AC216TS

216mm Table Saw

Code 104926

Original Instructions

Code: 104931 Floor Stand

for AC216TS Table Saw

Code: 104932 Cabinet Stand

for AC216TS Table Saw

Code: 104930 Sliding Table Kit for AC216TS Table Saw

AT&M: 21/03/2019

BOOK REF : 105785

Index of Contents

EU Declaration of Conformity 02

What’s Included 03

Optional Accessories 04-05-06

General Instructions for 230V Machines 06

Specific Instructions for Table Saws 07

Specification 08

Assembly 08-09-10-11-12-13-14-15-16-17

Illustration and Parts Description 18-19-20-21

Set Up and Adjustment 22-23

Operating Instructions 24

Changing the Saw Blade 25

Maintenance 26

Exploded Diagrams/Lists 27-28-29-30-31

Cert No: MJ2320,MJ2325R,

MJ2325G-2, MJ2331-2, MJ2330

Axminster Tools & Machinery Ltd

Axminster Devon

EX13 5PH UK

axminster.co.uk

declares that the machinery described:-

Type Table Saw

Model AC216TS

Signed

Andrew Parkhouse

Operations Director

Da te: 06/12/2018

The symbols below advise the correct safety procedures when using this machine.

EU Declaration of Conformity

This machine complies with the following directives:

2006/42/EC

EN 1870-19:2013

EN 60204-1:2006+A1+AC

and conforms to the machinery example for which the

EC Type-Examination Certificate No BM 50424431

has been issued by Laizhou Fulin Machinery Co., Ltd.

at: Wenchang Road Street Nanwuli Industry Yard Laizhou, Shandong261400 China

and complies with the relevant essential health and safety requirements.

