Page 1

AXIS Dyno

USER MANUAL

MODEL

Moto VX-12

Page 2

2

Page 3

Table of Contents

Page

Introduction

- Dimensions & Weight

5 - Warning, Cautions and Notes

Axis Instalation

- Outdoor

- Dyno room

AXIS Dyno Operation

- Software Instalation

- Graph Legend Customization

Troubleshooting

- Axis Manager disappear

3

Page 4

4

Page 5

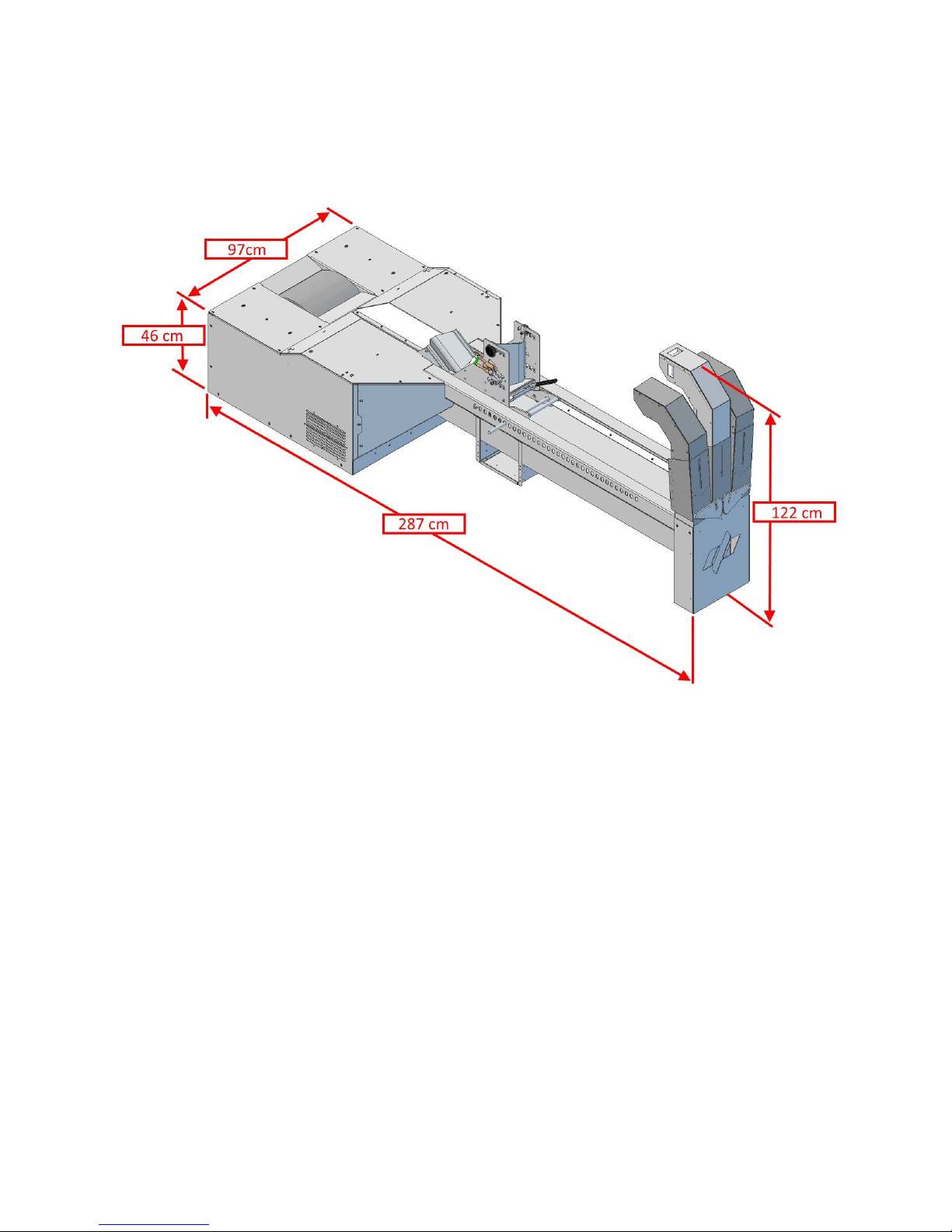

Introduction

The Moto VX-12 AXIS Dyno will come to your workshop in wooden crate package

SAE

Metric

Remarks

Width

38”

97cm

Length

114”

290cm

Height

50”

127cm

Volume

150 CFT

4 CBM

Weight

1600 Lbs

725kg

Shipping Insurance purpose.

Please check the package condition before sign on the bill of lading, check for any sign of

damage, drop, puncture,etc.

We strongly recommend that you inspect the shipping crate for potential damage.

We had a case where the shipping company put a fragile label over a fork puncture and went

unnoticed until it was opened. The shipping company denied the insurance claim.

If you see damage, it is important to take pictures and document fully for the claim.

Unloading.

Use forklift with capacity more than weight listed above.

Note:

