Page 1

FC-29W 9” UN-UNIVERSAL

Dome Housing

Installation Instructions

Page 2

1

Page 3

Safe Use of Equipment

2

WARNING

WARNING

To reduce the risks of an electric shock, do not expose inside of this

unit to rain or moisture.

Installation on a rainy day may also cause fog around the capsule.

Installation

Installation shall be done by qualified installer only and should

conform to all local codes.

Ensuring strength of supporting Dome Housing Unit

The unit must be properly and securely mounted to a supporting

structure capable of sustaining the weight of the unit. Recommend

use 3/8” stainless screws x four (4).

Prohibit changes or modifications of equipment

You are cautioned that any changes or modifications not expressly

approved in these instructions could void your authority to operate

this equipment.

Basic Operating Environment Condition

We provide warranty for the products that are installed under normal

outdoor -20°C ~ +50°C conditions. We are unable to provide warranty

for the products which are installed indoor and exposed to constant

high temperature over +50°C and over 90% humidity.

Operating temperature and humidity of camera varies from camera to

camera. You are requested to confirm to camera specification with

camera manufacturer and housing specification with us in advance.

i.e. -20°C or below, you are requested to use additional heater and

+50°C or above you are requested to use two blowers and Sunshield.

Fasten wires tightly.

Attention:

Keep wires away from the Fan / Heater, and do not disturb

Fan/Heater’s performance

Page 4

Table of contents

3

1. AXIS 214 PTZ network camera housing installation………………………..P.4

2. AXIS 215 PTZ network camera housing installation……………………..…P.6

3. AXIS 233D PTZ network dome camera Housing installation……………...P.8

4. AXIS P55XX series PTZ network dome camera Housing installation…....P.10

5. AXIS Q6034 PTZ network dome camera Housing installation………...….P.12

6. Installation of FC-9002 Pole Mount Bracket and Dome housing………….P.14

7. Installation of FC-9005 Ceil Mount Bracket and Dom e housing …..….…..P.15

8. Installation of FC-9006 Ceil Mount Bracket and Dom e housing …….....…P.16

9. Installation of FC-9007 Corner Adapter with Wall Mount Bracket and Dome

housing……………………………………………………………………….….P.17

10. Installation of FC-9008 Corner Adapter with Wall Mount Bracket and Dome

housing ………………………………………………………………….………P.18

11. Installation of FC-900 9N Wall Mount Bracket and Dome housing …….....P.19

12. Installation of FC-9009 Wall Mount Bracket and Dome housing……….…P.20

13.Installation of FC-9011 Ceil Mount Bracket and Dome housing……….…..P.21

14.Dimensions …………………………….………….....................……………..P.22

Page 5

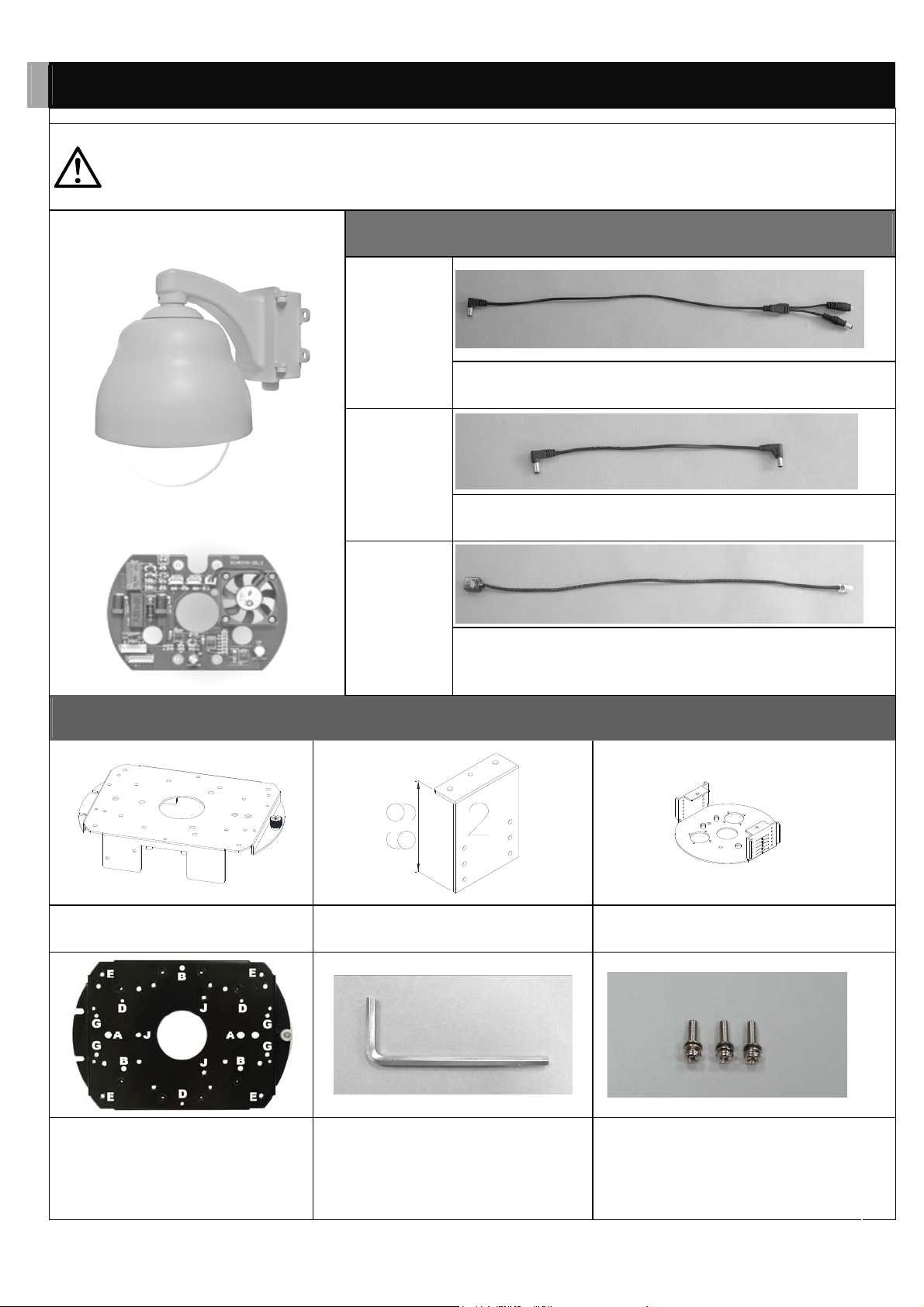

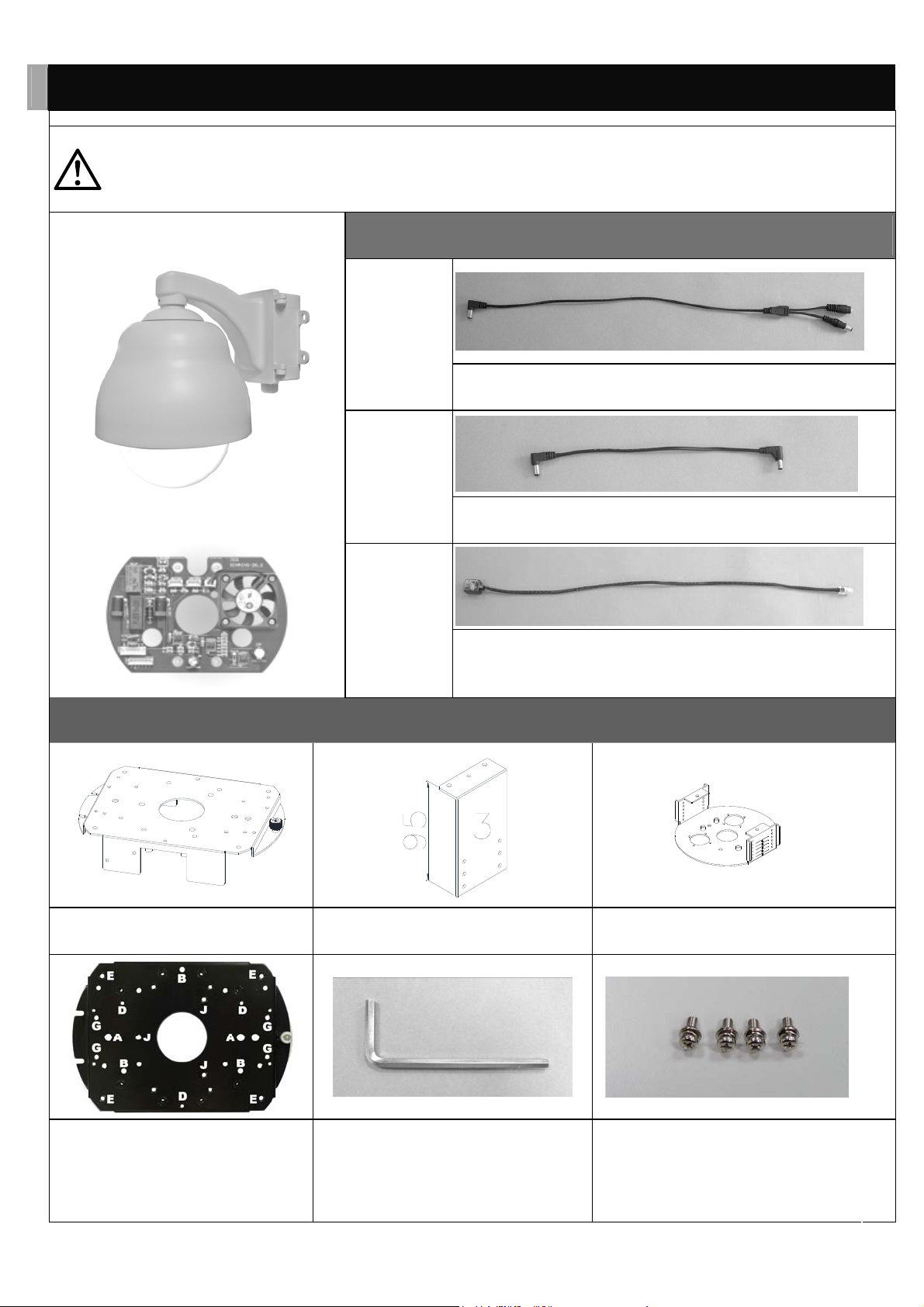

1 AXIS 214 PTZ network camera Housing installation

4

The unit must be properly and securely mounted to a supporting

WARNING

structure capable of sustaining the weight of unit. Recommend use

stainless screws.

9” dome housing

DC12V Fan+Heater

Cables

L603

L704

L705

Power cable to PC board and external power supply

Power cable to PC board and PTZ network camera

Network extension cable to internet

Component Parts for Assembly

Square-shaped upper board No. 2 side board Round-shaped bottom board

Screw the camera on, through hole B,

with washer in the back

No. 3 Allen Key ( for cover and wall

mount bracket tighten)