Fully read manual

and safety instructions

before use

Ear protection

should be worn

Eye protection

should be worn

2

Dust mask

should be worn

Two Man

Assembly

HAZARD

What’s Included

Quantity Item Part Model Number

AC216TS

1 Basic Table Saw A

1 Side Extension Table B

1 Rear Extension Table C

2 Operating Handle Wheel Knobs D

1 Rip Fence Assembly E

1 Rip Fence Extension F

1 Rip Fence Rail with Scale G

1 Riving Knife H

1 Hose Support Bracket I

1 Dust Extraction Moulding J

1 Crown Guard with Clamping Handle K

Code 104926

1 Flexible Hose L

2 Hose Clips M

1 Push Stick N

1 Blade Locking Bar O

1 24mm Spanner P

1 13-15mm Spanner Q

4 Hex Keys 6,5,3,2mm R

1 Handle Hex Key S

4 M8 Threaded Feet with nut/washer T

10 M8 Bolts Nuts & Washers U

I

L

J

D

C

H

M

K

F

B

G

E

A

P

N

Q

O

R S

3

T

U

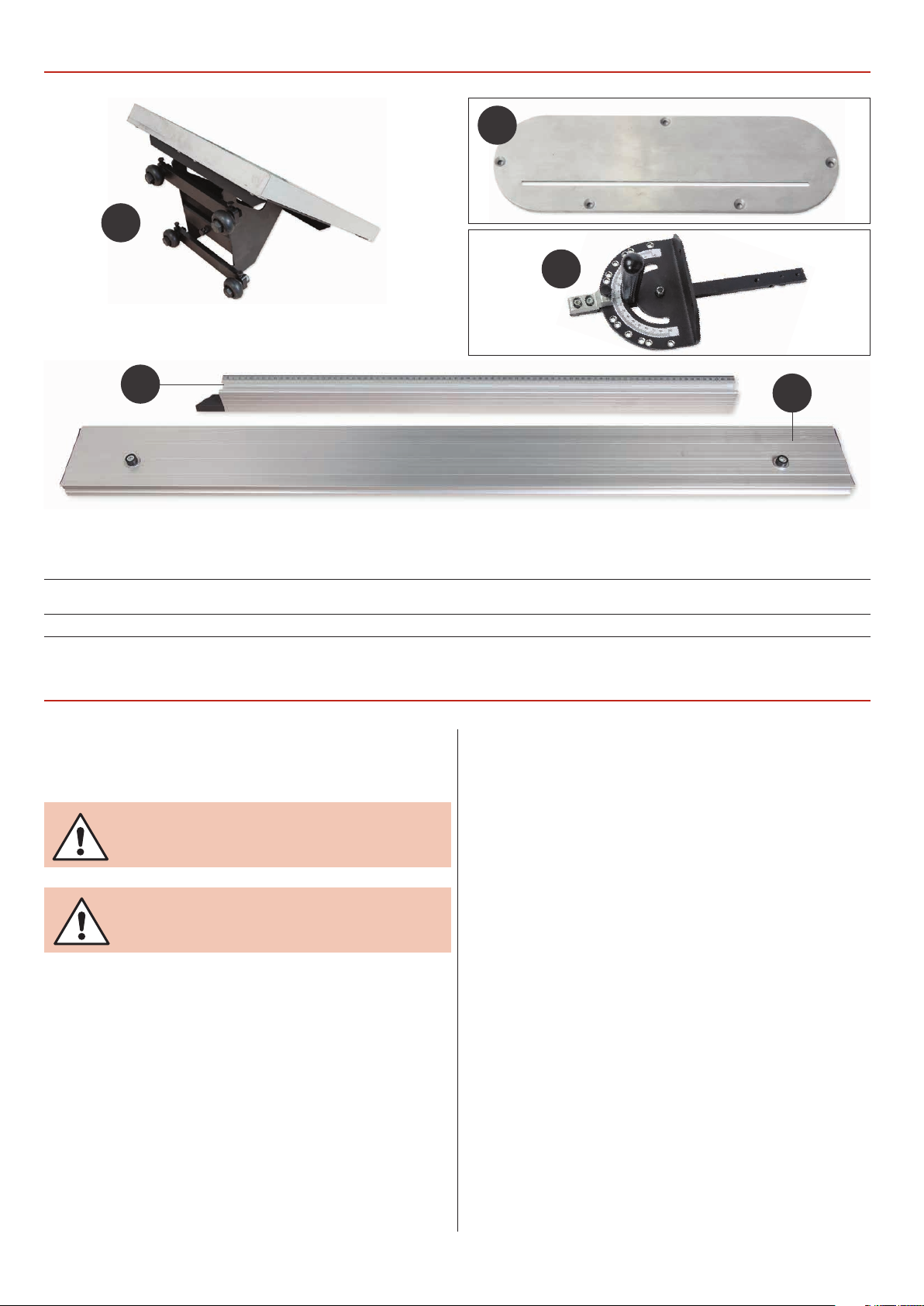

Optional Accessories

Code 104931 Floor Stand Assembly

Quantity Item Part

4 Leg Brackets 1

2 Long Upper Support Struts 2

2 Short Upper Support Struts 3

2 Long Lower Support Struts 4

2 Short Lower Support Struts 5

2 Threaded Rubber Feet 6

1 Floor Stand Bag of Fixings 7

6 7

1

2

3

4

5

Code 104932 Cabinet Stand Assembly

Quantity Item Part

1 Right Side Panel with Door Cut out 8

1 Left Side Panel 9

1 Rear Panel 10

1 Right Panel Door with Locking Knob 11

1 Cabinet Shelf 12

2 Upper and Lower Support Struts 13

1 Moulded Red Front Panel 14

1 Cabinet Stand Moulded Top 15

4 M8 Threaded Feet with Nut/Washer 16

11 M8 Cap head Bolts with Nut and Washers 17

4 Short Cap head Screws and Washer 18

5 M8 Cap head Bolts and Washers 19

9

8 11

10

4

Optional Accessories

12

13

15

14

17

16

18 19

Code 104930 Sliding Table Kit Assembly

Quantity Item Part

2 Sliding Carriage Support Bracket 20

4 Cap head Bolts and Washers for Support Brackets 21

2 Height Adjusting Blocks 22

1 Hex Key 23

1 Fence Mitre Casting with Lift & Shift Clamping Handle 24

1 Tool Post with Washer/Nut for Hold Down Clamp 25

1 Hold Down Clamp 26

1 Fence Distance Stop with Micro Adjuster & Clamping Handle 27

1 Sliding Table Assembly 28

1 Fence 29

1 Sliding Carriage Assembly 30

24

21

22

23

25

20

5

26

27

Continues over...

Optional Accessories

28

31

32

29

Code 104933 Craft Table Insert / Code 104928 Mitre Fence

30

Quantity Item Part

1 Table Insert for the AC216TS Table Saw 31

1 19mm Mitre Fence 32

General Instructions for 230V Machines

The following will enable you to observe good working

practices, keep yourself and fellow workers safe and maintain

your tools and equipment in good working order.

WARNING!! KEEP TOOLS AND EQUIPMENT

OUT OF REACH OF YOUNG CHILDREN

KEEP WORK AREA AS UNCLUTTERED AS IS PRACTICAL.

UNDER NO CIRCUMSTANCES SHOULD CHILDREN BE

ALLOWED IN WORK AREAS.

Mains Powered Tools

• Tools are supplied with an attached 13 Amp plug.

• Inspect the cable and plug to ensure that neither are

damaged. Repair if necessary by a suitably qualified person.

• Do not use when or where it is liable to get wet.

Workplace

• Do not use 230V a.c. powered tools anywhere

within a site area that is flooded.

• Keep machine clean.

• Leave machine unplugged until work is about to commence.

• Always disconnect by pulling on the plug body and not the

cable.

• Carry out a final check e.g. check the cutting tool

is securely tightened in the machine and the correct

speed and function set.

• Ensure you are comfortable before you start work,

balanced, not reaching etc.

• Wear appropriate safety clothing, goggles, gloves,

masks etc. Wear ear defenders at all times.

• If you have long hair wear a hair net or helmet to prevent it

being caught up in the rotating parts of the machine.

• Consideration should be given to the removal of rings and

wristwatches.

• Consideration should also be given to non-slip footwear etc.

• If another person is to use the machine, ensure they are

suitably qualified to use it.

• Do not use the machine if you are tired or distracted

• Do not use this machine within the designated safety areas

of flammable liquid stores or in areas where there may be

volatile gases.

• Check cutters are correct type and size, are undamaged

and are kept clean and sharp, this will maintain their

operating performance and lessen the loading on the

machine.

• OBSERVE…. make sure you know what is happening

around you and USE YOUR COMMON SENSE.

6

Specific Instructions for Table Saws

Make sure the saw blade is the correct type for the job in hand.

Do not force the saw, if the saw begins to ‘stall’ you are ‘forcing

the cut’ or over working the saw.

Ensure that the saw blade is clean and sharp.

Resin build up on the blades will increase the friction of the

saw passing through the timber, and cause over heating of

the blade, blunt teeth will work harder tearing the fibre of

the timber as opposed to shearing it, also with subsequent

overheating. Both faults unnecessarily load the machine

beyond normal usage, and shorten its longevity.

