Page 1

PASTA COOKER Model : AX-SPG & AX-DPG

USER AND TECHNICAL MANUAL

PRODUCTION YEAR: SERIAL NR:

PUBLISHED ON : : 07.12.2006

VERSION . 06

1/19

GAS TYPE/PRESSURE

Natural gas

Propane gas

MVP GROUP CORPORATION 5659 ROYALMOUNT MONTREAL, QC. CANADA H4P 2P9

Tel: (514)737-9701 Fax: (514)342-3854

www.mvpgroupcorp.com www.axis-equipment.com

Page 2

TABLE OF CONTENTS

PAGE

TOPICS

1 COVER PAGE

2 TABLE OF CONTENTS

3 INTRODUCTION

4 TECHNICAL SPECIFICATIONS (TECHNICAL MANUAL)

5 DIMENSIONS

6 SAMPLE DATA PLATE AND WARNING NOTICES

7 TRANSPORTING AND MOVING

2/19

8-9-10 INSTALLATION OF THE APPLIANCE

11 SETTING AIR ADJUSTER AND MINIMUM GAS RATE

12 POSSIBLE FAILURES AND WAYS OF ELIMINATING

13-14-15-16 OPERATION OF THE APPLIANCE (USER MANUAL)

17 CLEAN-UP AND MAINTENANCE

18 SUMMARY OF SAFETY DETAILS

19 TERMS OF WARRANTY

Page 3

INTRODUCTION

☞ Please read and ensure that that your operation person also reads this

Dear User,

Thank you for purchasing our appliance and for your reliance upon our

company. Our appliances are used in professional kitchens in 90 countries.

Important: Please read this user’s manual in order to achieve the

desired performance in line with your expectations and to use your

appliance for many years. Please take the warnings mentioned above

into consideration before calling for service.

☞ Please read and ensure that that your operation person also reads this

user’s manual carefully before using the appliance. If the appliance is operated

other way than written in this manual, it will not be covered by the warranty.

☞ The manual contains information about installation, usage and maintenance of

our product and should be read carefully. Please ensure that gas connection

to the appliance is installed by qualified personnel according to the local

regulations.

☞ If you are confused or you don’t have enough information

please get in touch with our authorized service by phone.

☞ Please keep in mind that, if the service technician is delayed

at your site, related expenses and delay costs will be charged to

you on hourly basis.

