Page 1

OXALIS

Unit B Sutton Park Way

Oddicroft Lane, Sutton in Ashfield

NG17 5FB

tel: +44 (0)1623 444400

IMI+70-XF-XC-XP-XT Issue 7

IECEx/ATEX Certified

II 2 G Ex db IIC

II 2 D Ex tb IIIC

Whilst every effort has been made to ensure that all information in this document is correct at the time of

publication, due to our policy of continuous improvement, the company reserves the right to change any

information contained herein without notice or reference.

With the exception to Annexe B which must be referred to the certification Body.

2400 & 1400 Series (XP, XT, XC & XF)

Flame Proof Camera Housings

& Pan Tilt Units

Installation & Maintenance Instructions

This equipment shall be installed in accordance with the latest local/national codes of practice, and standards

This manual should be read before attempting to connect or operate the equipment

eg :- BS EN 60079-14:2014 Explosive atmospheres – Part 14: Electrical installations design, selection and erection

(IEC 60079-14:2013)

Page 2

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 2 of 21

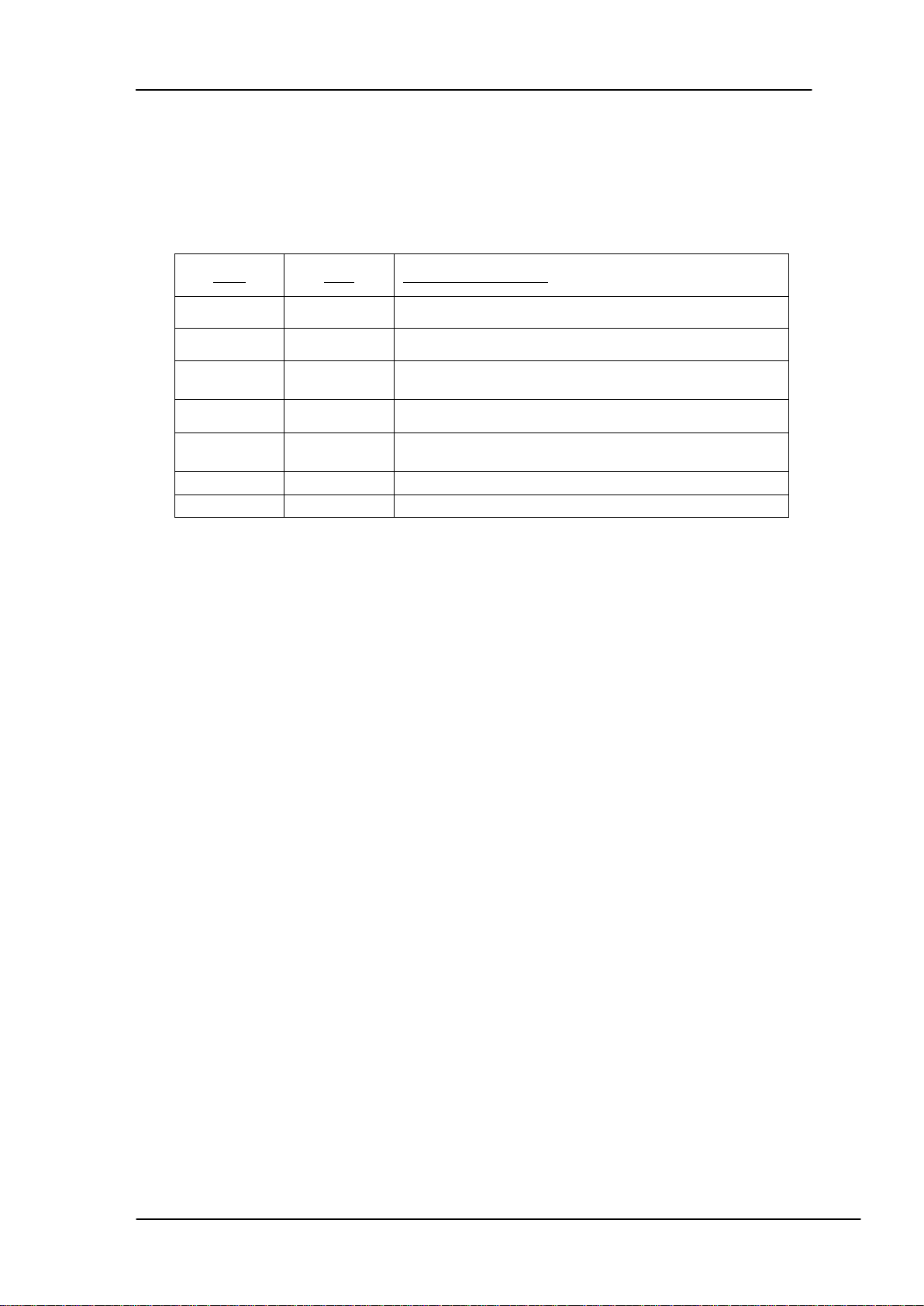

Issue

Date

Details of Amendment

1.0

First Issue

2.0

09/03/2016

Inclusion of Annexes

3.0

05/04/2016

Inclusion of Ex ia removal of ratings page 5 Additions to

annexe E

4.0

06/04/2016

Change in Harmonised standard issues

5.0

01/09/2016

Change Cert Number, Address, authorised signatory.