Do not use blades that are deformed in any way.

Do not remove the blade guard. The design of the riving knife

on the machine will not allow for slotting or ‘blind’ grooving,

so there is no reason to remove the guard.

FOR YOUR OWN SAFETY NEVER OPERATE

THE TABLE SAW WITHOUT THE RIVING KNIFE

IN PLACE!

Do not remove the riving knife.

Do not use any blades that cut a smaller kerf than the riving

knife thickness. Make sure the riving knife is correctly adjusted

to the blade and is securely fastened. If the table insert

becomes damaged or broken, and will not support the timber

‘up close’ to the blade, replace it.

After switching off, never try to slow the saw down more

quickly by applying side pressure (with a piece of wood?) to

the blade. Apply the old joiner’s adage of never getting hands

within one handbreadth of the blade. Leave the machine

disconnected from the mains supply until you are about to

commence work.

Always disconnect the machine if you are leaving it unattended.

Never leave the vicinity of the machine unless the blade has

come to a complete stop.

Do not attempt to carry out any maintenance, corrective work,

setting up etc., unless the machine is disconnected from the

mains supply. If any tools have been used during setting up

procedures, make sure they are removed from the machine

and stowed safely away.

USE THE SUPPLIED PUSH STICK

WHEN CUTTING SMALL PIECES.

Do not attempt to carry out cross cutting operations ‘freehand’,

always use the mitre fence for small stuff and the sliding

carriage for larger work pieces. Do not attempt to ‘rip’ freehand,

always use the guiding facility of the rip fence.

It is perfectly acceptable to support guide and feed the timber

with your hands whilst ripping stuff of some length, however,

as you approach the blade ensure that the push stick is to hand,

and you use it.

UNDER NO CIRCUMSTANCES SHOULD

CHILDREN BE ALLOWED IN THE WORK AREA

AND KEEP TOOLS AND EQUIPMENT OUT OF

REACH OF YOUNG CHILDREN!

CONNECT A DUST EXTRACTION

MACHINE TO THE SAW.

Do not start the saw with the work piece touching the blade.

Do not commence sawing until the blade has run up to full

speed.

Remember the emphasis of the ‘push’ should be between the

blade and the fence and close to the fence. Use your free hand

to support and guide the material on the offside of the saw

blade and at least 100mm away from it. If the timber does not

extend to at least 100mm to the offside of the saw blade,

the material possibly does not need guiding or supporting.

WARNING! IF THE SAW JAMS!

SWITCH OFF IMMEDIATELY.

Check that there are no foreign objects e.g. old nails, screws,

small stones etc embedded in the material you are about to cut.

If necessary take a wire brush to the timber before working.

7

Specification

Code 104926

Model AC216TS

Rating Craft

Power 1.1 kW

Blade Dia/Bore 216mm/30mm

Blade Tilt 0° to 45°

Max Depth of Cut @ 45˚ 45mm

Max Depth of Cut @ 90˚ 65mm

Max Width of Cut with Fence 370mm

Table Size Cast Iron Table 570mm x 400mm

Table Height 320mm (bench mounted)

Table Size With Extensions 570mm x 675mm

Dust Extraction Outlet 100mm

Min Extraction Airflow Required 850m³/hr

Overall L x W x H 670mm x 695mm x 420mm

Weight 70 kg

Assembly

104926 Basic Saw

WARNING! THE SAW IS HEAVY SEEK

ASSISTANCE BEFORE LIFTING.

1. With assistance lift the saw assembly (A) from the box onto

a suitable work surface. Locate the two operating wheel knobs

(D) and attach one to each operating wheel, see fig 01-02.

Fig 01-02

Fig 03-04

T

2. Find the four threaded feet (T), with assistance very carefully

tilt the saw over to gain access to the underside and screw each

foot in turn into the machined holes in each corner of the

chassis, see fig 03-04.

3. Lower the saw down, locate the side and rear extension

tables (B-C) and M8 bolts (U). Remove the nuts from the bolts

and place safely aside. Insert the bolts with washers through

the holes in the extension table (B), line up the holes in both

tables and secure the extension table (B) to the side of the cast

iron table, see fig 05-06-07.

D

Fig 05

B

U

8

Fig 06-07-08

U

Assembly

Fig 12-13

B

4. Repeat for the rear extension table (C), making sure you line

up the machined slots in the table with the 19mm mitre ‘T’ slots

in the cast iron table. Secure both extension tables together,

see fig 09-10-11.

Fig 09-10-11

C

Hose mounting plate

6. Undo and remove the Phillips screws/washers/nuts hold

the hose mounting plate from inside the housing. Place the

moulding (J) over the dust outlet, line up the holes and replace

the screws to secure it in position, see fig 14-15-16. Replace the

access panel.

Fig 14-15-16

5. Locate the dust extraction moulding (J). Undo the four

cap head bolt/washers holding the side access panel, place to

one side. Remove the panel to gain access to the saw assembly,

see fig 12-13.

9

J

Continues over...

Assembly

Fig 17

Insert plate

7. Raise the saw by first releasing the rise & fall operating

wheel clamping knob, remove the five cross head screws

holding the table insert and place safely aside, see 17. Raise

the saw to it’s maximum height by turning the operating

wheel clockwise.

8. Find the riving knife (H) Loosen the two nuts holding the

riving knife clamping plates, slide the riving knife down

between the two plates and lightly tighten to hold the riving

knife in place. Check that the tip of the knife has a clearance

of 3-8mm between the blade then tighten the nuts to secure

the riving knife in place. Replace the insert plate, see fig

18-19-20-21.

