Page 1

UHF Bandselective Bi-Directional Amplifier

90dB 40/5W

User/Maintenance Handbook

For

Pacific Wireless Communications L.L.C.

AFL Works Order Q116107

AFL Product Part No. 55-199102

Aerial Facilities Limited

Technical Literature

Document Number 55-199102HBKM Issue No. 1 Date 05/10/2007 Page 1 of 28

UHF Bandselective BDA

90dB 40/5W

Page 2

Table of Contents

1. INTRODUCTION..........................................................................................................................3

1.1. Scope and Purpose of Document ............................................................................................. 3

1.2. Limitation of Liability Notice ......................................................................................................3

2. SAFETY CONSIDERATIONS......................................................................................................4

2.1. Earthing of Equipment ..............................................................................................................4

2.2. Electric Shock Hazard............................................................................................................... 4

2.3. RF Radiation Hazard ................................................................................................................4

2.4. Lifting and other Health and Safety Recommendations............................................................ 4

2.5. Chemical Hazard ......................................................................................................................5

2.6. Laser safety ..............................................................................................................................5

2.7. Emergency Contact Numbers...................................................................................................5

3. EQUIPMENT OVERVIEW............................................................................................................6

3.1. UHF Bandselective, BDA (55-199102) List of major sub modules ...........................................7

3.2. UHF Bandselective, BDA (55-199102) Specification................................................................7

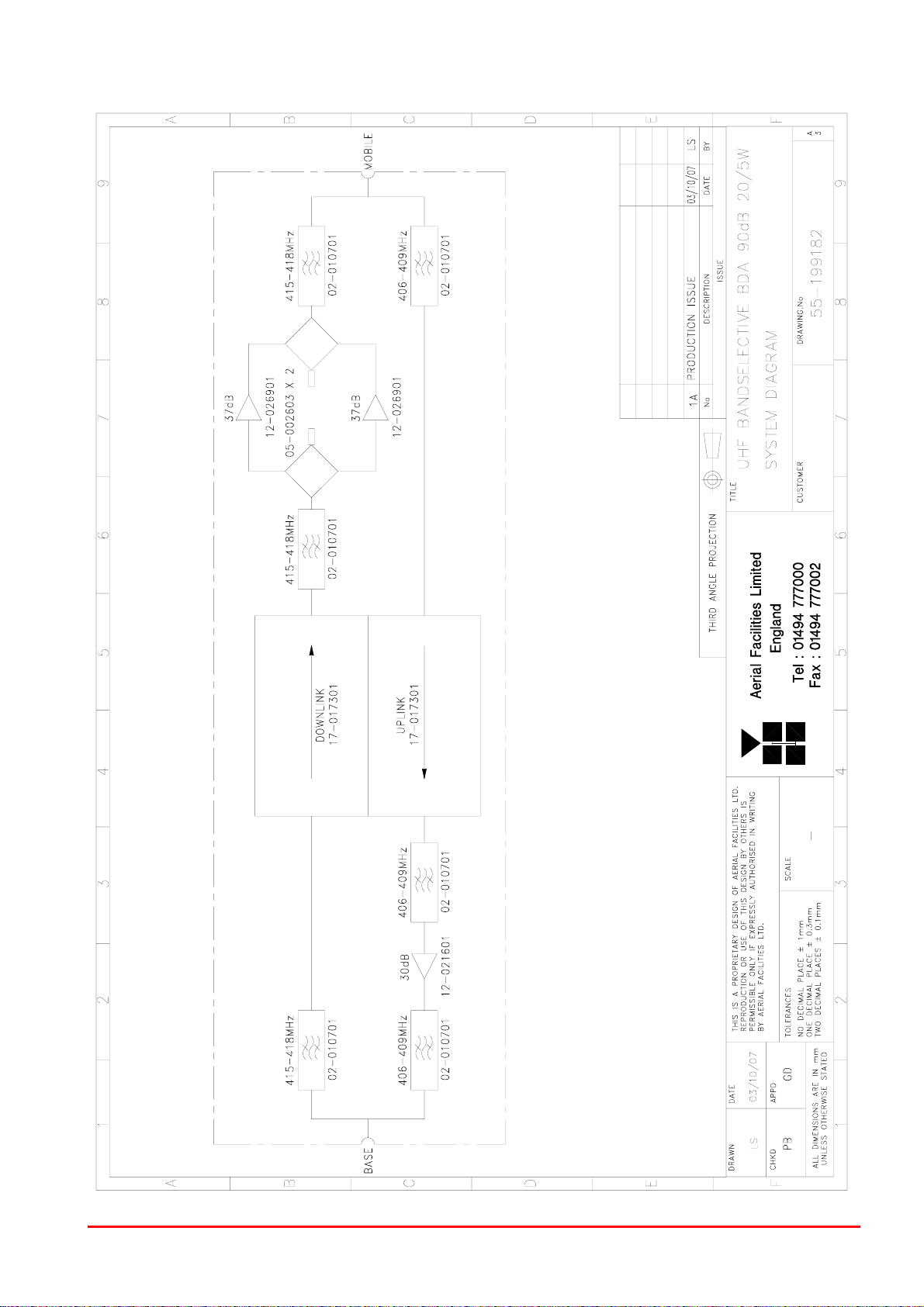

3.3. UHF Bandselective, BDA (55-199102) System Schematic..........................................................8

3.4. Photographs.............................................................................................................................. 9

3.4.1. Front of case – door closed................................................................................................ 9

3.4.2. Front of case – door open ................................................................................................ 10

3.4.3. Right Hand and Left Hand sides ...................................................................................... 11

4. UHF BANDSELECTIVE, BDA (55-199102) SUB MODULES...................................................12

4.1. Bandpass Filter (02-010701) ..................................................................................................12

4.2. 3dB Splitter/Combiner (05-002603) ........................................................................................13

4.3. Remote Attenuator Switch Assembly (‘10-001725’) ...............................................................13

4.4. 5 Watt Tetra Amplifier (12-021601)......................................................................................... 14

4.5. Linearised Power Amplifier (12-026901)................................................................................. 15

4.6. Voltage Regulator Board 9.0V (13-001714)............................................................................ 16

4.7. DC/DC Converter, 24V in, 12V 8A out (13-003011) ...............................................................16

4.8. Bi-Directional Amplifier (17-017301) ....................................................................................... 17

4.9. 12V (Single) Relay Board (80-008901)...................................................................................18

4.10. 24V Switch-Mode PSU (96-300054).................................................................................... 18

5. INSTALLATION & COMMISIONING.........................................................................................19

