Page 1

DOC-0440-010, RED

DEMOAC

Development Board for Freescale FLEXIS AC MCU Family

Supports:

MCF51AC256

MC9S08AC128

MC9S08AC60

MC9S08AC16

Hardware User Guide

Web Site: www.axman.com

Support: support@axman.com

Page 2

DEMOAC USER GUIDE APRIL 10, 2008

CONTENTS

CAUTIONARY NOTES ..............................................................................................................4

TERMINOLOGY.........................................................................................................................4

FEATURES ................................................................................................................................5

REFERENCES ...........................................................................................................................6

GETTING STARTED..................................................................................................................6

APPLICATION DEVELOPMENT ...............................................................................................6

HARDWARE CONFIGURATION ...............................................................................................6

INTEGRATED BDM............................................................................................................... 6

BDM PORT CONNECTOR ............................................................................................... 7

POWER................................................................................................................................. 7

EXTERNAL POWER......................................................................................................... 7

BDM POWER.................................................................................................................... 8

POWER SWITCH – PWRSW............................................................................................ 8

VOLTAGE INDICATORS .................................................................................................. 8

PWR_SEL OPTION HEADER........................................................................................... 8

VX_EN OPTION HEADER................................................................................................ 9

MCU POWER........................................................................................................................ 9

MCUVDD......................................................................................................................... 10

VDDAD............................................................................................................................ 10

VSSAD............................................................................................................................ 10

VREFH............................................................................................................................ 10

VREFL............................................................................................................................. 10

RESET SWITCH ................................................................................................................. 11

RESET LED .................................................................................................................... 11

LOW VOLTAGE DETECT............................................................................................... 11

MEMORY ............................................................................................................................ 11

TIMING................................................................................................................................ 11

COMMUNICATIONS ........................................................................................................... 12

VIRTUAL COM PORT..................................................................................................... 12

COM_EN......................................................................................................................... 12

CAN PORT...................................................................................................................... 12

IIC PORT......................................................................................................................... 12

POTENTIOMETER.............................................................................................................. 13

USER PUSHBUTTON SWITCHES ..................................................................................... 13

USER LED’S ....................................................................................................................... 13

ACCELEROMETER.................................................................................................................13

ACCELEROMETER CONFIGURATION ............................................................................. 14

MCU_PORT ........................................................................................................................15

TROUBLESHOOTING..............................................................................................................16

2

Page 3

DEMOAC USER GUIDE APRIL 10, 2008

INITIAL FLASH PROGRAMMING................................................................................... 16

FIGURES

Figure 1: BDM Connector ...........................................................................................................7

Figure 2: PWR Jack....................................................................................................................8

Figure 3: PWR_SEL Option Header ...........................................................................................9

Figure 4: VX_EN Option Header ................................................................................................9

Figure 5: USB_COM Option Header ........................................................................................12

Figure 6: Accelerometer Sensitivity Select Header...................................................................14

Figure 7: MCU_PORT Connector.............................................................................................15

TABLES

Table 1: OSC_SEL Option Header...........................................................................................11

Table 2: POT ............................................................................................................................13

Table 3: Push Button Switches.................................................................................................13

Table 4: User LED’s..................................................................................................................13

Table 5: ACC_OUT Option Header ..........................................................................................14

REVISION

Date Rev Comments

March 20, 2008 A Initial Release.

March 29, 2008 B Minor text corrections

April 3, 2008 C Remove references to 51JM128 MCU

April 10, 2008 D Updated Troubleshooting section to account for

power-cycling board when powered from USB BDM

3

Page 4

DEMOAC USER GUIDE APRIL 10, 2008

CAUTIONARY NOTES

1) Electrostatic Discharge (ESD) prevention measures should be used when handling this

product. ESD damage is not a warranty repair item.

2) Axiom Manufacturing does not assume any liability arising out of the application or use of

any product or circuit described herein; neither does it convey any license under patent

rights or the rights of others.

