Page 1

OMU

Optical Master Unit

© Axell Wireless Ltd

Page 2

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Optical Master Unit, OMU

Product Description and User’s Manual

This manual is valid for Firmware release version

Common Commands and Attributes v 1.3.0

OMU Commands and Attributes v 1.0.0

Copyright © 2009 Axell Wireless Ltd

All rights reserved.

No part of this document may be copied, distributed, tran smitted, trans cribed, stored i n a retrieval sy stem, or

translated into any human or computer language without the prior written permission of Axell Wireless Ltd.

The manufacturer has made every effort to ensure that the instructions contained in this document are

adequate and free of errors and omissions. The manufacturer will, if necessary, explain issues w hich may not

be covered by this document. The manufacturer's liability for any errors in the document is limited to the

correction of errors and the aforementioned advisory services.

This document has been prepared to be used by professional and properly trained personnel, and the

customer assumes full responsibility when usi ng them. The manufacturer welcomes customer comments as

part of the process of continual development and improvement of th e documentation i n the best way poss ible

from the user's viewpoint. Please submit your comments to the nearest Axell Wireless sales representative.

© Axell Wireless Ltd A1829300 rev H 1 (86)

Page 3

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Table of Contents

Safety Instructions and Warnings.................................................................................................. 4

References..................................................................................................................................... 5

Contact Information....................................................................................................................... 4

Definitions, Abbreviations and Acronyms ................................................................................... 7

1 Repeater Technology................................................................................................................ 10

1.1 Basic Repeater Features .................................................................................................... 10

1.2 Software Overview............................................................................................................ 10

2 Product and System Description..............................................................................................12

2.1 Overview........................................................................................................................... 12

2.2 Building Blocks................................................................................................................. 16

2.3 Block Diagram .................................................................................................................. 24

2.4 Back Panel......................................................................................................................... 25

2.5 Radio Signal and Data Communication Paths................................................................... 26

3 Monitoring and Control........................................................................................................... 27

3.1 Software Features - Overview........................................................................................... 27

3.2 Network Nodes.................................................................................................................. 28

3.3 Fibre Loss Compensation and Master Volume..................................................................30

3.4 Alarm System.................................................................................................................... 31

3.5 OMU Heartbeat................................................................................................................. 43

3.6 Hardware Identification..................................................................................................... 51

3.7 ID and TAG....................................................................................................................... 51

3.8 User Access....................................................................................................................... 52

3.9 Integration into AEM ........................................................................................................ 53

3.10 Upgrading Firmware ......................................................................................................... 53

4 Installation................................................................................................................................. 54

4.1 Unpack the OMU .............................................................................................................. 54

4.2 Mount the OMU................................................................................................................ 54

4.3 Ensure Proper Grounding.................................................................................................. 54

4.4 Attach Cabling................................................................................................................... 55

4.5 Start-up the OMU.............................................................................................................. 59

4.6 Initiate Local Communication........................................................................................... 61

4.7 Configure the OMU........................................................................................................... 62

4.8 Set Up OMU-Repeater System.......................................................................................... 63

4.9 Balance the System ........................................................................................................... 66

4.10 Initiate Fibre Loss Compensation...................................................................................... 68

4.11 Set up Remote Communication......................................................................................... 71

4.12 Integrate into the AEM...................................................................................................... 82

© Axell Wireless Ltd A1829300 rev H 2 (86)

Page 4

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

4.13 Installation Examples ........................................................................................................ 83

5 Maintenance.............................................................................................................................. 85

5.1 General.............................................................................................................................. 85

5.2 Preventive Maintenance.................................................................................................... 85

5.3 Product Disposal................................................................................................................ 85

6 Specifications............................................................................................................................. 86

© Axell Wireless Ltd A1829300 rev H 3 (86)

Page 5

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Safety Instructions and Warnings

Guarantees

All antennas must be installed with Lightning protection. Damage to power modules, as a result of lightning are

not covered by the warranty.

Switching on AC or DC power prior to the connection of antenna cables is regarded as faulty installation

procedure and therefore not covered by the Axell Wi rel ess warranty.

Safety to Personnel

Before installing or replacing any of the equipment, the entire manual should be read and understood. The user

needs to supply the appropriate AC or DC power to the OMU System. Incorrect power settings can damage the

OMU System and may cause injury to the user.

Throughout this manual, there are "Caution" warnings. "Caution" calls attention to a procedure or practice,

which, if ignored, may result in injury or damage to the system, system component or even the user. Do not

perform any procedure preceded by a "Caution" until the described conditions are fully understood and met.

Caution

This notice calls attention to a procedure or practice that, if ignored,

may result in personal injury or in damage to the system or system component.

Do not perform any procedure preceded by a "Caution" until described

conditions are fully understood and met.

Safety to Equipment

When installing, replacing or using this product, observe all safety precautions during handling and operation.

Failure to comply with the safety precautions and with specific precautions described elsewhere in this manual

violates the safety standards of the design, manufacture, and intended use of this product. Axell Wireless

assumes no liability for the customer's failure to comply with these precautions. This entire manual should be

read and understood before operating or mainta ini n g the O M U Syst em.

Class 1 Laser

This product is equipped with class 1 lasers, as per definition in EN 60825-1.

Caution

Un-terminated optical receptacles may

emit laser radiation. Do not stare into beam

or view with optical instruments.

Optical transmitters in the opto module can emit high energy invisible laser radiation. There is a risk for

permanent damage to the eye.

Always use protective cover on all cables and connectors which are not connected. Never look straight into a

fibre cable or a connector. Consider that a fibre can carry transmission in both directions.

During handling of laser cables or connections ensure that the source is switched off. Regard all open

connectors with respect and direct them in a safe direction and never towards a reflecting surface. Reflected

laser radiation should be regarded as equally hazardous as direct radiation.

© Axell Wireless Ltd A1829300 rev H 4 (86)

Page 6

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Electrostatic Sensitivity

Observe electrostatic precautionary procedures.

Caution

ESD = Electrostatic Discharge Sensitive Device

Semiconductor transmitters and receivers provide highly reliable performance when operated in conformity

with their intended design. However, a semiconductor may be damaged by an electrostatic charge inadvertently

imposed by careless handling.

Static electricity can be conducted to the semiconductor chip from the centre pin of the RF input connector, and

through the AC connector pins. When unpacking and otherwise handling the OMU, follow ESD precautionary

procedures including use of grounded wrist straps, grounded workbench surfaces, and grounded floor mats.

© Axell Wireless Ltd A1829300 rev H 5 (86)

Page 7

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

References

References to standards apply as relevant to the repeater type being connected to the OMU. Please see

respective repeater manual for details.

© Axell Wireless Ltd A1829300 rev H 6 (86)

Page 8

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Contact Information

Headquarters Axell Wireless

Aerial House

Asheridge Road

Chesham

Buckinghamshire HP5 2QD

United Kingdom

Tel: +44 1494 777000

Fax: +44 1494 777002

Commercial inquiries

Web site

Support issues

Technical Support Line, English speaking +44 1494 777 777

Contact information for Axell Wireless offices in other countries can be found on our web site,

www.axellwireless.com

info@axellwireless.com

www.axellwireless.com

support@axellwireless.com

© Axell Wireless Ltd A1829300 rev H 7 (86)

Page 9

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Definitions, Abbreviations and Acronyms

AEM Axell Element Manager

A software tool for operation and monitoring a network consisting of Axell Wireless

elements such as OMUs and repeaters.

ALC Automatic Limit Control

BCCH Broadcast Control Channel

BTS Base Transceiver Station, one part of a base station.

A base station is composed of two parts, a Base Transceiver Station (BTS) and a Base

Station Controller (BSC). A base station is often referred to as BTS.

The BTS is also sometimes called an RBS or Remote Base Station.

Channel In all Axell Wireless documentation a channel is the same as a carrier.

Channel

Selective

Repeater

DL Downlink, RF signals transmitted from base stations to mobile radio equipment

EMC Electromagnetic Compatibility

GND Ground

LED Light Emitting Diode

LMT Local Maintenance Terminal

LNA Low Noise Amplifier

MS Mobile Station (e.g. mobile phone)

MTBF Meantime Between Failures

NA Not Applicable

NC Not Connected

NF Noise Figure

NMS Network Management System

A repeater that operate on a specified channel within the operating band of the

repeater.

The ability of a device or system to function in its intended electromagnetic

environment

Node In this manual a node is the OMU or a rep eater

ODF Optical Distribution Frame, used for connection and patching of optical cables

OMC Operations and Main tenance Center

PSTN Public Service Telephone Network

Repeater

RF Radio Frequency, 9 kHz – 300 GHz

© Axell Wireless Ltd A1829300 rev H 8 (86)

A bi-directional Radio Frequency (RF) amplifier that can amplify and transmit a

received Mobile Station (MS) signal in the MS transmit band. Simultaneously it

amplifies and transmits a received Base Transceiver Station (BTS) RF signal in the

BTS transmit band.

