AXICON

LINEAR BARCODE VERIFIERS

Models: 6015, 6515, 7015

DOCUMENTATION BOOKLET

www.axicon.com

CONTENTS

AXICON VERIFIER CERTIFICATION

START UP GUIDE

Introduction

Important Information

What’s in the transit case

Software Installation for Windows (all versions)

Hardware installation for Windows

Software and Hardware Installation for Apple Macintosh

User Calibration

Page

3

5

5

7

8

9

13

14

Getting started with the Axicon verifier

Configuring the Axicon Verifier

AXICON SOFTWARE LICENCE AGREEMENT

Axicon Software Licence Terms – Licence Grant

Ownership of Software

Copies of Software

No Disassembly or Decryption of Software

Transfer of Software Licence

Termination of Software Licence

Export Requirements

Disclaimer

16

19

24

24

24

24

24

25

25

26

AXICON WARRANTY AND SERVICE CONTRACT

Warranty on all Products

Service Contract

- 1 -

27

28

VERIFIER SERVICING & FACTORY RECALIBRATION (VCAS)

Why CCD based verifiers require factory recalibration

Axicon Factory Recalibration Service (VCAS)

Other faults or damage

Equipment Rental Scheme

VCAS RECORD

CONTACT US

29

31

31

32

33

34

- 2 -

Church Road, Weston on the Green, Oxfordshire, OX25 3QP, UK

Tel: +44 (0) 1869 351155 / Fax: +44 (0) 1869 351205 /

Conformance Certification

We Axicon Auto ID Ltd

of Church Road, Weston on the Green, Oxfordshire, OX25 3QP, UK

Declare under our sole responsibility that the product has been designed and

manufactured at our address in the year 2014 to perform verification of barcode

quality in accordance with the following standards:

ANSI X3. 182 ISO/IEC 15416 ISO/IEC 15420 ISO/IEC 16388

ISO/IEC 16390 ISO/IEC 15417 ISO/IEC 24724

We further declare that the verifier has been designed and manufactured to ensure

conformance to Primary Reference Test Symbols available from N.I.S.T. and

Traceable Reflectance Standards available from N.P.L. in accordance with ISO/IEC

15426-1.

Tolerances: Decodability: ±8%

Rmin: ±3%

Rmax: ±5%

Defect: ±8%

Modulation: ±12%

We also certify that this equipment conforms to the following standards:Barcoding: ISO/IEC 15426-1 VERIFIER CONFORMANCE STANDARD

European Safety EN 60950

Electromagnetic Compatibility EN 55022 &

We also certify that the standards EN 60825 is not applicable to the product.

This equipment meets the requirements of the directives 89/336/EEC (Electromagnetic

Compatibility), 73/23/EEC (Low Voltage), based on our own relevant test reports.

Axicon Auto ID Ltd also certifies that this equipment, when used in conjunction with the

latest verifier software has all of the features required to meet the 21CFR Part 11 standard.

EN 55024

- 3 -

INTRODUCTION

Thank you for purchasing an Axicon Verifier. This short guide will enable

you to get started with your Axicon Verifier quickly and easily. A full

manual is available in electronic form on the software CD

The Axicon Verifier is designed to work with any PC running a version of

Microsoft Windows currently supported by Microsoft (some earlier

versions may also be supported – see notes) and with any Apple Macintosh

computer running Mac OS X version 10.4 or higher (up to but not including

Lion and Mountain Lion).

IMPORTANT INFORMATION

1. Your Axicon verifier is a piece of high precision quality control

equipment and should be handled with due care.

2. Please retain the plastic transit case. It will protect the equipment in

transit.

3. Only use power and data cables supplied by Axicon. Use of nonapproved accessories will invalidate the warranty.

4. If the verifier is dropped (or subjected to similar misuse) the accuracy

of the results may be affected. The unit should be returned to Axicon

immediately for servicing.

5. Axicon recommends that the verifier is factory recalibrated annually.

The unit should be returned to Axicon or to your approved Axicon

reseller for this check to be performed.

6. As the owner of an Axicon Verifier you are entitled to free software

updates for life. The latest copy of the software is always posted on

our website (www.axicon.com).

7. Subject to the terms of the license you are permitted to make

additional copies of the Axicon Verifier software.

- 5 -

8. For further, detailed information, including a trouble-shooting guide,

please read the manual which is available on the software CD.

- 6 -

WHAT’S IN THE TRANSIT CASE?

Please ensure that the following items are present upon receipt.

One of the following verifiers and the relevant cables:

• Axicon 6000 Series – CCD verifier with USB cable attached.

