide the nose of the fence (the black tongue) up to

the blade, secure. Check the parallelity of the sliding table

movement by sliding the table forward and checking the

tongue/blade are still in contact, or that the movement

has not jammed the tongue against the saw. If there is a

slight discrepancy, it may be acceptable to you (a 1mm

difference across the face of the blade (fully extended) is

about one quarter of a degree).

Tilt the blade fully over. Using a mitre square, set the angle

of the saw to 45˚. Check that the index mark gives a

corresponding reading against the scale. Adjust the

pointer if necessary. Reset the blade upright, check that

Make sure the

extension fence is

up against the 90˚

extension fence stop,

see fig 47 and using

a 90˚ square, place it

against the fence and

the blade (not on

the teeth), check that

the angle is correct, if

Setting Scoring Blade

90˚ Degrees

Lower the saw assembly with the Rise and fall control

hand wheel until the scoring saw is just below the table,

using a straight edge adjust the cap head screw (A ), set

the saw blade to the desired height using the Hex key

provided, turn (clockwise to raise the blade and

anti-clockwise to lower the blade), until the scoring saw

is level with the table, then recheck the height of the

scoring and adjust to 1 or 2mm if required. Lock the

scoring blade in position using the cap head screw (B),

see figs 48-49.

Fig 48-49

A

B

Scoring blade

45˚ Degrees

With the blade assembly at 90˚ degrees, turn the cap head

screw (A) one and half turns anticlockwise, (you may need

to change to get the desired scoring blade height). Lock

the scoring blade in position using the cap head screw

(B). Lower the saw assembly until the scoring saw is just

below the table. Then tilt the blade assembly until it reads

45˚ degrees on the tilt angle scale, check that the scoring

26

Setting Up the Machine

blade is sitting just proud of the table, see fig 50.

Fig 50

NOTE: If you change the main blade saw blade

at anytime, the kerf width of the replacement

blade must be slightly narrower, (3.2mm) than

the kerf width of the scrolling blade.

Connect the machine to the mains supply, press the

power selector switch to the ‘I’ position for spindle

moulder/panel saw, turn the selector switch to ‘2’ panel

saw (see page 21) and give the machine a quick burst. i.e.

On/Off. Check that everything is sound and feels O.K. (No

knocking, scraping, belt squeal, rubbing etc.,)

Reconnect the mains, give the machine a longer run,

and press the emergency stop button on the front of the

machine. Check that the blade comes to a complete stop.

When you are happy that everything seems OK, switch

the machine off, disconnect from the mains supply.

Spindle Moulder

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Spindle Speed Setting

The spindle speed must be selected according to the

cutting diameter. The speed is set by changing the V-belt

location on the pulleys, see diagram below.

With the blade assembly at 90˚degrees, turn the cap head

screw (A) one and half turns anti-clockwise. Lock the

scoring blade in position using the cap head screw (B).

Lower the saw assembly until the scoring saw is just

below the table.

Tilt the blade assembly until it reads 45˚degrees on the

tilt angle scale, check that the scoring blade is sitting just

proud of the table.

Alignment Screw

Turn the alignment screw as required to align the scoring

blade with the main blade, see fig 51.

Fig 51

Upper location (H)....7000rpm Centre location

(M)....5500rpm Lower location (L)....3500rpm

7000rpm

H

5500rpm

M

3500rpm

L

Spindle

Pulley

PLEASE NOTE: If the spindle speed is set at

(3500rpm) and the tool diameter is smaller

than 120mm there is an increased risk of the

work piece kicking back at you!

The Cutting Tool

The cutting tool may only be changed when the spindle

rotation lock is engaged and the mains plug is pulled.

Motor

Pulley

Blade alignment screw

Check that everything that should be tight, is tight; saw

blade guard, rise and fall lock mechanism, fence clamps

etc.

There is a risk of personal injury by cuts from the cutter

knives. Wear suitable gloves when changing cutters.

Clean all surfaces of cutters and spindle arbor with a

suitable solvent.

Only use tooling with manual feed cutter blocks

marked “MAN”.

27

Continues Over....

Setting Up the Machine

Unsuitable, incorrectly mounted, dull, cracked or bent

cutter knives can break or increase the risk of kickback

considerably.

The installation of sanding or polishing tools is not

permissible.