Addition of amendment record. Special Conditions.

6.0

13/10/2016

Change in Name and cert labels

7.0

16/11/2016

Removed DOC

Amendment Record

Page 3

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 3 of 21

Section Page

Amendment Record 3

1.0 General 4

1.1 Important Safeguards and Warnings 4

2.0 Description 5

2.1 Versions 6

2.2 Supplied Equipment 6

2.3 Associated Equipment 6

2.4 Recommended Tools 6

2.5 Recommended Spares 6

3.0 Installation 7

3.1 Unpacking and Handling 7

3.1.1 Unpacking 7

3.1.2 Handling 7

3.2 Mounting 7

3.2.1 Mounting the XP & XT Series 7

3.2.2 Mounting the XC Series 7

3.2.3 Mounting the XF Series 10

3.3 Accessory Installation 11

3.3.1 Sunshield Installation 11

3.3.2 Washer Nozzle Installation 12

3.4 Electrical Installation 13

3.4.1 Electrical Installation XP & XT Integrated Pan, Tilt, housing assembly 13

3.4.2 XP & XT Common Connection Examples 14

3.4.3 Electrical Installation XF & XC Series units 15

3.4.4 XC & XF Common Connection Examples 16

4.0 Maintenance 17

4.1 Corrosion Protection 17

5.0 Labelling 18

5.1 Standard Enclosure label 18

5.2 OP PR Enclosure label 18

5.3 OP IS Enclosure label 18

5.4 [Ex ia] Enclosure label 18

6.0 Specifications, Technical data 19

7.0 Special Conditions for safe use 19

Annexe to Manual

A. Ex Annexe (ATEX Controlled Document) 21-22

Before Installation of the equipment ensure that:

1 The installation instructions are read and understood

2 The correct tools are available for use when installing

Page 4

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 4 of 21

1.0 General

This symbol indicates that there are important operating and maintenance instructions in the

literature accompanying this unit.

Prior to installation and use of this product, observe the following warnings.

1. Installation and servicing should only be carried out by qualified service personnel and

2. It is essential that provision is made for overload, short circuit and earth fault protection

3. A readily accessible disconnection device shall be incorporated in the electrical

4. Only use tools and replacement parts supplied or recommended by EATON.

5. Care must be taken to ensure selection of suitable cables connecting to these units,

6. The equipment is designed to satisfy the requirements of Clause 1.2.7 of the Essential

7. Be aware that aggressive substances may require extra protection of the equipment to

8. The equipment may need additional means of protection if it is to be installed in

9. Any repairs or replacement parts must be done by the manufacturer or an approved

10. Due to the large weight of the units, correct planning and equipment must be used

11. Systems can be fitted with integral Fibre Optic transmitters, the label coding includes the

12. When batteries are fitted to electronic equipment they must be removed and are not to

13. After installation, operatives must adhere to the following warning on the units label:

14. IR Illuminator “CAUTION Possibly hazardous optical radiation emitted from this

This symbol indicates that dangerous voltage constituting a risk of electric shock may be present

within this unit.

1.1 Important Safeguards and Warnings

in accordance with all local/national codes of practice and standards e.g. EN60079-14

2014 and IEC 60079-14:2013 no modification to the certified product allowed.

for this equipment. Therefore we recommend that a double pole, mains rated,

miniature circuit breaker rated to the max power consumption of the unit, must be

incorporated in the electrical installation of the power supply to this product.

installation wiring, to provide all pole isolation of the supply to the equipment.

This unit does not contain any user serviceable parts.

when installed in operating temperatures above +70°C.

Health and Safety Requirements ANNEX II of ATEX Directive 2014/34/EU.

maintain its integrity and explosion protection.

locations where it may be exposed to excessive external stresses e.g. vibration, heat,

impact and damage.

repair agent.

when unpacking and installing also for the P&T units the correct lifting points must be

adhered to (see section 3.1.2)

lettering “op pr” after Ex d, denoting that the enclosure employs the type of protection

b) protected optical radiation, type of protection “op pr” according to clause 5.1 of

EN60079-28:2015. This means that the fibre optic cabling used has additional protective

measures to ensure that the optical radiation is confined within the cabling, by the use

of a robust conduit covering externally, and Kevlar braided cable inside the conduit and

the enclosure.

be replaced.

product.”

WARNING: DO NOT OPEN WHEN ENERGISED OR WHEN

AN EXPLOSIVE ATMOSPHERE IS PRESENT.