3) EMC Information on the DEMOAC board:

a) This product, as shipped from the factory with associated power supplies and cables,

has been verified to meet with FCC requirements as a CLASS A product.

b) This product is designed and intended for use as a development platform for hardware

or software in an educational or professional laboratory.

c) In a domestic environment, this product may cause radio interference in which case the

user may be required to take adequate prevention measures.

d) Attaching additional wiring to this product or modifying the product operation from the

factory default as shipped may effect its performance and cause interference with other

apparatus in the immediate vicinity. If such interference is detected, suitable mitigating

measures should be taken.

TERMINOLOGY

This development board applies option selection jumpers. Terminology for application of the

option jumpers is as follows:

Jumper on, in, or installed = jumper is a plastic shunt that fits across 2 pins and the shunt is

installed so that the 2 pins are connected with the shunt.

Jumper off, out, or idle = jumper or shunt is installed so that only 1 pin holds the shunt, no 2

pins are connected, or jumper is removed. It is recommended that the jumpers be placed

idle by installing on 1 pin so they will not be lost.

Cut-Trace – a circuit trace connection between component pads. The circuit trace may be

cut using a knife to break the default connection. To reconnect the circuit, simply install a

suitably sized 0-ohm resistor or attach a wire across the pads.

Signal names followed by an asterisk (*) denote active-low signals.