Clamping knob

H

3-8mm Gap between the

riving knife and the blade

9. Locate the crown guard (K), flexible hose (L) and hose

clips (M). Loosen the lift & shift handle on the crown guard.

Introduce the slot to the rear of the crown guard (K) over the

riving knife and slot pin bolt into the curved slot in the riving

knife. Tighten the handle, see fig 22.

Fig 22

K

Fig 18-19-20-21

Clamping plates

H

Curved slot

NOTE: DO NOT OVER TIGHT AS THE CROWN

GUARD IS PLASTIC AND COULD BE DAMAGED!

10. Locate the flexible hose (L), place a hose clip (M) over one

end. Insert the hose over the extraction outlet on the crown

guard (K) and tighten the clip. Place the remaining clip over

the opposite end of the hose, insert the hose over the

extraction out moulding (J) and tighten, see fig 23-24.

Fig 23-34

L

M

10

J

Assembly

Fig 35

G

B

U

11. Put to hand four M8 Bolts with washer/nuts (U) and rip

fence rail with scale (G). Insert two bolts with washers up

through the holes to the underside end of the side extension

table (B) and lightly screw on two bolts. Place the remaining

two bolts with washer into the threaded holes to the underside

of cast iron table, see fig 35. Note: make sure give enough

clearance between the tables and bolts for the next step.

12. Line up the machined slots in the rip fence rail (G) with the

bolts and slide the rail up against the tables. Nip up the bolts to

secure the rail, see fig 36-37.

Fig 38-39-40

E

‘T’ Slot

F

Butterfly knob

‘T’ bolt

Fig 36-37

G

13. Locate the rip fence (E) and lower the clamp assembly

down over the fence rail (G) and press down the locking lever

to secure in position, see fig 38.

15. Locate the hose support bracket (I) and secure it to the side

extension table (B) using a M8 bolt washer/nut (U). Insert the

holes (L) into the hose bracket, see fig 41.

Fig 41

I

U

14. Find the rip fence extension (F), slot the two ‘T’ bolts

mounted in the rip fence (E) into the ‘T’ slot on the fence

extension and nip up the butterfly knob clamps, see fig 39.

Note: the extension (F) can be set in two positions,

see fig 40.

16. Place a straight edge across the tables and check they are

level and make adjustment until correct.

11

Continues over...

Assembly

104926 Basic Table Saw

AC216TS Table Saw assembled for work bench setup

104931 Optional Floor Stand

Locate all the components on page 04 and assemble as follows.

Step 1

3

Step 4

Step 5

6

Step 2

Step 3

1

Step 6

7

Step 7

5

3

2

4

Remove the table saw’s feet, see figs 03-04, remove the two

access panels on either side of the saw. With assistance, place

the saw onto the stand and line up the holes in the chassis

with the ones in the stand, and secure using four M8 x16 bolts,

washer/nuts. Go round and fully tighten all the bolts. Replace

the access panels.

12

Assembly

104932 Optional Cabinet Stand

Locate all the components for the cabinet stand as shown on

page 04-05 and follow the instructions below.

Step 1

17

9

10

Step 2

14

11

Step 5

18

Step 6

Hinges

Step 3

Step 4

8

Step 7

15

12

Line up the holes

13

Step 8

16

19

13

Assembly

104930 Optional Sliding Table Kit

1. Locate the carriage support brackets (20) and cap head

bolts/washers (21). Offer up the elongated slots in the right/left

hand brackets with the threaded holes to the side of the saw

assembly (A) and secure in place using the cap head bolts/

washers (21), see fig 42-43-44.

Fig 42-43-44

A

Threaded holes

Fig 45-46-47

Cap head bolt

22

21

20

a

2. Find the two height adjusting blocks (22), unscrew the

height adjuster thread to gain access to the cap head bolt, see

fig 45. Fix the blocks against the saw using the threaded holes

beneath each bracket, see fig 46. Screw the height adjuster

thread, so it touches the base of the bracket (20), see fig 47.

3. Locate the sliding carriage (30), loosen the two cap head

bolts/nuts (a) on the brackets (20). Introduce the first two nuts

into the ‘T’ slot rails on either side of the carriage (30) and slide

on, repeat for the opposite end. Adjust the carriage to your

preference and nip up the four bolts, see fig 48-49.

Fig 48-49

14

Assembly

Fig 50-51-52

Fig 54-55-56-57

22

Table stop pin knob

4. Locate the sliding table (28), turn the table over and pull

out and twist the table stop pin knob so it’s in the unlocked

position, see fig 50-51.

5. Position the sliding table (28) so the wheel assembly engages

either side of the sliding carriage (30) and roll on the table, see

fig 52. Reengage the stop pin and slide it up against the stop on

the carriage, see fig 53.

Fig 53

Carriage stop

6. Place a level across both tables, using a hex key adjust both

height adjusting blocks (22) and the two pivot bolts on each

support bracket (20), until both sliding table (28) and cast iron

table are level, see fig 54-55-56-57.

7. The sliding table (28) can also be raised or lowered

independently in small increments by adjusting the wheel

assembly. Adjust each wheel in turn, loosen the wheel locking

nut (a), undoing the stop bolt (b) and using a Hex key adjust the

grub screw (c). Repeat until you are satisfied, see fig 58-59 on

next page. Nip-up the wheel nuts (a).

Cap head bolts

Pivot bolts

Note: you will need to loosen the cap head

bolts on both carriage support brackets

(20), just enough to adjust the pivot bolts.

15

Continues over...