• Axicon 6500 Series – CCD verifier with USB cable attached.

• Axicon 7000 Series – CCD verifier with USB cable attached.

• Software CD.

• Wallet containing Documentation Booklet (includes Start Up Guide)

and Calibration Sheet

- 7 -

SOFTWARE INSTALLATION

WINDOWS (ALL CURRENT VERSIONS)

1. Insert the CD into the CD drive

2. The Install Program should now start automatically. (If not, open the

CD using Windows Explorer and double-click the Autorun Program.)

3. Click “Install Axicon Verifier”

4. Follow the on-screen installation instructions for the next four

windows (Select a language, Welcome, Software License Agreement

and choose destination location) until you get to the “Select

Components to install” window.

5. At the “Select Components to Install” screen ensure that the boxes

relating to “Drivers” and “Main Program” are both ticked.

6. (If you have purchased certain additional optional features which are

password-protected you may be asked to enter the password(s) at

this stage through a separate dialogue box).

7. Click “Next” again to pass the “Select folder in start menu” window

8. If you have selected any password-protected features you will be

prompted to enter your serial number and passwords now. The

description appears in bold for the features you have chosen to

install and the passwords are at the front of this booklet.

If you have more than one verifier with password protected features

(see point 6 above) you should enter the serial number and

passwords for the first unit, then click “Enter Another” to enter the

serial number and passwords for the additional verifiers.

Click on “Next”

9. The software will now be installed.

10. Leave the software CD in the PC in order to install the USB drivers.

- 8 -

HARDWARE INSTALLATION FOR WINDOWS

LOADING USB DRIVERS

1. Plug the verifier into any available USB port directly on the

computer.

2. When prompted to install the drivers, make sure the CD is inserted

into the CD driver and follow the instructions.

After installation is completed you will find the “Axicon Verifier”

directory in “Start Menu/Programs” and a shortcut to the program on

your desktop.

• Double clicking the Axicon Verifier shortcut icon will now start the

software.

• Two windows will open: the Command window and the Summary

window.

• The LED array of your CCD should now be lit and the text in the

bottom right hand corner of the Command window should read “Ready

to scan”. If not, refer to the troubleshooting section of the manual on

the CD.

- 9 -

INSTALLATION FOR EARLIER VERSIONS OF WINDOWS AND

WHEN MANUAL INSTALLATION OF DRIVERS IS REQUIRED.

LOADING USB DRIVERS.

Note: When using much older (and Microsoft-Unsupported) versions of

Windows you may need to install the older version of the USB drivers.

These are available from Axicon on request.

Manual installation/Updating of the USB drivers (if required)

This section provides some guidance to users of the Axicon Verifiers who

need to update the USB drivers.

Firstly install the Axicon Verifier software (version 2.0.25.1 or later – note

that it is always possible to download the latest software from our

website).

As part of the software installation, the USB driver files will have been

copied to the folder that was chosen for the installation.

Connect the verifier and wait for the Hardware Wizard to start, or

initiate the Hardware Wizard from the Device Manager.

