THE BARCODE EXPERTS

Partner

Axicon 12600-12900 range

2D barcode veriers

user guide

Industry

Church Road, Weston on the Green, Oxfordshire, OX25 3QP, UK

Tel: +44 (0)1869 351155 | Email: sales@axicon.com

Web: www.axicon.com

www.axicon.com

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 2 of 24

Contents

Introduction 5

Installation 6

Software (1D) 8

Software (2D) 10

Using the verier 12

Calibration 13

Verication results 14

Using the 12800 - 12900 16

Software licence agreement 19

www.axicon.com

Annual servicing 20

Axicon Warranty 21

Certicate of conformance 23

Contact us 24

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 3 of 24

www.axicon.com

Introduction

An Axicon verier is a high-precision quality control device and should be handled

with due care.

Only use power and data cables supplied by Axicon. Use of non-approved

accessories will invalidate the warranty.

If the verier is dropped (or subjected to similar misuse) the accuracy of the results

may be aected. The unit should be returned to Axicon immediately for servicing.

Axicon recommends that the verier is factory re-calibrated annually. The unit

should be returned to Axicon or to your approved Axicon reseller for this servicing.

The following table shows the various models in the Axicon 12000 series which can

be used in conjunction with this software – and their typical applications:

Model Field of view Application

12000 24 x 18mm High resolution 2D codes

12500 40 x 24mm High to medium resolution 2D

codes

12600 51 x 38mm EAN/UPC and 2D codes

12700 70 x 51mm EAN/UPC and large 2D codes

12800 34 x 25.5mm Direct part marked (DPM) items

12900 34 x 25.5mm Direct part marked (DPM) items

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 4 of 24

www.axicon.com

What is in the case

• Axicon 12600, 12700, 12800 or 12900 2D verier.

• Power supply and y lead.

• Mains lead.

• Wallet containing this documentation booklet, software CD and the calibration

card.

Optional extras

Axicon also oer the following optional extras to be used in conjunction with the

system:

• Installation qualication and operational qualication procedural

documentation.

• Performance Qualication Test Kit – Comprising a set of test cards traceable to

international standards and full procedural instructions.

• Set of Reference Test Cards – traceable to international standards.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 5 of 24

www.axicon.com

Installation

System requirements

A Microsoft-supported version of Windows (32 or 64 bit)

512 MB of RAM (Minimum)

A USB 2.0 port

Microsoft .NET Framework Version 3.5 SP1 or later

Please do not connect the verier to your PC before the software has been

installed. If the software has not been installed, Microsoft Windows will attempt

to nd the appropriate drivers for the verier online, and the wrong ones will be

installed.

The Webscan TruCheck software requires the .NET Framework version 3.5 to be

installed. The software installation process will check whether the .NET framework

is present, and install it if necessary.

Insert the software CD into an appropriate drive and the Install program should

start automatically. If not run Setup.exe. Set the location where you would like the

software installed, and specify whether the installation should be for a single user

or all users. You will be asked to conrm the installation before it takes place, and

it will then be conrmed. The software will then ask you if you want to install the

USB drivers.

After the software installation has been completed, please connect the verier to

install the USB drivers prior to running the software.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 6 of 24

www.axicon.com

Hardware installation

Connect the metal connector on the end of the verier y-lead to the metal

connector on the power supply lead. Plug the mains lead into the power supply

module, and connect the mains lead to the power supply.

Plug the USB lead from the verier into a USB2 port on the computer. The USB2

drivers that are needed will be installed automatically.

Running the software for the rst time

When running the software for the rst time, you will be asked to specify certain

application options.

The application mode ‘UDI/HIBC’ relates to requirements of the Health Industry

Barcode Standard, so choose this if necessary. Most users choose the “Don’t print

report after each scan” option. You can always change these later if you need to.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 7 of 24

www.axicon.com

Software (1D)

