Axis D201-S XPT Q6055 Explosion-Protected PTZ Network Camera Manufacturer specific manual

SPECTRUM D201-(1)-Q6055-E-BD Series

D201-A-Q6055-E-BD

D201-S-Q6055-E-BD

Explosion Proof Network Camera

Installation Manual

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

1

This pageintentionallyleftblank

INSTALLATION MANUAL REV-1

2D201-1-Q6055 REV 4 105607312018 D SERIES

Information in this document is subject to change without notice. All terms

Aug 30, 2018

Oct 10, 2018

July 15, 2019

Feb 5, 2020

Feb 18, 2020

mentioned in this manual that are known to be trademarks have been

appropriately capitalized. Spectrum Camera Solutions LLC acknowledges

all trademark(s) and the rights of the trademark(s) owned by the company

referred to herein.

Release Date:08/30/2018

Document Name D201-(1)-Q6055-E-BD

© Copyright 2019 by Spectrum Camera Solutions LLC All rights

reserved

Revision Record

Rev. Description Date

0 Initial Release

1 Updated

2 EU

3 Format adjust

4 coc

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

3

Copyright Notice:

This document contains information proprietary to Spectrum Camera Solutions LLC

with all rights reserved worldwide. Any reproduction or disclosure of this publication,

or any part thereof, to persons other than Spectrum Camera Solutions, Inc.

personnel or customers is strictly prohibited, except by written permission of

Spectrum Camera Solutions, Inc. Unauthorized use, disclosure, reproduction, or

translation of this publication will result in Spectrum Camera Solutions, Inc.

exercising maximum possible legal action against all persons and / or organizations

involved.

Disclaimer:

Spectrum Camera Solutions LLC makes no representations or warranties with

respect to the contents hereof. Further, Spectrum Camera Solutions LLC reserves

the right to revise this publication and to make changes in the content hereof, without

obligation to notify any person or organization of such revision or changes.

Patent Notice:

Manufactured under United States US Patent 9917428 & US Patent D858611

Trademark Information:

Spectrum Camera Solutions LLC and its logo(s) are trademark(s) of Spectrum

Camera Solutions LLC.

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

4

Table of Contents

Legal Notices and Revision History Inside front cover

DESCRIPTION 6

MODEL MATRIX 7

LABELS 8

STANDARDS AND CERTIFICATIONS 9

DOCUMENT SYMBOLS 10

HOW TO USE THIS MANUAL 11

Page

GENERAL SAFETY AND OPERATING INFORMATION 12

SPECIFICATIONS 15

UNBOXING 17

HARDWARE BOM 18

WIRING ENTRIES 19

INSTALLATION 20

DIMENTIONAL GENERAL ASSEMBLY 25

DISMANTLING & MAINTENANCE 26

MOUNTING OPTIONS 28

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

5

DESCRIPTION

The “D” Series includes a full range of Stainless Steel or Anodized Aluminum camera stations

specifically designed for Hazardous Area Applications.

Spectrum’s D Series is the first Class I II III Division 1 rated dome style explosion proof

housings and utilizes the most robust and advanced camera technologies available. The D

Series was designed with the integrator in mind and offers features not available in competing

EX camera systems available in the market. The solution is Patented with features including a

uniform constructed enclosure consisting of an integrated junction box milled directly to the

camera housing. This eliminates the need for extra equipment, reduces installation time,

reduces labor expenses, and increases safety by lessening the potential for mismatched

hazardous rated components. Additionally, the D Series are constructed with a proprietary

explosion resistant polymer blend offering maximum clarity and enhance optical performance.

To enhance optical performance, the explosion proof lens is equipped with our Virtual Wiper

Nano Technology. The series are available in anodized aluminum or 316L Stainless steel

ensuring protection against rain, dust and corrosion within a wide temperature range between 20°C to 55°C. This feature ensures operation under extreme weather conditions and hazardous

environments. It is suitable for monitoring wide open indoor/outdoor spaces such as refineries,

wellheads, pipelines, offshore installations, remote and harsh locations where high-level

reliability and precision are always required.