5

Page 6

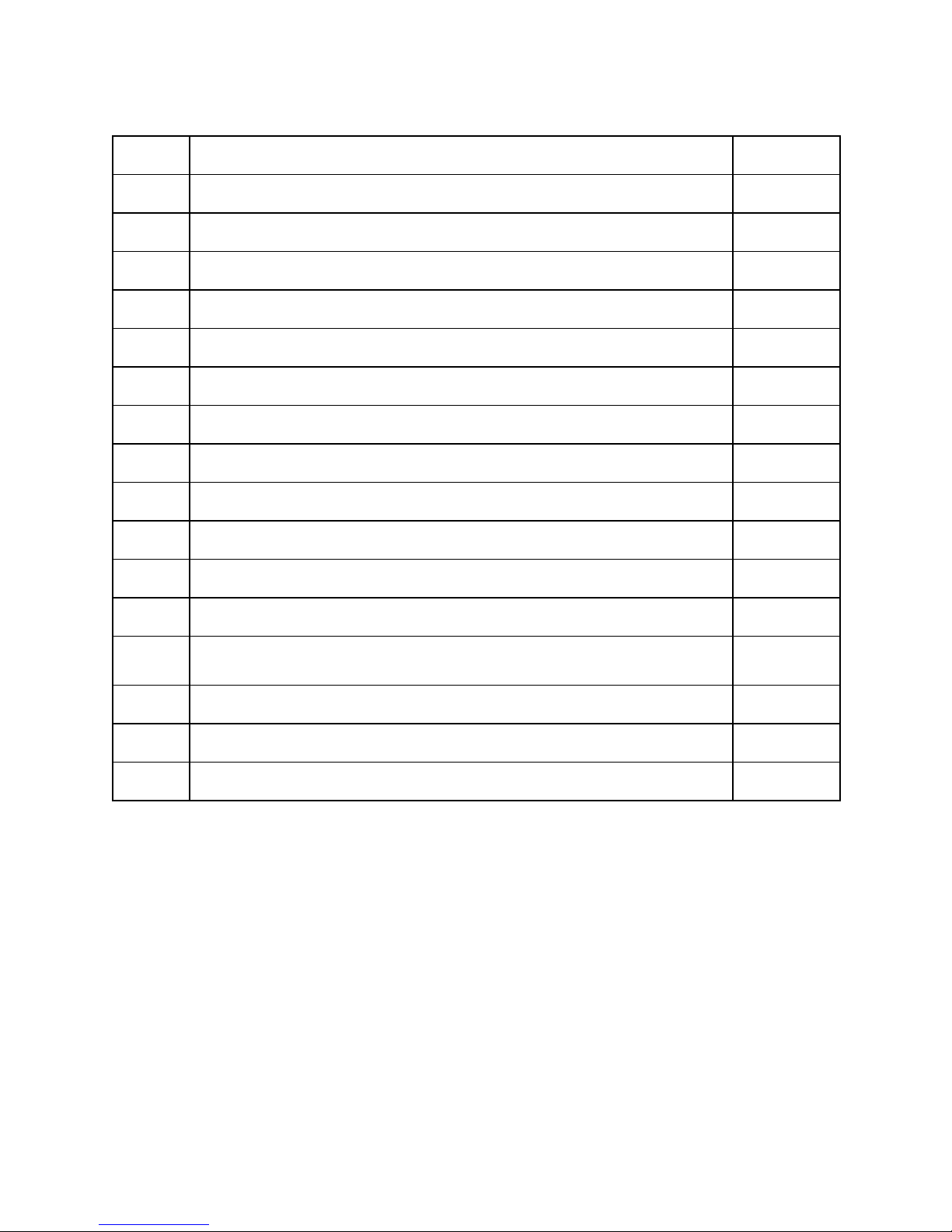

Introduction

The Moto VX-12 AXIS Dyno dimensions

AXIS Dyno Moto VX-12

SAE

Metric

Remarks

Width

38”

97 cm

Length

114”

290 cm

Height

50”

127 cm

Weight

1200 Lbs

545 kg

Max. Torque

1000 ft-lb

1356 Nm

Max. Speed

160 MPH

250 Km/h

Dyno Display

Wheelbase

40” ~ 84”

100 cm ~ 213 cm

Shaft to shaft

Inertia Adjustability

250 lbs ~ 950 lbs

114 kg ~ 430 kg

Bike + Rider

Power Requirement

Input AC 100 ~ 240 VAC, 50/60Hz, 2.0-1.0A

Output 15VDC 9.6A, 144W Max.

6

Page 7

AXIS Installation

AXIS Chassis Dyno placement

Outdoor

WARNING

Keep clear of air inlet, any debris sucked will be go toward air outlet at the front of the vehicle,

use safety glasses.

7

Page 8

Indoor, Dyno Room

Install air duct from outside of the dyno room to the inlet of the air turbine.

