Page 1

Coating Thickness Gauge

Model: AX-CTG10

User’s Manual

Page 2

Coating Thickness Gauge

Model:AX-CTG10

Introduction

AX-CTG10 coating thickness gauge adapts principles of electromagnetic induction and

magnetic induced edd current. It can measure the thickness of non-metal coatings on metal

surface. Press the button to select magnetic metal or non-magnetic metal. It is a ideal instrument in

manufacture, metal machining industry, chemical industry and commodity inspection, especially

in automobile trading.

AX-CTG10 has been designed as a user friendly and economical way, with the function of

LCD displaying and measurement data hold automatically. It has the advantages of easy operation,

rapid measurement, safe usage and portability.

Battery Safety Instructions

● Please remove the batteries when clean the product.

● Remove the batteries before long term storage

● Please install the batteries properly as the instructions of the positive and negative charges

● Please dispose the batteries properly. High temperature will cause explosions and do not burn

the batteries. Strap insulated tape around the battery charges to avoid unsafe contacts wit

other objects. Many countries have regulations about the batteries disposing. Please follow the

local regulations of battery disposing.

Page 3

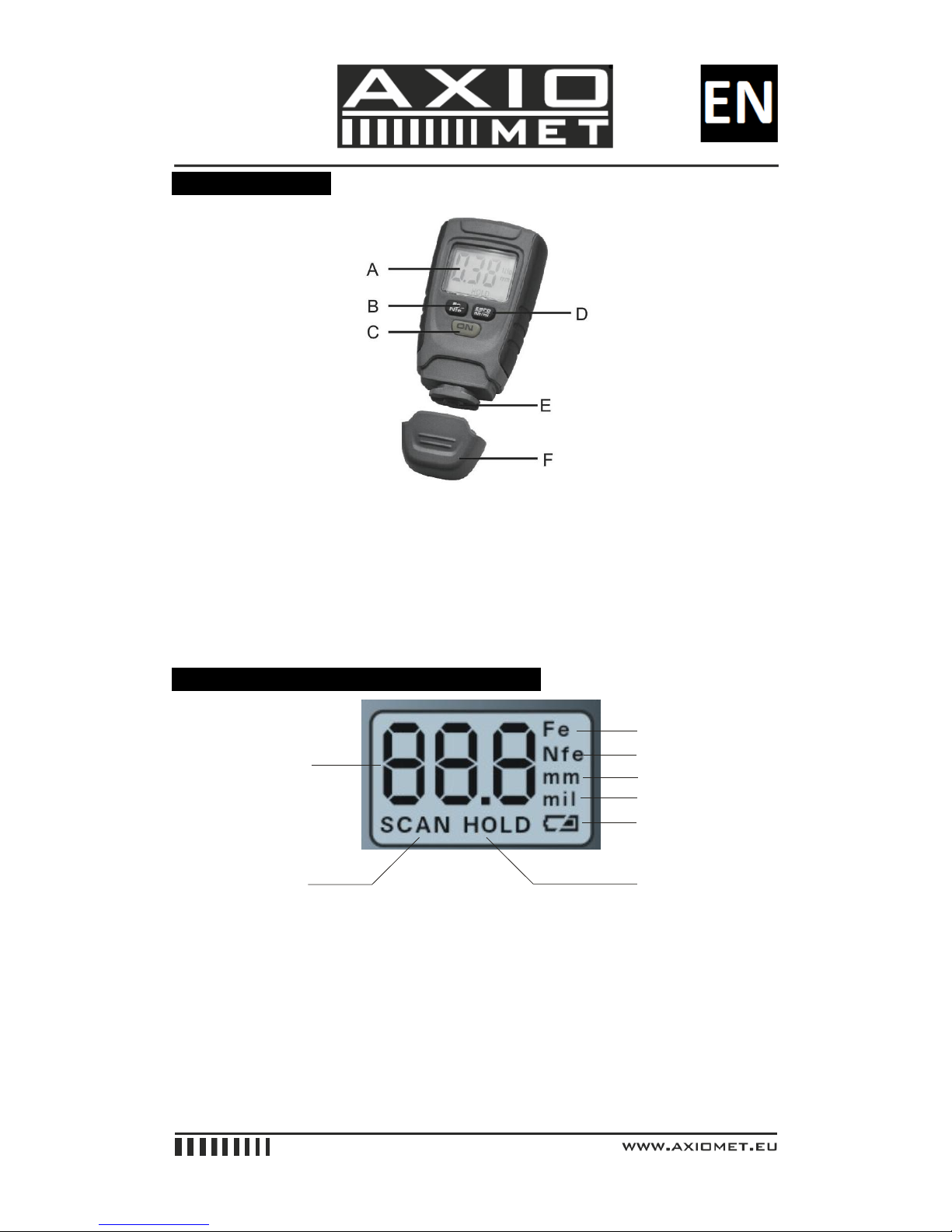

Product Overview

A. Display

B. Metal type selection button

C. Power on/ measurment button

D. Measurement units selection / zero calibration button

E. Detection sensor

F. Detector protection cap

ILLUSTRATION OF DISPLAY SCREEN

A

B

C

D

E

F

G

H

A:Measurment readings display

B:Measurement working indicator

C:Lock measurement result indicator

D: Magnetic metal indicator

E: Non-magnetic metal indicator

F: Metric unit indicator

G:British unit indicator

H:Low battery display indicator

Page 4

Operation Instructions

● Battery Install and Remove

The unit uses a CR2032 battery. When the screen displays low battery indicator “ ”,

press the salient point on the battery cover on the back of the unit. Clockwisely rotate at 5

mins angle to screw the battery cover. Put the battery in the battery compartment with the

negative end downward. Then cover up the battery cover and rotate in place

counterclockwisely.

● Coating Thickness Measurement

1. Press the measuremnt button “C” to power on the unit and press the button “B” to

choose metal type, then press button “D” to choose measurement units;

2. Remove the protection cap ahead of the unit;

3. Press the detector head on the measured surface, don’t leave the target surface until the