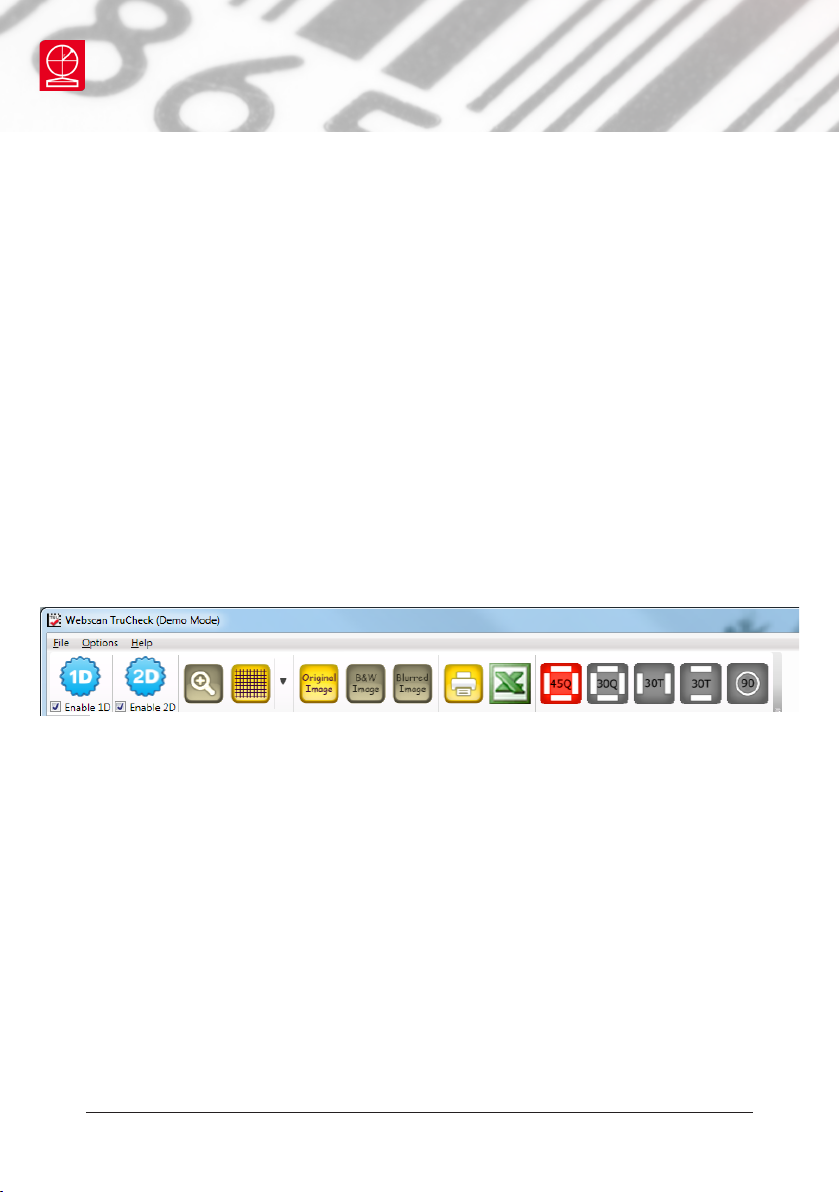

The Webscan TruCheck software will enable you to verify both 1D (linear) and

2D barcodes. The software can be congured to meet your requirements when

verifying both types of barcode.

Conguration of the 1D mode

Double click on the 1D icon to display the conguration screen.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 8 of 24

www.axicon.com

If you are using the verier to check GS1 barcodes, make sure that the GS1 option

is selected in the top right of this window. This will automatically set the correct

pass grade for the symbols. In the Decode Options section you can choose how

many scans are to be used for each verication (ISO/IEC 15416 species 10), the

size of aperture to be used if you do not want this to be decided automatically, and

whether to use the general ITF (Standard I25) or GS1 ITF-14 decode algorithm.

The Report Options section allows you to decide how much information you would

like included in the verication report. You will need to have ISO 15416/5 selected.

If you choose Quality Parameters, more information about each parameter will be

provided. If you also choose Per Scan Details, information relating to each of the

scans will be provided individually. To include an image of the barcode that has

been veried, select Image of Symbol.

The Report and Print Options section allows you to choose in which format

the verication reports should be produced, and where they will be saved

automatically. Select Metric Units at the right of this section if you would like

measurements in µm or leave blank if you would like measurements in mils

(thousandths of an inch). It is not possible to save verication reports manually, so

it is important to choose a le directory where they can be easily accessed. The

reports will be named in the format decoded data in the symbol_DD_MM_YY HH_

MM_SS., for example 12345678_25_12_16 13_45_20.