4

Page 5

DEMOAC USER GUIDE APRIL 10, 2008

FEATURES

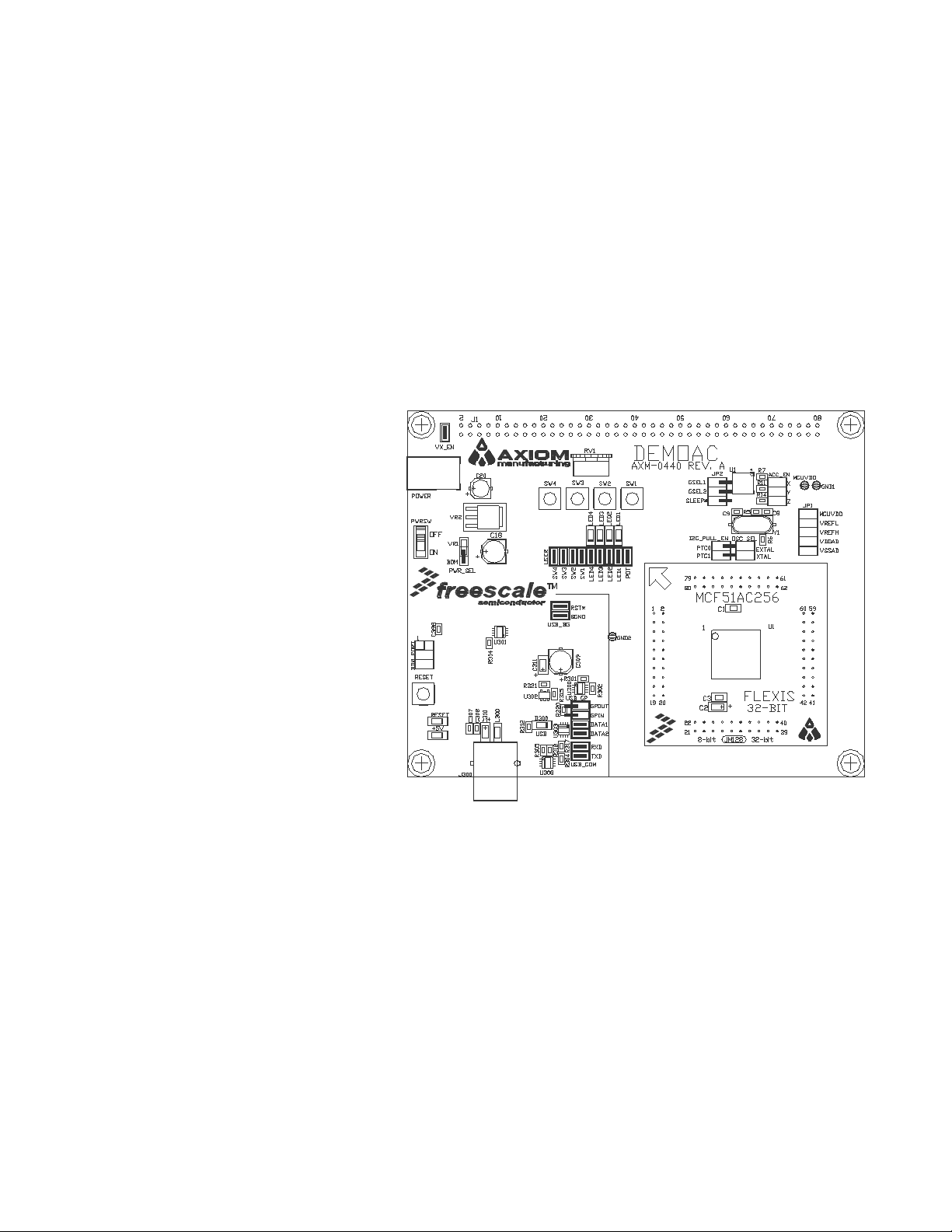

The DEMOAC provides a platform supporting a line of Freescale microcontrollers which are

part of the Flexis Continuum. Target microcontrollers mount on plug-in modules to support

quickly changing the target MCU. Available microcontrollers for the DEMOAC include; the

ColdFire V1 MCF51AC256, and the MC9S08AC128/60/16. Application development on the

DEMOAC is quick and easy with the integrated USB-BDM, sample software tools, and examples. An optional BDM_PORT port is also provided to allow use of an external BDM cable. An

80-pin MCU_PORT connector provides access to all IO signals on the target MCU. An expanded feature set, including an E-Field sensor, is provided on the DEMOACEX board. The

DEMOACEX connects to the DEMOAC through the 80-pin MCU_PORT connector.

MCU Modules:

• MCF51AC256, 80LQFP

• 256K bytes FLASH

• 32K bytes RAM

• ColdFire V1 Core

• 50.3 MHz bus

• MC9S08AC128/60/16

• 128K/60K/16K bytes FLASH

• 8K/2K/1K bytes RAM

• HCS08 Core

DEMOAC Features:

• Integrated, USB BDM

• ON/OFF Power Switch

• Power Input Select Option Header

• On-board 5V regulator

• Power from USB BDM

• Optional Power Sourced to

Connector J1

• 4MHz XTAL Oscillator

• 3-axis accelerometer

• LEDs – 4 User, 1 Power, 1 Reset

• Push button switches – 4 user, 1 Reset

• 5K ohm POT

• Jumpers to disconnect User Features

• 80-pin MCU PORT provides access to MCU signals

• 4 20-pos pin-headers support plug-in MCU modules

• IIC Termination Select Header

DEMOAC Board Size: 5.0” x 4.0

5

Page 6

DEMOAC USER GUIDE APRIL 10, 2008

REFERENCES

The following documents should be referenced during application development using the

DEMOAC. These documents are available on the MCF51JM128 and DEMOAC web pages

(http://www.freescale.com/coldfire).

DEMOAC_UG.pdf DEMOAC User Guide (this document)

DEMOAC_QSG.pdf DEMOAC Quick Start Guide

DEMOAC_SCH_A1.pdf DEMOAC Schematic

DEMOAC_Silk_A.pdf DEMOAC Top Silk

GETTING STARTED

To get started quickly, please refer to the DEMOAC Quick Start Guide. This quick start will illustrate connecting the board to a PC, installing the correct version of CodeWarrior Development Studio, and running a simple program.

APPLICATION DEVELOPMENT

CodeWarrior Development Studio for Microcontrollers, Special Edition is provided along with

the DEMOAC to support application development and debug. CodeWarrior provides an IDE

for application debug and an integrated FLASH programmer to load application code. Refer to

the CodeWarrior Development Studio User Guide further details.

HARDWARE CONFIGURATION

The DEMOAC board provides a development or evaluation platform for a line of AC Flexis microcontrollers; including the MCF52AC256, MC9S08AC128, MC9S08AC60, and

MC9S08AC16 MCU’s. Following are descriptions of the components and options provided on

the board.