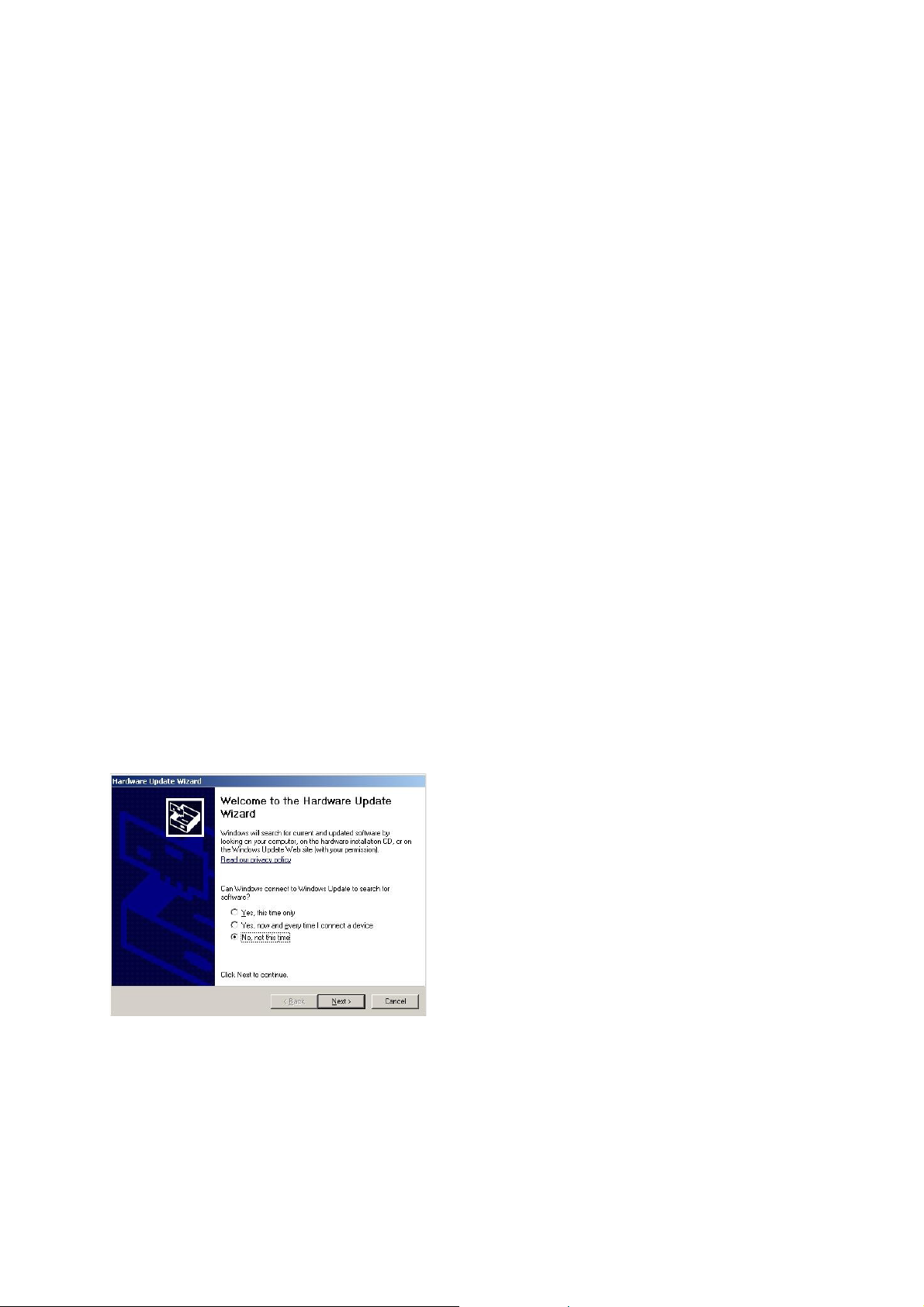

The following screen will appear for computers running Windows XP.

Select the option 'No' on this screen and then click the Next button.

- 10 -

Now choose the “Advanced” option to install from a list or specific

location and then click the “Next” button.

On this screen choose the 'Don't Search' option and again click on Next.

If any previous versions of the drivers have been installed, then you may

see them listed as shown above, however, at this point click on the Have

Disk button which will open the following dialogue.

If the default installation location was chosen when the Axicon Verifier

software was installed, then the appropriate driver files will have been

copied to the location shown in the dialogue above.

Browse to this location, or to the equivalent location if the default was

not chosen and then OK this dialogue.