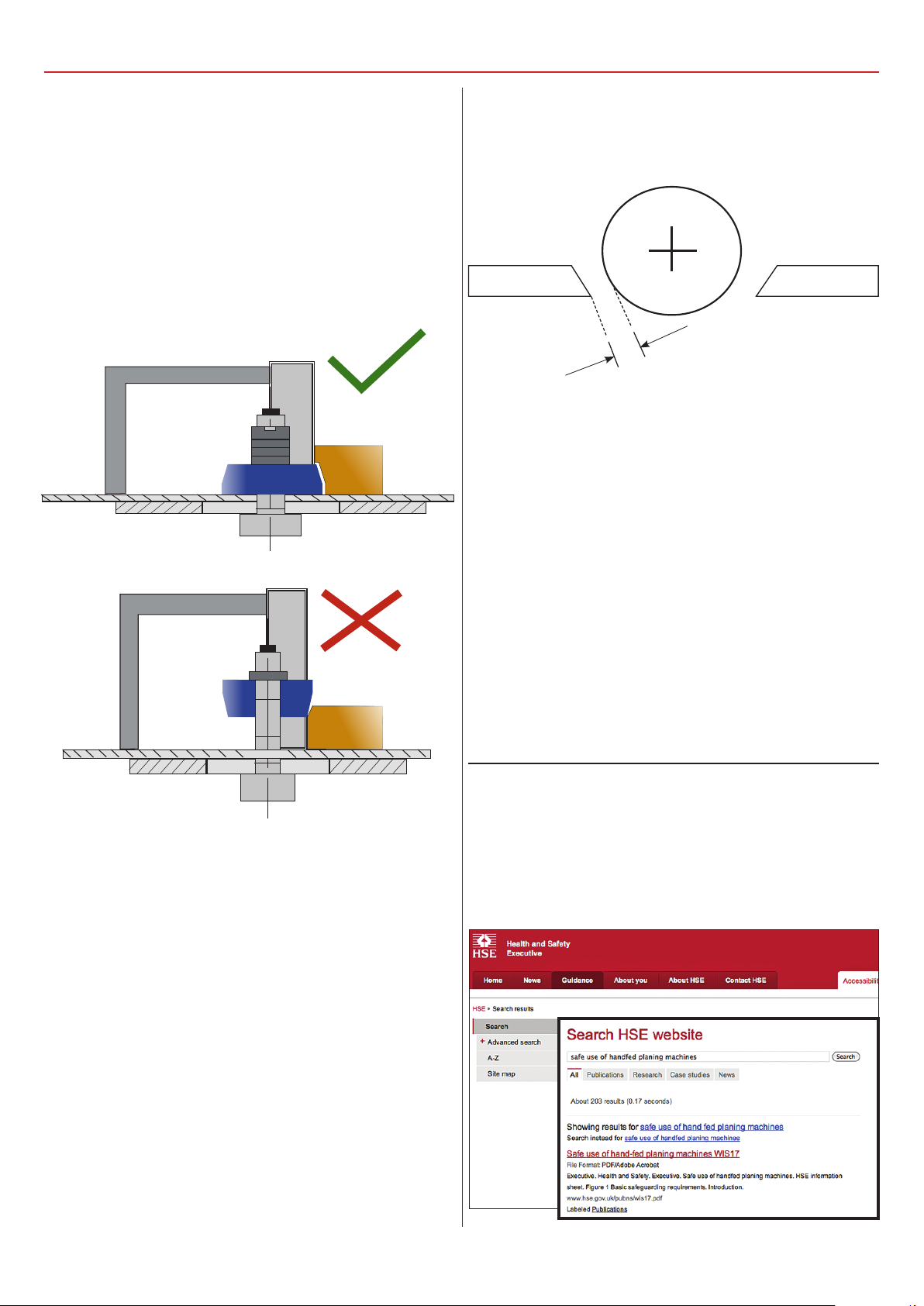

The cutter block must be positioned on the arbor as low

as possible, see diagrams below.

Close up the aluminium fences to give approximately

5mm clearance around the cutter, see diagram below.

Spindle

Fence Fence

5mm

The fence is used to guide small work pieces through the

cutter without them being trapped between the fence

and the cutter.

The top cover should be kept closed when the machine is

in operation; it can be opened to give access to the cutter

when the machine is stationary.

Watch the direction of rotation (counter-clockwise) when

mounting the cutter.

Fill the space between cutter and clamping washer with

spacing collars.

Tighten the arbor cap head screw securely.

Don’t use a wrench extension or a hammer to tighten the

cap head screw.

The dust extraction hose is connected to the aperture at

the rear of the fence casting.

Before starting work, carefully check that the cutter can

rotate freely without fouling the inside of the

guard and that the guard is clamped firmly in place.

Operating Instructions

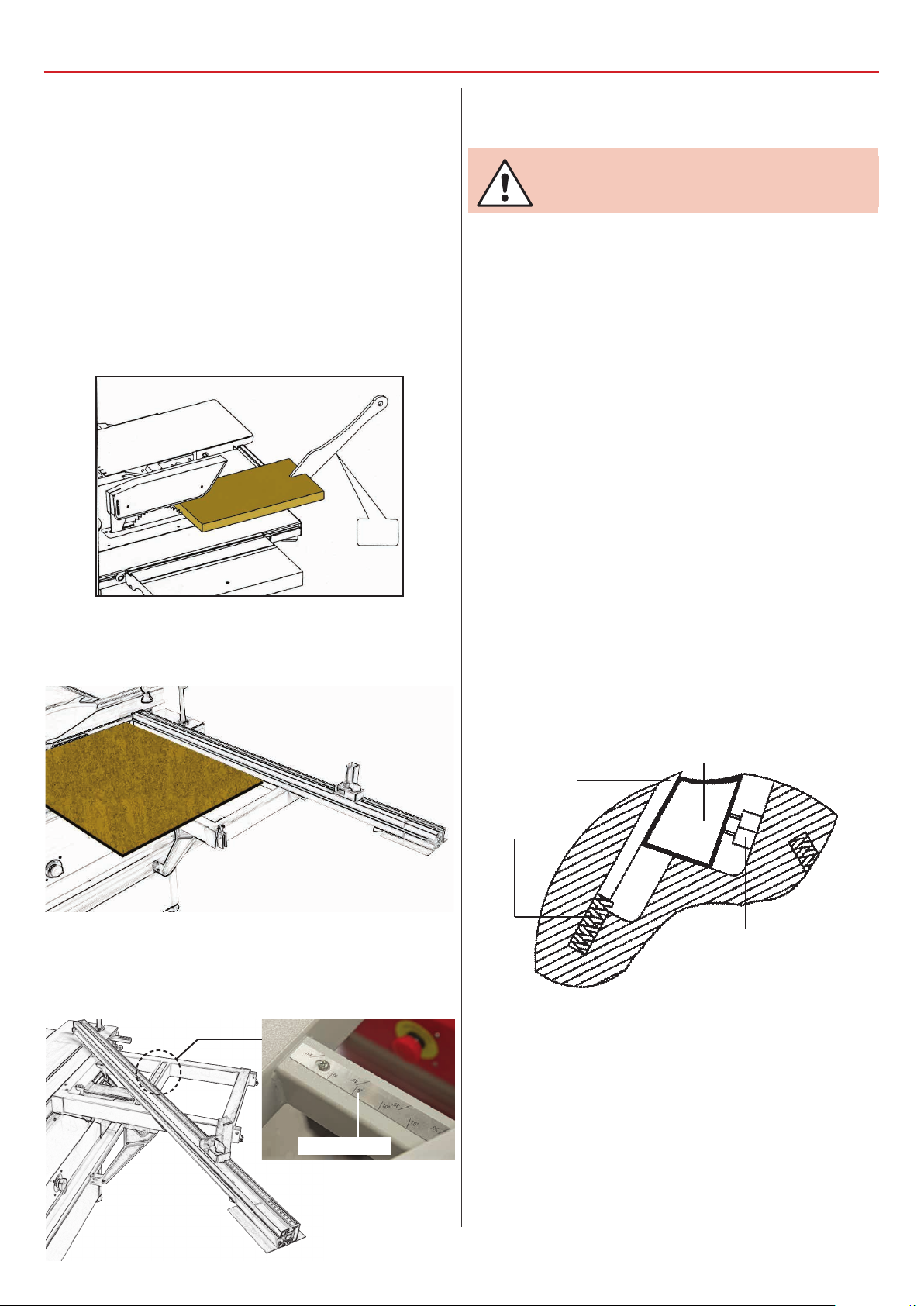

Planning Function

To operate the planer correctly, it is recommended to

read the HSE (Health and Safety Executive) information

working sheet on the safe use of handfed planing

machines, see image below.

Cover the clearance zone around the cutter with table

insert rings, see figs 35-36-37.

Setting the Fence

Adjust the position of the fence assembly to give both

the required cutter protrusion and adequate clearance

between the cutter and the fence.

28

Operating Instructions

Power On Procedure:

1) Rotate the selector switch (A) in the vertical position.

2) Press the selector switch (B) to select the planer/thick-

nesser icon (I).

3) Press the NVR ON/OFF switch (C) to the “ON” position,

then press one of the green “ON" buttons to start the

machine, see figs 52-53.

Thicknessing Function

• Rotate the cutter guard arm out of the way.

• Remove the fence assembly.

• Unlock the in feed/out feed tables, rotate to the side.

• Use a honing guide to sharpen the blades.