Having saved the verication reports automatically, you will be able to rename

them manually using the normal Save as option.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 9 of 24

www.axicon.com

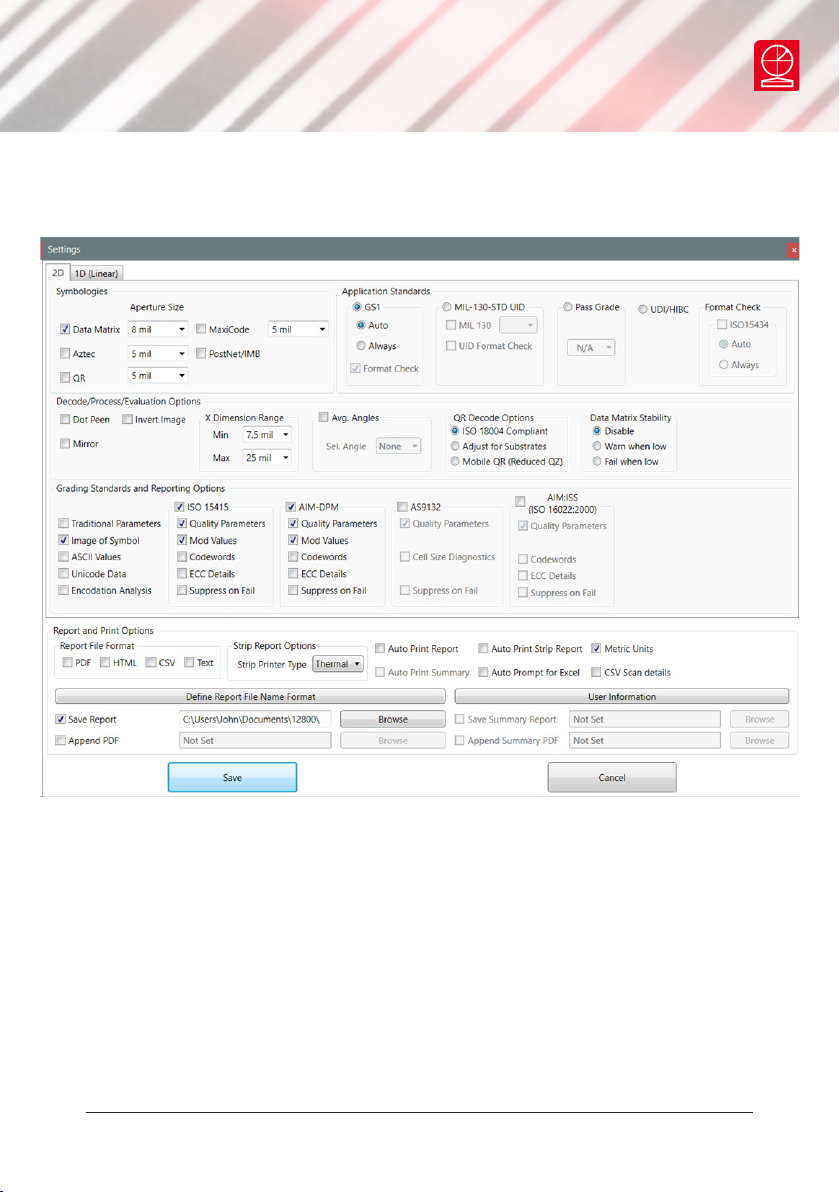

Software (2D)

Conguration of the 2D mode

Double click on the 2D icon to display the conguration screen.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 10 of 24

www.axicon.com

These settings are for the verication of Data Matrix, GS1 DataMatrix, QR Code,

GS1 QR Code and Aztec codes. Maxicode verication is an extra feature that may be

added if required.

Under the Application Standards section, select the GS1 option if this is relevant.

The MIL-130-STD setting relates to the USA’s Department of Defense standard for

unique identication. The UDI/HIBC setting relates to the Health Industry Barcode

standard for unique identication.

In the Grading Standards and Reporting Options section you can choose how much

information will be included in the verication report. GS1 users should ensure that

ISO 15415 option is selected. The other options to the right of this are only usable

with the Axicon 12800 and 12900 verier which is designed to verify direct part

marked symbols.

Saving and printing

The saving of reports takes place automatically, and you will have established

where they will be saved during the conguration process. They will be saved in

the format you have chosen (PDF, HTML, CSV or text) and you can print them as you

would any other document.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 11 of 24

www.axicon.com

Using the verier

It will be easier to use the verier if you position it so that the cable is away from

you with the Start button on its right hand side.