5.1. Antenna Installation & Gain Calculations................................................................................ 19

5.2. Initial Installation Record......................................................................................................... 19

6. FAULT FINDING / MAINTENANCE.......................................................................................... 20

6.1. Tools & Test Equipment.......................................................................................................... 20

6.2. Basic Fault Finding .................................................................................................................20

6.3. Quick Fault Checklist .............................................................................................................. 21

6.4. Downlink ................................................................................................................................. 21

6.5. Uplink......................................................................................................................................21

6.6. Fault repair.............................................................................................................................. 21

6.7. Service Support ......................................................................................................................21

6.8. Care of Modules...................................................................................................................... 22

6.9. Module Removal (LNAs, general procedure):......................................................................... 22

6.10. Module Replacement (general): ..........................................................................................22

6.11. Power Amplifiers.................................................................................................................. 22

6.12. Low Power Amplifier Replacement......................................................................................23

6.13. Module Transportation:........................................................................................................ 23

APPENDIX A.......................................................................................................................................24

A.1. Glossary of Terms used in this document ...........................................................................24

A.2. Key to Drawing Symbols used in this document.................................................................. 25

A.3. EC Declaration of Conformity .............................................................................................. 26

A.4. Amendment List Record Sheet............................................................................................ 27

APPENDIX B.......................................................................................................................................28

Initial Equipment Set-Up Calculations...............................................................................................28

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 2 of 28

Page 3

1. INTRODUCTION

1.1. Scope and Purpose of Document

This handbook is for use solely with the equipment identified by the Aerial Facilities Limited (AFL) Part

Number shown on the front cover. It is not to be used with any other equipment unless specifically

authorised by AFL. This is a controlled release document and, as such, becomes a part of Aerial

Facilities’ Total Quality Management System. Alterations and modification may therefore only be

performed by AFL.

AFL recommends that the installer of this equipment familiarise themselves with the safety and

installation procedures contained within this document before installation commences.

The purpose of this handbook is to provide the user/maintainer with sufficient information to service

and repair the equipment to the level agreed. Maintenance and adjustments to any deeper level must

be performed by AFL, normally at the company’s repair facility in Chesham, England.

This handbook has been prepared in accordance with BS 4884, and AFL’s Quality procedures, which

maintain the company’s registration to BS EN ISO 9001:2000 and to the R&TTE Directive of the

European Parliament. Copies of the relevant certificates and the company Quality Manual can be

supplied on application to the Quality Manager.