8

Page 9

Bike ramp sample drawing,

9

Page 10

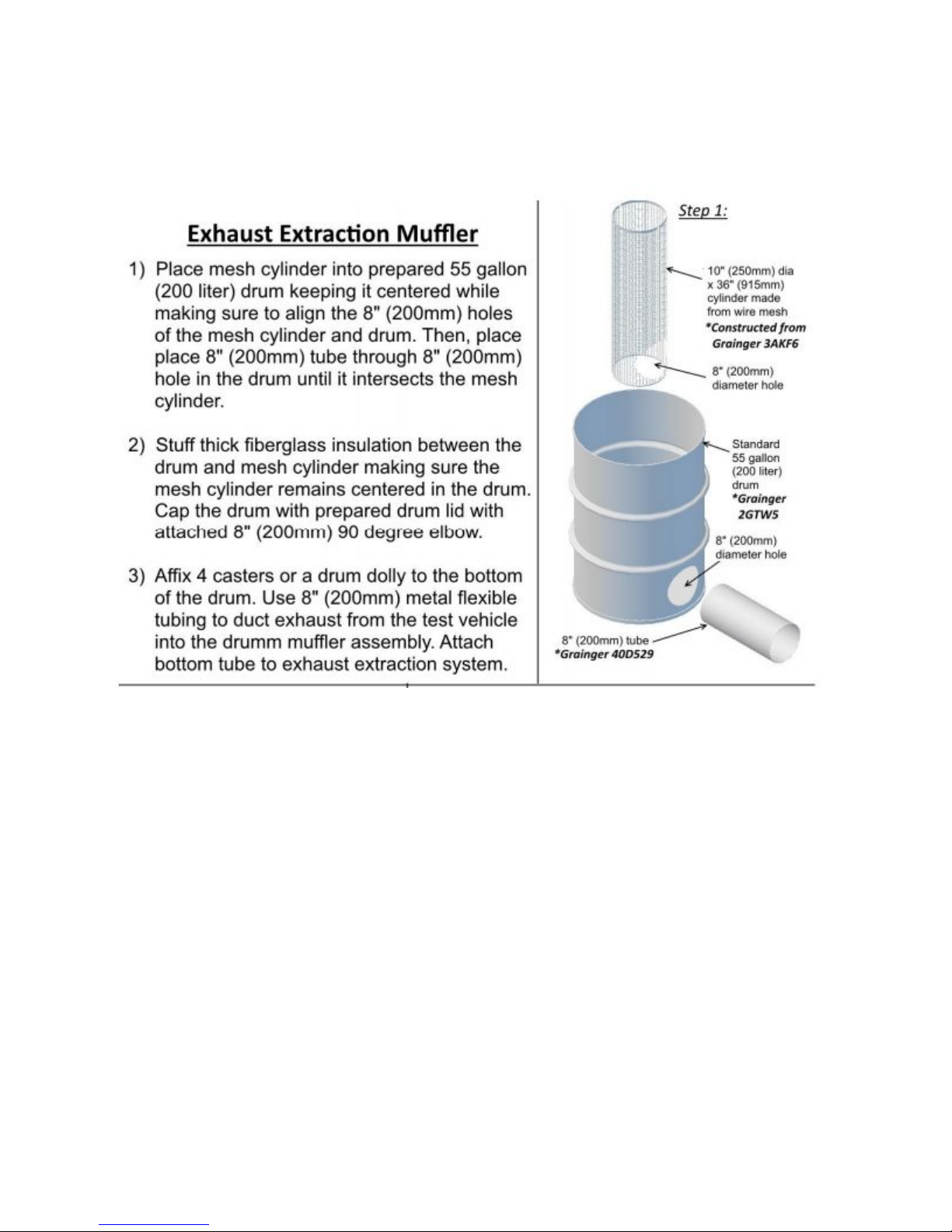

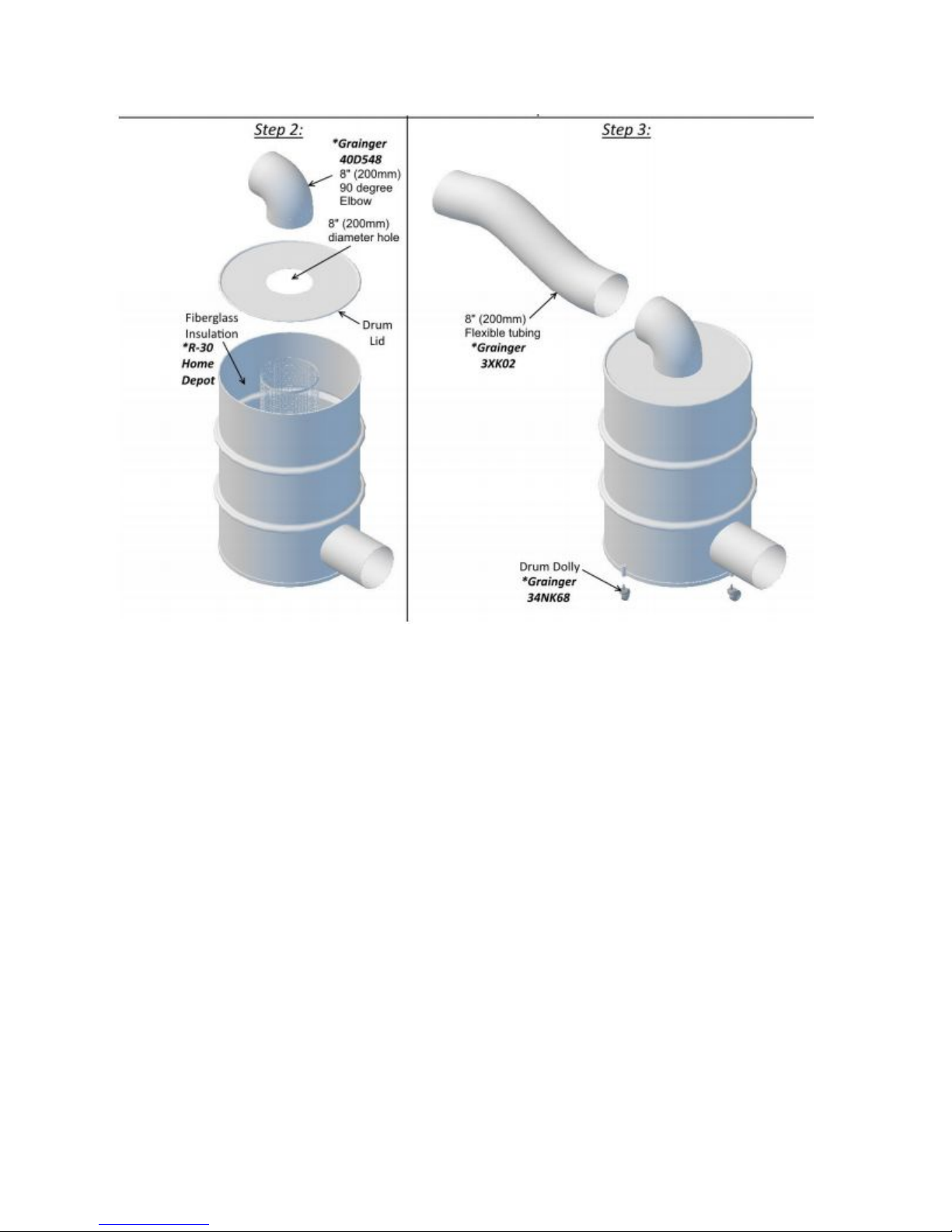

Exhaust options

Exhaust gases must be expelled outside. If you need an exhaust db killer to suppress sound,

please contact your local supplier for design plans to help you make it.

10

Page 11

11

Page 12

Computer Control

We recommend follow the computer specifications to run the Axis software.

Here is a list of the major components needed:

1. Hard Driver - SSD at least 250 GB or higher

2. Dedicated Graphics with 2GB RAM minimum (Nvidia GTX 1050ti or

higher)…..absolutely no intel onboard graphics. These will pull power away from processor and

cause issues with data collection.

3. Intel i5 or higher processor (No U Series Processors) - We custom build our computers

and use the K Series which is an unlocked and overclockable processor.

4. 8 GB of DDR4 RAM 2133 mhz or higher

Sample : Dell Inspiron 15 5000 Gaming, Lenovo Legion Y520 – GTX 1050TI

We recommend good lighting for the workspace, good air ventilation and internet access for the

dyno computer to be able to email and share charts and results.

12

Page 13

AXIS Visual Software

AVS Axis Visual Software.

Software Installation

AXIS Dyno Software and updates will be send via email.