3/19

Page 4

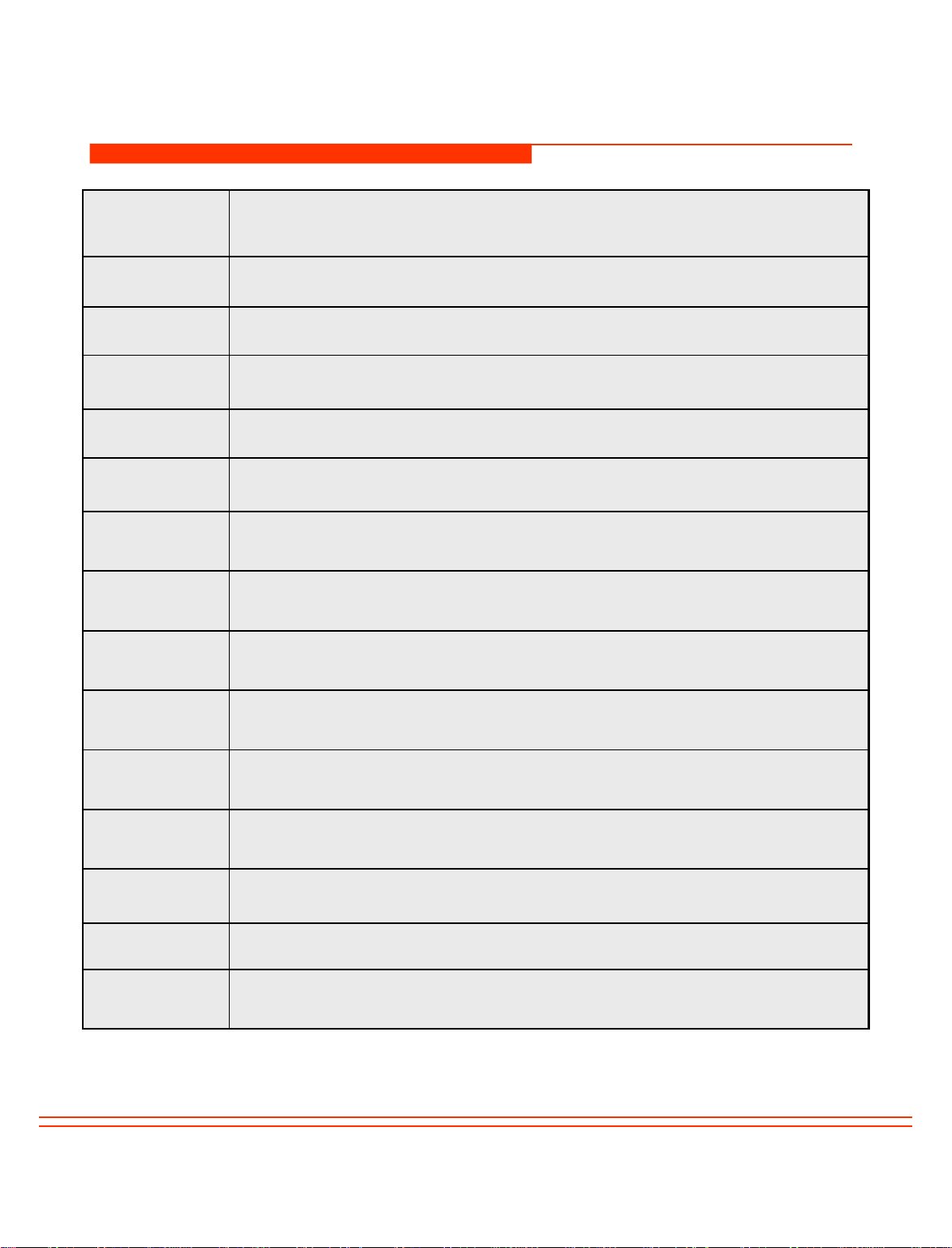

TECHNICAL SPECIFICATIONS

MODEL NAME

AX-SPG AX-DPG

APPLIED STANDARD ANSI Z83.11a-2004,

CSA 1.8a-2004;

Addenda A:2004,

Issue 2002/07/01

ANSI Z83.11a-2004,

CSA 1.8a-2004;

Addenda A:2004,

Issue 2002/07/01

Qn (HEAT INPUT Hi) (Btu/h) 61416 122832

BURNERS 2 4

CONSUMPTION Natural gas:1,615 m³/h

Propane:1,482 kg/h

Natural gas:3,23 m³/h

Propane:2,96 kg/h

GAS CONNECTION 1/2” ISO 7-1:1982 3/4” ISO 7-1:1982

Natural gas 7” WC

Natural gas 7” WC

4/19

GAS PRESSURE

Natural gas 7” WC

Propane gas 11” WC

Natural gas 7” WC

Propane gas 11” WC

BURNER NOZZLES

DIAMETER

Natural gas: Ø 2,25 mm

Propane gas: Ø 1,45

mm

Natural gas: Ø 2,25 mm

Propane gas: Ø 1,45 mm

PILOT NOZZLE ( only for oven)

Ø 0.35 mm Ø 0,35 mm

PRIMARY AIR DISTANCE (X)

(fixed by the manufacturer see

fig.6)

Open Open

TYPE OF FLUE

Not designed for

compulsory connection

to any extraction system

Not designed for

compulsory connection to

any extraction system

AIR REQUIREMENT FOR

COMBUSTION+VENTILATION

(at least 2 m³/kW in one hour)

min. 30 m³/h min. 60 m³/h

The data plate is located behind of front panel and back side of appliance.

