Page 1

AXELL BSF-4004 BSF0038 SERIES REPEATER

BSF-4004 UHF Repeater

Product Description and User’s Manual

Doc No. PN 4004 BSF0038 Series-UM Rev. 1.0

PRODUCT DESCRIPTION AND USER’S MANUAL

THIS DOCUMENT IS VALID FOR THE

BSF 4004 (424/429MHz) REPEATERS for the US Market

Page 2

AXELL BSF-4004 BSF0038 SERIES REPEATER

Copyright © 2014 Axell Wireless Ltd

Contact Information

Headquarters

Axell Wireless

Commercial inquiries

info@axellwireless.com

Web site

www.axellwireless.com

Support issues

support@axellwireless.com

Technical Support Line, English speaking

+44 1494 777 747

PRODUCT DESCRIPTION AND USE R’S MANUAL

All rights reserved.

No part of this document may be copied, distr ibuted, transmitted , transcr ibed, stored in a retrieval syste m, or

translated into any human or computer language witho ut the pr ior wri tte n per m ission of Axell Wireless Ltd.

The manufacturer has made every effort to ensure that the instructions contained in this document are

adequate and free of er rors and omiss ions. The manufa cturer will, if nece ssary, exp lain issues whic h may not

be covered by this document. The manufactur er's liability for any errors in the document is limited to the

correction of errors and the aforementio ne d advis or y s ervices.

This document has been prepared to be used by professional and properly trained personnel, and the

customer assumes full responsibility w hen using them. The manufacturer welcomes customer comments as

part of the process of continual de velopme nt and improv ement of the docume ntation in the be st way p ossible

from the user's viewpoint. Please submit your comments to the nearest Axell Wireless sales representative.

Aerial House

Asheridge Road

Chesham

Buckinghamshire HP5 2QD

United Kingdom

Tel: +44 1494 777000

Fax: +44 1494 777002

Contact information for Axell Wireless offices in other countries can be found on our web site,

www.axellwireless.com

II Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 3

AXELL BSF-4004 BSF0038 SERIES REPEATER

About This Manual

Intended Audience

Notice

Disclaimer of Liability

PRODUCT DESCRIPTION AND USE R’S MANUAL

This Product Manual provides the following information:

• Description of the BSF-4004 repeater

• Procedures for installation, setup, configuration and checking the proper operation of the unit

• Maintenance and troubleshooting procedures

This Product Manual is intended for experienced technicians and engineers. It is assumed that the

customers installing, operating, and maintaining Axell Wireless Repeaters are familiar with the basic

functionality of Repeaters.

Confidential - Authorized Customer Use

This document may be used in its complete form only and is solely for the use of Axell Wireless

employees and authorized Axell Wireless channels or customers. The material herein is proprietary to

Axell Wireless. Any unauthorized reproduction, use or disclosure of any part thereof is strictly

prohibited.

All trademarks and registered trademarks are the property of their respective owners.

Contents herein are current as of the date of publication. Axell Wireless reserves the right to change

the contents without prior notice. The information furnished by Axell Wireless in this document is

believed to be accurate and reliable. However, Axell Wireless assumes no responsibility for its use.

In no event shall Axell Wireless be liable for any damage resulting from loss of data, loss of use, or

loss of profits and Axell Wireless further disclaims any and all liability for indirect, incidental,

special, consequential or other similes damages. This disclaimer of liability applies to all products,

publications and services during and after the warranty period.

Safety to Personnel

• Before installing or replacing any of the equipment, the entire manual should be read and

understood.

• This equipment is to be installed only in a restricted access location.

• Throughout this manual, there are "Caution" warnings. "Caution" calls attention to a procedure or

practice, which, if ignored, may result in injury or damage to the system, system component or

even the user. Do not perform any procedure preceded by a "Caution" until the described

conditions are fully understood and met.

CAUTION! This notice calls attention to a procedure or practice that, if ignored, may result in

personal injury or in damage to the system or system component. Do not perform any procedure

preceded by a "Caution" until described conditions are fully understood and met.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 III

Page 4

AXELL BSF-4004 BSF0038 SERIES REPEATER

Compliance with FCC

excess of $100,000 for each continuing violation.

installations.

PRODUCT DESCRIPTION AND USE R’S MANUAL

Part 90 Signal Boosters THIS IS A 90.219 CLASS B DEVICE

WARNING: This is NOT a CONSUMER device. This device is designed for installation

by FCC LICENCEES and QUALIFIED INSTALLERS. You MUST have an FCC

LICENCE or express consent of an FCC Licensee to operate this device.

You MUST register Class B signal boosters (as defined in 47 CFR 90.219) online at

www.fcc.gov/signal-boosters/registration.

Unauthorized use may result in significant forfeiture penalties, including penalties in

The installation procedure must result in the signal booster complying with FCC

requirements 90.219(d). In order to meet FCC requirements 90.219 (d), it may be

necessary for the installer to reduce the UL and/or DL output power for certain

FCC Part 15

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

If not installed and used in accordance with the instructions, this equipment generates, uses and can

radiate radio frequency energy. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to RF reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the Donor antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Unauthorized Changes to Equipment

Changes or Modifications not expressly approved by the manufacturer responsible for compliance

could void the user’s authority to operate the equipment

FCC RF Exposure Limits

This unit complies with FCC RF exposure limits for an uncontrolled environment. This equipment

can only be installed in in-building applications, driving passive or active DAS systems. All antennas

must be operated at a minimum distance of 49 cm between the radiator and any person’s body.