CLEAN WITH DAMP CLOTH.

Page 5

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 5 of 21

2.0 Description

The 2400 & 1400 series camera assemblies have been developed to meet the rigorous

requirements of Flame proof and dust-ignition-proof electrical equipment for installation and use

in hazardous locations found in the onshore and offshore, oil & gas and petro-chemical

installations. The units may also be used in marine and industrial hazardous environments.

The housing body and all external parts are manufactured entirely of AISI 316L stainless steel for

low maintenance and protection from corrosion.

Each of the main end covers is fixed to the body by five (5), M6 x 16-mm stainless steel hex cap

screws, with the cable entry cover of the XP and XT systems using five M5 x 12-mm stainless

steel hex cap screws; all conforming to the requirements of EN60079-0:2012/IEC 60079-0:2011.

The weatherproof seal of the union between the body and end covers is maintained by use of ‘O’

ring seals fitted in purpose made grooves.

The camera housings feature an internal sliding camera mounting rail which is fitted with an

internal heating element/de-mister, thermostatically controlled, to maintain operating

temperature, and ensure clarity of vision through the window, together with the optional

integral window wiper mechanism.

The viewing window is made with toughened glass, or in the case of the Thermal Imager and

Dual Imager versions, is made from Infra red transparent material and which is factory fitted with

a mechanical window guard.

The mechanical thermal window guard MUST not be removed.

There are four system types that are made up from different combinations of the 2400 and 1400

series certified units; these are:

XF series, fixed camera housings.

XC series, P&T units with integral tilt shaft only.

XP series, P&T units with integral pan and tilt shafts and a fixed base section for cable

connection.

XT series, P&T units with integral pan and tilt shafts and a fixed base section for cable

connection, also a secondary housing for integrated illuminator.

The XF series fixed housings comprise a single tube section with either 3 cable entries in the rear

cover or 1 in the side (model dependant).

The XC series comprise a camera housing fixed to a P&T unit via an integrated tilt shaft; there are

3 cable entries in the rear cover of the housing or 1 into the blank side of the T unit (model

dependant).

The XP and XT units have a single cable entry into the fixed base section, this prevents any

trailing cables.

The 2400 & 1400 series housings and integrated pan/tilt units have been designed and certified

to the ATEX Directive 2014/34/EU and IECEX, with the ratings as detailed in:

Section 6.0 Specifications, Technical data & Special conditions for safe use.

Note: T class and ambient temperature, is dependent on the assembly configuration and

maximum internal power dissipation.

Page 6

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 6 of 21

2.0 Description (continued)

The project requirements and unit certification label must be checked by the installer before

installation, to confirm that the product supplied is suitable for the intended installation zone

and environment.

Manufactured in accordance with CE & IEC norms

EN 60079-0:2012, EN 60079-1:2014, EN 60079-28:2015 & EN 60079-31:2014, IEC 60079-0:2011,

IEC 60079-1:2013 & IEC 60079-31:2014

2.1 Versions

There are various camera configurations available within the range; these include Day/Night

cameras with optional wiper, integral washer or external washer, Thermal Imager and Dual

Camera Day/Night and Thermal units.

The range also includes options for Standard Analogue Video and Data, HD IP cameras, Hybrid IP

encoders, Digital Fibre optic convertors and Media convertors.

Due to the large variations of possible configurations, this manual only covers the standard

installation of the units.

For detailed connection and configuration of units, the installer should refer to individual project

specific drawings and information.

In addition to this manual there are various addendums available that cover the specific function

of electronics that can be included within the camera assemblies.

2.2 Supplied Equipment

Contained in the package are the following items:

Camera system

Installation/Technical Manual

Optional Sunshield and Fixings

Optional Washer Nozzle Kit

2.4 Recommended Tools

For installation and maintenance purposes, we recommend the following hand tools:

Voltmeter/Ohmmeter

Torque wrench kit Set to 7.5Nm, Hex Allen wrench bits of 5, 4 & 3mm

Spanners 8mm, 10mm & 13mm A/F

Screw drivers standard and Phillips head

Pliers side cutting and long nose

2.5 Recommended Spares

For Maintenance purposes, we recommend the following spares:

OX10-00188 EX Base Cable Entry Seal Kit (50.8x3.53 O-ring + 5x M5x12 A4 socket head screws)

OX10-00190 EX Main Flange Seal Kit (117.07x3.53 O-ring + 5x M6x16 A4 socket head screws)

OX10-00008 WIPPER BLADE ASSEMBLY

OX10-00062 HOUSING WASHER NOZZLE ASSEMBLY

OX10-00063 XP20 CONTINUOUS ROTATION WASHER NOZZLE ASSEMBLY

OX10-00134 XP40 CONTINUOUS ROTATION WASHER NOZZLE ASSEMBLY

Page 7

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 7 of 21

3.0 Installation

In order to ensure proper wiring and system operation of all components, it is recommended

that all units and all associated control equipment be tested at your Factory before field

installation is attempted.

