Page 1

D O C - 0479- 0 1 0 , R E V A

DEMO9S08SV16/FL16

Demonstration Board for Freescale MC9S08SV16 or

MC9S08FL16 Microcontroller

USER GUIDE

Web Site: www.axman.com

Support: support@axman.com

Page 2

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

U S E R G U I D E

CONTENTS

CAUTIONARY NOTES .............................................................................................................. 4

TERMINOLOGY ......................................................................................................................... 4

FEATURES ................................................................................................................................ 5

REFERENCES ........................................................................................................................... 6

MEMORY MAP .......................................................................................................................... 6

SOFTWARE DEVELOPMENT ................................................................................................... 7

DEVELOPMENT SUPPORT ...................................................................................................... 7

INTEGRATED BDM .............................................................................................................. 7

BDM_PORT HEADER ........................................................................................................... 7

POWER ...................................................................................................................................... 8

POWER SELECT .................................................................................................................. 8

PWR_SEL ......................................................................................................................... 8

VX_EN ............................................................................................................................... 9

RESET SWITCH ...................................................................................................................... 10

LOW VOLTAGE RESET .......................................................................................................... 10

TIMING ..................................................................................................................................... 10

COMMUNICATIONS ................................................................................................................ 10

COM PORT ......................................................................................................................... 10

VIRTUAL COM PORT ......................................................................................................... 11

COM_SEL ........................................................................................................................... 11

COM CONNECTOR ............................................................................................................ 12

USER OPTIONS ...................................................................................................................... 12

PUSHBUTTON SWITCHES ............................................................................................ 12

LED INDICATORS .......................................................................................................... 12

POTENTIOMETER .......................................................................................................... 12

TEMPERATURE SENSOR ............................................................................................. 13

BUZZER .......................................................................................................................... 13

MCU I/O PORT ......................................................................................................................... 14

2

Page 3

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

Date

Rev

Comments

June 5, 2009

A

Initial Release

U S E R G U I D E

FIGURES

Figure 1: Memory Map................................................................................................................ 6

Figure 2: BDM_PORT Header .................................................................................................... 7

Figure 3: V_SEL Option Header ................................................................................................. 8

Figure 4: VX_EN Option Header ................................................................................................ 9

Figure 5: COM_EN Option Header ........................................................................................... 11

Figure 6: COM Connector ......................................................................................................... 12

Figure 7: MCU I/O PORT – J1 .................................................................................................. 14

TABLES

Table 1: COM Connections ...................................................................................................... 11

Table 2: User Option Jumper Settings ...................................................................................... 13

REVISION

3

Page 4

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

U S E R G U I D E

CAUTIONARY NOTES

1) Electrostatic Discharge (ESD) prevention measures should be used when handling this

product. ESD damage is not a warranty repair item.

2) Axiom Manufacturing does not assume any liability arising out of the application or use of

any product or circuit described herein; neither does it convey any license under patent

rights or the rights of others.

3) EMC Information on the DEMO9S08SV16/FL16 board:

a) This product as shipped from the factory with associated power supplies and cables,

has been verified to meet with requirements of CE and the FCC as a CLASS A product.

b) This product is designed and intended for use as a development platform for hardware

or software in an educational or professional laboratory.

c) In a domestic environment, this product may cause radio interference in which case the

user may be required to take adequate prevention measures.

d) Attaching additional wiring to this product or modifying the products operation from the

factory default as shipped may effect its performance and cause interference with

nearby electronic equipment. If such interference is detected, suitable mitigating

measures should be taken.

TERMINOLOGY

This development module utilizes option select jumpers to configure default board operation.

Terminology for application of the option jumpers is as follows:

Jumper – a plastic shunt that connects 2 terminals electrically

Jumper on, in, or installed – jumper is a plastic shunt that fits across 2 pins and the shunt is

installed so that the 2 pins are connected with the shunt.

Jumper off, out, or idle – jumper or shunt is installed so that only 1 pin holds the shunt, no 2

pins are connected, or jumper is removed. It is recommended that the jumpers be placed

idle by installing on 1 pin so they will not be lost.