screen “SCAN” change to “HOLD”,the thickness of coatings on metal surface will

display on the LCD screen.

4. If you want to repeat measuring, be sure to start after at least 1s.

5. Removing from the measured surface, the unit will power off automatically if no

operation in 1 minute.

● Operation Notes

1. When the battery voltage is low, low battery indicator will display on LCD after turn on the

unit or during the usage. Please replace the battery. Rotate the battery cover through a angle to

remove the battery cover when replace the battery.

2. After every battery replacement, wait for about 15s to stabilize the power source, then

power on the unit.

3 . The measurement way of the unit is easy, free, rapid and direct. The measurement data will

lose permanently after the unit power off.

4. Please put back the protection cap after use.

5.To ensure the measurement prescision, zero calibrate before measurement. Choose iron

base or non-iron base and keep measuring 5 times, then holding the button “D”, release the button

when “CAL” shows on the screen. Leave the base plate until the screen displays 0.00. Then make

measurement.

Notes: Calibration is not requested for each measuring. It is only needed when out of accuracy.

Page 5

Factors Affecting the Measuring Precision

1. The magneic nature of metal base

Measuring the thickness with magnetic method can be affected by the change of base

metal’s magnetic field (in pratical application, the magnetic change of mild steel can

be considered as slight). To avoid the effect of heat treatment and cold processing, we

should calibrate the unit with the standard tablet which has the same magnetic nature

with base metal specimen.

2. The electric nature of metal base

The conductivity of base metal has the effect on measurement. And the conductivity

of base metal has connection with its composition and heat treatment method.

Calibrate the unit with the standard tablet which has the same electric nature with base

metal specimen.

3. The thickness of metal base

Every unit has a critical base metal thickness. If above this thickness, the

measurement will not be affected by the thickness of base metal.

4. Edge effect

The unit is sensitive to the specimen’s surface shape. Therefore, the result is

unreliable if approaching the specimen’s edge or inner corner.

5. Curvature

The curvature of the specimen has an effect on the measurement. And the effect is

always increasing obviously with the derease of curvature radius, Therefore, the measuremment is

not reliable for the flexible specimen.