Assembly

Fig 58-59

a

c

b

Fig 62

25

9. Remove the washer/nut from the tool post (25), insert the

post down through the machined holes in both mitre casting

(24) and sliding table (28) and secure using the washer/nut,

see fig 62.

10. Loosen the hold down clamping knob (26) and slide the

assembly down the tool post (25) and clamp in position, see

fig 63.

Fig 63

8. Locate the mitre casting with lift and shift hand (24). Insert

the locking handle with washer through the elongated slot in

the mitre casting into the threaded hole in the scale casting,

mounted to the side of the sliding table (28), see fig 60-61.

Fig 60-61

28

26

11. Loosen the butterfly knobs on the mitre casting (24), insert

the ‘T’ bolts into the fence’s ‘T’ slot rail (29), lift-up the 90˚ stop

located in the corners of the sliding table (28) and push the

fence up against the stop, see fig 64-65.

Fig 64-65-66-67

Butterfly knobs

29

24

‘T’ Bolt

16

90˚ Stop

Assembly

27

14. Using a 90˚ square check that the blade is at 90˚ to the

fence assembly (29) and make adjustments accordantly,

see fig 70.

Fig 70

Butterfly knob

12. Slide the fence (29) near the blade but not touching, tighten

the butterfly knobs, see fig 66-67. Note: check that the fence

does not foul the riving knife.

13. Locate the fence distance stop (27). Loosen the clamping

handle, slide the assembly into the ‘T’ slot to the opposite end

of the fence (29) and secure in place, see fig 68-69.

Fig 68-69

104930 Sliding Table

Sliding table kit assembled

17

Illustration and Parts Description

Code 104926 Basic Table Saw

Crown guard

Riving knife

Rear extension table

Saw blade

Flexible hose

Rip fence rail

Rip fence

clamping handle

Saw assembly

access panel

19mm ‘T ’ slots

Cast iron table

45˚ Scale

NVR Control panel

Rip fence extension

Rip fence

Hose support bracket

Side extension table

Rise & fall operating handle

18

45˚ Operating wheel

Saw assembly

access panel

Illustration and Parts Description

A

C

B

ON/OFF NVR switch (A), Emergency stop button (B)

Rise and Fall operating wheel (C)

32

Optional 104928 Mitre Fence

Tilt scale pointer and adjusting screw 100mm Dust extraction moulding Rip fence magnifying glass

and index marker

31

Motor and saw assembly Optional 104933 insert gives

better material support for

cutting thin strips

19

Illustration and Parts Description

Code 104931 Floor Stand

Code 104932 Cabinet Stand Code 104930 Sliding Table

20

Illustration and Parts Description

a

Cabinet stand storage door Distance stop (27) with micro adjusting wheel (a)

Fence mitre scale, pointer

and clamping handle

Table stop pin knob, engage to

prevent the table from sliding

off the carriage assembly

Fence mitre adjusting screw stops for -45˚ to +45˚

28

Hold down clamp assembly Sliding carriage stop,

prevents the sliding table

from coming off the carriage

21

Set Up and Adjustment

The Riving Knife

1. Raise the saw blade to its highest point and remove the saw

blade crown guard (K) and the table insert, place safely aside,

see fig 71-72.

Fig 71-72

K

Adjusting the Rip Fence to the Blade

The fence assembly must be parallel to

the saw blade for producing accurate cuts.

1. Remove the crown guard (K) and rip fence extension (F) and

‘T’ bolts. Slide the rip fence assembly up against the saw blade

and check it reads “ZERO” on the fence rail scale, see fig 75-76.

Fig 75-76

2. Using the spanner loosen the riving knife and check that the

tip of the knife has a clearance of 3-8mm between the blade

then tighten the nuts to secure the riving knife in place. NOTE:

Check that the riving knife is parallel to the saw blade by

placing the fence up against them, see fig 73-74.

Fig 73-74

Riving knife

3-8mm

Fence

Zero marker

NOTE: If adjustment is required loosen the Hex screws on

the fence clamping assembly and lightly tap the end of the

fence rail until the marker reads ‘zero’ on the scale, see 77.

Re-secure once correct. Check the tables are still level by

placing a straight edge across the front edge and adjust

until correct.

NOTE: Use the 19mm ‘T’ slot to the right side of the saw

blade as a reference to check the fence (E) is parallel, see fig

78. Regularly check the fence is parallel to ensure a perfect

cut.

Fig 77-78

22

Adjusting the Pivot

Set Up and Adjustment

E

‘T’ Slot

2. The rip fence extension can be repositioned from the vertical

to a horizontal position for guiding thin pieces through. Loosen

the two butterfly knobs holding the fence extension, remove,

lay the fence extension down in the horizontal position and

remount the fence extension as before, see fig 79-80. Move

the extension down until the end face is centred with the

blade and tighten the two butterfly knobs.

Fig 79-80

Release the locking knob to the centre of the operating wheel

(a) to the side of the saw assembly and turn clockwise to pivot

the saw to a maximum of 45˚ degrees, indicated on the scale,

see fig 82-83-84.

Fig 82-83-84

a

Saw pivot scale

Adjusting the Cutting Height

Release the clamping knob, adjust the blade height with the

rise and fall operating wheel, see fig 81, so that the blade teeth

are protruding through the work piece.

Fig 81

Clamping knob

45˚

23

Operating Instructions

NOTE: BEFORE USING YOUR SAW, GO

ROUND AND MAKE SURE EVERYTHING

IS SECURE, FASTENED DOWN, THAT ALL

TOOLS ARE CLEARED AWAY FROM THE

WORK AREA!