IV Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 5

AXELL BSF-4004 BSF0038 SERIES REPEATER

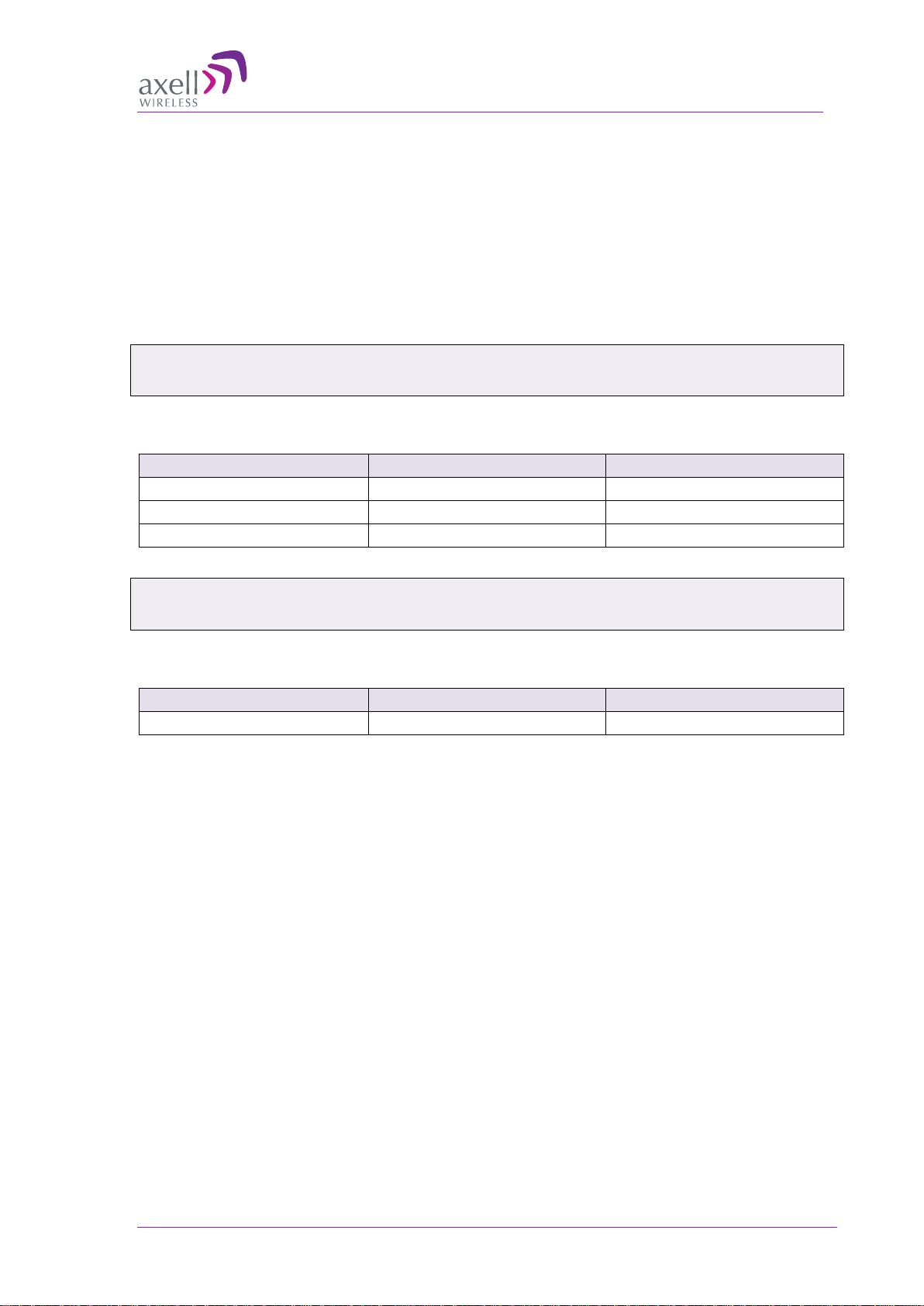

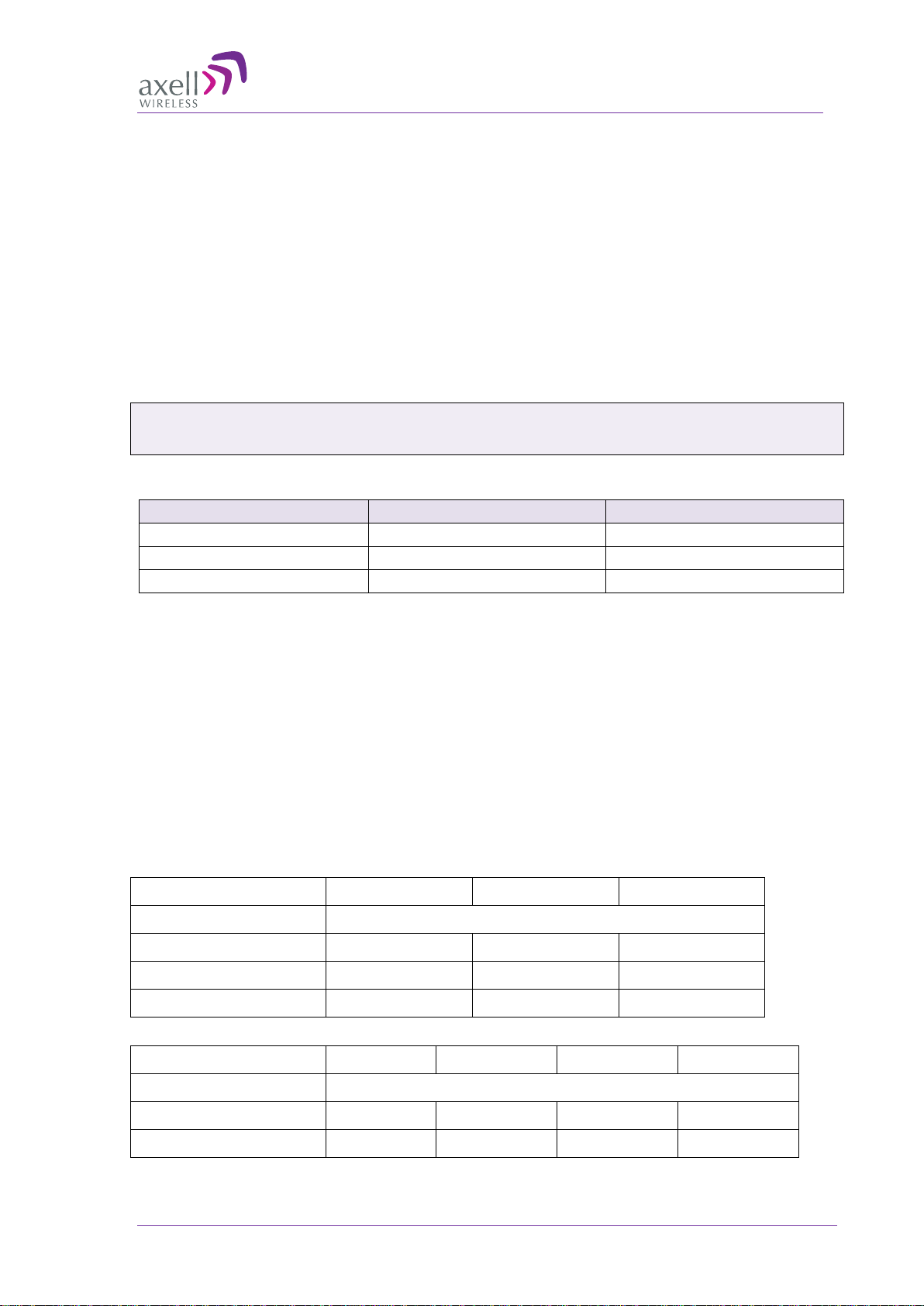

No. of Antennas

Cable Losses

Max Allowed Antenna Gain

4

3

39.1 - (37-6-3) =11.1dBi

1

3

39.1- (37-0-3) = 5.1dbi

10

3

39.1- (37-10-3) = 15.1dbi

No. of Antennas

Cable Losses

Max Allowed Antenna Gain

1

10

39.1 - (37-10) = 12.1dBi

PRODUCT DESCRIPTION AND USE R’S MANUAL

Antenna Installation

Installation of an antenna must comply with the FCC RF exposure requirements. The antenna used

for this transmitter must be mounted on permanent structures.

The FCC regulation mandate that the ERP of type A signal boosters should not exceed 5W, this is

equivalent to 8.2W EIRP.

Therefore the max antenna gain allowed for this type of signal booster should be limited to the values

given by equation (1) for the service antenna and equation (2) for the donor antenna

Equation (1) - Max SERVICE antenna gain

Max SERVICE antenna gain (dBi) = 39.1 – (37dBm - # of antennas in dB – cable losses in dB).

For example:

Equation (2) - Max DONOR antenna gain

Max DONOR antenna ga in (dBi) = 39.1 – (37dBm - cable losses in dB).

For example:

Compliance with FCC deployment rule regarding the radiation of noise

Good engineering practice must be used in regard to the signal booster’s noise radiation. Thus, the

gain of the signal booster should be set so that the ERP of the output noise from the signal booster

should not exceed the level of -43 dBm in 10 kHz measurement bandwidth.

In the event that the noise level measured exceeds the aforementioned value, the signal booster gain

should be decreased accordingly.

In general, the ERP of noise on a spectrum more than 1 MHz outside of the pass band should not

exceed -70 dBm in a 10 kHz measurement bandwidth.

The 3604 BSF0038 Series Repeater has a noise level of -45 dBm in 10 kHz measurement at 1 MHz

spectrum outside the passband of the signal booster and an in-band noise level at around -45 dBm in

a 10 kHz bandwidth. Therefore, the noise at the antenna input port should be calculated based on

equation (3).

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 V

Page 6

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

Equation (3) - Input Noise to service antenna

Input Noise to service antenna:

-45 dBm + Service Antenna gain – Antenna splitter losses in dB – cable loss in dB

Example:

Signal booster connected to 20 service antennas with a 100m long ½ inch cable.

Losses of such a cable with the connectors = ~ 12dB

Gain = ~ 2 dBi

Assuming 20 service antennas: antenna spli tte r losses = 15 dB

Based on equation (3) Input antenna noise (to the antenna) = -45+2-12 -15=-70 dBm

The inband input noise to the antenna should be -45+2 -12-15= -70dbm

NOTE: In this example there is no need to add an external band pass filter to attenuate the out of

band noise. If fewer antennas are deployed then additional filtering may be required

Conclusion:

Good engineering practice requires that in general when the out of band noise measured at the

service antenna input is more than -70 dBm per 10 kHz measurement bandwidth, an external band

pass filter should be added to attenuate the out of band noise level.

All Axell Wireless repeaters include high selectivity duplexers and filters to attenuate the out of band

noise. Should additional filtering be required, we have a comprehensive range of interference filters

which can be supplied upon request.

VI Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 7

AXELL BSF-4004 BSF0038 SERIES REPEATER

General Safety Warnings Concerning Use of This System

Throughout this manual, there are "Caution" warnings. "Caution" calls

r practice, which, if ignored, may result in

injury or damage to the system, system component or even the user.

Do not perform any procedure preceded by a "Caution" until the

Shock

To prevent electrical shock when installing or modifying the system

power wiring, disconnect the wiring at the power source before

The user needs to supply the appropriate AC or DC power to the

repeater. Incorrect power settings can damage the repeater and may

during certain conditions

become very warm and can cause minor injuries if handled without any

RF radiation, arising from transmitter outputs connected to AWL’s

terminated. Either of these

conditions would impair the system’s efficiency. No investigation

sources have been removed.

This would always be a wise precaution, despite the severe mismatch

frequency burns could also be a hazard,

local & statutory) regarding exposure of personnel to RF radiation.

ed to an antenna, the unit is capable of producing RF

field strengths, which may exceed guideline safe values especially if

used with antennas having appreciable gain. In this regard the use of

personnel must remain behind the screen while the RF power is on, is

Where the equipment is used near power lines or in association with

temporary masts not having lightning protection, the use of a safety

PRODUCT DESCRIPTION AND USE R’S MANUAL

Always observe standard safety precautions during installation, operation and maintenance of this

product.

attention to a procedure o

Caution labels!

described conditions are fully understood and met.

Danger: Electrical

working with un ins u la te d w ires or terminals.

Before installing or replacing any of the equipment, the entire manual

should be read and understood.

Caution: Safety to

personnel

cause injury to the user.

Please be aware that the equipment may,

protection, such as gloves.

equipment, must be considered a safety hazard.

This condition might only occur in the event of cable disconnection, or

because a ‘spare’ output has been left un-

should be carried out until all RF power

between the impedance of an N type connector at 50Ω, and that of free

space at 377Ω, which would severely compromise the efficient

radiation of RF power. Radio

if any RF power carrying components were to be carelessly touched!

Caution: RF Exposure

Antenna positions should be chosen to comply with requirements (both

When connect

directional antennas with backscreens and a strict site rule that

strongly recommended.

earth connected to the case-earthing bolt is strongly advised.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 VII

Page 8

AXELL BSF-4004 BSF0038 SERIES REPEATER

When installing, replacing or using this product, observe all safety

following general safety precautions and with specific precautions

Access Location

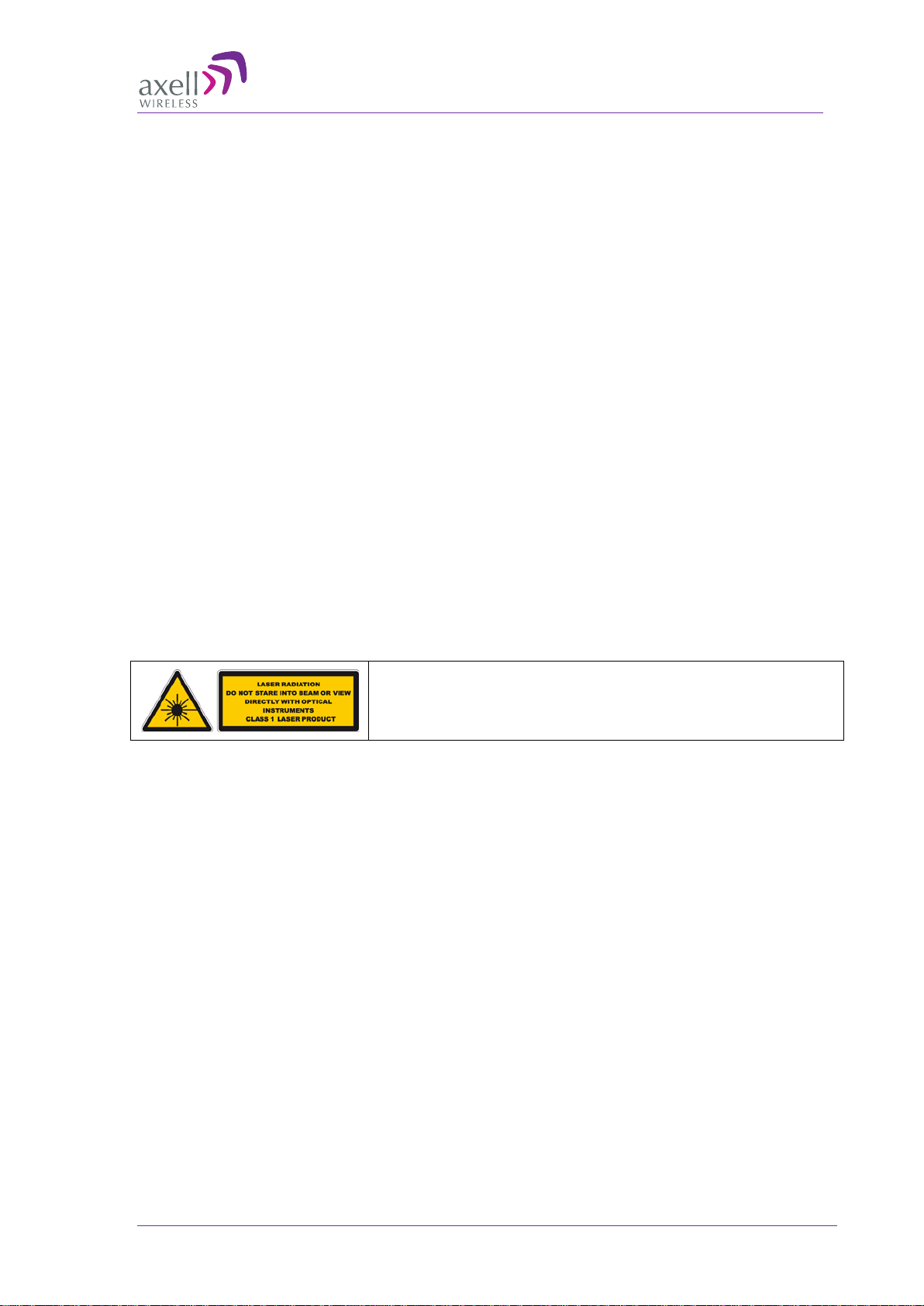

The repeaters described in this manual are equipped with class 1 lasers,

terminated optical receptacles may emit laser radiation.

PRODUCT DESCRIPTION AND USE R’S MANUAL

precautions during handling and operation. Failure to comply with the

described elsewhere in this manual violates the safety standards o f the

design, manufacture, and intended use of this product.

Caution: Safety to

equipment

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

Axell Wireless assumes no liability for the customer's failure to

comply with these precautions. This entire manual should be read and

understood before operating or maintaining the repeater.