- 11 -

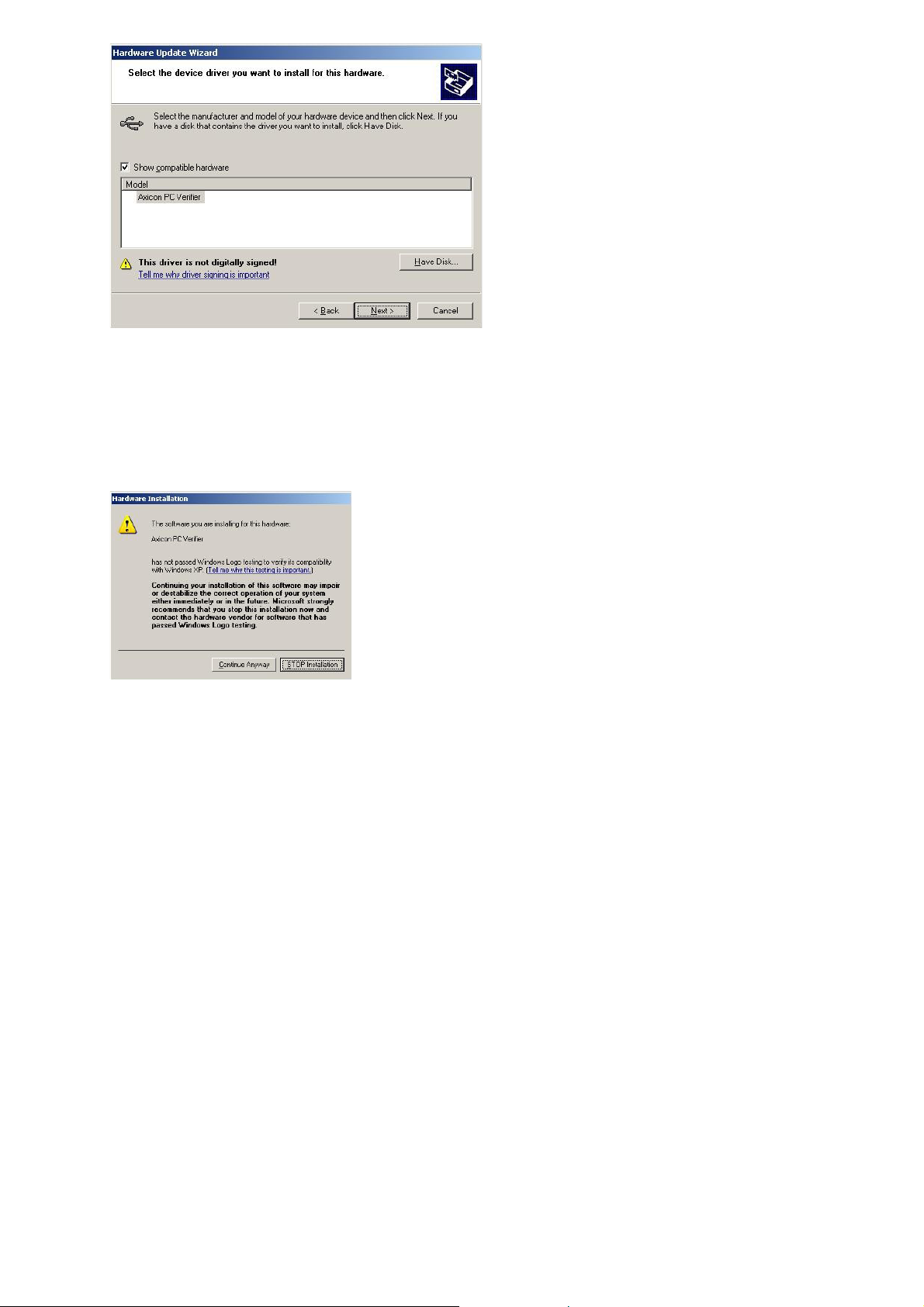

The Hardware Wizard screen should now look like the one above and the

next step is to click the “Next” button to begin the driver installation.

A dialogue will pop up asking the user to confirm whether to continue the

installation or not.

Click on the 'Continue Anyway' button.

At this point, the driver files will be copied to the appropriate locations

and as soon as the installation finishes the verifier hardware will be heard

to beep as it powers up and becomes ready to use.

The Axicon Verifier software can now be launched and the software will

find and connect to the verifier hardware.

- 12 -

INSTALLATION FOR APPLE MACINTOSH

SOFTWARE

1. Insert the CD and double click on CD icon

2. Install USB Driver by double-clicking the USB Driver* icon. You will

need an administrator password. Installer will need to restart your

Mac after it has installed the driver.

3. To install the Verifier application, drag the icon to wherever you want

it.

4. To run the application double-click the Verifier icon.

* If you are using OS X 10.4 the text “You cannot install this software on

this disk (null)” may appear. If it does, click the “Go Back” button and

then the “Continue” button again and the driver should install.

HARDWARE

Plug the verifier into any available USB port.

- 13 -

USER CALIBRATION

Calibration with known reflectance values is essential to ensure the

accuracy of this equipment. It should be carried out after installation and

at regular intervals. (see below)

When the software detects an uncalibrated reader the following dialogue

box will appear “Reader XXX has not been calibrated”. You must click OK

to continue.

Please switch on your verifier at least five minutes before you start

to calibrate.

To calibrate you will need your calibration sheet, which you will find

in the wallet.

Take the calibration sheet out of the wallet and place it on a flat

surface.

For the Axicon 6000 Series use the EAN13 calibration code at the top

left of the sheet.

For the Axicon 6500 and 7000 Series use the large calibration code at

the bottom of the sheet.

Select the calibrate option.

For Windows versions: This is located in the “Options” menu

(or you can use the icon)

For Mac versions: This is located in the “Reader” menu

- 14 -

You will see a window with two edit boxes for minimum and

maximum reflectance values.

Ensure that the values shown in the window match the values printed

at the bottom of the calibration sheet.

(Modify the figures on the screen if necessary to ensure that they are

the same as the card

With the Calibration window open scan the calibration barcode 10

times. Then click the OK button.

