Page 1

User Manual

Moisture Analyser

AGS series

Measuring method description

Ver. 1 2014-08-28

Page 2

2

USER MANUAL

Contents:

1. General description 3

2. Completeness 3

3. Security rules 4

4. Environment protection 5

5. Technical data 5

6. Keys and indicators 6

7. Preparing moisture analyser to work 7

8. Interfaces 9

9. General working rules 9

10. Description of thermogravimetric analysis 10

10.1 Infrared radiation source 10

10.2 Infrared radiation drying description 10

10.3 Drawing and preparation of a sample 11

10.4 Tools requirements 11

10.5 Single-use pans 11

10.6 Placing a sample 11

10.7 Glass fibre filter 12

10.8 Selection of drying parameters to the sample material 12

10.9 Other practical notes 13

11. Moisture analyser functioning description 14

11.1 Switching on 14

11.2 Drier operation modes 15

11.3 Calculation methods 16

11.4 Drier operation parameters setting 17

11.4.1 Drying profiles 18

11.5 Moisture analyser settings storing 19

11.5.1 Saving settings 19

11.5.2 Loading saved settings 20

11.6 Initial moisture analysis 21

11.7 Proper moisture analysis 23

11.8 Internal thermometer indications correction 24

12. Connecting to a computer or a printer 27

13. Testing and calibration of the balance 29

14. Moisture analyser as a balance 31

14.1 Units 31

14.2 Auto-zeroing 32

14.3 Calibration 33

15. Maintenance and repairs of small defects 35

Declaration of Conformity 37

Drying parameters for different substances (examples) 38

Page 3

USER MANUAL

3

1. General description

AGS series moisture analyser is destined for fast and precise moisture determination.

The moisture analyser is based on two cooperating devices: the balance, used to

measure current sample weight, and the dryer, which dries the sample using halogen

heaters. Drying parameters may be set according to user preferences. See appendix.

Moisture analysers are mainly destined for use in quality control in food industry,

building materials industry, biotechnology, pharmacy, environment protection and

others.

Moisture analysers may be also used as laboratory balances for routine weighing

(without drying).

2. Completeness

Standard package consists of:

1. Moisture analyser,

2. Pan shield, pan support, pan handle,

3. Single-use pans – 10 pcs,

4. Power supply cord,

5. User manual,

6. Guarantee card.

Options on demand:

6. PT-105 control thermometer with GT-105 sk-8 probe (silicon cable, 160°C) or with

GT-105 so-8 probe (cable with steel braid)

7. Distance sleeve 15mm – 1 piece

Page 4

4

USER MANUAL

3. Security rules

To avoid electrical shock or damage of the moisture

analyzer or connected peripheral devices, it is necessary

to follow the security rules below.

To feed the analyser use only mains socket with ground contact.

Dryer chamber cover heats up to 40°C, but perforated cover at the top may

heat up over 60°C. Do not touch the cover top during drying as it may cause

severe burns!

During heating, the halogen heaters warm up to very high temperature. Avoid

touching the heaters as it may cause severe burns!

All repairs and necessary regulations can be made by authorised personnel

only.

Do not use the analyser when its cover is opened.

Do not use the analyser in explosive conditions.

Do not use the analyser in high humidity.

If the device seems not to operate properly, plug it out of the mains and do not

use it until checked by authorised service.

Page 5

USER MANUAL

5

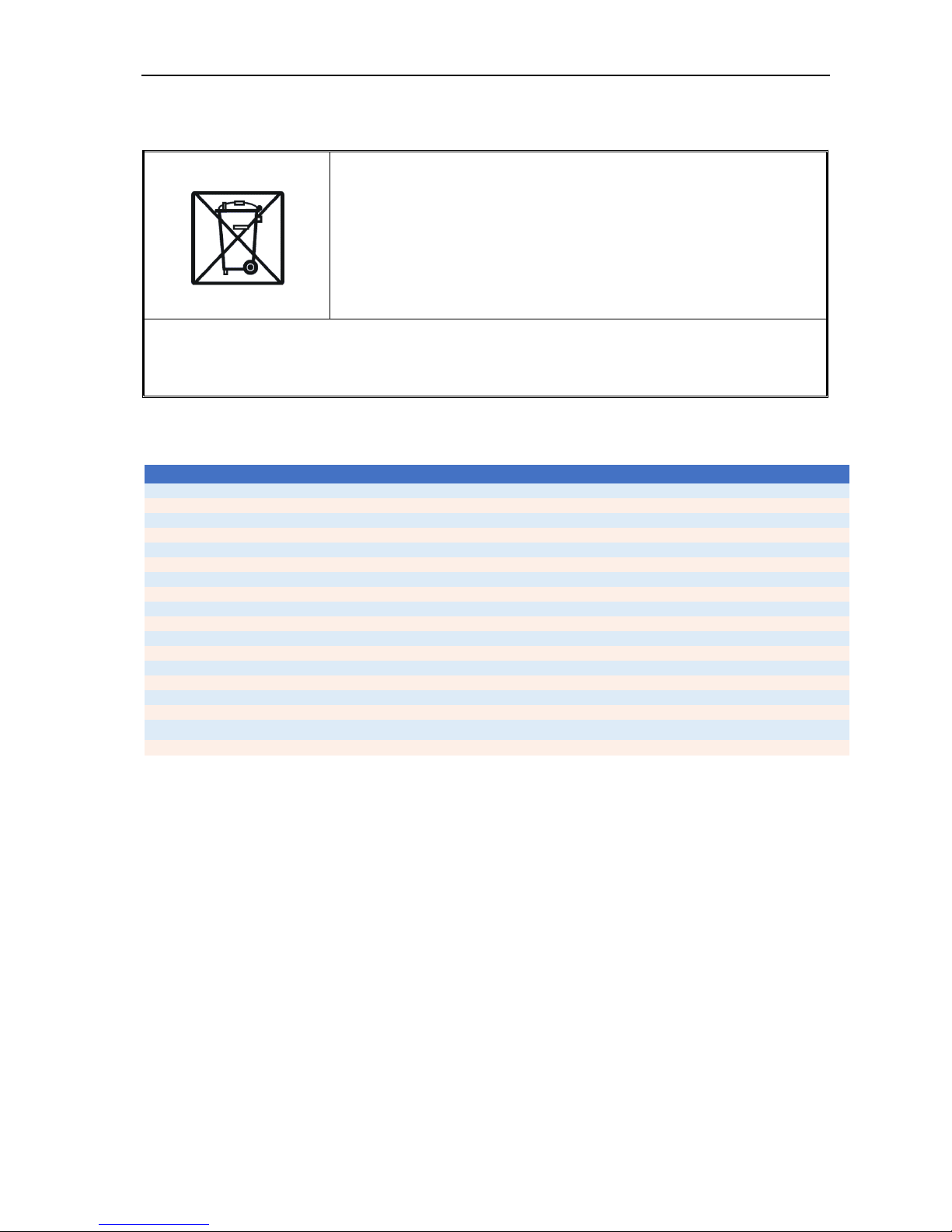

4. Environment protection

According to legal regulations it if forbidden to dispose

wasted electronic equipment in waste containers.

Please return wasted device to the point of purchase or other company

specialised in recycling of wasted electronic components.

5. Technical data

Technical data Moisture analyzers

Model AGS200/T250

Range (Max) 200g

Readout unit (d) 1mg

Work temperature +18 + +33°C

Humidity readout precision 0,01%

Humidity results repeatibility

for sam ple 2g … ± 0,3%, for 5g … ±0,06%

Drying maximal temperatura 250°C

Sample time

1 ÷ 180s

Maximal drying time 10h

Halogen radiators 2 x 500W 118mm

Chamber heating time up to 100°C about 1 min.