Access to the Axell unit insta l la tio n loc a tion is restricted to SER VICE

Warning: Restricted

PERSONNEL and to USERS who have been instructed on the

restrictions and the required precautions to be taken.

Observe electrostatic precautionary procedures.

ESD = Electrostatic Discharge Sensitive Device

Attention:

Electrostatic

Sensitivity

Static electricity can be conducted to the semiconductor chip from the

centre pin of the RF input connector, and through the AC connector

pins. When unpacking and otherwise handling the repeater, follow

ESD precautionary procedures including use of grounded wrist straps,

grounded workbench surfaces, and grounded floor mats.

.

as per definition in EN 60825-1

Caution - Un-

Exercise caution as follows:

• Do not stare into beam or view with optical instruments. Optical

transmitters in the fibre optic conv erter can send o ut high energy

invisible lase r radiation. There is a risk for permanent damage to

the eye.

• Always use protective cover on all cables and connectors which

Caution: Class 1 Laser

are not connected.

• Never look directly into a fibre cable or a connector.

• Consider that a fibre can carry transmission in both directions.

• During handling of laser cables or connections, ensure that the

source is switched off.

• Regard all open connectors with respect and direct them in a safe

direction and never towards a reflecting surface. Reflected laser

radiation should be regarded as equally hazardous as direct

radiation.

VIII Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 9

AXELL AXELL BSF-4004 BSF0038 SERIES REPEATER

Table of Contents

PRODUCT DESCRIPTION AND USER’S MANUAL

BSF-4004 UHF Repeater .................................................................................................... I

FCC Part 90 ................................................................................................................................. IV

Unauthorized Changes to Equipment ...................................................................................... IV

FCC RF Exposure Limits ........................................................................................................... IV

Antenna Installation .................................................................................................................... V

Compliance with FCC deployment rule regar d ing the radiation of noise ............................. V

1 Introduction ................................................................................................................ 1

1.1 Features and Capabilities .................................................................................................... 2

1.2 ALC ........................................................................................................................................ 3

1.3 Operating Temperature ....................................................................................................... 3

1.4 Management WEB GUI ........................................................................................................ 4

1.5 Interfaces .............................................................................................................................. 4

1.5.1 Securing the Unit ....................................................................................................... 4

1.5.2 External Interfaces .................................................................................................... 5

1.5.3 Internal Interfaces ...................................................................................................... 6

2 Antenna and Repeater Installation Requirements ................................................... 7

2.1 BSF-4004 Installation Requirements .................................................................................. 7

2.1.1 Safety Guidelines ...................................................................................................... 7

2.1.2 Criteria for Repeater Installation Location ................................................................. 7

2.1.3 RF Cable Installation Guidelines ............................................................................... 8

2.1.4 F/O Cable Installation Guidelines .............................................................................. 8

2.2 Service Antenna Requirements .......................................................................................... 8

2.2.1 Required Antenna Information .................................................................................. 8

2.2.2 Indoor Installations .................................................................................................... 9

2.2.3 Service (Mobile) Antenna Installation Criteria ......................................................... 10

2.3 RF Cabling Requirements ................................................................................................. 10

3 Installation .................................................................................................................. 1

3.1 Unpacking ............................................................................................................................. 1

3.2 Mount the Repeater .............................................................................................................. 1

3.2.1 Selecting a Location to Ensure Proper Cooling ........................................................ 2

3.2.2 Wall-Mounting Preparation ........................................................................................ 2

3.2.3 Mount the Repeater on the Wall................................................................................ 5

3.3 Grounding ............................................................................................................................. 7

3.4 Ensure Good EMV Protection ............................................................................................. 8

3.5 Fibre Optic Connection ..................................................................................................... 10

3.6 External Alarm and Relay Connections ........................................................................... 13

3.6.1 External Alarm ......................................................................................................... 13

3.6.2 Relay ....................................................................................................................... 13

3.7 Power and Backup Battery ................................................................................................ 14

3.7.1 Circuit Breaker ......................................................................................................... 14

3.7.2 Power Connections ................................................................................................. 14

3.7.3 Power ON ................................................................................................................ 18

3.8 Closing and Securing the Repeater ................................................................................. 18

4 BSF-4004 Commissioning ........................................................................................19

4.1 Open a Session to the BSF-4004 via the OMU II ............................................................. 19

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 IX

Page 10

AXELL BSF-3604 TETRA REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

4.2 BSF-4004 Optical Loss Adjustment (OLA) ...................................................................... 20

4.3 RF Balancing ...................................................................................................................... 22

4.3.1 Manual RF Balancing .............................................................................................. 22

4.3.2 Automatic BSF-4004 RF Balancing ......................................................................... 24

4.4 Integration into the AEM .................................................................................................... 25

4.5 What Next? .......................................................................................................................... 25

5 BSF-4004 Full GUI Description ................................................................................. 26

5.1 Opening a Direct Web Session ......................................................................................... 26

5.1.1 Connecting Locally .................................................................................................. 26

5.1.2 Remote Connection and Login ................................................................................ 27

5.2 Navigating the Web Interface ............................................................................................ 28

5.2.1 Management Options Buttons ................................................................................. 29

5.2.2 Home Screen Overview .......................................................................................... 30

5.2.3 Configuration Screen Overview ............................................................................... 31

5.3 Configuring General Parameters ...................................................................................... 32

5.3.1 Site Information – BSF-4004 Identification .............................................................. 32

5.3.2 Date & Time ............................................................................................................. 33

5.3.3 Configure External Alarms ...................................................................................... 33

5.3.4 IP Address ............................................................................................................... 34

5.4 Remote Communication Setup ......................................................................................... 35

5.4.1 TCP/IP and Ethernet ............................................................................................... 35

5.4.2 Modem Setup .......................................................................................................... 36

5.5 SNMP Support .................................................................................................................... 38

5.6 User Accounts .................................................................................................................... 40

5.6.1 Default User Accounts ............................................................................................. 40

5.6.2 User Access Level s ................................................................................................. 40

5.6.3 Change Password ................................................................................................... 41

5.7 Reboot ................................................................................................................................. 41

5.8 Axell Shell (Command Line Interface).............................................................................. 42

5.9 Attribute Reference ............................................................................................................ 43

6 Monitoring, Fault Sourcing and Maintenance ......................................................... 44

6.1 Cautions and General Statements .................................................................................... 44

6.2 Monitoring Via the BSF-4004 Home Screen .................................................................... 45

6.3 Logs Screen ........................................................................................................................ 49

6.4 Module LEDs ....................................................................................................................... 50

6.4.1 Control Module LEDs .............................................................................................. 51

6.4.2 F/O Converter LEDs ................................................................................................ 52

6.4.3 Power Supply LEDs ................................................................................................. 53

Appendix A - Specifications ............................................................................................ 54

Appendix B - F/O Cleaning Procedure ........................................................................... 55

X Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 11

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USER’S MANUAL

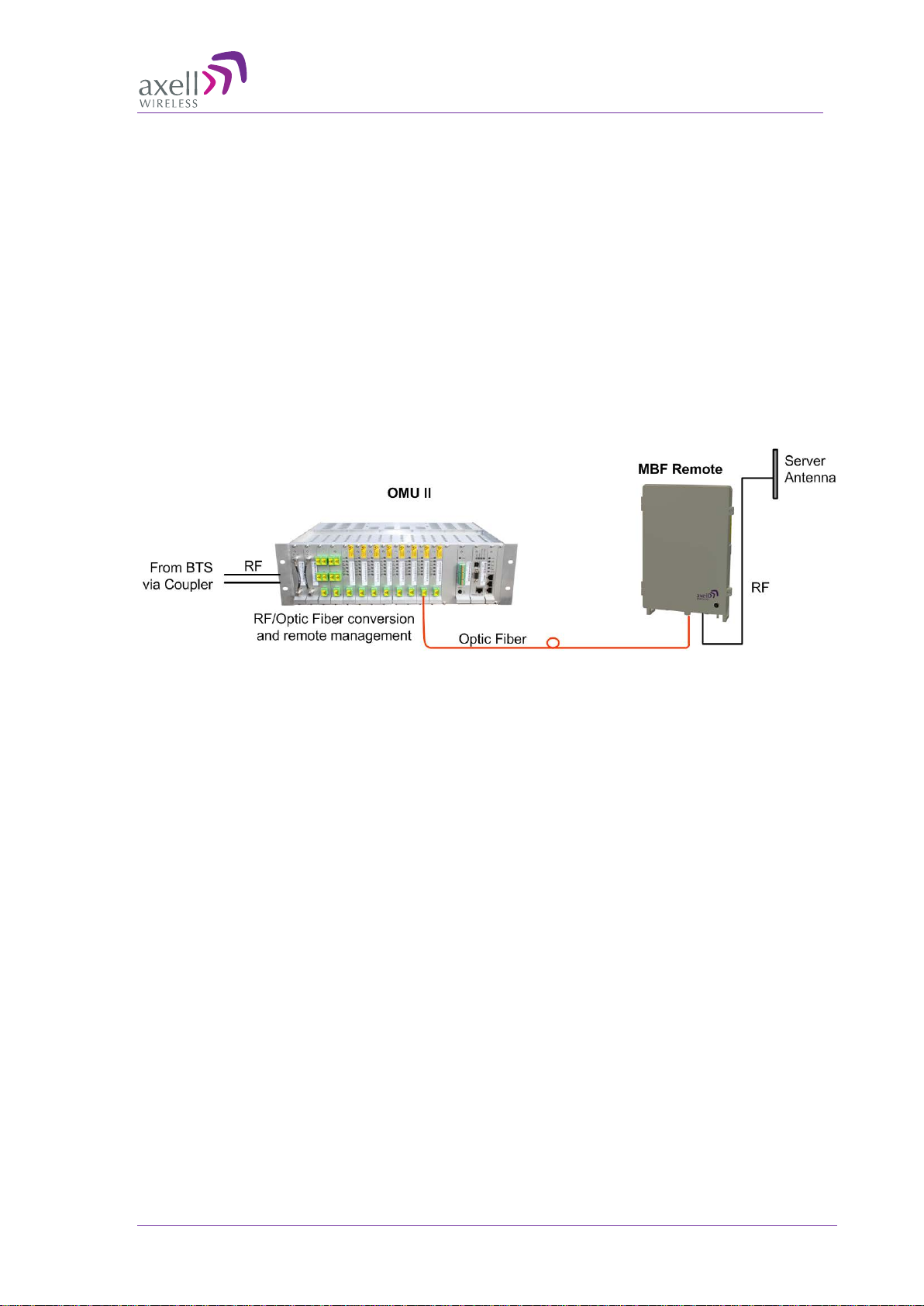

1 Introduction

The BSF 4004 is a fibre optic fed UHF repeater. It is part of a system that is fed from an Optical

Master Unit (OMU), supporting WDM technology, lowering the number of fibres needed per system.

The ma ximum optical loss of up to 10dB is allowed over the fibre interconnecting the OMU II and

the most distant last remote unit that the OMU supports. This offers great flexibility when providing

RF coverage in areas where it is not possible to rely on off-air transmission.

The fibre optic system is easily remotely monitored and controlled by Axell Wireless effective

supervision tool, Axell Wireless Element Manager.

The BSF-4004 includes automatic optical gain settings, where the gain is adjusted in the downlink

chain by measuring the level of the pilot carrier sent from the Optical Master Unit (OMU). The level

of the received pilot carrier is continuously monitored.