Integrated BDM

The DEMOAC board features an integrated USB BDM debugger. The integrated debugger

supports application development and debugging via the background debug mode. A type B,

USB connector provides connectivity between the target board and the host PC.

NOTE: Using the integrated USB BDM requires CodeWarrior Development Studio for Micro-

controllers Special Edition, V6.0 or later. Development tools from P&E Microcomputer

Systems also support the target device.

6

Page 7

DEMOAC USER GUIDE APRIL 10, 2008

The integrated debugger provides power and ground to the target, thereby eliminating the

need to power the board externally. Power from the integrated USB BDM is derived from the

USB bus; therefore, current consumption is limited by the USB specification. Total current

consumption for the target board, and any connected circuitry, must not exceed 350 mA. Excessive current drain will violate the USB specification causing the bus to disconnect. This will

force a target POR.

CAUTION: Violating the USB specification will cause the USB bus to disconnect forcing the

target to reset. Damage to the board or host PC may result.

The integrated USB BDM provides a virtual COM port for serial communication applications.

The BMD also provides virtual instrument analyzer function. Refer to the P&E Micro Demo

Toolkit for details.

BDM Port Connector

As standard 6-pin BDM connector is also provide to allow use of external BDM cables capable

of supporting the MCF51AC26 or MC9S08AC128/60/16 devices.

Figure 1: BDM Connector

BKGD*/MS

1 2

3 4

5 6

VSS

RESET*

VDD

POWER

The DEMOAC may be powered from the integrated USB BDM, an on-board voltage regulator,

or from the MCU connector at J1. Alternatively, the DEMOAC may be configured to provide

power to external circuitry connected to the MCU connect J1.

The PWRSW power switch controls input voltage to the board regardless of input voltage

source.

External Power

The power jack at POWER allows the board to be powered from an externally connected

power source. This connection accepts a standard 2.1mm, center-positive, barrel plug connector. +VIN should fall between +7VDC and +18VDC. Input voltage applied to the barrel

connector should be kept as lows as possible to minimize device heating.

7

Page 8

DEMOAC USER GUIDE APRIL 10, 2008

Figure 2: PWR Jack

2.1mm, center-positive, +V input

Applied voltage: +7V to +18V

PWR

A voltage regulator provides +5V to the target MCU and board circuitry. The regulator provides a maximum of 500 mA. The regulator is over-current and over-temperature protected to

prevent damage during fault conditions.

BDM Power

The integrated USB BDM is configured to provide power to the target device and connected

circuitry. After the BDM enumerates on the USB bus, the BDM will provide up to 350 mA to

the board. Excessive current drain will violate the USB specification and cause de-enumerate

the BDM. This will disconnect power to the board and cause a target reset.

CAUTION: Violating the USB specification will cause the USB bus to disconnect forcing the

target to reset. Damage to the board or host PC may result.

Power Switch – PWRSW

The PWRSW easily connects and disconnects input voltage to the board. The silkscreen

clearly marks the ON and OFF positions. This switch controls all voltage levels on the board.

Voltage Indicators

A +5V LED indicates the board is powered.

PWR_SEL Option Header

The PWR_SEL option header selects the source of input power to the EVB. The board may

be powered from a voltage source connected to either the POWER connector or the integrated

USB BDM. The BDM can provide up to 350 mA of current to the EVB.

8

Page 9

DEMOAC USER GUIDE APRIL 10, 2008

Figure 3: PWR_SEL Option Header

PWR_SEL

• • •

Selects input voltage from POWER connector

BDM VR1 NOTE: The VR1 input is connected to the regulator at VR2.

This is an error in the board silkscreen.

PWR_SEL

• • •

Selects input voltage from the integrated BDM

BDM VR1

NOTE: The voltage regulator reference designator at the PWR_SEL option header does not

match the reference designator of the voltage regulator.

VX_EN Option Header

The VX_EN option header is a 2-pin jumper that connects the target-board voltage rail to IO

connector position J1-1. IO connector position J1-3 connects directly to the ground plane.