The verifier is now calibrated and ready to use.

After calibration is completed, store the calibration sheet in its wallet,

away from light and physical damage. If your calibration sheet should

ever become damaged or discoloured in any way, please contact Axicon

or your supplier for a replacement.

NB: During the calibration process the software displays the

uncalibrated data and therefore reflectance values and grades

displayed behind the calibration window can be ignored.

Under normal operating conditions Axicon recommends calibrating the

verifier monthly (the verifier software is set up to remind you when it is

time to calibrate). In variable light and temperature conditions we

recommend more frequent calibration. The frequency can be changed if

required by using the “Options / Set-up /Calibration” path.

- 15 -

GETTING STARTED WITH YOUR AXICON VERIFIER

In countries where Axicon offer training courses we would strongly

recommend the use of these as the best way to get the most out of your

verifier and to understand all of it’s features.

For others, the following provides a general overview and start-point in

the verification process:- (This is not intended to be a comprehensive

instruction but will guide the user in the most frequently used features.)

When you first start the software you will see…

The “Command” Window :

This gives access to all of the main features of the verifier:Access can be by using pull down menus or by using icons

Icons are grouped according to function.

As you start using the verifier the main ones that you will use are the

display screens grouped at the centre of the top line of the command

window – From here to here:-

These cover the Command Screen (that we have seen already )…

A ”Summary Screen” that gives

the general quality of the

barcode

- 16 -

This Summary Screen shows the overall print quality of the barcode as

measured by the ISO/ANSI standards (the overall grade can be expressed

either as a number (ISO) – or as a letter (ANSI) – this can be altered as

required through the “Set-Up” icon (see below)

Information is also given on the bar-gain (ink spread), the overall

magnification of the barcode, validation of the check digit, structure,

and light margins (Quiet zones).

Ideally these will all show in green (pass) – any that have an amber or red

warning light beside them should be investigated.

NOTE: Be aware that just because a barcode receives a “pass” grade for

print quality does not necessarily mean that it is “fit for purpose” – after

all the wrong barcode number on a product may be printed perfectly but

that would not make it acceptable – Things like the size of the barcode

(magnification) and the location of the barcode are important if the

barcode is going to be “fit for purpose”.

The Details Screen…. Press

to get:-

This screen shows each of

the ISO/ANSI parameters

that are measured and

individually graded (as

both grades and

percentages).

Seven parameters are

graded and the lowest single grade becomes the overall grade for that

scan. (Ideally you should take a number of scans at different points in

the height of the same barcode – the verifier will automatically average

these for you to produce an overall print quality grade)

- 17 -

If the “Summary” Screen has shown poor print quality then the “Details”

screen is the ideal point to initially see what went wrong with the

barcode and hence focus the user on appropriate corrective action.

The Scan Profile Screen…. Press

The Scan profile screen shows the user exactly what the barcode will look

like to a scanner.

At the top of the graph are the higher levels of reflectance from the

background and at the bottom of the graph are the lower levels of

to get:-

reflectance from the darker bars.

Ideally the “sweep” (contrast) from top to bottom should be as great as

possible with smooth curves between the two, the “peaks” should ideally

be all around the same level and the “troughs” also at the same level.

If the cause of barcode problems is poor “modulation” or a high level of

defects then these can be shown overlaid on the graph by clicking the

appropriate box at the top of the Scan Profile Screen.

The Dimensional Measurements Screen…. Press

to get:-

If your “Details” screen has

- 18 -

shown a poor “Decodability”

grade then this is normally

because of bad dimensional

accuracy – this screen will show the accuracy of the bar/space dimensions

and highlight any problem areas.

The Pass/Fail Screen…. Press

FIXING THE SCREENS:- Most of the screens described above can be moved,

expanded or shrunk as required. When you have decided which screens

to get:This screen is ideal for users

who need a quick visual

indication of whether the

barcode meets the right print

quality standards.

you want displayed on your PC just use the “View” pull-down menu and

click on “Save positions”. Then whenever the software is started it will

always have those screens in those positions.

CONFIGURING THE VERIFIER

All of the primary configuration of the verifier is done through the “Setup” icon

Press this to enter the “Set-Up” dialogue.

There are a range of tabs to cover the different groups of parameters.

Here is shown the “General”

Standards: Click on “ISO” if you want

only the numeric ISO result to be shown –

- 19 -

group

or click on “ANSI” if you would prefer to be shown both results.

Units:- The “default” is to track the Windows settings for metric or

imperial measurements – alternatively you can set this as required.