Figure 1-1 Illustration of OMU II Connection to BSF Remote

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 1

Page 12

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

1.1 Features and Capabilities

• Supports frequency bands 423-430MHz

• Operational bandwidth: 2 MHz

• Duplex Distance: 5 MHz

• Output Power per carrier UL/DL:

• 1 carrier: + 36dBm

• 2 carriers: + 33dBm

• 3-4 carriers: +30dBm

• 8 carriers: +27dBm

• Supports WDM technology

• Automatic Optical Gain Setting via OMU II

• Remote configuration and management:

• Via OMU II intuitive Web GUI

• Via AEM – automatically detected via AEM no local setup required

• Optionally via Ethernet or GSM, GSM-R PSTN modem

• SNMP v1/v2c support

• Automatic Level Control (ALC) - provides constant gain in both uplink and downlink paths

according to the defined maximum output level

• Very low noise factor - minimizes interference to BTS and increases high speed data throughput

• Backup battery for ‘last gasp’, sending fault error before power failure

• Wall or pole mount conforming to IP65 and NEMA 4 standard

• Power source: 115VAC, 230 VAC or -48V power (depending on your order)

2 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 13

AXELL BSF-4004 BSF0038 SERIES REPEATER

+20

Input Signal, dBm

Output Power Level, dBm

Gain 70dB

-

50

ALC

ALC one carrier

Input signal, dBm

Output power, dBm

+36,5

+33,8

-24 -16

Gain: 60 dB

+35

ALC two carriers

PRODUCT DESCRIPTION AND USE R’S MANUAL

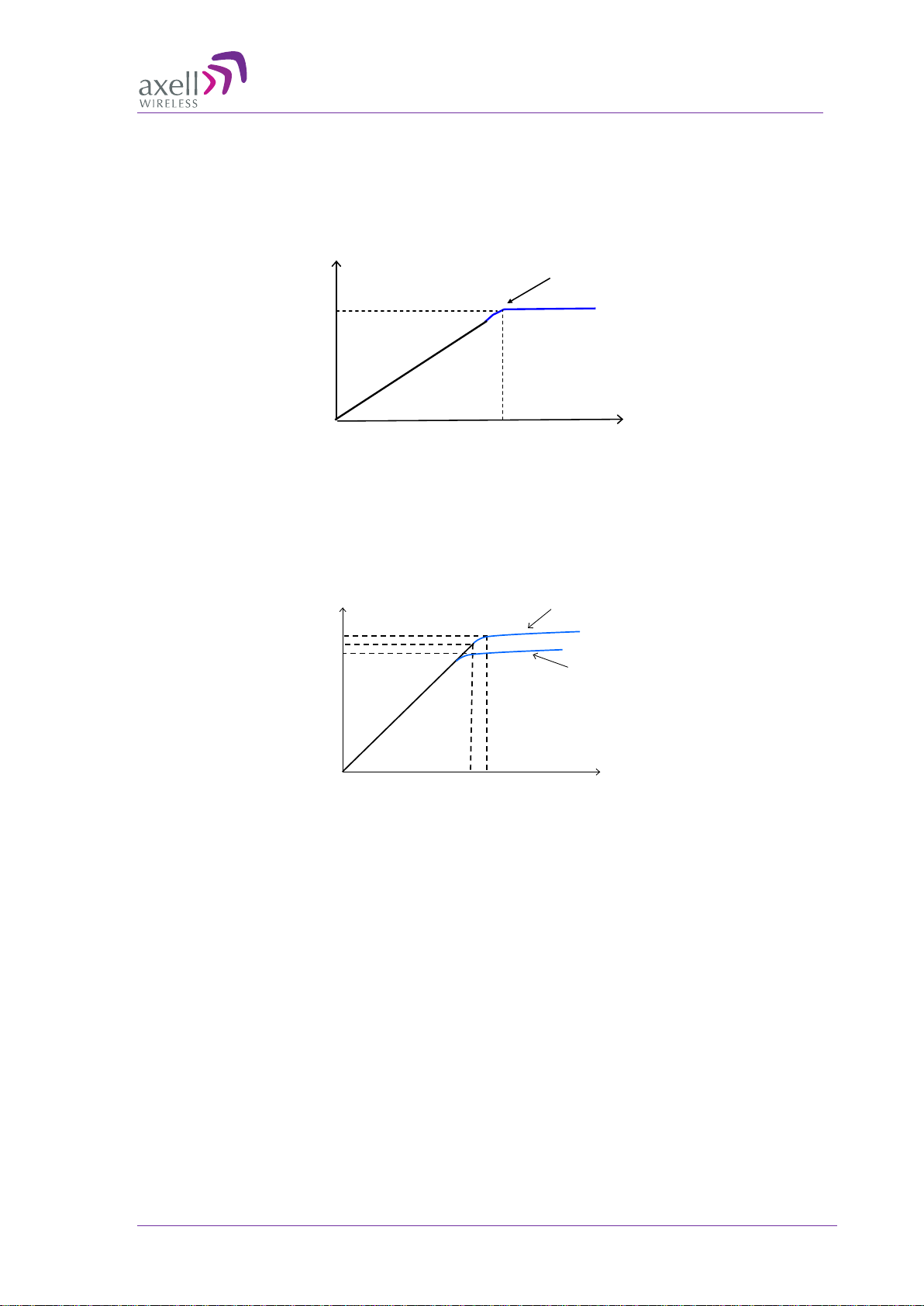

1.2 ALC

The repeater is equipped with an ALC, Automatic Level Control. The ALC feature enables

maintaining the maximum defined output level.

The repeater has a defined maximum output level. If the input signal amplified by the gain set

exceeds the set output limit, an ALC (Automatic Level Control) loop is activated. This ALC ensures

that the amplifier does not add distortion to the radio signal. Below are examples of the ALC function

for one and two carriers.

1.3 Operating Temperature

The BSF-4004 is designed primarily for multi carrier purposes. If the repeater is run at full output

power over a long period of time, the convection cooling may not be enough. The repeater is

equipped with a power management function that steps down the power and, if needed, fully shuts

down the amplifier chains until temperature reaches normal values. In situations where a repeater will

be run in such a manner extra cooling can be provided by putting the repeater in a temperature

controlled environment or via external fans.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 3

Page 14

AXELL BSF-4004 BSF0038 SERIES REPEATER

Screws

Connectors

Lock

PRODUCT DESCRIPTION AND USE R’S MANUAL

1.4 Management WEB GUI

BSF-4004 is remotely commissioned and monitored via an OMU II session. Local access to the unit

is not required for commissioning.

Additional configuration and troubleshooting options are available via a direct connection to the

BSF-4004 IP address. A direct session can be opened locally or remotely.

Note: Direct remote communication requires connecting the BSF-4004 to an Ethernet network and

configuration of an IP address, or via GSM/GSM-R PSTN modem.

1.5 Interfaces

The BSF-4004 unit provides four types of interfaces:

• Lock and screws for protection and security

• External service antenna and GND connections

• Internal connections for power, fibre optics and alarm cables routed via openings in the front

panel.

• Internal USB/Ethernet connection for (optional) management and analysis via Web GUI

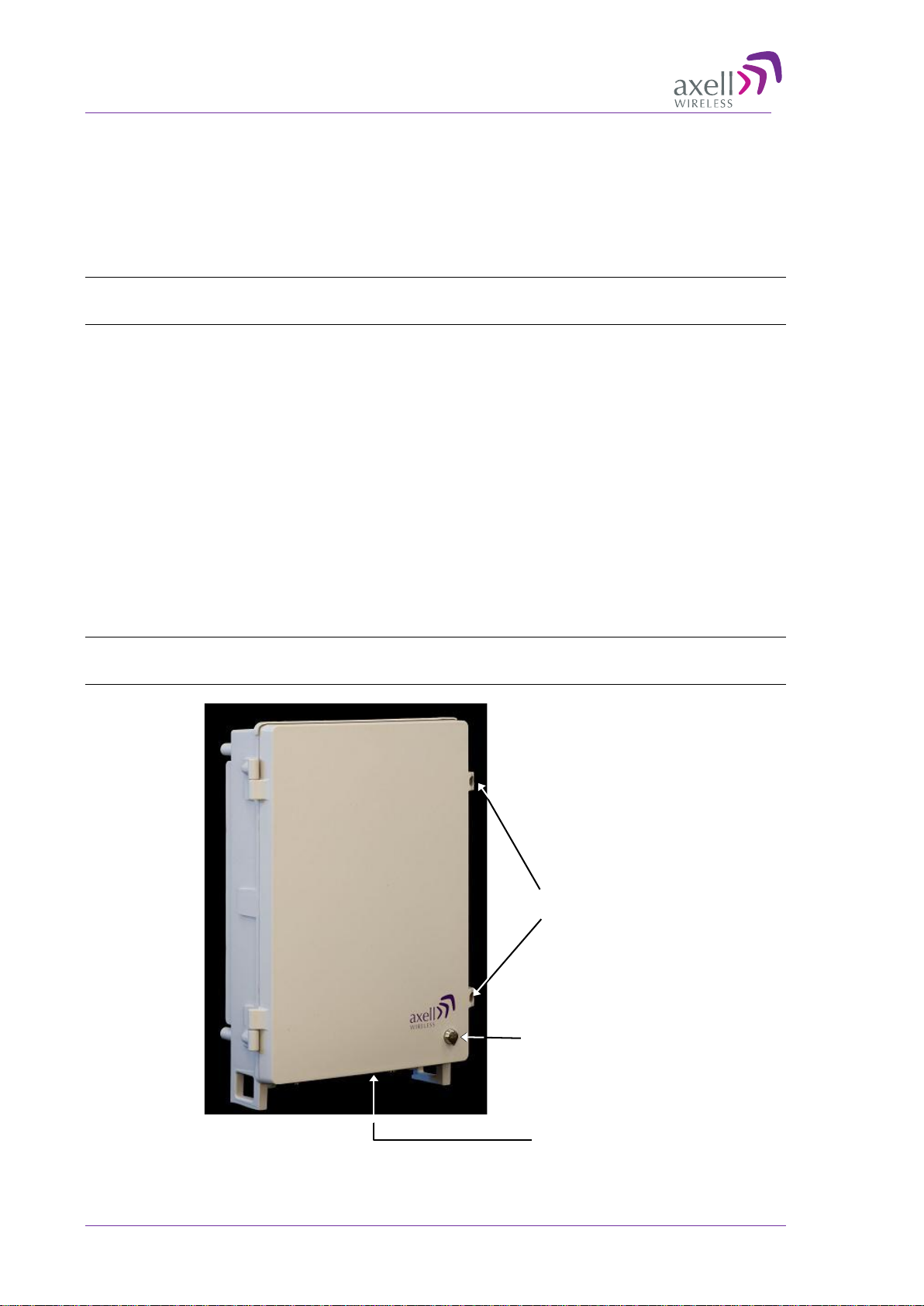

1.5.1 Securing the Unit

The repeaters are secured with two hex screws (M8) and can also be locked with a key.

Note: The two screws must be fully tightened. Failure to do so may affect the IP65 compliancy and

therefore any warranty.

Figure 1-2: Securing the Unit

4 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 15

AXELL BSF-4004 BSF0038 SERIES REPEATER

Power Fiber inputGround

Server

antenna

External

alarms

PRODUCT DESCRIPTION AND USE R’S MANUAL

1.5.2 External Interfaces

The repeater’s interfaces are located on the underside panel.

Note: The external connections at the bottom of the repeater can be protected by a cover which is

screwed in place.

The following table provides a description of the front panel ports and connections.

Port Description

Server Service antenna connection – N type connector, female

Optic SC/APC fibre optic connector through which the optic fibre is routed for

internal connections (section

Power

Alarms Plinth connector for routing external ala rms and relay wiring cable for

GND

Plinth connection for routing p ower for internal connection (section

internal connections (section

Grounding lug (sectio n

3.5).