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

6

Option A- Model Matrix- D100-D500*

CODE “XX”

01

D(N)(XX)-(1)-(CCCCCC)-BD

N=(1) HOUSING LENGTH=3.32 in

N=(2) HOUSING LENGTH=7.75 in

N=(3) HOUSING LENGTH=4.5 in

N=(4) HOUSING LENGTH=5 in

N=(5) HOUSING LENGTH= 5.5 in

XX= Internal Equipment Manufacturer Code**

1= (A) Aluminum Housing with SS 316L Dome Ring

1= (S) Stainless Steel 316L Housing

C= Internal Equipment Part Number from Manufacturer***

BD= Optional Breather drain model****

*Internal components and D Series must be approved by Spectrum

**Internal Equipment Manufacturer Code below

***Must be approved and verified by Spectrum

****Models supplied with Breather Drains will have IP66 ingress protection level

Manufacture

AXIS COMMUNICATIONS

D201-1-Q6055 REV 4 105607312018 D SERIES

INSTALLATION MANUAL REV-1

7

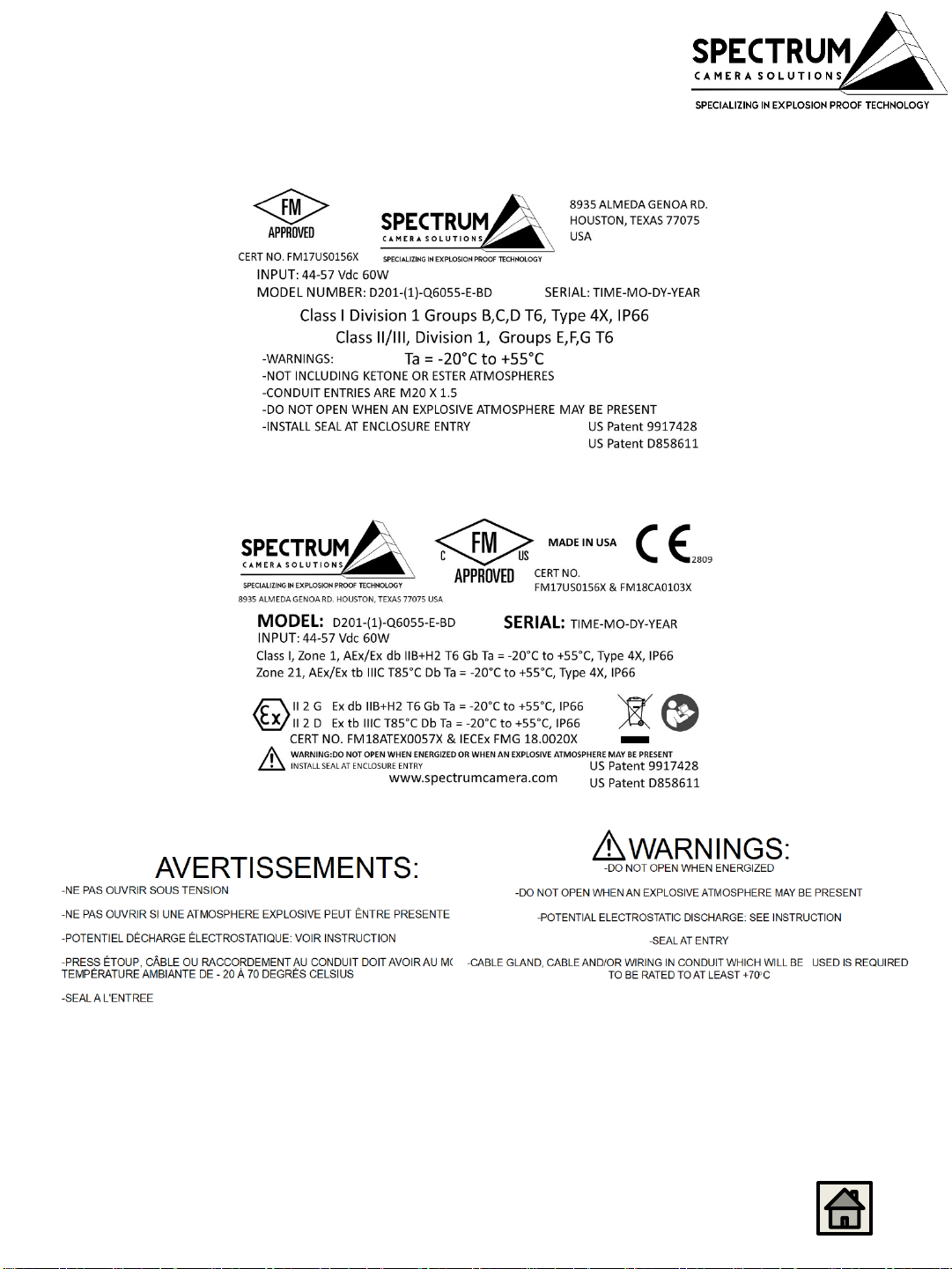

Labels Option A

BREATHER DRAIN MODEL

BREATHER DRAIN MODEL

INSTALLATION MANUAL REV-1

8D201-1-Q6055 REV 4 105607312018 D SERIES

STANDARDS & CERTIFICATIONS

STANDARDS-

The equipment is manufactured in accordance with the IECEX scheme, the ATEX Directive 94/9CE and with the

following standards :