3x12 Double Washer screws for

camera to Square-shaped upper

board,

Page 6

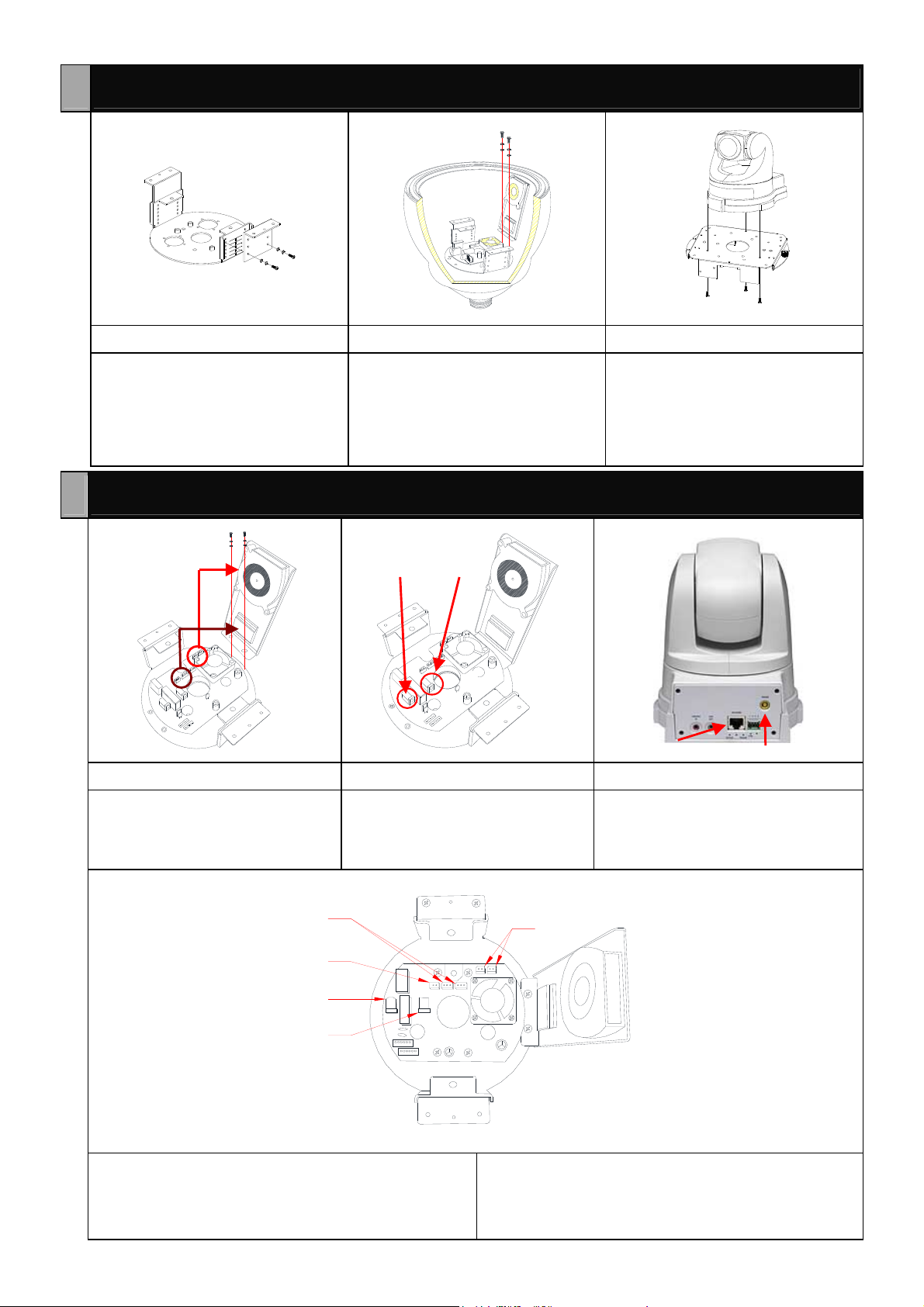

5

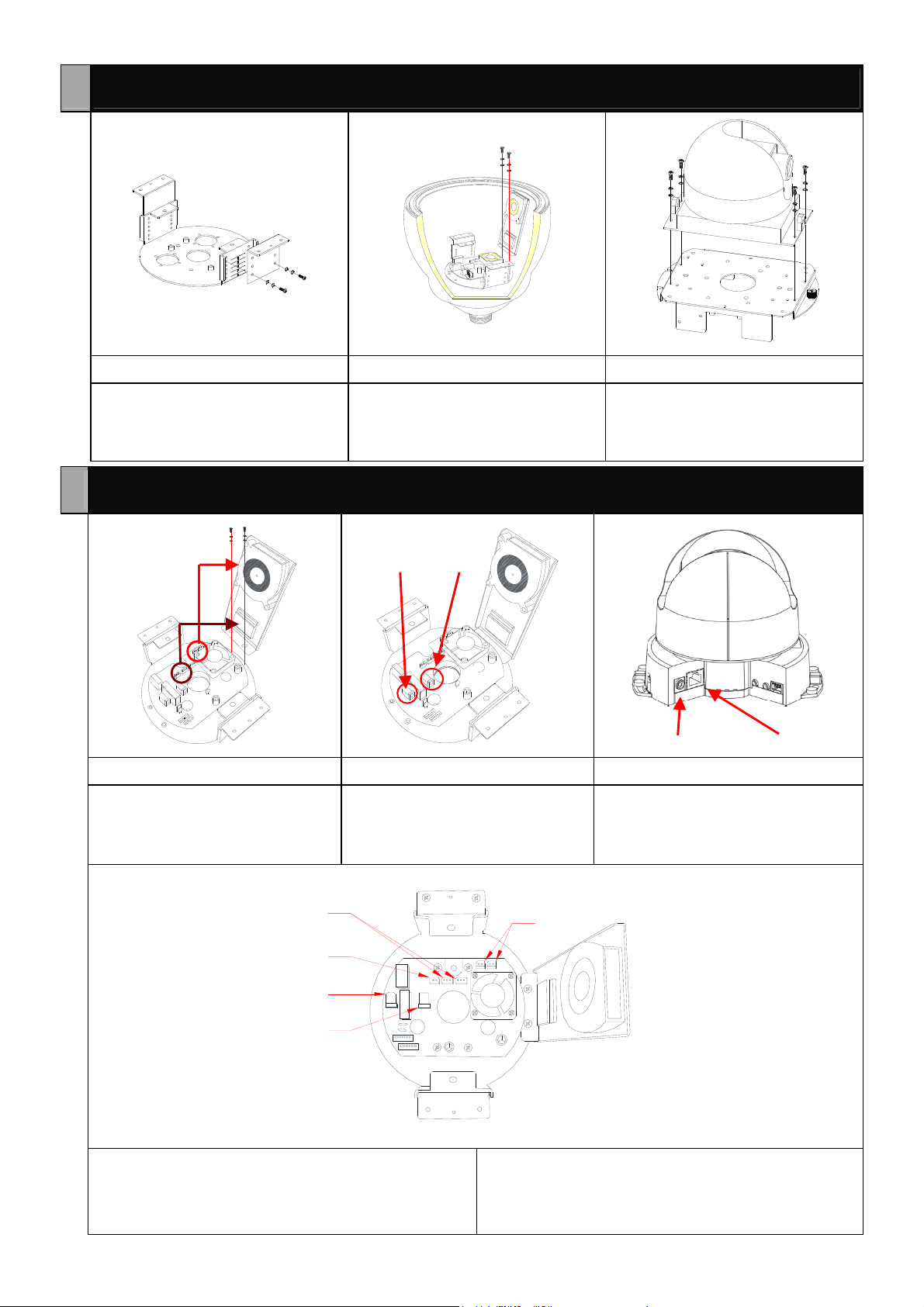

Assembly Steps of the Camera and the Dome Housing

1-1-1 1-1-2 1-1-3

Fix No. 2 side board (Hole 2) to the

round-shaped bottom board (Hole 5)

with 3x8 Double Washer screws.