3.7)

3.6).

3.3)

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 5

Page 16

AXELL BSF-4004 BSF0038 SERIES REPEATER

Controller module – USB/Ethernet

Rechargeable backup

Power and battery switches

PRODUCT DESCRIPTION AND USE R’S MANUAL

1.5.3 Internal Interfaces

This section shows the internal interfaces for the repeater. You will need to open the Repeater in

order to do the following:

• Connect power

• Connect optic fibres

• Connect alarms (if relevant)

• Power-on (Power-ON and Battery ON switches)

• Optional – USB/Ethernet port for local setup

battery pack, see 2.7.6

See section 2.7

local setup connections. Refer to

section

6.3.1 for LED descriptions

Figure 1-3: Single Band Repeater with Door Open

F/O Converter LEDs and optic

connector to which routed optic

fiber is connected (section 2.5)

Alarms and relay connections.

Refer to section 2.6 for

descriptions

Power connections

(section 2.7)

6 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 17

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

2 Antenna and Repeater Installation

Requirements

This chapter provides information on the Remote installation site requirements, on the installation

requirements of the antennas, the specifications of the service antennas suitable for operation with

this remote and RF and F/O cable requirements.

2.1 BSF-4004 Installatio n Requirements

2.1.1 Safety Guidelines

Before installing the Repeater, review the following safety information:

• Follow all local safety regulations when installing the Repeater.

• Only qualified personnel are authorized to install and maintain the Repeater.

• Ground the Repeater with the grounding bolt located on the external lower side of the Repeater.

• Do not use the grounding bolt to connect external devices.

• Follow Electro-Static Discharge (ESD) precautions.

• Use low loss cables to connect the antennas to the Repeate r.

Class 1 Laser

This product is equipped with class 1 lasers, as per definition in EN 60825-1.

Caution!!!

Un-terminated optical receptacles may emit laser radiation.

Do not stare into beam or view with optical instruments.

2.1.2 Criteria for Repeater Installation Location

The following criteria should be considered when selecting the Repeater installati o n site location:

• Application type

• General surroundings

• Available installation

• Install the Repeater in a shielded, ventilated, and easy-to-reach area.

• Verify that there is a minimum of a 50 cm (20”) radius of space around the Repeater, enabling

easy access to the repeater for maintenance and on-site inspection.

• Distance from antenna site - It is recommended that the installation location be as close as

possible to the antenna site in order to maintain the cable loss to a minimum.

• The Repeater is convection cooled so airflow and alternation should be possible.

• Follow Electro-Static Discharge (ESD) precautions.

• Install the Repeater close to the service area to monitor the output power.

• Use low loss cables to connect the antennas to the Repeate r.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 7

Page 18

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

2.1.3 RF Cable Installation Guidelines

Required:

• For all coaxial connections to/from the Repeater - high performance, flexible, low loss 50Ω

coaxial communications cable.

• All cables shall be weather-resistant type

• Cable length - determined by the Repeater installation plan. When calculating the cable length,

take into account excess cable slack so as not to limit the insertion paths.

.

2.1.4 F/O Cable Installation Gui del ines

Use the following over the complete link between the Remote and OMU:

• Use angled APC connectors at 8deg angle.

• APC type ODF connections.

• Cable length - determined by the Remote installation plan. When calculating the cable length,

take into account excess cable slack so as not to limit the insertion paths.

Recommended fibre-optic cable:

• Single mode 9/125

2.2 Service Antenna Requirements

WARNING!!!

a. The installer is held accountable for implementing the rules required for deployment.

b. Good engineering practice must be used to avoid interference.

c. Output power should be reduced to solve any IMD interference issues”

The Service antenna type depends on the design of the indoors DAS.

2.2.1 Required Antenna Information

The following antenna requirements, specifications and site considerations should be met:

• Type of installation – indoor DAS/Radiating Cable

• Service area type and size

• Antenna type and characteristics

• Height

• Length and type of coaxial cable required for connecting the antenna to the Repeater and the

attenuation.

8 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 19

AXELL BSF-4004 BSF0038 SERIES REPEATER

No. of Antennas

Cable Losses

Max Allowed Antenna Gain

4

3

39.1 - (37-6-3) = 11.1dBi

1

3

39.1- (37-0-3) = 5.1dBi

10

3

39.1- (37-10-3) = 15.1dBi

PRODUCT DESCRIPTION AND USE R’S MANUAL

2.2.2 Indoor Installations

2.2.2.1 Recommended Antennas

The following describes the requirements for an omni-directional mobile used for indoor

applications.

Specifications:

• One or a combination of the following antennas can be used: Ceiling Mount Patch antenna, Wall

Mount Patch antenna, Corner Reflector.

• Choose an antenna with high side lobe attenuation which enables maximum isolation from the

service/ mobile antenna.

Equation (1) - Max SERVICE antenna gain

Max SERVICE antenna gain (dBi) = 39.1 – (37dBm - # of antennas in dB – cable losses in dB).

For example:

Typical Antenna Types:

• Indoor Dome 2.1dBi beam width 360

• Indoor Panel 4.2dBi beam width 106

o

o

• Radiating Cable Typically < -50dBi

2.2.2.2 Recommended Splitters and Couplers

Axell Wireless can supply a comprehensive range of splitters and Couplers to aid the

installation of the internal DAS system. Typical specifications as below:

Splitter Part Numbers 90-851202 90-851203 90-851204

Frequency Band 300 - 500MHz

Split 2 way 3 way 4 way

Max Insertion Loss 0.3dB 0.5dB 0.4dB

Split Loss 3dB 4.8dB 6dB

Coupler Part Number 90-852306 90-852310 90-852315 90-852320

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 9

Frequency Band

Coupling -6dB ±1.0dB -10dB ±1.0dB -15dB ±1.0dB -20dB ±1.0dB

Max Mainline Loss 1.7dB 0.8dB 0.4dB 0.22dB

300 - 500MHz

Page 20

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

2.2.2.3 Installation Criteria

Determine the antenna installation configuration, according to the transmission

requirements and the installation site conditions.

Installation requirements:

• An indoor antenna should be installed at a convenient location. It should be free of metallic

obstruction.

Install the Service Antenna at the designated height and tune it roughly toward the Service coverage

area.

2.2.3 Service (Mobile) Antenna Install a ti on Cri teria

Determine the antenna installation configuration, according to the transmission requirements and the

installatio n site co nd it io n s .

Installation requirements:

• An indoor antenna should be installed at a convenient location. It should be free of metallic

obstruction.

• Install the Service Antenna at the designated height and tune it roughly toward the Service

coverage area.

• Installation of this antenna must provide a minimum separation distance of 49 cm from any

personnel within the area.

2.3 RF Cabling Requirements

• For all coaxial connections to/from the Repeater - high performance, flexible, low loss 50Ω

coaxial communications cable.

• All cables shall be weather-resistant type

• Cable length - determined by the Repeater installation plan. When calculating the cable length,

take into account excess cable slack so as not to limit the insertion paths.

• Make sure that cable and connector are compatible. Using cables and connectors from the same

manufacturer is helpful.

• All connectors must be clean and dry

• Waterproof all outdoor connections using silicone, vulcanizab le tape or other suitable substance

as moisture and dust can impair RF characteristics.

• Make sure enough room has been allocated for the bending radius of the cable. RF cables must

not be kinked, cut or damaged in any way

• Connect the RF cable to the antenna tightly but without damaging threads

• Fasten cables tight to cable ladder or aluminum sheet

• For short length of feeder cables use ½ “, for longer fe eder cab les use 7/8”. Chose thicker coax

cables for lower attenuation. Minimize the length of the coax cables to reduce the attenuation

• Use jumper cable for easy installation. The RF Coaxial cable can be substituted at each end with

a jumper cable.

.

10 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 21

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USER’S MANUAL

3 Installation

3.1 Unpacking

Inspect the shipped material before unpacking the equipment, document any visual damage and

report according to routines.

A delivery of a repeater from Axell Wireless contains:

• Checklist with delivered items

• Repeater

• Mounting brackets

• 4 bolts for attaching repeater to mounting kit

• Cable cover

• Keys to repeater and insex tool for bolts

• Hose for fibre inlet

• CD containing User’s Manual and RMC

• Any other specifically ordered item

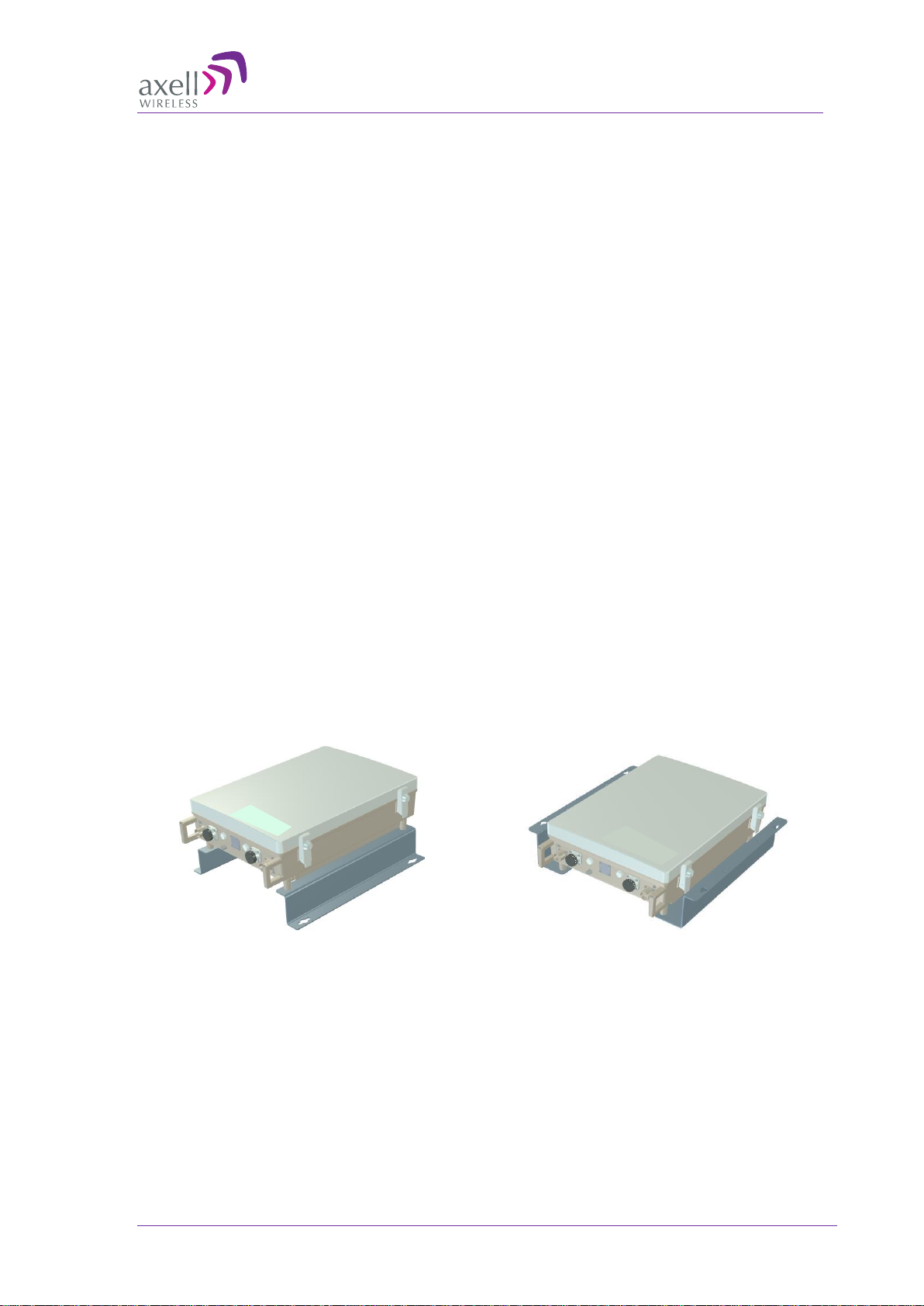

3.2 Mount the Repeater

You can mount the BSF-4004 Remote on a wall or in a 19” inch rack. The Repeater is delivered with

mounting brackets.