3.1 Unpacking and Handling

3.1.1 Unpacking

On receipt of the units ensure that the cartons are undamaged and that the contents are all

correct and complete.

After unpacking it is recommended that the packing materials are kept safe in case they are

needed for returning the unit for repair or maintenance.

The protective white film should be removed from sunshields prior to fitting.

3.1.2 Handling

Due to the large weights of the products, correct handling is of great importance.

Lifting into position of P&T units should always be completed using suitable lifting equipment

that is capable of supporting loads in excess of 65Kg. P&T systems should only be lifted using

the T section of the P&T, with equal support on both sides; the camera housing section of the

unit must not be used for lifting. To avoid causing damage to the unit do not rotate by hand.

The units should not be handled having direct contact with ferrous metal equipment. (see

section 4.1 for details)

3.2 Mounting

Ensure the mounting surface and the selected mount can support four times the combined

weight of the complete unit.

Do not stand or place objects “directly under” installed system.

Due care must be taken to ensure sufficient clearance is allowed to permit full rotation of the

unit with its associated equipment mounted and that the moving unit cannot make contact

with personnel.

It is strongly suggested that where possible the EATON range of mounting brackets are used

3.2.1 Mounting the XP & XT Series

The XP and XT pan/tilt/housing assembly may be mounted onto various structures such as

bulkheads, walls or towers, it can be mounted in the inverted position but this must be

specified upon order.

The complete assembly is mounted to the support structure via its base mount which has

11mm clearance holes for four (4) No. M10 fixings. (Fig 1)

The type and size of these fixings to be supplied by the user/installer and must be suitable

for the specific installation requirements.

An alternative is to use the BPW6800 Wall mount bracket (Fig 2)

3.2.2 Mounting the XC Series

The XC pan/tilt/housing assembly may be mounted onto various structures such as bulkheads,

walls or towers, it can be mounted in the inverted position but this must be specified upon

order.

The complete assembly is mounted to the support structure via its Pan shaft and this has four

(4) No. M8 Threaded fixing points on an industry standard spacing PCD of 101.6mm (4”). (Fig 3)

The type and size of these fixings to be supplied by the user/installer and must be suitable for

the specific installation requirements. An alternative is to use the BFW5000 Wall mount

bracket (Fig 4) or one of the BFP**00 Column Spacers. (Fig 5)

Page 8

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 8 of 21

Fig.1 XP26VW Example XP Series unit showing base mount fixing points

Fig.2 BPW6800 Wall Bracket

Page 9

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 9 of 21

Fig.3 XC40VW Example XC Series unit showing shaft mount fixing points

Fig.5 BFP0600/900/1200 Column Spacer

Fig.4 BFW5000 Wall Bracket

Page 10

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 10 of 21

Fig.6 XF60VN Example XF Series unit showing mount plate fixing points

Fig.7 BFP00SW Swivel Joint & Pole Top Adaptor

Fig.8 BFW32SW Swivel Joint & Pole Top Adaptor

3.2.3 Mounting the XF Series

The XF Series fixed housing assemblies may be mounted onto various structures such as

bulkheads, walls or towers. The units have a mounting plate on the bottom of the housing tube

that have

four (4) No. M6 Threaded fixing points. (Fig 6)

The type and size of these fixings to be supplied by the user/installer and must be suitable for

the specific installation requirements.

To gain flexibility of the cameras view direction one of the EATON is needed, these comprise of

the BFP00SW Swivel joint (Fig 7), the BFW32SW (Fig 8) or a combination of the BFW5000 and

BFP00SW. (Figs 4 & 7)

Depending on Housing length, some wall brackets do not allow for the camera to view directly

away from the Wall and must be rotated or tilted to allow room for gland entry.

Page 11

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 11 of 21

Fig.9 Mid and Long Housing Sunshield Installation

Fig.10 Short Housing Sunshield Installation

3.3 Accessory Installation

3.3.1 Sunshield Installation

Sunshields are supplied uninstalled to prevent damage during shipping and unpacking. They are

supplied with a protective white film that must be removed prior to installation.

The correct sunshield fixings, for each model, are supplied with the camera system and should

be positioned as detailed below.

To mount the sunshields, first they must be positioned correctly and fixed with a Nylon spacer

between the sunshield and the camera housing, the M6 A4 Button head screws supplied must

have the red fibre washer fitted before fixing the sunshield. (Fig 9 & 10)

Long and Medium sunshield have four equally sized fixings for each corner but the short

sunshield has two fixing types, one for the front and shorter screws and nylon spacer at the

rear. (Fig 10)

Page 12

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 12 of 21

Fig.11 260mm Housing washer nozzle

Fig.12 400mm Housing washer nozzle

Fig.13 Non-continuous Rotation P&Ts and Fixed housings washer nozzle

3.3.2 Washer Nozzle Installation

A continuous rotation P&T system, if supplied with an external washer unit, is supplied with a

suitable washer nozzle and mounting bracket. These should be fitted during installation with

the supplied fixing and positioned to allow cleaning fluid to reach the camera housing window

when the wash command is sent. The supplied washer nozzle brackets are specific to housing

type and are delivered pre-aligned for use.(Fig. 11 & 12)

When a wash command is sent to the camera, the unit will move to the factory set position to

allow for the screen to be washed.