Use 4x8 double washer screws to

Fix Fan/Heater side board on

Round-shaped bottom board,

connect power cable to Fan/Heater

Fix screws on back of

square-shaped upper board which

go through from back to front to fix

the camera on the square-shaped

upper board (Hole B) with 3x12

double washer screws.

Assembly Steps of the Cables

L704 L603

1-2-1 1-2-2 1-2-3

Use 4x8 double washer to Fix

Fan/Heater side board on

Round-shaped bottom board,

connect power cable to Fan/Heater

Connect L603 to the PC board.

Connect L704 to the PC board.

Connect L704 and L705 to the

camera. Cables used for camera.

L705 L704

2

3

4

1

5

1. DC 12V FAN

2. DC 12V HEATER

3. H/SENSER

4. DC 12V OUT

5. DC 12V IN

Page 7

6

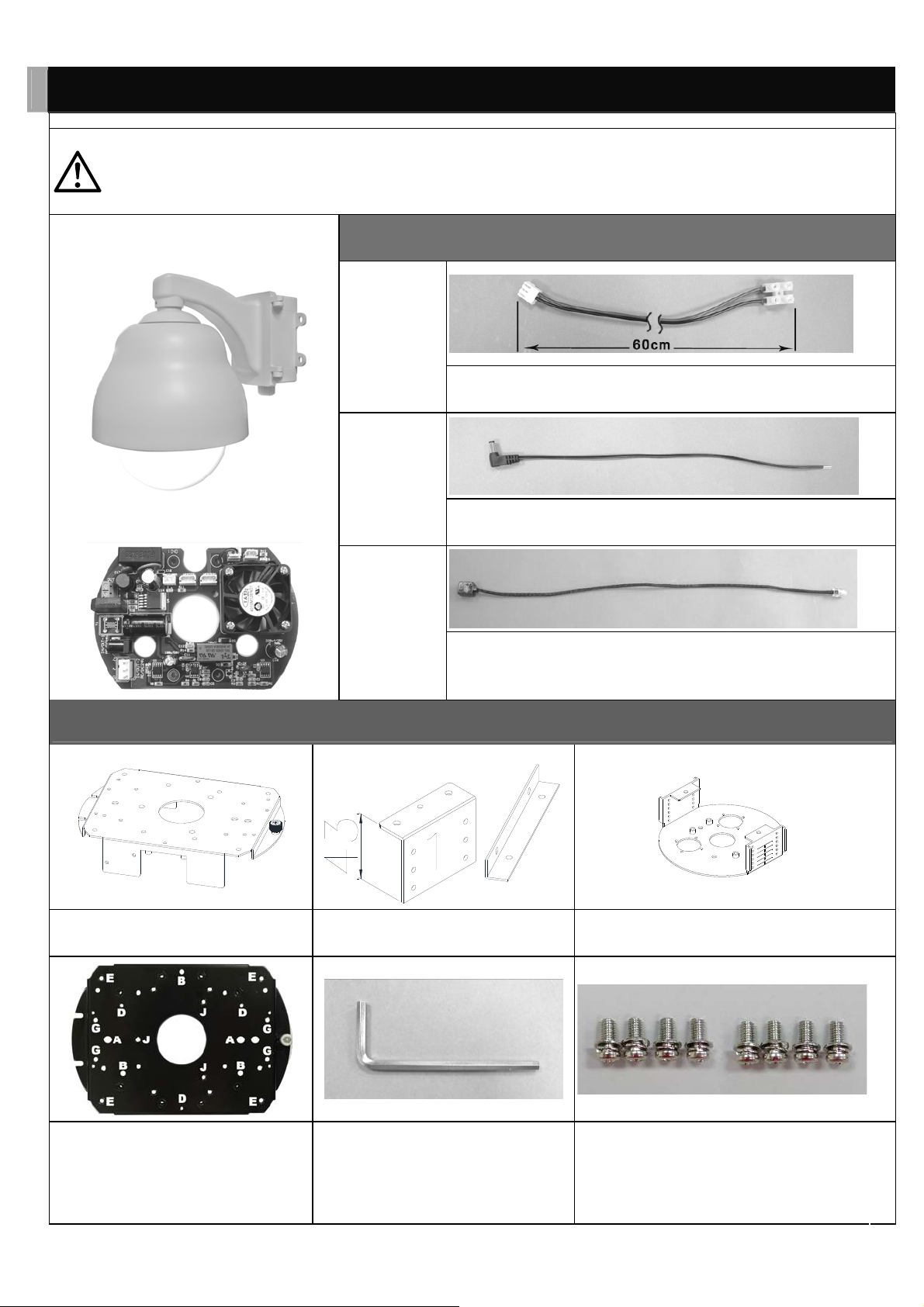

2 AXIS 215 PTZ network camera Housing installation

The unit must be properly and securely mounted to a supporting

WARNING

structure capable of sustaining the weight of unit. Recommend use

stainless screws.