6. Deformation of specimen

The detector can distort the specimen with soft coating. Therefore, the datum are unreliable that

measured from these specimens。

7. Surface roughness

The base metal and the surface roughness degree has effects on the measurement. The effect

increases as the roughness degree increases. The rough surface can cause the system error and

accidental error. When make every measurement, add the measuring times on different positions

to avoid the accidental error. If the base metal is rough, select several positions to calibrate the

unit’s zero point from the base metal which is uncoated and has the similar roughness, or calibrate

the unit’s zero point after using the liquor which has no corrosion to the base metal to dissolve the

coating

Page 6

8. Magnetic field

The strong magetic field produced by the all kinds of surrounding electrical

equipments can severly disturb the thickness measurement with magnetic method.

9. Attached materials

The unit is sensitive to the attached materials which obstruct the detector to touch with the coating

surface closely. So, the attached materials must be removed to make sure the detector touches with

the measured specimen directly.

10.The detector’s pressure

How much pressure the detector takes on the specimen will also affect the readings. So, keeping

the pressure constant is necessary.

11.The detector’s orientation

The detector’s placing method has influences on the measurement. During the measurement, make

the detector vertical to the specimen’s surface.

Rules that must be followed when use the instrument

1. The feature of base metal

For the magnetic method, the magnetism and surface roughness of standard tablet’s

base metal shoud be similar to the specimen’s base metal.

For the eddy method, the electric nature of the standard tablet’s base metal should be

similar to the specimen’s base metal.

2. The thickness of base metal

Check if the base metal’s thickness exceeds the critical thickness. If not, we can

calibrate as the ways in “CAUTIONS”

3. Edge effect

Don’t measure the specimen’s mutation position, for example, edge, hole and inner

corner.

4. Curvature

Don’t make measurement on the curved surface of specimen.

5. Reading times

Pick up some readings in every measurement area as every reading is different and the

coating thickness exists local differences. It’s also the same when the surface is rough.

6. Surface clearness

Before measurement, clear away any materials on the material, for instance, dust, grease

and corrosive. But, any coating materials can’t be removed.

Page 7

Maintenance

1. Tool service must be performed only by qualified repair personnel. Performed by

untrained repair personnel could result in injury.

2. To avoid damages to the instrument, do not use it near following places:

a. Environment has vapor and dust;

b. EMF places(Electro-magnetic fields: such as arc welders, induction heaters);

c. Static environment;

d. Heat shock (by abrupt temperature changes, allow 30 minutes for unit to stabilize

before use.);

e. Keep the unit away from high temperature objects. Keep clean and avoid shock and

wet. Using the wet sponge or soft cloth touching soapy water or clear water to

clean the unit.