Mount the repeater in an accessible location and in a location that fulfils the environmental

requirements. Mounting must be tight to eliminate vibrat ion .

Figure 3-1: Mounting bracket position for wall

mounting

Figure 3-2: Mounting bracket position for rack

mounting

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 1

Page 22

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.2.1 Selecting a Location to Ensure Proper Cooling

• Mount the repeater so that heat can be dispersed from it.

• The repeater wall mounting kit ensures an optimum airflow between the wall and the repeater.

• Do not block this air channel as it will cause the MTBF of the repeater to drop dramatically, or

even in the worst case cause the repeater to fail completely.

• If possible, use a wall in the shade to minimize the overall sun loading. If sufficient shielding

cannot be obtained, an additional sun shield should be mounted.

Figure

3-3: Example of a sun shield

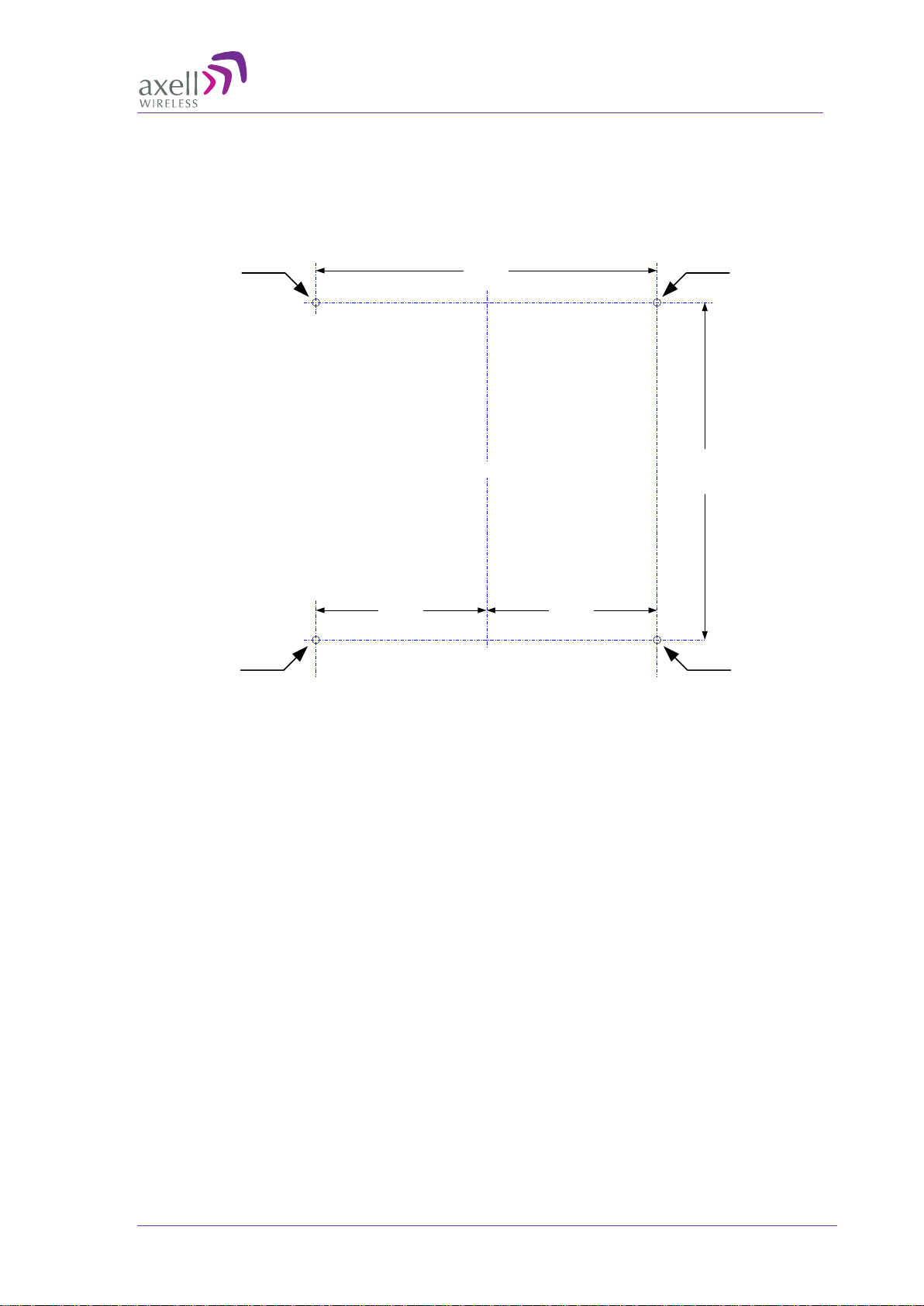

3.2.2 Wall-Mounting Preparation

Caution!! It is recommended that two people lift the repeater since (depending upon the

configuration) the BSF-4004 weighs approximately 28 kg.

• Wall compatibility - check the suitability of the wall on which the BSF-4004 is to be to be fitted.

• Plan mount - check the actual fixing centres (see below) and overall dimensions of the BSF-

4004 enclosure. The BSF-4004 is supplied with two wall mounting brackets; when the BSF4004 is mounted on these brackets adequate ventilation is provide d between the BSF -4004 and

the wall to which it is fix e d .

• Plan connection cable clearances - the Optical, RF and power connections located on the

underside of the BSF-4004 will need at least 300mm vertical clearance below the BSF-4004 to

enable the connections to be made. The minimum bend radius for Optical and RF cables must not

be less than the recommendations made by the cable manufacturer. Plan the cable runs and

ensure adequate space is available.

• Allow for door opening - ensure that there is sufficient space at the front of the BSF-4004 to

allow the door to be fully opened and for maintenance engineers to get access to the unit with test

equipment such as a spectrum analyzer. Allow an additional 500mm of space in front of the BSF3604 when the door is fully open.

2 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 23

AXELL BSF-4004 BSF0038 SERIES REPEATER

368mm

378mm

Hole to take

M6 rawl bolt

Hole to take

M6 rawl bolt

189

mm 189mm

Centre Line of MBF

Hole to take

M6 rawl bolt

Hole to take

M

6 rawl bolt

PRODUCT DESCRIPTION AND USE R’S MANUAL

• Fix bolts –f ix M6 Rawbolts or similar (50 to 75mm in length) into the wall at the dimensions as

illustrated in figure 1 below using equipment as specified by the fixing manufacturer. A

recommended method is set out below. Care must be taken to ensure the alignment of the four

fixings. A spirit level or plumb line should be used to ensure horizontal/vertical alignment.

Figure 3-4: Fixing Centres

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 3

Page 24

AXELL BSF-4004 BSF0038 SERIES REPEATER

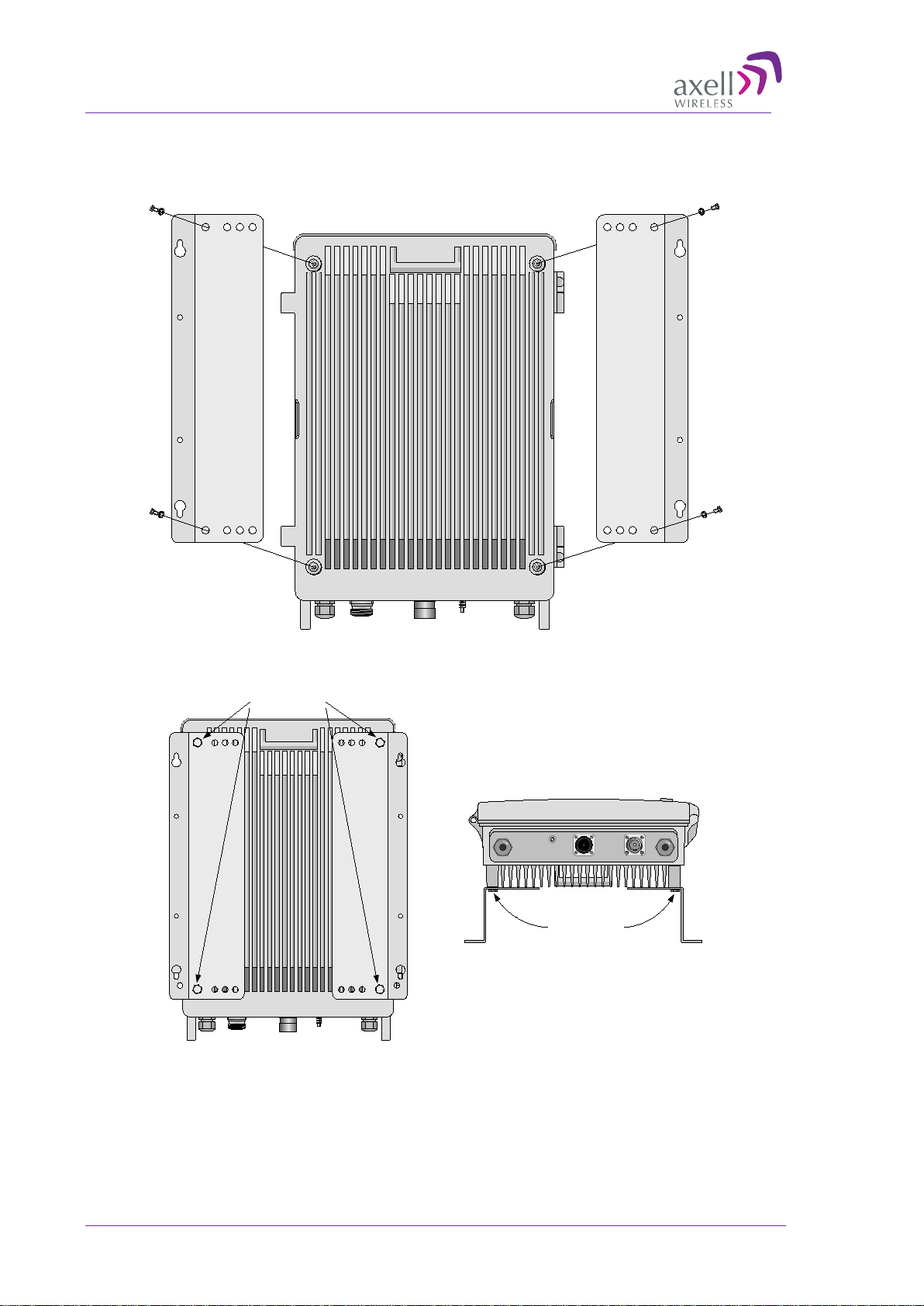

Fix mounting brackets to MBF with M8

fixing bolts and spring washers supplied

POWER GND OPTO

SERVER

ALARM

M8 fixing bolts

M8 fixing bolts

PRODUCT DESCRIPTION AND USE R’S MANUAL

Fix mounting brackets to BSF – use the supplied four M8 bolts and spring washers.

