Axial Racing AX0320 User Manual

Spec 2s Nitro Engines

AX0320-I001

Warranty

Your Axial engine is warranted to be free from defects in materials and workmanship for a period of two (2) years

from date of purchase. If there are any defects with the materials, workmanship, or assembly of your engine, Axial

will gladly repair or replace it for you at our discretion. Engines that have been worn out, abused, or improperly

operated will not be covered under this warranty.

Not covered by Warranty:

This warranty does not cover problems from normal wear, abuse, neglect, or any damage arising as a result of

improper use, use of improper fuel, overheating, continuous neglect, or crash damage.

Axial shall not be liable for any loss or damages, whether direct, indirect, special, incidental, or consequential,

arising from the use, misuse, or abuse of this product and any accessory or chemical to operate this product.

Servicing:

repairs made to engines resulting from neglect or misuse will be charged parts and labor before the work is

Any

started. Please contact customer service at Axial for any warranty claims at 949-600-8642. Our customer service

hours are Monday through Friday 8:00am to 5:00pm, Pacific Standard Time.

If an engine needs to be sent in, customer service will issue a RMA#. All engine returns require a RMA#.

The engine must be returned complete with crankcase, crankshaft, piston, sleeve, connecting rod, cylinder head,

carburetor, and pull starter. You should not return the clutch, flywheel, flywheel collet, nut, air cleaner, manifold,

or muffler.

Please contact Axial customer service if you have any issues with your engine.

Axial

21092 Bake Parkway Suite 114

Lake Forest, CA 92630

Engine Features

Carburetor

Reducer

High Speed

Needle

Fuel Inlet

Idle Adjustment

Throttle

Linkage

Low Speed

Needle

Crankshaft

* *NOTE** Some features and parts may differ depending on which model engine you have.

Heat Sink

Exhaust Outlet

Pull Start

Crankcase

Engine Break In

Important

The piston and cylinder sleeves are designed to achieve proper running tolerances when they are

properly broken in. New engines need a break-in period of about 6-8 tanks before they can be run at full

throttle. Be sure to follow all the steps in the break in process or the engine will suffer damage.

Fill the fuel tank and prime the carburetor1

Use of wrong fuel will void the

engine warranty.

20-30% Nitro

Minimum of 10% oil.

Fill the fuel tank completely. Use only

20-30% nitro content fuel with a

minimum of 10% oil. Use a high quality

branded model car fuel only. To prime

the engine, use a piece of cloth to cover

the exhaust tip. Pull the starter cord

several times until the

carburetor and no bubbles are seen.

fuel reaches the

Factory Carburetor Settings

Idle Adjustment Screw

Flush with Groove

High Speed Needle

Do not adjust your carburetor. The needles are preset from

the factory for engine break in.

The needles are designed to sit flush, this makes it easy to reset

them to the factory break in settings. If your engine is already

broken in, this setting may be too rich for your engine. If engine is

over heating from stock setting please adjust both needles 1 full turn

out and continue break in process

About 1mm (0.04”)

Low Speed Needle

Flush

Adjust the carburetor and start the engine2

Make sure the receiver is switch is off. Manually

turn the throttle servo until the carburetor is 1/4

of the way open.

Attach the glow plug igniter to the engine. Start

the engine by pulling the starter cord (30cm

MAX!).

Adjust the throttle servo so the engine runs

fast enough to idle without engaging the

clutch or turning the wheels.

Run the engine for three tanks of gas. If the

motor shuts off repeat steps the steps.

Drive at 1/2 throttle for 3 tanks3

The vehicle should not move when idling. If it

does, adjust the trim settings on the transmitter.

Drive the vehicle in a 20 foot oval, do not apply

more than 1/2 throttle. Coast for short amounts

of time to allow the engine to cool, then accelerate

again.

Continue this process for a total of three tanks

of fuel.

Tip - Stopping the motor

1) Use a Rag

Use a rag to cover the exhaust tip. This will stop the motor. Be

careful! The exhaust is extremely hot so be sure to use a thick

rag.

2) Pinch the Fuel Line

In extreme cases or emergencies you can pinch the fuel line to

stop the flow of fuel to the carb. Be careful, this can make the

motor run lean which can damage the motor. It is best to stop

the motor using a rag.

Tuning After Break In

High Speed Needle

Turn the high speed needle in 1/8 turn increments to lean out the

fuel mixture for increased top speed and throttle performance.

Drive the car to notice the changes in speed and throttle responses.