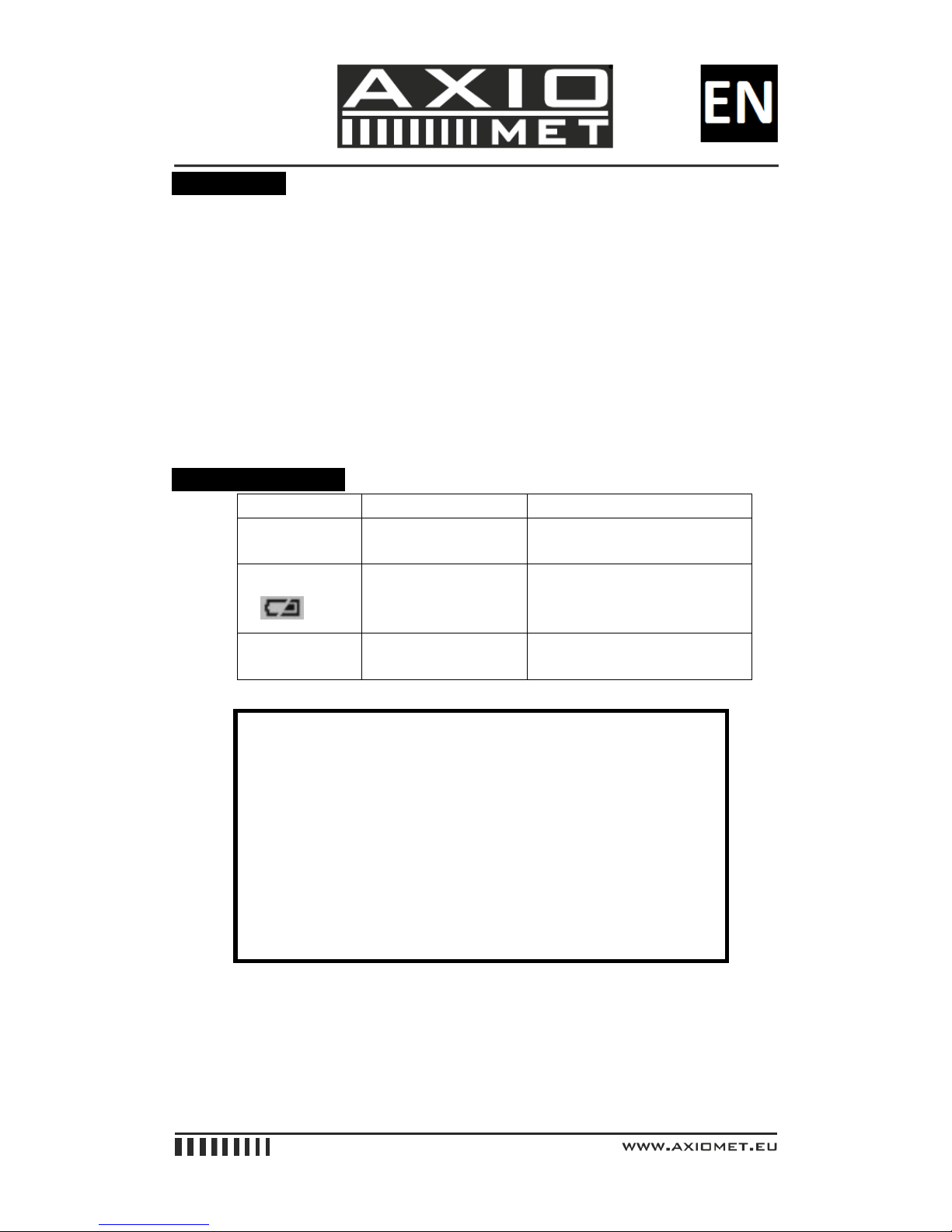

● Trouble shootings

Problems

Causes

Solutions

No display on the

screen

Battery runs down

Check and replace the battery

Show

“ ”

Low battery

Replace the battery

Show “---”

The thickness is beyond

the range

Choose the target which is within

the range

CAUTIONS

● Handle with care and do not let the unit drop down.

● Do not disassemble the unit to avoid failure.

● Please put back the protection cap when not in use.

● Do not place the unit together with corrosive gases or objects.

● Please keep clean and keep away from water.

● Avoid dust and water, which may stain the unit.

● Don’t immerse the product into water, which will result in damage to

product.

● Please remove the battery, if it is not for use for a long time.