Page 10

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

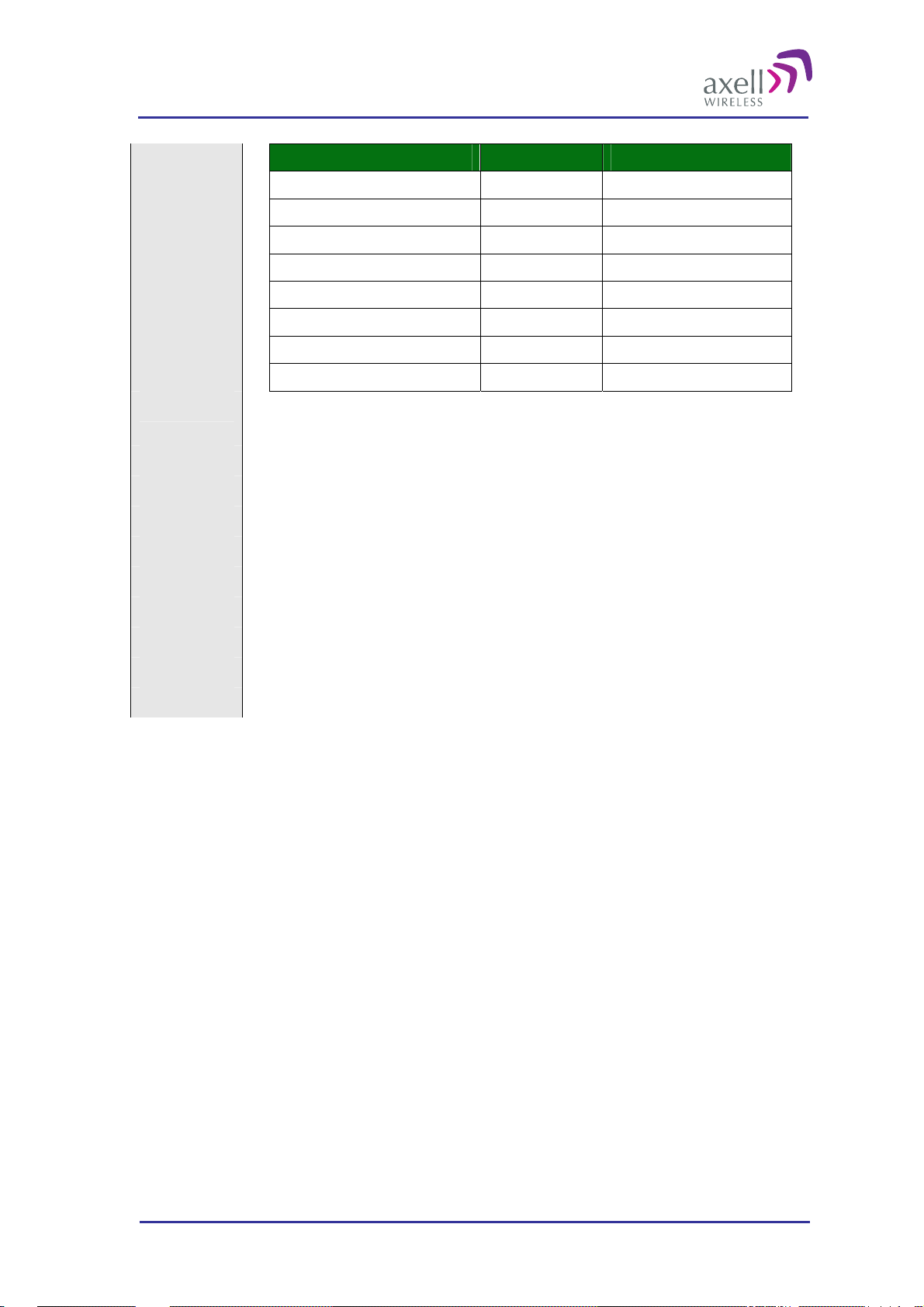

Designation Abbreviation Frequencies

Very Low Frequency VLF 9 kHz - 30 kHz

Low Frequency LF 30 kHz - 300 kHz

Medium Frequency MF 300 kHz - 3 MHz

High Frequency HF 3 MHz - 30 MHz

Very High Frequency VHF 30 MHz - 300 MHz

Ultra High Frequency UHF 300 MHz - 3 GHz

Super High Frequency SHF 3 GHz - 30 GHz

Extremely High Frequency EHF 30 GHz - 300 GHz

RMC Repeater Maintenance Console

Software tool to monitor and control Axell Wireless repeaters.

RS232 Serial interface standard

RS485 Serial Interface standard

SIM Subscriber Iden tity Module

SMS Short Messaging Service

SMSC Short Messaging Service Center

SW Software

UE User Equipment

UL Uplink, RF signals transmitted from mobile radio equipment to a base station

WDM Wavelength Division Multiplexing

© Axell Wireless Ltd A1829300 rev H 9 (86)

Page 11

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

1 Repeater Technology

1.1 Basic Repeater Features

A basic feature of a mobile communication system is to transmit RF signals between base stations and mobile

radio equipment.

When there is a blocking object, such as a mountain or a building, preventing the base station signal to reach the

mobile equipment, a repeater can be used to extend the base station’s coverage area.

In the downlink path (from the base station to the mobile phone) the repeater picks up the signal in the air via a

donor antenna, amplifies it and re-transmits it into the desired coverage area via a server antenna. In the uplink

path (from the mobile phone to the base station) the repeater receives the signals from mobile transmitters in the

covered area and re-transmits them back to the base station.

Donor antenna

BTS

Undisturbed transmission Obstacle creating a coverage hole

A repeater can work off-air, as the repeater in the example above, or be fe d ove r fibre from an optical master

unit, OMU. The OMU taps the signal directly off a base station via a coupler, converts it to light and transmits

it to a number of repeaters via fibre.

MS MS

BTS

Server antenna

Repeater

1.2 Software Overview

There are three types of software products; dedicat ed firmware for each Axell Wireless repeater or OMU,

Repeater Maintenance Console (RMC) and Axell Element Manager (AEM).

1.2.1 Firmware

The firmware is the software inside the Control Module of the repeater or OMU. It is command line based, with

simple SET and GET commands. A rich variety of commands is available to control and monitor all subsystems

of the repeater from a normal VT100 terminal emulation program, such as HyperTerminal™. This also means

that any standard laptop is able to control a repeater without additional software installed.

The firmware has three main tasks:

Set and configure parameters in the repeater, such as channel numbers, gain, power levels, and different

report configurations

Monitor and measure alarm sources, alarm parameters and repeater utilization

Send reports and alarms to the repeater OMC

Communication with the repeater or OMU can be performed either locally or remotely via a modem or

Ethernet.

© Axell Wireless Ltd A1829300 rev H 10 (86)

Page 12

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

1.2.2 The RMC, Repeater Maintenance Console

RMC is an online software program with an intuitive graphical interface that simplifies control and installation

of the repeater or OMU. The RMC is a graphical shell for the repeater’s Control Module. It reads commands

and attributes from the Control Module and displays them in an intuitive layout. This eliminates the need to

learn commands and attributes for controlling the repeater or OMU.

Login can be made locally via the LMT port or remotely via a modem or via Ethernet. As soon as the RMC is

connected it constantly polls the repeater or OMU for parameters such as power supply levels, in and out levels,

temperature, traffic, etc. If the repeater is a slave type re peater, t he OMU ma nage s the data collection from the

repeater.

The RMC program can be installed from a CD. It is a Windows based application that runs on Windows 2000

and Windows XP.

1.2.3 The AEM, Axell Element Manager

AEM is a complete operations and maintenance centre for Axell Wireless repeater networks.

The AEM takes control of the repeater – or the OMU-Repeater system - once the installation at site is

completed. The repeater gets integrated into the network and will be controlled by the Element Manager.

During integration all repeater parameters and statuses are downloaded into a database. The database is

regularly updated with all incoming alarms and reports, and will hence contain a copy of the repeater

configuration so that current repeater information will be accessible without setting up communication with the

repeaters.

Communication between the AEM and the repeaters are message based. This m eans tha t the operator does not

have to await message delivery, but will be informed when the message is delivered to the repeater

The Axell Element Manager is a Windows™ based application that runs on Windows 2000, Windows 2003

Server and Windows XP.

For more information please refer to the separate AEM User’s Manual.

© Axell Wireless Ltd A1829300 rev H 11 (86)

Page 13

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2 Product and System Description

2.1 Overview

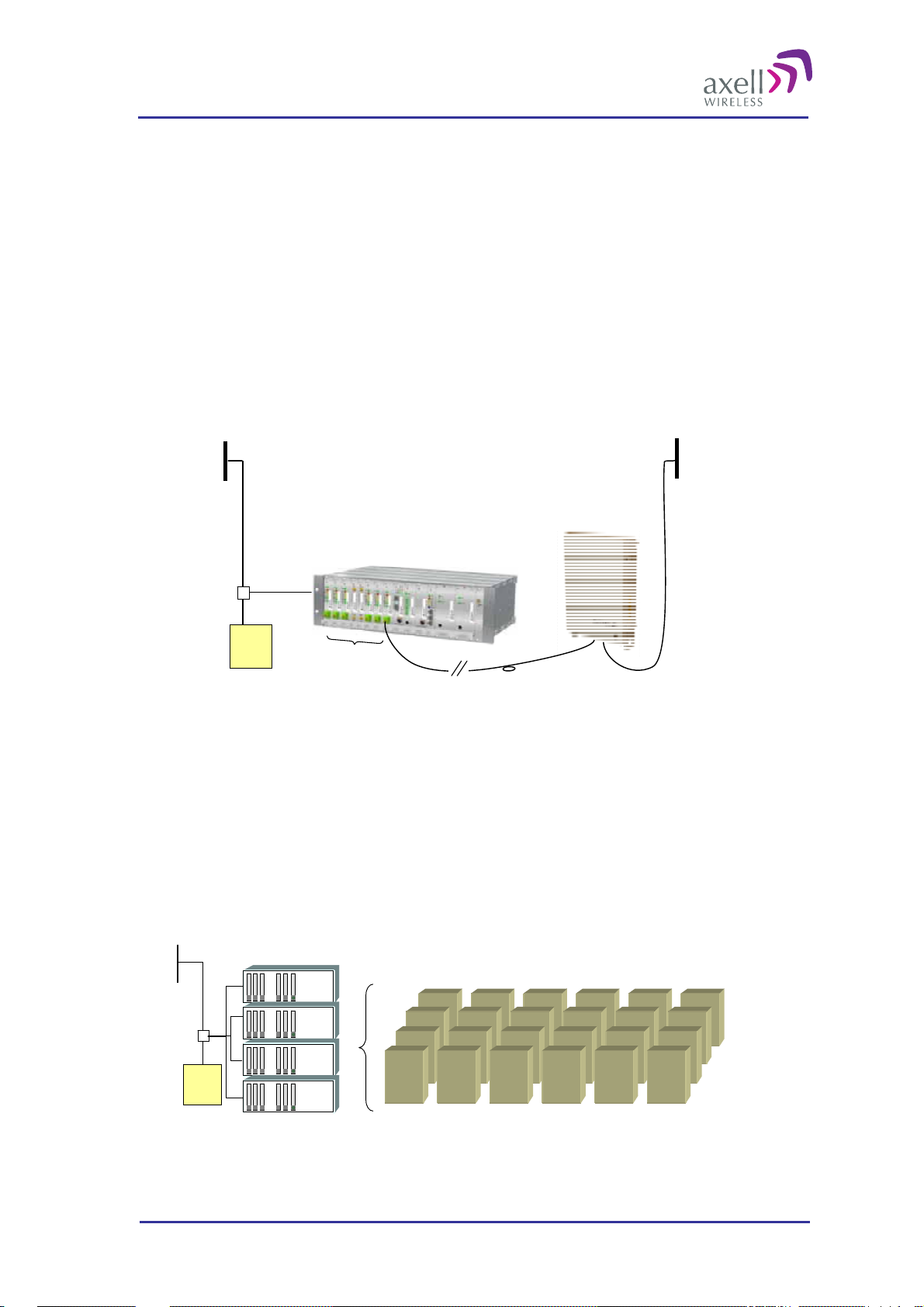

The Axell Wireless OMU is a product used in combination with fibre fed repeaters. An OMU can be equipped

to be used for frequency ranges from 88MHz to 2 170MHz.

An OMU’s basic function is to translate RF signals to light to be sent over an optical fibre, and vice versa.