Cut-Trace – a circuit trace connection between component pads. The circuit trace may be

cut using a knife to break the default connection. To reconnect the circuit, simply install a

suitably sized 0-ohm resistor or attach a wire across the pads.

Signal names followed by an asterisk (*) denote active-low signals.

4

Page 5

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

U S E R G U I D E

FEATURES

The DEMO9S08SV16/FL16 is a demonstration board for the MC9S08SV16 or MC9S08FL16

microcontroller. Application development is quick and easy with the integrated, Open-Source,

USB-BDM, sample software tools, and examples. An optional BDM_PORT port is also

provided to allow use of a BDM_PORT cable. One, 40-pin connector provides access to all IO

signals on the target MCU.

MC9S08SV16 or MC9S08FL16, 32 SDIP

16K Bytes Flash

1K Bytes RAM

RS-232 Serial Data Physical Layer Transceiver

Integrated Open-Source, USB-BDM

BDM_PORT header for external BDM cable

support

MCU_PORT pin header for access to MCU IO

signals

On-board +5V regulator

Optional Power from USB-BDM or MCU_PORT

connector

Power Input Selection Jumpers

Power input from USB-BDM

Power input from on-board regulator

Power input from Connector J1

Optional Power output through Connector

J1

User Components Provided

3 Push Switches; 2 User, 1 Reset

5 LED Indicators; 2 User, VDD, STATUS, TPWR

5K ohm POT w /LP Filter

2300 Hz Piezo Buzzer w/ External Drive Circuit

User Option Jumpers to disconnect Peripherals

Connectors

40-pin MCU I/O Pin Header

2.0mm Barrel Connector

BDM_PORT Connector for External BDM Cable (not installed)

USB Connector

DB9 Connector

Specifications:

Board Size 3.25” x 3.0”

5

Page 6

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

$0000

$003F

Direct Page Registers

$0040

$043F

RAM

1024 bytes

$0440

$017F

Unimplemented

$1800

$187F

High Page Registers

$1880

$BFFF

Unimplemented

$C000

$DFFF

FLASH

16,384 bytes

U S E R G U I D E

REFERENCES

The following reference documents are available on the CD or DVD provided with this board in

Acrobat Reader format. These documents are also available at www.axman.com/support.

DEMO9S08SV16_FL16_UG.doc DEMO9S08SV16/FL16 User Guide (this document)

DEMO9S08SV16_FL16_SCH_A.pdf DEMO9S08SV16/FL16 Schematic Rev. A

DEMO9S08SV16_FL16_Silk_A.pdf DEMO9S08SV16/FL16 Top Silk, Rev A

DEMO9S08SV16_FL16_Assy_A.pdf DEMO9S08SV16/FL16 Default Shunt Placement

DEMO9S08FL16.zip DEMO9S08FL16 LED Demo Application

DEMO9S08SV16.zip DEMO9S08SV16 LED Demo Application

MEMORY MAP

Figure 1 below shows the default memory map for the MC9S08SV16 and the MC9S08FL16

immediately out of reset. Refer to the MC9S08SV16 or MC9S08FL16 Reference Manual

(RM) for further details.

Figure 1: Memory Map

NOTE: The memory map above applies to the MC9S08SV16 and MC9S08FL16

microcontrollers

6

Page 7

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

BKGD

1

2

GND

See the MC9S08SV16 or MC9S08FL16 Reference

Manual for details

3

4

RESET*

5

6

VDD

U S E R G U I D E

SOFTWARE DEVELOPMENT

Software development requires the use of a compiler or an assembler supporting the HCS08

instruction set and a host PC operating a debug interface. CodeWarrior Development Studio

for Microcontrollers is supplied with this board for application development and debug. Refer

to the supporting CodeWarrior documentation for details on use and capabilities.

DEVELOPMENT SUPPORT

Application development and debug for the target MC9S08SV16 or MC9S08FL16 is supported

through the integrated, Open-Source Background Debug Mode (BDM) interface. An optional

6-pos BDM_PORT header allows connecting an external HCS12/HCS08 BDM cable. The

BDM_PORT header is not installed in default configurations.

Integrated BDM

The DEMO9S08SV16/FL16 board features an integrated Open Source BDM (OSBDM-JM60)

based on the Freescale MC9S08JM60 MCU. The integrated USB BDM supports application

development and debugging via background debug mode. The integrated BDM is fully

supported by CodeWarrior development tools.