CHECK: THE BLADE FOR SHARPNESS,

MISSING TEETH, RESIN BUILD UP ETC.,

CLEAN IF NECESSARY. CHECK THE BLADE

IS SECURELY CLAMPED IN PLACE (I.E. NOT

LOOSE)!

CONNECT A DUST EXTRACTION

MACHINE TO THE SAW.

UNDER NO CIRCUMSTANCES SHOULD

CHILDREN BE ALLOWED IN THE WORK AREA

AND KEEP TOOLS AND EQUIPMENT OUT OF

REACH OF YOUNG CHILDREN!

N

NOTE: Secure larger pieces of timber to

the table by using the hold down clamp.

Cutting Narrow Pieces

Use the small flat surface of the rip fence extension (F) to cut

thin timber narrower that 120mm, note: use a push stick.

The Optional Mitre Fence

The mitre fence (32) can be mounted on either side of the saw

blade in the two 19mm ‘T’ slots, pre machined into the cast iron

table. The mitre fence can be angled from 90˚ to 45˚ degrees,

see fig 88-89-90.

Fig 88-89-90

CONNECT THE SAW TO

THE MAINS SUPPLY!

Give the machine a ‘quick’ burst check ( i.e. quick ON-OFF) to

ensure everything is O.K. If everything is satisfactory, the table

saw is ready for use.

Feeding the Work by Hand

Start up the saw, wait until it has reached full speed and slowly

feed the timber through using both handles, (making sure to

keep your hands well clear of the blade and using a push stick

for small pieces), until the timber is behind the riving knife.

Switch off the saw, wait until the blade has come to a complete

stop and remove the timber, see fig 85-86-87.

Fig 85-86-87

HOLD THE

WORK FIRMLY

32

THE BLADE IS SET

AT AN ANGLE

LESS THAN 90˚

DEGREES FOR

BEVEL CUTS

BLADE GUARD

24

LOCK THE MITRE

FENCE AND HOLD

THE WORK FIRMLY

DISCONNECT THE MACHINE

FROM THE MAINS SUPPLY!

Changing the Saw Blade

Fig 95-96-97-98

1. Raise the saw blade to its highest point, remove the saw

blade crown guard, remove the five cross head screws that

secure the table insert, place carefully aside and remove the

table insert, see fig 91-92.

Fig 91-92

2. Turn the saw until the locking bar hole (a) is visible and insert

the blade locking bar (O) into the hole, see fig 93-94.

Fig 93-94

P

O

b

a

O

3. Hold the locking bar (O) undo and remove the nut using the

24mm spanner (P), see fig 95-96. Remove the saw plate washer

(b) and the saw blade and place to one side, see fig 97-98.

4. Give the interior of the machine, the dust extraction

channels, etc. a thorough clean. Check the new blade for

damage, missing teeth, sharpness etc. Fit the new blade, ensure

that the teeth are pointing towards the front of the machine.

Put the saw plate washer onto the shaft and replace the ‘Nut’

until finger tight and check the saw is correctly seated.

25

Teeth pointing front

5. Tighten up the ‘Nut’, using the blade locking bar (O) to hold

the shaft steady. Check the riving knife is aligned with the saw

blade, and correctly positioned. Replace the table insert and

secure with the cross head screws. Replace the crown guard.

When everything is satisfactory, turn the saw blade once by

hand to check it doesn’t foul anywhere.

6. Reconnect the machine to the mains supply. Give the

machine a ‘quick’ burst (i.e. quick ON-OFF) check to ensure

everything is O.K. If everything is satisfactory, continue to use

the machine.