9” dome housing

DC12V Fan+Heater

Cables

L603

L704

L705

Power cable to PC board and external power supply

Power cable to PC board and PTZ network camera

Network extension cable to internet

Component Parts for Assembly

Square-shaped upper board No. 3 side board Round-shaped bottom board

Screw the camera on, through h ole G,

with washer in the back

No. 3 Allen Key ( for cover and wall

mount bracket tighten)

4x10 Double Washer screws for

camera to Square-shaped upper

board,

Page 8

7

Assembly Steps of the Camera and the Dome Housing

2-1-1 2-1-2 2-1-3

Fix No. 3 side board (Hole 1) to the

round-shaped bottom board (Hole 6)

with 3x8 Double Washer screws.

Use 4x8 double washer screws to

Fix Fan/Heater side board on

Round-shaped bottom board,

connect power cable to Fan/Heater

Fix screws on front of square-shaped

upper board to fix the camera on

square-shaped upper board (Hole G)

with 4x10 double washer screws.

Assembly Steps of the Cables

L704 L603

2-2-1 2-2-2 2-2-3

Use 4x8 double washer to Fix

Fan/Heater side board on

Round-shaped bottom board,

connect power cable to Fan/Heater

Connect L603 to the PC board.

Connect L704 to the PC board.

Connect L704 and L705 to the

camera. Cables used for camera.

L704 L705

2

3

4

1

5

1. DC 12V FAN

2. DC 12V HEATER

3. H/SENSER

4. DC 12V OUT

5. DC 12V IN

Page 9

8

3 AXIS 233D PTZ network dome camera Housing installation

The unit must be properly and securely mounted to a supporting

WARNING

structure capable of sustaining the weight of unit. Recommend use

stainless screw s.

9” dome housing

AC24V Fan+Heater

Cables

L605P-2

L704P-2.0

L705

Power cable to PC board and external power supply

Power cable to PC board and camera

Network extension ca ble to internet

Component Parts for Assembly

Square-shaped upper board No. 1 side board & L board Round-shaped bottom board

Screw the camera on, through hole E,

with washer in the back

No. 3 Allen Key ( for cover and wall

mount bracket tighten)

4x10 Double Washer screws for camera

to Square-shaped upper board,

Page 10

9

Assembly Steps of the Camera and the Dome Housing

3-1-1 3-1-2 3-1-3

Fix No. 1 side board (Hole 1) to the

round-shaped bottom board (Hole 5)

with 3x8 Double Washer screws.

Fix screws on front of square-shaped

upper board to fix the L board on

square-shaped upper board (Hole E)

with 4x10 double washer screws.

Fix the camera to the L board with

4x10 double washer screws.

Assembly Steps of the Cables

L704P-2.0 L605P-2

3-2-1 3-2-2 3-2-3

Use 4x8 double washer to Fix

Fan/Heater side board on

Round-shaped bottom board,

connect power cable to Fan/Heater

Connect L605P-2 to the PC board.

Connect L704P-2.0 to the PC board .

Connect L704P-2.0 and L705 to the

camera. Cables used for camera.

L705 L704P-2.0

2

3

4

1

5

6

1. DC 12V FAN

2. AC 24V HEATER

3. H/SENSER

4. DC 12V OUT

5. AC 24V OUT

6. AC 24V IN

Page 11

10

4 AXIS P55XX series PTZ network dome camera Housing installation

The unit must be properly and securely mounted to a supporting

WARNING

structure capable of sustaining the weight of unit. Recommend use

stainless screws.

9” dome housing

AC24V Fan+Heater

Cables

L605P-2

L704P-2.0

L705

Power cable to PC board and external power supply

Power cable to PC board and camera

Network extension cable to internet

Component Parts for Assembly

Square-shaped upper board No. 2 side board Round-shaped bottom board

Screw the camera on, through hole J,

with washer in the back

No. 3 Allen Key ( for cover and wall

mount bracket tighten)

4x10 Double Washer screws for

camera to Square-shaped upper board,

Page 12

11

Assembly Steps of the Camera and the Dome Housing

4-1-1 4-1-2

Fix No. 2 side board (Hole 2) to the

round-shaped bottom board (Hole 5)

with 3x8 Double Washer screws.

Fix screws on front of square-shaped upper board to fix the camera base

on square-shaped upper board (Hole J) with 4x10 double washer screws.

Then tighten camera on camera base.

