Page 1

USER

MANUAL

ATA and ATZ Series

File: 2017-01-02 ATA ATA0111 GB

ATA1200, ATA2200

ATZ1200, ATZ2200

ATA220÷ATA520

ATZ220÷ATZ520

Page 2

2 USER MANUAL

__________________________________________________________________________________________________________________

Contents:

1. General description ............................................................................................................................ 3

2. Set ...................................................................................................................................................... 3

3. Safety rules ........................................................................................................................................ 4

4. Technical data .................................................................................................................................... 5

5. General scale view ............................................................................................................................. 6

6. Keys and indicators ............................................................................................................................ 8

7. Preparing working environment .......................................................................................................... 9

8. Preparing scale to work .................................................................................................................... 10

9. General operation principles ............................................................................................................ 11

10. Internal calibration ........................................................................................................................... 12

11. Checking the balance ....................................................................................................................... 13

12. Connection with a computer or a printer ........................................................................................... 14

12.1 Detailed protocol description in standard mode ............................................................................... 15

13. Start-up ............................................................................................................................................ 18

14. Weighing with tare ............................................................................................................................ 19

15. Scale menu ...................................................................................................................................... 20

16. Menu navigation rules ...................................................................................................................... 21

17. Scale setup (SEtUP) ........................................................................................................................ 27

17.1 Scale calibration (CALIb) .................................................................................................................. 28

17.2 Autozeroing function (AutotAr) ........................................................................................................ 32

17.3 Weight unit selection (UnIt) .............................................................................................................. 33

17.4 Serial port parameters setting (SErIAL) ........................................................................................... 34

17.5 Printout configuration (PrInt)........................................................................................................... 35

17.6 Weighing speed selection (SPEED) ................................................................................................ 37

17.7 Entering reference zero value (ZErO) .............................................................................................. 38

18. Special functions description ............................................................................................................ 39

18.1 Product and user identification (Prod and USEr) .............................................................................. 40

18.2 Pieces counting function (PCS) ....................................................................................................... 42

18.3 Percentage weighing function (PErC) ............................................................................................. 43

18.4 Label choosing function (LAbEL) ...................................................................................................... 44

18.5 Weighing animals function (LOC) ..................................................................................................... 45

18.6 Constant tare memory function (tArE) .............................................................................................. 46

18.7 Maximum value indication function (UP) .......................................................................................... 48

18.8 Total weight function (totAL) ............................................................................................................. 49

18.9 Checkweighing function (thr) ............................................................................................................ 51

18.10 Setting date and time function (dAtE) ............................................................................................. 54

18.11 Statistical calculations function (StAt) ............................................................................................ 55

18.12 Function for summing recipe ingredients (rECIPE) ........................................................................ 58

19. Troubleshooting and maintenance ................................................................................................... 62

Page 3

USER MANUAL 3

__________________________________________________________________________________________________________________

1. General description

ATA i ATZ series electronic scales are destined for laboratory works which require high accuracy and for

wide range of technical purposes as well. ATA balances have internal calibration, which corrects

weighing precision during exploitation. ATZ series are not equipped with internal calibration system.

SPEEd option enables to change weighing speed that allows to adjust the balance to working conditions.

In particular, if user chooses FASt speed setting then small weight portion batching for eg. in pharmacy

is possible.

All scales are metrologically tested by manufacturer.

All balances can have legal verification (except ATZ520) or be calibrated by laboratory with PCA

accreditation.

According to an order balances can be calibrated.

NACE classification: 33.20.31.

2. Set

Standard set consists of:

1. Scale

2. Feeder

3. Draft shield with cover,

4. User manual

5. Guarantee card

Page 4

4 USER MANUAL

__________________________________________________________________________________________________________________

3. Safety rules

It is necessary to follow safety rules of work with the scale shown

below. Obeying those rules is the condition to avoid electrical shock or

damage of the scale or connected peripheral devices.

All repairs and necessary regulations can be made by authorised personnel only.

To avoid fire risk use a feeder of an appropriate type (if feeder is supplied with the scale) and

supply voltage has to be compatible with specified technical data.

Do not use the scale when its cover is opened.

Do not use the scale in explosive conditions.

Do not use the scale in high humidity environment.

If the scale seems not to operate properly, switch it off and do not use until checked by

authorised service.

According to current acts of low about protection of natural

environment, wasted scales should not be put into waste containers

together with ordinary waste.

Wasted scale after operation period can be delivered to units authorized for gathering wasted

electronic devices or to the place where it was bought.

Page 5

USER MANUAL 5

__________________________________________________________________________________________________________________

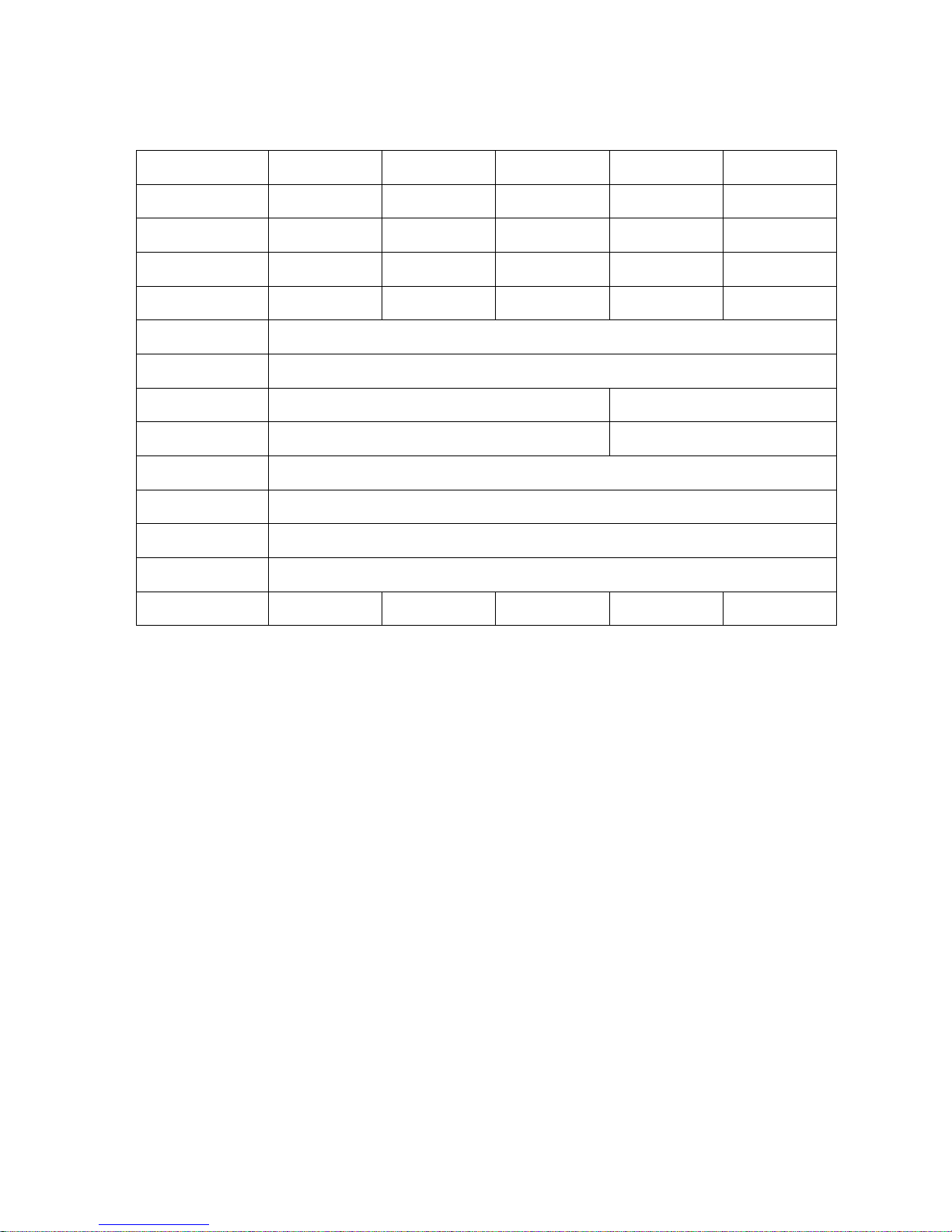

4. Technical data

Type

ATA220

ATZ220

ATA320

ATZ320

ATA520

ATZ520

ATA1200

ATZ1200

ATA2200

ATZ2200

Load (Max)

220g

320g

520g

1200g

2200g

Readout unit (d)

0,001g

0,001g

0,001g

0,01g

0,01g

Verification plot

(e)

0,01g

0,01g

0,01g

0,1g

0,1g

Tare range

-220g

-320g

-520g

-1200g

-2200g

Accuracy class

II

Working

temperature

+10 ÷ +40°C

Weighing time

< 3s

< 2s

Pan dimension

Ø115mm

Ø150mm

Dimensions

185x290x90mm

Interfaces

In standard: RS232C and USB (ATA) Options: LAN, Wi-Fi or RS485

Supply

~230V 50Hz 6VA / =12V 1,2A

Scale weight

ATA : 2,6kg ATZ: 2,1kg

Recommended

standard of mass

F2 200g

F2 200g

F1 500g

F2 1000g

F2 2000g

Note:

F2 and F1 are names of international calibration weight classes according to O.I.M.L. Requirements

about calibration weight accuracy are connected with these classes.