Pass Grade:- If you are working on barcodes within the retail supply chain

then the “Apply GS1 General Specifications” should always remain ticked

on. The user can select the pass/fail grade for other barcode types as

specified either by an Industry Application Specification or by their

customer.

Magnification factor:- This remains for past support for Axicon customers

who have model 5000 verifiers. For all others the settings in this field

have no effect.

The next tab is “Check Characters”

This screen is to allow the user to select specifically for the barcode

types that have optional check digits. If these are being used then the

verifier can be set to validate them, if not then to ignore any checks.

The next tab is “Appearance” –

Most barcode symbologies (types) have

mandatory check digits and these will be

automatically validated as to their

correctness. A few barcode types have no

check digits at all.

This can be used to adjust any display

colours/shades for the pass, warning

and fail messages – and can also be

used to add Windows wave sounds to

give an audible indication of quality if

required.

- 20 -

The next tab is “Printing”

The user can pre-select any

particular reports that are required –

some users take the view that if the

barcode passes they will just save

the electronic report but that if the

barcode fails they want all of the

information possible – the required prints can be pre-selected.

This includes the option to have a personalised report generated through

the built-in Report Generator, although we do recommend that if you

have any particular non-standard requirements these should be discussed

with Axicon.

The verifier can also be set to “Auto-print” in order to avoid a user

forgetting to print a particular report.

“Print graph in Black and White” – essential to tick this is you are using a

monochrome (black and white) printer, otherwise a scan reflectance

profile will only show the outline and not the detail.

Also, the standard printed report can be personalised if required using

the “Report Header” feature.

The “Logging”

tab

The “logging” tab is used to

set the electronic saving of

records and to run preconfigured external programs

from the verifier.

We strongly advise all users to

click on “Enable” to the “Auto

Save Scan File” and to set a suitable location for the records to be

stored.

- 21 -

The files saved through this process can be regarded as “audit quality”

records of the verifications made and can also be used for remote

diagnostics purposes.

The files can be saved automatically with a filename comprising the

decoded number, date and time, sequentially numbered or by using a

dialogue box.

The centre part of this screen is used specifically to drive external

programs automatically from the verifier.

The bottom of this screen is saving data in a format suitable for legacy

purposes only.

The “Calibration

verifier has been calibrated on that PC.

Features are included to stop users inadvertently or incorrectly using a

wrong barcode for calibration purposes.

Axicon recommend that under normal circumstances user calibration is

” tab

The user can define the location

for the storage of the calibration

records – this should be in a

directory where the user has both

read/write access.

The verifier will store details of

each and every time that the

carried out on a monthly basis (more frequently where there are high

dust levels or significant changes in ambient temperature.

The “Plug-ins”

Plug-ins are an important

feature of the Axicon verifier

– allowing it to be tailored to

industry specific or user

- 22 -

Tab

specific features, such as running a Product lookup database, validation

of the structure of variable weight items, or identifying the formats of

European pharmaceutical codes – and a whole lot more.

The Plug-ins can be installed from the CD by using the “Install Optional

Plug-ins” – Please be careful to only install the plug-ins that you need

otherwise some confusing results may be displayed. . If you inadvertently

install Plug-ins you do not need, simply ensure the box alongside remains

unticked and it will be ignored.

Please contact Axicon or your local Axicon reseller for more information

about the range of available plug-ins and their applications.

The “E-Mail”

The “Advanced” Tab

For most users, the key part of this screen

is the ability to put password control on

all of the set-up parameters to eliminate

tab

To be used only if you want data to

be automatically e-mailed to a third

party.

the risk of unauthorised changes to the

saving or printing options.

Please do remember to keep a note of the password in a safe place.

Remember: There are many great features in the Axicon verifier – this

guide has been provided just to “Get you started”. We strongly advise all

users to take advantage of the Axicon Training Courses (where offered) so

that they can utilise all of the beneficial features of the verifier.

- 23 -

AXICON SOFTWARE LICENCE AGREEMENT

This software is Copyright © 1995-2014 Axicon Auto ID Limited

Use of the Software is subject to the Axicon Software Licence terms set

forth below. Using the Software indicates your acceptance of these

Licence terms. If you do not accept these Licence terms within 14 days,

you may return the entire unused product for a full refund.

AXICON SOFTWARE LICENCE TERMS -LICENCE GRANT

Axicon grants you a Licence to use any number of copies of the

Software, but only for Use in conjunction with the Axicon hardware

product that accompanied the Software.

"Use" means storing, loading, installing, executing or displaying the

Software.

You may not modify the Software or disable any licensing or control

features of the Software.