13

Page 14

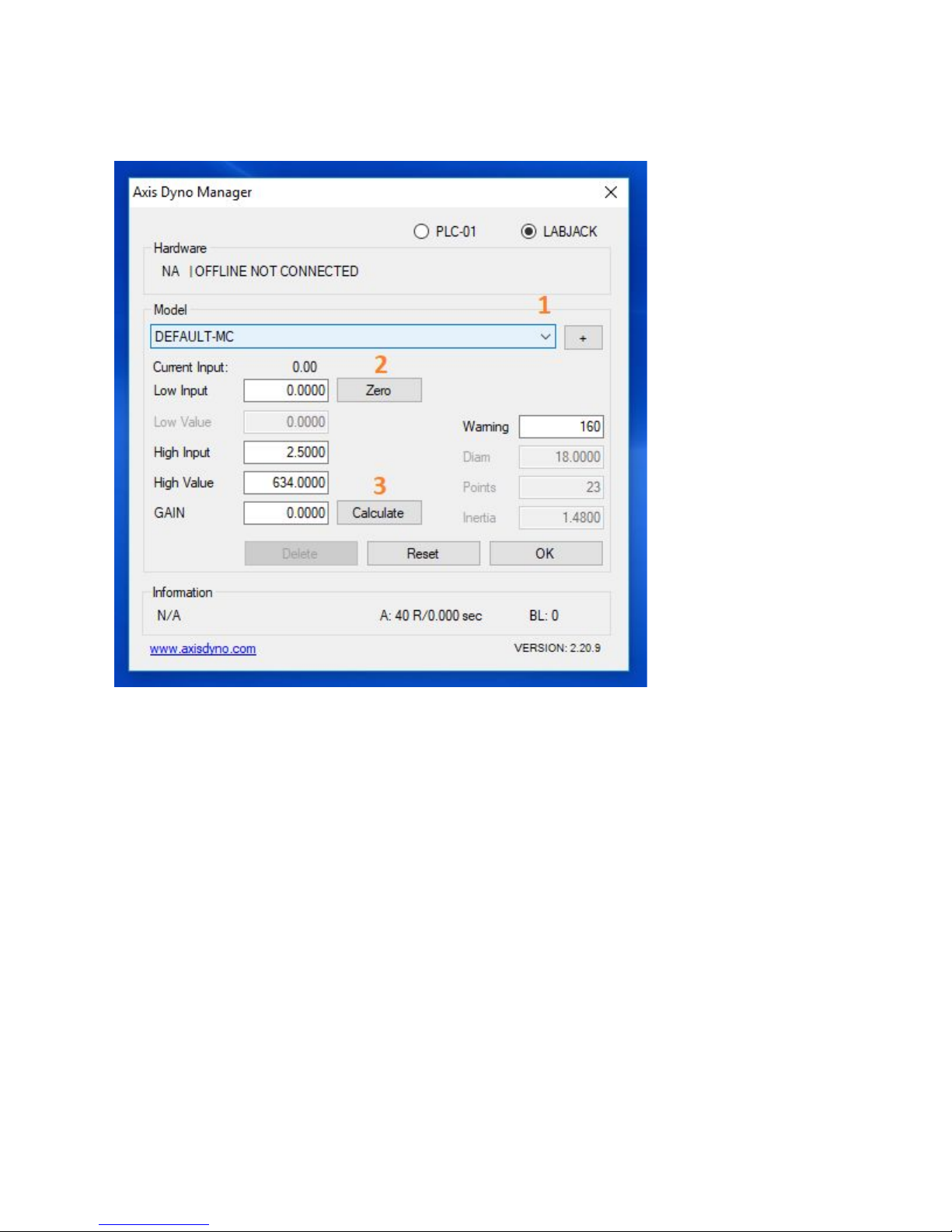

Dyno Manager

Follow these steps to set your Dyno Manager calibration figures:

- In the drop down menu, select which Model dyno you are using.

“Default-MC” for motorcycle, “Default-UTV” for UTV, and “Default-TRI” for trike.

- Put the Drum at TDC mark, Current Input voltage 0.47 ~ 0.53 click Zero button.

- Click “Calculate.” The value in the “Gain” box will change.

- Calibration numbers are now set.

14

Page 15

If your Dyno electronics are connected, you should see the Hardware showing Connected.

Run Start Speed?

Run Start RPM?

Correction Factor?

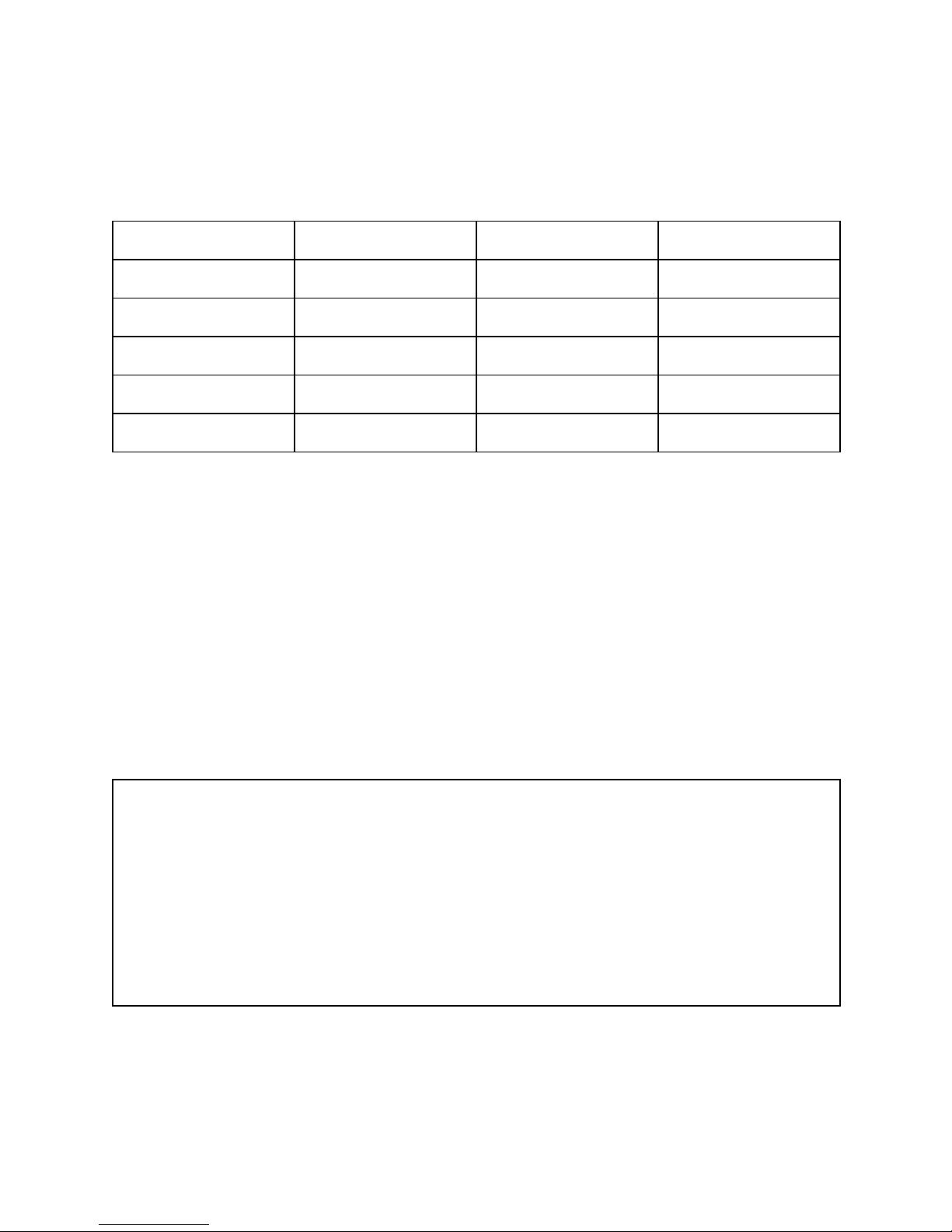

Setting up the Inertia Disks

The Axis Dyno inertia can be adjusted to reflect the total weight being accelerated.