• Rotate the dust extraction hood.

Fig 53

Green button

Green button

• Measure the timber thickness, raise the thicknessing

table & reading against the scale, until the desired

measurement is reached and lock the table in position.

• Release the main emergency stop button on the

planer/thicknesser.

Power On Procedure:

1) Rotate the selector switch (A) in the vertical position.

2) Press the selector switch (B) to select the planer/thick-

nesser icon (I).

3) Press the NVR ON/OFF switch (C) to the “ON” position,

then press one of the green buttons to start the machine,

see figs 52-53.

Fig 52

C

Spindle Moulder Function

Power On Procedure:

1) Rotate the selector switch (A) to the spindle moulder

icon (1).

2) Press the selector switch (B) to select the spindle

moulder/panel saw icon (R).

3) Press the NVR ON/OFF switch (C) to the “ON” position,

to start the spindle moulder, see fig 54.

Fig 54

C

B

A

29

B

A

Continues Over....

Operating Instructions

Correct Operating Position

Position yourself offset to the machine as shown above

Work Piece Handling

Fig 55

C

B

• Feed the work piece straight across the machine table,

holding the fingers close together and guiding the work

piece with the palms of your hands.

• Never put your hands under or behind the cutter guard.

• Always keep your hands well clear of the rotating cutter.

• Always feed the work piece against the cutter rotation as

shown by the arrow in illustration.

• Use a push stick when working the ends of narrow stock.

• Use a feeding aid if you are going to machine a work

piece shorter than 300mm.

• Always machine the work piece over its entire length.

Recess machining may only be carried out with the

aid of suitable longitudinal work piece stops.

• When working complex shapes, make jigs and guides to

guide the work piece properly and safely.

• Make trial cuts on a piece of scrap before working the

actual work piece.

• Support long work pieces with roller stands or table

extensions.

A

4) Regulate the cutting height by raising or lowering the

rise and fall control hand wheel (A). Lock the blade in

place by turning the Rise & fall control handle lock.

A

5) Adjust the rip-fence extension (B) to the desired

position by loosening the two rip fence extension

butterfly knobs (C) then tighten the knobs. Set the

height of the guard to 3-4mm above the work piece

and lock it in position. When done, lower the guard

to board level.

•Always work one work piece at a time.

Panel Saw Function

Power On Procedure:

1) Rotate the selector switch (A) to the panel saw icon (2).

2) Press the selector switch (B) to select the spindle

moulder/panel saw icon (R).

3) Press the NVR ON/OFF switch (C) to the “ON” position,

to start the panel saw, see fig 55.

C

B

30

Operating Instructions

6) • Check that the room is well lit.

• Make sure that the saw table is clear of any tools.

• Check that the saw guard is against the top of the

board.

• Start the saw, wait until the saw is at full speed, use a

push stick (D) to safely push the work piece through.

• Turn off the saw, wait until the saw comes to a

complete stop before removing the board.

D

7) Use the extension table/fence when cutting large

pieces of board at 90˚.

Planer/Thicknesser Blades

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

The planer blades are mounted into 3 slot housings

machined in the cutter block. The slot housing comprises

of a slot cut on a radial axis with a reverse tapered slot

alongside it, see fig 56.

The depth of the first slot governs the seating of the

chip breaker/wedge, the second slot allows the blade to

be set to its correct depth in the block. The chip breaker/

wedge is machined with a tapered face set at the same

angle as the slot. This allows the blade to be clamped

between parallel faces. The block will accept blades

250mm x 3mm x 30mm. After sharpening, the blades will

reduce over their height dimension, but the blades can be

safely used until their overall height dimension is 17mm,

then the blades must be discarded as they can no longer

be securely clamped in the housing.

The reverse taper slot has a series of blind holes bored in

the bottom surface into which springs are fitted. These

springs act against the bottom of the planer blade, to

push it into contact with the setting tool, when the

blades are being positioned after changing.

8) There is an angle scale mounted on top of the

extension table, to set the fence at required angles

for cutting parallel cuts.

Angle scale

Fig 56

Chip breaker/wedge

Planer knife

Spring

Clamping Nut

Changing the Blades

Locate the 5.5mm x 7mm A/F spanner in the tool kit.

Turn the cutter block until one of the slots is uppermost,

(between the tables). Using the spanner drive the 5 No.

bolts into the chip breaker/wedge, thus removing the

clamping effect. This should allow the blade to ‘spring’ up

to protrude clear of the edge of the cutter block.

Carefully remove the blade, lay aside. Remove the

chip breaker/wedge, lay aside, finally remove the springs

31

Continues Over....

Operating Instructions

from the slot and lay them aside. Repeat the process

for the other two blades. If the block becomes difficult

to hold located, being out of balance with the blade/s

removed; use a thin wedge of material to jam the cutter

block in position.

Now is a very good time to clean the slot housings

thoroughly, remove the resin build-up, sawdust, chips

and any old joiners/carpenters etc., that have recently

disappeared without trace. Ensure the circumference of

the cutter block is likewise cleaned thoroughly.

Remove the clamping bolts from the chip breaker/

wedges, clean the bolts and the threaded holes, clean the

springs and the chip breaker/wedges thoroughly. Apply

a little light oil to the springs. Remove the new/sharpened

blades from their ‘keeper’ set carefully to hand and put

the ‘old’ blades away in the ‘keeper’ to be sent for

sharpening.

Locate the blade setting tool and put it to hand. Screw

the bolts into the chip breaker/wedges. Select one of the

slot housings and wedge the cutter block to maintain it

in position. Set the springs into the holes in the bottom

of the slot, introduce the chip breaker/wedge, position it

against the ‘back’ of the slot, introduce a blade in front of

it. Using the spanner start to unscrew the bolts, take care

at this time as the blade could be protruding well above

the block. Unscrew the bolts until the wedge just starts a

‘nip’ on the blade, then screw them back in half a turn.

At this point all the components should be loose in the

slot (not slack), carefully position the blade and the wedge

to line up with the edge of the cutter block. Press the

blade setting tool gently down onto the blade, see fig 57

ensure that the locating feet are firmly in contact with the

cutter block, and the blade is against the setting recess,

see fig 58-59. Holding the blade and the setting tool in

this position, tighten at least two of the clamping bolts

to provide a firm clamp of the blade, with the setting tool

held firmly in place. Tighten the remaining bolts.

Tighten hard, but do not overtighten, remember, these are

M4 bolts. Repeat this procedure for the remaining blades.

Fig 58-59

Blade setting tool

When all the

blades are fitted,

rotating the

cutter block by

hand in reverse

and visually

inspecting the

edge of the

blades against

a fixed point. If this appears satisfactory, carry out a final

‘tightness’ check on the clamping bolts; remove all the

tools and stow away.

NOTE: If at any point you need to adjust the tables so

they are parallel, adjust by the following method:

1) Remove the transport pins (A) using a pin punch and

hammer.