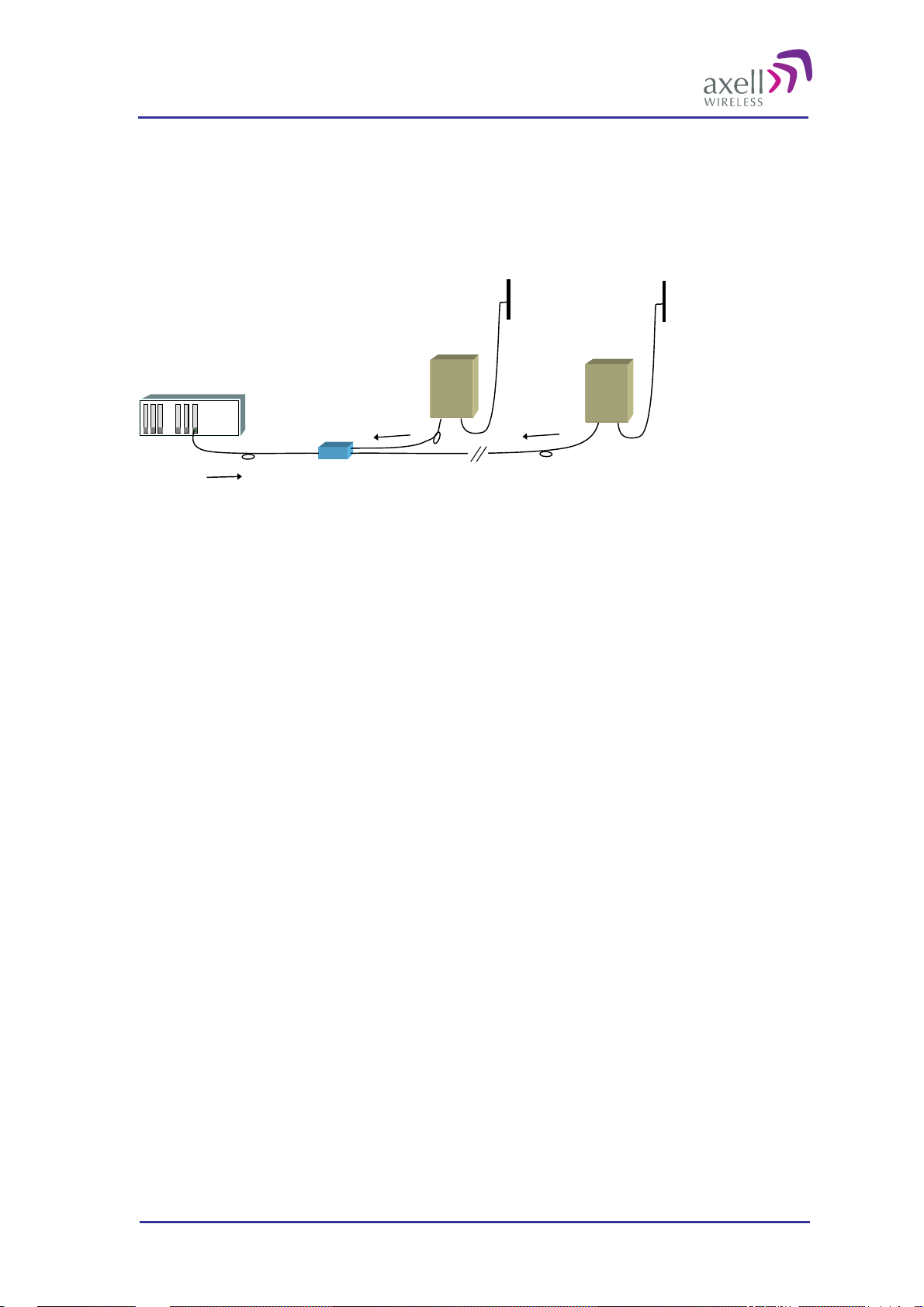

In the downlink direction the OMU picks up the signal from the base station via an RF coupler system,

converts it into an analogue optical signal and transfers it over a fibre optical cable to the repeater were it is

translated back to RF and sent out via an antenna. An OMU can also be connected to a repeater. In that

case the signal is tapped from the repeater’s server antenna.

In the uplink direction the OMU receives the signal from the repeater via the fibre optical cable, converts it

to an RF signal and sends it back to the base station.

Server

Antenna

Repeater

OMU

Directional

Coupler

BTS

An OMU-Repeater system consists of one or more Optical Master Units, OMUs and one or several fibre fed

repeaters. An OMU-Repeater system can be expanded to handle up to 24 repeaters, and cover a distance of to

up to 20 km of fibre between the OMU and the most distant repeater.

Each OMU can be equipped with up to 6 fibre optic converters. If more than 6 repeaters are needed in the

network there are two ways of expanding the system: link several OMUs together or use laser systems with

three or four colors.

Up to 4 OMUs can be cascaded and operate up to 24 repeaters as one system. When OMUs are cascaded

only one is equipped with a Control Module. This OMU is called an OMU Master and the other three

OMU slaves. The OMU Master manages the OMU slaves as well as the connected repeaters.

RF

FiberOptic

Converters

Opto Fiber

RF

BTS

RepeatersOMU Units

Four OMUs cascaded in one system

© Axell Wireless Ltd A1829300 rev H 12 (86)

Page 14

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

A laser system with two colors can operate one repeater for each fibre optic converter in a OMU-Repeater

system – one color is used for the uplink and one for the downlink. A laser system with three or more

colors can operate two or more repeaters per fibre optic converter. One color is used for the downlink

which is the same for all repeaters, and in the uplink each repeater has its own color.

The connection from one repeater to the next is done via so called add-drop couplers. The difference in

distance between the repeaters and the OMU can be compensated for automatically.

OMU

1310

Add-drop

Coupler

Slave 1

1550

Slave 2

1510

Two repeaters are connected to the same converter in the OMU via the same fibre but the wavelength for the

uplink differs between the units. Slave 1: 1550 ± 3 nm, Slave 2: 1510 ± 3 nm. The downlink signal is the same

for both repeaters.

© Axell Wireless Ltd A1829300 rev H 13 (86)

Page 15

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.1.1 Access to the System

Important Generic Information

Axell Wireless repeaters and OMUs can be configured in three different ways as regards communication

and control. They can be “stand-alone units”, “node masters” or “slaves”.

Stand-alone units do not control any other unit or take control from any other unit. All communication

with a stand-alone unit needs to be made directly with the unit – either locally or remotely via a modem or

Ethernet. Most stand-alone units are equipped with Ethernet and/or a modem for this purpose.

Node Masters keep track of the slaves that are connected to it. It is the single point of contact for alarm

reports and for heart beats in the entire system, and communicates with the AEM. All configuration and

control of all units in the network go through this Node Master. Most Node Masters are equipped with

Ethernet and/or a modem for this purpose.

Slaves are linked to a Node Master and contain a slave interface allowing for a Node Master to

communicate with the slave.

An OMU-Repeater system can be designed using repeaters that operate as slaves to the OMU or as stand alone

units regarding communication, configuration, alarms etc. Either all communication is handled by the OMU

that acts as a node master and the repeaters are slaves, or each repeater (and the OMU) handles this

communications and reporting separately.

The most common configuration is the master-slave set up which has several advantages:

All nodes can be reached from any node in the system. An operator can log in from any node in the system

and access all parameters in all nodes, including those in the OMU

Only one modem is needed for remote communication and configuration of the whole system

Since the communication runs on the same fibre as the RF, this arrangement gives a reliable supervision of

the radio link. If communication between the OMU and a repeater is broken, an alarm can be generated

immediately.

Several users at a time can be logged on to the system, for instance one locally via the RS232 interface and one

remotely via modem or Etthernet. Only one user at a time can be logged in remotely.

1

Note! If the network has an OMU from an earlier generation

accessed via a local login to a slave repeater.

, there are some limitations of what can be

2.1.1.1 Local Access

Local access is achieved via an RS232 interface to the LMT port in the repeater or the OMU. This port is

accessible on the front of the OMU and inside the repeater.

2.1.1.2 Remote Access

Remote access is achieved via modem or Ethernet. Different types of modems are supported, for example

GSM, GSM-R, HSDPA/UMTS, TETRA, GPRS and PSTN.

The modem is either placed on the Control Module or as a separate unit. When cascaded OMUs are used, the

modem is placed in the OMU unit that holds the Control Module. Ethernet connection is available on the

Control Module.

1

The earlier versions of the OMU where called HUBs.

© Axell Wireless Ltd A1829300 rev H 14 (86)

Page 16

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.1.2 SW for Configuration and Control

There are two SW tools for configuration and control of the Axell Wireless OMU-Repeater system. The RMC,

Repeater Maintenance Consol and the AEM, Axell Wireless Element Manger.

The RMC is an on-line tool that can be used locally or remotely for configuration and monitoring of all

parameters in the system. It is installed on a lap-top computer and holds pre-configured screens for each

repeater type or OMU that shows the parameters live in a user-friendly manner. All parameters can be

accessed and changed on-line. In the RMC there is also a terminal mode that allows for command based

communication.

The AEM is a tool for monitoring and control of a whole network. Data from the network elements are

collected at regular intervals and alarm information are sent to the AEM as they occur. All data are stored

in a data base and can be presented in maps, reports and diagrams.

OMU

GSM, PSTN or TCP/IP

data connection

Modem

AEM or RMC for remote monitoring via modem or Ethernet

Repeaters

RMC for local access

© Axell Wireless Ltd A1829300 rev H 15 (86)

Page 17

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2 Building Blocks

The OMU is built in a 19” sub rack.

Modem Status

Modem Power

Status

PWR

Login

PWR

PWR

ERR

ERR

UL

UL

DATA

DATA

DL

DL

DATA

DATA

.

.

.

.

.

.

.

.

.

.

Ethernet

LinkOK

IN

IN

OUT 1

OUT 1

OUT 2

OUT 2

LMT Port

.

.

.

.

.

.

.

.

On

Off

Out OK

In OK

On

Off

Out OK

In OK

On

Off

Modem

ANT

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

PWR

PWR

ERR

ERR

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

PWR

PWR

ERR

ERR

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

PWR

PWR

ERR

ERR

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

UL in

RF out

DL out

RF in

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

PWR

PWR

ERR

ERR

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

PWR

PWR

ERR

ERR

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

DATA

DATA

DATA

DATA

OPTO

OPTO

OPTO

OPTO

PWR

PWR

ERR

ERR

UL

UL

DL

DL

Rx

Rx

Tx

Tx

SC/APC

SC/APC

PWRPWR

Battery

Power

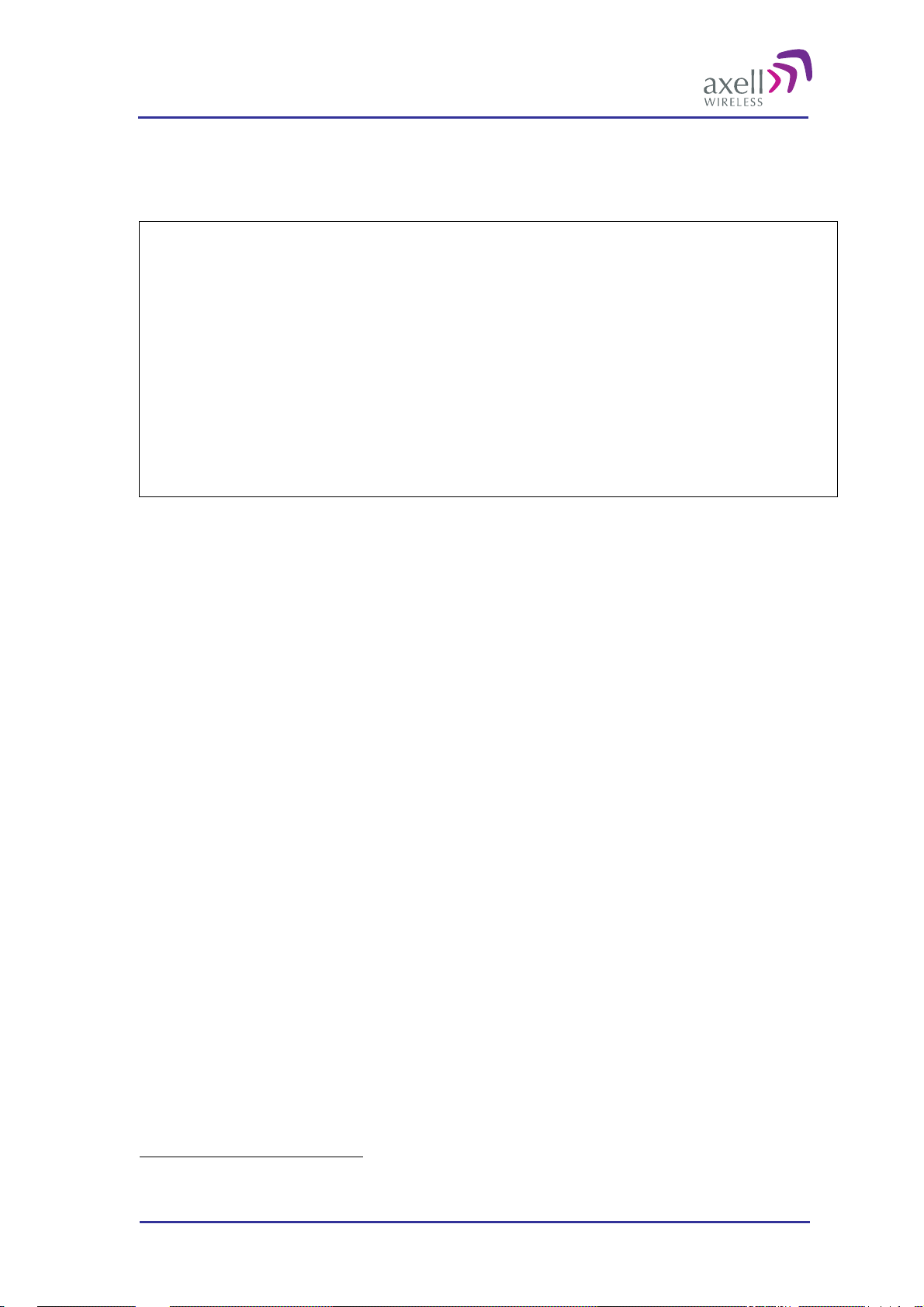

21 1 543 6 7 8

An OMU unit can contain the following modules:

1. Fibre Optic Converters (1 to 6 pcs can be installed)

2. Uplink (UL) Combiner and Downlink (DL) Splitter. These modules are always installed.

3. Modem Unit. This module is optional. This unit is used for modems that are not mounted on the Control

Module

4. External Alarm and Battery Module. This module is optional. This module is only used for Master OMUs

5. Control Module. This module is only used for Master OMUs

6. Rack Communication Board. This module is always installed.

7. Power Supply A and B (B is optional)

8. Modem Antenna Connection. This module is optional. This is used for OMUs with wireless modems

installed that need a separate antenna. This module can also be equipped with two connectors. For details,

see section

2.2.8 Modem Antenna Connection

In the next sections all modules are described in detail.

© Axell Wireless Ltd A1829300 rev H 16 (86)

Page 18

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

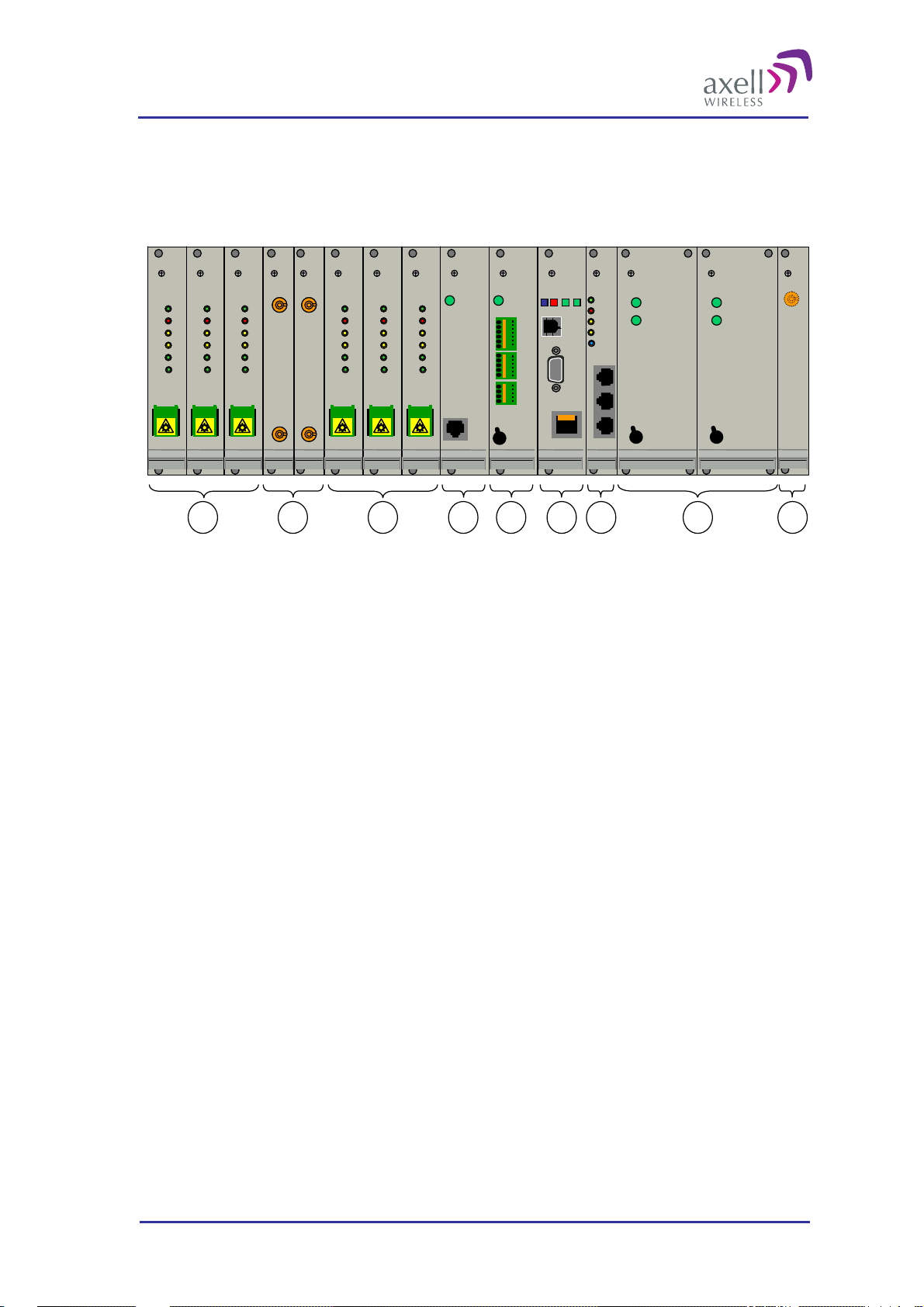

2.2.1 Fibre Optic Converter

The Fibre Optic Converters are placed in slots 1, 2, 3 and 6, 7, 8.

A Fibre Optic Converter translates back and forth between RF and optical signals. The optical signals are

analogue. Each module contains both an optical receiver and a transmitter. The optical signals for downlink and

uplink are combined utilizing WDM technology (Wavelength Division Multiplexing). Hence only one fibre is

necessary for the transmission to and from the repeater.

Each Fibre Optic Converter in the OMU works in parallel with a corresponding unit in the repeater which is

linked via the fiber. A pilot tone can be sent between the Fibre Optic Converters in the OMU and the repeater to

define the loss in the fibre. Based on this information the repeater automatically adjusts the attenuation to

compensate for the fibre loss.

On the Fibre Optic Converter module there are six LED indicators; one for power status, one for error, two for

the data communication and two for the RF signals.

PWR Indicates that the power is on

ERR

DATA

DATA

OPTO

OPTO

PWR

UL

DL

Rx

Tx

ERR Indicates that there is something wrong in the module

UL DATA Ongoing communication in the uplink direct io n

DL DATA Ongoing communication in the downlink direction

OPTO Rx Received signal on fiber channel

OPTO Tx Transmitted signal on fiber channel

SC/APC

Fiber link connection

UL DATA and DL DATA reflect the ongoing data communication

OPTO Rx reflects received RF signal

OPTO Tx reflects transmitted RF signal

The fibre connector is SC/APC. The connector house is SC, the connector type is APC.

Note!

Angled connectors, APC, need to be used throughout the whole link between

the OMU and the repeater. The angle needs to be 8 degrees.

Also the ODF connections need to be APC type.

The fibre must be monomode type.

Caution

Un-terminated optical receptacles may

emit laser radiation. Do not stare into beam

or view with optical instruments.

© Axell Wireless Ltd A1829300 rev H 17 (86)

Page 19

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2.2 UL Combiner and DL Splitter2

The UL Combiner and DL Splitters are placed in slots 4 and 5.

These two modules contain the combiners and splitters that combine and distribute the RF signals between the

OMU’s RF port and the Fibre Optic Converters. They also contain attenuators that are used for setting the

master signal levels in the downlink and uplink.

Via these modules the RF in/out can be connected on the front of the OMU instead of the back, if needed.

The connectors are QMA type.

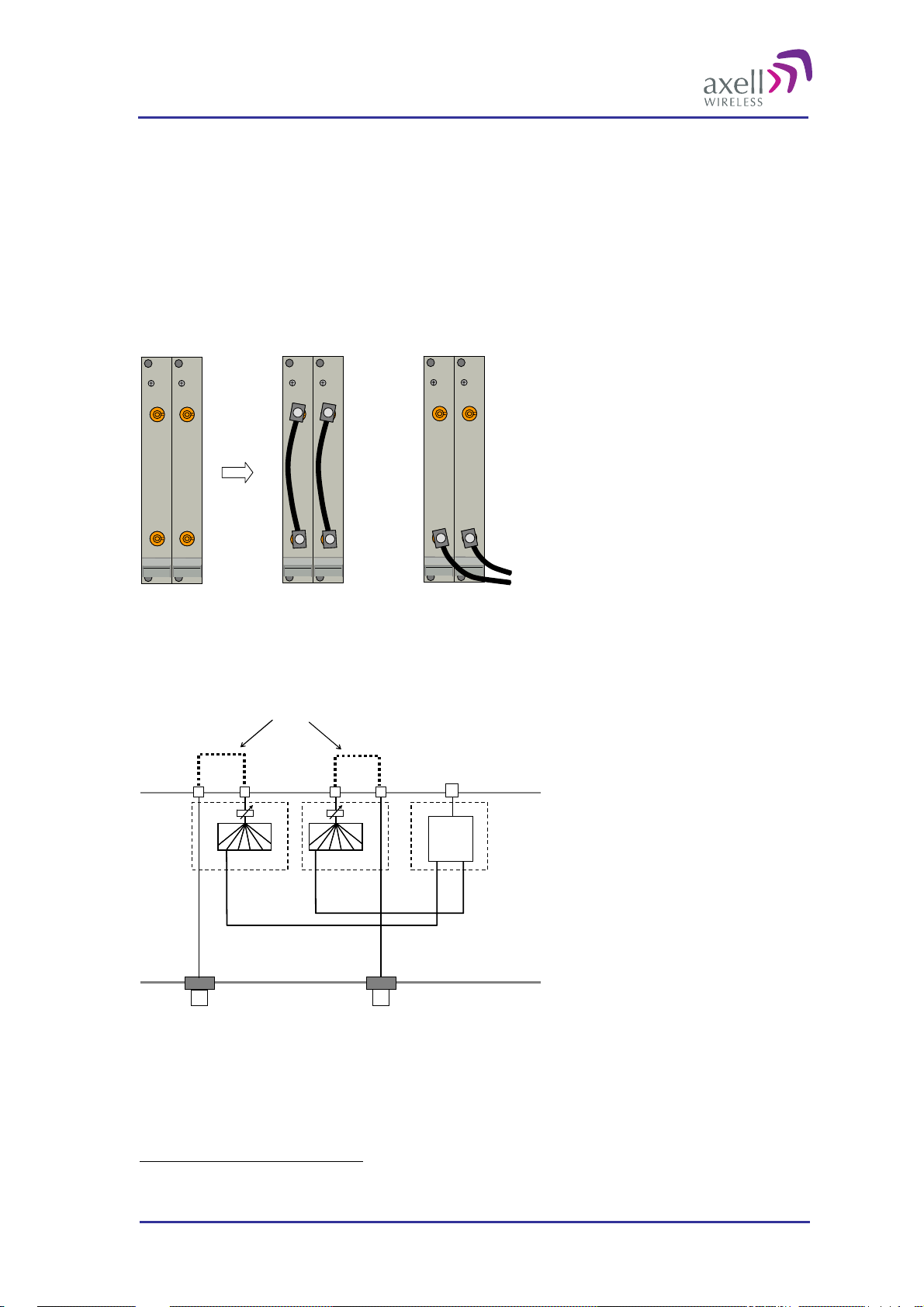

The modules can to be configured in two ways as shown in the illustration below.