Page 6

6 USER MANUAL

__________________________________________________________________________________________________________________

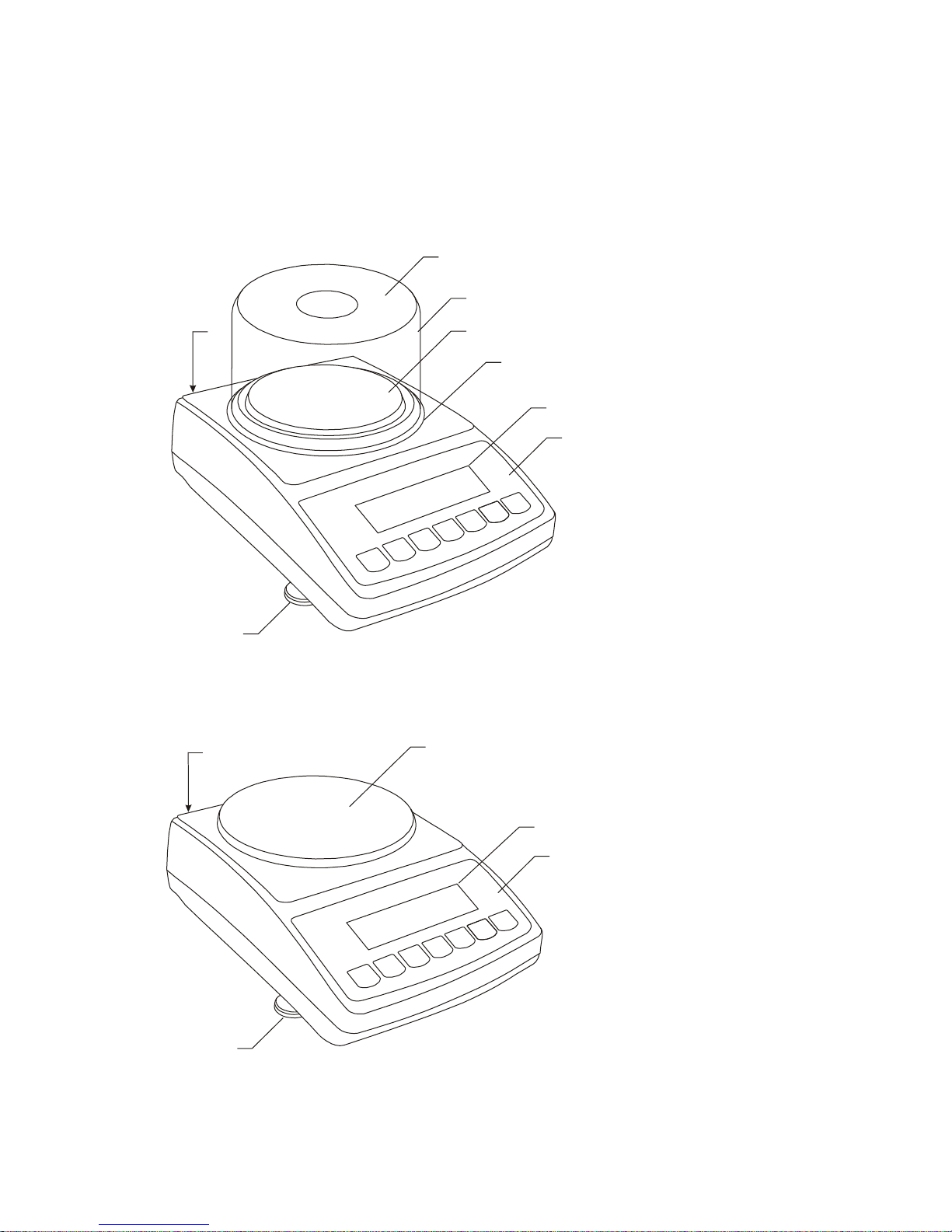

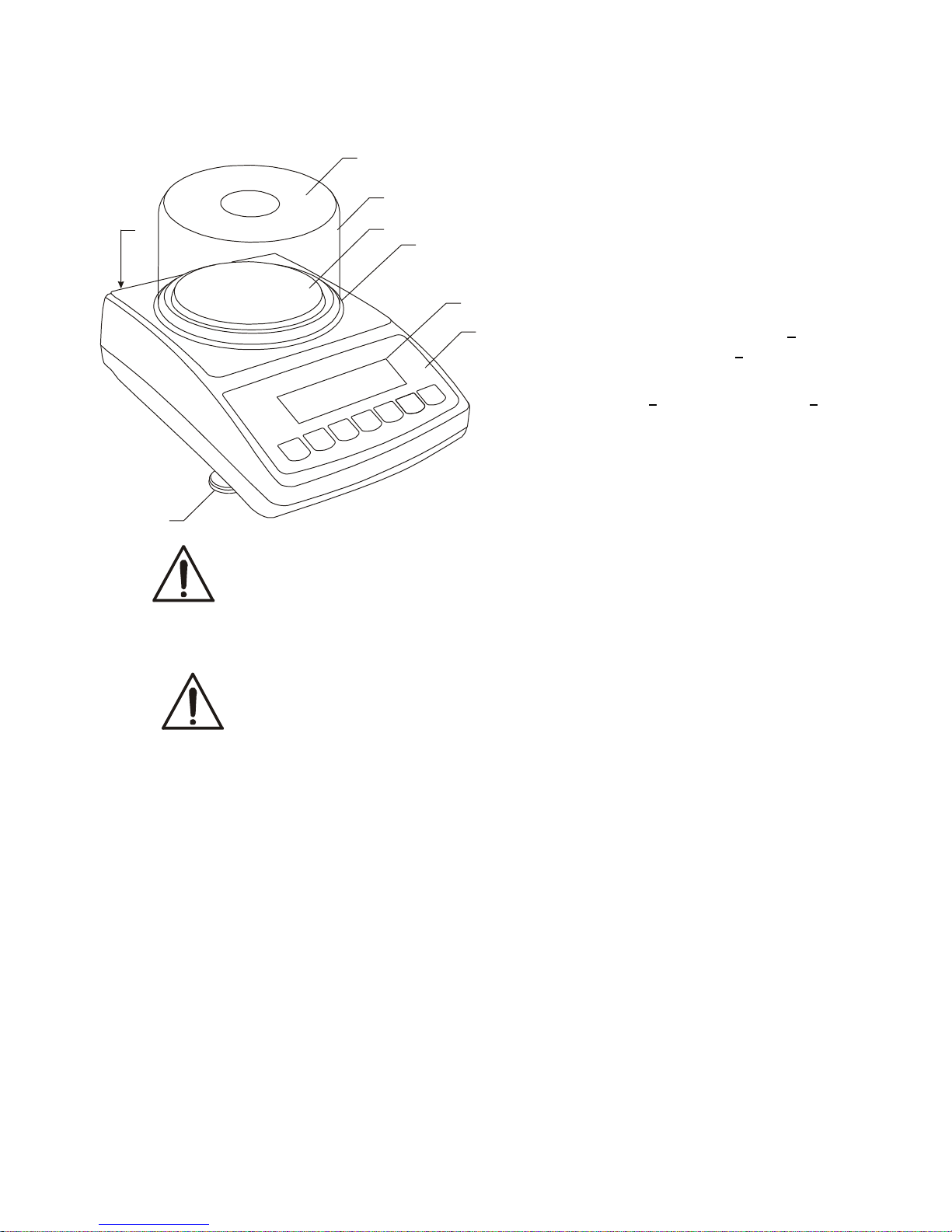

5. General scale view

ATA120÷ATA520 and ATZ120÷ATZ520 scale:

1 – pan

2 – pan support

(under pan)

3 – pan ring

(against blows)

4 – display LCD

5 – keys

6 – rotating legs

7 – water level

8 – draft shield

(option)

9 – draft shield cover

(option)

ATA1200÷ATA2200 and ATZ1200÷ATZ2200 scale:

1 – pan

2 – pan support

3 – information window

4 – display LCD

5 – keys

6 – rotating legs

7 – level

6

1

2

5

4

7

6

1

8

9

2

5

3

4

7

Page 7

USER MANUAL 7

__________________________________________________________________________________________________________________

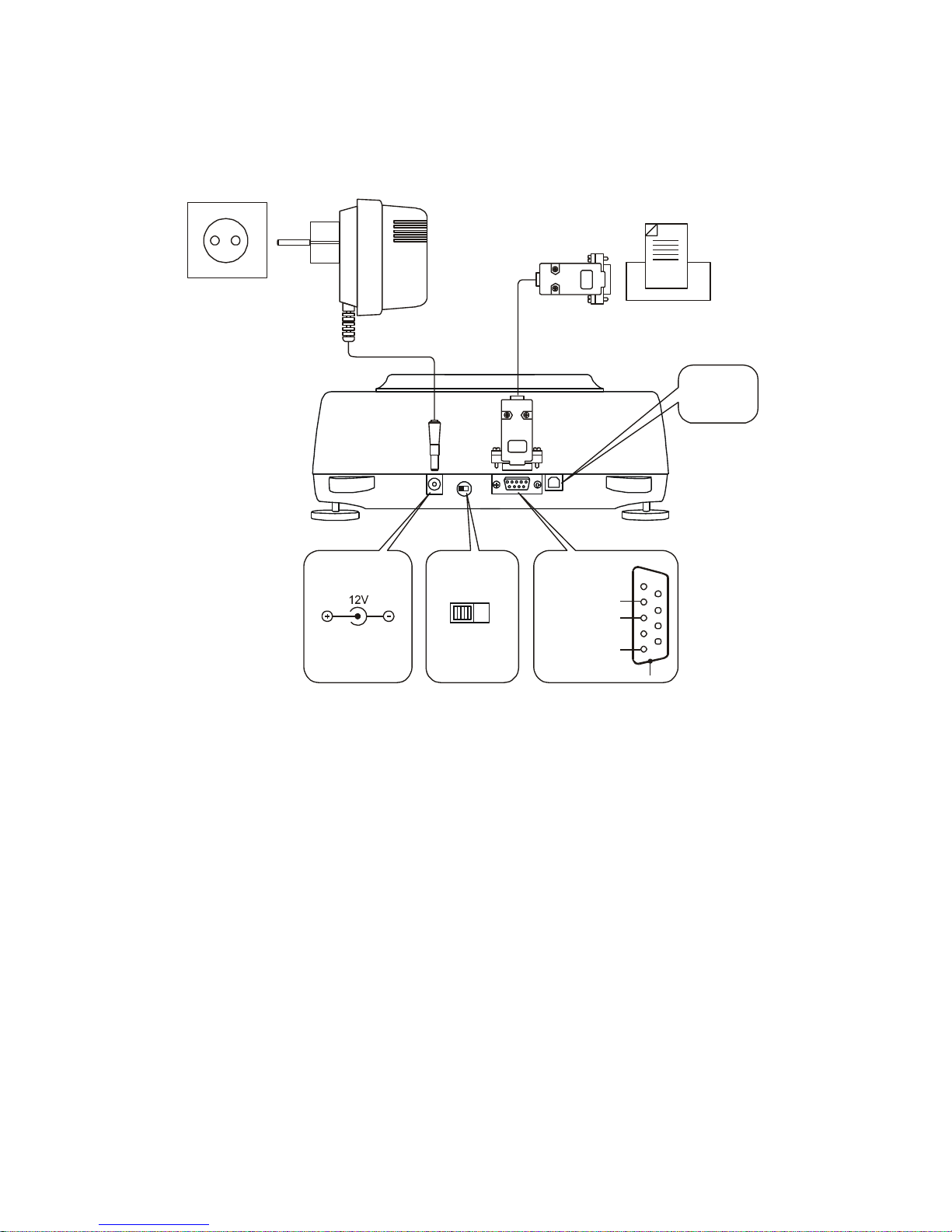

Connectors view:

ON OFF

Adjustment

switching

RxD (receiver)

TxD (transmitter)

ground

case

RS232C

USB

Feeder

Feeder Printer or computer

1

2

3

4

5

6

7

8

9

~230V

Page 8

8 USER MANUAL

__________________________________________________________________________________________________________________

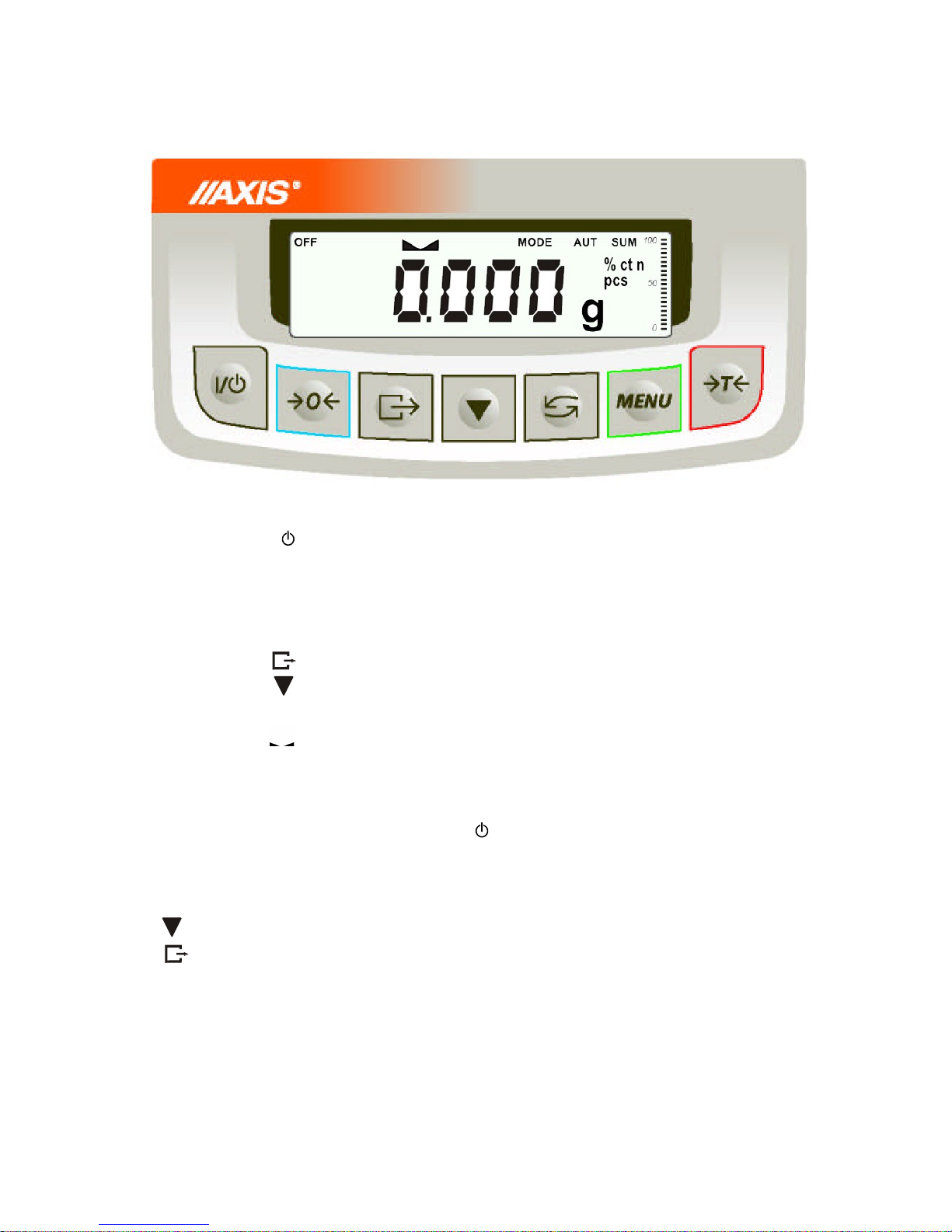

6. Keys and indicators

key

I/

- switch on / switch off (standby),

"

T

- taring (storing package mass subtracted from weighed mass)

"

- change mode of balance work,

"

0

- zeroing the scale when pan is empty (option) ,

"

MENU

-special function menu,

"

- result printout,

"

- internal calibration / changing menu position,

indicator

0

- zero indicator (when scale pan is empty),

"

- indicator of weighing result stabilisation,

"

NET

- net mass (after use of →T← key),

"

MODE

- indicator of switching special function on,

bar

indicator

- indicator of scale load (0-100%).

indicator

OFF

- switching scale with key (standby),

"

pcs

- indication in pieces

The use of keys during entering numeric values (special functions):

- increment current digit,

- insert comma,

T - move to next position,

MENU - finish entering

Note:

0 keys and 0 indicators only work in balances with d=e.