Pan dimensions

ɸ 90mm

Connections Rs232C (for computer and printer), USB (for computer), PS2 (for computer keyboard)

Dimensions (with legs) 215(235)x345x200mm

Drying chamber dimensions ɸ 108 x 20mm

Supply 110V 60Hz 300VA

Weight 7 kg

Recommended calibration weifht (OIML) F2 200g

Page 6

6

USER MANUAL

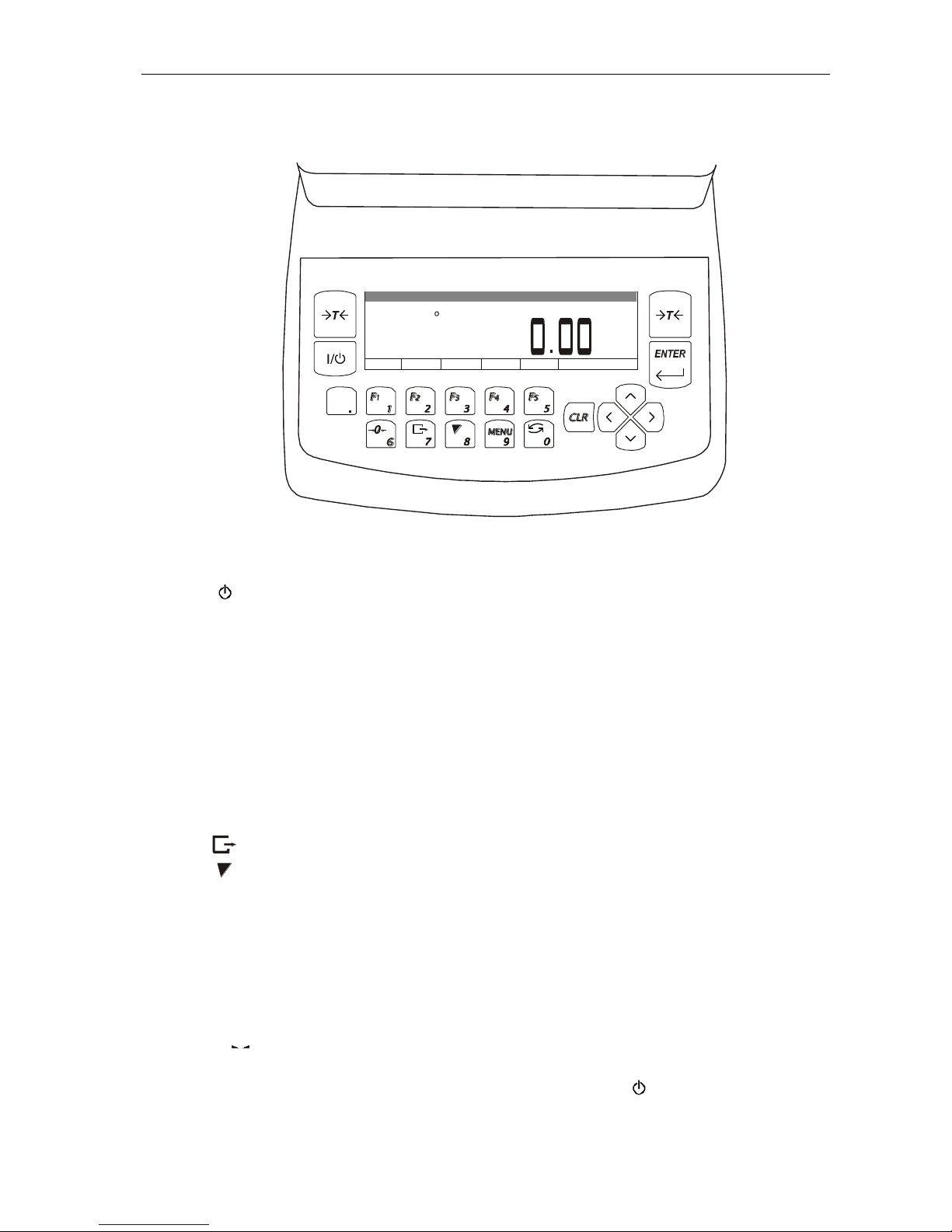

6. Keys and indicators

T = 24,35 C

m = 4,321g

t = 0:00:00s

m0= 0.000g

%

START

SET

RAP

MEM

STOP

T

- tare (subtract package weight from weighed mass)

I/

- switch- on / switch-off (standby),

ENTER

CLR

- confirmation / select the option,

- cancel operation

.

- decimal point,

1/F1

- digit key 1 / START – start measurement (drying),

2/F2

- digit key 2 / SETTINGS – moisture measurement parameters

setting,

3/F3

- digit key 3 / STAT – drying chart, measurement report,

4/F4

- digit key 4 / MEM – settings memory,

5/F5

- digit key 5 / STOP – instant drying termination,

6/0

- digit key 6 / zeroing (optional)

7/

- digit key 7 / printout (data transmission),

8/

- digit key 8 / autocalibration (unused function),

9/MENU

- digit key 9 / enter the function menu

0/

- digit key 0 / mode switching (analyser – balance)

>

- enter the option,

<

- leave the option,

∧

- navigation / move the cursor up,

∨

- navigation / move the cursor down,

indicator

- result stabilisation,

bar indicator

- total load indicator (0-100%),

indicator OFF

- stand-by mode (when switched-off with I/ , key),

Max, Min, d, e

- metrologic parameters.

Page 7

USER MANUAL

7

7. Preparing moisture analyser to work

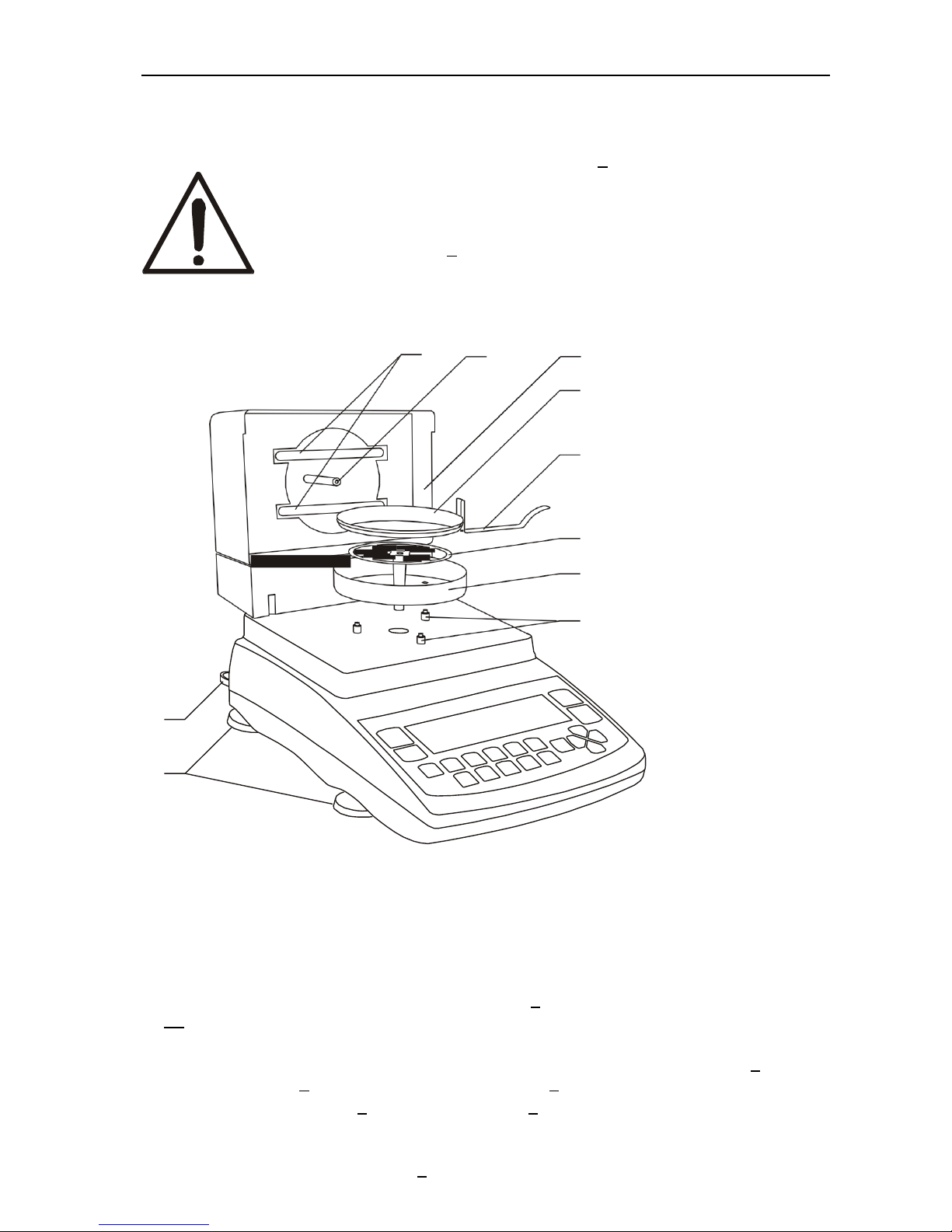

During heating, the halogen heaters 1 warm up to very high

temperature. When drying chamber is opened avoid touching the

heaters as it may cause severe burns or damage the heaters!