DL out

UL in

DL out

UL in

DL out

UL in

RF in

RF out

RF in

RF out

RF in

Alternative 1

RF out

Alternative 2

Input to OMU

In Alternative 1 the connectors on each module are linked and the input to the OMU is made via the N-

connectors on the back of the OMU. See also illustration below.

In Alternative 2 the input to the OMU is made via the QMA connectors marked RF in/RF out.

Optional links

Fibre port

DL out

RF in

DL

Splitter

RF out

UL

Combiner

UL in

RF in

RF out

OMU front side

Fibre Optic

Converter

DL

UL

Note! In the illustration above only one Fibre Optic Converter is shown. The other converters are connected in

a corresponding way.

The configuration at delivery is Alternative 1.

OMU back side

2

In some cases, for specific needs, these modules can be designed in alternative ways.

© Axell Wireless Ltd A1829300 rev H 18 (86)

Page 20

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2.3 Control Module

The Control Module is placed in slot 9 or 11. Note! If there is a wireless modem mounted in the Control

module it has to be placed in slot 11 to access the modem antenna. See section

Connection.

2.2.8 Modem Antenna

The Control Module manages and controls the OMU and handles alarms. The Control Module

Modem Powe r

keeps track of all modules in the OMU based on their serial numbers. The Control Module

collects data from active modules within the OMU such as Optic Fibre Converters and Rack

Communications Board. The collected data is processed and if an error is detected the Control

Modem Status

Status

Login

Module can send an alarm via a built in modem to an Operations and Maintenance Center

(OMC). All alarms are also stored for later access via the LMT port.

The Control Module can collect the status of 4 external alarm sources connected to the

External Alarm and Battery Module. The summary alarm status of the OMU and the whole

system can be indicated via a relay port. This relay can be used to indicate to external

equipment if the OMU-Repeater system is functioning properly.

LMT Port

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

The Control Module includes a Real Time Clock (RTC). The RTC keeps track of at what time

alarms and events occur. This RTC has its own backup battery.

The Control Module can be configured in two different modes:

Standalone Mode – the OMU only reports its own status

Ethernet

Node Master – being a node master means that the OMU controls all slaves (repeaters)

connected to it and manages all communication to the AEM for the whole OMU-Repeater

system.

2.2.3.1 Connectors

The Control Module contains a RS232 port used for local access to the repeater, the LMT Port.

The Control Module has an Ethernet connection for remote access placed on the front panel.

If the Control Module is equipped with a wireless modem, a SIM card holder is accessible on the front panel.

Note! The USB connector is not used in this version of the product.

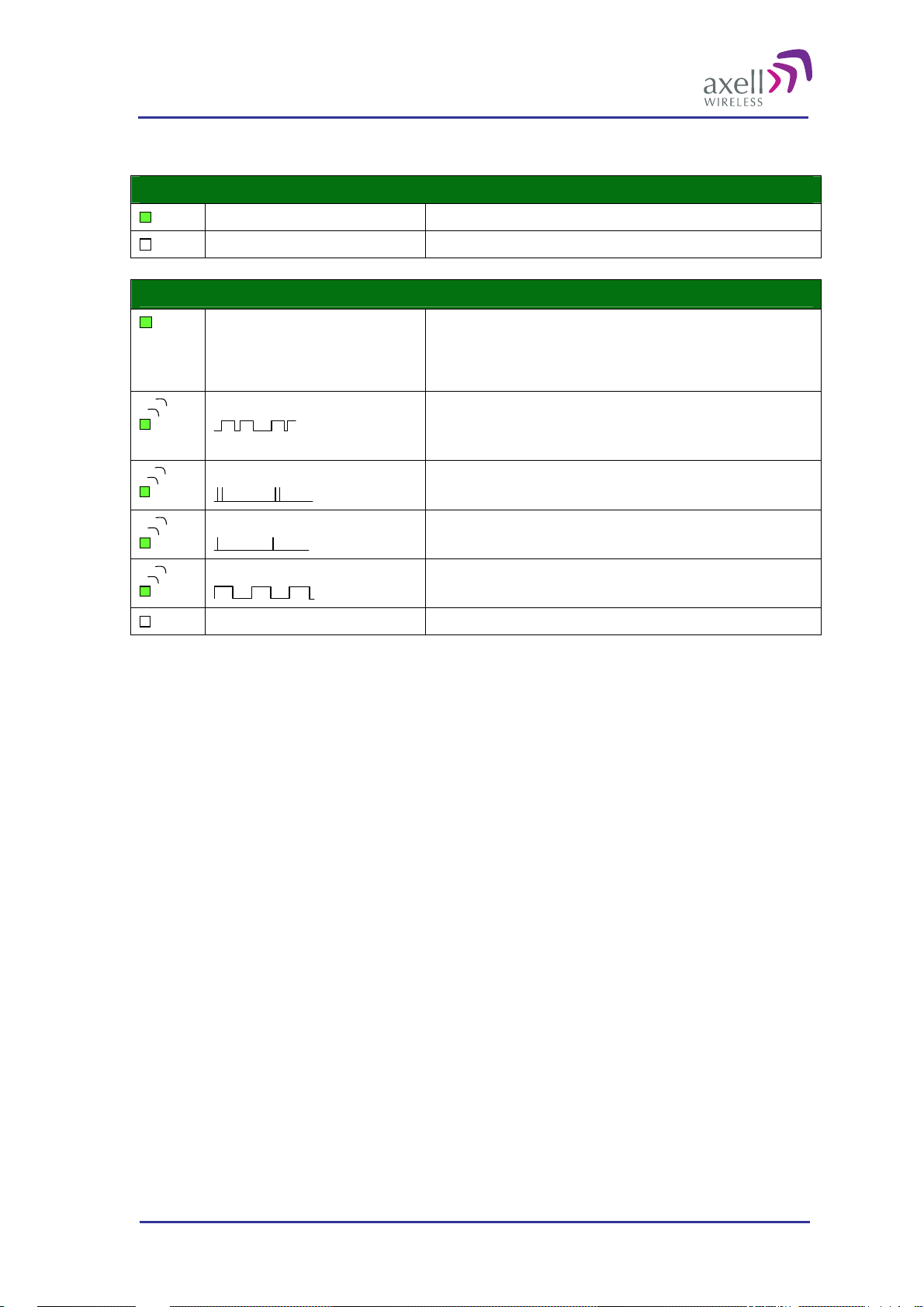

The Control Module has four LEDs which give information regarding the status

of the OMU.

If the OMU is configured for Ethernet communication the two LEDs Modem

Power and Modem Status do not fill any function and can be disregarded.

Blue LED - Login

Red LED - Status

Quick flash Control Module switched on, someone logged in locally and/or remotely

Off (except for a quick flash every 10th

second)

Off (permanent) Control Module switched OFF

Quick flash Control Module switched on, one or more errors/alarms detected

Off (except for a quick flash every 10th

second)

Off (permanent) Control Module switched off

Control Module switched on, no one logged in

Control Module switched on, status OK

Modem Power

Modem Status

Status

Login

© Axell Wireless Ltd A1829300 rev H 19 (86)

Page 21

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Green LED – Modem Power

Green LED – Modem Status

On Modem Power is on

Off Modem Power is off

On

Flashing

(irregular)

75ms on/75ms off/75ms on/3s off

75ms on/3s off

600ms on/600ms off

Off Modem is off

Depending on type of call:

Voice call: Connected to remote party

Data call: Connected to remote party or exchange of parameters while

setting up or disconnecting a call

Indicates GPSR data transfer. When a GPRS transfer is in progress the LED

goes on within 1 second after data packets were exchanged. Flash duration

in approximately 0.5s.

One or more GPRS contexts activated

Logged to network (monitoring control channels and user interactions). No

call in progress

No SIM card inserted, or no PIN entered, or network search in progress, or

ongoing user authentications, or network login in progress

2.2.4 External Alarm and Battery Module

The External Alarm and Battery Module is placed in slot 10.

This module has two functions.

It holds a rechargeable battery pack

It has plinths for external alarms and a sum alarm relay

2.2.4.1 Battery

The rechargeable battery pack will provide the Control Module in the OMU and the modem with enough

capacity to send an alarm in case of an input power failure. This battery can be switched on and off with the

switch on the front of the module.

2.2.4.2 External Alarms

Four external alarm sources can be connected to the External Alarm and Battery Module via the patch panels.

These sources must generate a voltage between 12 and 24VDC. The presen ce or ab sence of this voltage will

trigger the alarm depending on how the alarm thresholds have been configured. The module can also supply

+15V to external alarm sources. The maximum allowed load on this supply is 100mA.

2.2.4.3 Relay

The module contains a relay that can be connected to an external device to indicate an alarm. The relay can be

configured to trigger on any number of internal and external alarms. The maximum current through the relay is

100mA.

© Axell Wireless Ltd A1829300 rev H 20 (86)

Page 22

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2.4.4 Patch Panels

GND

GND

External alarm 1A

External alarm 1B

External alarm 2A

External alarm 2B

Relay Output 1A

Relay Output 1B

+15VDC Output

GND

GND

External alarm 3A

External alarm 3B

External alarm 4A

External alarm 4B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Battery

Power

PWR

On

Off

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

External Alarm and Battery Module with pin out for external alarms and relay

The external alarm wires are linked to the module via patch panels. These panels can be released from the

module for easier access at installation.

2

The panels can be used for wires of up to 0.5mm

. To connect a wire, press the yellow lever with a pen or other

pointy item, insert the wire and release the lever.

2.2.5 Modem Unit

The Modem Unit is placed in slot 9 or 11. Note! If there is a wireless

modem in the Modem Unit it has to be placed in slot 11 to access the

modem antenna. See also section

The Modem Unit is used for modems that are not placed on the Control

Module. This can be for instance PSTN modems or wireless modems with

a form factor that prevents it from being integrated with the Control

Module.

The access to a PSTN modem is via an RJ11 connector on the font of the

module.

2.2.8 Modem Antenna Connection.

PWR

RJ11 connector

© Axell Wireless Ltd A1829300 rev H 21 (86)

Page 23

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2.6 Rack Communication Board

The Rack Communication Board is placed in slot 12.

This module serves as a communications link between the Control Module and the Fiber Optic Converters.

The unit is also used when several OMUs are to be linked together. The cables for cascading OMUs are

provided by Axell Wireless in case these are needed. The connections are RJ45 . How to link the OMUs to one

another is described in section 6 Installation.

There are three LEDs that reflect the status of the communication between the Control Module and the Fiber

Optic Converters.

UL DATA and DL DATA reflect the data communication that is ongoing between this module, the

Control Module and the Fibre Optic Converters.

Link OK is lit when the communication between this unit and the Control Module has been established.