2) Adjust the table height locating bolts (B).

3) Loosen the Hex bolt (C) and eccentric cam (D), place

a straight edge across both tables and adjust until the

tables are in line. When you are satisfied tighten (C and D),

see fig 60. Reset the feed scale to ‘0’, see page 23.

NOTE: BY RESETTING THE TABLES THE HOLES

FOR THE TRANSPORT PINS MAY BE OUT OF

ALIGNMENT. WE SUGGEST RE-DRILLING NEW

HOLES NEAR ORIGINALS THEN REPLACING THE

PINS.

Blade

Cutter block

Fig 60

A

Fig 57

Blade setting tool

32

C

D

B

Operating Instructions

Changing the Panel Saw Blade

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Raise the saw blade to it’s highest point. Remove the saw

blade guard. Pull the sliding table locking knob towards

you and slide the table to the side to expose the blades.

Using the spanner and the tommy bar (A) provided, put

the spanner onto the flats on the nut. Turn the saw until

the tommy bar hole (B) is visible. Insert the tommy bar

and turn the saw to allow it to rest against the front edge

of the saw slot, see figs 61-62.

Fig 61

A

B

Fig 63

Riving knife

Changing the Scoring Blade

Using the 8mm Hex key and the tommy bar (A) insert the

Hex key into cap head bolt, turn the scoring saw until the

tommy bar hole is visible. Insert the tommy bar and turn

the saw to allow it to rest against the front edge of the

saw slot. Remove the blade check the new blade for

damage, missing teeth,sharpness etc. then replace the

scoring saw and tighten, see fig 64.

Fig 62

A

Spanner

Slacken off the saw nut (remember left hand thread).

Remove the saw nut, then remove the sawplate washer

and the saw blade. Now is a good time to give the

interior of the machine, the dust extraction channels,

etc. a thorough clean. Check the new blade for damage,

missing teeth,sharpness etc. Fit the new blade, ensure

that the teeth are pointing towards the front of the

machine. Put the saw plate washer onto the shaft and

twist on the saw nut. Spin the nut up finger tight and

check the saw is correctly seated.

Tighten up the saw nut, using the tommy bar to hold the

shaft steady. Check the riving knife is aligned with the saw

blade, and correctly positioned, see fig 63.

Fig 64

A

Slide the table back until the locking knob pin engages

the pin recess, replace the saw blade guard. When

everything is satisfactory, turn the saw blade once by

hand to check it doesn’t foul anywhere. Reconnect the

machine to the mains supply.

Give the machine a ‘quick’ burst check ( i.e. quick ON-OFF)

to ensure everything is O.K. If everything is satisfactory,

continue to use the machine. Check the old blade for

sharpness, missing teeth, resin buildup, etc., clean if

necessary and send for refurbishment/re sharpening if

required. If the blade is not to be resharpened, clean and

pack away in its stowage case.

33

Continues Over....

Operating Instructions

Changing the Spindle Moulder Cutter

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Raise the spindle to the maximum height by unlocking

the spindle moulder rise/fall locking handle and

turning the spindle moulder rise/fall handle clockwise

then lock in place. Using the 12mm hex key provided

remove the cap head clamping block (D), spacing collar/s

(E) and clamping washer (F) and place them safely aside,

remove the cutter block, see fig 65.

Fig 65

D

E

F

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Changing the Spindle Moulder Speed

Open the spindle moulder access door to the side of the

machine, see fig 66. Lower the spindle to it’s lowest point,

if not done so already. Locate the 16mm socket spanner

(B), loosen the two bolts (A) on top of the motor, push the

motor to the side, to allow the belt to go slack, reposition

the belt on the pulleys as required. When your are happy

push the motor back and tighten the clamping bolts (A)

to keep the tention, see figs 67-68.

Fig 66-67

Check the new cutter block for damage,sharpness

etc. Fit the new cutter block on the arbor as low as

possible, see diagram below. Watch the direction of

rotation counter-clockwise when mounting the cutter.

replace the clamping washer (F), spacing collar/s (E) and

clampling block (D). Tighten the clamping block securely.

Cutter block

Turn the cutter block round once by hand to check it

doesn’t foul anywhere. Reconnect the machine to the

mains supply. Give the machine a ‘quick’ burst check (i.e.

quick ON-OFF) to ensure everything is fine.

If everything is satisfactory, continue to use the machine.

Check the old cutter block for damage, sharpness, resin

buildup, etc., clean if necessary and send for refurbishment/re-sharpening if required. If the cutter block is not

to be re-sharpened, clean and pack away in its stowage

case.

34

Spindle

Pulley

Fig 68

A

A

B

7000rpm

H

5500rpm

M

3500rpm

L

Motor

Pulley

Operating Instructions/Routine Maintenance

Close the access door, raise the spindle, reconnect the

machine to the mains supply. Give the machine a ‘quick’

burst check ( i.e. quick ON-OFF) to ensure everything is

O.K. If everything is satisfactory, continue to use the

machine.

WARNING!! DISCONNECT THE MACHINE FROM

THE MAINS BEFORE CONTINUING!

Your combination machine requires minimum

maintenance, but it is essential that it is carried out

to ensure the longevity and correct function of the

machine.

Planer/ Thicknesser

• Check the overhand tables and the thicknessing

bed are clean, not coated with resin etc. Apply a

proprietary cleaner/lubricating agent.

• Check the cable and the plug for damage or

defects.

height of the table lock stud. Hold the stud firmly and

loosen the lock nut, adjust the stud, lightly ‘pinch’ with

the lock nut. If correct, fully tighten the lock nut, if

not, repeat the process until the ‘lock down’ is correct.

Panel Saw

• Keep the saw as clean and free from saw dust build up

as practical.

• Periodically, unlock the sliding table and push to one

side to gain access to the saw mechanism. Raise the saw

blade to it’s highest point. Remove the saw blade guard,

lower the blade cover and blow out or brush out the

saw inner workings, using a proprietary resin cleaner.

Note: You may require an air line to blow out areas

physically not possible to reach, i.e the threaded

drive shafts of the rise and tilt mechanisms.

• Check the saw and scoring saw blade/s regularly for

chipped, missing, damaged teeth etc. and remove

any resin build up from the blade/s, riving knife etc.

• Mount the planer fence and check it is set upright.

• Check the dust extraction hood and ensure there is

no excessive build up of sawdust/resin, especially in the

mouth of the chip deflector and around the mouth of

the extractor.

• Check the blades for sharpness and damage.

• Clean the machine thoroughly, remove any shavings,

sawdust, chips etc, from in, under and around the

machine.

• Check the cutter block for resin build up, especially

behind the blade and in the scallop of the chip breaker/

wedge.

• Raise the tables and brush out and clean any debris or

build up around the area of the noise attenuating slots

in the edges of the overhand tables.

• Check the in feed and take off pressure rollers are

not clogged, clean as necessary.