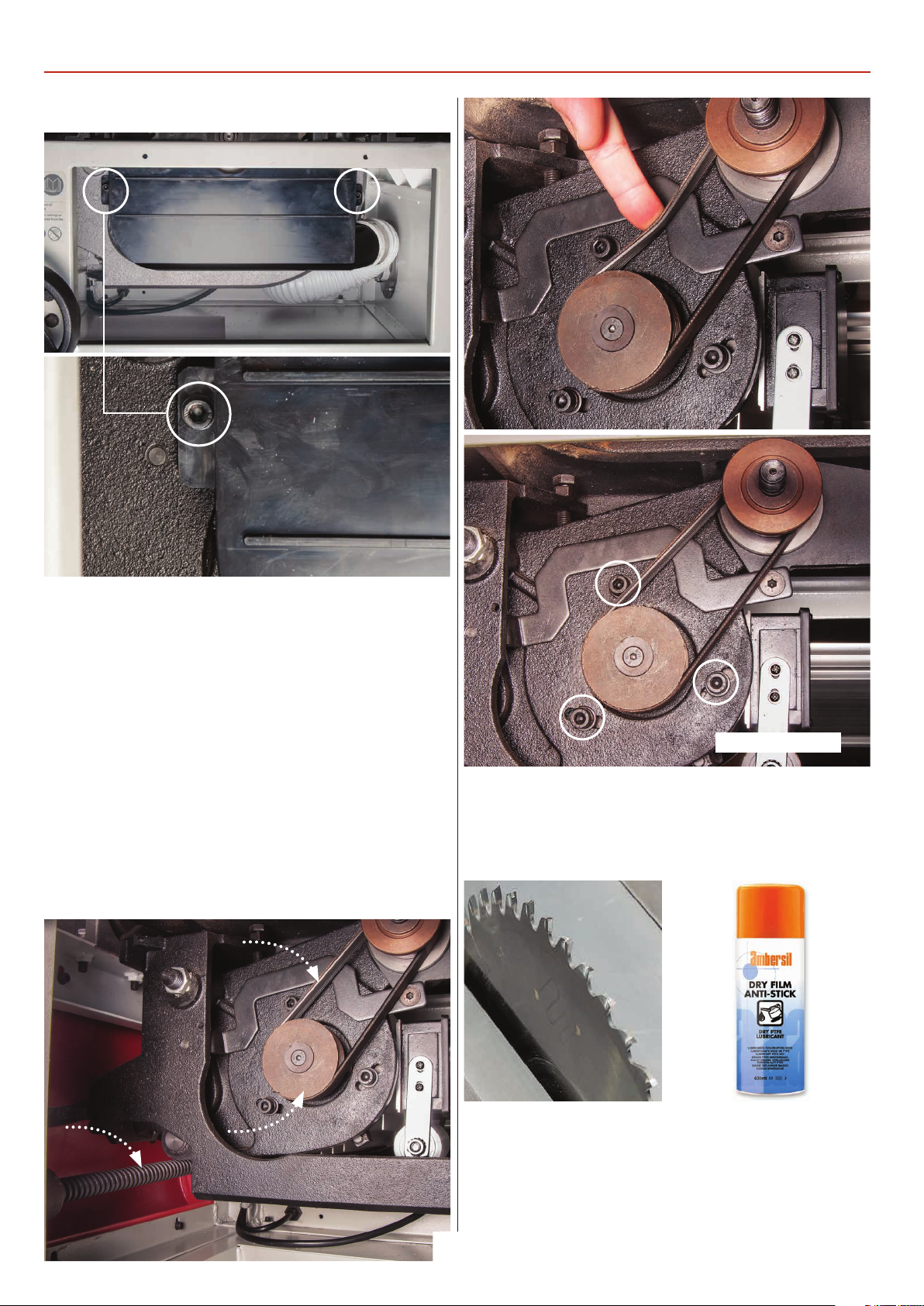

Maintenance

Fig 99-100

1. Keep the saw as clean and free from saw dust build up as is

practical. Periodically, remove the saw gullet by removing the

side access panel to the side of the machine and undo the two

Hex screws on either side of the gullet, see fig 99-100. Vacuum

out and clean out the saw box and the extraction housing.

Remove any resin build up in the saw box, using a proprietary

resin cleaner.

2. Clean the threaded drive shafts of the rise and fall and tilt

mechanisms, see fig 101. At the same time check the belt drive,

i.e. the belt is not ‘glazing’ with resin build up, likewise with

the pulley wheels. Check the belt tension, see fig 102. If the belt

is becoming slack, loosen the motor Hex bolts and push the

motor down, see fig 103. Re-tighten the Hex bolts.

Fig 101-102-103

Motor Hex bolts

3. Check the saw blade regularly for chipped, missing, damaged

teeth etc. and remove any resin build up from the blade, riving

knife etc, see fig 104.

Fig 104

4. If you have finished using the saw bench, clean above and

below the work table, wipe the saw bench over. If the saw is not

going to be used for a period of time, use ‘Ambersil Dry PTFE

Film Antistick’, spray, code 952137 over the work table, blade, tilt

and rise and fall screw threads and place a dust sheet over the

saw bench.

26

Basic Table Saw Diagram A

Exploded Diagrams/Lists

27

Continues over...