PWR Indicates that the power is on

PWR

PWR

ERR

ERR

UL

UL

DATA

DATA

DL

DL

DATA

DATA

Link OK

Link OK

ERR Indicates that there is something wrong in the module

UL DATA On going communication in the uplink dir ection

DL DATA Ongoing communication in the downlink direction

IN OUT 1

IN OUT 1

Link OK Communication with Control Module established

OUT 2

OUT 2

RJ45 connectors

2.2.7 Power Supply

The Power Supplies are placed in slot 13 and 14.

Each OMU unit is equipped with one or two power supplies. There are power supplies

for 115 - 230VAC 50/60 Hz and 24 - 48VDC.

It is possible to mount two different power supplies (with different voltage) if they are

fed from two different sources.

The power supplies works in parallel and are independent of each other.

Out OK

In OK

Out OK

There are two green LEDs on the Power supplies

“Out OK” indicates that the power levels the unit is delivering

are OK

In OK

“In OK” indicates that the input power to the unit is OK

On

Off

Each Power Supply can be switched off using the switches on the front panel.

Note! Even when the power supplies are switched off the OMU still has live power from the power input on the

back.

© Axell Wireless Ltd A1829300 rev H 22 (86)

Page 24

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.2.8 Modem Antenna Connection

If a wireless modem is installed din the OMU, an antenna is needed. Either a separate antenna is connected to

the modem antenna port, or the connection is be made via a coupler connected to the RF input to the OMU. The

latter alternative can only be used if the OMU runs on the same frequency as the wireless modem and is

equipped with a duplex filter.

2.2.8.1 OMU without Duplex Filter

OMUs that are not equipped with a duplex filter and use a

wireless modem has a modem antenna port to the rightmost side

of the rack.

An external antenna can be connected to the “Modem Ant” port.

The connector is SMA type.

Modem

ANT

To external

antenna

2.2.8.2 OMU with Duplex Filter

OMUs that are equipped with duplex filters and a wireless modem are of two kinds:

Alternative 1

The OMU and the wireless modem operate on

the same band (for example an OMU for

GSM with a GSM modem).

In this case the OMU will have two ports with

a link between them.

If the link is in place the modem will be

connected to the OMU’s RF in/out via a

coupler. The coupler is either a separate

unit or included in the duplex filter.

If the link is removed an external

antenna can be connected to the top

connector.

Modem

Modem

ANT

ANT

Coupler

Coupler

The wireless

modem is

linked to the

RF in/out via

a coupler

Modem

Modem

ANT

ANT

Coupler

Coupler

An external

antenna is

connected

To external

To external

antenna

antenna

© Axell Wireless Ltd A1829300 rev H 23 (86)

Page 25

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Alternative 2

The OMU and the wireless modem operate on different bands

(for example an OMU for TETRA with a GSM modem)

In this case the OMU will have one port where an external

antenna can be connected.

The connector is SMA type.

Modem

ANT

To external

antenna

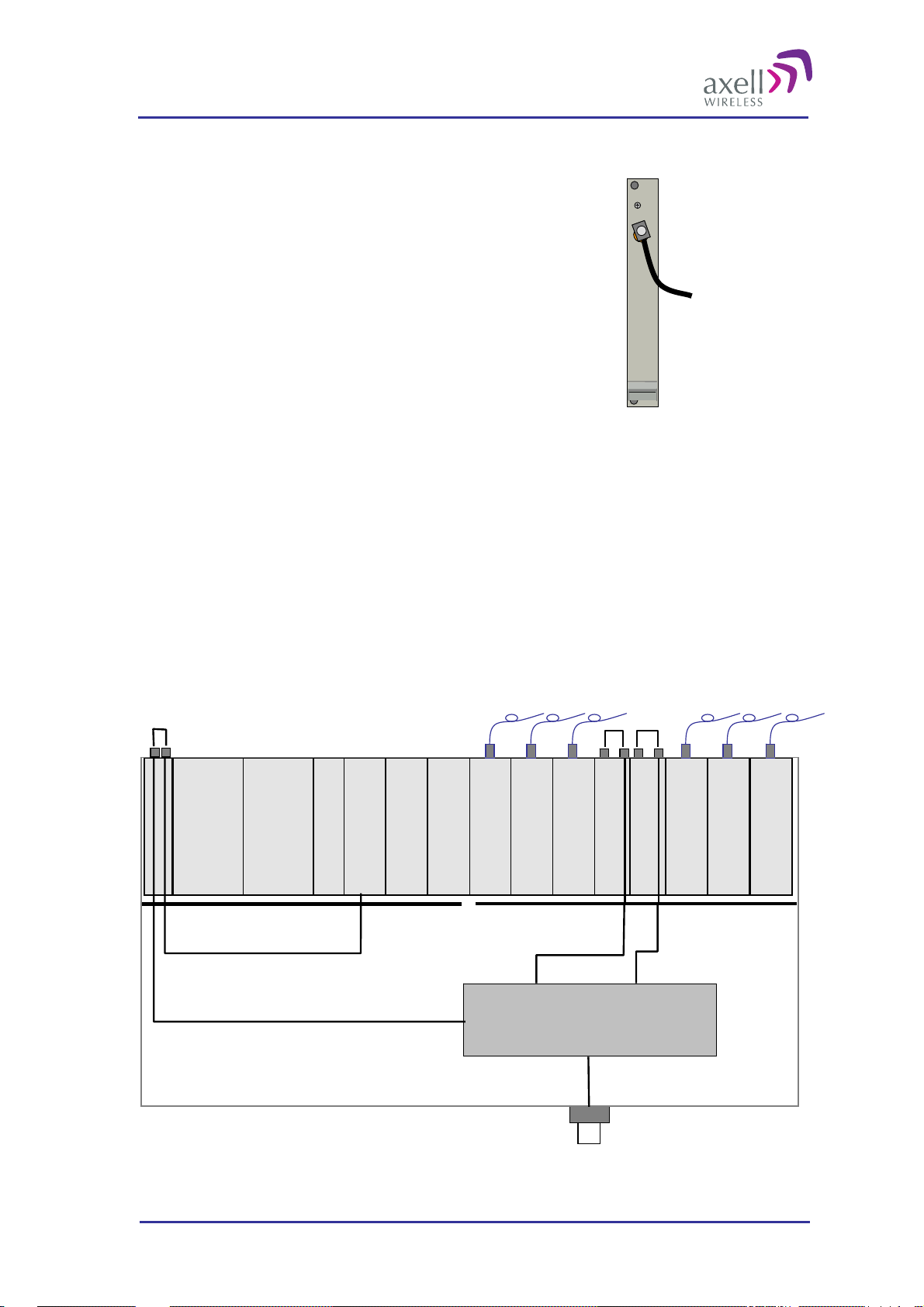

2.3 Block Diagram

An OMU can be configured in many different ways. These are two examples.

Example 1

In this example the OMU is fed from the back so the links on the UL Combiner and the DL Splitter units are

mounted.

There is a duplex filter and therefore a combined RF in/out.

The wireless modem, which is placed on the Control Module, is connected to the coupler in the filter via the

Modem Antenna Connection Module.

Digital Backplane

Opto

Module

Opto

Module

Opto

Module

Opto

Module

RF

RF

RF

IN

Power

Module A

Power

Module B

Rack Com Board

Control Module

External Alarm and

Battery Module

OUT

RF

RF

OUT

RF

IN

OUT

DL Splitter

IN

UL Combiner

RF

IN

Opto

Module

RF

OUT

RF

IN

Opto

Module

RF

OUT

RF

IN

Opto

Module

RF

OUT

RF Backplane

Duplex Filter

To coupler for

modem antenna

RF in/out

© Axell Wireless Ltd A1829300 rev H 24 (86)

Page 26

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

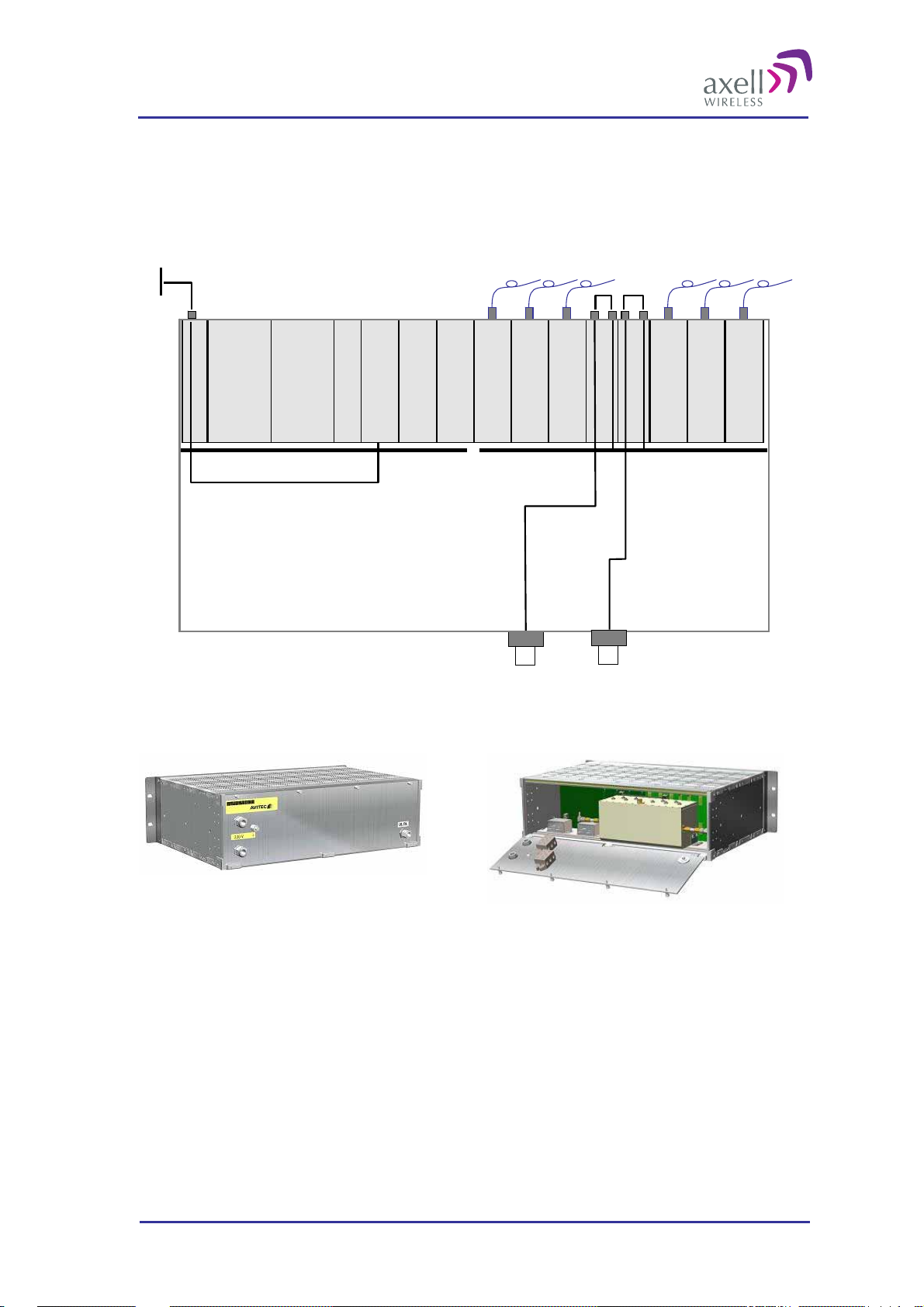

Example 2

In the example below there are separate inputs for Rx and Tx and no duplex filter. An external modem antenna

is connected and linked to the modem on the Control Module.