Total weight = vehicle + fluids + cargo + passengers

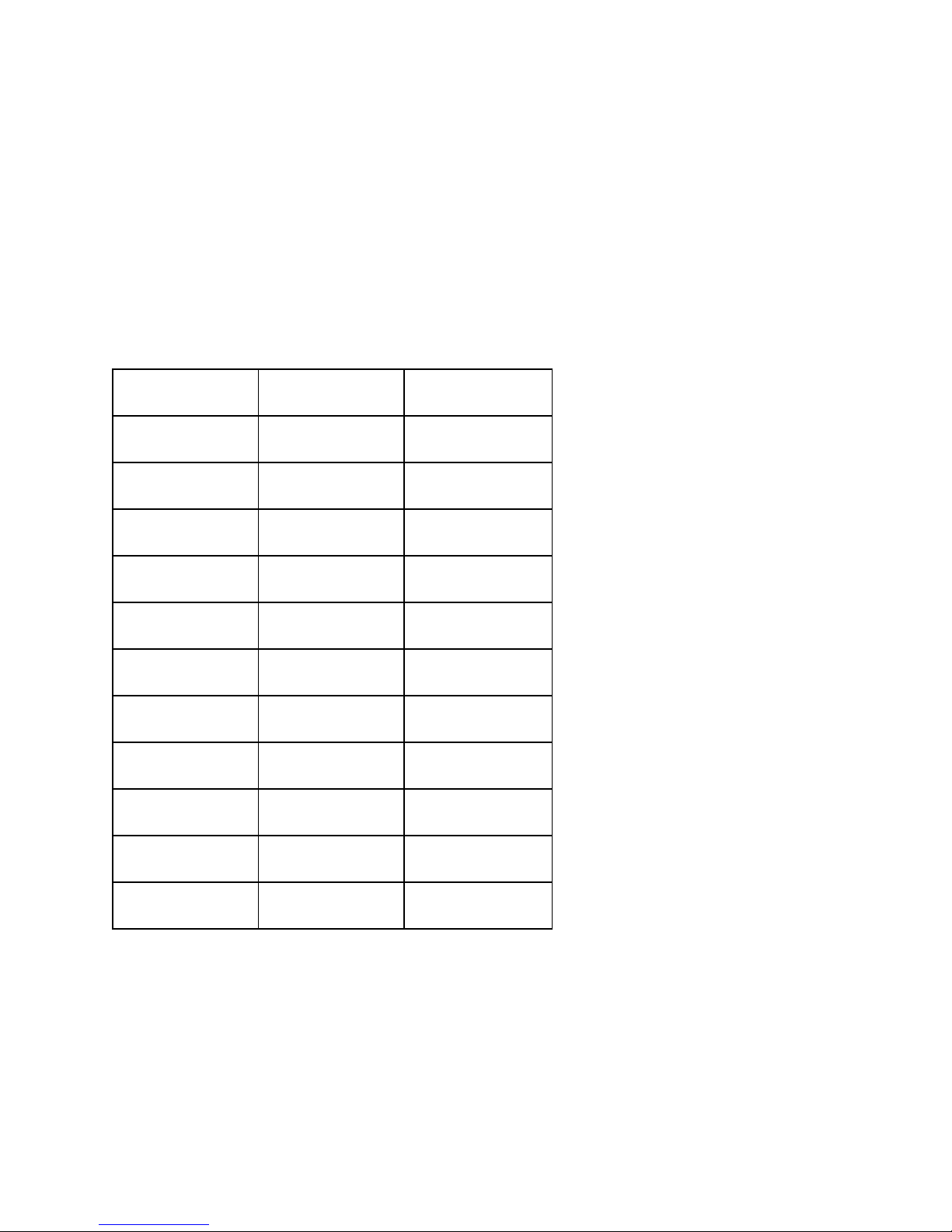

Disk Weight Chart

Weight (Kg)

Weight (lbs)

# of Disks

104

230

0

129

285

1

156

345

2

181

400

3

208

460

4

235

520

5

263

580

6

288

635

7

315

695

8

342

755

9

369

815

10

Note: Use spacers with 5 disks or less

18 in dia drum, 80t driver, 28t driven, and 17 in dia disks

When changing inertia discs, it is very important that they are aligned correctly in order to

maintain balance. The punch mark on the ½” stud needs to be aligned with the punch mark on

each disk and must be oriented vertically before tightening.

15

Page 16

16

Page 17

Perform an inspection before loading a vehicle

● Check the fluids - oil, coolant and fuel levels, leaks.

● Check the tires - overall condition, pressure and tire speed rating.

● Check the chain - tension and lubrication.

● Overall bike inspection, fasteners.

Loading up your vehicle

Secure front wheel

Centering rear wheel

Strap down the bike, put the strap down diagonal front of the motorcycle, equal tension both left

& right.

1.c.4 - Pre-run Checklist

● Check bike alignment on dyno

● Check tie-down straps

● Check the dyno - ensure drum rotates freely and the dyno is free of debris

● Ear and eye protection

● Staying clear - do not stand behind the dyno during operation

● Warm up - both bike and dyno need to come to operating temperature for best results

1.c.5 - Making your first run

Focus on repeatability

Nothing connected to the bike

The Dyno result to the rear wheel Speed

- Horse power

- Dyno Torque

1.d - Getting More Out of Your Axis Dyno

17

Page 18

1.d.1 - RPM

Injector pickup

- Attach AXIS ground clip to the best ground position on the vehicle.

- Locate fuel injector position, remove wire connector, match injector connector and install

the injector signal pick-up cables, swap the connector end if the rpm not displayed.

Inductive pickup

- Attach to high tension ignition cable, (spark plug cable)

Calculated RPM

1.d.2 - AFR

AFR probe install

AFR Signal

1.d.3 - Auxiliary inputs

18

Page 19

Maintenance

Maintenance should be done after every 80 hours of use. All bolts should be checked for

loosening and thread locker added if needed. Remove all top covers for maintenance.

2.a.1 - Belt Tension

Belt tension should not need to be changed but can be checked using one of the following:

● Pluck the belt like a guitar string and measuring the frequency using a phone guitar tuner

app. Belt tension should be between 62 to 70 Hz.

● The belt should deflect 5/16” with a 30 lb force at the center of the span.

If the belt tension is wrong, use the following procedure:

● Loosen the two 3/8 bolts located behind the tensioner and next to the drum

● Adjust the belt tension from the top using the long 1⁄2-13 bolt

Tighten the 3/8 bolts and check the tension again.

● Repeat if necessary.

2.a.2 - Bearings and Bushings

It is recommended to lubricate the bearings every 80 hours of use. A high speed and

temperature lubricant (e.g. Lithium base NGLI #2) is recommended.

The bearings are shown for reference.

19

Page 20

The keyless bushings on blowers should be checked and re torqued to ____(spec).\

2.a.3 - Centering The Drum

If at some point, the drum is removed from the dyno chassis for service, follow these instructions

to re-center the drum.

20

Page 21

2.a.4 - Rust Treating The Drum

21

Page 22

Section 3 - Support

3.a - Dyno Electronics

3.a.1 - AFR Setup

22

Page 23

Setting up your AFR signals in the Axis Dyno software (Configure Settings Menu):

Value

AFR 1

AFR 2

Wire Pink/Yellow

Purple/Yellow

Input AIN07

AIN00

Input Delay

0.00

0.00

Low Volt Reading

0

9.4

9.4

High Volt Reading

2.5

17.2

17.2

Scale Factor

1 1

23

Page 24

24

Page 25

3.Chassis Coil Replacement

3.a.4 - Cleaning Reflective Disk

If your graph for dyno runs presents wavy symptoms such as these:

Check your graph when plotting Speed Vs Time if it shows a graph with large anomalies such

as these then you will need to perform the reflective disk cleaning process.

25

Page 26

Follow these steps:

1. Loosen set screw on reflective disc collar

2. Back collar up as far as it can go so you can access the front of the reflective disk

3. Spin the drum as you hold a cloth with alcohol on it to clean the pads on the disc

4. Once clean move the collar and disc back up until the disk is close to .030” or 0.762mm

away from the chassis disk

1. 2.

3. 4.

26

Page 27

Chassis Board Replacement

To replace the chassis board on the Axis VX12, please take the following steps:

1. Disconnect Dyno Power and Data Cables

2. Remove Left Side Roller Cover

3. Remove Three Connectors From Chassis Board

4. Remove Two Phillips Head Screws Holding Board

5. You may need to remove the screws holding the square board in place and shift over the

reflective disk collar to gain access to the screws in Step 4

6. Remove and Replace Chassis Board

7. Reverse steps to reassemble

1. 2.