This input requires a regulated +5.0V voltage source. This power input is decoupled to minimize noise input but is not regulated. Also, no protection is applied on this input and damage

to the target board may result if over-driven. Do not attempt to power the target board through

this connector while also applying power through the PWR connector as damage to the board

may result.

Power may be sourced to off-board circuitry through the MCU_PORT. The current limitation of

the on-board regulator must be considered when attempting to source power to external circuitry. Excessive current drain may damage the target board or the on-board regulator. The

figure below shows the VX_EN option header connections.

Figure 4: VX_EN Option Header

ON

VX_EN

▪ ▪ OFF

VX_EN

CAUTION: Do not apply power to connector J1 while also sourcing power from either the

PWR connector. Damage to the board may result.

NOTE: Do not exceed available current supply from on-board regulator when sourcing power

through connector J1 to external circuitry.

Enable power connection to connector J1

Disable power connection to connector J1

MCU Power

Each power input is routed through an option header. The option header is not installed in

default configurations and a cut-trace on each power input provides default connections. To

9

Page 10

DEMOAC USER GUIDE APRIL 10, 2008

apply an alternate power input, simply remove the cut-trace using a sharp knife. Then either

solder a wire to the thru-hole via or install a pin header and wire-wrap a wire connection.

The various power inputs are grouped together at JP1. This allows each voltage input to be

selected individually using multiple 1x2 pin headers or all voltage input may be selected using

a 2x5 pin header.

MCUVDD

The VDD option header applies board VDD to the target MCU. This jumper may be used to

apply alternate voltage levels or to measure input current under operating conditions.

VDDAD

The VDDA option header connects the target device VDDA input to the VDD rail by default.

This jumper may be used to apply alternate voltage input or to measure input current under

operating conditions.

VSSAD

The VSSA option header connects the target device VSSA input to the EVB digital ground rail

by default. This option header may be used to apply ultra clean ground or to measure input

current under operating conditions.

VREFH

The VREFH option header connects the target device VREFH input to the VDD rail by default.

This jumper may be used to apply alternate voltage input or to measure input current under

operating conditions.

VREFL

The VREFL option header connects the target device VREFL input to the ground rail by default. This option header may be used to apply ultra clean ground or to measure input current

under operating conditions.

10

Page 11

DEMOAC USER GUIDE APRIL 10, 2008

RESET Switch

The RESET switch allow the manual application of the RESET* signal. Application of RESET

halts the current operation and initializes internal registers to their default state. The previous

operating state of the target device will be lost.

External reset may also be applied directly to the RESET * signal at connector J1A-4.

Reset LED

The RESET indicator will be ON for the duration of a valid RESET* signal. The RESET * signal is driven active while the MCU is in the RESET state.

Low Voltage Detect

The different AC MCU’s apply a Low Voltage Detect (LVD) module to detect under-voltage

conditions. The LVD may be configured to generate a RESET or an interrupt. Refer to the

target device Reference Manual for further details.

MEMORY

No external memory is applied to the DEMOAC board. Memory for application development is

internal to the target MCU. Refer to the target device Reference Manual for further details.

TIMING

The DEMOAC board provide a 4Mhz oscillator timing source for use with the target MCU. The

OSC_SEL option header allows this input to be disconnected if necessary. In default configurations, the OSC_SEL option header is not installed and cut-traces provide the default connections.

To either disconnect the oscillator input or to apply an alternate frequency, remove the cuttraces. To restore the default connection, install a 2x2 pin header and 2 shunts.

Table 1: OSC_SEL Option Header

●●EXTAL Oscillator or External Clock Input w/ cut-trace in default configurations

●●XTAL Oscillator Input w/ cut-trace in default configurations

CAUTION: Communications with the target may be lost if clock frequency or baud rate

changes during application execution.

11

Page 12

DEMOAC USER GUIDE APRIL 10, 2008

Communications

The DEMOAC board provides 2 UART ports, 1 IIC port, and 1 CAN port. Serial RS-232 communications is support through the integrated BDM. Access to each MCU UART is also available at connector J1. RS-232 translation is not provided on signals to connector J1.