External Modem A ntenna

Opto

Module

Opto

Module

Opto

Module

Opto

Module

RF

RF

RF

IN

Power

Module A

Power

Module B

Rack Com Board

External Alar m an d

Control Module

Battery Module

OUT

RF

RF

OUT

RF

IN

OUT

DL Splitter

IN

Opto

Module

Opto

Module

Opto

Module

RF

RF

RF

IN

OUT

UL Combiner

RF

RF

OUT

RF

IN

OUT

IN

Digital Backplane

RF in/out

RF Backplane

2.4 Back Panel

An OMU with one RF in/out The inside of the back lid with two plinths for power

connections, a duplex filter and one RF in/out

The back panel of an OMU unit has a layout as illustrated above. The layout can vary depending on the

configuration.

The connections are:

Plinths for power connections are found on the inside of the back panel. There are two plinths. If two

modules with the same power feed are installed these plinths should be interconnected.

Screw for earthing

N-connector for RF input. There is one connector if the Rx/Tx input is combined and two connections if

the Rx and Tx are to be fed separately.

To gain access to the plinths for power connections, duplex filter, optional attenuators and optional coupler the

back panel needs to be opened. It is fastened with 4 screws.

© Axell Wireless Ltd A1829300 rev H 25 (86)

Page 27

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

2.5 Radio Signal and Data Communication Paths

In the downlink the radio signal is tapped from a BTS using a coupler installed in series with the BTS’s antenna

cable. The Fibre Optic Converter in the OMU converts the RF signal to an optical signal and sends it to the

repeater over a fibre.

In the uplink the Fibre Optic Converter receives the optical RF signal from the repeater, converts it to electrical

RF signal and sends it to the BTS. The signal is transferred to the antenna cable using a coupler.

The Control Module in the OMU monitors all units in the OMU.

The Control Module also monitors and controls the repeaters (if they are set up as slaves). The data

communication with the repeaters is handled over the same fibre as the RF signals.

Coupler

BTS

OMU

RF

O

RF + data

Optical

In/Out

Optical

In/Out

Repeater

RFORF

O

Server

Antenna

© Axell Wireless Ltd A1829300 rev H 26 (86)

Page 28

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

3 Monitoring and Control

The Optical Master Unit, OMU as well as the whole OMU-Repeater system can be accessed locally on site

through a Local Maintenance Terminal (LMT) port on any of the units in the system, or remotely via modem or

Ethernet.

When an RS232 cable is plugged in to the LMT port or a remote access has been established, there are two

options for communication; terminal mode or RMC mode.

Terminal mode is accessed by using a terminal emulation software, such as HyperTerminal™ or MiniCom

(Linux/Unix) Settings should be AN SI o r VT100 emulation, baud rate 9600, 8 data bits , 1 st op bit , N o

parity and No flow control. A simple command language is used to control the repeater in th is mode.

Repeater Maintenance Console (RMC) mode allows configuration and control of the repeater via a user

friendly Windows software.

Note! All instructions in this chapter assumes that the OMU is controlled using the Repeater Maintenance

Console, RMC.

For terminal mode commands please refer to the documents “Common Commands and Attributes” and “OMU

Commands and Attributes” which contain detailed description of all attributes and commands.

Firmware Documentation Structure

The documents “Common Commands and Attributes” and “OMU Commands and Attributes” together describe

all functionality in the OMU. The Common part contains functionality that is common for all Axell Wireless

repeaters as well as the OMU, and the OMU part contains functionality that is specific for the OMU. For

repeaters there are corresponding documents available.

Help Functions

When being logged in to a unit using the terminal mode the command

HELP

lists all attributes and their modes of operation and displays them in alphabetic order on the screen.

Further help regarding specific commands can be obtained by typing

INF <command>

The INF attribute gives detailed information about a specific attribute.

3.1 Software F eatures - Overview

The firmware in the Control Module controls and monitors all parameters in the unit. If the OMU is configured

as a node master it also handles alarms and heartbeats from slave repeaters connected to it. Statuses and

measured levels can be read online via the RMC. This includes for instance voltage levels, RF-levels and

temperatures.

In the event of a failure, an alarm is logged in the OMU. If the OMU is intergraded in the AEM, the alarm is

also transmitted to the AEM. The OMU can be configured to handle alarms concerning a number of different

parameters. Each alarm can also be individually configured in a number of ways. The OMU stores

approximately 2 000 alarms in a local alarm log. The data stored regarding each alarm is the time at which an

alarm occurred and the alarm information which consists of alarm source, alarm severity, alarm attributes and in

some cases an additional alarm description.

On regular intervals, the OMU can send a heartbeat report to the AEM to confirm that the unit is functioning.

The heartbeat message contains information about the RF-configuration and the alarm sources. It ensures that

the data communication from the OMU to the AEM is working properly. The latest 2 000 heartbeats

(approximately) are stored in a log.

The Control Module contains a battery backed-up real time clock, which will stay active even during a power

failure. The real time clock is used for instance to keep track of when an alarm occurred, when to retransmit an

alarm and at what time of the day to send traffic report to the AEM. If the OMU is controlled by the Axell

© Axell Wireless Ltd A1829300 rev H 27 (86)

Page 29

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Element Manager, the AEM will automatically time synchronize repeaters, to ensure that the time is always set

correctly in the entire repeater network. Slave repeaters are synchronized from the OMU.

3.2 Network Nodes

Note! The description in this section is based on a master-slave set-up of the system, where the OMU is the

node master and the repeaters are the slaves.

An Axell Wireless OMU-Repeater system consists of an OMU and a number of remote nodes (repeaters)

connected to the OMU unit via fibre. During software setup of the system, all nodes installed in the system are

configured in the Control Module. Hence, the node master contains a list of all the repeaters in the system. Once

a node is added to the system, it is also written to all the nodes installed. This means that all nodes in the

repeater system have information about all other nodes, allowing for a very good overview of the entire repeater

system no matter what node the repeater system login is made from.

3.2.1 Node Identification

All nodes have a unique address within the system. This address is based on the serial number of the node.

When the system is installed to the Axell Element Manager, the node master unit is assigned a unique repeater

ID within the AEM database.

This number is on the form:

XX-YY-ZZZZ

where

XX is the AEM installation number within the network

YY is the region number within the AEM-system

ZZZZ is the site installation number

Within the repeater system, all slave nodes (repeaters) are given a unique ID, based on the AEM assigned ID.

The nodes share the XX-YY- part of the master ID, but the ZZZZ is replaced by the node’s serial number.

Example:

If the node master’s ID is 17-42-4711 and the serial number for a node in the system is 23BJ. The node’s ID

will be 17-42-23BJ.

3.2.2 Node Addressing Modes

When logging in to the OMU-repeater system, it is possible to view information about any of the nodes in the

system, as long as they are added to the node list. All nodes can be addressed in four different ways, all starting

with the @-sign.

Numeric Addressing

Each node in the network gets a unique ID-number in the Node List as they are added to the system. Node 0 is

always the master node.

Addressing is on the format:

@K

K from 0 to N where N is number of nodes

Reading a parameter from node 3 is entered as:

AVITEC AB> @3 GET ATD

14

Serial Number Addressing

A node can be accessed using the serial number of the node.

Example:

© Axell Wireless Ltd A1829300 rev H 28 (86)

Page 30

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

AVITEC AB> @2J34 GET MDL

BSF424-I

AVITEC AB>

Node ID Addressing

A node can also be addressed using the full Node ID.

Example:

AVITEC AB> @01-01-2J34 GET TAG

SITE3_TUNNEL_OPENING

AVITEC AB>

Direct Node Addressing

When many attributes are intended for another node, the user can enter Direct Node Access mode, where the

node the user is logged in redirects all commands to the destination node. This mode is configured by sending

the command:

SET DNA [Node Address]

where any of the node addressing modes can be used as Node Address.

When going into direct node addressing, the command prompt is changed to reflect what node is currently

addressed:

AVITEC AB> SET DNA 2J34

AVITEC AB @2J34>

Refer to attribute DNA in OMU Command and Attribute Summary for further details on direct node addressing.

3.2.3 System Wide Parameters

System Wide Parameters are parameters that when configured should be written to all nodes in the system.

When setting a system wide parameter, the parameter is always set in the node master, which is then

responsible for setting the parameter to all other nodes. If attempting to set a system wide parameter from a

node as access to the node master is not available, setting the parameter will fail.

The following “standard” parameters are treated as system wide parameters (please refer to OMU Command

and Attribute Summary for details):

LMT Local Maintenance Terminal timeout

TIM Setting the time

DAT Setting the date

TPD Setting the time for sending traffic / utilization report to the AEM

UID User ID’s

PWD Passwords

RID Repeater ID

In slave repeaters the OMU is responsible for the communication with the AEM.

3.2.4 Node Access

An operator can login to the OMU-Repeater system from any node in the network and access all parameters in

all nodes, including those in the node master unit. This can be done using a serial cable connected to the node’s

LMT-port or by remote access over a modem or Ethernet.

Select “System Nodes”

© Axell Wireless Ltd A1829300 rev H 29 (86)

Page 31

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Node detailes: number,

ID, Model

Node name

Node status

Select a node by clicking on

The OMU unit polls the connected repeaters / nodes regularly and keeps control of login requests. If a user at a

repeater site wants to log in to the system, the OMU Control Module is responsible for granting / denying the

login request. If a user forgets to log out from the node when a session is finished, the system will automatically

log the user out after a configurable number of minutes of inactivity.

. The RMC will connect to the selected node.

3.3 Fibre Loss Compensation and Master Volume

The OMU has a master attenuation that can be set in downlink (DL) and uplink (UL) separately. This

attenuation is useful for balancing of the whole system. See section

information about this feature.

Each fibre optic link in the system will induce a loss. This loss will also differ in magnitude from one link to

another since the distances between each repeater and the OMU is different. The Axell Wireless OMU-repeater

system can automatically calculate this loss, compensate for the loss in each link and by that also balance the

system.

4.9 Balance the System for more

This is accomplished by using a pilot tone of a well defined level which is sent from the master node to the

slave and vice versa. The received level of the pilot tone is measured and the loss is calculated. The Fibre Optic

Converter is automatically adjusted to compensate for the loss. The adjustment is made towards a target value

which means that the system will be balanced, i.e. all fibers will appear to have the same loss. The maximum

compensation is 10dB which equals an unbroken fibre distance of 20 km. For each connection in the link (for

instance at the ODF) approximately 0.5 dB of loss will have to be added.

The loss compensation function is activated as the system is set up. Please see section

Repeater System. Each time the system has been changed or fib res ha ve been exc ha ng e d or moved for some

reason, it is recommended to re-activate this function.

Note!

If the OMU is connected to repeaters of an earlier

release that has a fibre optic convert of the type in

the photograph, the Fibre optic loss cannot be

measured with this command.

4.8 Set Up OMU-

© Axell Wireless Ltd A1829300 rev H 30 (86)

Page 32

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

3.4 Alarm System

The OMU monitors a number of parameters to see that the unit works as intended. Furthermore, the Control

Module constantly polls all the nodes for new alarms. If a new alarm is detected, it is stored in the OMU alarm

log. If the OMU is integrated to the Axell Element Manager, the OMU dials up the AEM using the built in

modem and delivers the alarm.

3.4.1 Alarm Sources

Temperature Related Alarms

Alarm Code Description Trigger

Temperature TEM Measures the temperature in the Control Module. Temperature too high or

too low

Radio Board

Temperature

RBT Measures the temperature on the Rack

Communication Board or Fibre Optic Converter

Temperature too high or

too low

Power Related Alarms

Alarm Code Description Trigger

Power Supply 1 PW1 Measures the +28V generated by the re peat er ’s

power supply.