Page 5

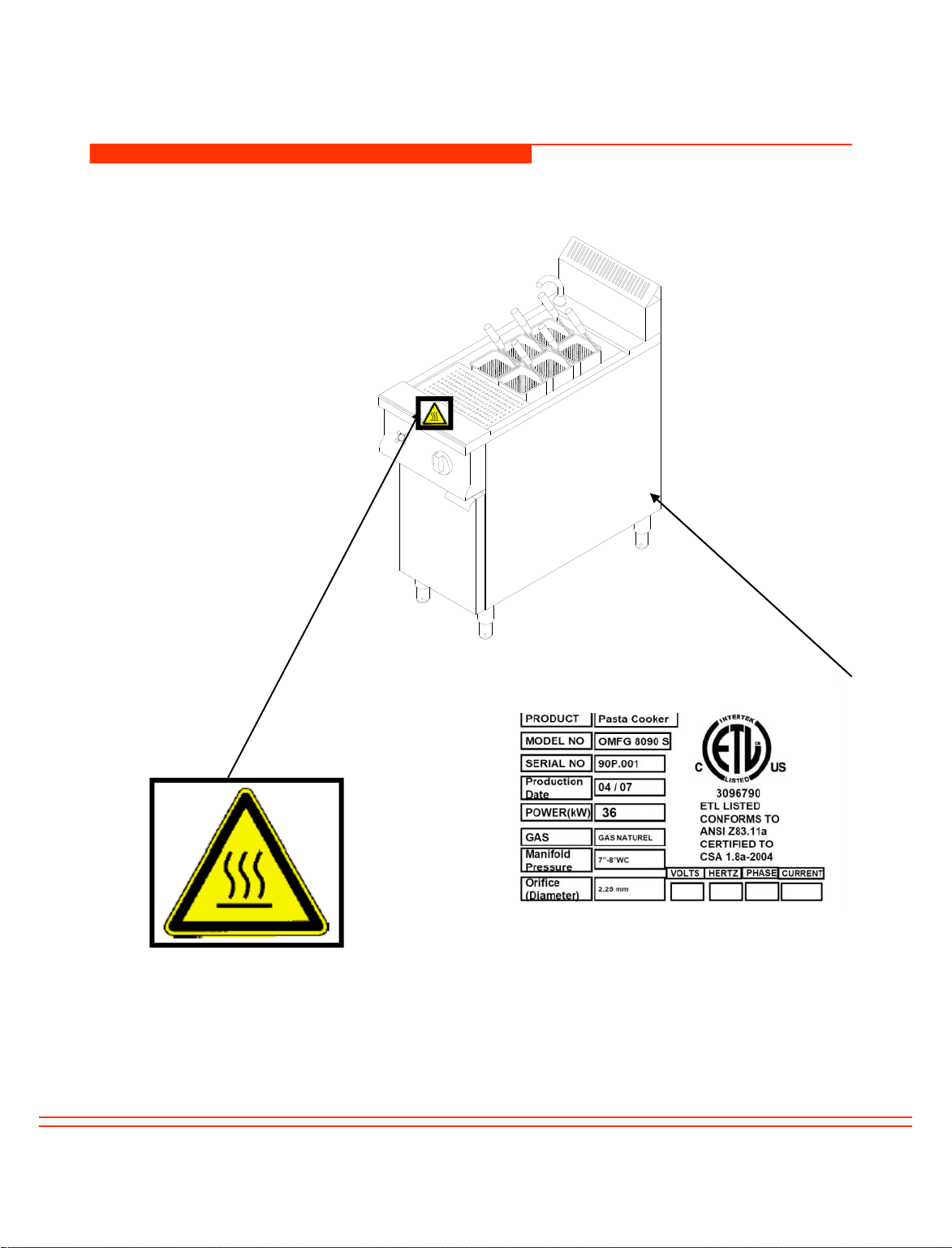

MAIN DIMENSIONS AND WARNING NOTICES

☞ MODELS AX-SPG & AX-DPG

5/19

HOT SURFACE SAMPLE LABEL

Figure 1 : Main dimensions

Page 6

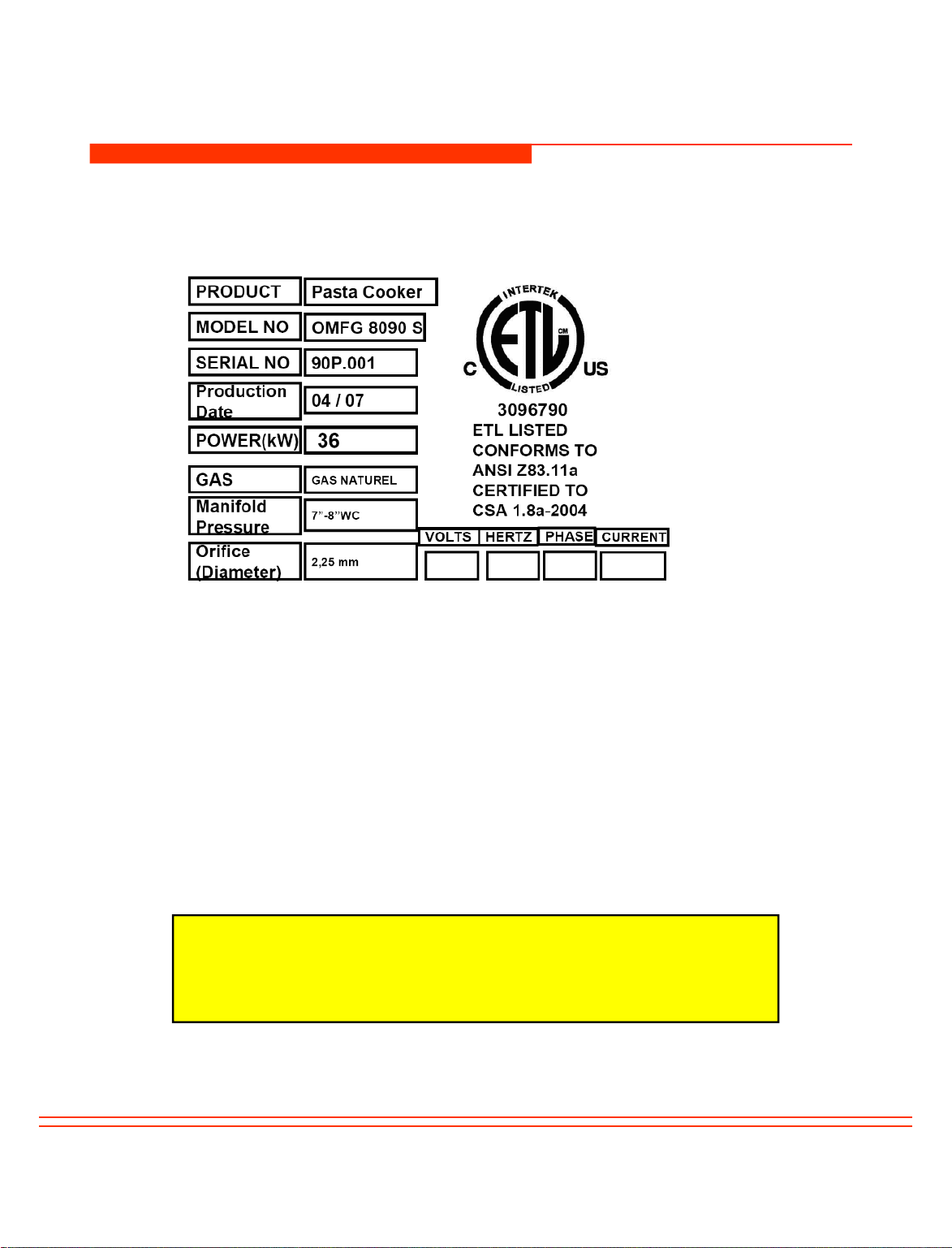

SAMPLE DATA PLATE & WARNING NOTICES

6/19

These appliances shall be installed in conformity with the

current regulations and used only in a well ventilated

location. Consult the instruction before installing and using

this appliance

Figure 2: Sample data plate

Page 7

TRANSPORTING AND MOVING

Figure 3: Transportation

☞ The appliances can be moved with supplementary vehicles like fork lift

☞ Feet of the fork lift should be placed under the appliances.

☞ During the transportation, the machine should be moved slowly and

the appliances should be fixed on the palette or supported in order to

prevent jolt.

☞ Do not hit or drop the appliance when moving.

CHANGING THE LOCATION;

Appliances installed by an authorized

technician CANNOT BE MOVED

ELSEWHERE, CONNECTION HOSES CANNOT

BE EXTENDED OR REPLACED except by an

authorized technician.