Figure 3-5: Fix mounting plates to BSF

Figure 3-6: Mounting Plates Fixed to BSF

4 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 25

AXELL BSF-4004 BSF0038 SERIES REPEATER

50 - 75mm

6mm dia.

Bolt head

Washer

Sleeve

/

Anchor

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.2.3 Mount the Repeater on the Wall

The Repeater wall mount brackets assembly should be fixed to a solid wall (these include brickwork,

blockwork, and concrete.);

(Due to the weight of the Repeater, it is NOT recommended to fix to a hollow wall).

Figure 3-7: M6 Rawlbolt – recommended for wallmount.

IMPORTANT!

Always check that there are no pipes or cables hidden in the wall beneath the area to be drilled.

Various pipe and cable detectors are available for this type of inspection.

To provi de secure fixing to a solid wall, the most common method is drilling and plugging. The size

of fixing is dependent on the item to be fixed and the nature of the wall, The Repeater should be fixed

with mild steel, M6 (50mm to 75mm) rawlbolts or similar.

1. Mark out the fixing centres of the repeater on the chosen wall (see

3.2.2).

2. Mark and drill the wall with the correct size masonry bit as specified by the fixing manufacturer.

Note: It is good practice to wear goggles to protect your eyes from flying debris when using power

tools.

3. Hold the drill bit against the mark and begin drilling slowly so that the bit does not wander from

the position. The wall should be drilled to a depth which is sufficient to accommodate the full

length of the fixing.

4. Insert the fixings so that the top of the sleeve/anchor section is level with the wall surface.

5. Gently tighten the bolt by hand so that the anchor section of the fixing expands and grips the

inside of the hole.

Figure

3-8: Inserting Fixing and Tightening.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 5

Page 26

AXELL BSF-4004 BSF0038 SERIES REPEATER

Align Repeater

PRODUCT DESCRIPTION AND USE R’S MANUAL

6. As the bolt pulls its way in, the sides of the anchor section are forced outwards, gripping the

surrounding surface.

Figure 3-9: Anchor Sides Pushed Outwards.

7. Once all four fixings are in place, carefully withdraw the four bolts.

Figure 3-10: Withdraw Bolts.

8. Align repeater with the four fixings. Great care should be exercised here as the repeater is very

heavy. Once repeater is held in the chosen position (a suitably rated heavy duty scissor lift

table/trolley may be suitable for this operation). Carefully insert the fixing bolts through the

mounting lugs of the Repeater and into the sleeve/anchor sections of the fixing in the wall and

tighten the bolts.

and Secure Bolts

Figure

3-11: Mount Repeater

6 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 27

AXELL BSF-4004 BSF0038 SERIES REPEATER

Ground

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.3 Grounding

Connect the grounding protection as follows:

• Ensure that good grounding protection measures are taken to create a reliable repeater site.

• Make sure to use adequately dimensioned grounding cables. The minimum recommended

conductive area for a grounding cable is 16mm

• Make sure the grounding product used is suitable for the kind and size of cable being used.

• Connect the repeater box bolt to the same ground.

Figure 3-12: Grounding the BSF-3604

2

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 7

Page 28

AXELL BSF-4004 BSF0038 SERIES REPEATER

Repeater

Fiber

BTS

-30dB

Coupler

OMU

Antenna

Primary

Protective

Device

Equipotential

Grounding Bar

230VAC/

-48VDC

Protective

Device

The top of

the mast

must be

higher than

the antennas

and be

grounded

properly

The

grounding

path must

have reliable

continuity

and be

dimensioned

correctly

BTS area

Repeater area

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.4 Ensure Good EMV Protection

CAUTION! If insufficient Electromagnetic Protection is provided, or if EMV measures are not

taken, warranties issued by Axell Wireless are not valid.

Connect the lightning protection

The lightning hazard to electric and electronic equipment consists in the interferences of direct

lightning current infections and high surge voltages induced by the electromagnetic field of nearby

lightning channels or down conductors. Amplitudes from cloud-to-earth lightning amounts to several

10kA and may last longer than 2ms. The damage caused depends on the energy involved and on the

sensitivity of the electronics systems.

Ensure that lightning protection measures are taken to create a reliable repeater site. Protect all

coaxial cables and power cables from the transients caused by lightning. Fit all cables with suitable

lightning protection devices.

For detailed information please refer to IEC 61024-1 and 61312-1 for international standards for

protection of information systems against LEMP (Lightning Electromagnetic Pulse), including radio

transmitters. They define proper planning, installation and inspection of effective lightning protection

Figure 3-13: Example of EMV protection for a repeater system

systems.

The Axell Wireless repeaters comply with the EN standard ETS 301 498-8 which stipulates demands

on lightning/surge protection for typical infrastructure telecom equipment installations.

Several lightning protection devices should be used in series with declining threshold voltages to help

attenuate the pulse component which makes it through the first layer of protection.

8 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 29

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

The primary protective device is part of the site installation and is not supplied by Axell Wireless.

Coaxial lightning protection is normally one of these three types: Gas capsule, High-pass and

Bandpass.

There also need to be a protective device installed on the power supply cord.

Figure 3-14: Protective device installed in connection with the power supply

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 9

Page 30

AXELL BSF-4004 BSF0038 SERIES REPEATER

Class 1 Laser

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.5 Fibre Optic Connection

This product is equipped with class 1 lasers, as per definition in EN 60825-1.

Caution!!!

Un-terminated optical receptacles may emit laser radiation.

Use the following over the complete link between the R epeat er and OMU :

• Use angled APC connectors at 8deg angle

• APC type ODF connections

• Mono-mode type fibre

Connecting the Fibre Optic Cable

1. Select type of optic fibre (Recommended fibre cable is single mode 9/125).

2. Run the fibre through a corrug ated sleev e (not supplied).

Do not stare into beam or view with optical instruments.

3. Insert the optic fibre hose fitter (may be pre-assembled) and route the fibre cable(s) via the F ibr e

input (see front panel interfaces in section

1.5.2).

10 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 31

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

4. Connect the fibre to the Fibre Optic Converter inside the repeater.

Note: Make sure the fibre is not bent too sharply inside the repeater as to avoid communication

disruptions.

5. Place the fibre in the rubber seal.

Note: The sleeve (not supplied), together with the rubber seal, meets the protection standard IP65.

6. Adjust the fibre length inside the repeater and insert the seal into the fibre input interface.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 11

Page 32

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

7. Attach the sleeve to the fibre optic inlet.

Note: Clean the fibre connector before connecting it to the system. See instruction in Appendix B F/O Cleaning Procedure.

12 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 33

AXELL BSF-4004 BSF0038 SERIES REPEATER

1 External alarm 1A

2 External alarm 1B

3 External alarm 2A

4 External alarm 2B

5 External alarm 3A

6 External alarm 3B

7 External alarm 4A

8 External alarm 4B

9 Alarm +15V

10 Alarm 0V

11 Relay Output 1A

12 Relay Output 1B

13 GND

14 NC

15 NC

16 NC

17 NC

18 NC

Pin # Signal

Pin 1

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.6 External Alarm and Relay Connections

The repeater is equipped with an external alarm interface card. The connector plinth for the external

alarms is located at the bottom of the repeater.

The strain relief fitting in is a Pg 13.5 suitable for a 6-12 mm cable diameter.

Connect the alarm cords to the plinth according to the pin layout below (in the standard version pins

14 – 18 are not used).

3.6.1 External Alarm

• Four external alarm sources can be connected to the repeater.

• Alarm operating voltage: between 12 and 24VDC.

• Alarm polarity can be configured:

• Active-low - when there is no voltage the alarm indicator will turn red

• Active-high - an applied voltage of between 12 and 24 V will cause the external alarm

indicator to turn red.

• The repeater can supply +15 VDC to an external alarm source through pin 9 and 10. The

maximum allowed load is 100mA.

3.6.2 Relay

• Relay (pin 11 and 12) can be connected to an external device to indicate an alarm.

• Can be configured to trigger on any number of internal and external alarms. The maximum

current that can be supplied is 100mA.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 13

Page 34

AXELL BSF-4004 BSF0038 SERIES REPEATER

115/230 VAC

Backup battery pack

Battery (BATT)

Power ON/Standby

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.7 Power and Backup Battery

Caution! Make sure the antenna cables or 50 ohm terminations are connected to the repeater’s

antenna connectors before the repeater is turned on.

Caution! Be sure a CIRCUIT BREAKER meeting the instructions given in this section is

connected near the unit at an easily reachable and accessible location fro m th e unit.

3.7.1 Circuit Breaker

The power connections to the unit are hard-wired. To disconnect the unit (either manually or

automatically in case of overcurrent), it is required to install a circuit breaker on the wall near the

unit, at an easily accessible distance and location from the unit.

Circuit-breaker minimum requirements

• 10AT, 250VAC

• Needs to be SAFETY approved

• Requires minimum contact separation of 3mm.

• Install on the wall near the unit

3.7.2 Power Connections

The image below shows the location of the various power elements. These are described in detail in

the following sections.

ON/OFF switch

Figure 3-15: Power Elements – Located Inside Repeater

switch

power

connections

14 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 35

AXELL BSF-4004 BSF0038 SERIES REPEATER

Connector

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.7.2.1 Backup Battery

• On the Power Supply unit a rechargeable battery pack in mounted. This part also includes

charging and supervision electronics.

• The backup battery will provide the Control Module and modem with enough capacity to send an

alarm in case of input power failure.

• The battery can be switched on and off. The switch is placed adjacent to the main power switch

on the power supply.

• At delivery the back-up battery is connected.

• The battery is replaced by lifting the battery pack out of the crate and disconnecting the cable.

Figure 3-16: Backup Battery

3.7.2.2 Connecting the Power Source

• Power Source: 230 VAC 50 Hz, 115 VAC 60 Hz or -48 VDC

• The -48VDC version of the power supply is designed to turn off if the supply voltage falls below

-36V (±1V). It will turn on again as the supply voltage reaches -43V (± 1V).

• The power supply has a switch which allows it to be set in “on” position or in “stand by”.

Notes:

1. In the stand by position the repeater is still connected to the power supply but not

operational.

2. On repeaters mounted in an extended box with two power supplies, both power supplies

needs to be switched on.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 15

Page 36

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.7.2.3 230 VAC Power Source

Connect the power cable to the plinth as show below:

• Phase linked to the brown cable

• Neutral linked to the blue

• Ground to the yellow/green. See illustration below.

Figure 3-17: 230 VAC Power Connections

3.7.2.4 115 VAC Power Source

Cable requirements:

• Cable should be NRTL (safety) approved with a minimum of 14AWG (2.5mm) per conductor.

• For safety, the GND cable must be 10mm longer than the Phase and Neutral cables.

Connect the power cable to the plinth as show below:

• Phase linked to the Black cable

• Neutral linked to the White

• Ground to the Green where for SAFETY, the GND cable must be 10mm longer than the Phase

and Neutral cables.

Figure 3-18: 115VAC Power Connections

16 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 37

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.7.2.5 -48V Power Source Connection

Note: The -48VDC version of the power supply is designed to turn off if the supply voltage falls below

-36V (±1V), not to drain the feeding battery. It will turn on again as the supply voltage reaches -43V

±

1V).

(

-48V power supply requirements

The 48VDC power supply must comply with SELV requirements, as defined in EN60950, which

implies double isolation. The output power needs to be 48VDC +25%/-15%. The maximu m input

current is 8A.

Connect the power cable to the plinth as show below:

• Phase linked to the Brown cable

• Neutral linked to the Blue

• Ground to the Green and Yellow. See illustration below.