OWNERSHIP

The Software is owned and copyrighted by Axicon Auto ID Limited.

Your Licence confers no title or ownership in the Software and is not a

sale of rights in the Software.

COPIES

You may only make copies of the Software for archival purposes or

when copying is an essential step in the authorised use of the

Software.

You must reproduce all copyright notices in the original Software on

all copies.

You may not copy the Software onto a bulletin board or similar

publicly accessible system.

- 24 -

NO DISASSEMBLY OR DECRYPTION

You may not disassemble or decompile the software without prior

written consent from Axicon.

TRANSFER

Your Licence will automatically terminate upon any transfer of the

Software. Upon transfer, you must deliver the Software, including any

copies and related documentation, to the transferee.

The transferee must accept these Licence Terms as a condition of the

transfer.

TERMINATION

Axicon may terminate your Licence upon notice of failure to comply

with any of these Licence Terms.

Upon termination, you must immediately destroy the Software,

together with all copies, adaptations and merged portions in any

form.

EXPORT REQUIREMENTS

You may not export or re-export the Software in contravention of any

applicable laws or regulations.

This agreement should be construed in accordance with the laws of

England.

- 25 -

DISCLAIMER

In the following the expression "Verifier" means the verifier hardware and

the associated software.

We have taken care to ensure that this Verifier is free from defects.

However since we have no control over the circumstances in which you

might use the Verifier you must satisfy yourself that the performance of

the Verifier is suitable for your needs. Neither Axicon Auto ID Limited nor

the vendor of this Verifier can accept any liability for any loss or damage

(consequential or otherwise) which may be caused by use of this Verifier.

If the Verifier or any part of it is defective in any way, or in some other

way does not meet your expectations, the liability of Axicon Auto ID

Limited is limited to the cost of the product. You should bear this

limitation in mind if you use this Verifier in any situations where the

acceptance or rejection of shipments of goods or your reputation may

depend upon the quality of a bar code.

Under no circumstances is this Verifier licensed or authorised for use in

any situation whatsoever where the health or safety of humans or animals

might be put at risk

- 26 -

AXICON WARRANTY AND SERVICE CONTRACT

WARRANTY ON ALL PRODUCTS

All Axicon products covered by this documentation (Axicon 6015, 6515

and 7015 series verifiers) are sold with a two year parts and labour

warranty against manufacturing defects.

This is a Return to Bench warranty with shipping costs in one direction

being borne by the customer/distributor.

Should you need to return the unit to Axicon the original transit case

(plus appropriate packaging) must be used. If the equipment is

returned without the original transit case, Axicon will automatically

charge an additional sum for the replacement of this case.

Axicon’s standard repair turn-around is 7-10 working days from receipt

of the defective unit.

Our standard warranty does not include the provision of a loan unit.

Loan units can only be supplied if you have a Service Contract.

Axicon reserves the right to charge an inspection fee for any

equipment returned under warranty for which no fault is found.

Please contact Axicon to obtain an RMA number before returning any

equipment. This number must be quoted on all documentation. Axicon

cannot accept responsibility for equipment returned without a RMA

number.

- 27 -

SERVICE CONTRACT

A Service Contract may be purchased within 30 days from the date of

dispatch.

The service contract period will start from the date of dispatch of the

unit. You may select the number of years for which you want the Service

Contract to run (up to a maximum of 10 years). The appropriate payment

must be made in full prior to the unit(s) being accepted as being covered

by the Service Contract.

The Service Contract covers the following:

All parts and labour to repair the unit except where damage has been

caused by misuse of the equipment, in which case labour will be

included but not parts.

The availability of a swap-out unit to be used while the customer’s

unit is being repaired.

NOTE: Please see your Service Contract for full details including hire

charges.

For current cost of a Service Contract or equipment hire please contact

either Axicon or your approved Axicon reseller.

- 28 -

RECALIBRATION REQUIREMENT

WHY DO CCD BASED VERIFIERS REQUIRE A FACTORY RECALIBRATION?

Axicon 6000, 6500 and 7000 verifiers all use linear CCD sensors to capture

scan reflectance profiles of barcodes. These CCD sensors work very much

like digital cameras in the manner in which they capture an image, but

they only image a single line scan across a barcode, similar to the scan

line that you see with a hand held laser scanner.

The accurate measurement of reflectance across the full width of the

scan relies on the barcode symbol being imaged as if the illumination

were perfectly uniform and the sensor element equally sensitive at all

points along the scan line. In practice this is not necessarily the case,

however, the electronics within the head of these units applies a function

that enables the units to perform as if this were the case, so that when

the scan reflectance profile reaches the PC or Macintosh computer the

application can make this assumption and proceed with analysis. To

achieve this, the heads need to undergo a factory calibration process.