• If the “Panel Saw” is not going to be used for a

period of time, spray a light coat of oil over the table

surface and blades that will help prevent rust.

Spindle Moulder

• Keep the cutter block clean and free from dust build up.

• Check the cutter block regularly for chipped blades and

damage to block i.e cracks in the cutter block.

• When changing the cutter block, remove the cutter

block and place safely away, clean the spindle by

spraying a light coating of oil over the shaft and install

a new cutter block.

• Opening the access door for the spindle moulder, check

the belt tension. If the belt is loose, using the 16mm

socket spanner loosen the motor bolts and push/pull

until the belt is under tension again, tighten the motor

bolts to keep the tension.

• Check the action of the anti-kickback fingers, again

clean and lubricate as required.

• If the “Planer/Thicknesser” is not going to be used for a

period of time spray a light coat of oil over the table

surface that will help prevent rust.

• Re-tighten the table lock. If the table lock downs

becomes ‘slack’ they can be adjusted by altering the

After several months of constant use the condition of

the chains, sprockets,tension of the drive belts and the

threaded drive shafts of the rise and fall tilt mechanisms

will need to be checked, that may require a service

engineer to oversee the job.

If you find that the machine is not performing as

it should please contact our “Technical Sales Team”

by phone on 03332 406406.

35

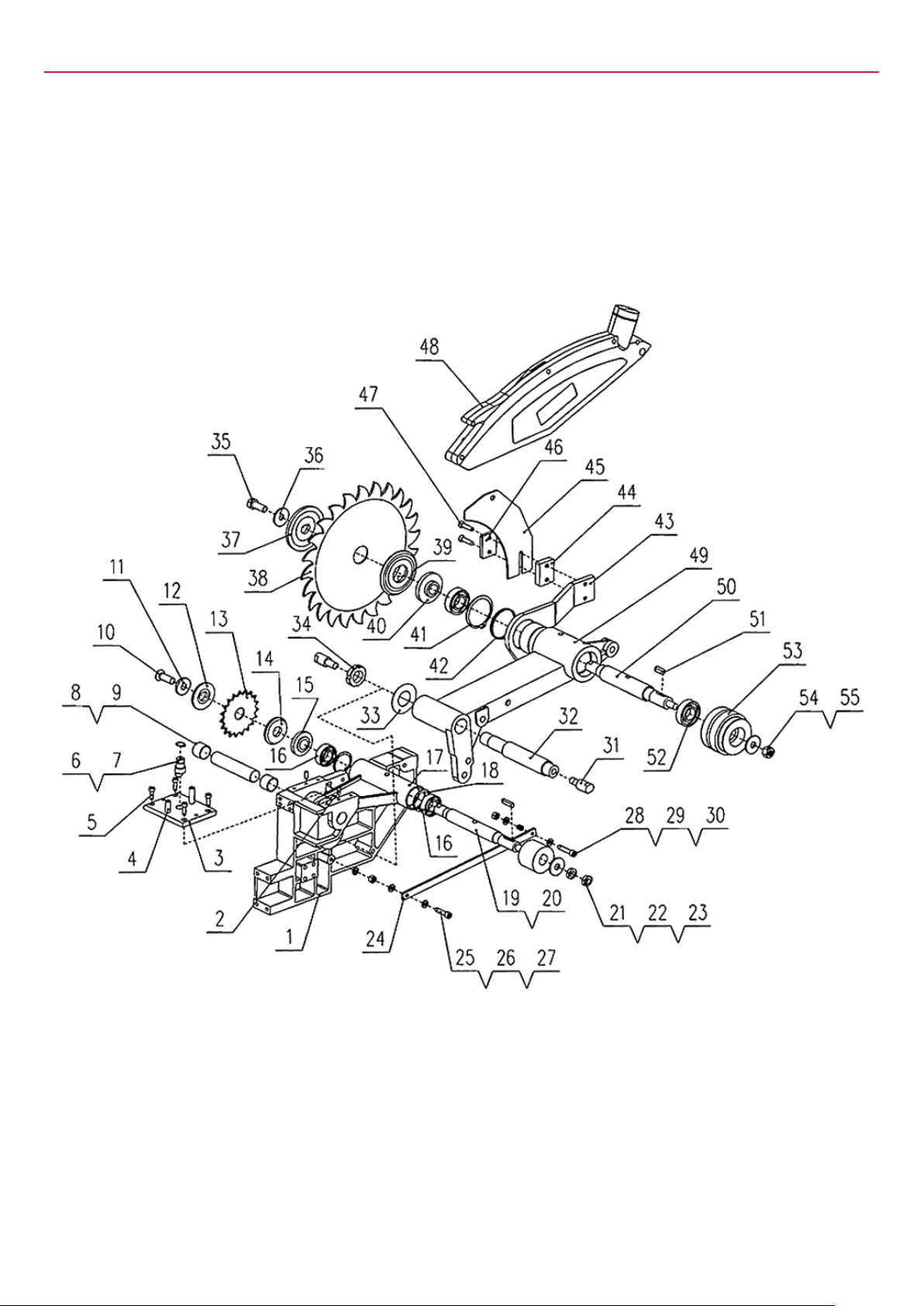

Exploded Diagrams/Lists

Planer Thicknessser Assembly

36

Exploded Diagrams/Lists

37

Exploded Diagrams/Lists

38

Planer Thicknessser Assembly

Exploded Diagrams/Lists

NO DESCRIPTION QTY

1 Right and left

Support plate

3 Plate 2

4 Right plate 1

5 Bearing tube 1

11 Support base 4

12 Right cutter block

support

13 Left cutter block

support

14 Right adjusting wing 1

15 Left adjusting wing 1

16 Right Locking block 1

17 Left Locking block 1

18 Out feed table 1

19 In feed table 1

20 Adjusting axle 2

21 Metal plate 2

22 Locking handle

assembly

23 Eccentric bush 2

24 Screw M8x8 2

25 Kick block 20

26 Axis 1

27 Support axle 2

28 Hex nut M10 4

30 Scale 1

31 Adjusting wheel 2

32 Locating plate 1

33 Scale 1

35 Hex bolt M10x60 2

36 Cutter block

assembly

37 Bail bearing bush 2

38 Cutter block pulley 1

39 Protective plate 1

40 Cutter block 1

41 Blade locking block 3

42 Blade 250x30x3 3

43 Spring 6

44 Dust chute 1

1

1

1

2

1

45 Dust chute head 1

46 Locking plate 1

47 Change-over plate 1

48 Screw M5x6 2

49 Thicknessing table

assembly

50 Lifting tube 1

51 Lifting tube bracket 1

52 Support base 1

53 Gear assembly 1

54 Adjusting bar 1

55 Block 1

56 Block 1

57 Locking bar assembly 1

58 Hand wheel 1

59 “C” ring 1

60 Pointer 1

61 Depth scale 1

62 Washer 1

63 Thicknessing table 1

64 Plate 4

66 Gear box 1

67 Gear 1

68 Guide screw 1

69 Gear axle 1

70 Bush 1

72 Locking handle 1

74 Control handle

assembly

75 Sprocket assembly 1

76 Sprocket assembly 1

77 Tension system

assembly

78 Pin 1

79 Long pin 1

80 Sprocket IV 2

81 Driving roller 1

82 Pressing roller 1

83 Bush 4

84 Double-head bolt 4

85 Spring 1

86 Connecting plate 1

89 Sprocket I 1

90 Sprocket II 1

91 Iron friction wheel 1

92 Sprocket III 1

1

1

1

94 Tension plate 1

95 Spring 1

97 Guiding fence 1

98 Cutter block

protective fence

99 Fence plate 1

100 Supporting plate 1

101 Guiding block 1

102 Right metal plate 1

103 Left metal plate 1

104 Connecting plate 1

105 Protective plate 1

106 Left sliding block 1

107 Right sliding block 1

108 Handle 1

109 Double head bolt 1

110 Protective cover 1

111 Sensitive switch plate 1

112 Short locating bar 1

113 Long locating bar 1

114 Motor pulley 1

115 U-shaped metal tube 1

116 Locking handle 1

117 Long locking handle 1

118 Short locking handle 1

119 Angle iron 1

120 Support plate 1

121 Protective plate 1

122 U-shaped bracket 1

123 Locking plate 1

124 Plastic insert 2

125 Switch mounting

plate

126 White sensitive

switch

128 Spring 3

129 Hex bolt M6x20 2

131 Handle wheel bar 1

1

1

1

39

Continues Over....