Page 9

USER MANUAL 9

__________________________________________________________________________________________________________________

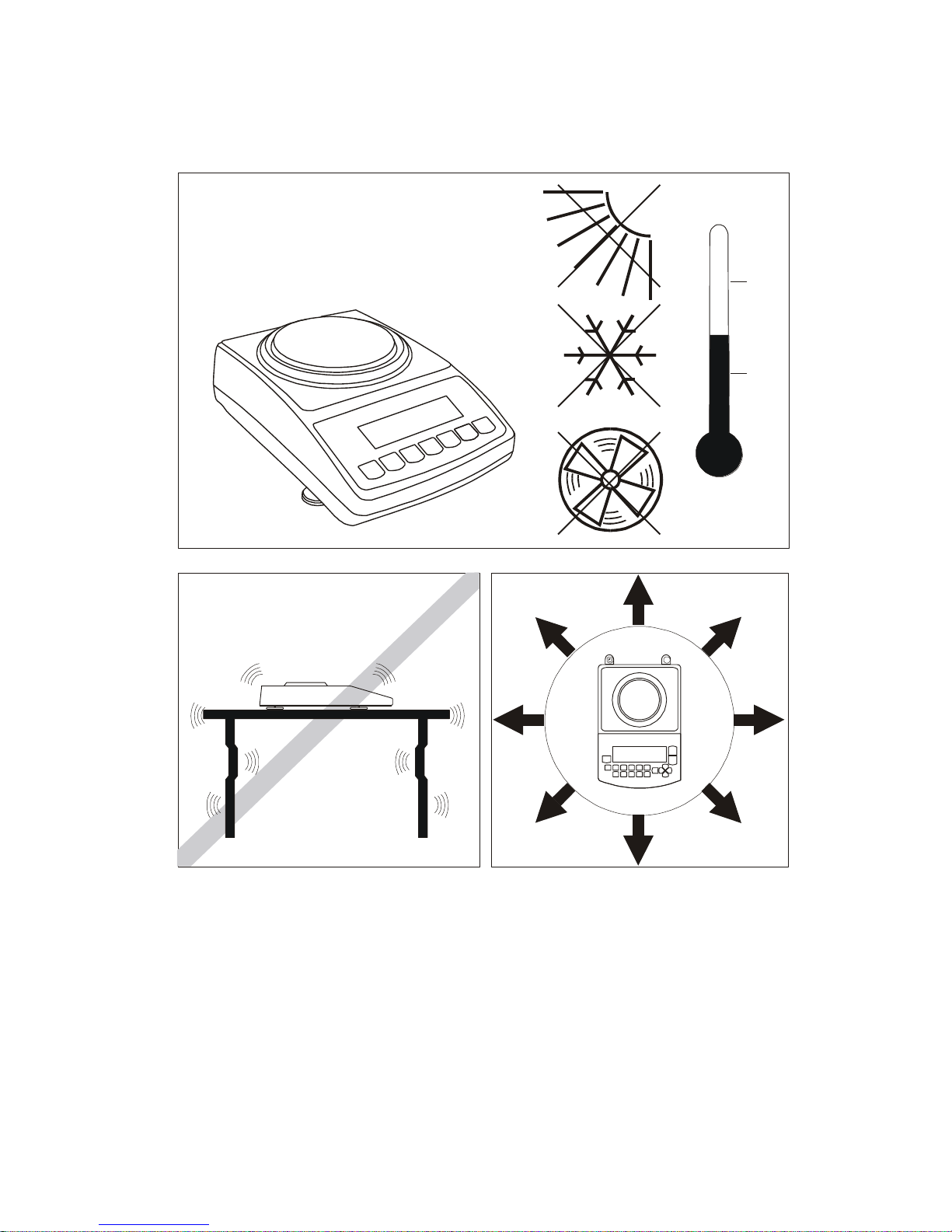

7. Preparing working environment

+18°C

+33°C

Location for the scale should be chosen with care in order to limit influence of the factors that can

interrupt working scale. This location has to maintain proper temperature for working scale and necessary

space for its operating. The scale should stay on stable table made of material that does not influence

magnetically on the scale.

Rapid air blasts, vibrations, dust, rapid temperature changes or air humidity over 90% are not allowed in

scale surrounding. The scale should be far from heat sources and devices emitting strong

electromagnetic or magnetic fields.

Page 10

10 USER MANUAL

__________________________________________________________________________________________________________________

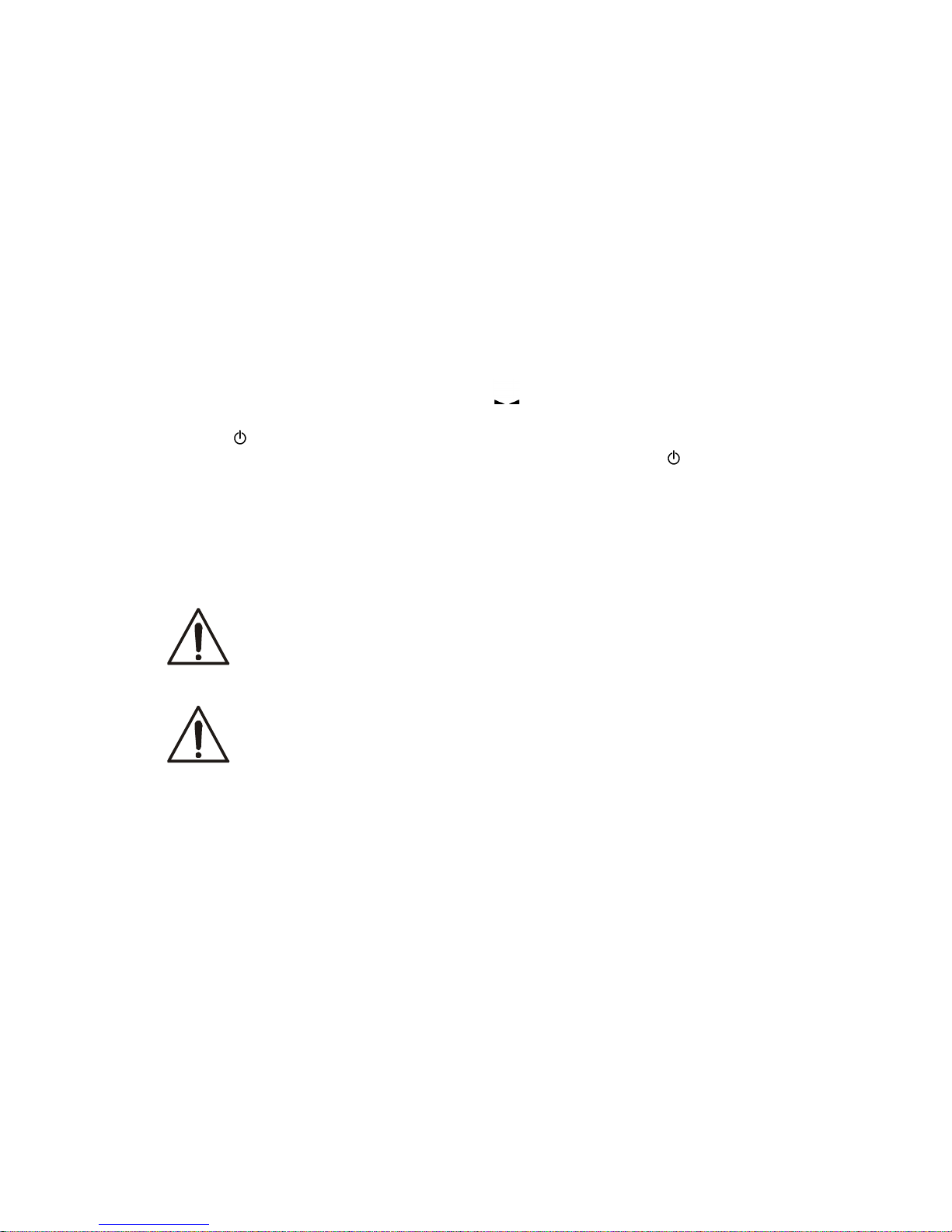

8. Preparing scale to work

1. Take the scale and feeder out of the

package. It is recommended to keep the

original scale package in order to transport

the balance safely in future.

2. Place the scale on a stable ground not

affected by mechanical vibrations and

airflows.

3. Level the scale using rotating legs 6 so

that the air bubble in water level 7 at the back

of the scale is in the middle.

4. Put draft shield 8 on the scale and cover 9

on it.

Scale should be transported in the way, that there is no risk of accidental pressing or

overweighing a pan.

If the scale was taken from a lower temperature surrounding to a room with higher

temperature, e.g. in winter, moisture can liquefy on the scale casing. Do not connect power

supply to the scale, because this can cause damage or improper work of the scale. In this

case leave the scale for at least 4 hours unplugged for acclimatization.

6

1

8

9

2

5

3

4

7

Page 11

USER MANUAL 11

__________________________________________________________________________________________________________________

9. General operation principles

1. In order to confirm correctness of the scale during its operation, before starting and after finishing

every valid measurement series it is recommended to check weighing accuracy putting calibration

weight or other object of exactly known mass on the scale. In the case when allowable measurement

error of the scale is exceeded, it is recommended to perform calibration with external weight or

contact authorised service centre.

2. Weighed mass should be placed in the middle of the pan.

3. The scale allows taring in the whole measuring range. To tare the scale press

->T<- key. Taring does not extend measuring range, but only subtracts tare value from mass value of

a sample placed on the pan. To make the control of a load on the pan easier and to avoid exceeding

measurement range, the scales have load indicator calibrated 0÷100%.

4. Weighing result should be read when the indicator lights, which signalises result stabilisation.

5. When the scale is not used but it is necessary for it to be ready to work, it can be switched off by

pressing I/ key. The scale reading system is then switched off and scale goes to standby mode

signalled with OFF indicator. Switching the scale on is preformed by pressing I/ key.

6. In sales having →0← key (zeroing) active it should be checked if zero indicator →0← is displayed

before sample is placed on the pan. If not, press →0← key and wait until the scale is zeroed and

zero indicator appears. After that load can be placed on scale pan.

7. Scale mechanism is a precise device sensitive to overweight, mechanical shocks and strokes.

8. After every change of balance position, level the balance and perform internal calibration.

Do not overload the scale more than 20% of maximum capacity.

Do not press the pan with a hand.

For transportation time, pan support and pan ring should be packed

separately.