3 & 4.

5. 6.

27

Page 28

Drum Board Replacement

Follow these steps:

1. Remove the top panel from the left side of the drum (when viewed from behind)

2. Locate the red drum board mounted on the side of the drum

3. Remove the black, 3 pin Molex connector from the drum board

4. The drum board is affixed to the drum by two Phillips head screws and two nylon

spacers

5. Remove the two Phillips head screws while being careful not to drop the spacers

6. Loosen the 5 flathead screws on the green terminal block, then pull back on the wires to

release the board

7. To replace the drum board with a new one, follow the steps in reverse order while paying

particular attention to the arrangement of wires into the green terminal block.

1. 2. 3.

28

Page 29

5.

29

Page 30

6.

30

Page 31

Labjack Replacement

Follow these steps:

1. Remove the 8 screws (4 on each end) from the faceplates of the electronics box.

2. Bend the faceplate containing the USB plug down as shown below.

3. Slide the top body of the box off the bottom plate and over the faceplate as shown

below.

4. Remove the USB, smoothing box, and power filter board from the Labjack. The

smoothing box and power filter board are held on with Velcro. See below.

5. Loosen all terminals on the Labjack and pull wires back out of terminal slots.

6. Remove Labjack from bottom plate. It is held to the bottom plate with Velcro.

7. Add mating Velcro strip to bottom of Labjack, then place Labjack in position on the

bottom plate.

8. Replace wires into the correct terminal slots, and tighten each. See image below for

wire positions. Note that all terminals marked “VS” are connected and all terminals

marked “GND” are connected and which of these slots are utilized may vary from box to

box.

9. Reassemble box following steps 1-4 in reverse order.

31

Page 32

Smoothing Box Replacement

Follow these steps:

1. Remove the 8 screws (4 on each end) from the faceplates of the electronics box.

2. Bend the faceplate containing the USB plug down as shown below.

3. Slide the top body of the box off the bottom plate and over the faceplate as shown

below.

4. Disconnect the 4 pin clear connector and remove smoothing box, which is held on with

Velcro.

5. Add Velcro to new smoothing box, place on Labjack, and plug in 4 pin connector.

6. Reassemble electronics box by following steps 1-3 in reverse order.

32

Page 33

Splicing the Load Cell Cable

Follow these steps:

1. Cut each end of the splice to the desired length. Note that roughly 1” will be lost through

the splicing process.

2. Cut a 4” section of ½” adhesive lined shrink tubing and slide it over one of the ends and

out of the way.

3. Strip back 2” of insulation from each end of cable.

a. Start by making a circumferential cut into only the insulation.

b. Next, score the end piece of insulation linearly along the entire length.

c. Peel back the insulation to reveal the shielding.

4. Peel back the shielding to reveal a white and red wires as well as a bare wire and two

more wires in another layer of shielding.

5. Peel back the second layer of shielding to expose two more wires; green and black .

6. Cut away excess shielding up to the insulation.

7. Repeat process for both ends of the splice to get to the point pictured above.

8. To keep the splice small, offset the wires by trimming each ¼” more than the last as

pictured.

9. Trim the wires of the other side of the splice in opposite order of the last so that the wires

match up as shown above.

33

Page 34

Checking The Load Cell

Follow these steps:

1. Check the Wheatstone bridge

a. Set your multimeter to ohms (Ω). If your meter does not auto scale, set it to the

just high enough to read 350 Ω. This will likely be the 2k or 2000 setting.

b. Referring to the picture above, place one of the probes on terminal 1 (red wire).

c. Place the second probe on terminal 2, 4, and 5 recording the resistance at each

terminal. The resistances should match the table below.

2. Check Static Output

a. Set your multimeter to the millivolt (mV) setting.

b. Check and record the voltage between terminals 1 and 5. A good load cell will

read very close to 00.0mV at rest with no vehicle loaded.

3. Check Dynamic Output

a. Set your multimeter to millivolt (mV) as with the last test.

b. Place the multimeter pins on terminals 1 and 5 again.

c. Have another person rock the drum back and forth a couple inches (careful not to

pinch fingers) each way while you watch the multimeter display.

d. Record the high and low numbers seen while rocking the drum.

e. Depending on the force applied in rocking, the readout should be ~±.3mV.