This calibration is not the same as the calibration that is performed by

the software application on the computer. The calibration that occurs

within the application assumes that a uniform profile is already achieved

by the scanning head and simply shifts the overall signal so that the

maximum and minimum reflectance reading with a scan taken of a known

calibration, or reference test sheet gives the correct reading for that

sheet. This process is the user calibration.

After many thousands of hours of use, the intensity of the LEDs that

illuminate the barcode symbol will gradually change.

- 29 -

If this gradual dimming is not completely uniform then a factory

recalibration would be required to re-establish the situation of creating

uniform scan reflectance profiles from the scanning heads.

If a uniform profile is not being achieved then a barcode symbol may start

to achieve lower grades, particularly for modulation, than it should be

getting. However, this may not always be obvious to the user when simply

trying to verify barcodes symbols.

- 30 -

VERIFIER SERVICING AND FACTORY RECALIBRATION

Axicon equipment is designed and manufactured to the highest

specifications and complies with all relevant international standards.

Barcode verifiers are precision measuring and testing devices. It is normal

practice for all inspection, measuring and test equipment to be regularly

checked and recalibrated and a precision quality control instrument such

as a barcode verifier is no exception.

To ensure that your equipment is working correctly, we recommend that

you return your verifier annually for servicing / factory recalibration

(please note that a factory recalibration is different to the user

calibration procedure explained on page 29 of this booklet). Axicon Auto

ID Ltd offers a high quality verifier factory recalibration service to ensure

that your Axicon verification equipment provides only the best results and

complies fully with GS1 standards. We recommend that this service is

carried out annually on verifiers aged 12 months or older. Please contact

us (or your reseller) for details of costs.

There is a silver sticker on your verifier which will tell you when it was

last factory recalibrated.

Should you decide not to take advantage of this service, we must remind

you that Axicon Auto ID Ltd is unable to accept any responsibility for noncompliance to the appropriate GS1 STANDARDS once your verifier has

exceeded the standard guarantee period provided on date of purchase.

- 31 -

To arrange for your verifier is to be factory calibrated.

1. Contact the Axicon Auto ID Ltd on

Telephone: +44 (0) 1869 351155

Fax +44 (0) 1869 352404

Email: vcas@axicon.com

2. We will provide you with a RMA number (Return to Manufacturer

Authority) for your authorisation.

3. Please fill in all details requested on the RMA form enclosed with this

letter, including the RMA number.

4. Return the verifier (including all cables) in its original case, the

completed RMA form, purchase order, your payment details and this

documentation booklet to our VCAS Bureau at Axicon Auto ID Ltd,

Church Road, Weston on the Green, Bicester, Oxfordshire OX25 3QP.

Axicon Auto ID Ltd cannot take responsibility for units returned in

alternative packaging.

5. Axicon Auto ID Ltd will normally complete the service and re-

calibration of your verifier within 7-10 days from the date received.

OTHER FAULTS OR DAMAGE

If, during the service /re-calibration of your equipment other faults or

damage are found additional costs may be applicable. We will

automatically send you details of the necessary repair and an estimate of

cost.

EQUIPMENT RENTAL SCHEME

Axicon Auto ID Ltd also offers an equipment rental scheme for customers

who require replacement equipment for the duration of the service

Please contact us for further details.

- 32 -

HOW TO CONTACT AXICON

Axicon Auto ID Ltd

Church Road, Weston on the Green, Oxfordshire OX25 3QP, UK

Tel.: +44 (0) 1869 35 11 55

Fax: +44 (0) 1869 35 1 205

Fax VCAS/Repairs: +44 (0) 1869 35 24 04

Email : info@axicon.com

Email VCAS/Repairs: vcas@axicon.com

Technical Support: support@axicon.com

Website: www.axicon.com

For service and support in the Americas please log on to

www.axicon.com

Due to Axicon’s continuing product improvement programs, specifications and

features herein are subject to change without notice.

All trademarks are acknowledged as belonging to their respective companies.

for contact details

YOUR AXICON DISTRIBUTOR

- 33 -

VCAS SERVICE RECORD

Verifier Model

Serial Number

Date Service

Undertaken

Serial no. of

calibration card

Name &

Signature

Axicon Auto ID Limited

Company Registration Number: 2003365

VAT Registration Number: GB 578651102

Verifier Documentation Booklet

Version 5 – Jan 2014

- 34 -

Loading...

Loading...