7/19

Figure 3: Transportation

Page 8

If this appliance is located near any wall, separation, kitchen

furniture, decorative coating etc. the distance in between should be

at least 8 in. If those are coated with fireproof heat insulating material, the

distance should be also at least 5 in. It is strongly recommended that local

fire safety protection instructions are observed.

INSTALLATION OF THE APPLIANCE

☞ All of the gas supply connections of the appliances should be comply

with ISO 7-1:1982

8/19

All of the items mentioned below in connection with the

installation of the appliances should be carried out by an

authorized technician.

Page 9

☞ Remove the appliance from the packaging.

INSTALLATION OF THE APPLIANCES

☞ Remove all plastic adhesive film from parts before installing the

appliance. Clean parts thoroughly to remove all adhesive residue.(Do

not use abrasive substances)

GAS LEAKAGE CHECKING

☞ Before putting into service, ensure that there are no gas leakages from

the gas system of appliance. Brush soapy water over the unions and

couplings; leaks are detected by the appearance of bubbles.

WARNING: Never use open flames to detect gas leakages.

9/19

GAS PRESSURE CHECKING

☞ Measure gas pressure by means of a water type pressure gauge (e.g. a

U-type pressure gauge with 0.1 mbar minumum resolution).

• Remove the pressure gauge test point screw “A” on the inlet gas pipe

(fig.4)

• Connect the U-type pressure gauge.

• Read the gas pressure.

• Note: If the pressure value is not within the specified limits (see

technical specifications ), do not use the appliance under any

circumtances.Inform the gas supplying company immediately.

• After pressure checking, remove the pressure gauge and tighten the

screw with a correct seal.

Page 10

INSTALLATION OF THE APPLIANCES

gas inlet

10/19

☞ Nominal power of the device cannot be changed upon

customers request. Any modifications made on valves and

injectors are very dangerous and, leaves the appliance out of

warranty coverage.

☞ Any use of non-original spare part will VOID the original warranty.

Figure 4: Gas pressure checking

Page 11

SETTING AIR ADJUSTER AND MINIMUM GAS RATE

THE ADJUSTABLE PART OF THE PRIMARY AIR UNIT , AND MINUMUM

GAS ADJUSTER FIXED (B), PLEASE KEEP THIS SETTING DURING

OPERATION.