Dryer chamber cover 3 heats up to 40°C, but perforated cover may

heat up over 60°C. Do not touch the top cover during drying as it may

cause severe burns!

1

2

3

7

6

5

4

1 – halogen heaters

2 – temperature sensor

3 – chamber cover

4 – dryer chamber

5 – pan plate

6 – single-use pan grip

7 – single-use pa

8 – distance stake

9 – regulated legs

10 – level

8

10

9

1. Take all contents out of a package: the moisture analyser and packed separately: the

tin pan shield, single use pans, the pan handle and the pan support. It is

recommended to keep the original moisture analyzer package in order to transport

the moisture analyzer safely in future

2. Place the moisture analyzer on a stable ground not affected by mechanical vibrations

and airflows.

3. Level the moisture analyzer with rotating legs 9 so that the air bubble in water-level

10 at the back of the moisture analyzer is in the middle and the moisture analyser

rests on all four legs.

4. Open the dryer chamber with the handle at the front. Put the pan shield 4 on three

distance sleeves 8. Gently insert the pan support 5 into the mechanism hole.

5. Place a single use pan 7 on the pan handle 6 and put the pan on the pan support

(the handle shou ld rest on the pan shield so that it does not touch the pan or the pan

support).

6. Close the drying chamber cover 3 and plug the device to the mains (230V).

Page 8

8

USER MANUAL

7. After self-tests and result stabilisation zero indication is displayed. The dryer starts

initial heating (signalised with an appropriate communicate). After initial heating the

moisture analyser is ready to work.

When temperature during initial heating exceeds 105°C or heating

time is longer than 1 minute, terminate initial heating with CLR key and

check if the temperature sensor 2 works properly and if both halogen

heaters light 1 (see chapter 15).

In case any defect occurs contact an authorised service point.

8. The moisture analyzer should not be used to weigh ferromagnetic materials due to

accuracy decrease.

Page 9

USER MANUAL

9

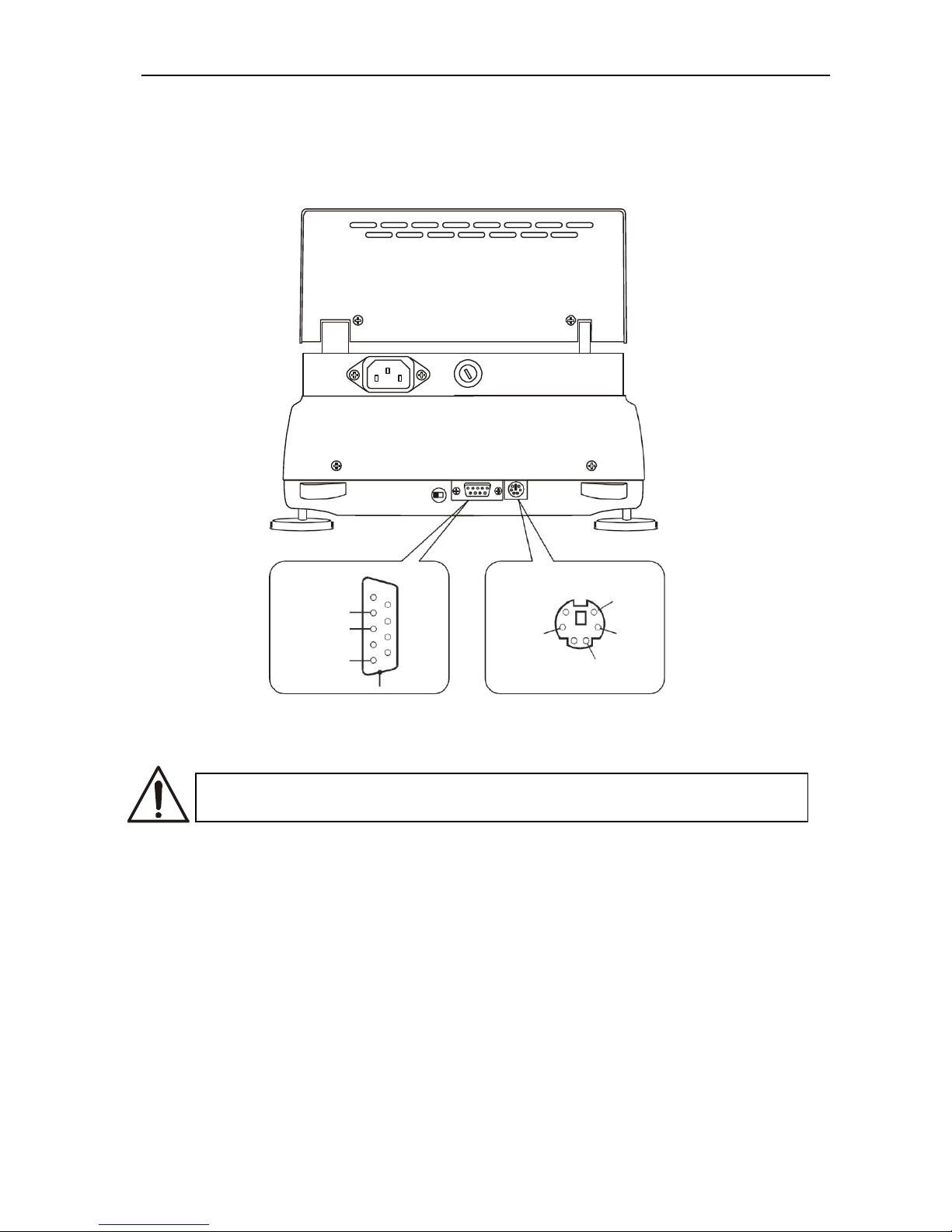

8. Interfaces

The moisture analyser is equipped with RS232C interface to connect a printer or a

computer and with PS2 port to connect an external computer keyboard.

RS232C

PS2

1

RxD

(receiver)

2

TxD

(transmitter)

3

4

GND

5

7

8

case

+5V

6

5

4 3

2 1

Data

Clock

GND

9. General working rules

During transportation remove the pan, the pan support and the pan

shield and place it in a separate package.

1. Distribute a sample all over the pan. A sample surface should not touch temperature

sensor placed above the pan.

2. The balance is equipped with the tare equal to its range. To tare the balance press

T key. Writing the tare does not extend measuring range, but only subtracts the

tare value from a load placed on the pan. To make weight control easier and to avoid

range overdrawing, the balance is equipped with weight indicator (graduated in

percentages).

3. Do not overload the moisture analyzer more then 20% of maximum load (Max).

4. The mechanism of the balance is a precise device sensitive to mechanical strokes

and shocks. Do not press the pan with a hand.

Page 10

10

USER MANUAL

10. Description of thermogravimetric analysis

This section gives some practical details about moisture analysis using infrared

radiation for reliable results and easier use of moisture analyser. The description is

based on a pre-production experience and

customers‟

suggestions.

Moisture in substances is an essential quality factor of technical and economical

importance.

Methods of determining moisture may be grouped in two main categories: absolute and

deductive.

Absolute methods are based on simple relations, e.g. weight decline during drying.

Thermogravimetric analysis used in AXIS moisture analyser is an example of this

method.

Deductive (indirect) methods measure physical quantity related with moisture, e.g.

electromagnetic waves absorption, electrical conductance, acoustic wave speed. Some

of these methods, unlike thermogravimetric analysis, enable to determine water content.

Thermogravimetry - lat. thermo – heat, gravi – weight, metry – method

Thermogravimetric analysis – a process of determination of a substance mass

decline as a result of heat-up. The sample is weighed before and after heating-up, the

difference is calculated in relation to initial weight or final weight (dry mass).