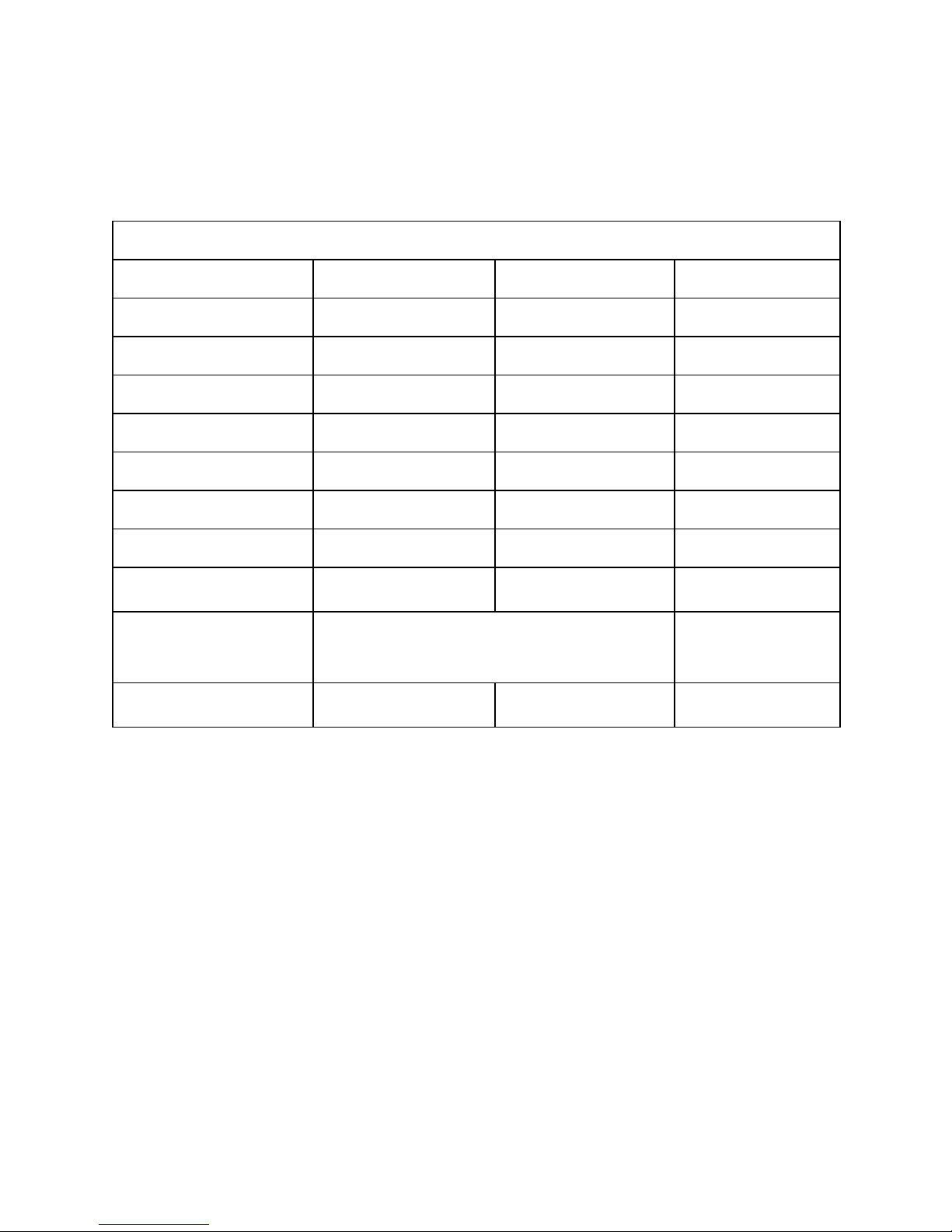

Wheatstone Bridge Readings

Terminals

Resistance

1>2

~280Ω

1>4

~280Ω

1>5

~350Ω

34

Page 35

3.b - Dyno Mechanical

3.b.1 - Belt Tension Adjustment

Belt tension should not need to be changed but can be checked using one of the following:

1. Pluck the belt like a guitar string and measuring the frequency using a phone guitar tuner

app. Belt tension should be between 62 to 70 Hz

2. The belt should deflect 5/16” with a 30 lb force at the center of the span

If the belt tension is wrong, use the following procedure:

1. Loosen the two 3/8 bolts located behind the tensioner and next to the drum

2. Adjust the belt tension from the top using the long 1⁄2-13 bolt

3. Tighten the 3/8 bolts and check the tension again. Repeat if necessary.

3.b.2 - Blower Belt Replacement

3.b.3 - Centering The Blower Wheel

3.b.4 - Centering Drum

3.b.5 - Changing Blower Bearings

3.b.6 - Changing Drum Bearings

3.b.7 - Rust Treating The Drum

35

Page 36

3.c - Dyno Software

3.c.1 - Adding Your Logo to Graphs

3.c.2 - Calibration

1. With no bike on and load cell at top dead center, take note of the dyno torque in settings.

(Dyno torque will only show up without speed if you manually select it in settings and

watch in the settings screen. Dyno torque should display where the yellow box is in

picture 2)

a. If your dyno torque is within +-5 of 0 with no bike on and load cell TDC, then your

low number is good and does not need adjusting and you may skip to step 2.

b. If your dyno torque falls outside of this range, then the zero torque value should

be adjusted for maximum accuracy.

c. In settings select one of your AUX channels and change the settings to match the

settings in the orange box in picture 1 below.

d. With these settings entered, a non-zero value should show up in the green box in

picture 1 below. Note this voltage.

e. Navigate to the 'AVS 1.1' folder by right clicking the 'AXIS 1.1' desktop icon and

selecting "Open File Location."

f. From within the 'AVS 1.1' folder open the folder named 'AXIS-SETTINGS.'

g. Open the file named ‘baseconfig.txt.’

h. Replace the number next to the label “vLi” with the number from step (d). The

number in question is shown in the blue box in picture 3 below. (Note, be sure

not to change anything but the number itself. Any change to the syntax such as

deleting a comma or parenthesis will make the software crash or not boot up

correctly. Attached is a picture of the number that needs to be replaced.)

i. Repeat step 1 to ensure that your dyno torque now rests within a few ft-lb’s of 0.

If it does, move on to step 2.

2. To adjust your resulting HP and torque values, navigate back to the baseconfig.txt file as

described in steps (e) through (g) above.

3. Adjust the value shown in the purple box below in picture 3. Increasing this number will

increase your overall HP and torque values, and lowering it will decrease your numbers.

4. After making an adjustment, do a couple runs with a known vehicle and evaluate the

results. You’ll likely have to make a few adjustments to get the numbers correctly dialed

in.

36

Page 37

37

Page 38

38

Page 39

Dyno Manager Calibration Input

Follow these steps to set your Dyno Manager calibration figures:

1. In the drop down menu, select which dyno you are using. “Default-MC” for motorcycle,

“Default-UTV” for UTV, and “Default-TRI” for trike.

2. Enter your low input, “vLi,” in the blue box.

3. Enter your high input, “vHi,” in the orange box.

4. Enter your high value, “vHv,” in the green box.

5. Click “Calculate.” The value in the “Gain” box will change.

6. Calibration numbers are now set.

Note: Each dyno has the Low Input and High Value values determined at the factory. Please

contact your sales representative for these values.

39

Page 40

3.c.4 - Dos and Don'ts of Calculated RPM

3.c.5 - Split Screen Commands & Dual Displays

40

Page 41

Installing & Updating LabJack Drivers

1. Open a web browser and navigate to labjack.com

2. Click the “Support” tab along the top

3. Under the header “Software & Driver” select “Installation Package Downloads.”

4. Under the header “U3, U6, and UE9 Installation Packages” click and expand the

“Downloads” tab.

5. In the expanded view, click the link under the “Beta” header to download the driver.

6. If you already have a version of the Labjack driver installed, you will be asked to remove

the old version; click “OK.”

7. Skip to step 10 if this is a first time install.

8. Click “Uninstall” in the new window.

9. Once the old version has completed uninstalling click “Close.”

10. To start the installation, click “Next” on the Labjack Setup Wizard window.

11. At this point you may select which extra Labjack applications will install. It is recommend

to keep these default settings, then click “Next”

12. Choose a directory to install the Labjack driver and applications. The default directory is

in the “Program Files” Folder. Once done click “Next.”

13. On the next window you may create shortcuts to the labjack applications. Click “Install”

when you are complete.

14. During the installation you may be required to click “Next” several times.

When the installation is complete, click “Finish” on the final screen.

15. Labjack driver is now installed.

Firefox Users:

A. When prompted click “Save File.”

B. Click the blue arrow in the top right corner, then select the Labjack Driver.

C. Select “Run” when prompted.

Chrome Users:

A. Once the download is complete, click the file on the download tab along the bottom of

the window.

B. When prompted, select “Run.”

Explorer Users:

A. Click “Run” on the tab along the bottom.

41

Page 42

Troubleshooting

These are 2 steps to fix the Axis Manager from disappearing in Windows 10

How to set file permission in windows 10.

1. Right Click on the Axis Manager Shortcut

2. Click on properties and go to security tab, check whether any permission have

been set.

3. Once the security tab opens click on “edit”

4. Then click on the user in the list of user names and then in the window below

make sure “Full Control is checked”

How to run a program as the “Administrator” on Windows 10:

1. Right click on the axis icon Then click on properties.

2. Once the windows opens click on the “Compatibility Tab”.

3. On the next window click on “Change settings for all users”

4. Make sure the following has a check mark in the windows.

5. Once this is check click “Apply”

42

Page 43

General Troubleshooting Guide

Step 1: LED Check

A. Remove the top panel/cover of the dyno to the left of the drum when viewed from

behind.