The integrated USB BDM provides power and ground to the target board eliminating the need

to power the board externally. Power from the USB BDM is derived from the USB bus. The

integrated USB BDM is designed to sink a maximum of 300mA of current from the USB bus.

Therefore, total current consumption for the target board, and connected circuitry, must not

exceed 300mA. This current limit describes the current supplied by the USB cable to the

BDM circuit, the target board, and any connected circuitry. Excessive current drain will violate

the USB specification causing the bus to disconnect. Damage to the host PC USB hub or the

target board may result.

BDM_PORT Header

A compatible HCS12 BDM cable may also attach to the 6-pin BDM interface header

(BDM_PORT). Figure 2 below shows the pin-out for the BDM_PORT header.

Figure 2: BDM_PORT Header

NOTE: The BDM_PORT header is not installed in default configuration.

7

Page 8

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

CAUTION:

Damage to the board may result if voltages greater than +5.5V are applied

at connector J1 input.

PWR_SEL

Enable power to board from integrated BDM

VB VR1

PWR_SEL

Enable power to board from external power supply

VB VR1

U S E R G U I D E

POWER

The DEMO9S08SV16/FL16 may be powered from the integrated USB-BDM or from an onboard voltage regulator and external power connector. The desired power source is selected

using the PWR_SEL option header.

For application development and debug, the board may be powered from the integrated USB

BDM. As noted above, total current consumption from this source is limited to 300 mA. A

2.0mm, center-positive, barrel connector (VIN) and on-board regulator supports stand-alone

operation and higher power requirements.

Power may also be applied to connector J1 or the board may be configured to supply power

from connector J1 to external circuitry.

POWER SELECT

Power may be applied to the board through the integrated BDM circuitry, a 2.0mm barrel

connector, or through connector J1. Power selection is achieved using 2 selection headers:

the PWR_SEL option header and the VX_EN option header.