There are adjustable primary air unit and minimum gas rate srews on

every gas value

11/19

Figure 5: minumum gas flow adjuster screw (B) fixed on valve

Page 12

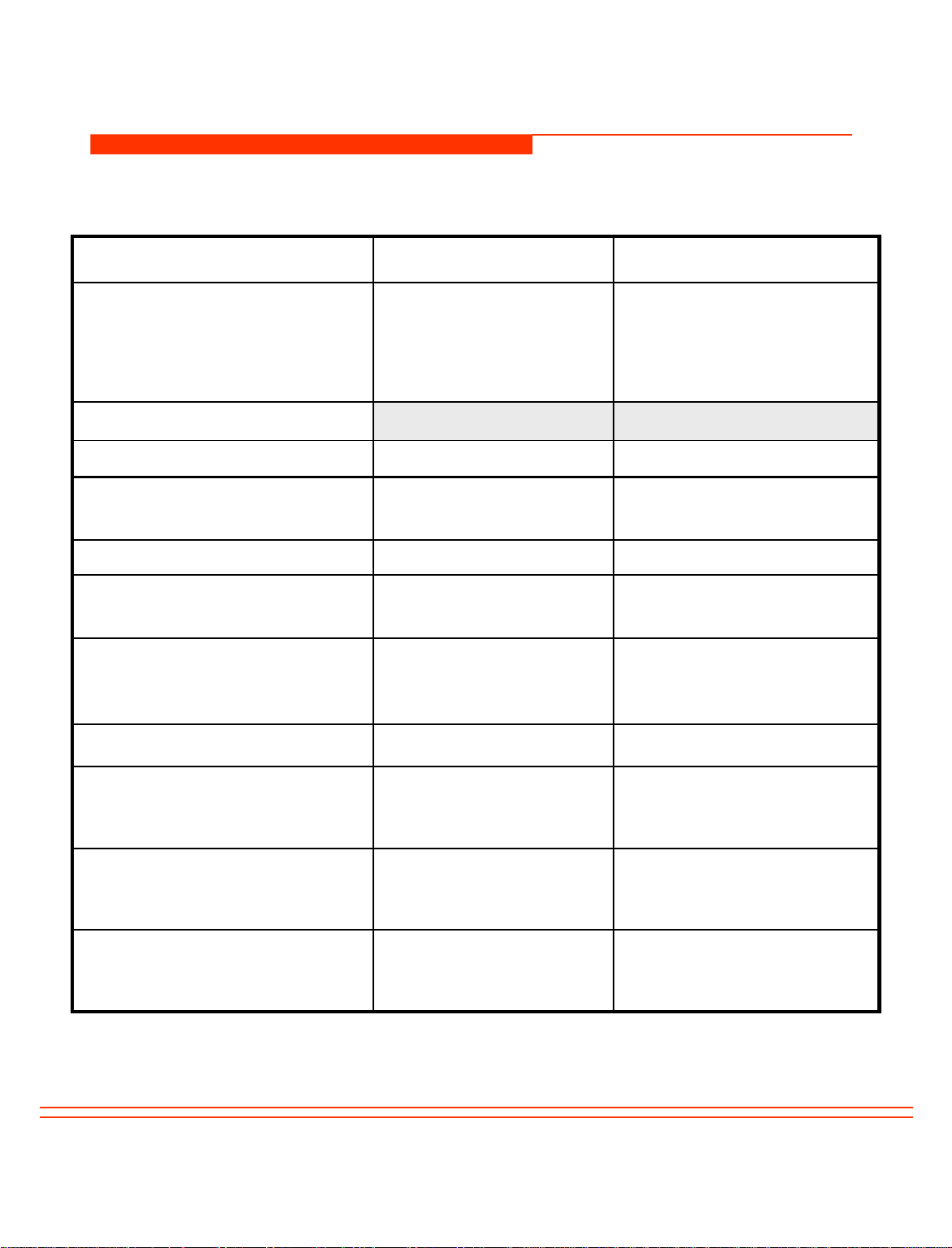

POSSIBLE FAILURES AND WAYS OF ELIMINATING

NO POSSIBLE FAILURES METHOD OF ELIMINATION

1

Appliance valve is open, but no gas is

running.

1. Check the main valve that may be

closed.

2. Main valve or appliance valve can be

damaged, call service.

2

Appliance valve is open, gas is running,

but burner does not operate.

1. Check the pilot burner position.

2. In case of thermocouple failure,

call service

3

Ignition is OK, valve is in pilot position,

the flame goes out.

1. The flame control system does not

work. Call service.

12/19

4 The temperature can not be controlled. 1. Call service.

5

Main valve is open, appliance valve is

closed, smell of gas.

1. Must control all gas connections by

checking for any leaks.

2.In case of any leakage, call service

Page 13

2. Clean the instrument exterior and the water container before use for the first

time using a wet cloth.

3. Place the cooker under an exhaust with a filter connected to an air ventilation

system.

4. Add water or replace it completely at certain intervals depending on the

frequency of use.

NOTE : Please do not use other than for its intended purpose.

The instrument must be used by a person who knows the safety and

technical conditions of use and who has read the manual.

B. USE OF THE INSTRUMENT

ATTENTION

1. Put water of the amount specified in the table for technical specifications

based on the capacity.

* the level of water must not be below the specified level.

Water level below that does not provide optimum cooking.

A. GENERAL

1. Pasta cooker is used to cook pasta, rice, vegetables, and very useful for

rethermalization..

OPERATION OF THE APPLIANCE

2. Clean the instrument exterior and the water container before use for the first

time using a wet cloth.

3. Place the cooker under an exhaust with a filter connected to an air ventilation

system.

4. Add water or replace it completely at certain intervals depending on the

frequency of use.

NOTE : Please do not use other than for its intended purpose.

The instrument must be used by a person who knows the safety and

technical conditions of use and who has read the manual.

B. USE OF THE INSTRUMENT

ATTENTION

1. Put water of the amount specified in the table for technical specifications

based on the capacity.

* the level of water must not be below the specified level.

Water level below that does not provide optimum cooking.

* The level of water must not be above the maximum level specified.

There is a risk of over boiling of water at levels above that.

* NEVER operate when there is no water inside tank.