Page 8

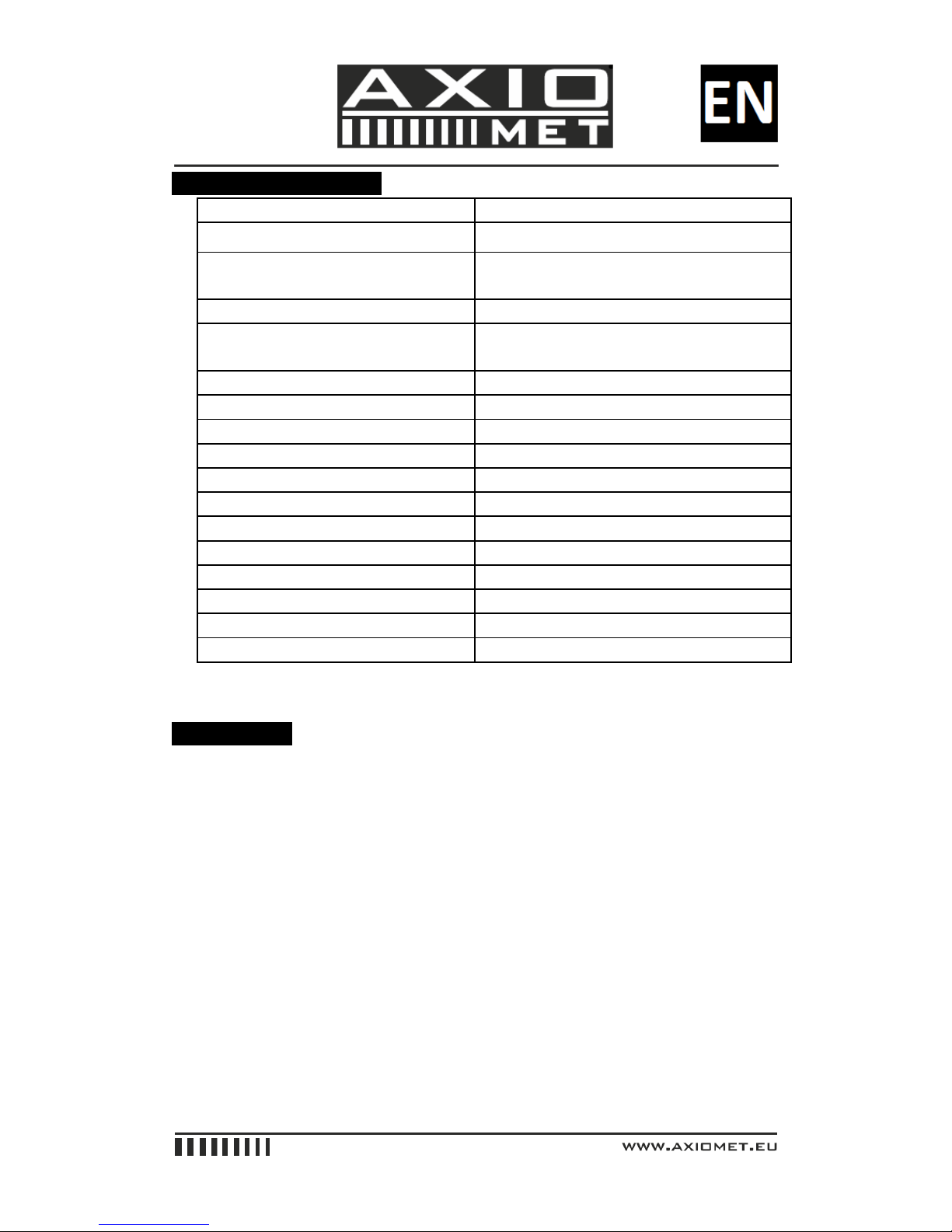

Technical Specifications

Product name

Coating thickness gauge

Model

AX-CTG10

Measure target

Non-metal coating thickness on the metal

surface

Measuring ability

0~1.25mm nonmetal coating on metal surface

Measuring precision

2%RDG±0.02mm(2%RDG±1mil) (steel and

aluminum only)

Power supply

one 3V CR2032 button battery

Working current

<10mA

Auto power off time

No actions in 1 min if leave the measured object

Minimum diameter of base

Ф10mm

Critical thickness of base

0.5mm

Display resolution

0.02mm/1mil

Operation temperature

-5℃~+40℃

Working humidity

5%~95%RH non-condensing

Storage environment

-20~60°C,<85% RH(w/o battery)

Dimensions

80mm×42mm×24mm

Weight

About 36 g (w/o battery)

Attachment

1pcs of Iron base and 1pcs of aluminum base

WARRANTY

The product is warranted to be free from defects in materials and workmanship

for a period of one year from the date of purchase on the basis of providing relevant card.

The warranty does not apply to the following conditions:

● Unauthorized disassembling the device will void the warranty.

● We are not responsible for any damage resulting from abrasion, water, dropping or

disassembling.

Tips:Most parts of the product could be recycled, please refer to your local regulations for

disposing of them instead of throwing into the dustbin.

Loading...

Loading...