Notice the large Go Live button at the bottom of the main command window. When

you click this, or press the Start button on the verier, a live image will appear in

the window. Position the verier so that the barcode is in its centre.

The Go Live button will now say Verify code. Click on this, or press the Start

button again, and the verication will begin. After a few seconds the results will

appear in the window, with the ISO grade appearing in the centre.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 12 of 24

Calibration

You must calibrate the verier on a regular

basis and we recommend that this is done at

least every 15 days. You can set a calibration

notication message with the software, and

this can be set to a maximum interval of 90

days.

Take the calibration card out of the plastic

wallet and check that it is not damaged or

marked. Place the verier over the card

so that the bars of the largest barcode are

vertical in the camera window.

Click on the Start button of the verier to

activate the camera.

Go to Options, then select Calibrate

Remote. The calibration dialogue box will be

displayed:

www.axicon.com

Select the linear barcode, and make sure

the Rmin and Rmax values match those on

your calibration card. Set the calibration

reminder to 15 days, and then click on the

calibrate button. The calibration will take

about 5 seconds and then the successful

window will appear. Press OK, and then

close the window.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 13 of 24

www.axicon.com

Verication results

The Main tab provides an image of the barcode that has just been veried, together

with its overall grade to the right of the image, and at the far right, a detailed

summary of the results that includes the aperture reference number and the

wavelength of light being used.

When a linear barcode has been veried, the details for each of the ten scans the

verier has used to calculate the nal result are also provided.

The other tabs provide the results set out in slightly dierent ways.

The most interesting tab is called SRP (for Scan Reectance Prole) and this

provides a graph showing the brightness of the symbol measured across its width.

The high points represent the spaces, while the lowest points represent the bars.

The round green arrow buttons allow you to move through the ten dierent scans,

and as you do this, the SRP will change as will the results shown to their right. You

can also magnify the size of the barcode by using the icons on the far left of the

screen.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 14 of 24

www.axicon.com

When you look above the SRP itself you will see three bands. The rst one, called

Original Scan, represents what the verier saw as it scanned that part of the

barcode. The Nominal Modules band represents the dierent module widths

(x-dimension widths) of a perfect barcode, and if you hover over these with

your cursor, the software will tell you how wide each element (bar or space) is.

The Threshold Edges band shows you the edges that have been detected by the

verication algorithm. If you move your cursor over this band, a small window will

appear that provides the reectance value for each element, and the letter grades

and percentage values for Modulation, Defects, and Decodability.

Verifying 2D symbols

You follow the same procedure as for linear symbols, after making sure that you

have selected Enable 2D below the blue 2D conguration icon at the top of the

command window. The results screen will now include an image of the code, with

additional details that are required by ISO/IEC 15415.

There is no SRP tab for 2D barcodes, so the one called Histogram provides details

of the dierent reectances of all the modules. The Advanced Detail tab provides

a diagram that shows the modulation values for each element. In this example, one

module is missing, so its value is 0.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 15 of 24

www.axicon.com

Using the 12800 and 12900

Direct part marked symbols

The Axicon 12800 and Axicon 12900 are designed to read direct part marked (DPM)

2D symbols that are often etched or dot peened onto metallic surfaces. These

symbols can be veried in accordance with ISO/IEC 15415 or ISO/IEC TR 29158

(formerly known as the AIM Quality Guideline for Direct Park Marking). This second

approach allows for the angle of illumination to be changed, so the user can select

angles of 45º, 30º, or 90º, and also whether the 30º illumination should be on all

four sides or only two sides.

The Axicon 12800 is designed to read symbols on the same plane as its base, while

the Axicon 12900 has an adjustable height. This means that the Axicon 12900 can

be used to read DPM symbols marked on more unusually shaped objects or where

the marking is slightly recessed. The appropriate buttons to change the angle of

illumination appear at the top of the main command window, to the right of the

green x icon.

You should rst try to see if you can obtain an acceptable pass grade by using the

ISO/IEC 15415 standard, and then if not, by using the ISO/IEC TR 29158 (AIM-DPM)

approach. The 2D conguration settings will need to be changed to allow for the

AIM-DPM approach and for any other requirements such as those for the USA’s

Department of Defense’s MIL 130 standard.

If you are verifying 2D symbols produced on highly reective surfaces, you will have

to try out these options to see if you can obtain a suitable pass grade.