Virtual COM Port

The serial link through the integrated USB BDM is implemented as a virtual COM port running

through the USB connection. Use of this link require installation of the P&E Micro Demo Board

Toolkit. This toolkit is available on the DVD provided with the DEMOAC.

Refer to the P&E documentation for details and instructions on use of the virtual COM port.

COM_EN

The USB_COM option header individually connects and disconnects the target UART signals

to the integrated USB BDM. Removing a shunt disconnects the associated signal. Installing a

shunt connects the associated signal.

Figure 5: USB_COM Option Header

Shunt

On Off

▪ ▪

▪ ▪

(*) – Default condition

NOTE: TGT_TXD and TGT_RXD connect TXD2 and RXD2 lines to the serial input of the inte-

grated BDM.

RXD Enabled (*) Disabled

TXD Enabled (*) Disabled

CAN Port

CAN port signals connect directly between the target MCU and the MCU Port connector at J1.

Refer to the target MCU device Reference Manual for details on using this feature.

IIC Port

IIC port signals connect directly between the target MCU and the MCU Port connector at J1.

Refer to the target MCU device Reference Manual for details on using this feature. Each IIC

signal is pulled up to VDD at the I2C_PULL_EN option header.

12

Page 13

DEMOAC USER GUIDE APRIL 10, 2008

Potentiometer

A 5k ohm, single-turn, thumb-wheel type, potentiometer at RV1 provides continuous, variable

resistance input for user applications. The potentiometer is connected between VDD and GND

with the center tap providing the divider output. The center tap is connected to the MCU at :

Table 2: POT

POT

PTD0/AD1P8/ACMP1+

User Pushbutton Switches

Four user push-button switches are provided for user application input as needed and are configured for active-low signaling. SW1 – SW4 are applied to keyboard interrupt inputs on the

target MCU. Use of target device internal pull-ups is required for proper operation. No external

bias is applied to any push-button switch input. Use of target device internal pull-ups is required for proper operation.

Table 3: Push Button Switches

Switch Signal

SW1 PTG0/KBI1P0

SW2 PTG1/KBI1P1

SW3 PTG2/KBI1P2

SW4 PTG3/KBI1P3

User LED’s

Eight user LED's are provided for output indication and are configured for active-low signaling.

The table below details the LED connections to the target MCU

Table 4: User LED’s

LED Signal

LED1 PTF0/RGPIO8/FTM1CH2

LED2 PTF1/RGPIO9/FTM1CH3

LED3 PTF4/RGPIO12/FTM2CH0

LED4 PTF5/RGPIO13/FTM2CH1

ACCELEROMETER

13

Page 14

DEMOAC USER GUIDE APRIL 10, 2008

The DEMOAC applies the MMA7260Q, 3-axis accelerometer for tilt and motion-sense applications. The accelerometer supports 4 user selectable sensitivities - 1.5g / 2g / 4g / 6g. The

SLEEP* input allows the device to be placed in a low-power mode. Separate X-, Y-, and Zaxis readings are routed to the MCU. The X-axis output is routed to two separate inputs on the

target MCU. Low-pass filters remove hi-frequency components on each axis output.

Accelerometer Configuration

Accelerometer sensitivity configuration is controlled manually using option select header JP2.

Figure 6: Accelerometer Sensitivity Select Header

Shunt

JP2 On Off

GSEL1

GSEL2

SLEEP*

(*) – Default condition

▪ ▪

▪ ▪

▪ ▪

Enabled Disabled (*)

Enabled Disabled (*)

Enabled Disabled (*)

An option header at ACC_OUT allows the user to disconnect the accelerometer output if necessary. The ACC_OUT option header is not installed default configurations and cut-traces

provide default connections

Table 5: ACC_OUT Option Header

Signal MCU Input

X PTD0/ADP8/ACMP+

X PTB3/SS2*/ADP3

Y PTB0/MISO2/ADP0

Z PTB1/MOSI2/ADP1

14

Page 15

DEMOAC USER GUIDE APRIL 10, 2008

MCU_PORT

The MCU PORT provides user access to the DEMOAC I/O ports. Refer to the MCF51AC256

or MC9S08AC128/60/16 Integrated Device Reference Manual for signal details.