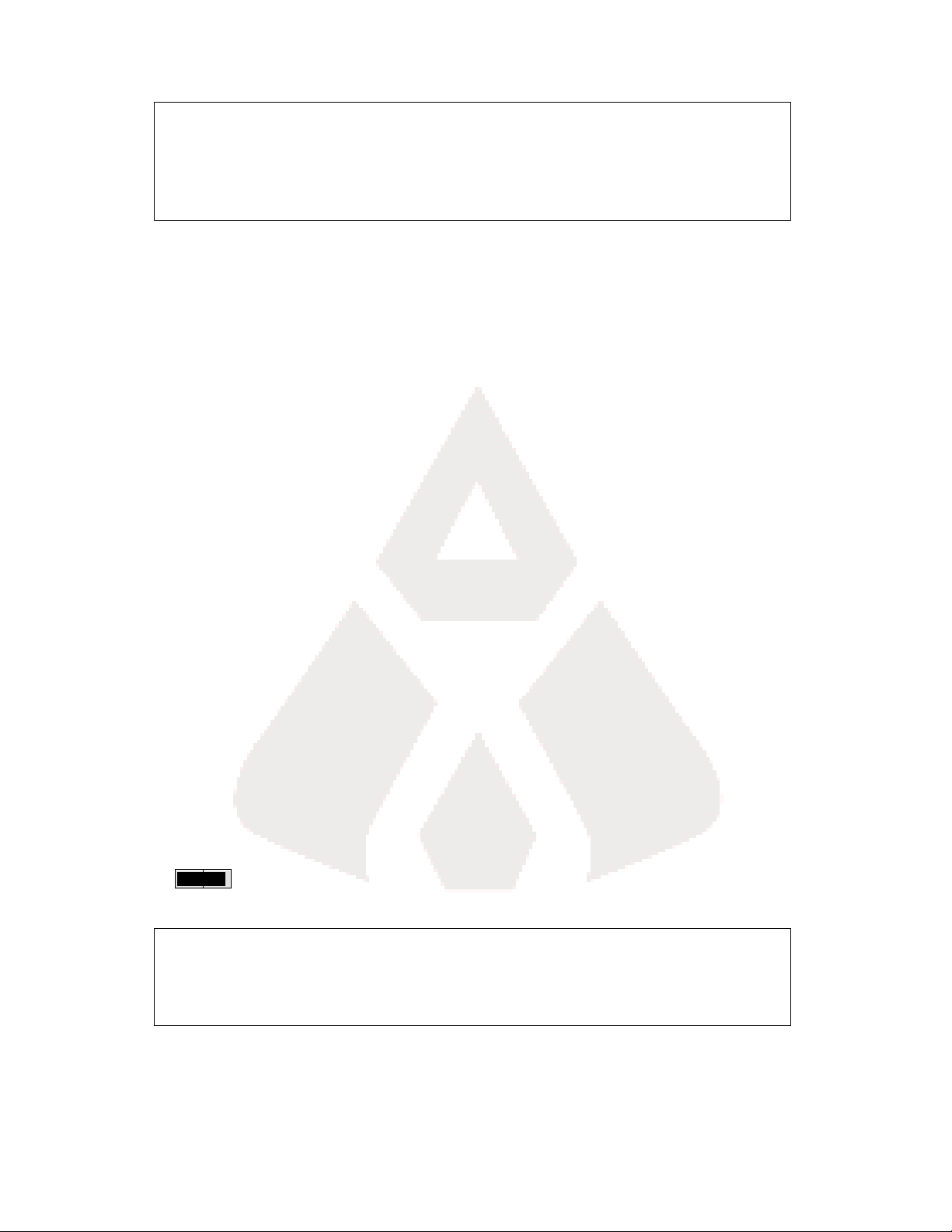

PWR_SEL

The PWR_SEL option header allows the user to select power input either from either an

external power source connected to the VIN connector or from the integrated USB-BDM.

Figure 3 below details the PWR_SEL header connections.

Figure 3: V_SEL Option Header

8

Page 9

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

CAUTION:

Do not configure the target board to draw more than 300mA when

powered from the integrated USB BDM. Damage to the target board or

host PC may result otherwise.

ON

OFF

1

2

Enabled

Disabled

VX_EN

CAUTION:

Do not exceed available current from USB-BDM or on-board regulator

when sourcing power through connector J1 to external circuitry.

U S E R G U I D E

Power from the integrated BDM is drawn from the USB bus and is limited to 300 mA. This

current limit accounts for the total current supplied over the USB cable to the BDM circuit, the

target board, and any connected circuitry. Current drain in excess of value violates the USB

specification and will cause the USB bus to disconnect. This will cause the board to exhibit

power cycling where the board appears to turn off and back on continually. Damage to the

host PC or the target board may result.

Although the on-board regulator can accept voltage input to +25VDC, the applied voltage

should not exceed +12V to prevent the regulator (VR1) from overheating.