Exploded Diagrams/Lists

132 Hand wheel 1

505 Nut M10 8

506 Screw M5x8 5

507 Screw M5x8 4

508 Hex bolt M8x16 2

509 Hex nut M8 8

510 Washer ɸ 5 12

511 Washer ɸ 8 22

512 Socket cap screw

M8x25

513 Spring washer ɸ 8 18

514 Socket cap screw

M8x25

515 Spring washer ɸ 8 4

516 Socket cap screw

M8x30

517 Pin A8x30 2

518 Socket cap screw

M8x30

519 Hex bolt M6x10 2

520 Screw M6X20 1

521 Hex nut M16 4

523 “C’ring ɸ 12 2

525 Pin 5x16 1

526 Socket cap screw

M5x12

528 Screw M4x6 2

529 Bolt M6X10 15

531 Pin 6X20 1

532 “C’ring ɸ 25 1

534 Screw M6X10 4

535 Socket cap screw

M6x8

536 Hex bolt M6x10 2

537 Spring washer ɸ 5 12

538 Screw M6x25 3

539 Hex bolt M6x10 14

540 Hex nut M6 22

542 Support cylinder 1

542 Support cylinder 1

544 Anti-vibration washer 2

545 Socket cap screw

M8x16

4

4

2

4

1

8

10

546 Socket cap screw

M8x30

547 Screw M8x8 1

548 Screw M6x10 4

549 Socket cap screw

M6x35

550 Screw M4x6 2

551 Screw M4x6 2

552 Hex nut M12 1

553 Nut M6 4

554 Pin 5X12 1

555 Lubricating injection

hole M10

556 Seal 1

557 Ball bearing 51102 1

558 Spring washer 10 2

559 Hex bolt M6x65 2

560 Hex nut M10 2

561 Pin 4x25 1

562 “C” ring ɸ 10 1

563 “Cring ɸ 18 1

564 Screw M4x6 12

565 Spring 4

566 Hex bolt M6x10 1

568 Nut M3 4

569 Chain 05B-1x86 1

570 Chain 05B-1x76 1

571 Locking bar 2

572 Long handle

assembly

573 Axle bush 8

574 Pin 5X16 2

575 Handle 1

577 Bait bearing

61901-2Z

578 Screw M6x10 4

579 “Cring ɸ 24 4

580 Screw M6x14 4

582 Bail bearing 6303-2Z 1

583 Pin 1

586 Z-belt(L=1092) 1

587 Washer ɸ 10 6

7

1

1

1

4

588 Socket cap screw

M6x12

589 Hex bolt WI5x50 1

590 Screw ST5x40 4

591 Nut MS 4

592 Nut MS 7

595 Hex bolt M8x16 4

596 Socket cap screw

M6x12

597 Screw M5x8 6

598 Spring washer ɸ 5 6

599 Motor 1

600 Electromagnetic

switch

605 Hex bolt M8x25 4

606 Socket cap screw

M6x40

608 Screw M5x50 2

613 Socket cap screw

M6x16

614 C- ring ɸ 6 2

615 Hex nut M6 1

616 Socket cap screw

M5X12

617 Nut M12 1

619 Long handle

assembly

621 Protective cover 1

700 Base assembly 1

701 Planing table

assembly

702 Cutter block

assembly

703 Thicknessing table

assembly

704 Sprocket system

assembly

705 Extraction system

assembly

706 Fence assembly 1

707 Protective cover

assembly

6

2

1

1

2

2

1

1

1

1

1

1

1

40

Panel Saw/ Planer Thicknesser Assembly

Exploded Diagrams/Lists

NO DESCRIPTION QTY

01 SAW BENCH AND MILLING BODY 1

02 PLANER THICKNESSER BODY 1

03 FRONT CONNECTED PLATE 1

04 BACK CONNECTED PLATE 1

05 CAP SCREW M8X20 6

06 SPRING WASHER 8 6

07 FLAT WASHER 8 6

08 CAP SCREW M8X20 6

09 SPRING WASHER 8 6

10 FLAT WASHER 8 6

41

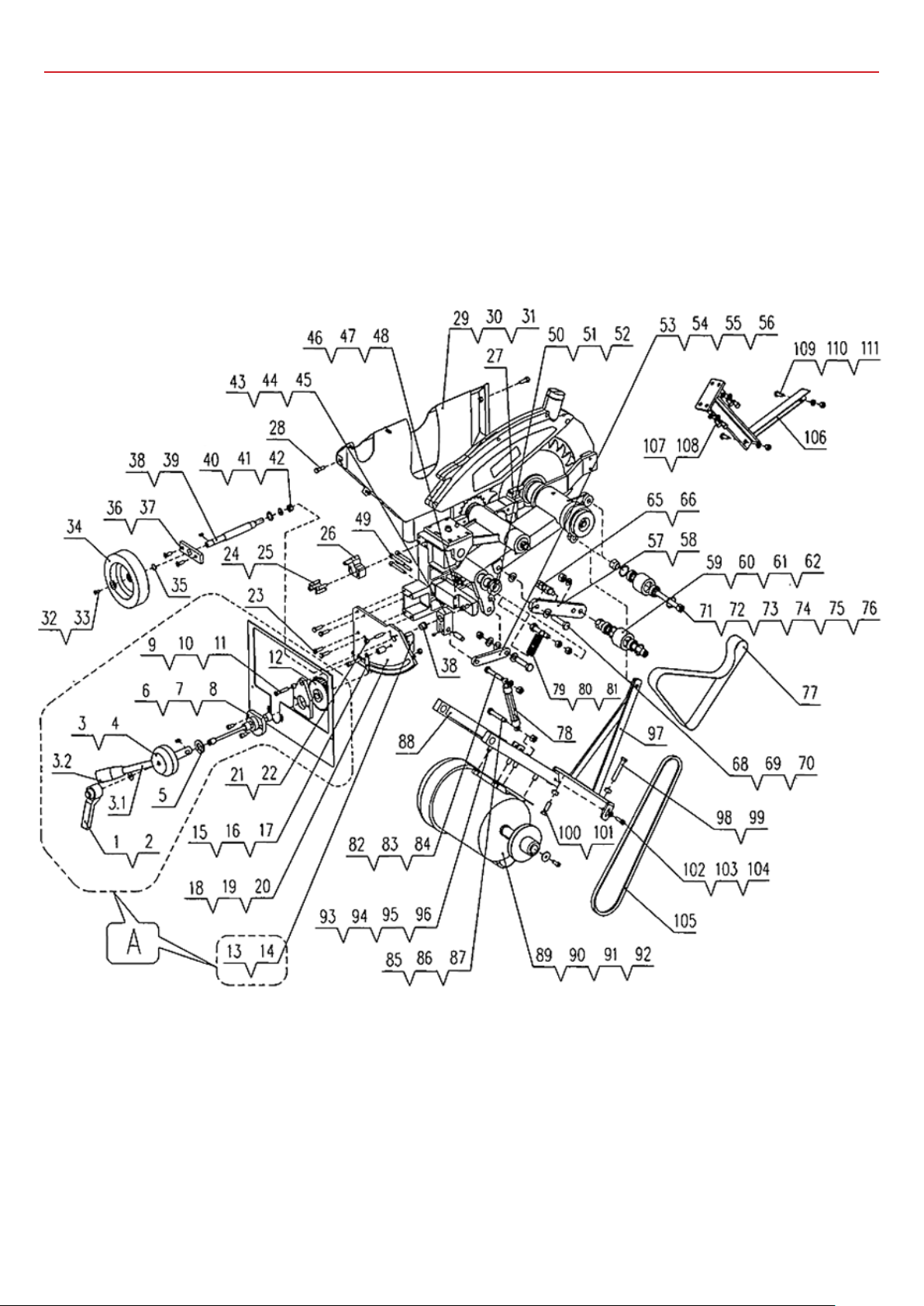

Exploded Diagrams/Lists

Panel Saw/ Spindle Moulder Assembly

42

Exploded Diagrams/Lists

NO DESCRIPTION QTY

01 Saw bench and moulder body 1

02 Saw bench and moulder table 1

03 Phillips screw M10X70 4

04 Hex nut MIO 12

05 Flat washer MO 8

06 Double saw blade assembly 1

07 Locking block 2

08 Cap screw M8x50 4

09 Hex locking nut M8 4

10 Flat washer 8 4

11 Moulder assembly 1

12 Cap screw M8x30 4

13 Flat washer 8 4

14 Spring washer 8 4

15 Fence for saw bench assembly 1

16 Locking handle assembly 2

17 Flat washer 6 2

18 Plate 2

19 Cap screw M10x65 2

20 Hex nut MIO 2

21 Bolt M8X55 4

22 Hex nut M8 4

23 Flat washer 8 4

24 Sliding table assembly 1