Moisture in substances

Thermogravimetric analysis includes all ingredients evaporating from substances during

heating-up, which results in weight decrease.

In result of the above, determining of moisture content in substances is not equal water

content. Beside water, moisture consists of all other volatile matter: fats, alcohol,

aromas, organic dissolvent and other substances resultant as en effect of thermal

decomposition.

Thermogravimetric analysis does not distinguish water from other volatile matters.

Infrared radiation drying is more effective than traditional methods (e.g. in an oven) as

the radiation deeply penetrates the substance, which shortens drying time.

10.1 Infrared radiation source

ADS series moisture analyser uses 2 halogen heaters (rated power 200W, l=118mm) in

serial connection as a radiation source. The heaters emit also visible radiation, which

does not affect drying process.

10.2 Infrared radiation drying description

Sample drying is a result of absorption of infrared radiation, which results in sample

temperature increase and evaporation of volatile matters.

Infrared radiation penetrates surface layers, the depth depends on penetrability of a

sample (different in various substances). Part of radiation is reflected by the sample

surface. Penetrated layers absorb the radiation and convert its energy into heat. Emitted

heat propagates inside the sample. Effectiveness of the propagation depends on

thermal conductivity of the sample. The better the conductivity, the faster drying process

and volatile matter evaporation. During drying process sample parameters change, its

thermal conductivity decreases so there is a risk of burning the sample. Some

parameters may be estimated “by sight”, e.g. smooth and light surfaces reflect radiation

better. This must be taken into account when setting drying parameters.

Page 11

USER MANUAL

11

10.3 Drawing and preparation of a sample

As sample of given substance must be representative, drawing and preparing a sample

is very important process as it affects repeatability of measurements. The most common

method of homogenizing a sample is mixing. The other method is to draw few samples

from different but specific points in a substance and calculate an average value.

Another – to draw few samples from different points in a substance, mix them and draw

a sample from the mixed samples.

Sampling method depends on the object of a research. For quality pu rpose many

representative samples are analysed. In production control it is enough to assure

sampling repeatability, which enables to study a tendency.

While preparing and drawing, it is important that the sample does not absorb moisture

from the environment – it is advised that operation time is as short as possible.

If it is necessary to analyse more than one sample at the same time, the samples

should be closed in plastic bags or other isolated containers. Give attention that

samples must not lose moisture inside the container (the container should not consist of

to much air, the moisture condensed on the sides of the container should be mixed with

the sample again).

10.4 Tools requirements

Tools and instruments used in preparation process may affect measurement accuracy,

so it is advised not to use tools that transmit heat, as it makes the sample lose moisture

before analysis.

Use only special mills and pestles.

In case of liquids with consisting of solid materials use a glass mixer, a spoon or a

magnetic mixer.

10.5 Single-use pans

To analyse the moisture, put a sample on a single-use pan and place it in the dryer

chamber.

Using non-reusable pan helps to avoid false results by remains of previous samples.

10 single use pans are provided with the moisture analyser. Any quantity may be

delivered on demand.

10.6 Placing a sample

A sample should be placed uniformly all over the pan, so that heat propagates equally

all over the sample and dries whole sample effectively and quickly without leaving “wet”

places.

Correct Incorrect

Page 12

12

USER MANUAL

Attention:

Due to temperature sensor localisation, max sample height is 10mm.

When substance ply is too thick, surface layers will be heated too much and internal –

not enough. This may result in burning the sample or surface incrustation, which will

make drying process difficult and measuring result false.

A sample should be placed in uniformed layers 2†5mm thick, weighing 5†15g,

depending on a substance.

10.7 Glass fibre filter

When drying liquids, pastes or substances that may melt or loose liquid during drying, it

is advised to use glass fibre filters.

Filters ensure equal liquid distribution or, in case solid materials, avoiding burning a

sample.

10.8 Selection of drying parameters to the sample material

Selection of proper temperature and drying time is essential to achieve precise humidity

measurement. Drying parameters are selected properly if repeatability is on satisfactory

level, usually between 0,11%.

Parameters choice should be made in 3 steps:

Step 1: Drying temperature is related to the physico-chemical properties of the sample.

It is determined by the number of tests carried out in several successive temperatures,

e.g., at intervals of 10 ° C. Proper temperature is the highest value for which the sample

for a few minutes does not change color and smell. Changing the color or odor indicates

the start of the oxidation of the sample, which changes the properties of the sample,

which usually affects the measurement accuracy.

Step 2: Weight of sample used should be large enough to use the entire surface of the

pan, however, the thinner the layer of sample the better the drying process proceeds.

The top and bottom layers of the material should be dried similarly at the same time. If

the material is covered with shell and some moisture is trapped in the material, user

should disintegrate the material or reduce the drying temperature. For liquid materials

is preferable to use filter which accelerates the drying.

Step 3: Select drying time to chosen mass of sample. To do this, set the moisture

analyzer‟s drying time as long as possible and observe the drying process. Minimum

drying time is the one at which the sample

doesn‟t

change its weight by more than

allowed by the examiner measurement error. Proper drying time is designated minimum

drying time with reserve. The percentage value of the reserve must exceed the mass of

the sample dispersion - the drying sample time is proportional to the mass of the

sample.

After a few measurements with the designated drying parameters and making sure that

the reproducibility of the results is satisfactory user can proceed to optimize the

measurement time by selecting favorable Drying profile and using Short measurement

mode. Of course you should check that the reproducibility of the results was not

seriously affected.

Sample values for the most common materials are given in the Appendix, however, be

regarded only as preliminary data and it is recommended to carry out the procedure for

parameters selection for the test material.

Page 13

USER MANUAL

13

10.9 Other practical notes

It is preferable to work with the same mass of the sample at each measurement to

measure the size of the sample in a reproducible way. It is best to use the same

instruments for the application of the sample.

Put a sample on the pan as quickly as possible to avoid losing moisture.

Temperature inside the chamber is much higher than outside, so the sample may

evaporate partly before measurement begins, which will result in a false result.

When analysing the same substance quantity in successive measurements, use the

same tools to put a sample to be sure that samples are each time of the same size.

Before putting a sample, tare a single-use pan and take it out of the chamber. Right

after putting a sample on the pan, place it inside the analyser chamber, close the

chamber and press START.

Be sure that no dirt sticks under the pan, as it may increase sample weight and result in

false values.

Page 14

14

USER MANUAL

11. Moisture analyser functioning description

11.1 Switching on

After switching-on the moisture analyser proceeds with self-tests.

model INITIALIZATION program version

CPU

EEPROM

...

...

After completing self-tests, the analyser is tared and the dryer begins initial heating

necessary to create thermal conditions suitable for measurements.

m0-m/m0*100% Ts=120C ts= 0:10:00s

T= 32.23C

m=0.000g

INITIAL

HEATING

Initial heating should warm the drying chamber up to 105°C within 1 minute.

When temperature during initial heating exceeds 105°C or heating time is longer than 1

minute, terminate initial heating with CLR key and check if the analyser is not damaged

(see chapter 15).

After initial heating is completed (or terminated), the device displays the following

information:

m0-m/m0*100% Ts=120C tp= 10s

T = 32.23C

m= 0.000g

t =0:00:00s

m0= 0.000g

0.00 %

START

SET

RAP

MEM

STOP

Legend:

m0-m/m0*100% - formula used to calculate the moisture

Ts – defined drying temperature

ts – defined drying time

T – current temperature in the drying chamber

m – current weight,

t – current drying time

m0 – initial weight

- indicator of drying profile

Page 15

USER MANUAL

15

11.2 Drier operation modes

During the balance – drier operation sampling of the mass on the pan takes place.

Sampling time is set by the user, according to drying process speed. As a result of

sampling the current humidity value is calculated and displayed. Measurement is

finished depending on selected Drying mode:

1. In Time mode total humidity measurement time (Drying time) is defined by the user,

2. In Short mode humidity measurement is finished, when drying is stopped and

differences of a few successive mass samples are smaller than threshold value (2 mg).

Amount of successive samples taken into consideration is defined as Samples quantity.