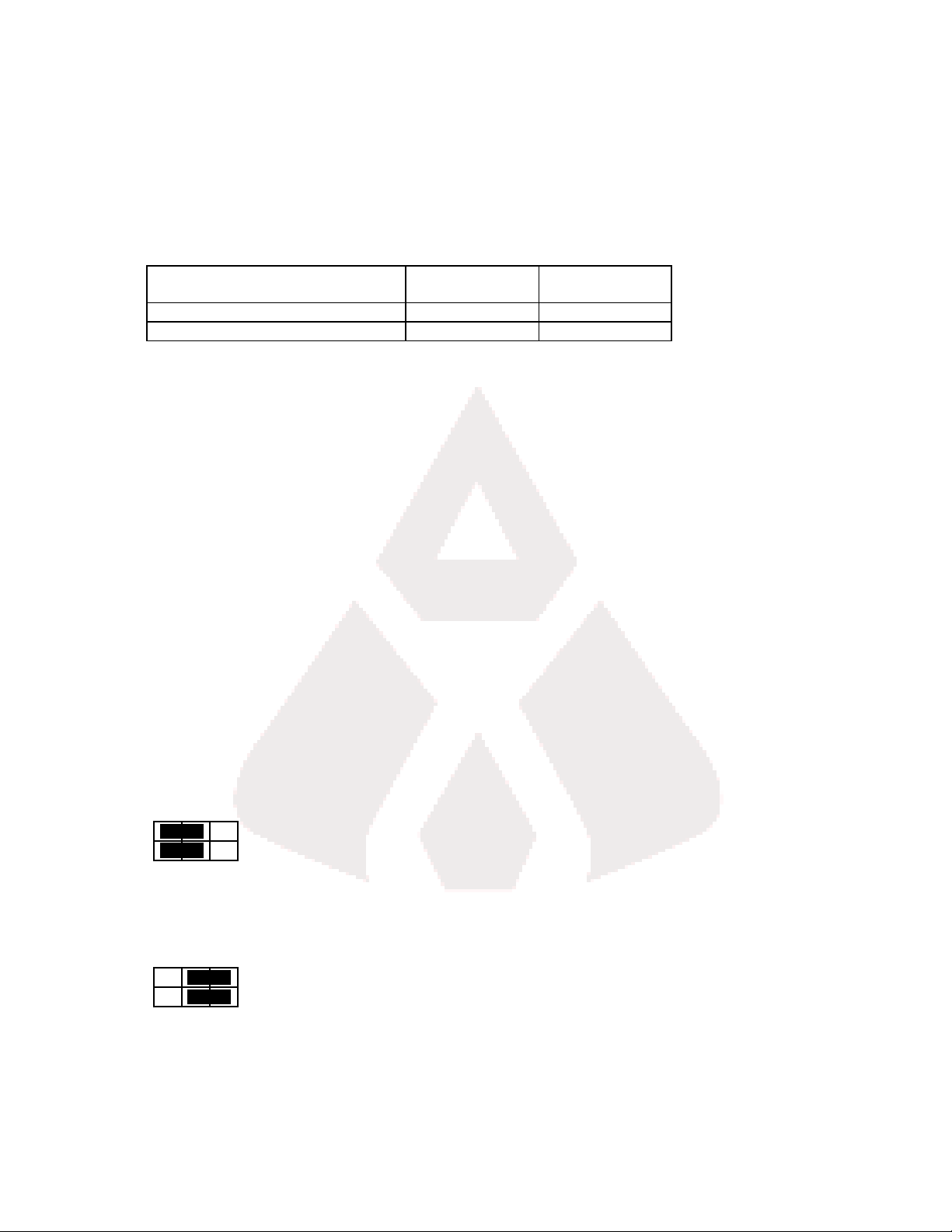

VX_EN

The VX_EN option header is a 2-pin jumper that connects or disconnects input J1-1 directly to

the target board voltage rail. J1-3 connects directly to the target board ground plane. Use of

this feature requires a regulated input power source. This power input is decoupled to

minimize noise but is not regulated or protected. Care should be exercised when using this

feature; no protection is applied on this input and damage to the target board may result if

excessive voltage is applied. Also, do not attempt to power the target board through this

connector while also applying power through the USB BDM or the PWR connector; damage to

the board may result.

Power may also be sourced to off-board circuitry through the J1 connector. The current

supplied from the USB bus or the on-board regulator limits current available to external

circuitry. Excessive current drain may damage the target board, the host PC USB hub, or the

on-board regulator. The figure below details the VX_EN header connections.

Figure 4: VX_EN Option Header

9

Page 10

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

U S E R G U I D E

RESET SWITCH

The RESET switch applies an asynchronous RESET to the MCU. The RESET switch is

connected directly to the RESET* input on the MCU. Pressing the RESET switch applies a

low voltage level to the RESET* input. A pull-up bias resistor allows normal MCU operation.

Shunt capacitance ensures an adequate input pulse width.

Both the MC9S08SV16 and MC9S08FL16 MCU’s apply a multiplexed RESET* input. To use

the RESET switch, the RESET pin must be enabled (SOPT1_RSTPE). Refer to the

MC9S08SV16 or MC9S08FL16 Reference Manual for details on configuring using the RESET*

input.

LOW VOLTAGE RESET

Both the MC9S08SV16 and the MC9S08FL16 apply an internal Low Voltage Detect (LVD)

circuitry. The LVD holds the MCU in reset until applied voltage reaches the appropriate level.