For non-continuous rotation P&Ts and fixed housings the washer nozzle is installed on the front

window flange. (Fig. 13)

Page 13

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 13 of 21

3.4 Electrical Installation

Electrical installation and servicing should only be carried out by qualified service personnel

and in accordance with all local/national codes of practice and standards e.g. EN 6007914:2014 and IEC 60079-14:2013.

Due to the large variations of possible configurations, this manual only covers the standard

installation of the units.

For detailed connection and configuration of units, the installer should refer to individual

project specific drawings and information.

Units can be supplied, as required, with either 24VAC, 110VAC or 230VAC Supply; all ±10%

The units should only be powered from the specified voltage, no allowance is made for

varying voltage supply.

Warning : Irreparable damage to the unit will result from the application of

incorrect Power Supply Voltage

3.4.1 Electrical Installation XP & XT Integrated Pan, Tilt, housing assembly

1. Always use colour-coded conductors or other identification of conductors for ease

of wiring and identification of function at a later date.

2. Keep a wiring diagram with the system for later use and reference.

3. Provision is made for one cable entry, at the base mount of the pan tilt.(Fig 14)

To maintain the certification requirements of the unit all cables/conduits must be

fitted at the entry, with certified Ex d Flameproof, compound filled barrier glands,

either brass, nickel plated or stainless steel.

4. The cable entry to the unit is M25 x1.5 ISO thread, or M20 using an Exd certified

reducer, dependent on what was specified at order.

5. A minimum of 10 mm depth of engagement must be maintained for all glands.

6. All glands/reducers must be ingress protected to IP67 or better, to maintain the

weatherproof rating of the equipment.

7. For maintenance purposes, consult separately supplied additional wiring drawings

specific to the purchase order, for as built wiring and connection details of the unit.

Page 14

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 14 of 21

Fig.14 Gaining access to the XP and XT Base junction box

230VAC N

SWITCH L 24VAC

PUMP SUPPLY

DATA A +

DATA B -

N 24VAC

PUMP SUPPLY

EARTH

230VAC L

VIDEO SCREEN

VIDEO SIGNAL

110VAC N

SWITCH L 24VAC

PUMP SUPPLY

DATA A +

DATA B -

N 24VAC

PUMP SUPPLY

110VAC L

VIDEO SCREEN

VIDEO SIGNAL

24VAC N

SWITCH L 24VAC

PUMP SUPPLY

DATA A +

DATA B -

N 24VAC

PUMP SUPPLY

24VAC L

VIDEO SCREEN

VIDEO SIGNAL

230VAC MODEL WITH PUMP OUTPUT

110VAC MODEL WITH PUMP OUTPUT

24VAC MODEL WITH PUMP OUTPUT

230VAC N

DATA A +

DATA B -

230VAC L

VIDEO SCREEN

VIDEO SIGNAL

110VAC N

DATA A +

DATA B -

110VAC L

VIDEO SCREEN

VIDEO SIGNAL

24VAC N

DATA A +

DATA B -

24VAC L

VIDEO SCREEN

VIDEO SIGNAL

230VAC MODEL WITH NO PUMP OUTPUT

110VAC MODEL WITH NO PUMP OUTPUT

24VAC MODEL WITH NO PUMP OUTPUT

NC

EARTH

NC

EARTH

NC

EARTH

EARTH

EARTH

110VAC N

110VAC L

110VAC FIBRE OPTIC MODEL

230VAC N

230VAC L

23VAC IP MODEL

NC

EARTH

EARTH

RJ45 INLINE

CONNECTOR

ETHERNET

VARIOUS FIBRE

BULKHEAD CONNECTORS

FIBRE

Caution should be taken when removing and inserting the cable entry flange to avoid

internal cable becoming snagged on corners or screws.

THE CABLE ENTRY FLANGE SHOULD NEVER BE REMOVED WHEN THE UNIT IS ENERGISED

3.4.2 XP & XT Common Connection Examples

Always refer to project specific drawings and information

Page 15

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 15 of 21

Fig.15 Removing the Wiper Arm

Fig.16 Removing the Front Window flange

Fig.17 Removing the rear flange

To gain access to the internal camera rail,

first the rail will need to be slid out to allow

connections to be made.

If a wiper is fitted, first take note of the

parked position of the wiper arm and then

remove it by loosening the M4 cap head

screw that clamps to the wiper shaft. Keep

the wiper and nylon washer safe for refitting.