Measurement is finished when Drying time is exceeded at the latest.

m

<2mg

Stop

>2mg

Start

Ts

Qualifying amount

t

(3 samples)

Drying chart in Short mode for Samples quantity = 3.

Page 16

16

USER MANUAL

11.3 Calculation methods

Humidity may be calculated upon the basis of various mathematic formulas, defined in

balance – drier as Calculation method:

1. Relative humidity, defined in relation to initial mass

w [%] = m0-m/m0*100% ,

where m0 – initial mass, m- current mass

2. Relative humidity, defined in relation to current mass

w [%] = m0-m/m*100% ,

3. Percent current mass content in sample

w [%] = m/ m0*100% .

Drying temperature is maximum temperature, measured by sensor, located in the dried

material vicinity. Note that the dried material temperature may be higher than its

surrounding temperature.

Page 17

USER MANUAL

17

START

SET

RAP

MEM

STOP

11.4 Drier operation parameters setting

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

m = 0.000g

t = 0:00:00s

Select Settings option by pressing F2

key.

and ∨

m0= 0.000g

0.00 %

successive menu positions are

selected, e.g. Mode.

F1 F2 F3 F4 F5

SETTINGS

1. Drying temp. : 60C

2. Mode : Time mode

3. Calculation : m0-m/m0*100%

4. Samples quantity : 2

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles

8. Settings storing : 1

ENTER

SETTINGS

1. Drying temp. : 60C

2. Mode : Time mode

3. Calculation : m0-m/m0*100%

4. Samples quantity : 2

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles

8. Settings storing : 1

<

>

ENTER

SETTINGS

1. Drying temp. : 60C

2. Mode : Time mode

3. Calculation : m0-m/m0*100%

4. Samples quantity : 2

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles

8. Settings storing : 1

9.Temp. correction

10. Exit

To go to options selection press

ENTER.

Appropriate option, e.g. Time mode,

is selected with the navigation keys <

and >. Selected option is accepted

after pressing ENTER.

Set the following positions:

- Operation Mode – Time mode or

short mode,

- Calculation method – humidity

calculation formula,

- Drying temperature –temperature in

drying chamber),..

- Samples quantity (2, 3, 4 or 5) –

amount deciding of drying end (in

case of Short mode only)

- Sampling interval – interval

between successive mass

measurements (1180s.),

- Drying time (1s 10h) (in Short

mode it will be the maximum

allowable time for drying process)

- Drying profile – (standard, slow,

step or quick type)

- Settings storing– number of

memory location (110), where the

settings will be stored.

To finish settings, select Exit and

press ENTER.

Note: All defined parameters are stored in the memory until the next changed (also

after unplugging the device from the mains).

Page 18

18

USER MANUAL

11.4.1 Drying profiles

DRY

ING

PROFILES

1. Drying temp. : 120C

2. Mode : Short mode

3. Calculation : m0-m/m0*100%

4. Samples quantity : 2 samples

5. Sampling interval : 10s

6. Drying time : 0:10:00s

7. Drying profiles : standard

8. Settings storing : 1

9. Temp. correction

ENTER

DRY

ING

PROFILES

Drying profile : <standard>

T=120C T

Exit

Drying profile will be used to

optimization of drying process by

accommodation a process to

physical properties of sample

material.

Step or slow profile can be used to

oxidizing or surfaces thicken

materials. Quick profile can be used

to immune materials.

Profile chooses and his parameters

should be the result of experience

with the test material.

120C

Selected a drying profile by ENTER

key, choose a adequate profile

(standard, slow, step or quick) and

t

set a temperature (T) and time (t)

value.

DRY

ING

PROFILES

Drying profile : <slow>

t1=100s T

Exit

120C

t1

DRY

ING

PRO

FILES

Drying profile : <step>

t1=100s

T1=60C T

t2=100s 120C

T2=90C

Exit t1 t2

t

DRY

ING

PROFILES

Drying profile : <quick>

t1=100s

T1=140C T T1

Exit 120C

Caution:

The ending temperature can be

setting on Standard profile or Setting

(Main menu) only

t1

t

.

Page 19

USER MANUAL

19

11.5 Moisture analyser settings storing

The moisture analyser enables to save 10 different drying settings. Saved settings are

kept in the memory even after unplugging moisture analyzer from the mains.

11.5.1 Saving settings

To save drying settings follow the instructions below:

ms-ma/ms*100% T=120C ts= 0:10:00s

T = 32.23C

m = 0.000g

t = 0:00:00s

m0= 0.000g

START SET RAP MEM STOP

Press F2 key to choose SET option.

SETTINGS

1. Mode : Time mode

2. Calculation : m0-m/m0*100%

3. Drying temp. : 60C

4. Samples quantity : OFF

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles

8. Settings storing : 1

Exit

Set necessary drying settings (see

chapter 11.4).

Select Settings storing option using ∧

and ∨ and press ENTER to accept.

< >

ENTER

SETTINGS

1. Mode : Time mode

2. Calculation : m0-m/m0*100%

3. Drying temp. : 60C

4. Samples quantity : OFF

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles

8. Settings storing : < 2 >

Exit

Choose a reference number for

specific setting using < and > keys

and press ENTER to accept. Than

chose Exit and press ENTER.

< >

ENTER

SETTINGS

Save settings?

NO

YES

To save settings choose YES and

press ENTER to accept.

ENTER

Page 20

20

USER MANUAL

SETTINGS

MEMORY

Memory location < 1 >

Settings

Time mode

m0-m/m0*100%

Sq = 4 samples

ts = 0:010:00s

Ts = 120C

tp = 10s

<

>

ENTER

SETTINGS

Saving . . .

The analyser displays a short

communicate Saving.... After the

parameters are saved the analyser is

ready to work with new drying

parameters.

11.5.2 Loading saved settings

ms-ma/ms*100% Ts=120C ts= 0:10:00s

T = 32.23C

m = 0.000g

t = 0:00:00s

m0= 0.000g

START SET RAP MEM STOP

To load saved settings, stored in the

memory, choose MEM option using

F4 key.

F1 F2 F3 F4 F5

Select a number of desired settings

using navigation keys < and >. Press

ENTER to accept.

Page 21

USER MANUAL

21

11.6 Initial moisture analysis

To determine optimal drying parameters for unknown sample, it is recommended to

perform initial measurement with activated drying chart displaying. To do this, set the

following drying parameters (see Drying parameters setting):

- Operation Mode: Time mode

- Calculation method: m0-m/m0*100%

- Drying temperature:

organic substances: 80 - 120 0C

inorganic substances: 140 - 160 0C

- Samples quantity: do not set

- Sampling interval: 1 second

- Drying time: set time, after which the sample will be definitely dried

To activate displaying of drying chart, which will be visible on the display instead of

humidity indication, perform the following actions:

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

Choose RAP option with F3 key,

select Drying chart and press

m= 0.000g

t =0:00:00s

m0= 0.000g

0.00 %

ENTER.

START

SET

RAP

MEM

STOP

F1 F2 F3 F4 F5

DRY

ING

REPORT

1. Drying chart : OFF

2. Product name :

3. Operator :

4. Notes :

5. Transmission : OFF

Exit

Choose Drying chart using ∧ and ∨

keys and press ENTER.

ENTER

DRY

ING

RAPORT

1. Drying chart : ON

2. Product name :

3. Operator :

4. Notes :

5. Transmission : OFF

Exit

< > ENTER

Using < and > keys choose ON and

press ENTER.

Set the following positions:

- Product name,

- Operator,

- Notes.

Use number keys or external keyboard with PS-2 socket (option).

Page 22

22

USER MANUAL

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 118.34C 30%

m = 0.592g

t = 0:04:33s

m0= 0.695g

When drying chart is visible, place a

sample on the pan and choose

START option (F1 key). Drying

parameters and drying process chart

are presented on the display.

START

SET

RAP

MEM

STOP

F1 F2 F3 F4 F5

Observing drying process chart it is possible to evaluate its course and define time

required for complete drying. The chart shows 160 time samples on the X axis (for

longer times chart is scaled to 360 samples, 720, etc.) and humidity value according to

selected formula on the Y axis (chart is automatically scaled to 10%, 30%, 50%, etc.).

Selecting 1 s of sampling time allows for more precise chart.