25 Mitre gauge and alum, guide 1

26 Extension table 1

27 Side protective cover 1

28 Cap screw M5x8 6

29 Flat washer 5 6

30 Upper protective cover 1

31 Cap screw M5x8 3

32 Cap screw M5x10 2

33 Flat washer 5 5

34 Cap screw M6x45 2

35 Hex nut M6 2

36 Steel foot 4

37 Hex nut MIO 4

38 Support pole 1

39 Hex nut M16 3

40 Flat washer 16 1

41 Side cover 1

42 Cap screw M5x8 4

43 Flat washer 5 4

44 Main control switch 1

45 Switch guide label 1

46 Cap screw M5x12 4

47 Cap bolt ST4X25 4

48 Scale cover 1

49 Tilting scale 1

50 Cap screw M5x6 4

51 Flat screw 5 4

52 Milling blade protective cover 1

53 Saw blade cover 1

54 Cap screw M4X8 3

55 Emergency switch box 1

56 Cap screw M5x12 2

57 Flat washer 5 2

58 Emergency switch cover 1

59 Cap screw M4x35 4

60 Label for emergency switch 1

61 Dust outlet 1

62 Cap screw M6x16 3

43

Exploded Diagrams/Lists

Panel Saw Assembly 1

44

Exploded Diagrams/Lists

NO DESCRIPTION QTY

01 Small blade stand 1

02 Phillips screw M6X10 2

03 Adjusting plate 1

04 Phillips screw M8X30 2

05 Cap screw M5x10 4

06 Adjusting axle 1

07 “C” ring 12 1

08 Little axle 1

09 Sleeve 2

10 Cap screw M10X30 1

11 Washer 1

12 Little outer plate 1

13 Small blade

80x ɸ20x3.2x2.2x8T

14 Little inner plate 1

15 Small location sleeve 1

16 Bearing 6003-2Z/Z2 2

17 Small staff 1

18 “C” ring 35 2

19 Small spindle 1

20 Key A5X20 1

21 Small vice-pulley 1

22 Flat washer 10 1

23 Left thin nut M10 2

24 Connected pole 1

25 Cap screw M6x20 1

26 Nut M6 1

27 Flat washer 6 3

1

28 Cap screw M6x30 1

29 Hex nut M6 2

30 Flat washer 6 3

31 Pin 2

32 Big axle 1

33 Adjusting washer 1

34 Round Nut M20x1.5 1

35 Hex bolt M10x25 (left) 1

36 Washer 10 1

37 Big outer plate 1

38 Blade ɸ250xɸ30x3.2x24T 1

39 Big inner plate 1

40 Big location sleeve 1

41 “C” ring 50 1

42 Washer 1

43 Blade arm 1

44 Support plate 1

45 Riving knife 1

46 Fixed plate 1

47 Cap screw M6X25 2

48 Protective guard 1

49 Big staff 1

50 Big spindle 1

51 Key A6X20 1

52 Bearing 6004-227Z2 2

53 Big vice pulley 1

54 Hex locking nut M10 1

55 Washer 10 1

45

Exploded Diagrams/Lists

Panel Saw Assembly 2

46

Exploded Diagrams/Lists

NO DESCRIPTION QTY

01 Lock handle 1

02 Washer 8 1

03 Turning handle 1

04 Key A5X10 1

05 Flat washer 16 1

06 Connected plate 1

07 Inner sleeve 1 2

08 Cap screw M6x12 2

09 Clamp plate 1

10 Inner sleeve 2 1

11 Cap screw M6x35 1

12 Gear 1

13 Rack 1

14 Hex locking nut M8 1

15 Pointer 1

16 Pointer sleeve 1

17 Cap screw M6x30 1

18 Rack plate 1

19 Cap screw M4x20 2

20 Hex nut M4 2

21 Phillips screw

M6X25

22 Hex nut M6 1

23 Hex bolt M6x20 4

24 Cap screw M6x25 4

25 Pin A6X25 4

26 Front turning block 1

27 Back turning block 1

28 Hex bolt M6x12 2

29 Dust collecting

cover

30 Cap screw M6x10 3

31 Flat washer 6 3

32 Cap screw M5x12 1

33 Hand wheel washer 1

34 Hand wheel

ɸ12xɸ160

35 “C” ring 9 1

36 Small adjusting

plate

1

1

1

1

37 Cap screw M5x12 2

38 Lifting pole 1

39 Key A4X12 1

40 Hex locking nut M8 1

41 Flat washer 12 1

42 Flat washer 8 1

43 Exchange block 1

44 Pin A10X30 1

45 Phillips screw M5X8 1

46 Rack stand 1

47 Phillips SCREW

M6X25

48 Hex nut M6 1

49 Cap screw M6x45 4

50 Location nut 1

51 Phillips screw

M6X10

52 Flat washer 20 1

53 Lifting staff 1

54 Hex bolt M10x40 1

55 Flat washer 10 3

56 Hex nut MIO 1

57 Shifter bar 1

58 Inner location

sleeve

59 Cap screw M10x60 1