This is best done without the sunshield fitted.

Remove the front window flange by

first removing the 5 x M6 screws

and then carefully extracting the

flange.

Next slide out the camera

mounting rail, if required.

Remove the rear flange by first

removing the 5 x M6 screws

and then carefully extracting

the flange.

Next slide out the camera

mounting rail to reveal the

incoming cable connection

terminals.

3.4.3 Electrical Installation XF & XC Series units

1. Cable entry type to the housing is via 1 x M20 x 1.5 ISO entry at the side adaptor of the

housing, or for some version via the triple M20 cable entry end cover on the rear of the

housing, solely for connection of power and signal wiring, no internal user wiring is

allowed in this unit.(Fig 15, 16 & 17)

2. Keep a wiring diagram with the system for later use and reference.

3. For maintenance purposes, consult separately supplied additional wiring drawings

specific to the purchase order, for as built wiring and connection details of the unit.

Warning : This cover must not under any circumstances be removed until at least 5 minutes

after the disconnection of power source.

Page 16

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 16 of 21

230VAC N

DATA A +

DATA B -

230VAC L

230VAC MODEL WITH PUMP OUTPUT

NC

EARTH

SWITCH L 24VAC

PUMP SUPPLY

N 24VAC

PUMP SUPPLY

VIDEO DIRECT TO CAMERA

24VAC MODEL WITH PUMP OUTPUT

J1

TH

HEATER

22O 10W

HEATER

22O 10W

J3

J2

24VAC N

DATA A +

DATA B -

24VAC L

NC

EARTH

SWITCH L 24VAC

PUMP SUPPLY

N 24VAC

PUMP SUPPLY

VIDEO DIRECT TO CAMERA

24VAC N

24VAC L

EARTH

DATA A +

DATA B -

24VAC MODEL NO PUMP OUTPUT

J1

TH

HEATER

22O 10W

HEATER

22O 10W

J3

J2

24VAC N

24VAC L

EARTH

24VAC IP MODEL NO PUMP OUTPUT

VIDEO DIRECT TO CAMERA

ETHERNET DIRECTLY TO

CAMERA OR ENCODER

VIA CAT5E, RJ45

3.3.4 XC & XF Common Connection Examples

Always refer to project specific drawings and information

Page 17

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 17 of 21

4.0 Maintenance

Recommended inspection interval: 6 Months.

Inspect the unit every six months to ensure trouble free operation and extend product life.

Due to the rugged construction of the unit, little or no maintenance should be required.

However when the unit is exposed to extreme weather conditions the ‘O’ ring weather seals

may need replacement approximately every five years.

Fixings and fastenings should be checked for tightness and integrity at regular intervals.

All cable entries and cables should be checked for integrity at regular intervals.

Extremely Harsh Environments may require more frequent inspection and maintenance

checks.

At every Inspection carry out the following:

• Clean the unit.

• Check the ‘O’ ring weather seals and replace if necessary.

• Check and if necessary replace the washer nozzle.

• Check and if necessary replace the window wiper blade assembly.

Please read and be familiar with the instructions before servicing the Pan/Tilt or housing.

4.1 Corrosion Protection

Although all external metal components are produced from 316L Stainless Steel, if the units

are not correctly maintained, handled and cleaned there is the possibility of mild

discolouration due to Oxidation.

If ferrous metal equipment is used when handling the units, small ferrous deposits could be

left on the stainless steel or if ferrous metal particles come to rest upon the units from

nearby works, this can cause accelerated corrosion of the ferrous deposits and discolour the

units due to oxidation. In the event of ferrous deposits, the units should be cleaned

immediately following EATON guidelines.

In atmospheres that are high in corrosive particles the units should be cleaned every 3 to 4

months using only EATON recommended cleaning products and procedures. (contact EATON

for details)

EATON takes no responsibility for oxidisation due to failure in correctly following cleaning

procedures.