The LVD also protects against under-voltage conditions. Consult the MC9S08SV16 or

MC9S08FL16 Reference Manual for details on LVD operation.

TIMING

Default timing for the DEMO9S08SV16/FL16 is provided by the MC9S08SV16 or

MC9S08FL16 internal timing source which is active out of RESET. External circuitry for an

external 32 kHz XTAL oscillator is provided; however, these components are not populated in

default configuration. Refer to the MC9S08SV16 or MC9S08FL16 Reference Manual for

details on configuring the timing source.

COMMUNICATIONS

Serial communication on the DEMO9S08SV16/FL16 board is supported through an RS-232

physical layer interface and DB-9 connector and through a virtual serial port implemented in

the USB-BDM. The COM_SEL option header selects between the applied serial function.

NOTE: Virtual serial port services are not functional as of the date of this document

COM Port

An RS-232 transceiver provides RS-232 to TTL/CMOS logic level translation between the

COM connector and the MCU. The COM connector is a 9-pin Dsub, right-angle connector. A

ferrite bead on shield ground provides conducted immunity protection. Communication signals

TXD and RXD are routed from the transceiver to the MCU. These signals are also available

on connector J1. Hardware flow control signals RTS and CTS are available on the logic side

10

Page 11

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

MCU Port

COM Signal

I/O PORT

CONNECTOR

PTB1/KBIP5/TXD/ADP5

TXD

J1-5

PTB0/KBIP4/RXD/ADP4

RXD

J1-7

BDM COM

●

Select virtual COM port through USB-BDM

●

COM_SEL

COM BDM

●

Select RS-232 PHY

COM_SEL

U S E R G U I D E

of the RS-232 transceiver and are routed to test point vias located near the transceiver. RTS

has been biased properly to provide handshaking if required.

RS-232 signals TXD and RXD are connected to the MCU through the COM_SEL option

header. Table 1 below shows the RS-232 signal connections.

Table 1: COM Connections

Virtual COM Port

The UART output from the target MCU is connected to the BDM through the COM_SEL

header. Future enhancements to the BDM firmware will support a Virtual COM Port through

the USB-BDM. This functionality is not currently supported.

NOTE: Virtual serial port services are not functional as of the date of this document

COM_SEL

The COM_SEL option header selects between the virtual serial port implemented through the

USB-BDM or the RS-232 PHY. Figure 5 below shows the shunt positions to select between

the two options.

Figure 5: COM_EN Option Header

NOTE: Virtual serial port services are not functional as of the date of this document

11

Page 12

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

4, 6

1

Female DB9 connector that interfaces to the HC(S)08 internal SCI1 serial

port via the U2 RS232 transceiver. It provides simple 2-wire

asynchronous serial communications without flow control. Flow control is

provided at test points on the board.

Pins 1, 4, and 6 are connected together.

6

1, 4

TXD

2

7

RTS

RXD

3

8

CTS

1, 6

4

9

NC

GND

5

U S E R G U I D E

COM Connector

A standard 9-pin Dsub connector provides external connections for the SCI port. The Dsub

shell is connected to board ground through a ferrite bead. The ferrite bead provides noise

isolation on the RS-232 connection. Figure 6 below, shows the pin-out of the DB9 connector.

Figure 6: COM Connector

USER OPTIONS

The DEMO9S08SV16/FL16 includes various input and output devices to aid application

development and debug. User I/O includes 2 momentary pushbutton switches, 2 green LEDs,

1 potentiometer, 1 temperature sensor, and 1 piezo buzzer. Each device may be enabled or

disabled individually with the USER_EN option header. Each user enable is clearly marked as

to functionality.

Pushbutton Switches

Two push button switches provide momentary, active-low input, for user applications. Pull-ups

internal to the MCU must be enabled to provide error free switch operation. Pushbutton

switches SW1 and SW2 are enabled to the MCU I/O ports by the USER option bank. Table 2

below shows the user jumper settings and MCU connections.

LED Indicators

Two LEDs provide visual output for user applications. Both LEDs are configured for activehigh operation. Table 2 below shows the user jumper settings and MCU connections.