This document fulfils the relevant requirements of Article 6 of the R&TTE Directive.

1.2. Limitation of Liability Notice

This manual is written for the use of technically competent operators/service persons. No liability is

accepted by AFL for use or misuse of this manual, the information contained therein, or the

consequences of any actions resulting from the use of the said information, including, but not limited

to, descriptive, procedural, typographical, arithmetical, or listing errors.

Furthermore, AFL does not warrant the absolute accuracy of the information contained within this

manual, or its completeness, fitness for purpose, or scope.

AFL has a policy of continuous product development and enhancement, and as such, reserves the

right to amend, alter, update and generally change the contents, appearance and pertinence of this

document without notice.

All AFL products carry a twelve month warranty from date of shipment. The warranty is expressly on a

return to base repair or exchange basis and the warranty cover does not extend to on-site repair or

complete unit exchange.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 3 of 28

Page 4

2. SAFETY CONSIDERATIONS

2.1. Earthing of Equipment

Equipment supplied from the mains must be connected to grounded outlets and earthed

in conformity with appropriate local, national and international electricity supply and

safety regulations.

2.2. Electric Shock Hazard

The risk of electrical shocks due to faulty mains driven power supplies whilst

potentially ever present in any electrical equipment, would be minimised by adherence

to good installation practice and thorough testing at the following stages:

a) Original assembly.

b) Commissioning.

c) Regular intervals, thereafter.

All test equipment must be in good working order prior to its use. High current power supplies can be

dangerous because of the possibility of substantial arcing. Always switch off during disconnection and

reconnection.

2.3. RF Radiation Hazard

RF radiation, (especially at UHF frequencies) arising from transmitter outputs

connected to AFL’s equipment, must be considered a safety hazard.

This condition might only occur in the event of cable disconnection, or because a

‘spare’ output has been left un-terminated. Either of these conditions would impair the

system’s efficiency. No investigation should be carried out until

removed. This would always be a wise precaution, despite the severe mismatch between the

impedance of an N type connector at 50, and that of free space at 377, which would severely

mitigate against the efficient radiation of RF power. Radio frequency burns could also be a hazard, if

any RF power carrying components were to be carelessly touched!

Antenna positions should be chosen to comply with requirements (both local & statutory) regarding

exposure of personnel to RF radiation. When connected to an antenna, the unit is capable of

producing RF field strengths, which may exceed guideline safe values especially if used with

antennas having appreciable gain. In this regard the use of directional antennas with backscreens

and a strict site rule that personnel must remain behind the screen while the RF power is on, is

strongly recommended.

Where the equipment is used near power lines or in association with temporary masts not having

lightning protection, the use of a safety earth connected to the case-earthing bolt is strongly advised.

2.4. Lifting and other Health and Safety Recommendations

Certain items of AFL equipment are heavy and care should be taken when lifting them

by hand. Ensure that a suitable number of personnel, appropriate lifting apparatus

and appropriate personal protective equipment is used especially when installing Cell

Enhancers above ground e.g. on a mast or pole.

all RF power sources have been

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 4 of 28

Page 5

2.5. Chemical Hazard

Beryllium Oxide, also known as Beryllium Monoxide, or Thermalox™, is sometimes

used in devices within equipment produced by Aerial Facilities Ltd. Beryllium oxide

dust can be toxic if inhaled, leading to chronic respiratory problems. It is harmless if

ingested or by contact.

Products that contain beryllium are load terminations (dummy loads) and some power amplifiers.

These products can be identified by a yellow and black “skull and crossbones” danger symbol (shown

above). They are marked as hazardous in line with international regulations, but pose no threat under

normal circumstances. Only if a component containing beryllium oxide has suffered catastrophic

failure, or exploded, will there be any danger of the formation of dust. Any dust that has been created

will be contained within the equipment module as long as the module remains sealed. For this reason,

any module carrying the yellow and black danger sign should not be opened. If the equipment is

suspected of failure, or is at the end of its life-cycle, it must be returned to Aerial Facilities Ltd for

disposal.

To return such equipment, please contact the Quality Department, who will give you a Returned

Materials Authorisation (RMA) number. Please quote this number on the packing documents, and on

all correspondence relating to the shipment.

PolyTetraFluoroEthylene, (P.T.F.E.) and P.T.F.E. Composite Materials

Many modules/components in AFL equipment contain P.T.F.E. as part of the RF insulation barrier.