Page 18

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 18 of 21

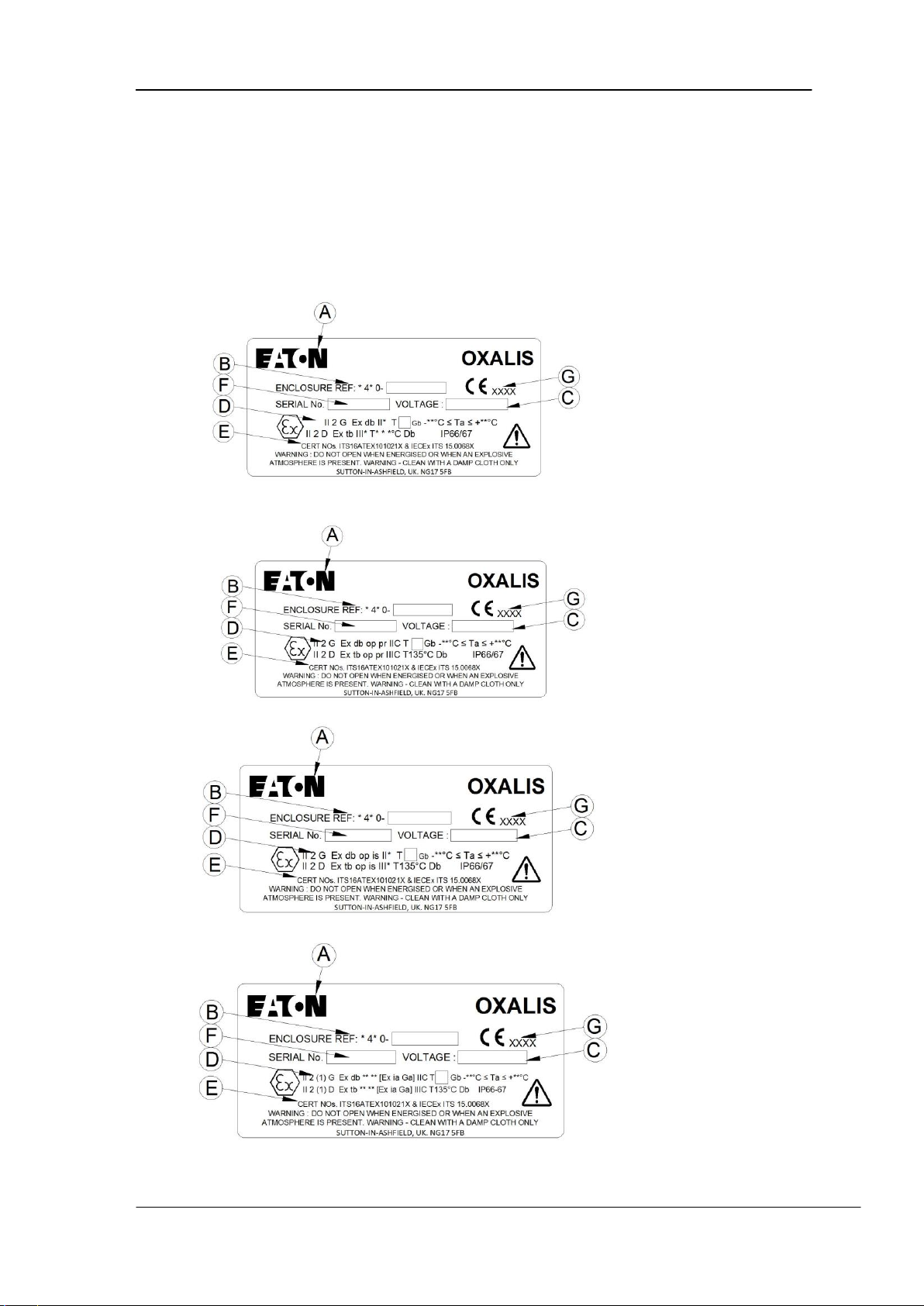

5.0 Labelling

The Labels are printed on self adhesive metalized vinyl and affixed product.

The contents of the label will be in ENGLISH.

The label shows: A - Name of Manufacturer , B - Model/Type and reference,

C - Operating Voltage,

D - EX ratings, E - ATEX Certificate & IECEX certificate numbers,

F - Serial Number, G - Notified Body Number

5.1 Standard Enclosure label

5.2 OP PR Enclosure label

5.3 OP IS Enclosure label

5.4 [Ex ia Ga] Enclosure label

Page 19

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 19 of 21

6.0 Specifications, Technical data & Special conditions for safe use.

Coding IECEx & ATEX II 2 G Exdb IIC T6-3*Gb -##°C ≤ Ta ≤ +##°C

II 2 D Ex tb IIIC T135°C Db IP66/67

Illuminator II 2 G Exdb op is IIC T4/3 Gb -##°C ≤ Ta ≤ +##°C

II 2 D Ex tb op is IIIC T135°C Db IP66/67

Fibre Optic II 2 G Exdb op pr IIC T6…3*Gb -##°C ≤ Ta ≤ +##°C

II 2 D Ex tb op pr IIIC T135°C Db IP66/67

Wireless II 2 G Ex db ????[Ex ia Ga] IIC T6…T5 Gb -##°C ≤ Ta ≤ +##°C

II 2 D Ex tb ????[Ex ia Ga] IIIC T135°C Db IP66/67

???? = Optional op pr/op is coding

Note: T class and ambient temperature, is dependent on the assembly configuration and

maximum internal power dissipation.