B. With the cover off, power on the dyno.

C. Locate the red chassis board (the red board mounted to the chassis, NOT the drum).

D. On the red board there are 3 LED’s

a. Green LED: This LED should always be on while there is power coming to the

chassis board.

b. Blue LED: This LED will flash while the drum is rotating at a frequency

determined by the speed of the drum

c. Red LED: This LED blinks (~50Hz) to indicate communication with the drum

board. If this light is solid or not on it means the chassis board is not

communicating with the drum board and torque is not being read from the load

cell. If this is the case, skip to Step 4.

Step 2: Load Cell Wires

A. Open up the software and navigate to the “technical” tab which displays the raw labjack

inputs.

B. Locate the red drum board on the side of the drum.

C. While watching the input voltage of AIN06 wiggle each of the wires going into the green

terminal block on the drum board. (See picture) If the voltage jumps at all while agitating

any of the wires, try to narrow down which wire it is and examine for loose connections

or broken wires.

Step 3: Load Cell Check

A. Check the Wheatstone Bridge

a. Set your multimeter to ohms (Ω). If your meter does not auto scale, set it to the

just

high enough to read 350 Ω. This will likely be the 2k or 2000 setting.

b. Referring to the picture above, place one of the probes on terminal 1 (red wire).

c. Place the second probe on terminal 2, 4, and 5 recording the resistance at each

terminal. The resistances should match the table below.

Terminals

Resistance

1 > 2

~ 280 Ω

1 > 4

~ 280 Ω

43

Page 44

1 > 5

~ 350 Ω

Step 3: Load Cell Check - cont.

B. Check Excitation Voltage

a. Set your multimeter to measure up to 5V. This is commonly the 20V setting.

b. Place the black probe on terminal 3 (bare wire).

c. Place the red probe on terminal 2 (black wire). The meter should read between

-5.1V and -4.9V.

d. Place the red probe on terminal 4. The meter should read between 4.95V and

5V.

C. Check Static Output

a. Set your multimeter to the millivolt (mV) setting.

b. Check and record the voltage between terminals 1 and 5. A good load cell will

read

very close to 00.0mV at rest with no vehicle loaded.

D. Check Dynamic Output

a. Set your multimeter to millivolt (mV) as with the last test.

b. Place the multimeter pins on terminals 1 and 5 again.

c. Have another person rock the drum back and forth a couple inches (careful not to

pinch fingers) each way while you watch the multimeter display.

d. Record the high and low numbers seen while rocking the drum.

e. Depending on the force applied in rocking, the readout should be ~±.3mV.

Step 4: Grey Cable Check

A. Locate the Grey Cable connecting the red drum board to the black drum coil board. (see

picture below)

B. While watching the input voltage on AIN06, wiggle the wires at each end of the

connector. In addition to watching the voltage on AIN06, also look to see if wiggling the

wires have any effect on the red LED.

C. Unplug the grey cable from each connector and using a multimeter check for continuity

through each wire. To do this set your multimeter to ohms and place one probe on either

end of the wire in question. A good wire will read within a few ohms of 0.

D. With the grey cable still unplugged check to see that each end is pinned the same.

When viewed from behind with the tab up and order should be red-white-black.

E. Plug the grey cable back into each board.

F. If the grey cable checks out proceed to step 5.

44

Page 45

Step 5: Air Gap Check

A. Loosen the set screw on the plastic collar holding the drum coil board on. (See picture

below)

B. Move the collar and drum board towards the other black board so the two black boards

are in contact.

C. Check to see If the red LED is blinking now. If it is, back the collar far enough so the

black boards are no longer touching but the red LED is still blinking and tighten the set

screw.

D. If the red LED still is not blinking, place collar back in original location and tighten set

screw.

45

Page 46

RPM Troubleshooting Guide

1. First check to make sure that RPM is the only reading not present. If other readings are

also not present then a bigger issue is likely present causing the loss of RPM. If only

RPM is not present, continue on to step 2.

2. Check that the ground cable is connected between the electronics box and the vehicle.

In order to read RPM, the box needs a common ground with the vehicle. Once

connected check again for RPM. box as well as the USB which provides the 5V power.

Wait 30 seconds then reconnect the USB and DC power, order is not important. Check

again for RPM.

3. If the injector harness used has two connectors to mate with the RPM harness, try

4. Power cycle the entire system by unplugging both the DC power to the electronics

swapping them. One of the connectors will have the injector signal while the other will

have a steady ~12V. Applying the 12V to the RPM input will not damage anything;

however you will not have an RPM reading with this configuration. After swapping check

again for RPM.

5. Check for continuity in the injector harness as well as the RPM harness with a

multimeter.

a. If no continuity is present, narrow it down to which harness has the open circuit

and contact Dobeck Performance for a replacement.

b. If both harnesses have continuity, move on to the next step.

6. Disassemble electronics box to expose the internals. Depending on the generation of

box in question the procedure to accomplish this will vary.

7. Make sure that the white/yellow wire is going into the terminal labeled FIO4 on the

labjack.

a. If the wire is going into wrong terminal, swap wires to match the picture below.

Check for RPM.

8. Measure the resistance between FIO4 and VS on the labjack. There should be ~1k

between the two.

a. If resistance reading varies beyond 10 ohms, contact Dobeck Performance.

9. With vehicle hooked up and running, probe the yellow wire inside the electronics box.

Work the throttle to increase RPM’s and look for a corresponding decrease in voltage on

the yellow line.

a. Repeat previous step on while probing the white/yellow wire. If decrease in

voltage with rising RPM is seen only on the yellow wire, then the RPM smoothing

box is bad; contact Dobeck Performance for replacement.

46

Page 47

4.a.3 - Drum Board Voltage Rail Check & Air Gap Adjustment

1. Remove dyno panel to expose the drum board, which is mounted on the side of the

drum. On most models this is on the back left side of the dyno (while looking from

behind).

2. Set multimeter to the highest precision DC voltage readout while still being able to read

5V (generally a 20V setting).

3. Place black/common probe on the center terminal (labeled A in the picture above) of the

green 5 position terminal block located on the drum board.

4. Place red probe on the terminal adjacent to the common terminal, labeled B in the

picture above. Reading should be between -4.95V to -5V.

5. Place red probe on the other terminal adjacent to the common terminal, labeled C in the

picture above. Reading should be between 4.95V and 5V.

6. If either of these readings falls out of the acceptable range check the distance of the air

gap between the transformer boards.

a. Loosen the set screw on the collar holding the circular transformer board.

b. Adjust the air gap spacing while checking the two readings to bring them into

range.

c. Make sure the transformer boards are not so close that they may rub with

vibration or flexing.

d. If adjusting the air gap space has no effect on the voltage readings and they are

still out of range, contact technical support at Dobeck Performance.

47

Page 48

48

Loading...

Loading...