Page 12

12 USER MANUAL

__________________________________________________________________________________________________________________

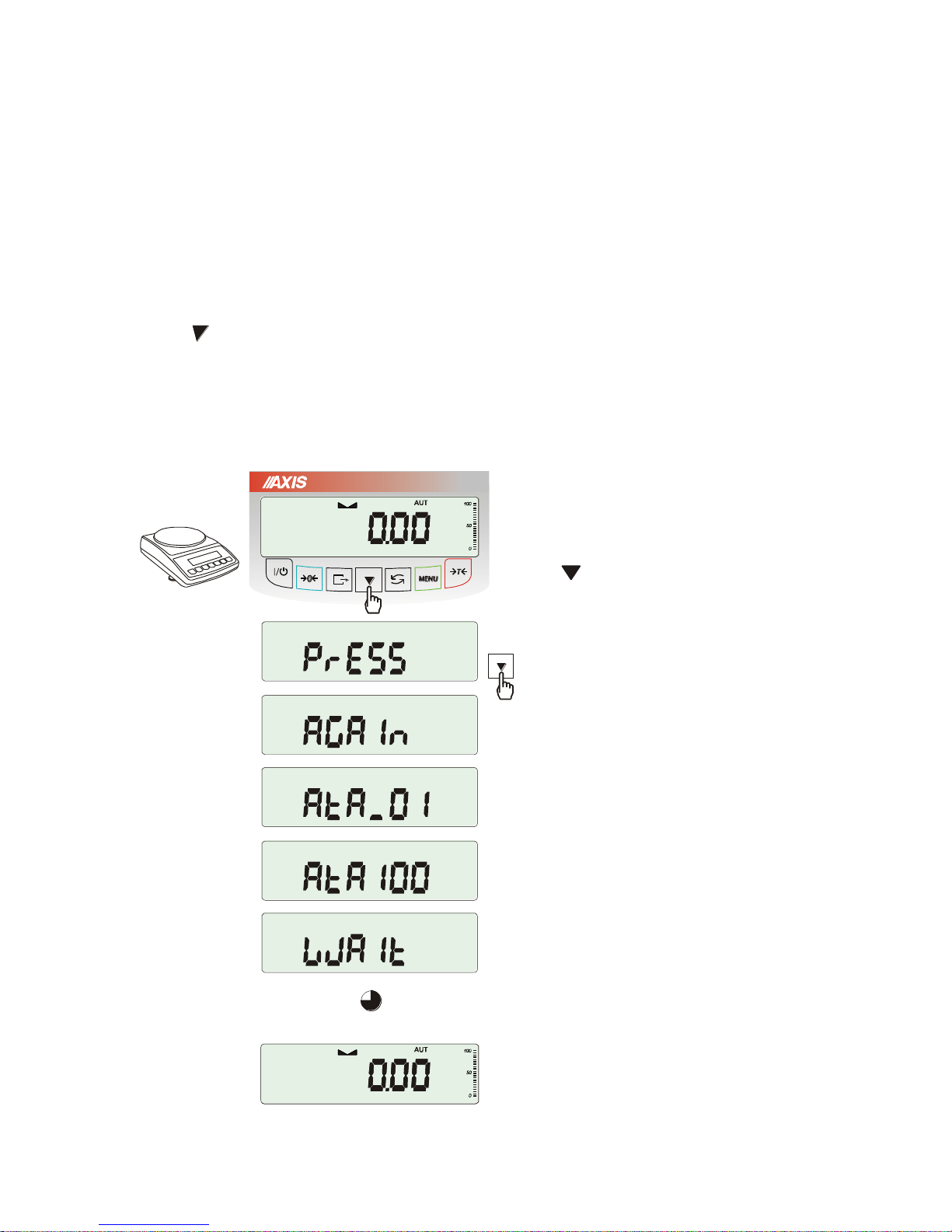

10. Internal calibration

The ATA balances are equipped with internal calibration system, which general task is to maintain

required measurement accuracy.

Internal calibration is the process of putting internal weight on automatically by balance mechanism and

correcting accuracy in balance firmware. The correction is necessary because of differences between

values of gravitational acceleration in the place where the balance was manufactured and in the place

where it is operated, as well as due to changes of balance level and temperature.

Internal calibration is performed in the following situations:

- when key is pressed twice,

- after defined time interval (for balances comply with verification requirements - 2 hours),

- after temperature change (for balances comply with verification requirements – more than 1oC).

For balances comply with verification requirements time interval is set to 2 hours and defined temperature

change is 1oC. In other balances those values can be set as calibration options. The reason of starting

internal calibration is shown as an icon near weight picture.

In order to perform internal calibration proceed

with the following:

Empty the pan.

Press key twice (double pressing the key

helps to avoid accidental starting calibration

procedure).

During calibration internal weight is put three

times on and obtained results are compared.

Discrepancy of results is signalled with a

message and causes the balance being

blocked.

Until calibration process is finished do not

perform any operation on the balance. Any

vibrations and shocks interfere calibration

process and may delay it or deteriorate

accuracy of its result.

When internal calibration is performed

successfully the balance indicates zero on the

display at empty pan.

g

g

~45 sekund

Page 13

USER MANUAL 13

__________________________________________________________________________________________________________________

Note:

In order to terminate internal calibration process in balances that do not comply with verification

requirements press key and wait until balance mechanism is settled in initial position.

11. Checking the balance

In order to confirm correctness of the balance during its operation, before starting and after finishing

every measurement series it is advised to check weighing accuracy. It can be done by weighing external

calibration weight or other object with exactly known mass.

If exceeding of allowable measurement error is affirmed, the following things should be checked:

- if the balance stands stable and it is levelled,

- if the balance is exposed on rapid air blasts, vibrations, rapid temperature changes or air

humidity,

- if the balance is not affected directly by heat source, electromagnetic radiation or magnetic field.

The cause of inaccuracy can be too low temperature of the balance as well, when it was unplugged from

power supply. In this situation leave the balance switched on for several minutes in order to adjust its

internal temperature.

If none of above causes of inaccuracy occurs, calibration with external weight should be performed to the

balance. Recommended external calibration weight (to buy for additional charge) is given in technical

data table. In order to calibrate the balance with external weight in legally verified balances verification

seals should be removed and another legal verification should be performed. In this case it is

recommended to contact authorized service centre.

Calibration with external weight is described in details in chapter 17.1.

Page 14

14 USER MANUAL

__________________________________________________________________________________________________________________

12. Connection with a computer or a printer

The scale is equipped with RS232C, which can be used to connect external devices such as computer

or a printer.

When cooperating with computer, the scale sends weighing result after initialize signal from computer or

after pressing key on the scale.

When cooperating with a printer data is send automatically after result stabilisation, but next transmission

is possible after removing previously weighted sample.

When cooperating with label printer after pressing key, the scale sends instructions set for the label

printer. Label number 0001, hour, data (if the clock is installed and on) and nett weight. During

transmission LabEL communicate is displayed.

The way of sending data and transmission parameters is set using SErIAL special function.

Set of send data is set using special function PrInt.

The following data can be send:

- Header (scale type, Max, d, e, serial number),

- Operator identification number,

- Successive printout number (measurement),

- Identification number or product bar code,

- Number of pcs (PCS function only),

- Single detail mass (PCS function only),

- Nett weight,

- Tare (package mass),

- Gross weight,

- Total mass (Total function only).

If the scale is equipped with two serial joints Print function is set independently for both interfaces.

Computer must have a special program for cooperation with data from a scale.

Dedicated programs are also offered by AXIS.

Except RS232C joint, the scale can be equipped with USB or Wi-Fi interface.

Needed controllers and instruction can be found on a CD supplied with Axis scales.

Page 15

USER MANUAL 15

__________________________________________________________________________________________________________________

12.1 Detailed protocol description in standard mode

LonG protocol

Transmission proceeds in the following way:

1. Communication parameters: 8 bits, 1 stop bit, no parity, baud rate 4800bps,

2. Available orders send from computer and balance answers:

Readout of scale indication ( corresponds to pressing key

ComputerScale: S I CR LF (53h 49h 0Dh 0Ah),

ScaleComputer: scale response according to description below (16 bytes):

Byte

1 - sign „-” or space

Byte

2 - space

Byte

34

-

digit or space

Byte

5÷9 - digit, decimal point or space

Byte

10 - digit

Byte

11 - space

Byte

12 - k, l, c, p or space

Byte

13 - g, b, t, c or %

Byte

14 - space

Byte

15 - CR

Byte

16 - LF

Attention:

Network number different than zero (SErIAL / nr function) changes scale working mode: communication

with a computer is possible after logging the scale in with 02h scale number command. To log the scale

out use 03h command.

For example: Using a program to test RS232 interface ( program is available on www.axis.pl in computer

programs section) for scale number 1 please write: $0201 to log in, then SI, and write: $03 to close

communication.

Asking for scale presence in system (testing scale connection with computer):

ComputerScale: S J CR LF (53h 4Ah 0Dh 0Ah),

ScaleComputer: M J CR LF (4Dh 4Ah 0Dh 0Ah),

Displaying a sign on scale display (text message from computer):

ComputerScale: S N n n X X X X X X CR LF (53h 4Eh 0Dh 0Ah), nn-displaying time in

seconds; XXXXXX- signs to display

ScaleComputer: M N CR LF (4Dh 4Eh 0Dh 0Ah),

Scale tarring (calling

T

key press) :

ComputerScale: S T CR LF (53h 54h 0Dh 0Ah),

ScaleComputer: without response,

Scale zeroing (calling

0

key press):

Computer Scale: S Z CR LF (53h 5Ah 0Dh 0Ah),

Scale Computer: without response,

Page 16

16 USER MANUAL

__________________________________________________________________________________________________________________

Scale turning on / off (calling I/ key press):

Computer Scale: S S CR LF (53h 53h 0Dh 0Ah),

Scale Computer: without response,

Entering to special function menu (calling MENU key press):

Computer Scale: S F CR LF (53h 46h 0Dh 0Ah),

Scale Computer: without response,

Setting low threshold value (option):

Computer Scale: S L D1...DN CR LF (53h 4Ch D1...DN 0Dh 0Ah)

D1...DN – threshold value, maximum 8 characters („-” – negative value, digits, dot – decimal

separator), number of digits after dot should be the same as on scale display,

Scale Computer: without response,

Example:

in order to set low threshold 1000g in scale B1.5 (d=0.5g) the following order should be sent:

S L 1 0 0 0 . 0 CR LF (53h 4Ch 31h 30h 30h 30h 2Eh 30h 0Dh 0Ah),

in order to set low threshold 100kg in scale B150 (d=50g) the following order should be sent:

S L 1 0 0 . 0 0 CR LF (53h 4Ch 31h 30h 30h 2Eh 30h 30h 0Dh 0Ah),),

Setting high threshold value (option):

Computer Scale: S H D1...DN CR LF (53h 48h D1...DN 0Dh 0Ah),

D1...DN – threshold value (see )

Scale Computer: without response.