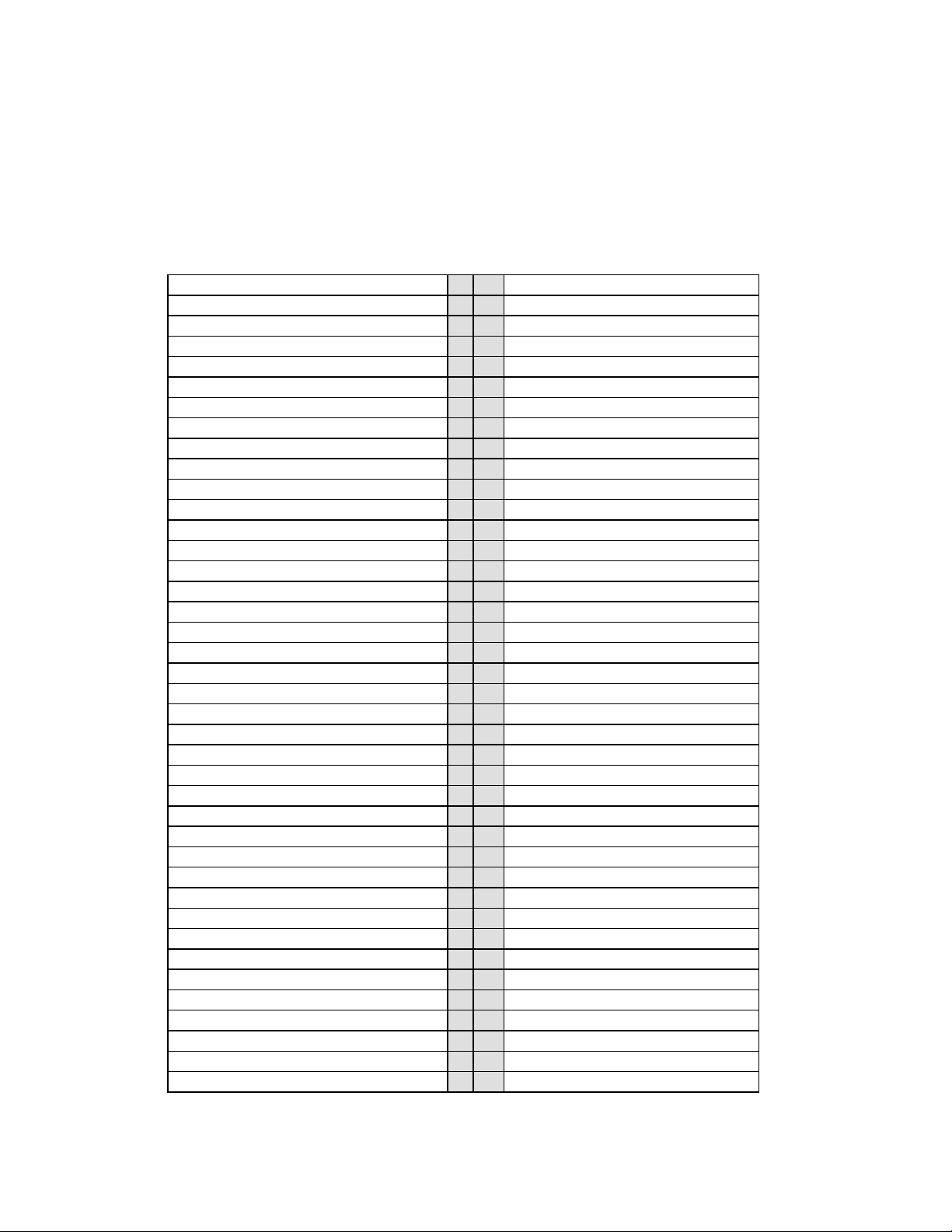

Figure 7: MCU_PORT Connector

VDD

VSS

PTE0/RGPIO0/TXD1

PTE1/RGPIO1/RXD1

PTG0/KBI1P0

PTG1/KBI1P1

PTE2/RGPIO2/FTM1CH0

PTE3/RGPIO3/FTM1CH1

PTE6/RGPIO6/MOSI1

PTE5/RGPIO5/MISO1

PTE7/RGPIO7/SPSCK1

PTE4/RGPIO4/SS1*

PTD2/KBI1P5/AD1P10/ACMP1O

PTD3/KBI1P6/AD1P11

PTG2/KBI1P2

PTG3/KBI1P3/AD1P18

PTF0/RGPIO8/FTM1CH2

PTF1/RGPIO9/FTM1CH3

PTF4/RGPIO12/FTM2CH0

PTF5/RGPIO13/FTM2CH1

PTF2/RGPIO10/FTM1CH4

PTF3/RGPIO11/FTM1CH5

PTF6/RGPIO14/FTM1FLT

PTF7/RGPIO15

PTB4/AD1P4

PTB5/AD1P5

PTB6/AD1P6

PTB7/AD1P7

PTD4/FTM2CLK/AD1P12

PTD5/AD1P13

PTD6/FTM1CLK/AD1P14

PTD7/KBI1P7/AD1P15

VDDAD

VSSAD

PTG4/KBI1P4/AD1P19

NC

PTH0/FTM2CH2/AD1P20

PTH1/FTM2CH3/PSTCLK0/AD1P21

PTH2/FTM2CH4/PSTCLK1/AD1P22

PTH3/FTM2CH5/BKPT/AD1P23

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

51 52

53 54

55 56

57 58

59 60

61 62

63 64

65 66

67 68

69 70

71 72

73 74

75 76

77 78

79 80

IRQ*/TPMCLK

RESET*

BKGD/MS

PTD6/FTM1CLK/AD1P14

VREFH

VREFL

PTD0/AD1P8/ACMP1+

PTD1/AD1P9/ACMP1-

PTB3/AD1P3

PTB2/AD1P2

PTB0/TPM3CH0/AD1P0

PTB1/TPM3CH1/AD1P1

PTA0/TXCAN

PTA1/RXCAN

PTH5/MOSI2

PTH6/MISO2

PTH4/SPSCK2

PTC4/SS2*

PTC3/TXD2

PTC5/RXD2

PTC0/SCL1

PTC1/SDA1

PTC2/MCLK

PTC6/FTM2FLT

PTA2

PTA3/ACMP2O

PTA4/ACMP2-

PTA5/ACMP2+

PTA6/AD1P16

PTA7/AD1P17

PTG5/XTAL

PTG6/EXTAL

PTJ0/PST0

PTJ1/PST1

PTJ2/PST2

PTJ3/PST3

PTJ4/DDATA0

PTJ5/DDATA1

PTJ6/DDATA2

PTJ7/DDATA3

15

Page 16

DEMOAC USER GUIDE APRIL 10, 2008

TROUBLESHOOTING