The tabs in the main window provide the same type of information as they do for

the Axicon 12600 and 12700.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 16 of 24

www.axicon.com

If both the GS1 ISO/IEC 15415 and AIM-DPM approaches are selected, the

verication report will include both sets of results.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 17 of 24

www.axicon.com

Using the 12900

You will use the aluminium handwheel at the top of the verier to adjust its height

above the base plate. The software for this verier is identical to that for the

Axicon 12800, except that it will check if the verier is the correct distance away

from the symbol to be veried after you have clicked on the Go Live button.

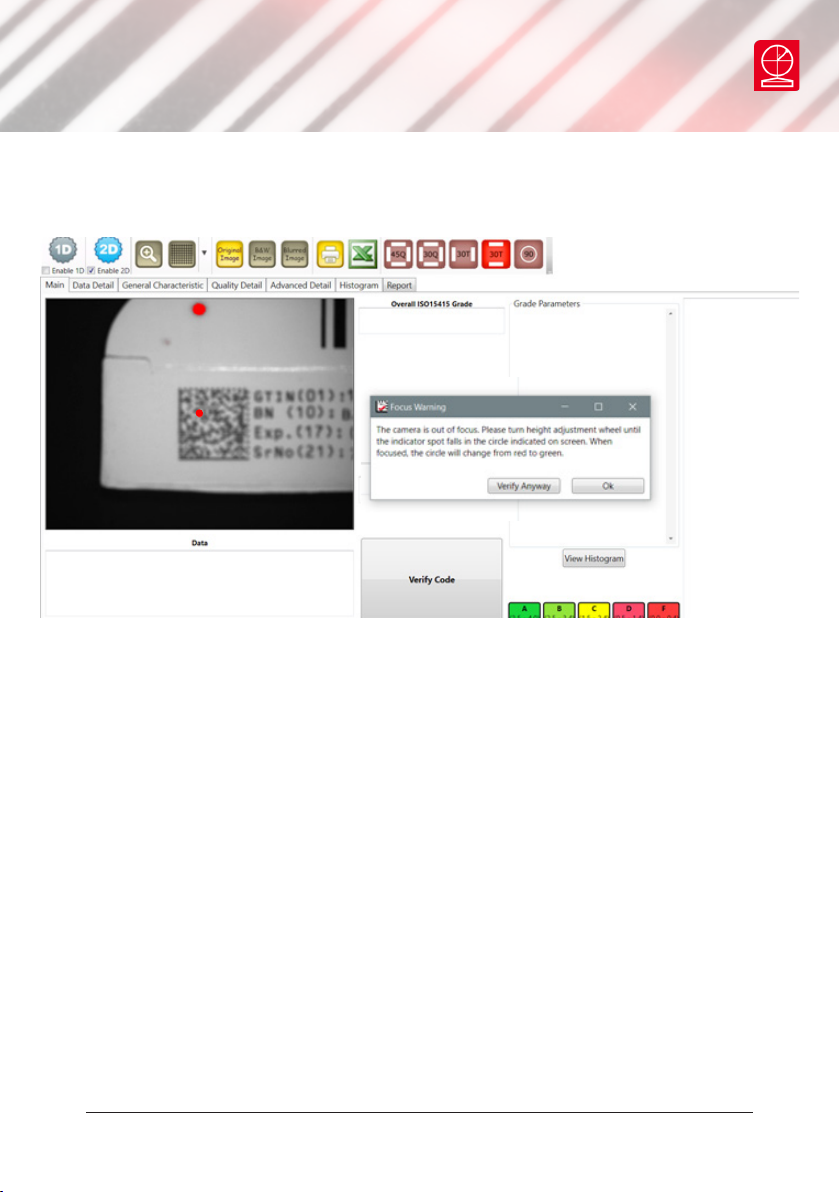

The screen will look like this, with a new ‘Focus warning’ window in the middle, if

the Verify Code button has been clicked before focussing the image.

Adjust the height using the handwheel, so that the two red dots overlap. The red

laser spot will move up or down the image as the handwheel is turned. Best focus

will be achieved when the red laser spot is aligned with the small red ring that is

shown in the middle of the image and when these two coincide, the red ring will

change to a green coloured ring and the Verify code button can then be clicked to

decode and verify the symbol.

Caution: Take care when adjusting the height of the verier above an awkwardlyshaped item to make sure that no part of it damages the unprotected components

inside the verier. The Axicon 12900 uses a Class 2 laser beam during its height

adjustment process.