Figure 3-19: -48VDC Power Connections

Recommended cable areas for 48VDC

Distance Cable Area

0 - 10 meters between repeater and

power supply

10 – 50 meters between repeater and

power supply

Over 50 meters between repeater

and power supply

2,5 mm²

4 mm²

Recommendation is to reconfigure the

installation, or to make special

arrangements to increase cable area

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 17

Page 38

AXELL BSF-4004 BSF0038 SERIES REPEATER

Main Power

Battery

PRODUCT DESCRIPTION AND USE R’S MANUAL

3.7.3 Power ON

3.7.3.1 Switching Power ON

Caution!!

Make sure the antenna cables or 50Ω te rm inati ons are conn ec ted to the repeat er ’s anten na conn ec to rs

before the repeater is turned on.

1. Switch on the Main Power Switch.

2. Switch on the Battery power.

Switch

Switch

Figure 3-20: BSF-3604 Power Module

Note: The power switches have two positions: “on” and “stand by”. In the stand by position the

repeater is still connected to the power supply but not operational.

3.7.3.2 Verifying LEDs

Verify the LEDs from the following modules are indicating correct operation (see section 6.4):

• Control module

• F/O converter

• Power supply modules

3.8 Closing and Securing the Repeater

Close lid, tighten the screws and lock repeater. Continue with the following section to setup the

repeater.

Note: The two screws must be fully tightened. Failure to do so may affect the IP65 compliancy and

therefore any warranty.

18 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 39

AXELL BSF-4004 BSF0038 SERIES REPEATER

USB cable

Ethernet cable

Connect to either the USB

PRODUCT DESCRIPTION AND USE R’S MANUAL

4 BSF-4004 Commissioning

After the repeater is connected, it is identified by the OMU II via the fibre connection and the unit is

commissioned from the OMU II. The commissioning process consists of a few simple steps.

To commission the BSF-4004 - overview:

1. Open an OMU II session – used to access the BSF-4004 configuration window (via OMU II).

2. Perform Optical Loss Adjustment.

3. Set the required RF attenuation and gain levels

4. Assign the unit a recognizable name (according to its location).

4.1 Open a Session to the BSF-4004 via the OMU II

1. Open a local or remote session to the host OMU II:

• Remote session – open a Browser session in the same subnet as the host OMU II and enter

the IP of the host OMU II (see OMU user manual for detailed procedure). Enter the OMU II

User Name (e.g. axell) and Password (provided by your system administrator).

• Local session– connect to the OMU II Control Module's USB or Ethernet ports. Enter the

OMU II User Name (e.g. axell) and Password (provided by your system administrator).

• After accessing an OMU II session, commission the BSF-3604 according to the following

section.

port or Ethernet port

Figure 4-1: Connection to OMU II

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 19

Page 40

AXELL BSF-4004 BSF0038 SERIES REPEATER

Click to access

OLA screen

OMUII Main

window

Rack#:Opto-

Module

Select nodes

for UL/DL

Adjustment

F-DAS

Remotes via

Optic Splitter

PRODUCT DESCRIPTION AND USE R’S MANUAL

4.2 BSF-4004 Optical Loss Adjustment (OLA)

BSF-4004 OLA is performed from the OMU II.

To perform BSF-4004 OLA (via OMU II)

1. From the OMU II main window, click the Opto Adjust button.

Figure 4-2: OMU II Main window

The OLA screen appears. The screen lists the OLA options (and status) for each link. (The links

are listed according to the OMU II slot to which the remote is connected.).

Figure 4-3. Configure and Initiate Optical Loss Adjustment

20 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 41

AXELL BSF-4004 BSF0038 SERIES REPEATER

Each Rack corresponds to an OMU unit whereas each Slot

PRODUCT DESCRIPTION AND USE R’S MANUAL

Column Description

Pos

corresponds to an Opto-Module. Slots are numbered according to their

position in the OMU Chassis (numbered left to right).

Select All Batch selection options:

- mark all remotes for UL opto-adjustment.

- mark all remotes for DL opto-adjustment.

- mark all remotes for DL and UL adjustment.

Node Node list number and identification (e.g. AHFK)

Status Displays an Error if process failed. If successful the pilot tone used

and the adjustment level will be displayed.

Resulting Attenuation Compensation level used for the opto-module (in dB).

9. Mark the check-boxes corresponding to the remotes (each connected to the designated Optomodule/Opto-Splitter) to which to perform the adjustment.

10. OLA (DL/UL) may be performed on each node individually (or a batch) or on all node s at once

by marking the checkbox next to the desired corresponding Opto-module and clicking Adjust.

To easily mark all checkboxes mark the checkbox named OLA.

NOTE: The process may take several minutes depending on the size of the system and remote

distance.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 21

Page 42

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

4.3 RF Balancing

The BSF-4004 RF Balancing procedure can be performed manually (the automatic option specified

in section

4.3.1 Manual RF Balancing

NOTE: If connected locally, enter the BSF-4004 Home screen and skip to step 2.

The manual balancing procedure consists of the following steps:

• Verifying the DL RF output level is maximized by setting the required DL attenuation of the

• Setting the UL attenuation according to the DL.

• In case of noise, adjusting the UL attenuation to reduce noise

To balance the BSF-4004 UL and DL outputs

1. Access the BSF-4004 Configuration window:

4.3.2 will be available in the future) via the OMU II web interface.

signal.

• Click on the Nodes button. The below pane appears

• Click Control next to the node to be balanced.

Figure 4-4: OMU II System Nodes window

2. The resulting pane can be displayed in two views:

• Basic – defau lt vie w (Basic button)

• Advanced – provides more information (Advanced button)

The dialog below shows an example of the Basic (default) view.

Note: The various elements monitoring options are described in detail in section 6.

22 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 43

AXELL BSF-4004 BSF0038 SERIES REPEATER

UL Attenuation

DL Attenuation

UL/DL bandwidth

Saturation

status

PRODUCT DESCRIPTION AND USE R’S MANUAL

Figure 4-5: Example of Partial view of BSF-3604 Configuration window

3. In the Downlink section:

• Verify the Amplifier is set to ON.

• Set Attenuation to maximum value (15dB).

• Lower the Attenuation level step by step until the desired Output power level is reached

(Zero attenuation = maximum gain).

• Verify the Amplifier Saturation is GREEN.

Figure 4-6: BSF-4004 Downlink Configuration Section

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 23

Page 44

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

4. In the Uplink:

• Verify the Amplifier is set to ON.

• Set UL Attenuation == DL Attenuation value.

Figure 4-7: BSF-4004 Uplink Configuration Section

5. If noise is detected, adjust only the uplink value.

4.3.2 Automatic BSF-4004 RF Balancing

NOTE: This feature will be available in future release.

To access the Automatic RF Adjustment pane

1. Access the OMU II Home window and click on RF Adjustment.

Figure 4-8: OMU II Main window

2. The following pane appears.

24 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 45

AXELL BSF-4004 BSF0038 SERIES REPEATER

Remote with

selected bands

to adjust

PRODUCT DESCRIPTION AND USE R’S MANUAL

3. Select the bands of each remote to be adjusted (e.g. 1900MHz band on Node #3)

4. Adjust the following for each band:

• Nominal Level (dBm)

• Uplink Delta (dB)

5. Click Adjust. The procedure may take several minutes depending on the number of units

selected.

4.4 Inte gration into the AEM

NOTE: All integration into the AEM is performed from the AEM side – no action is required from the

BSF-4004 side.

The AEM automatically connects to the repeater, downloads all the repeater parameters and statuses

into a database. When all parameters have been downloaded, the AEM configures the repeater with

the IP address where alarms and reports should be sent to, and optionally with a secondary IP address

where the repeater can connect to in case connect ion t o primary I P fails.

When heartbeat reports and alarms are sent from the repeater to the AEM also the latest information

about the status and RF-configuration is included. This means that the AEM operator always has

information about the current status in the AEM database (and do not need to call the repeater to find

this out).

NOTE: Once the repeater is integrated to the AEM, all changes to the repeater should preferably be

done from the Axell Element Manager in order to ensure that the database always contains correct

information.

4.5 What Next?

The BSF-4004 unit is now ready for operation. You may monitor the unit's general status via the

OMU II Home screen and if the node is faulty (red LED), access the Home screen in Advanced mode

for more detailed information.

Note: Consult the OMU II User Manual for additional information on RF and Optical adjustments.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 25

Page 46

AXELL BSF-4004 BSF0038 SERIES REPEATER

USB cable

Ethernet

PRODUCT DESCRIPTION AND USE R’S MANUAL

5 BSF-4004 Full GUI Description

This chapter provides a detailed description of the complete BSF-4004 Web GUI that is accessed

when a direct session is opened to the BSF-4004.

When an indirect session (via OMU II) is opened to the BSF-4004, only the BSF-4004 Main window

is available. The additional options are available when a direct session is opened to the BSF-4004

(not via OMU II).

This chapter describes how to open local and remote direct sessions to the Remote and the available

options when such a session is opened.

5.1 Opening a Direct Web Session

You may open a direct Web session to the BSF-4004 by connecting to the unit either:

A. Locally

B. Remotely via an Ethernet/modem connection – requires to unit to be connected to the

network.

5.1.1 Connecting Locally

NOTE: This connection requires downloading the USB driver from the provided setup disk (or

connection to the internet, where the driv er is autom a t ica lly loaded ).

To open a local session:

1. Open the BSF-4004 cover

• Connect to the USB/Ethernet port on the Controller module. If the USB driver is not

already installed on your laptop, the system will search for the driver on the provided

setup disk or on the internet (if a network connection is available).

• Run a browser and login according to the following section.

Figure 5-1: BSF-4004 Controller Module Connection

26 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Page 47

AXELL BSF-4004 BSF0038 SERIES REPEATER

PRODUCT DESCRIPTION AND USE R’S MANUAL

1. Open the web browser and type "axell-ne" in the address bar.

The Axell login dialog appears.

Figure

5-2: Login Screen

2. Use the following username and password to login:

• Username: axell

• Password: AxellPasswd

For backwards compatibility, you may also use:

• User Name: Avitec

• Password: AvitecPasswd

Note: It is highly recommended to change the default passwor d acco rdi ng to section 5.6.3.

The Web GUI Main Window appears. This is the same window is also viewed via the OMU II.

5.1.2 Remote Connection and Login

This type of Web session requires connecting the Repeater to the network and defining an IP address.

See section

To login:

• Open a standard Browser.

• Enter the IP address of the Repeater in the address bar.

• Enter the User Name and Password as described in the following section.

5.3.4.

© Axell Wireless Ltd Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 27

Page 48

AXELL BSF-4004 BSF0038 SERIES REPEATER

Menu options buttons

Home

screen

PRODUCT DESCRIPTION AND USE R’S MANUAL

5.2 Navigating the Web Interface

The Web GUI window provides access to the management options of the BSF-4004. Several tabs

(and sub-tabs) are available: Home, Nodes, Logs, etc., while the Home tab (illustrated below), is

displayed on login.

28 Doc. No. PN 4004 BSF0038 Series-UM Rev. 1.0 © Axell Wireless Ltd

Figure 5-3: BSF-4004 Home Screen

Page 49

AXELL BSF-4004 BSF0038 SERIES REPEATER

Provides a range of BSF-4004 configuration procedures such as

PRODUCT DESCRIPTION AND USE R’S MANUAL

5.2.1 Management Options Buttons

The following table briefly describes the main functions of each tab:

Tab Description

Provides a general status and alarm information. Switching to Advanced View will

toggle a more detailed view of each band and module. Section