Achieved chart allows for initial settings selection for main measurement. Drying

temperature should be selected according to dries material type, so the drying is

performed quickly an d sample does not change colour. Material drying moment is

visible on the chart as drying characteristic bending. As Drying time for main humidity

measurement select time from the beginning to chart “flattening”. As the time axis is not

described on the chart, use “evaluation with high margin”. Too short drying time does

not allow to achieve precise humidity measurement results.

In case of Short mode, in main measurement select Sampling time, which allows to

include approx. 10 samples in time of characteristic bending. If drying is finished too

quickly, increase Samples quantity or Sampling time.

Notes:

1. Before main measurement remember about deactivating of chart displaying.

2. To improve operation it is possible to use Promas software (available on demand),

which generates precise drying chart.

Page 23

USER MANUAL

23

START

SET

RAP

MEM

STOP

END

11.7 Proper moisture analysis

Before measurement carefully prepare the sample (as described in chapter Description

of Thermogravimetric Analysis) and set correct drying parameters (see chapter Working

Parameters Setting).

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

m= 0.000g

Place an empty single-use pan and

tare the balance with T key.

Open the drying chamber and using

the pan handle place the single-use

t =0:00:00s

m0= 0.000g

0.00 %

pan with the sample on the pan

support. Close the chamber.

START

SET

RAP

MEM

STOP

SAMPLE

T

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

m= 2.033g

Start the measurement choosing

START option (F1 key).

Drying in progress is signalised with

t =0:00:00s

m0= 2.033g

0.00 %

alternating SAMPLE /DRYING

communicate.

START

SET

RAP

MEM

STOP

SAMPLE

F1 F2 F3 F4 F5

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

Wait until END communicate

appears. Now read the result.

Attention: No STB communicate

and m0 sign in negative, marks

m= 2.013g

t =0:00:50s

m0= 2.033g

1.00

%

acceptance of unstable initial mass

value m0, caused by pressing the

pan to chamber wall or by too fast

sample drying, which can cause to

measurement failures.

During the measurement the following information is displayed:

m0-m/m0*100% - mathematic formula used for calculations

T s – defined drying temperature

ts - defined drying time

T – current drying temperature

m – current weight

t – current drying time

m0 – initial weight

Page 24

24

USER MANUAL

0.00 %

11.8 Internal thermometer indications correction

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

m= 0.000g

If necessary 2 point indication

correction of internal moisture

analyzer thermometer based on

measurement made by external

t =0:00:00s

m0= 0.000g

0.00 %

control thermometer is available

(inscribe temperature values T1 and

T2 and their equivalent values

START UST RAP PAM STOP

measured by external thermometer

and then set Status to ON).

F1 F2 F3 F4 F5

SETTINGS

1. Mode : Time mode

2. Calculation : m0-m/m0*100%

3. Drying temp. : 60C

4. Samples quantity : OFF

5. Sampling interval : 10s

6. Drying time : 0:00:10s

7. Drying profiles : Slow

8. Settings storing : 1

9. Temp. correction : OFF

Exit

Chooose option Settings by pressing

F2 key.

By using navigation keys ∧ and ∨

choose option Temp.correction

ENTER

CORRECTION TEMPERATURE

1. Device temp. T1 =

2. Contr. temp. T1=

3. Device temp. T2 =

4. Contr. temp. T2=

5. Status <ON>

6. Exit

In order to inscribe temperatures

press ENTER key.

In order to end setting option choose

Exit and press ENTER.

Maximal correction depth: 20oC.

Conditions:

- T2 > T1

- T1 i T2 160 oC (for AGS../T250: T1 i T2 250 oC)

- T2-T1 25 oC

If the conditions

aren‟t

fulfilled, during status change to ON, a error communicate will appear.

Suggested thermometer type: PT-105 with probe GT-105

Page 25

USER MANUAL

25

The way of entering control thermometer probe to moisture analyzer drying chamber:

2

100 o C

3

1

1 – control thermometer probe

2 – 15 mm distance sleeve that

ensures proper level above pan

3 – moisture analyzer internal sensor

Before executing temperature correction (inscribing T1 and T2 temperature) drying

cycle must be made with inscribed T1 temperature and drying time 15 minutes. Singleuse pan (a new one) should be put on the pan . When drying process is almost done

write down moisture analyzer temperature indication ( T value on the left side of

moisture analyzer display) and control thermometer indications.

Both indications are needed for correction:

CORRECTION TEMPERATURE

1. Device temp. T1 =

2. Contr. temp. T1=

3. Device temp. T2 =

4. Contr. temp. T2=

5. Status <ON>

6. Exit

Subsequently make drying cycle for T2 temperature (drying time as above 15 minutes)

and write down indications again.

This way both T2 indications are inscribed:

CORRECTION TEMPERATURE

1. Device temp. T1 =

2. Contr. temp. T1=

3. Device temp. T2 =

4. Contr. temp. T2=

5. Status <ON>

6. Exit

Page 26

26

USER MANUAL

Moisture analyzer internal thermometer correction is made with internal thermometer

and control thermometer on the same level (11mm) above the sample.

Attention: The temperature indicated by thermometer situated on some level

above the sample can differ from real temperature of the sample. In this case if there

is a need for temperature indication correction simply lower the level of control

thermometer by removing distance sleeve.

During correction control thermometer

can‟t

touch the sample.

Correct: Uncorrect:

Page 27

USER MANUAL

27

m0-m/m0*100% Ts=120C ts= 0:10:00s

T = 32.23C

m= 2.033g

t =0:00:00s

0.00 %

m0= 2.033g

START

SET

RAP MEM

STOP

SAMPLE

11.9 Connecting to a computer or a printer

When drying process is finished measurement result can be printer or a computer via

RS232C interface.

Measuring data can be also completed with text information. To enter text descriptions it

is necessary to connect a computer keyboard to PS2 port at the back of the moisture

analyser.

Choose RAP option (F3 key).

F1 F2 F3 F4 F5

DRY

ING

REPORT

1. Drying chart : ON

2. Product name :

3. Executive :

4. Notes :

5. Transmission : OFF

Exit

DRY

ING

REPORT

1. Drying chart : ON

2. Product name :

3. Executive :

4. Notes :

5. Transmission : OFF

Exit

Using navigation keys and ENTER

key choose Drying chart and disable

or enable printing and displaying the

chart.

Set necessary options:

- Product name,

- Executive,

- Notes.

and with the connected computer

keyboard enter text information for

printed report. Use PS-2 socket.

Activation of Transmision option will

activate sending of all sampling

results through the RS232C port.

The may be printed by the printer or

stored in the computer, e.g. by the

Promas software.

Page 28

28

USER MANUAL

A set of characters available using the keyboard while you use Product name,

Executive or Notes:

1 . , ‟ ? ! ” - ( ) @ / : _ ; + & % * = < > $ [ ] { }\ ~ ^ „ # |

2 A B C a b c

3 D E F d e f

4 G H I g h i

5 J K L j k l

6 M N O m n o

7 P G R S p g r s

8 T U V t u v

9 W X Y Z w x y z

0 space

Erasing the mark and move the cursor to the left: the navigation key <.

To print the drying report press key.

Drying started:

- - - - - - - - - - - - - - - - - - -- - - - Date: 2004-06-10

Time.: 12:34:33

Serial number: 123456789

Drying parameters

- - - - - - - - - - - - - - - - - - -- - - - Product

Drying temperature : 130C Mode

: Short mode

Calculation : m0-m/m0*100%

Finished

: time over

Initial weight

: 0.000 g

Final weight :

0.000 g

Drying time

: 0:00:00s.

Sampling interval: : 10s

Moisture

: 0.00%

NOTE:

The analysis proceeded by:

Signature ....................................

It is possible to set necessary serial port parameter values (8bit, 1stop, no parity,

4800bps). To use RS232C Settings option press key (weighing mode) and pres

MENU key.

Page 29

USER MANUAL

29

12. Moisture analyzer menu diagram

All operations described in chapter 11 can also be executed using moisture analyzer

menu. In order to do that use MENU key and using navigation keys and ENTER key

choose proper options.