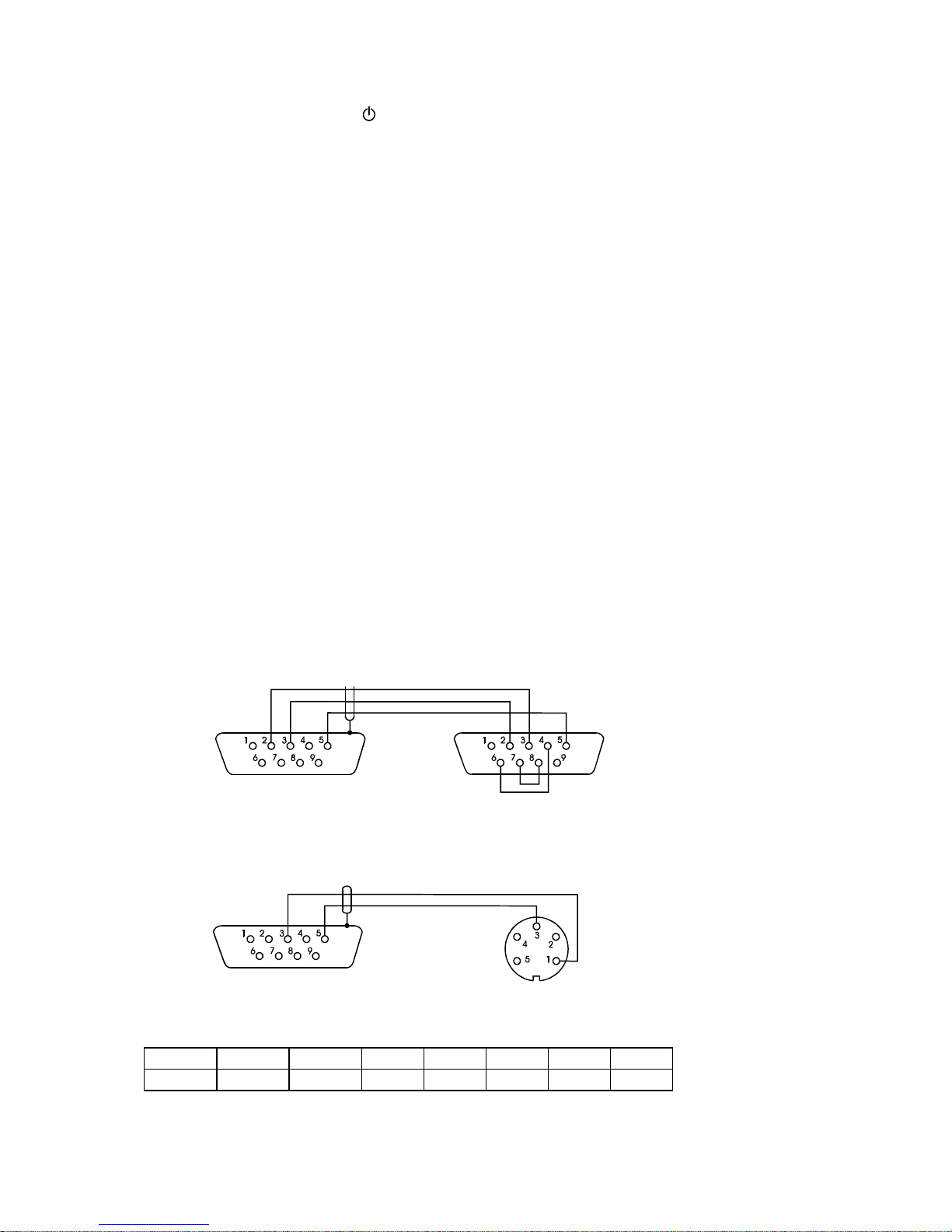

Connecting cable WK-1 (scale – computer / 9-pin interface):

Connecting cable WD-1 (connects printer with scale):

AXIS C-001 printer internal switches setting:

SW-1

SW-2

SW-3

SW-4

SW-5

SW-6

SW-7

SW-8

on

off

on

off

off

on

off

off

SCALE COMPUTER

SCALE

PRINTER

Page 17

USER MANUAL 17

__________________________________________________________________________________________________________________

12.2 Protocol ELTRON description

Transmission parameters: 8 bits, 1 stop bit, no parity, baud rate 9600bps,

After using key in scale:

ScaleLabel printer : set of instruction in EPL-2 language that initialize label printing:

US -

Steering instruction

FR"0001"

- Label number define instruction

? -

Instruction that starts list of variable signs

mm:gg

- 5 signs: minutes:hour

rrrr.mm.dd

- 10 signs: year.month.day

masa

- 10 signs: scale indication+ mass unit

P1 -

Steering instruction

Attention:

1. Except variable signs constant signs can also be inscribed e.g. factory name, product name and so

on.

2. In standard only one label pattern is possible to printout (number 0001). Using bigger amount of

patterns (other label numbers) is possible thanks to LAbEL special function.

3. To achieve label printout, label printer must have inscribed label pattern (label pattern is created on

computer and using computer it is saved to label printer memory). Label pattern is designed by

ZEBRA DESIGNER program which is supplied together with label printer.

Scales parameters and transmission protocol must corespond to label printer type.

Page 18

18 USER MANUAL

__________________________________________________________________________________________________________________

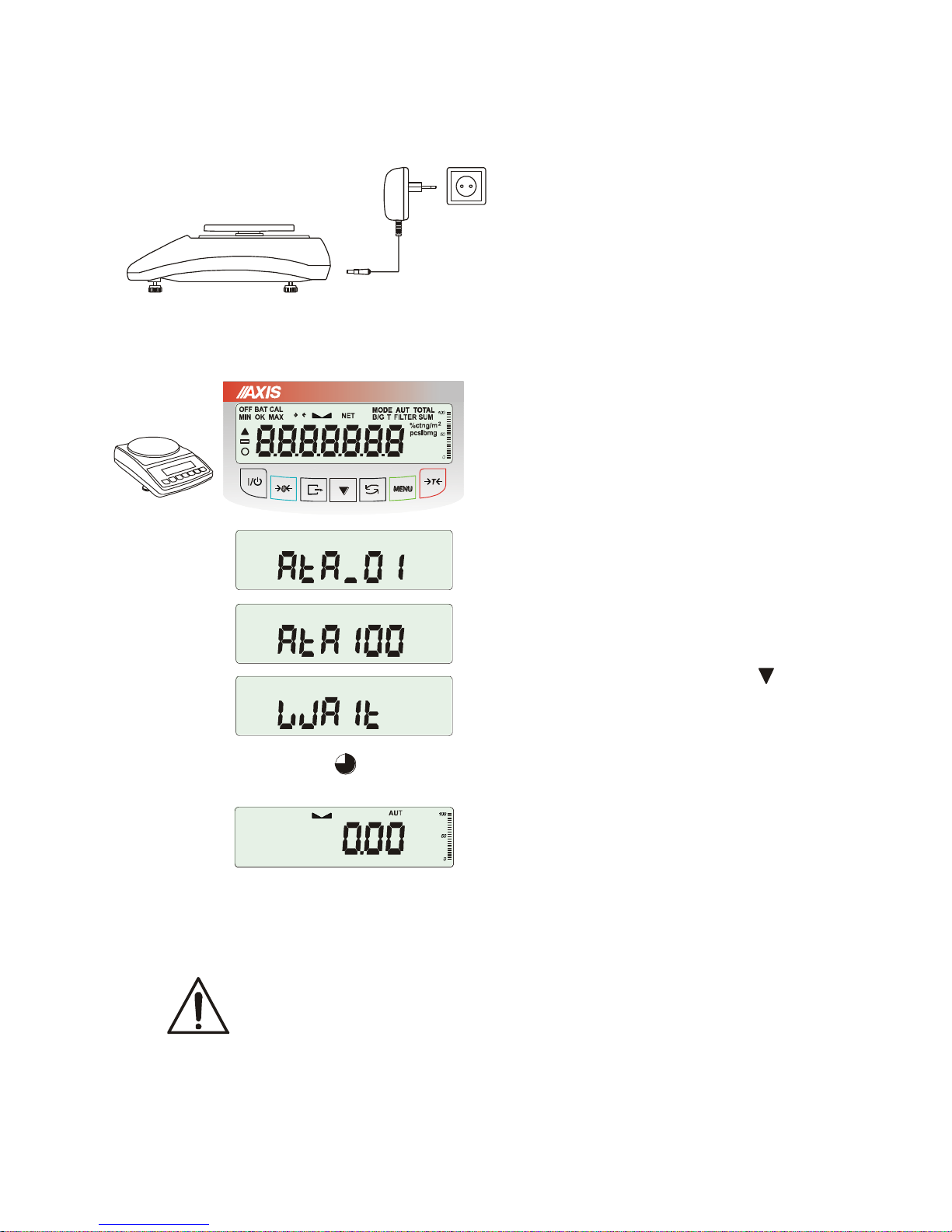

13. Start-up

Plug feeder into ~230V power supply socket.

When the pan is empty plug feeder output

connector into 12V socket at back of the scale.

Autotests and internal calibration will be

performed.

Autotest of balance display.

(autotests of internal electronic elements C1:8

displayed only when any test result is negative)

Showing scale program version.

Internal calibration – 45 seconds (press key if

You want to terminate calibration)

Ready to work.

Attention: UnLOAd communicate means that the

balance is loaded or the transport securing

elements were not clear away.

It is recommended that before you start measuring the internal temperature has

stabilized weight. For this to happen, the weight should remain enabled for at least 2

hours. To maintain the accuracy of the weight it is not recommended to turn off the

power.

g

0

kg

~45 sekund

Page 19

USER MANUAL 19

__________________________________________________________________________________________________________________

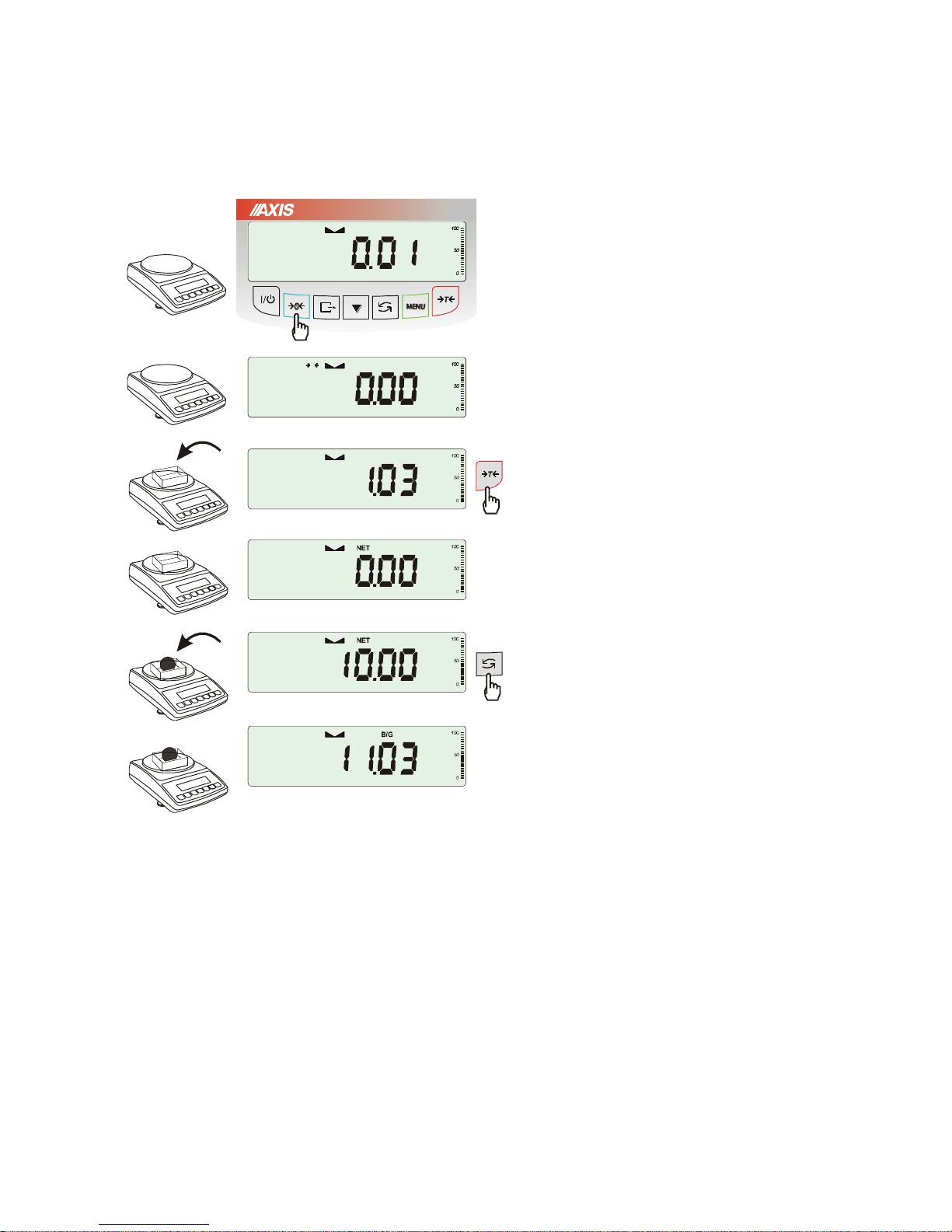

14. Weighing with tare

If the scale is not loaded and 0 indicator

doesn’t indicate, press 0 key.