60 “C” ring 26 2

61 Bearing 6000-227Z2 2

62 Adjusting pulley 1

63 Flat washer 10 1

64 Hex nut MIO 1

65 Hex bolt M10x40 1

66 Hex nut MIO 2

68 Hex bolt M10x40 1

69 Hex nut MIO 1

70 Flat washer 10 2

71 Cap screw M10x80 1

72 “C” ring 26 2

73 Bearing 6000-2Z/Z2 2

74 Adjusting pulley 1

75 Inner location

sleeve

76 Hex locking nut

M10

77 Combined belt

1.5x25x750

78 Flower bolt M8X( at

least)130

79 Adjusting spring 1

80 Hex bolt M10x40 1

81 Hex nut MIO 2

82 Hex bolt M8x50 1

1

1

1

1

83 Flat washer 8 1

84 Hex nut M8 1

85 Hex bolt M8x30 1

86 Flat washer 8 2

87 Hex nut M8 1

88 Motor plate 1

89 Motor 1

90 Pulley 1 1

91 Cap screw M6x16 1

92 Special washer 6 1

93 Hex bolt M8x20 4

94 Flat washer 8 4

95 Spring washer 8 4

96 Hex nut M8 4

97 Adjusting stand 1

98 Hex bolt M8x50 1

99 Hex nut M8 1

100 Hex bolt M8x25 1

101 Hex nut M8 1

102 Cap screw M6x20 2

103 Flat washer 6 2

104 Hex locking nut M6 2

105 Z-Vbelt (L=840) 1

106 Angle steel

assembly

107 Cap screw M6x12 4

108 Flat washer 6 4

109 Hex bolt M6x16 2

110 Hex locking nut M6 2

111 Flat washer 6 2

1

1

1

1

47

Exploded Diagrams/Lists

Panel Saw Assembly 3

NO DESCRIPTION QTY

01 Screw M5x12 1

02 Hand wheel washer 1

03 Hand wheel ɸ12x ɸ125 1

04 Small clamp plate 1

05 Cap screw M6x12 2

06 Flat washer 6 2

07 Worm gear axle 1

08 Worm gear body 1

09 Spring pin 4X16 2

10 Key A4X12 1

11 Spacer 1

12 Bearing 51101 2

13 Support block 1

14 Hex thin nut M12 2

15 Locking handle 1

16 Cap screw M8x16 2

17 Flat washer 8 2

18 Location stand 1

19 Stand block 1

20 Location pole 1

21 Little cover 1

22 Cap screw M6x35 2

23 Flat washer 6 2

24 Body assembly 1

25 Rack plate 1

48

Spindle Moulder Assembly

Exploded Diagrams/Lists

49

Continues Over....

Exploded Diagrams/Lists

Spindle Moulder Assembly

NO DESCRIPTION QTY

01 Spindle seat 1

02 Hex locking nut M12 1

03 Spindle 1

04 Bolt M5X16 3

05 Spring cover 1

06 Bearing 6206-2Z/Z2 1

07 “C” ring 30 1

08 Spindle sleeve 1

09 Bearing 6205-2Z/Z2 1

10 Motor plate 1

11 Hex screw M8x25 3

12 Flat washer 8 3

13 Spring washer 8 3

14 Pulley 1 1

15 Key C6X28 1

16 Washer (pulley 1) 1

17 Cap screw M8x20 1

18 Nut 4

19 Lifting nut 1

20 Long sleeve 2

21 Hex nut MIO 2

22 Flat washer 10 4

23 Motor 1

24 Pulley 2 1

25 Key C6X28 1

26 Washer (pulley 2) 1

27 Cap screw M6x20 1

28 Hex screw M10x100 2

29 Round nut M25x1.5 1

30 Lifting thread pole 1

31 Gear 2

32 Spacer 1

33 Bearing 51101 4

34 Sleeve B 1

35 Small round nut M12X1.25 4

36 Clamp block 1

37 Sleeve A 1

38 Cap screw M8x70 2

39 Washer 1

40 Spring pin 4X16 2

41 Pin 1

42 Inner plate 1

43 Outer plate 1

44 Cap screw M6x20 2

45 Key A4X12 1

46 “C” ring 9 1

47 Hand wheel ɸ 12x ɸ160 1

48 Hand wheel washer 1

49 Screw M5x12 1

50 Locking handle 1

51 V-belt (L=670) 1

50

Extension Table Assembly

Exploded Diagrams/Lists

NO DESCRIPTION QTY

01 Support plate 2

02 Knob bolt 2

03 Flat washer 6 2

04 Sliding block 2

05 Hex screw M6x16 8

06 Flat washer 6 8

07 Sliding staff 1

08 Cover 2

09 Cap screw ST4X10 4

10 Cap screw M6x25 2

11 Flat screw 6 2

12 Rubber ring 2

13 Inner sleeve 2

14 Arm 1

15 Adjusting centre Bolt 1

16 Bearing 6001 1

17 Flat washer 6 2

18 Hex nut M6 1

19 Cap screw M6x20 4

20 Flat washer 6 8

21 Extension table (total) 1

22 Combined scale (total) 1

23 Fence 1

24 Knob bolt 1

25 Washer 6 1