Potentiometer

A 5k ohm, thumb-wheel type, potentiometer at RV1 provides variable resistance input for user

applications. The output is the result of a voltage divider that changes as the thumb-wheel is

turned. The potentiometer is connected between VDD and GND with the center tap providing

the divider output. Table 2 below shows the user jumper settings and MCU connection.

12

Page 13

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

Jumper

On

Off

MCU PORT

BUZZ

Enable BUZZ

Disable BUZZ

PTB4/TMP1CH0

TEMP

Enable TEMP

Disable TEMP

PTA0/KBIP0/ADP0

POT

Enable POT

Disable POT

PTA1/KBIP1/ADP1

LED1

Enable LED1

Disable LED1

PTB2/KBIP6/ADP6

LED2

Enable LED2

Disable LED2

PTB3/KBIP7/ADP7

SW1

Enable SW1

Disable SW1

PTA2/KBIP2/ADP2

SW2

Enable SW2

Disable SW2

PTA3/KBIP3/ADP3

U S E R G U I D E

Temperature Sensor

A surface-mount, NTC Thermistor (B = 3900) is installed at location RZ1. This component

provides a voltage input to the MCU inversely proportional to temperature. Table 2 below

shows the user jumper settings and MCU connections.

Buzzer

An externally modulated piezo-buzzer, with a center frequency of 2300 Hz for audible

applications is applied. A push-pull drive circuit allows the target MCU to easily drive the

buzzer. Table 2 below shows the user jumper settings and MCU connections.

Table 2: User Option Jumper Settings

NOTE: Signal names in BOLD are not available on the 9S08FL16 derivative

13

Page 14

D E M O 9 S 0 8 S V 1 6 / F L 1 6 J U N E 5 , 2 0 0 9

SV16

FL16

FL16

SV16

VDD

VDD

1 2 PTA5/IRQ*/TCLK/RESET*

PTA5/IRQ*/TCLK/RESET*

VSS

VSS

3 4 PTA5/IRQ*/TCLK/RESET*

PTA5/IRQ*/TCLK/RESET*

PTB1/KBIP5/TxD/ADP5

PTB1/TXD/ADP5

5 6 PTA4/BKGD/MS

PTA4/ACMPO/BKGD/MS

PTB0/KBP4/RxD/ADP4

PTB0/RXD/ADP4

7 8 NC

NC

PTA2/KBIP2/ADP2

PTA2/ADP2

9

10

NC

NC

PTA3/KBIP3/ADP3

PTA3/ADP3

11

12

NC

NC

PTC0/ADP8

PTC0/ADP8

13

14

PTA0/ADP0

PTA0/KBIP0/ADP0

PTC1/ADP9

PTC1/ADP9

15

16

PTA1/ADP1

PTA1/KBIP1/ADP1

PTB3/KBIP7/ADP7

PTB3/ADP7

17

18

NC

NC

PTB4/TPM1CH0

PTB4/TPM1CH0

19

20

NC

NC

PTB2/KBIP6/ADP6

PTB2/ADP6

21

22

PTA6/TMP2CH0

PTA6/TPM2CH0

PTB5/TPM1CH1

PTB5/TPM1CH1

23

24

PTA7/TPM2CH1

PTA7/TPM2CH1

PTD1/SDA

PTD1

25

26

PTB7/EXTAL

PTB7/EXTAL

PTD2/TPM1CH2

PTD2/TPM1CH2

27

28

PTB6/XTAL

PTB6/XTAL

PTD0/SCL

PTD0

29

30

PTD4

PTD4/TPM1CH4

PTD3/TPM1CH3

PTD3/TPM1CH3

31

32

PTD5

PTD5/TPM1CH5

PTC2/ADP10/ACMP+

PTC2/ADP10

33

34

NC

NC

PTC3/ADP11/ACMP

PTC3/ADP11

35

36

NC

NC

PTC4/SS

PTC4

37

38

PTC7

PTC7/MISO

PTC5/SPSCK

PTC5

39

40

PTC6

PTC6/MOSI

U S E R G U I D E

MCU I/O PORT

The MCU I/O PORT connector provides access to the MC9S08SV16 or MC9S08FL16 I/O

signals. Figure 7 below show the pin-out for the MCU I/O connector.

Figure 7: MCU I/O PORT – J1

14

Loading...

Loading...