Zero indication and 0 indicator mean that

the scale is ready to work.

After putting container (package) tare the

scale using T key. NET indicator will

show up.

Put on weighted object and readout net weight

(NET indicator shows that scale indicates net

weight).

In order to readout gross weight press key

(B/G indicator shows that scale indicates gross

weight). Press again key in order to come

back to net indications.

00

g

g

g

g

g

g

Page 20

20 USER MANUAL

__________________________________________________________________________________________________________________

15. Scale menu

All scales except for basic metrological functions: weighing and taring, have many special functions and

configuration options.

In order to ease using functions user can

create his own (personalized) menu.

Creating personalized menu:

In „out of the box” scale after pressing MENU

key only SEtuP option (it contains all

configuration options) is available.

One of the configuration options is Menu that

is used to create personalized menu.

To add a function to personalized menu press

T

key when the function is indicating.

Chosen function is indicated with „o” sign on

the left side of display.

After adding all necessary functions press out

in order to come back to weighing mode. User

now after pressing MEnu key has access to

selected earlier functions and to SEtuP option.

dEFAULt option is used to set factory

settings.

0

kg

Page 21

USER MANUAL 21

__________________________________________________________________________________________________________________

16. Menu navigation rules

Choosing menu options:

Scale menu shows up after pressing Menu

key. First menu position is displayed for about

10 seconds. After 10 seconds successive

menu positions are displayed automatically.

Choosing menu position (option) is done by

pressing T key when it is displayed on

the screen.

After choosing position (option) usually several

options show up:

on – turning on selected option,

OFF - turning off,

out – out to menu.

Accelerated working with menu:

First menu position is displayed for about 10s.

User can change menu positions manually by

pressing key.

Immediate out to previous menu level is done

by using Menu key.

0

kg

0

kg

Page 22

22 USER MANUAL

__________________________________________________________________________________________________________________

key working method:

During standard weighing key is used to

switch between net and gross indication.

When special function e.g. PCS is turned on,

using key enables to go back to standard

weighing mode.

Sign „o” on the left side signalizes that special

function is turned on and user can go back to

function mode by pressing key.

0

0

0

kg

0

0

0

kg

kg

kg

Page 23

USER MANUAL 23

__________________________________________________________________________________________________________________

Inscribing numerical values:

Inscribing numerical values is needed in some

special functions e.g. tArE function requires to

inscribe tare values.

Keys:

- decimal point,

T

- next digit position,

- increasing digit inscribed value (use also

0),

MENU – end of inscribing.

Page 24

24 USER MANUAL

__________________________________________________________________________________________________________________

Menu diagram:

key

(PCS)

(totAL)

...

...

out

SEtUP

Prod

USEr

PCS

Unit

PErc

LOC

tArE

UP

totAL

thr

StAt

rECIPE

out

()o()o

MEnu

CALIB

AutoZEr

UnIt

MENU

- personalized function menu created using SEtUP / MEnu

- sensitivity calibraton (only not verificated scales)

- fast calibration (without confirmation of putting weight)

- calibration with confirmation

- calibration report printout

- internal calibration time interval

- internal calibration temperature interval

- exit

- autozeroing

- autozeroing on

- autozeroing off (lasts 10min)

- exit

- settings

- creating menu (” “- added to menu)

- choosing product

- choosing user

- pieces counting function

- actual unit selection

- percentage conversion function

- animals weighing function

- tare memory bank

- maximum value function

- summation series of measurements function

- threshold values comparing function

- statistics function

- recipe weighing function

- exit

o

CAL on

CAL StP

CAL Prn

CAL tM

CAL C

out

Aut on

AUt OFF

out

CArAt (ct)

MGrAM (mg)

HGrAm (kg)

Pound (Ib)

ounCE (oz)

ounCE (ozt)

GrAin

PEnnYW

GrAM (g)

out

- unit choice

- carat

- miligram

- kilogram

- pound

- ounce

- aphotecary ounce

- grain

- jednostka jubilerska

- gram

- exit

Page 25

USER MANUAL 25

__________________________________________________________________________________________________________________

- measure speed setting

- slow

-

- fast

-

- exit

medium

restore default setting

- serial ports settings settings

- port - 1

- transmission speed (1200, ... ,115 200 bps)

- bits quantity (7 or 8)

- parity control

- transmission type (Stab, no StAb, Auto,Cont.,rEMoVE)

- protocol (LonG, EPL, EPL_A, EPL-d, PEn-01)

- barcode reader MJ4209 cooperation

- exit

- port-2 (as above)

- printout data configuration / transmission

- port - 1

- header (scale type, Max, d, e, serial nr)

- scale operator id number

- data

- time

- succesive printout/measurement number

- product identification number

- product barcode number

- product name

- pieces quantity (PCS function)

- product unit weight

- net weight

- package weight (tare)

- gross weight

- total weight (totAL function)

- measurement number and value in one line printout

- exit

- port-2 (as above)

- exit

SErIAL

PrInt

SPEEd

bAUd

bItS

PArItY

SEndInG

Prot

Scann

out

HEAdEr

User Id

dAtE

tIME

Prn no

Prod Id

Prod bA

Cont

APW

nEt

tArE

Gross

totAL

no LCD

out

Port-1

Port-2

out

SLOW

MEd

FASt

dEFAULt

out

Port-1

Port-2

out

Page 26

26 USER MANUAL

__________________________________________________________________________________________________________________

- analog output setting

- restore default settings for all options

- options only for service

- exit

(dAtA)

(AnALoG)

dEFAULt

SErVICE

out

dAt oFF

dAt on

SEt

PIn

dat For

tM For

out

- setting time and date (if the scale is equipped with clock)

- date and time off

-

- set date and time

- accoes code

- data format

- time format

- exit

date and time on

Page 27

USER MANUAL 27

__________________________________________________________________________________________________________________

17. Scale setup (SEtUP)

SEtUP contains all options used for setting scale

work mode:

MEnu – creating personalized user menu,

CALIb – scale sensitivity calibration,

AutoZEro(ing) – self-maintaining zero indication

(unloaded scale),

UnIt – weight unit selection,

SErIAL – setting serial ports,

Print – transmission (printout) data selection,

dAtE – inscribing actual date and time,

dEFAULt – reset to factory settings,

SErVICE – service menu (only for service).

g

Page 28

28 USER MANUAL

__________________________________________________________________________________________________________________

17.1 Scale calibration (CALIb)

Calibration with external weight should be performed if balance accuracy after internal

calibration is not satisfactory. Calibration weight stated in technical data table for the

balance (or of better accuracy) with valid verification certificate should be used then.

Calibration of legally verified balance requires violating a mark used to

protect an access to adjustment switch and results in loosing legal

verification. To renew legal verification of the balance, it is necessary to

contact a service or notified body.

In balances comply with verification

requirements performing

calibration requires changing

adjustment switch position, which is

placed behind protecting mark

(sticker) of a notified body. An

access to the switch is possible

only after removing the mark.

Before proceeding with calibration for balances comply with verification requirements,

adjustment switch should be set to ON position using thin screwdriver (the balance will

display the message Pr ON).

When calibration process, described on next page, is finished, the balance will display

the message Pr ON. Adjustment switch should be set to OFF position using thin

screwdriver (the balance will move to weighing).

ON

OFF

Adjustment

switch

Page 29

USER MANUAL 29

__________________________________________________________________________________________________________________

Calibration with external weight:

Press MENU key.

Press T key when CALIb function

appears.

The following options will be displayed:

-CAL on – calibration with external

recommended standard of mass (see

technical data).

-CAL StP – calibration with external weight,

confirmation of successive steps - MENU key,

out – leave without changes

- CAL Prn – calibration report,

- CAL tM – set time interval for internal

calibration,

- CAL C – set temperature difference for

internal calibration,

- out.

Press T key when CAL StP option

appears (calibration in two steps).

Press T key when weight value used for

calibration is indicating or use othEr option

and inscribe proper value ( keys 0 ,

, T )

Press MENU and wait for writing zero to the

scale.

When LOAD message appears put standard

of mass on the pan. Press MENU key (CAL on

doesn’t need pressing MENU key).

Wait until internal calibration is finished and

zero indication is displayed.

0

g

g

1000g

g

Page 30

30 USER MANUAL

__________________________________________________________________________________________________________________

Internal calibration options:

Internal calibration of the balance is performed automatically every time the balance is

switched on, additionally after given time interval during work and after every

temperature change of more than given value.

In order to perform internal calibration in any moment, empty the pan and press key

twice (one more pressing terminates calibration).

Press MENU key to display function

menu and choose CALIb function by

pressing T key when it is displayed.

The following options will appear:

- CAL on – perform calibration with

external weight

- CAL Prn – printout of calibration report

- CAL tM – set time interval for internal

calibration (1h – 6h)

- CAL C - set temperature difference for

internal calibration (1C - 4C)

-out – switch internal calibration off

for internal calibration

Press T key when CAL tM option is

displayed. Predefined time intervals for

internal calibration will be displayed.

Select required value pressing T

key.

Accordingly choose CAL C option

pressing T key and selecting values

of temperature difference.

Select out option to finish.

MO DE

MO DE

MO DE

MO DE

MO DE

MO DE

MO DE

g

Page 31

USER MANUAL 31

__________________________________________________________________________________________________________________

The form of ATA balance calibration report printout (option CAL Prn):

The form of ATZ balance calibration report printout (option CAL Prn):

--------- CALIBRATION REPORT ----------

ATA2200 MAX=2200g e=0.1g d=0.01g

S/N : 1234

PROD.DATE: 2013-12-16

FIRM.VER.: ATA102 2015-01-12 AD7710 NTC

FACTORY EXT.LOAD : 2000.00 g

FACTORY INT.LOAD : 196.131 g

CALIBRATION NO. : 1

CALIBRATION DATE : 2015-01-22

CALIBRATION TEMP1: 30.346 'C

CURRENT EXT.LOAD : 2000.00 g

CURRENT INT.LOAD : 196.131 g

WEIGHT DIFFERENCE: 0.00 g

--------- CALIBRATION REPORT ----------

ATZ2200 MAX=2200g e=0.1g d=0.01g

S/N : 1234

PROD.DATE: 2013-12-16

FIRM.VER.: ATA102 2015-01-12 AD7710 NTC

FACTORY EXT.LOAD : 2000.00 g

CALIBRATION NO. : 1

CALIBRATION DATE : 2015-01-22

CURRENT EXT.LOAD : 2000.00 g

Page 32

32 USER MANUAL

__________________________________________________________________________________________________________________

17.2 Autozeroing function (AutotAr)

When the function is activated, the scale

automatically ensures stable zero indication if

the pan is empty or if zero indication was

acquired by pressing T key.

To turn on the function use MENU key and

using T key choose AutotAr and then Aut

on

To leave the function press MENU key, then

choose AutotAr and Aut OFF.

Note:

1. AUt sign occurs only in scales with LCD

display.

2. In scales with active 0 key function

function changes name into AutoZE

(autozeroing) and works only when the scales

is unbiased.

g

0

g

Page 33

USER MANUAL 33

__________________________________________________________________________________________________________________

17.3 Weight unit selection (UnIt)

The function allows selecting weighing unit:

- CarAt (1 ct= 0,2 g) - carat,

- MGrAM (1mg=0,001g) milligram,

- KGrAM (1kg=1000g) kilogram,

- Pound (1 lb=453,592374g) English pound,

- OunCE (1oz=28,349523g) - ounce,

- OunCEt(1ozt=31,1034763g) pharmaceutical ounce,

- GrAIn (1gr=0,06479891g) - grain

- PennYW (1dwt=1,55517384g) jewellery mass unit,

- GrAM (1g) - gram.