Assembly Steps of the Cables

L704P-2.0 L605P-2

4-2-1 4-2-2 4-2-3

Use 4x8 double washer to Fix

Heater side board on Round-shaped

bottom board, connect power cable

to Heater

Connect L605P-2 to the PC board.

Connect L704P-2.0 to the PC board .

Connect L704P-2.0 and L705 to the

camera. Cables used for camera.

L705 L704P-2.0

1. DC 12V FAN

2. AC 24V HEATER

3. H/SENSER

2

3

4

5

6

1

4. DC 12V OUT

5. AC 24V OUT

6. AC 24V IN

Page 13

12

5 AXIS Q6034 PTZ network dome camera Housing installation

The unit must be properly and securely mounted to a supporting

WARNING

structure capable of sustaining the weight of unit. Recommend use

stainless screws.

9” dome housing

AC24V Fan+Heater

Cables

L605P-2

L704P-2.0

L705

Power cable to PC board and external power supply

Power cable to PC board and camera

Network extension cable to internet

Component Parts for Assembly

Square-shaped upper board No side board needed Round-shaped bottom board

Screw the camera on, through hole J,

with washer in the back

No. 3 Allen Key ( for cover and wall

mount bracket tighten)

4x10 Double Washer screws for

camera to Square-shaped upper board,

5x10 Double Washer screws for

Square-shaped upper board to

Round-shaped bottom board

Page 14

13

Assembly Steps of the Camera and the Dome Housing

5-1-1 5-1-2

Use 4x8 double washer screws to

Fix Heater side board on

Round-shaped bottom board,

connect power cable to Heater

Fix screws on front of square-shaped upper board to fix the camera base

on square-shaped upper board (Hole J) with 4x10 double washer screws.

Then tighten camera on camera base.

Assembly Steps of the Cables

L704P-2.0 L605P-2

5-2-1 5-2-2 5-2-3

Use 4x8 double washer to Fix

Heater side board on Round-shaped

bottom board, connect power cable

to Heater

Connect L605P-2 to the PC board.

Connect L704P-2.0 to the PC board .

Connect L704P-2.0 and L705 to the

camera. Cables used for camera.

L705 L704P-2.0

1. DC 12V FAN

2. AC 24V HEATER

3. H/SENSER

2

3

4

5

6

1

4. DC 12V OUT

5. AC 24V OUT

6. AC 24V IN

Page 15

14

6 Installation of FC-9002 Pole Mount Bracket and Dome housing

6-1 6-2-1 6-2-2

FC-9002 Pole Mount Bracket

For installation with FC-9009 +

FC-9010 (wall mount bracket and

power box), screw FC-9010 power

box on FC-9002 Pole Mount Bracket

For installation with FC-9009N wall

mount bracket, screw FC-9009N on

FC-9002 Pole Mount Bracket

6-3 6-4

Thread the hoop through FC-9002 Fasten hoop tightly with flathead

screwdriver

Page 16

15

7 Installation of FC-9005 Ceil Mount Bracket and Dome housing

7-1 7-2 7-3

Fix FC-9010 power box on ceil Twist and Tighten the Pole to the

Top of FC-9005

Insert cables through power box

and FC-9005, buckle up the safety

rope, and then tighten up screws

7-4 7-5 7-6

Fix dome housing with FC-9005

bracket

Fix camera to dome housing and

connect the cables

Use Hex Head Cap nut to fix cover

and dome housing

Page 17

16

8 Installation of FC-9006 Ceil Mount Bracket and Dome housing

8-1 8-2 8-3

Top of FC-9006 Pendant Mount

Bracket

Twist and Tighten the Pole

clockwise to the Top of FC-9006

(Two HEX HEAD CAP SCREWS

are already installed on Pole), use

Allen Key to tighten the screws. .