IEC 60079-0:2011

IEC 60079-1:2014

IEC 60079-31:2013

IEC 60529:2013

EN 60079-0:2012 + A11:2013

EN 60079-1:2014

EN 60079-31:2014

EN 60529:1991 + A1:2000 + A2:2013

ANSI/ISA 60079-0:2013

ANSI/UL 60079-1:2015

ANSI/ISA 60079-31:2015

ANSI/IEC 60529:2004

CAN/CSA-C22.2 No. 60079-0:2015

CAN/CSA-C22.2 No. 60079-1:2016

CAN/CSA-C22.2 No. 60079-31:2015

CAN/CSA-C22.2 No. 60529:2016

Specific Conditions of Use:

-The flameproof joints of the equipment are not intended to be repaired. Consult the manufacturer if dimensional

information on the flameproof joints is necessary.

-Follow the manufacturer’s instructions to reduce the potential of an electrostatic charging hazard on the surface

of the equipment in Group II and III environments.

-The equipment meets the requirements according to the low level risk of mechanical danger. Therefore, the

equipment shall be located and installed such that the risk of impact or other mechanical damage is reduced or

avoided.

NOTE: Use a clean cloth dampened with pure water for cleaning.

CERTIFICATIONS-

CERT NO. FM17US0156X & FM18CA0103X

Class I Division 1 Groups B,C,D T6, Ta = -20°C to +55°CType 4X, IP66/67

Class II/III, Division 1, Groups E,F,G T6 Type 4X, IP66/67 Ta = -20°C to +55°C

Class I, Zone 1, AEx/Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, Type 4X, IP66/67

Zone 21, AEx/Ex tb IIIC T85°C Db Ta = -20°C to +55°C, Type 4X, IP66/67

CERT NO. FM18ATEX0057X & IECEx FMG 18.0020X

II 2 G Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, IP66/67

II 2 D Ex tb IIIC T85°C Db Ta = -20°C to +55°C, IP66/67

INSTALLATION MANUAL REV-1

9D201-1-Q6055 REV 4 105607312018 D SERIES

DOCUMENT SYMBOLS

The following symbols are used throughout this manual to alert users to potential

hazards or important information. Failure to heed the warnings and cautions listed

herein can lead to injury and equipment damage.

Symbol Label Description

WARNING:

CAUTION:

Consists of conditions, practices, or procedures that

must be observed to prevent personal injury and/or

equipment damage.

Risk of electric shock or high temperature parts may

result in injury if proper precautions are not taken.

NOTE:

Emphasizes important or essential information.

Locating Information:

NOTE: In the interest of completeness, manuals and drawings included with the

system may provide information pertaining to options not included with your

equipment. Information in application notes supersedes general information in

these documents. Information can be in this manual using any of the following aids.

INSTALLATION MANUAL REV-1

10D201-1-Q6055 REV 4 105607312018 D SERIES

How to use this Manual

General Manual:

This manual is intended to be used in conjunction with installed equipment

manual from internal equipment manufacturer.

Note: In the event of a conflict between the requirements of this general

installation manual and the internal equipment manual, the safety and

installation procedures described in this manual shall take precedence.

Safety Considerations:

This information that must be read and understood by all persons installing,

using, or maintaining this equipment. This manual is designed to aid

personnel in the correct and safe installation, operation, and maintenance of

the systems described. Personnel must consider all actions and procedures

for potential hazards or conditions that may not have been anticipated in the

written procedures. If a procedure cannot be performed safely, it must not be

performed until appropriate actions can be taken to ensure the safety of

equipment and personnel. The procedures in this manual are not designed to

replace or supersede required or common-sense safety practices. All safety

warnings listed in any documents applicable to equipment and parts used in

or with the system described in this manual must be read and heeded before

commencing work on any part of the system.

NOTE: Refer to all ATEX, CSA, IECEx, NEC, NFPA and FM certificates

for any Special Conditions of Use. If the sign “X” is placed after the

certificate number, it indicates that the equipment or protective

system is subject to special conditions for safe use specified in the

schedule of the certificate.

NOTE: Review all material and safety information in this manual and

install in accordance with this document and all other applicable

ATEX, CSA, IECEx, NEC, NFPA70 Installation Methods and FM and

National standards.

Warning- Failure to follow appropriate safety procedures or

appropriate use of the equipment described in this manual can lead to

injury of personnel or equipment damage.

WARNING – EXPLOSION HAZARD – Do not open equipment

unless power has been removed or the area is known to be nonhazardous.

INSTALLATION MANUAL REV-1

11D201-1-Q6055 REV 4 105607312018 D SERIES

Loading...

Loading...