Continue tuning the carburetor in this way, turning in 1/8 turn

increments only. (Maximum of 2 1/2 turn from flush)

Idle Adjustmen Screw

The idle speed is set after the engine is up to operating speed. To

properly set the idle speed turn on your radio and set the throttle

trim to neutral. Turn the idle adjustment screw counter clockwise to

reduce the idle speed, or clockwise to increase the idle speed. The

idle should be set high enough to keep the engine running, but low

enough to prevent the clutch from engaging.

Low Speed Adjustmen Screw

We recommend that you do not touch the low speed needle. If

adjustment is needed, the low speed needle is set after the high

speed needle is adjusted. If the low speed needle is set too lean you

will experience the following:

1. Flame out at part throttle

2. Overheating

If you experience any of the above, reset to factory settings and start

the tuning process over.

Important

Read this section carefully. Failure to follow

these tuning steps could result in damage to

your engine and void your engine warranty!

Tuning Tips

While a lean motor will have higher performance, it will lead to

premature engine wear and failure. Use the following information to

tune your engine to your driving conditions. Remember, a slightly rich

setting is a safer setting.

More Fuel = RICH

Rich Fuel Mixture

A slightly rich fuel mixture

delivers a cooler running

temperature and more

lubrication, but with slightly less

power and longer engine life.

Less Fuel = LEAN

Lean Fuel Mixture

Provides stronger combustion

and power, but if you lean out

too much the result is more

engine heat and a shorter

engine life. Symptoms of an

engine that are too lean are

sputtering, rough idle, no smoke

from the exhaust and hard to

restart.

Carb Reducer

2 carburetor reducers are included with

your engine ( 8mm yellow; 8.5mm orange)

these are used for restricting airflow. The

bigger the insert the more power. The

smaller the reducer the lower the power.

Use these to tune your engine for your local

track conditions.

Stop Tuning

if your engine shows any of the following signs,

please stop your engine and retune to a richer

setting. Further running will damage the engine.