Exploded Diagrams/Lists

Basic Table Saw Diagram A

No. Description

1 Adjusting thread rod

2 Locking knob

3 Semi-circle key 3x16

4 Angel connection knob

5 Stop A

6 Nut of adjusting thread rod

7 Mounting seat

8 Stop collar

9 Circlips for shaft D=20

10 Worktable

11 Hex.socket set screw M8X10

12 Mounting base A

13 Hex.socket set screw with flat point M10X50

14 Hex.nut M10

15 Machine body

16 Front panel

17 Switch

18 Mounting base B

19 Hex.bolt M8X20

20 Flat washer 8mm

21 Spring washer 8mm

22 Hex.bolt M8X30

23 Left panel

24 Right panel

25 Cross recessed pan head screw M6X12

26 Handwheel

27 Cross recessed socket screw M5X12

28 Cablegland M14

29 Rotating Scale

30 Blade guard

31 Tie-in B

32 Tie-in A

33 Table insert

34 Hex.socket set screw M8X8

35 Flat washer 10mm

36 Flat washer 6mm

37 Cross recessed pan head screw M5X20

38 Hex.nut M5

39 Flat washer 5mm

40 Dust collection tube inside the machine

41 Neck chain

42 Dust collection tube

43 Cross recessed pan head screw M4X15

44 Spring washer 4mm

45 Flat washer 4mm

46 Hex.nut M4

47 Cross recessed pan head screw M4X6

48 Hex.socket set screw M4X5

49 Extension table

50 Front rail

51 Right end captor front rail

52 Left end captor front rail

53 Taping screw ST4.2X10

54 Hex.bolt M8X16

55 Tube support

56 Locking guard,guard

57 Adjusting handle

58 Rotating bracket

59 Housing,knob

60 Shaft base

61 Motor

62 Motor pulley

63 Hex. socket cap head bolt M8X30

64 Multi-grooves belt

65 Saw blade

66 Saw blade sleeve

67 End bush of arbor shaft

68 Cross recessed socket screw M6X20

69 Arbor shaft bush

70 Spring pin 6

71 Arbor shaft bush

72 Bearing 6203

73 Arbor shaft

74 Pulley,blade

75 Nut M16

76 Flat key 5x20

77 Riving knife bracket

78 Outer blade washer

79 Hex. socket cap head bolt M10X30

80 Rotating block

81 Cross recessed socket screw M6X15

82 Shaft

83 Thin nut M16X1.5

84 Dust collection cover

85 Hex.bolt M10X40

86 Pointer block

87 Pointer

88 Locking knob

89 Height adjusting thread rod

90 Stop collar B

91 Pull-rod shaft

92 Connection rod of riving knife bracket

93 Pressing plate of riving knife

94 Hex. socket cap head bolt M8X20

95 Riving knife

96 Hex. socket cap head bolt M5X12

97 Hex.bolt M8X40

98 L shape fence

99 Scale rail housing

100 Rip fence

101 Eccentric wheel

102 Locking shaft

103 Locking Knob

104 Locking spring plate

105 Locking nut board

106 Fence plate

107 Right end cap for rail housing

108 Left end cap for rail housing

109 Screw guide

110 Hex. socket cap head bolt M6X16

111 Scale indicator

112 Circle ring

113 Hex.socket bolt M6X12

114 Front end cap for fence

115 Rear end cap for fence

116 Supporting plate

117 Locking screw

118 Wing nut

119 Big washer 6mm

120 Key 6x20

121 Mitre gauge base

122 Self-locking nut M6

123 Hex.pan head bolt M6X20

124 Bush

125 Mitre gauge guide rod

126 Block indicator

127 Set screw M6X12

128 Stop pin

129 Stop spring

130 Brass knob

131 Scale,gauge

132 Mitre gauge knob

133 Washer

134 Cross recessed socket screw M5x10

135 Hex.socket set screw M6X6

136 Spring washer 5

137 Bottom panel

138 Leveling foot

139 Hex.nut M8

28

Sliding Table Kit Diagram B

Exploded Diagrams/Lists

29

Continues over...

Exploded Diagrams/Lists

Sliding Table Kit Diagram B

No. Description

1 Mounting bracket

2 Mitre guage

3 Scale mount

4 Wing nut

5 Bolt guide

7 Locating bracket

8 Locating plate

9 Scale

11 Stop shaft

12 Knob-lever

13 Spring,stop shaft

14 Shaft,roller wheel

15 Bush,roller wheel

16 Roller wheel

17 Hex.bolt M8X20

18 Teeth shape washer 8mm

19 Hex.nut M10

20 Washer 10mm

21 Hex.socket set screw M6X6

23 Hex.bolt M6X15

24 Hex.bolt M6X55

25 Cross recessed pan head screw M5X30

26 Hex.nut M6

27 Self-locking nut M6

29 Hex.nut M5

30 Sliding table

34 Cross cut fence

35 End cap,cross cut fence

36 Taping screw ST4.2X10

37 Step bolt

38 Stud,hold down

39 Arm,hold down

40 Handle,hold down

41 Eccentric,hold down

42 Pin,hold down

43 Circlips for shaft 8mm

44 Washer 12mm

45 Circlips for shaft 12mm

46 Stud,hold down

47 Disc,hold down

48 Spring,hold down

49 Hex.nut M12

50 Hex. socket cap head bolt M5X12

51 Washer 5mm

52 Star-type knob,hold down

53 Ratchet lever

54 Flip stop

55 Hex.socket set screw M5X5

56 Stud,hold down

57 Flip stop base

58 Knurled knob

59 Screw guide

60 Spring,flip stop

61 Ratchet lever,flip stop

62 Step bolt M6X35

63 Spacer,ratchet lever

66 Sliding rail

67 End cap,sliding rail

68 Rubber bush

69 Hex. socket cap head bolt M8X16

70 Washer 8mm

71 Hex.nut M8

72 Carriage

73 Carriage,sliding rail

74 Hex. socket cap head bolt M10X20

75 Flat end set screw M10X50

76 Hex. socket cap head bolt M8X30

77 Washer 8mm

78 Spring washer 8mm

79 Hex.socket set screw M8X15

80 Hex.socket set screw M6X35

81 Washer 6mm

30

Cabinet Stand Diagram C

Exploded Diagrams/Lists

No. Description

1 Right panel,cabinet stand

2 Left panel, cabinet stand

3 Rear panel,cabinet stand

4 Sidelong support,front panel

5 Hex. socket cap head bolt M8X16

6 Leveling foot

7 Front panel,cabinet stand

Floor Stand Diagram D

8 Washer 8mm

9 Hex.nut M8

10 Spring washer 8

11 Cross recessed pan head screw M6X12

12 Access door,cabinet stand

13 Door knob

14 Internal shelf

15 Hex.bolt M8X16

No. Description

1 Stand leg

2 Upper long bracket,stand leg

3 Upper short bracket,stand leg

4 Lower long bracket,stand leg

5 Lower short bracket,stand leg

6 Leveling foot

8 Hex.bolt M8X20

9 Hex.nut M8

10 Washer 8mm

11 Spring washer 8mm

31

Continues over...

The Axminster guarantee is available on

Craft, Trade, Engineer, Air Tools & CNC Technology Series machines

Buy with confidence from Axminster!

So sure are we of the quality, we cover all parts and labour free of charge for three years!

For more information visit axminster.co.uk/3years

The packaging is suitable for recycling.

Please dispose of it in a responsible manner.

EU Countries Only

Do not dispose of electric tools together with household waste material.

By law they must be collected and recycled separately.

Axminster Tools & Machinery

Axminster Devon EX13 5PH

axminster.co.uk

Loading...

Loading...