Power Supply 2 PW2 Measures the +15V generated by the re peat er ’s

power supply.

Power Supply 3 PW3 Measures the +6.45 V generated by the repeater’s

power supply

Power Supply 4 PW4 Measures the backed up +6.45 V in rack 1

generated by the repeater’s power supply

Battery Level BAT Measures the power level in the battery Level too high or too

Level too high or too

low

Level too high or too

low

Level too high or too

low

Level too high or too

low

low

Communication Related Alarms

Alarm Code Description Trigger

Communication with

Active Devices

Node

Communication

Status

EEPROM CRC

Check In Active

Devices

© Axell Wireless Ltd A1829300 rev H 31 (86)

COM Detects errors in the communication between

Control Module and Rack Communication

Board/Fibre Optic Converter

NCO Detects error in the communication between the

Control Module and slave repeaters

CRC Controls checksum in Radio Communication

Board and Fibre Optic Converter

Errors in the

communication

Errors in the

communication

Checksum wrong

Page 33

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Opto Related Alarms

Alarm Code Description Trigger

Received Optical

Level

Transmitted Optical

Level

Synthesizer Pilot

Tone Generator

Input Signal Level

Downlink

RXO Measures the received optical signal level Optical signal level too

low

TXO Measures the transmitted optical signal level No transmission

SZP Measures the pilot tone frequency

ILD Measures the signal level in to the fibre optic

converters in the downlink

Error on pilot tone

Signal level too low

(default setting) or too

high (can be reconfigured

to use an upper threshold)

User Related Alarms

Alarm Code Description Trigger

Valid Login to

repeater

User logged out from

repeater

Changes made by

logged in user

VLI Detects a login to the unit, either locally or via

remote connection.

LGO Detects a logout from the repeater. A logout

CLR Detects all changes made to repeater settings by a

user logged in to the repeater.

A successful login

Changes made by a user

Firmware upgraded FWU Detects when a successful firmware upgrade has

been made

Firmware Upgrade

Failure

FWF Detects failure in the upgrade Upgrade failed

Upgrade successful

User Administration Alarms

Alarm Code Description Trigger

User Added UAD Detects when a user is added to the system User added

User Deleted UDE Detects when a user is deleted from the system User deleted

User Promoted UPM Detects when a user gets escalated user privileges User promoted

User Demoted UDM Detects when a user gets downgraded user

privileges

User Password UPW Detects when a password is changed Changed password

User demoted

External Alarms

Alarm Code Description Trigger

External Alarm 1-4 EX1-4 Monitors any alarm source connected to the

external interface.

Error from alarm source

© Axell Wireless Ltd A1829300 rev H 32 (86)

Page 34

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Relay Output for Sum Alarm

The External Alarm and Battery Module contains a relay output. The relay can be used to indicate the summary

status of the OMU. Each alarm source can be configured to affect the relay or not.

3.4.2 Alarms and End of Alarms

When the Control Module detects a failure, an alarm is transmitted to the Axell Element Manager, informing

the operator about the error condition. When the alarm has ceased, an end of alarm is sent to the AEM, stating

that the alarm source is now OK.

Each “alarm” and “end of alarm” updates the AEM database with the latest status of the alarm source, ensuring

that the AEM operator always has the correct repeater status in the system.

To generate an alarm a number of consecutive measurements must first show an error state. This can be

configured for each alarm source separately.

To generate an end of alarm only one OK measurement is needed.

Alarm level

Alarm is sent after three

seconds above threshold

End of alarm is sent as

soon as status is OK

Alarm threshold

Time

If an alarm should constantly toggle between OK and ERROR the communications interface might be blocked.

To prevent this there is a parameter called Minimum Alarm Repetition Cycle. This parameter defines how

many minutes must elapse before a new alarm can be transmitted from the same alarm source.

Alarm level

Initial alarm End of Alarm

Three minutes have elapsed and a

new alarm is transmitted

Alarm Threshold

Minimum alarm

repetition

Time

This illustration shows an alarm source with an upper threshold, and a fluctuating level around the alarm

threshold. The initial alarm will be sent as indicated. The next alarm will be transmitted after three minutes,

when the minimum alarm repetition period has elapsed.

© Axell Wireless Ltd A1829300 rev H 33 (86)

Page 35

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

Set Minimum Alarm Repetition Cycle

Select

“Configuration “ and

“Reports”

3.4.3 Alarm Retransmissions and Acknowledgements

As soon as the OMU detects an alarm or an end of alarm, a connection to the Axell Element Manager is

established and the alarm event is reported.

The 2 000 latest alarms and end of alarms are stored in the OMU’s local alarm log. In case an alarm is not

acknowledged the alarm will be retransmitted to the AEM after a configurable number of minutes. Allowed

values are 0 to 999. Default retransmit interval is 10 minutes.

The retransmission will be repeated a configurable number of times. This variable can be set from 0 to 99.

Default number of retries is three

Set Number of Retransmissions and Repetition Cycle for Non-acknowledged

Alarms

Select

“Configuration “ and

“Reports”

3.4.3.1 Alarm Acknowledgement using the RMC

Each alarm can be manually acknowledged using the Repeater Maintenance Console. However, if the OMU is

controlled by the Axell Element Manager, a manual acknowledgement of the alarm means that the AEM will

not be aware of the change in the repeater status.

3.4.3.2 Alarm Acknowledgement using the Axell Element Manager

If the OMU is integrated to and controlled by the Axell Element Manager, an alarm is considered

acknowledged when the alarm has been delivered to the AEM. Once delivered to the AEM, the

acknowledgement of the event is taken care of at the site of the AEM, why no dial-back needs to be performed

to acknowledge the alarms.

3.4.3.3 Alarm Acknowledgement using SMS

Note! SMS functionality is not implemented in this SW release.

If the OMU is configured to send alarms using SMS, alarm acknowledgement can be made in two different

ways.

© Axell Wireless Ltd A1829300 rev H 34 (86)

Page 36

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

the alarm is acknowledged as soon as the alarm SMS is successfully received by the Short Message

Service Centre

or

the alarm is acknowledged by sending a special alarm acknowledgement SMS back to the repeater from

the alarm destination.

Set Acknowledgement Type for SMS Alarms

Select

“Configuration “ and

“Reports”

Pick one alternative

from the drop-down

menu

All alarms transmitted from the OMU contain a message number. Acknowledgement of an alarm is done by

sending an SMS to the repeater containing this message number.

Note! Only the defined “Primary SMS address” can acknowledge alarms.

The table below displays the format of alarm acknowledgement messages.

Message field Format Description

Repeater ID XX-YY-ZZZZ ID of the repeater that the message is intended for

Message number NNNNN Message number set by originator

Command ACT Action command

Argument ACK Acknowledge action

Argument MMMMM Message number of the alarm message to acknowledge

The message fields are separated with blanks.

For example, sending an SMS to the repeater with the text

01-42-4711 00242 ACT ACK 00023

will acknowledge alarm number 00023 from repeater 01-42-4711.

© Axell Wireless Ltd A1829300 rev H 35 (86)

Page 37

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

3.4.4 Alarm Format

Each alarm transmitted from the OMU contains a number of fields, in detail describing the event that caused the

alarm. The alarm is transmitted as an ASCII text string, each fi el d separat ed by a blank/white space.

Using the Axell Element Manager to control the OMU, the alarm string is delivered to the transceiver for

further processing in the AEM system.

When SMS is used to control the OMU, the string is sent as clear text to the alarm address (main address).

Note! The SMS functionality is not implemented in this SW release.

Message

field

Repeater ID XX-YY-ZZZZ 10 ID of the repeater causing the alarm. When monitoring the

Message # N 1 to

Message type ALARM 5 This text string identifies the message as being an alarm (or

Date DDMMYY 6 Day, month and year when the alarm was detected

Time HHMMSS 6 Hour, minute and second when the alarm was detected

Alarm Name CCC 3 Identifies the alarm type (e.g. PW1, SZU, PDL, etc)

Alarm

Severity

Format # of

Description

char.

repeater using the AEM, this repeater ID is set by the AEM

during the repeater installation phase. Using SMS, this

repeater ID should be modified to uniquely identify the

repeater in the network.

This integer value uniquely identifies this message from the

10

CC 2 Abbreviation for severity of the alarm. This severity varies

repeater and may be from 0 to 2147483648 (231).

end of alarm)

between the different alarm sources.

CR = critical

MA = major

MI = minor

WA = warning

CL = cleared

When an and of alarm is sent, the severity is CL = cleared

Alarm Class CC 2 Abbreviation for kind of alarm

CO = communication alarm

EN = environmental alarm

QS = quality of service alarm

PR = processing alarm

EQ = equipment alarm

Status C 1 This status identifier is 0 if end of alarm and 1 if alarm.

Hardware

Enumeration

Position

Identifier

Additional

text

© Axell Wireless Ltd A1829300 rev H 36 (86)

CCCC 1 to 5 Denotes what hardware module the alarm originates from. If

not used, a '-' (dash) is replied.

CCCCCCCCCC

CC

<Text> 60 This quoted string contains additional alarm information, such

1 to

12

Gives detailed information about certain alarm sources. For

some alarms, such as VLI, LGO and CLR, this may contain

user information. If not used, a '-' (dash) is replied.

as measured levels when the alarm condition was detected.

Page 38

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

3.4.5 Alarm Class

Each alarm belongs to a class.

Class Description

CO communications

QS quality of service

PR software or processing

EQ hardware equipment

EN environment (enclosing or surrounding equipment)

All alarms are configured to a class at delivery but can be changed by the user. The external alarms do not have

a classification at delivery, but can be set by the user.

3.4.6 Alarm Severity

Alarms can be of five different severity levels.

Severity Level Description

Critical

Major

Minor

Warning

Cleared

The severity can be defined for each alarm source in the Alarm Configuration screen in the RMC. It is

recommended not to change the default settings.

A critical error has occurred which affects the functionality of the OMU. This type of

alarm requires immediate action.

A major error has occurred. This type of alarm should be invest i gat e d wi t hin a short

time.

A minor error has occurred. This type of alarm should be i nvest i gated, but is not

urgent.

Something has occurred that does not affect the operation of the OMU but may be

important to notice. For example, someone has logged on to the repeater.

A cleared alarm. This is the end of alarm.

© Axell Wireless Ltd A1829300 rev H 37 (86)

Page 39

Optical Master Unit

PRODUCT DESCRIPTION AND USER’S MANUAL

3.4.7 Alarm Configuration

A number of different parameters can be conf i gu red for how the alarms are transmitted to the repeater OMC.

Each alarm source can also be individually configured in a number of different ways.

Select

“Configuration “ and

“Alarms”

Alarm

Class

Severity

Sum alam

Alarm transmission

to OMC enabled

Requires

acknowledgement

Lower and upper

thresholds

Seconds in error

before an alarm is

triggered

Class – Each alarm can be linked to one of the following classes: Common, Quality, Process, Equipment

or Environment. The class is used when the information is presented in the AEM

Severity – Each alarm can be classified regarding severity - Critical, Major, Minor or Warning

Note! It is recommended not to change the default settings.

Enabl. – If this box is ticked the alarm is transmitted to the repeater OMC (AEM)

Note! This only affects the transmission of the alarm. The alarm is still measured, and corresponding alarm

status is still displayed in the repeater status screen and in the heartbeat reports transmitted to the repeater

OMC.

Ack. – All alarms will by default be transmitted to the repeater OMC (AEM) requiring acknowledgement