This material should never be heated to the point where smoke or fumes are evolved. Any person

feeling drowsy after coming into contact with P.T.F.E. especially dust or fumes should seek medical

attention.

2.6. Laser safety

General good working practices adapted from

EN60825-2: 2004/ EC 60825-2:2004

Do not stare with unprotected eyes or with any unapproved optical device at the fibre

ends or connector faces or point them at other people, Use only approved filtered or attenuating

viewing aids.

Any single or multiple fibre end or ends found not to be terminated (for example, matched, spliced)

shall be individually or collectively covered when not being worked on. They shall not be readily

visible and sharp ends shall not be exposed.

When using test cords, the optical power source shall be the last connected and the first

disconnected; use only approved methods for cleaning and preparing optical fibres and optical

connectors.

Always keep optical connectors covered to avoid physical damage and do not allow any dirt/foreign

material ingress on the optical connector bulkheads.

The optical fibre jumper cable maximum bend radius is 3cm; any smaller radii may result in optical

cable breakage or excessive transmission losses.

Caution: The FO units are

NOT weather proof.

2.7. Emergency Contact Numbers

The AFL Quality Department can be contacted on:

Telephone +44 (0)1494 777000

Fax. +44 (0)1494 777002

e-mail

qa@aerialfacilities.com

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 5 of 28

Page 6

3. EQUIPMENT OVERVIEW

The AFL UHF Bandselective, Bi-Directional Amplifier (BDA) (55-199102) is a 2-way on-band repeater.

The equipment is supplied in a four-point, wall-mounting, environmentally protected (IP65) aluminium

alloy lockable case. All RF ports and connectors are also IP65 standard making the entire enclosure

and connecting ports weatherproof. Handles are provided for carrying the unit and the door is fitted

with locks. A supply isolator switch is fitted inside the unit and there are D.C. and Alarm On indicators

on the outside of the door.

The UHF Bandselective, BDA (55-199102) is a 2-port device for direct connection to two antennas,

usually a highly directional Yagi or similar aligned towards the base (donor) site and an omnidirectional or leaky feeder antenna to cover the mobiles. The frequency bands that are passed by the

BDA are set as per the specific customer requirements.

Each active sub-module of the BDA carries its own volt-free, alarm relay contact interface which may

be easily integrated into any such summary system. In addition to this, over temperature and door

intrusion alarms are also fitted.

The Uplink signal enters at the ‘Mobile’ port, passes through a bandpass filter (02-010701) tuned to

the uplink band (415 - 418MHz) and then is amplified by the uplink path of Bi-Directional Amplifier

(17-017301) before passing through a second bandpass filter (02-010701)

The signal then passes through a second amplification stage (30dB gain 5Watt,), the signal then

passes through a third bandpass filter (02-010701) before exiting the unit at the ‘Base’ port

The Downlink signal enters at the ‘Base’ port and is passed through a bandpass filter (02-010701)

tuned to the downlink band (406 - 409MHz), the signal then passes through the downlink path of BiDirectional Amplifier (17-017301) and a second bandpass filter (02-010701) before being split into two

equal paths by 3dB Splitter/Combiner (05-002603). Each separate path is then passed through a

further amplification stage, each path pasing through a Linearised Power Amplifier (12-026901). After

exiting the amplifiers the two separate signals are recombined by a second 3dB Splitter/Combiner

(05-002603) before passing through a third bandpass filter (02-010701) and then exiting the unit at

the "mobile" port

The uplink and the downlink paths are fitted with signal attenuators providing an attenuation range of

0 to 30 dB per path, adjustable in 2dB steps. The attenuators themselves are integral to the sub

module Bi-Directional Amplifier (17-017301) and are controlled by toggle switches mounted inside the

case of the Bandselective, BDA (55-199102)