Menu diagram:

1. Drying settings

2. Memory settings

3. Drying options

4. Drying raport

5. Configuration

6. Settings default

7. Exit

1. Drying temp.

2. Mode

3. Calculation

4. Samples quantity

5. Sampling interv.

6. Drying time

7. Drying profile

8. Settings storing

9. Exit

1. Memory locat.

1. Average

2. Drying chart

3. Transmission

4. Temp. correction

5. Exit

1. Product name

2. Operator

3. Remarks

4. Print settings

5. Exit

1. Units

2. Auto-zeroing

3. Interface

4. LCD settings

5. Language

6. Time&Date

7. Keyboard

8. Defaults

9. Calibration

1. Date

2. Time

3. Nr

4. Name

5. Drying temp.

6. Profile

7. Mode

8. Method

9. Finished

10. Initial weight

11. Final weight

12. Drying time

13. Sampling int.

14. Moisture

15. Quantity

16. Average

17. Remarks

18. Performance

19. Signature

<PL><ENG><DE><ESP><ITA><FRA>

10. Info

11. Exit

MODEL

S/N

SOFT

AXIS Sp. z o.o.

Page 30

30

USER MANUAL

13. Testing and calibration of the balance

To check the weighing function of balance – drier, switch it to the simple weighing (

key) and check it by putting precisely weighed object, e.g. calibration weight F2 (OIML),

equal to device measurement range. In case of any inaccuracies perform the balance

calibration. It is performed by activating the calibration function, available in special

functions menu, and putting the calibration weight on the pan according to indications

on the display (see Sensitivity calibration function).

Control of humidity measurement precision requires use of standard substance –

disodium tartrate (di-Sodium tartrate dihydrate C4H4Na2O6*H2O). For the control use 5 g

sample, setting: short mode, calculations method: m/ m0*100% , temperature 150oC,

sampling time 10 s, samples amount 4 and drying time 00:15:00s.

The result should be contained in range 15.61 – 15.71%.

Page 31

USER MANUAL

31

14. Moisture analyser as a balance

The moisture analyser may be also used as a normal balance. To switch between

analyser / weighing mode press key.

In weighing mode MENU key opens a set of special functions. Standard functions are

described below. Other special functions may be delivered on demand.

14.1 Units

In order to change the unit used in balance and moisture analyzer use MENU key, in

Configuration window (User Menu window shows up when the normal weighing mode is

off).

USER MENU

1. Drying settings

2. Memory settings

3. Drying options

4. Drying report

5. Configuration

6. Settings default

7. Exit

1. Units

2. Auto-zeroing

3. Interface

4. LCD settings

5. Language

CONFIGURATION

CONFIGURATION

6.

Time&date

7.

Keyboard

8.

Defaults

9.

Calibration

10.

Info

Exit

Carat [ct]

Miligram [mg]

Gram [g]

Kilogram [kg]

Pound [lb]

Ounce [oz]

Ounce troy [ozt]

Grain [gr]

Pennyweight [dwt]

Newton [N]

Exit

Choice of unit is made using navigation keys and ENTER key.

Page 32

32

USER MANUAL

14.2 Auto-zeroing

Auto-zeroing function causes that the close to zero indication will be corrected

automatically and when the pan is unbiased zero indication will be hold independently

even when environment conditions change (temperature, air density etc).

USER MENU

1. Drying settings

2. Memory settings

3. Drying options

4. Drying report

5. Configuration

6. Settings default

7. Exit

CONFIGURATION

1. Units

2. Auto-zeroing

3. Interface

4. LCD settings

5. Language

6. Time&date

7. Keyboard

8. Defaults

9. Calibration

10. Info

Exit

AUTO-ZEROING

1. Status: OFF

2. Exit

AUTO-ZEROING

1. Status: <ON> <OFF>

2. Exit

In order to turn on Auto-zeroing function use navigation keys and ENTER key, choose

Status ON.

Page 33

USER MANUAL

33

14.3 Calibration

Calibration with external weight standard should be performed in case indications

exceed permissible error (for example more than 5 graduation overflow). To scale

calibration use weight standard presented in technical data table (or more precise).

Depending on the value of gravity acceleration the producer sets the scale to specific

location of use.

If the location of use change the scale should be calibrated once again

Attention: Scale sensitivity error

doesn‟t

cause directly humidity error thanks to

percentage calculation formula.

In order to calibrate the balance use MENU key and Configuration option, and then

Calibration.

USER MENU

1. Drying settings

2. Memory settings

3. Drying options

4. Drying raport

5. Configuration

6. Settings default

7. Exit

CONFIGURATION

1. Units

2. Auto-zeroing

3. Interface

4. LCD settings

5. Language

1. Calibration:

CALIBRATION

6. Time&date

7. Keyboard

8. Defaults

9. Calibration

10. Info

Exit

2. Load : 100g

3. Exit

1. Calibration:

CALIBRATION

2. Load : <20g><50g><100g><...>

3.

Exit

Load enables to inscribe standard mass value that will be used to calibrate. User can

choose from few values or inscribe his own value.

After setting the standard of mass prepare single-use pan, put the standard and choose

Calibration option by pressing ENTER.

Page 34

34

USER MANUAL

CONFIGURA

TION

1. Units

2. Auto-zeroing

3. Interface

4. LCD settings

5. Language

6. Time&date

7. Keyboard

8. Defaults

9. Calibration

10. Info

Exit

CALIBRATION

1. Calibration:

2. Load : 100g

3. Exit

CALIBRATION

Please wait ...

CALIBRATION

Taring

CALIBRATION

Put

load

Put the standard of mass

on the pan.

CALIBRATION

Please wait ...

100.000g

Displaying standard of

mass value means that

the calibration is done.

Page 35

USER MANUAL

35

15. Maintenance and repairs of small defects

1. A moisture analyser should be kept clean.

2. Take care that no dirt gets between the casing and the pan. If found any, remove

the pan (lift it up), remove dirt and then replace the pan.

3. In case of improper operation caused by a short-lasting power supply decay, unplug

the moisture analyzer from the mains and then plug it again after few seconds.

4. It is forbidden to make any repairs by unauthorised persons.

5. To repair the moisture analyzer, please contact an authorised service centre.

Moisture analyser can be sent for repair as messenger delivery only in original

package, if not, there is a risk of damaging the moisture analyzer and loosing

guarantee.

Measuring problems:

Problem

Solution

A sample burns down

Reduce temperature

Use glass fibre filter on the top of the sample

Reduce sample quantity and distribute it uniformly

Drying lasts too long

Increase temperature

Reduce sample mass

A sample loses weight

before measurement

Take out the pan and put a sample outside the chamber

A sample is liquid or paste

Use glass fibre filter

A sample does not consist of

enough volatile matters

Enlarge a sample

Page 36

36

USER MANUAL

Troubleshooting:

Display indication

Possible cause

Remedy

Initial heating Ts

temperature exceeds

105°C, the sensor

does not react when

touched with a finger

The temperature sensor is

damaged.

Contact an authorised service

point.

Initial heating Ts

temperature does not

reach 105°C,

the halogen heater(s)

do not light.

The heater is damaged.

Replace the heater.

"Test ..."

Auto-tests in progress /

electronic unit damage

wait for 1 minute

" - - - - "

The moisture analyzer is during

zeroing

/ mechanical damage

wait for 1 minute

check if the moisture analyzer is

placed on stable ground, not

affected by vibrations

„Tare range exceeded”

Tare key pressed during zero

indication

Moisture analyzer indications must

be different than zero

„Zeroing range

exceeded”

Permissible zeroing range was

exceeded

Remove the load from the pan

„Weighing range

exceeded”

Permissible weighing range

(Max +9e) was exceeded

Reduce the load

„Measuring range

exceeded (+)”

Upper limit of analog-digital

transducer measuring range was

exceeded

Remove the load from the pan

„Measuring range

exceeded (-)”

Lower limit of analog-digital

transducer measuring range was

exceeded

Check if there are all necessary

pan elements

Page 37

USER MANUAL

37

Declaration of Conformity

We:

AXIS Spółka z o.o. 80-125 Gdańsk, ul.Kartuska 375B, Poland

confirm with all responsibility that moisture analysers:

AGS60, AGS120 i AGS210

AGS60/T250, AGS120/T250, AGS210/T250

marked with CE mark comply with the following:

1. EN 61010-1 standard Safety requirements for electrical equipment for measurement, control

and laboratory use. General requirements harmonized with the directive 73/23/EEC

(replaced by 2006/95/WE).