Do not attempt to look directly at its source.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 18 of 24

www.axicon.com

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 19 of 24

www.axicon.com

Annual service

All veriers need servicing every year to ensure that they measure barcode quality

in accordance with the relevant ISO/IEC standards. This verier conformance and

alignment service (VCAS) ensures that the verier is internally dust-free, checks

that it is focused correctly, and adjusts the hardware to account for any change in

the brightness of the LEDs used to illuminate the barcodes.

This annual service is not the same as user calibration, as it looks at the output of

the LEDs and corrects for any variance in their evenness of illumination across the

whole eld of view. Over time the LEDs will fade but they will not fade uniformly.

User calibration ensures that the verier is measuring the darkest and brightest

reectances correctly but it cannot correct for any variance in the illumination.

After your verier has been serviced, we will return it you with the latest version

of the software on CD together with a new calibration card, and a new user guide

that will include the new certicate of ISO/IEC conformance. You will then need

to calibrate the verier before you use it again. The latest software can always be

downloaded free of charge from our website, www.axicon.com.

To arrange for your verier to be serviced:

1. Contact us on

Telephone: +44 (0) 1869 351155 | Fax +44 (0) 1869 352404

Email: vcas@axicon.com

2. We will provide you with an RMA number (Return to Manufacturer Authority)

and an RMA form.

3. Please ll in all details requested on the RMA form, including the RMA number.

4. Return the verier (including all cables) in its original case with the completed

RMA form, purchase order and your payment details to us at Axicon Auto ID

Ltd, Church Road, Weston on the Green, Oxfordshire OX25 3QP. We cannot take

responsibility for units returned in alternative packaging.

5. We will normally complete the service and re-calibration of your verier within

7-10 days.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 20 of 24

www.axicon.com

Axicon warranty

The Axicon 12600, 12700 or 12800 are sold with a one year parts and labour

warranty against manufacturing defects. This is a return to bench warranty with

shipping costs in one direction being borne by the customer/distributor.

Should you need to return the unit to us the original transit case (plus appropriate

packaging) must be used. If the equipment is returned without the original transit

case, we will automatically charge an additional sum for the replacement of this

packaging.

We reserve the right to charge an inspection fee for any equipment returned under

warranty for which no fault is found.

Please contact us to obtain an RMA (return to manufacturer authorisation)

number before returning any equipment. This number must be quoted on all

documentation. We cannot accept responsibility for equipment returned without an

RMA number.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 21 of 24

www.axicon.com

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 22 of 24

Church Road, Weston on the Green,

Oxfordshire, OX25 3QP, UK

Certicate of ISO/IEC

conformance

We, Axicon Auto ID Limited, of Church Road, Weston on the Green, Oxfordshire,

OX25 3QP, UK, hereby declare, that the following barcode verier(s):

Model number(s)

Serial number(s)

has been designed and manufactured at our address in the UK to verify barcode

quality and to conform to: ISO/IEC 15426-1 and ISO/IEC 15426-2 barcode verier

conformance specication.

The equipment has been tested and calibrated using primary reference test

symbols traceable to the USA’s National Institute of Standards and Technology’s

reectance standards. We also state that this equipment, when used with the

latest verier software, and congured appropriately has the features to meet

the requirements of the United States Food and Drug Administration regulation,

Title 21 CFR Part 11.

This verier has been quality assurance checked today, and conforms to these

ISO/IEC standards. This declaration of conformity is valid for a year.

Issue date

Expiry date

Authorised signatory

Signatory Name

At or before the expiry date the verier should be returned to Axicon for its

annual servicing. This VCAS (verier conformance and alignment service) will

ensure that the verier remains conformant to ISO/IEC 15426-1 and ISO/IEC

15426-2 for another year.

Axicon Auto ID Limited | 12600 - 12900 user guide | June 2017

Page 23 of 24

Contact us

Axicon Auto ID Ltd

Church Road

Weston on the Green

Oxfordshire

OX25 3QP

UK

Tel: +44 (0) 1869 351 155

Fax: +44 (0) 1869 351 205

Email: info@axicon.com

Website: www.axicon.com

As Axicon continually improves its products, their specications and features are

subject to change without notice. All trademarks are acknowledged as belonging to

their respective companies.

Your Axicon distributor

Loading...

Loading...