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 6 of 28

Page 7

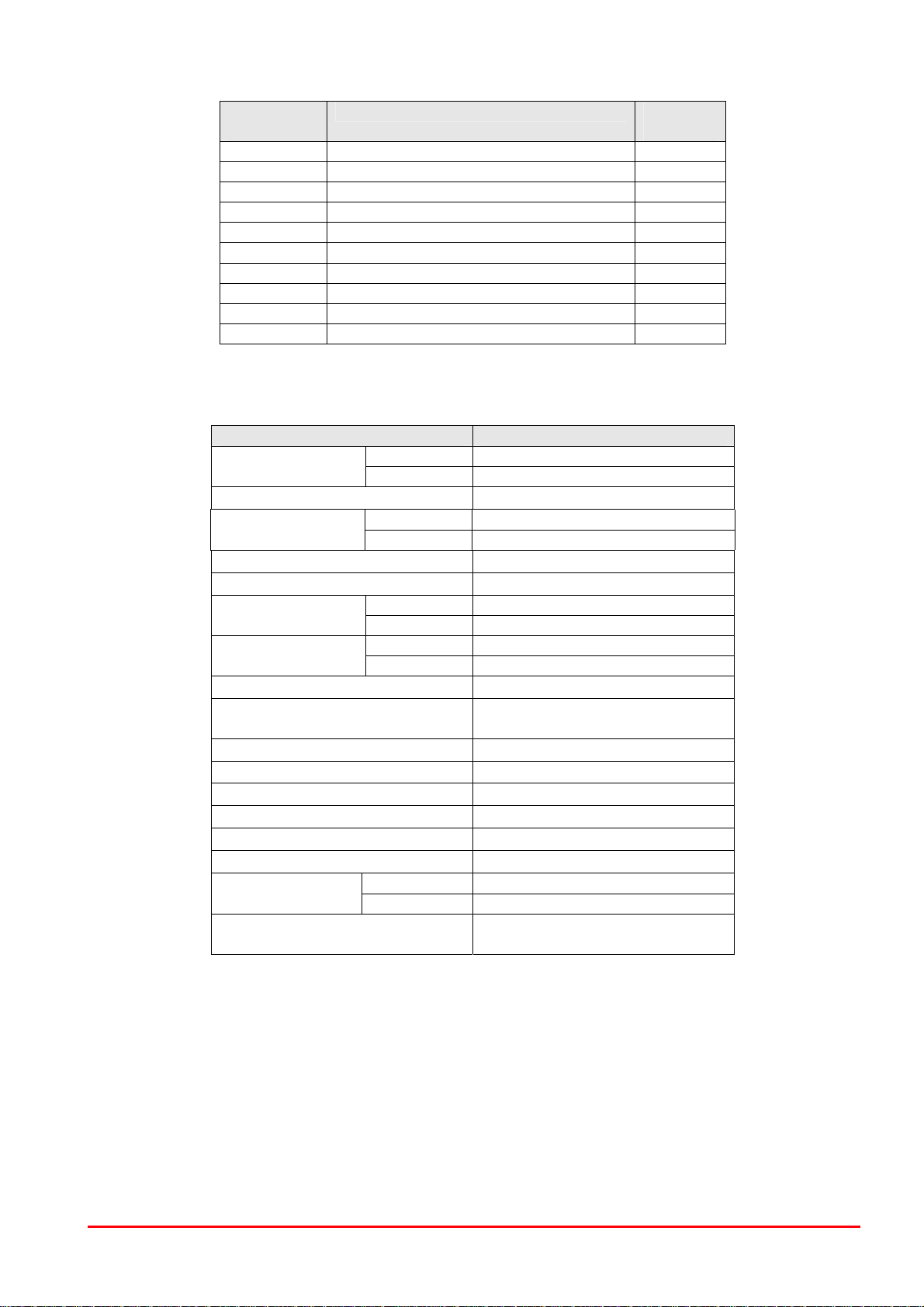

3.1. UHF Bandselective, BDA (55-199102) List of major sub modules

Component

Part

02-010701 Bandpass FIlter 6

05-002603 3dB Splitter/Combiner 2

10-001725 Remote Attenuator Switch Assembly 2

12-021601 5 Watt Tetra Amplifier 1

12-026901 Linearised Power Amplifier 2

13-001714 Voltage Regulator 2

13-003011 DC/DC Converter 1

17-017301 Bi-Directional Amplifier 1

80-008901 12V (Single) Relay Board 1

96-300054 24V Switch-Mode PSU 1

Component Part Description Qty Per

Assembly

3.2. UHF Bandselective, BDA (55-199102) Specification.

Parameter Specification

Passband

Passband gain 90dB

Power Amplifier

Passband Ripple <±1.5 dB

I/P Return Loss > 14dB

1dB Compression

Noise Figure <4dB (max.gain)

In Band Spurious Noise

30kHz Bandwidth

Uplink ALC Setting 1dB below 1dB Comp.

Switched Attenuator (U/L & D/L) 2 dB steps 2-30dB (± 1dB)

Power Supply Current Rating 400W , 17A @ 24VD.C.

Alarm Output Type Local Alarms

AC Supply Voltage 110V AC

RF Connectors N type female

Temperature

range:

(excludes h/sinks handles etc.)