2. EN 55011:2001 + A2:2004 Electromagnetic compatibility (EMC) – Industrial, scientific and

medical (ISM) radio-frequency equipment. Radio disturbance characteristics. Limits and

methods of measurement and EN 61000-4-3:2003 + A1:2004(U) - Electromagnetic

compatibility (EMC) - Part 4-3: Testing and measurement techniques - Radiated, radiofrequency, electromagnetic field immunity test harmonized with the directive 89/336/EWG

(replaced by 2004/108/WE).

Additional information:

Conformity evaluation for the Council Directive 73/23/ECC and 89/336/EEC (replaced by

2006/95/WE and 2004/108/WE) was carried out by Laboratorium Badawcze Oddziału Instytutu

Elektrotechniki in Gdańsk, accredited by PCA (reports from examinations No. 124/LBS-

780/2005 and 131/LMC-780/2005).

Per pro Director of AXIS Sp. z o.o.:

Production Manager Jan Kończak

Date: 25-04-2012

Page 38

38

USER MANUAL

Drying parameters for different substances (examples)

No

Substance

Initial weight

(g)

Temperature

(°C)

Preparation

Analysing time (min)

1.

Acrylate seal

3

mix a sample

9

2.

Granulated acryl

10-15

80

12

3.

Acryl ester

1.5

mix a sample

19

4.

Active coal

10

80

9.8

5.

Active coal

7.6

80

4.1

6.

Cream

1.5

10.9

7.

Cream

2

10.8

8.

Cotton seeds

3-4

110

grind a sample for 1 min.

6.3

9.

Cheese

2

160

13.3

10.

Bean

4.5

150

grind a sample

9.7

11.

Roasting sauce

2

6.1

12.

Butter

1.7

140

tear up a foil

4.3

13.

Cellulose acetan

5.5-6

50

1.3

14.

Photo paper

2

150

tear up in 1 cm2 pieces

6.4

15.

Dialyse membrane

0.5

80

cut into thin slices

2.2

16.

Dialyse membrane

0.5-0.7

80

cut into thin slices

2

17.

Leak stopper

3

160

7

18.

Glue dissolvent

1.5

140

9.5

19.

Dolomite

10-12

160

6.1

20.

Drawing ink

1.5

120

10

21.

Pea

3.5

135

grind for 30 sec.

7.9

22.

Peanuts

2.8

100

grind into thick powder

4

23.

Peanuts

3

100

grind into thick powder

6

24.

Mint pastilles

3-3.4

90

grind into thick powder

2.9

25.

Powder paint

1.5

120

3.5

26.

Ceramics clay

2.5

160

cut into thin slices

9

27.

River water

4

160

mix a sample

20

28.

Icing sugar

5

130

20

29.

Dissolvent

2

155

mix a sample

7.6

30.

Cottage cheese

6

140

mix a sample

31.

Feeding stuff

3-4

150

5.7

32.

Dry beans

3-4

105

grind a sample

5

33.

Dry peas

5-7

110

grind a sample for 10 sec.

9.6

34.

Dry carrot

5.5-6

120

grind a sample

3

35.

Dry chicken excrements

4

140

8

36.

Dry corn

5-7

110

grind a sample

10

37.

Glass powder

8-10

160

5

38.

Balsam

0.01

145

9

39.

Balsam

1

130

8

40.

Nuts

2.2

100

grind into thick powder

3.8

41.

Nuts in shells

2.6

100

grind into thick powder

4.5

42.

Soda bihydrate

1.6

160

12

43.

Coffee

2

150

8

44.

Instant coffee

5

mix a sample

10

45.

Coffee seeds

3.5-4

120

grind a sample for 1 min.

8

46.

Cocoa

2.5

105

4

47.

Cocoa

6

mix a sample

9

48.

Cocoa seeds

4-5

130

grind a sample for

powder

7.8

49.

Limestone

12-14

160

5

50.

Dry potato pieces

2.5-3.0

130

divide a mass

5.8

51.

Ketchup

2

120

18

52.

Silicon gel

9.5

115

4.5

53.

Silicon acid

1.5

mix a sample

3

54.

Coal powder

4

160

3.4

55.

Natural chalk

8

160

1.7

56.

Synthetic chalk

6

mix a sample

4

57.

Granulated sugar

3

90

2.8

58.

Resin dissolvent

2

160

mix a sample

5.9

Page 39

USER MANUAL

39

No

Substance

Initial weight

(g)

Temperature

(°C)

Preparation

Analysing time (min)

59.

Latex

1-2

160

5.2

60.

Latex LE1

3-5

125

10.8

61.

Latex LE2

3-5

125

9.4

62.

Latex O44

3-5

125

9.4

63.

Lentil

4

135

grind a sample for 30 sec.

5.4

64.

Loess soil

10-15

160

5.5

65.

Loess soil

2.5

160

cut into small pieces

14.5

66.

Skimmed milk

5

110

mix a sample

67.

Skimmed milk powder

4

90

5.5

68.

Cottage cheese

1.2

130

mix a sample

8

69.

Corn starch

2

160

5.2

70.

Almonds with caramel

3.5

80

grind into thick powder

4.8

71.

Normal almonds

2.5

100

grind into thick powder

5.3

72.

Almonds

3

100

grind into thick powder

5.3

73.

Margarine

2.2

160

4

74.

Margarine

0.7

160

3.5

75.

Margarine

0.7

160

5

76.

Materials for bricks

7

160

distribute a sample

20

77.

Mikronyl

7-8

60

8

78.

Mikronyl

8

80

5

79.

Mikronyl

8

80

5

80.

Skimmed milk powder

4.5

100

6.3

81.

Fat milk powder

4.5

100

5.5

82.

Whey

5

110

mix a sample

83.

Concentrated whey

2-3

90

10

84.

Mozzarella cheese

1.5

160

11.1

85.

Multivitamin bars

3-3.4

115

grind into thick powder

3.3

86.

Zeolite

3

160

87.

Zeolite

3

160

88.

Natural latex

1.4

160

mix a sample

5.3

89.

Chocolate

2.5

103

10

90.

Paste

0.55

160

5

91.

Concentrated orange juice

2-3

115

mix a sample

13

92.

Ultramid B3WG5

10

60

10

93.

Ultramid A3WG7

10

80

10

94.

Crastin SK645FR

10

80

10

95.

Macrolon

10-12

80

15

96.

Babyblend T65 MN

9-11

80

10

97.

Plexiglas 6N

10

70

10

98.

Polypropylene

13

130

9

99.

Polypropylene

3.3

120

2.2

100.

Polystyrene solution

2-2.5

120

8.7

101.

POM C9021

10

80

10

102.

Polystyrene 168 N

10

80

10

103.

Purine

2

105

mix a sample

3.8

104.

Cottage cheese

1

140

mix a sample

7

105.

Cheese 20%

2

mix a sample

12

106.

Fat cottage cheese

1.2

130

mix a sample

8

107.

Silicon sand

10-14

160

1.9

108.

Raclet cheese

1.5

160

14.4

109.

Oily seeds

3-4

90

grind a sample for 1 min

7.4

110.

Rice

3.5

105

grind a sample for 30 sec.

12.5

111.

Retentine

5

110

mix a sample

0.04

112.

Rye

4.5

150

grind a sample

11.5

113.

Beetroot

4.5

150

grind a sample

8.6

114.

Beetroot

4.5

150

grind a sample

8.9

115.

Beetroot

4.5

150

grind a sample

9.1

116.

Beetroot

4.5

150

grind a sample

8.5

117.

Sticks

3-4

75

grind into powder

4.5

118.

Processed cheese

1.5

70

tear up a foil

15

119.

Chocolate

2.5

103

cut into pieces

10

120.

Grinded chocolate

2-3

90

10

121.

Pig feeding stuff

4-5

160

mix a sample

21

122.

Speck

0.7

160

3.5

123.

Speck

0.8

160

3.5

124.

Soap

3

120

pinch some pieces

6

Page 40

40

USER MANUAL

Notes

Loading...

Loading...