Insert cables through FC-9006

8-4 8-5 8-6

Fix FC-9006 bracket on the ceil Assemble the dome housing and the

bracket, and use Allen Key to fix

screws tightly. Fix camera to dome

housing and connect the cables

Use Hex Head Cap nut to fix cover

and dome housing

Page 18

17

Installation of FC-9007 Corner Adapter with Wall Mount Bracket and

9

Dome housing

9-1 9-2 9-3

FC-9007 Exterior Angle 90°

Corner Adapter Part1

FC-9007 Exterior Angle 90° Corner

Adapter Part2

Join FC-9007 Part1 and Part2

together

9-4 9-5 9-6

Tighten Hex Head Cap screws

clockwise

Then fix whole FC-9007 Exterior Angle

90° Corner Adapter on the wall

Fix Wall Mount Bracket on FC-9007

Corner Adapter with washer in the front

and the screw nut in the back

Page 19

18

Installation of FC-9008 Corner Adapter with Wall Mount Bracket

10

and Dome housing

10-1 10-2 10-3

FC-9008 Interior Angle 90° Corner

Adapter Part1

FC-9008 Interior Angle 90° Corner

Adapter Part2

Join FC-9008 Part1 and Part2

together

10-4 10-5 10-6

Tighten Hex Head Cap screws

clockwise

Then fix whole FC-9008 Interior

Angle 90° Corner Adapter on the

wall

Fix Wall Mount Bracket on FC-9008

Corner Adapter with washer in the

front and the screw nut in the back

Page 20

19

11 Installation of FC-9009N Wall Mount Bracket and Dome housing

11-1 11-2 11-3

FC-9009N Wall Mount Bracket

Put cables through bracket Fix bracket on wall

11-4 11-5 11-6

Assemble the dome housing and the

bracket, and use Allen Key to fix

4x10 screws tightly.

Fix camera to dome housing and

connect the cables

Use Hex Head Cap nut to fix cover

and dome housing

Page 21

20

12 Installation of FC-9009 Wall Mount Bracket and Dome housing

12-1 12-2 12-3

Fix mounting holder to the Dome

housing.

Put cables through the bracket. Assemble the Dome housing and the

bracket.

12-4 12-5 12-6

Fix camera to dome housing and

connect the cables

Use Hex Head Cap nut to fix cover

and dome housing

Fix the power box to the wall or to the

column.

12-7 12-8

Have the bracket hooked up to the

tenon of the power box.

Buckle up the safety rope and then

connect cables with the outward

cables.

12-9

The completed assembl y.

Page 22

21

13 Installation of FC-9011 Ceil Mount Bracket and Dome housing

13-1 13-2 13-3

Twist and Tighten the Pole to the

Top of FC-9011

Fix FC-9011 on Ceil Insert cables through FC-9011

13-4 13-5 13-6

Fix dome housing with FC-9011

bracket

Fix camera to dome housing and

connect the cables

Use Hex Head Cap nut to fix cover

and dome housing

Page 23

22

14 Dimensions

133

115

52

14-1 14-2 14-3

FC-29W 9” housing Internal

dimensions

FC-9002 Pole Mount Bracket

FC-9005 Pendant Mount Bracket

100

43

193

175

14-4 14-5 14-6

FC-9009N or FC-9009 Wall Mount

Bracket dimensions

FC-9006-30 30cm Pendant Mount

Bracket dimensions

14-7 14-8 14-9

FC-9008 Interior Angle 90° Corner

Adapter dimensions

FC-9010 Power Box dimensions

FC-9007 Exterior Angle 90° Corner

Adapter dimensions

52

FC-9011 Pendant Mount Bracket

125

71

100

180

125

172

219

Page 24

23

IMPORTANT SAFEGUARDS

1. Read Instructions – All the safety and operating instructions

should be read before operating the unit.

2. Retain Instructions – The safety and operating instructions

should be retained for future reference.

3. Heed Warnings – All warnings on the unit and in the operating

instructions should be adhered to.

4. Follow Instructions – All operating user instructions should be

followed.

5. Electrical Connections – Only a qualified electr ician should make

the electrical connections.

6. Attachments – Do not use attachments not recommended by the

product manufacturer as they may cause hazards.

7. Cable Runs – All cable runs must be within permissible distance.

8. Mounting – This unit must be properly and securely mounted to a

supporting structure capable of sustaining the weight of the unit.

Accordingly:

a. The installation should be made by qualified installer.

b. The installation should be in compliance with local codes.

c. Care should be exercised to select suitable hardware to install

the unit, taking into account both the composition of the

mounting surface and the weight of the unit. Be sure to

periodically exami ne the unit and the supporting structure to

make sure that the integrity of the installation is intact. Failure

to comply with the foregoing could result in the unit

separating from the support structure and falling, with

resultant damages or injury to anyone or anything struck by

the falling unit.

SAFETY PRECAUTIONS

CAUTION

RISK OF

CAUTION: TO REDUCE THE RISK OF

ELECTRICA L SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE.

ELECTRIC SHOCK!

The lightning flash with an arrowhead

symbol, within an equilateral triangle, is intended

to alert the user to the presence of non-insulated

“dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamati on point within an equilateral

triangle is intended to alert the user to presence of

important operating and maintenance (servicing)

instructions in the literat ure accom panying th e

appliance.

UNPACKING

Unpack carefully. Ele ctri c compon ents can be damaged if

improperly handled or dropped. If any of the products appears to have

been damaged during the shipment, replace it properly in its carton and

notify the shippe r.

Be sure to save:

1. The shipping carton and packaging material. They are the safest

material in which to make future shipments of the equip ment

2. The Installation and Operating Instructions.

Page 25

Page 26

Page 27

Page 28

Loading...

Loading...