2. IGNITING PILOT BURNER

Turn safety valve to pilot position (*) (figure 8) and hold it pressed for awhile,(at

initial use wait for 20-25 second, allowing the air in the gas pipes to exhaust and

gas to flow inside) allowing gas to come at the pilot. Then light the pilot using igniter

by types with igniter and using another source of fire (like lighting stripe or match)

by types without igniter. Pilot flame can easily be monitored.(figure 6 D) Due to the

flame control set up, the valve is pressed further (maximum 20 seconds) to ensure

the continuity of the pilot fire. If pilot flame does not go off after the safety valve is

released, please stop pressing it.

3. IGNITING MAIN BURNER(S) :

Turn safety valve max. or min. position (figure 9) The main burners will be light on

during this position .

4. After the safety valve turned max. the water will start to heat up.

5. After the temperature of the water reaches the reguired level of temperature,

pasta may be put into the baskets and lowered into the tank.

13/19

Page 14

6. After the completion of the cooking cycle,(approx 4-11 min) the baskets are

placed above the water level for excess dripping.

7. After dripping, the baskets are taken out of the cooker and pasta is served.

8. For continuous use (depending on the material to be cooked and

freguency of processing) the water should be changedat certain intervals or

water maybe added. (figure 6 B)

9. After cooking is finished, water is emptied trough the tap underneath.

Water will be hot therefore utmost care is reguired during the process of

discharging of the water in pasta cooker. (figure 6 E)

10. Shutting off the pasta cooker

If the pasta cooker will not be operated for a period of time, turn safety gas

valve to the pilot position (*)(figure 8), that only the pilot burner will operate.

In order to turn the pasta cooker off completely, turn the safety valve to OFF

position.(figure 7)

Turning off the main gas connection or gas valve is recommendet to avoid

danger.

OPERATION OF THE APPLIANCE

14/19

FLAME CONTROL DEVICE:

If for any reason the pilot flame goes out when the cooker is still on,

the system will shut itself down automatically. Turning off supply of

gas may take up to 60 seconds.

Page 15

☞ AX-SPG/DPG

SERIES

A

B

C

OPERATION OF THE APPLIANCE

A- FRESH WATER INPUT VALVE

B- FRESH WATER CONTROL KNOB

C- SAFETY VALVE CONTROL KNOB

D- FLAME MONITOR PANEL

E- WATER DISCHARGE CONTROL KNOB

15/19

D

E

FIGURE 6

Page 16

FIGURE 7

SAFETY GAS VALVE OFF POSITION

FIGURE 8

SAFETY GAS VALVE ON POSITION

OPERATION OF THE APPLIANCE

16/19

FIGURE 9

SAFETY GAS VALVE ON - MAX POSITION

FIGURE 10

SAFETY GAS VALVE ON - MIN POSITION

FLAME CONTROL SETUP

If the pilot flame extinguishes for any reason when the appliances is on, the

system will close itself down automatically to avoid dangerous gas accumulation.

You can try to restart the system again after more than 60 seconds.

Page 17

1. CLEAN-UP:

Before first use of the appliance, and before and after subsequent uses,

complete outer surface with a sponge and liquid detergent.

Do not use any abrasive CHEMICAL CLEANING AGENT or hydrochloric acid

etc. during cleaning.

2. MAINTENANCE (Can be done by authorized service personel)

Periodic maintenance should be carried out by technical service personnel.

Depending on using frequency, maintenance period should be at least 6

months. Any charges due to regular and required maintenance carried out by

our authorized service personnel must be paid by the customer.

CLEAN-UP AND MAINTENANCE

2. MAINTENANCE (Can be done by authorized service personel)

Periodic maintenance should be carried out by technical service personnel.

Depending on using frequency, maintenance period should be at least 6

months. Any charges due to regular and required maintenance carried out by

our authorized service personnel must be paid by the customer.

Please follow the instructions below:

1. Injectors: Injector opening should be completely clean.

2. Pilot: Pilot flame should be correct and touching the thermocouples.

3. Gas burner: Gas passing pipes and openings should be clean and not

clogged.

4. The parts dismantled during clean-up should be installed back by the

technical service personnel and after the installation, gas leakage must be

checked.