*=T class, Gas Group

## = Ambient Temperature range

Construction: Stainless Steel AISI 316L

Ingress Protection rating: IP 66/7

Max Weight:

Integrated Pan Tilt with housing : 40-62Kg depending on model

Standalone housing: 12-22Kg depending on model

Mounting:

Integrated Pan Tilt with housing : 4-x M10 fixings on 182mm pcd

Standalone housing: Depending on mounting brackets

Supply voltage: 24VAC, 50/60Hz or

100 to 230VAC with integral transformer

Power consumption: Max 120 Watts depending on model

7.0 Special Conditions for Safe Use.

1. No modifications must be made to the flamepaths of the unit without consultation of the

drawings listed on the schedule.

2. Temperatures could exceed 70°C at the cable gland or 80°C at the branching point,

suitably rated cable must be selected.

3. Use only hex socket head fasteners with property class of A4-70 for securing end covers &

shafts to housings.

4. No electromagnetic or ultrasonic energy radiating equipment shall be fitted within the

enclosures other than armoured/protected fibre optic cables (op pr) or the IR illuminator as

specified in the documents.

5. When fitted the optical fibre output from the camera housing must always be terminated

within a suitably certified enclosure or safe area.

6. Only armoured cable or conduit is to be utilized when fitted with a fibre optic output in

order to protect the fibre optic cable.

7. Precautions must be taken to avoid dust from forming layers on the equipment.

Page 20

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 20 of 21

A. Ex Annexe

Special Conditions of certification

(a) Specific Conditions for Safe Use.

1. No modifications must be made to the flamepaths of the unit without consultation of the

drawings listed on the schedule.

2. Temperatures could exceed 70°C at the cable gland or 80°C at the branching point, suitably

rated cable must be selected.

3. Use only hex socket head fasteners with property class of A4-70 for securing end covers &

shafts to housings.

4. When fitted, the optical fibre output from the camera must always be terminated within a

suitably certified enclosures or safe area..

5. Only armoured cable or conduit is to be utilized when fitted with a fibre optic output in order

to protect the fibre optic cable.

6. Precautions must be taken to avoid dust from forming layers on the equipment.

7. Antennas used with the equipment shall be passive with nominal impedance of 50Ω and have a

minimum degree of protection IP6X. If the antenna utilizes a wire conductor the minimum

diameter shall be 0.1mm. Alternatively if a track antenna is used, the tracking shall have a

minimum width of 0.4mm

8. The antenna circuit does not meet the dielectric strength requirements of Clause 6.3.13. Refer

to manufacturers’ instruction manual for further details.

Labelling Details.

II 2 G Exdb II* T6-3*Gb -##°C ≤ Ta ≤ +##°C

II 2 D Ex tb III* T135°C Db IP66/67

II 2 G Exdb op is II* T4/3 Gb -##°C ≤ Ta ≤ +##°C (Illuminator)

II 2 D Ex tb op is III* T135°C Db IP66/67

II 2 G Exdb op pr II* T6…3*Gb -##°C ≤ Ta ≤ +##°C (Fibre Optic)

II 2 D Ex tb op pr III* T135°C Db IP66/67

II 2 G Ex db ????[Ex ia Ga] IIC T6…T5 Gb -##°C ≤ Ta ≤ +##°C (Wireless IS)

II 2 D Ex tb ????[Ex ia Ga] IIIC T135°C Db IP66/67

Note: T class, Gas Group and ambient temperature, is dependent on the assembly configuration

and maximum internal power dissipation.

???? = Optional op pr/op is coding

*=T class, Gas Group

## = Ambient Temperature range

Marked Ambient range can be any of the -40C to +40C, -60C to +40C, -40°C to +50°C ,

following -40°C to +55°C , -40C to +70C, -60C to +70C

Wireless Ex ia T6: -40°C ≤ Tamb ≤ +40°C

T5: -40°C ≤ Tamb ≤ +50°C or

T5: -40°C ≤ Tamb ≤ +55°C

Page 21

EATON

Installation & Maintenance Instructions

IMI+70-XF-XC-XP-XT Issue 7

© 2016, Eaton

Page 21 of 21

A. Ex Annexe continued

(b) Conditions of Manufacture, Routine tests,

A routine overpressure test in accordance with IEC 60079-1:2014 Clause 16.1 shall be carried out

on all enclosures, including all cemented window assemblies, at a pressure of 30.12bar for a

period of between 10 and 60 seconds, details must be recorded and records maintained.

There shall be no deformation or damage to the enclosures and no leakage through the cement

of any of the window assemblies integrity of the welded construction shall also be verified during

routine overpressure testing.

Empty enclosures may be tested.

The individual parts of a flameproof enclosure (for example, cover and base) can be tested

separately. The test conditions shall be such that the stresses are comparable to those to which

these parts are exposed in the complete enclosure.

If required during the construction, thread inserts needs to withstand the routine overpressure

test also.

Details must be recorded and records maintained.

WARNING: DO NOT OPEN WHEN ENERGISED OR WHEN AN EXPLOSIVE ATMOSPHERE

IS PRESENT. CLEAN WITH DAMP CLOTH.

Loading...

Loading...