The way of choosing carats as weighing unit is shown on

the example.

kg

g

g

Page 34

34 USER MANUAL

__________________________________________________________________________________________________________________

17.4 Serial port parameters setting (SErIAL)

The function allows setting independently

communication parameters of both of serial ports

Port-1 and Port-2 (executed in RS232C, RS485,

USB or LAN standard):

- transfer protocol (Prot):

LonG – cooperation with printer or computer,

EPL – cooperation with label printer in normal

mode (activates LAbEL function),

EPL_A – cooperation with label printer in

automatic mode (activates LAbEL function),

EPL_d – cooperation with special label printers,

Pen-01 – cooperation with PEN-01,

- baud rate (bAud): (4800, 9600, ….115 200bps),

- number of bits in single char. (bitS): 7, 8,

- parity control (PArItY):

nonE – no control

Odd –nonparity

Even – parity control,

- scale number in network (nr):

(if the scale doesn’t work in network the number

must be 0),

- transmission through serial interface (SendInG):

StAb – transmission after key is used and

result is stable,

noStAb – transmission after key is pressed

without need of stabilisation,

Auto - automatic transmission after load is put

on and result is stable (Auto),

Cont - continuous transmission, about 10 results

per second (Cont.),

Remove – transmission after putting off the

weight.

Default parameter values:

Long, 9600 bps, 8 bits, none, StAb,

- SCAnn – cooperation with MJ-4209 barcode

readers.

In order to set needed parameters choose SErIAL function, select appropriate parameter and press

T

key when required option or parameter value is displayed.

In scales with an additional serial port appear Port-1 and Port-2, for the independent setting of both ports.

g

Page 35

USER MANUAL 35

__________________________________________________________________________________________________________________

17.5 Printout configuration (PrInt)

Function is used for printing additional information

stored in scale memory, weighed product

identification data and scale operator id. That

information is inscribed using scale keys or

scanner.

The function allows to switch on/off following

positions on the printout:

- HEAdEr – header: name, model and scale

number,

- USEr Id – scale user identification number,

- USEr nA – user name,

- Prn no – successive printout number (choose this

option to zero counter),

- Prod Id – product number,

- Prod bA – product barcode (inscribed or

scanned),

- Prod nA – product name,

- Count – counting result (PCS function),

- APW – unitary mass (PCS function),

- nEt – net mass

- tArE – current tare value,

- GroSS – gross mass,

- totAL – total mass (totAL function)

Attention:

If Prod Id or USEr Id is chosen, it is possible to

inscribe quickly their new values (with omission

of main menu).

In order to do that hold (about 3 seconds) MENU

key and release it when Prod Id or USEr Id

indicates. Inscribe new value using keys:

0

- increasing digit,

- decimal point,

T

- next digit,

MENU - end.

While inscribing Prod id user can use barcode

reader connected to RS232C interface.

If the scale is equipped with two serial joints Print

function is set independently for both interfaces.

g

Page 36

36 USER MANUAL

__________________________________________________________________________________________________________________

Sample printout during normal weighing (all printout positions deactivated):

Sample printout during normal weighing with clock option (all printout positions

deactivated):

Sample printout during normal weighing ( some printout positions activated):

20.07 kg

20.04 kg

20.04 kg

20.07 kg 2012-11-08 10:01

20.04 kg 2012-11-08 10:01

20.04 kg 2012-11-08 10:01

ATA220

MAX: 30kg e=d=0.01kg

S/N :

ID OPER. : 000001

DATE : 2012-11-08

TIME : 12:26

NO : 3

ID PROD. : 01

COUNT : 0 PCS

APW : 0.000 g

NET : 3.08 kg

TARE : 0.00 kg

GROSS : 3.08 kg

TOTAL : 0.00 kg

Page 37

USER MANUAL 37

__________________________________________________________________________________________________________________

17.6 Weighing speed selection (SPEED)

Option enables to change weighing speed, that enables better performance thanks to adaptation to

environment conditions. In particular, if user chooses FASt speed setting then small weight portion

batching for eg. in pharmacy is possible.

To turn on the function use MENU key and

choose SPEEd option by using T key,

then select one of these options:

- SLOW – slow measurement (interferences),

- MEd – medium,

- FASt – fast (batching),

- DEFAULt – back to factory setting.

Attention:

When setting fast speed check if weighing

results are stable. Otherwise use slower

option.

0

g

Page 38

38 USER MANUAL

__________________________________________________________________________________________________________________

17.7 Entering reference zero value (ZErO)

Note: This function is enabled in non-legalized scales only.

ZEr0 function allows entering new value of reference zero (value referred to empty pan) without need of

contacting with authorised service centre.

Press MENU key.

When ZErO is displayed press T key.

On the display a sign ZEr Cod will show up

momentary and the a dash on last digit position.

To enter code ( in new scale: 1234) use keys:

0

- increasing digit,

T

- next digit,

MENU – end of inscribing.

The following options appear successively on

display:

ZEr Cod – enter new secure code value,

ZEr SEt – enter new zero value

Using T key, choose ZEr SEt. Direct result

from A/C converter will appear on scale display.

When the pan is empty press 0 key.

Wait for finishing zeroing process.

In order to change access code use

ZEr Cod option (as mentioned earlier).

0

kg

Page 39

USER MANUAL 39

__________________________________________________________________________________________________________________

18. Special functions description

All scales besides basic metrological functions: weighing and taring, have a set of special functions.

Depending on meter type functions set differs. Below a list of functions available in standard ME-01 type

meters:

Add id number to product (Prod),

Add id number to user (USEr),

pieces counting function (PCS),

change of mass unit (UnIt),

percentage weighing function (PErC),

selecting label number function (LAbEL),

weighing large animals function (LOC),

entering tare function (tArE),

maximum value indication function (UP)

statistical calculations (StAt)

paperweight calculation function (PAPEr) – on demand

and functions that require additional equipment to be completely functional:

options with the clock:

- setting current date and time function (dAtE)

- total weight function (totAL)

options with the transoptors connectors (WY ):

- checkweighing function (thr)

LabEL function is available in scales with EPL or EPL-A transmission protocol activates (go to

SetuP/SErIAL).

Page 40

40 USER MANUAL

__________________________________________________________________________________________________________________

18.1 Product and user identification (Prod and USEr)

The balance enables to inscribe product barcode and user identification number:

- Prod bA – product barcode,

- USEr Id – user identification number.

Balance product barcode and user readout together with external devices (e.g. printer, label printer and

computer) enables to build simple identification and archivisation systems.

Inscribing multi-digit data without using e.g. computer keyboard is inconvenient and using barcode reader

is beneficial.

Producent

Masa netto:

xxxxxxx

Data:

xx-xx-xxxx

Produkt:

Page 41

USER MANUAL 41

__________________________________________________________________________________________________________________

Inscribing data to base

Prod and USEr options enables inscribing single

product and user data.

To inscribe data use keys:

- increasing digit,

T - next dixit,

MENU – end of inscribing.

Barcode reader (connected to RS232C interface)

can also be used to inscribe data and this way it is

faster and more effective.

0

g

g

Page 42

42 USER MANUAL

__________________________________________________________________________________________________________________

18.2 Pieces counting function (PCS)

This function enables to count identical pieces,

e.g. turnbuckles or buttons.

A measurement is performed in two phases:

- first phase - single piece weight calculation

on the basis of defined pieces amount (5,

10, 20, 50, 100, 200 or 500 pieces),

- second phase – pieces counting.

First phase options:

- PCS . . – recalling of a value inserted earlier

(this quantity must be inscribed earlier),

-PCS SEt – set any amount of pieces in a

sample,

-PCS APW – set unitary mass directly,

-PCS rS – inserting number of details in a

sample and receiving of their mass from other

scale connected by RS-232C.

It is advised that single piece weight is not less

than one reading unit and sample weight used

in first phase is bigger than 100 reading units.

To leave function press MENU key and then

using T key chose PCS and PCS oFF.

Note:

1. APW too LOW communicate signalises

that a sample was not put on the pan or if

single piece weight is less than one-tenth

readout plot (counting is not possible).

2. APW LOW communicate signalizes that

single piece weight is more than one-tenth

but less than one readout plot. (counting

possible but with bigger errors, result

blinks).

3. In scales equipped with LED display pcs

sign is replaced with “ ■ ”.

g

5

+10

g

Page 43

USER MANUAL 43

__________________________________________________________________________________________________________________

18.3 Percentage weighing function (PErC)

This function allows displaying weighing result

in percents.

A measurement is performed in two phases:

- first phase – weighing a reference sample

(100%),

- second phase – measuring specific sample

as a percentage of the reference sample.

Weighing result is displayed in different format,

depending on the weight value of reference

sample.

The function has the following options:

- PEr oFF – disable the function,

- PEr on– set current scale indication as 100%

and activate percentage weighing,

-out- exit without changing settings.

Note:

1. PEr Err message informs that reference 100% mass is less than 0,5*Min or was not defined.

2. In scales with LCD display sign "■" is replaced with %.

100%

-5%

g

Page 44

44 USER MANUAL

__________________________________________________________________________________________________________________

18.4 Label choosing function (LAbEL)

This function is used in scale with ELTRON (SErIAL function) data protocol. This protocol enables label

printout with actual scale indication and chosen data from PrInt special function (variable data), for

example date and time. Other data, for example company address, product name, barcode can appear

on label as a constant text. Label patterns with number (4 digit) used by user should be saved in scale

memory according to printer manual. Label pattern choice is made by inscribing label number using

LAbEL function.

Press MENU button.

When LAbEL is displayed press T

key.

Actual label number will show.

To enter new label number press T

key, to exit function without number change

press MENU.

To inscribe label number use keys:

- digit increase,

T

- next digit,

MENU – end.

After entering label number, putting load and

pressing key will cause sending data to

label printer.

Data format sent to label printer (label nr 1,

language EPL-2):

US (55 53 0D 0A)

FR"0001" (46 52 22 30 30 30 31 22 0D 0A)

? (3F 0D 0A)

00:00 (30 30 3A 30 30 0D 0A)

2000.00.00 (32 30 30 30 2E 30 30 2E 30 30 0D 0A)

10 g (20 20 20 20 20 31 30 20 20 67 0D 0A)

P1 (50 31 0D 0A)

Page 45

USER MANUAL 45

__________________________________________________________________________________________________________________

18.5 Weighing animals function (LOC)

The function allows weighing animal moving on the scale.

Press MENU key.

When LOC function is displayed press T

key.

The following options appear on display

successively:

- LOC oFF – leave the function,

- LOC on – automatic weighing after loading the

scale,

- LOC Prn – the measurement initiated manually

by pressing key.

When LOC on is displayed press T key.

Tare the scale using T key if necessary and

place the animal on the pan.

Wait until the weighing result is averaged – scale

display blinks. Then scale will show stable

(averaged) result and will send it through serial

port.

The result remains on display for about 30

second.

Important notes:

1. The loads lower than Min value are not averaged.

2. In case when putting animal on scale takes more than 5s it is suggested to choose LOC PRN

option (measurement started manually by pressing key ).

g

g

g

g

Page 46

46 USER MANUAL

__________________________________________________________________________________________________________________

18.6 Constant tare memory function (tArE)

This function enables to measure gross weight of a sample placed in a container of a known weight value

(stored in the memory) and to display calculated net weight of the sample. Tare value is recalled from the

memory with 0 or T key when the pan is empty. Tare value may be entered using keypad or

by putting container on the pan.

Inscribing tare value to memory:

After pressing MENU key and choosing tArE

function using T key, the following options

are available:

- tAr 0FF – leave the function,

- tAr on – activate the function with the

previous tare value,

- tAr .. – sample tare value from the pan,

- tAr SEt– enter tare value with keys:

0

, , T and MENU

- out – printout a setting value of tare.

Press T key when tAr SEt is displayed.

By pressing T key choose proper

memory cell where tare will be stored: tAr

01, 02, ... , 10.

Choose inscribing method :

- MAnUAL – inscribing using keys: 0,

, T and MENU,

- Pan – inscribing mass value that is on the

pan.

After storing tare, the scale starts working with

inscribed tare value.

Note:

Tare value is stored in memory also after

unplugging the scale from the mains.

g

g

Page 47

USER MANUAL 47

__________________________________________________________________________________________________________________

Weighing with constant tare:

In order to use tare value that is located in

memory, choose from menu tArE function and

then tAr on option.

A list of memory cells will show up:

tAr 01, 02, ... , 10.

Cells with inscribed value are marked with "o"

sign on the left side, active value marked with

" ".

ATTENTION: In scales with LED display,

cells with inscribed value are marked with "■" .