17/19

Page 18

SUMMARY OF SAFETY DETAILS

☞ If the appliance is operated from a propane gas

tank, the distance between the appliance and tank must

be at least 20 in.

☞ Any kind of flammable solid and liquid material (cloths,

alcohol and derivatives, petrochemical products, wooden

and plastic materials, cutting blocks, curtains etc.) should

never be stored near the appliance.

☞ Do not clean up the appliance with pressurized water

☞ This appliance is designed for industrial use and

should only be operated by trained person according

to this manual.

18/19

☞ The appliance should only be repaired by the

manufacturer or authorized service personel

☞ In case of fire in the area with an open window or door

and the appliance is operated, close all gas valves, turn off

the power switches and use a fire extinguisher. Never use

water to extinguish the fire, as this will cause the fire to

spread faster.

Page 19

TERMS OF WARRANTY

MVP Group Corporation (MVP), hereby warrants all new equipment bearing the

name “AXIS” and installed within the continental United States of America or

Canada to be free from defects in material and workmanship, under normal and

regular usage and operation, for a period of one (1) year following the date of original

installation; or to a maximum of eighteen (18) months from factory date of shipment.

If a defect in material(s) or workmanship is detected; or found to exist within the stated

period above, MVP, at its sole discretion, shall either repair or replace any original

equipment manufacturers part which has proven to fail within the machine; providing

that the equipment has not been altered or tampered with in any form or manner

whatsoever, has been installed correctly as per the users manual, and

maintained and operated in complete accordance with this manual.

The labor cost (in terms of bench warranty) to repair or replace any part proven to be

defective, as per above clause(s), shall be covered by MVP, within the continental

United States of America or Canada; provided that prior authorization for this labor

was approved by MVP, the service work was performed by an authorized MVP service

agency; and that this agency installed an original and a genuine AXIS part in

the machine. Any repair work performed by a non-authorized service depot remains

19/19

MVP Group Corporation (MVP), hereby warrants all new equipment bearing the

name “AXIS” and installed within the continental United States of America or

Canada to be free from defects in material and workmanship, under normal and

regular usage and operation, for a period of one (1) year following the date of original

installation; or to a maximum of eighteen (18) months from factory date of shipment.

If a defect in material(s) or workmanship is detected; or found to exist within the stated

period above, MVP, at its sole discretion, shall either repair or replace any original

equipment manufacturers part which has proven to fail within the machine; providing

that the equipment has not been altered or tampered with in any form or manner

whatsoever, has been installed correctly as per the users manual, and

maintained and operated in complete accordance with this manual.

The labor cost (in terms of bench warranty) to repair or replace any part proven to be

defective, as per above clause(s), shall be covered by MVP, within the continental

United States of America or Canada; provided that prior authorization for this labor

was approved by MVP, the service work was performed by an authorized MVP service

agency; and that this agency installed an original and a genuine AXIS part in

the machine. Any repair work performed by a non-authorized service depot remains

the sole responsibility of the user, and thus MVP cannot be held responsible. The

installation of any generic part will not be valid; and therefore will void

this warranty. All authorized labor coverage shall be limited to bench rates only. Any

supplemental hourly rates or charges, such as transport, weekends or

emergency premiums remain the sole responsibility of the user.

Any charges exceeding those stated herein must have prior authorization by MVP.

Exceptions to above warranty are: (A) Damages resulting from shipping,

handling or abuse (B) Incorrect installation and/or connections (C) Adjustments or

calibration of any parts (D) Faults due to lack of regular maintenance or cleaning of

any internal part(s) (E) Replacement of any wearable items such as

accessories (F) Discoloration of any components due to chemical reaction

MVP GROUP CORP. STATES THAT THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, THAT ARE NOT SET FORTH HEREIN. MVP

GROUP CORP. SHALL ASSUME NO OTHER RESPONSIBILITY, EITHER DIRECT

OR NON-DIRECT, OR BE LIABLE FOR ANY OTHER OR ADDITIONAL LOSS

OR DAMAGE WHETHER BEING DIRECT OR CONSEQUENTIAL, AS A RESULT

OF ITS EQUIPMENT.

The manufacturer reserves the rights to alter design and specifications without notice

Page 20

Loading...

Loading...