1. There is no white smoke when at full throttle

2. The engine hesitates or bogs

3. Reduced top speeds or loss of power

4. Temperatures above 275° F (135° C)

AX1117

AX1121

AX1103

AX1118

AX1122

AX1116

AX1120

AX005

AX006

AX007

AX010

AX012

AX013

AX014

AX015

AX016

AX017

AX018

AX019

AX020

AX021

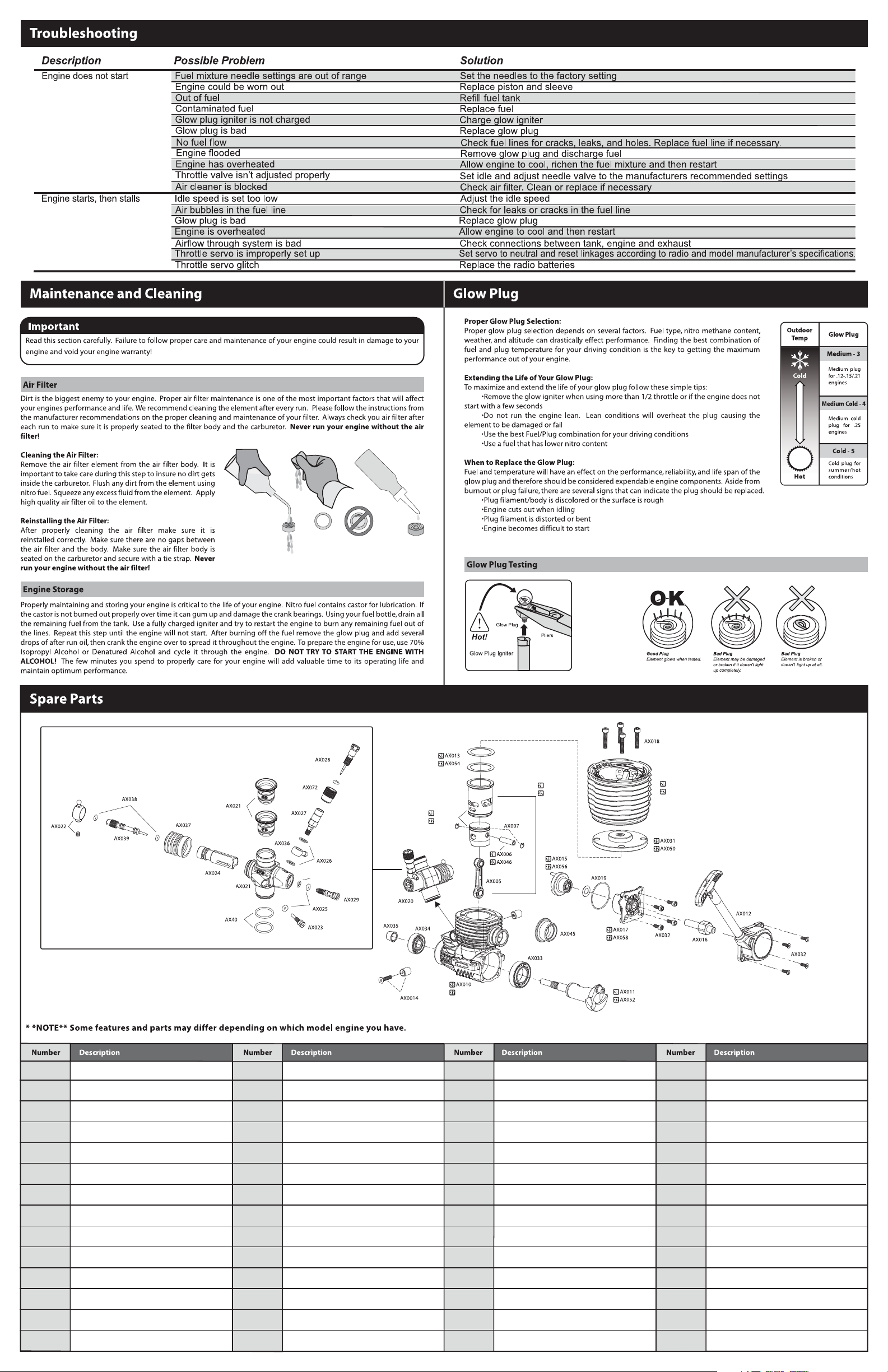

28 / 32 Engine Connecting Rod

28 Engine Piston/Pin Retainer Set

28 / 32 Engine Retainer for Piston Pin (3 Pcs)

28 Crankcase

28 / 32 Engine Pull Start Assembly

28 Engine Gasket Set (0.15mm/0.3mm)

28 / 32 Engine Lock Pin for Carburetor

28 Engine pull start shaft holder

28 / 32 Engine Starting Shaft

28 Engine cover plate set

28 / 32 Engine Screw

28 / 32 Engine Dust Protection Set

28 / 32 Engine Slide Carburetor Complete

28 / 32 Engine Slide Carburetor Main Body

AX022

AX023

AX024

AX025

AX026

AX027

AX028

AX029

AX030

AX031

AX032

AX033

AX034

AX035

28 / 32 Engine Uniball

28 / 32 Engine Idle Adjustment Screw

28 / 32 Engine Slide Valve

28 / 32 Engine O-Ring Set

28 / 32 Engine Fuel Line Fitting/Washer Set

28 / 32 Engine High-Speed Needle Valve

28 / 32 Engine High-Speed Needle with O-Ring

28 / 32 Engine Mid Range Needle

28 / 32 Engine High-Speed Needle Valve Set

28 Engine button head

28 / 32 Engine Pull Start Screw Set (8 Pcs)

28 / 32 Engine Rear Bearing 14 X 25 X 6

28 / 32 Engine Front Bearing 7 X 19 X 6

28 / 32 Engine Brass Collet

AX036

AX037

AX038

AX039

AX040

AX045

AX046

AX050

AX051

AX054

AX056

AX058

AX072

AX1103

28 / 32 Engine Fuel Inlet

28 / 32 Engine Carb Dust Boot

28 / 32 Engine O-Ring 2 X 1.5mm (2 Pcs)

28 / 32 Engine Low Speed Needle Valve

28 / 32 Engine O-Ring 11.5 X 1.25mm (2 Pcs)

28 / 32 Engine Silicone Exhaust Seal

32 Engine piston pin/retainer set

32 Engine Button Head

32 Engine crankcase

32 Engine Gasket Set

32 Engine Pull Start Shaft Holder

32 Engine Cover Plate Set

28 / 32 Engine High-Speed Needle Adjuster Cap

.28RR-2/.32RR Crankshaft

AX1116

AXA117

AXA118

AXA119

AX1120

AX1121

AX1122

.28 Spec 2s Heat Sink Head (Green)

.28-2s Piston/Sleeve Set

.28-2s Cylinder/Piston/Connecting Rod Set

28 spec 2s crankshaft

.32 Spec 2s Heat Sink Head (Green)

.322s Piston/Sleeve Set

.32-2s Cylinder/Piston/Connecting Rod Set

Loading...

Loading...