Choose proper memory cell using T

key.

tArE function is activated with chosen tare

value. Moreover the scale will indicate nett

weight (weight on the pan minus tare values).

Using T key (or0, while empty pan)

causes scale zeroing and then substraction of

recalled tare. Minus indication will show up.

g

g

Page 48

48 USER MANUAL

__________________________________________________________________________________________________________________

18.7 Maximum value indication function (UP)

This function allows holding maximum (or minimum) value that is indicating at the moment.

Before measurement scale should be tared.

Function has following options:

-UP oFF – function off,

-HIGH – holding maximum value,

-LOW – holding minimum value.

Pressing T key will cause result zeroing.

Note:

Autozeroing function and the stabilisation

indicator are deactivated when UP function is

running.

g

1g

g

Page 49

USER MANUAL 49

__________________________________________________________________________________________________________________

18.8 Total weight function (totAL)

The function allows calculating total weight for

series of measurements, which can be greater

than scale capacity. It allows calculating total

weight as well as average value.

Press MENU key.

When totAL is displayed press T key.

The following options will appear successively:

- tot Prn - report printout without clearing total

register,

- tot oFF - clearing total register, report printout

and leaving the function,

- tot - working with receipt printout after

each measurement,

- tot - working without receipt printout,

- tot CFG – saving measurement mode (using

key: Manual, after taking off the load : auto).

Press T key when tot is displayed.

Perform measurement series by pressing

key for storing results into total register.

In order to print and display results enter the

function by choosing totAL and tot Prn option

from menu.

The results are displayed in the following

sequence:

- total weight (SUM ),

- number of registered measurements (n),

- average value (=),

regarding that moving to display successive

result is performed after pressing key.

Attention: In scales with LED display SUM sign is

replaced by “”.

In order to go back to total weighing without

zeroing total register press key several

times.

0

0

0

g

g

g

g

g

g

Page 50

50 USER MANUAL

__________________________________________________________________________________________________________________

To leave the function with clearing total register, select totAL function from menu and choose tot oFF

option. Scale prints the communicate informing about clearing registers.

The form of receipt after each measurement:

Report form:

Note:

When the scale doesn’t have an internal clock, Date and Time do not appear on printout.

Maximum number of measurements is 99 999.

Maximum total load 99 999 000d.

The weighing unit of the total value from the register (Total) is the same as the weighing unit stated on

the keypad or is 1000 times greater, what is signalled by “o” indicator at the left of the display.

If the registered value is too big to be displayed, “E” communicate appears on the display. If the number

of series is too high and cannot be displayed, “Err1”communicate appears on the display

Date: ... Time. ...

measurement no weight

measurement no weight

Date: ... Time. ...

TOTAL WEIGHT =

NUMBER OF SAMPLES =

AVERAGE VALUE =

Page 51

USER MANUAL 51

__________________________________________________________________________________________________________________

18.9 Checkweighing function (thr)

This function allows comparing weighing result with two programmed reference values: lower and upper

threshold. Comparison result is signalled with indicators (MIN, OK, MAX) and sound signal generated

when threshold values are exceeded.

If comparison result is:

- smaller than zero threshold – no signal,

- smaller than lower threshold – the scale signals MIN (yellow colour),

- between threshold values - the scale signals OK (green colour, with the short sound signal),

- greater than upper threshold - the scale signals MAX (red colour, long sound signal).

The checkweighing results can be use to control:

- optical indicator (Indication mode),

- batching devices (Batching mode).

-

Standard scale is set for cooperation with optical indicator.

On outputs P1-P3 (Relays socket) short-circuit states appear as result of comparison scale indication

with threshold values.

On the chart below output states are shown during increasing load on the scale for both working modes:

Indication mode: Batching mode:

P3

P1

P2

P3

zero

zero

treshold

treshold

thr I

thr I

thr I

thr II

thr II

thr II

P1

P2

In Batching mode on P1 (thr I) and P2 (thr II) outputs short-circuit impulses appears for time of 0,5s. On

P3 (zero) output short-circuit state appears when indication does not exceed threshold value signalling

zero load.

Page 52

52 USER MANUAL

__________________________________________________________________________________________________________________

Operation sequence:

Press MENU key and choose thr pressing

T

key.

The following options are displayed successively:

- thr oFF – deactivate the function,

- thr on – activate the function,

- thr Prn – check last threshold values (press

key several times),

- thr CFG – choose Relays socket mode:

IMPULS - Batching mode

SIGNAL – Indication mode.

Choose thr-on option using T key. The

following options for entering thresholds are

displayed:

- SEt-LO - set lower threshold value,

- SEt-HI - set upper threshold value,

- SEt-ZEr - set zero signalisation threshold.

Using T key select SEt-LO option.

Set lower threshold value using the following

keys:

- digit increase,

- decimal point,

T - move to next digit,

MENU - finish.

Then select SEt-HI option and enter upper

threshold value.

Choosing out option will cause starting work with

signalisation of exceeding thresholds and zero.

To change Relays socket mode use thr CFG

option. Default option is Indication.

To leave the function, press MENU key and then

choose thr and thr oFF options.

g

g

Page 53

USER MANUAL 53

__________________________________________________________________________________________________________________

Relays connection diagram:

Relays output is the open collector transoptor output with load capacity 25mA / 24V. Transmitter inputs

must be protected with diodes, e.g. 1N4148.

It is advised to use MS3K/P electronic board (sold separately), consisting of RM96P transmitters, with

DC24V input voltage and AC250V, 3A output.

Important notes:

1. After switching the scale on, both thresholds are set to maximum values.

2. When setting upper threshold value, pay attention that its value is not below lower threshold value.

3. Setting lower and upper threshold value is possible after sending appropriate orders from computer,

what is described in scale user manual.

Imax < 25mA

Page 54

54 USER MANUAL

__________________________________________________________________________________________________________________

18.10 Setting date and time function (dAtE)

The function allows setting current date and time

of scale internal clock and mode of its use.

The function has the following options:

- dAt oFF – deactivate date and time during

printout of current weighing result,

- dAt on – activate date and time during printout

of current indication ( key),

- dAt SEt - change current date and time,

- dAt PIn – data and time secure password (to

prevent from changing date and time by

unauthorized personel),

- dAt For – data printout in USA or EU format

- tM For – time printout in 24h or 12h format.

The example at the left presents how to set

current date and time using

dAt SEt option.

After setting proper date and time activate it with

dAt on option.

UE: rrrr-mm-dd gg:mm

USA: mm-dd-rrrr gg:mm AM/PM

(gg – hours, mm – minutes, AM – before noon,

PM – after noon, mm - month, dd - day, rrrr year).

Attention: Inscribing non-zero PIN value causes

showing PIN sign during next date and time

changing and inscribing 4 digit code is necessary.

(using keys 0, T and MENU).

g

Page 55

USER MANUAL 55

__________________________________________________________________________________________________________________

18.11 Statistical calculations function (StAt)

This function evaluates from series of measurements (max 1000) statistical parameters of weighting

process.

Adding successively measurements to register is automatic and it occur after the scale is loaded and its

indications stabilize.

After each loading printout is made with: number of measurements, result, date and time (if clock is

installed and the function is activated).

For the obtained measurements series the scale evaluates:

- n -number of samples

- sum x -sum of all samples

nxxsum _

- x -average value (sum x)/n

- min -minimal value from n samples

- max -maximal value from n samples

- max-min -maximal value minus minima value

- S -standard deviation

2

)(

)1(

1

n

n

xx

n

S

- srel -variance factor

x

S

srel

Statistical calculations results can be printed.

Page 56

56 USER MANUAL

__________________________________________________________________________________________________________________

Order of operations:

Press MENU key.

When StAt is displayed press T key.

The following options are displayed:

- StA Prn – monitoring and printout of statistical

data,

- StA oFF – deactivate function,

- StA – activate function, work with printout of

chosen weighting results,

- StA - – activate function, work without printout,

- StA n – maximal samples value,

- Sta nM – inscribing nominal value for statistics,

- Sta tOL – inscribing tolerance in %,

- Sta tAr – automatic tare on/off

- StA CFG – function configuration:

-Auto – Automatic work (samples are confirmed

after loading the scale and indication

stabilization.),

-ManuAL – manual work (confirmation is made

by pressing key).

- out – exit from function.

Remember first to inscribe nominal weight value

and tolerance (mentioned above).

After that, push T key when StA o is

displayed.

Put on successive objects on the pan (remove

after indication stabilization) in order to add them

to measurements register.

In order to obtain printed statistical results from

measurements series press MENU key and

T

key when StAt is displayed and later StA

Prn.

After printout two options are enabled:

- rESET – erasing results,

- Contin – continuation.

g

g

g

Page 57

USER MANUAL 57

__________________________________________________________________________________________________________________

Pressing key printouts estimated values and histogram :

Nominal - nominal value,

Tolerance - accepted value in percentage.

N - number of sample

IN TOL. – number of samples in toleranc

-TOL – amount of measurements

under allowable lower value

+TOL – amount of measurements above

allowable upper value

TOTAL - sum of weights of all n samples

AVERAGE – average weight as (Total)/n

MIN – minimum weight in n samples

MAX– maximum weight in n samples

ST. DEV. – standard deviation

ST. DEV.% – standard deviation percentage

To finish work with this function and

zeroing result register press MENU

key and then when StAt. and Sta oFF is

displayed press T button.

Statistics function cooperation with computer and

Printer. Scale can be equipped with two serial ports

marked as RS232C-I (computer) and RS232C-II

(printer). After each data printout by printer identical

set of data is sent to computer. After sending by

computer initialization signal S A CR LF

(53h 49h 0Dh 0Ah) the scale sends to computer

statistic data enclosed in histogram.

Page 58

58 USER MANUAL

__________________________________________________________________________________________________________________

18.12 Function for summing recipe ingredients (rECIPE)

The function allows for separate weighing of

several ingredients in one container with the

possibility of reading current sum of all

weighed ingredients.

The function includes the following options:

-rEC oFF – leave the function with the

possibility of read sum mass,

-rEC on – start recipe weighing,

-rEC Con – continue previous recipe,

-out – exit without changes.

When proceeding with recipe, successive

ingredients (A, B, C, etc.) are weighed each

time starting from zero indication, which is

obtained after scale taring.

If several ingredients are weighed, their sum

mass can be read (despite several taring). For

this purpose use or rEC oFF option.

Using once again enables fast return to

recipe.

In order to turn off rECIPE fucntion press

MENU key and then using T key choose

rECIPE and rEC oFF.

Comments:

o indicator on the left side of scale display

shows rECIPE function is active.

SUM indicator shown when rEC oFF option is

used, disappears after using T key.

g

g

g

g

g

g

g

A

A+B+C

B

C

g

Page 59

USER MANUAL 59

__________________________________________________________________________________________________________________

18.13 Density determination (dEnSItY)

Solids density determination

This function calculates material density

basing on its weight in air and in water using

the formula below:

where, m1 – weigh in air

m2 – weight in water

L

- density of liquid

If distilled water (H2O) or ethanol (EthAnOL)

is used, enter its exact temperature (accurate

to 0,5°C) – the balance will calculate its

density automatically.

To enter the value use the following keys:

- digit increase,

- decimal point,

T - next digit,

MENU - end.

When using liquid other than distilled water or

ethanol, choose OTHER option and enter its

density according to its temperature.

Phase I: measurement in air.

Phase II: measurement in liquid.

To print measurement result and begin next

measurement press key.

L

mm

m

*

21

1

g

g

g

g

Page 60

60 USER MANUAL

__________________________________________________________________________________________________________________

To print a density determination report after all necessary measurements, connect a printer to the

balance and press key. A sample for solid mass density determination is shown below:

------------------DENSITY---------------------

Mass in the air

= ...

Mass in the liquid

= ... g

Mass density

= ... g/cm3

Density with comp.

Water density

Water temperature

= ... g/cm

3

= ... g/cm

3

= ... oC

Operation sequence (weighing in air and in liquid) for below-balance weighing:

Phase I: measurement in air.

Phase II: measurement in liquid.

Page 61

USER MANUAL 61

__________________________________________________________________________________________________________________