The DEMOAC is fully tested and operational before shipping. If it fails to function properly, inspect the board for obvious physical damage first. Verify the communications setup as described under GETTING STARTED.

Initial Flash Programming

To program target device FLASH initially, or if device FLASH is erased, apply external power

at the PWR jack and set the PWR_SEL option header to VR1. When prompted by P&E software to cycle target power, move the PWRSW to the OFF position momentarily then to the ON

position. Otherwise, the BDM will fail to connect to the target device.

Most common problems are related to improperly configured options or communications parameters.

1. If the simulator software requires a device power cycle during FLASH programming, en-

sure the board is powered externally and the PWR_SEL option header is set to VR1.

2. Verify the +5V voltage indicator is ON.

3. Verify input power is connected. If powered from an external power source, measure at

least +7V between VR2-1 and VR2-2 using a multi-meter. If powered from the integrated

BDM, measure +5V across capacitor C16

4. Ensure the PWRSW is in the ON position.

5. Verify default option jumper settings and RESET the board.

6. Ensure target module is securely, and correctly, seated on pin headers JM1 – JM4.

7. If a peripheral feature does not function properly, ensure all USER select jumpers are in-

stalled.

Contact support@axman.com by email for further assistance. Provide board name and a

complete description of the problem.

16

Loading...

Loading...