Uplink 415 - 418MHz

Downlink 406 - 409MHz

Uplink 5 Watt

Downlink 40 Watt

Uplink +35dB

Downlink +45dB

Uplink +48dBm OIP3

Downlink +62dBm

< -13 dBm

(at 90dB gain)

operation: -20°C to +60°C

storage: -40°C to +70°

Case Size

620x420x250 mm

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 7 of 28

Page 8

3.3. UHF Bandselective, BDA (55-199102) System Schematic

Drawing Number: 55-199182

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 8 of 28

Page 9

3.4. Photographs

3.4.1. Front of case – door closed

A Green LED “Power On”

B Red LED “Alarm”

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 9 of 28

Page 10

3.4.2. Front of case – door open

A Bandpass Filters (02-010701)

B Bandpass Filters (02-010701)

C Linearised Power Amplifier (12-026901) (Downlink)

D 24V Switch-Mode PSU (96-300054)

E Bi-Directional Amplifier (17-017301)

F Linearised Power Amplifier (12-026901) (Downlink)

G 5 Watt Tetra Amplifier (12-021601) (Uplink)

H 3dB Splitter/Combiner (05-002603)

I 3dB Splitter/Combiner (05-002603)

J Voltage Regulators (13-001714)

K DC/DC convertor (13-003011)

L Attenuator control switches, Uplink top row – Downlink bottom row

M Mains On/Off switch

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 10 of 28

Page 11

3.4.3. Right Hand and Left Hand sides

A Antenna Facing Mobile Port

B Alarm Output

C Earth Connection

D AC Input

E Antenna Facing Base Port

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 11 of 28

Page 12

4. UHF BANDSELECTIVE, BDA (55-199102) SUB MODULES

4.1. Bandpass Filter (02-010701)

The bandpass filters are multi-section designs with a bandwidth dependent upon the passband

frequencies, (both tuned to customer requirements). The response shape is basically Chebyshev with

a passband design ripple of 0.1dB. The filters are of combline design, and are carefully aligned during

manufacture in order to optimise the insertion loss, VSWR and intermodulation characteristics of the

unit. The tuned elements are silver-plated to reduce surface ohmic losses and maintain a good VSWR

figure and 50 load at the input and output ports.

Being passive devices, the bandpass filters should have an extremely long operational life and require

no maintenance. Should a filter be suspect, it is usually most time efficient to replace the module

rather than attempt repair or re-tuning.

02-010701 Specification

PARAMETER SPECIFICATION

Response type: Chebyshev

Frequency range:

Bandwidth: 3 MHz

Number of sections: 5

Insertion loss: 1.7 dB (typical)

VSWR: better than 1.2:1

Connectors: SMA

Power Handling: 100W max

Temperature range

operation: -20°C to +60°C

storage: -40°C to +70°C

Weight: 3 kg (typical)

415 - 418MHz (uplink)

406 - 409MHz (downlink)

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 12 of 28

Page 13

4.2. 3dB Splitter/Combiner (05-002603)

The 3dB Splitter/Combiner (05-002603) is a device for accurately matching two RF signals to a single

port or splitting an RF signal to two ports whilst maintaining an accurate 50 load to all inputs/outputs

and ensuring that the VSWR and insertion losses are kept to a minimum.

05-002603 Specification

PARAMETER SPECIFICATION

Frequency range: 380 - 520 MHz

Bandwidth: 140 MHz

Ports

Return Loss (VSWR) – Input: Better than 1.3:1

Return Loss (VSWR) – Output: Better than 1.3:1

Power Rating – Combiner: 0.5 Watt

Power Rating – Splitter: 20 Watts

As Combiner 2 inputs 1 output

As Splitter 1 input 2 outputs

Insertion loss: 3.5 dB (typical)

Isolation: >18 dB

Impedance: 50 Ω

Connectors: SMA female

Size: 54 x 44 x 21 mm

Weight: 200 gm (approximately)

4.3. Remote Attenuator Switch Assembly (‘10-001725’)

The remote attenuator switch assembly is used to control the amount of signal attenuation in the submodule, Bi-Directional Amplifier (17-017301). The switch assembly is mounted on the inside of the

Bandselective BDA (55-199102) case and consists of four miniature toggle switches, one row for

uplink and one row for downlink, built around the remote attenuator switch PCB (10-001725)

The switch assembly allows attenuation settings from 0 – 30dB in 2 dB steps The attenuation is

simply set using the four miniature toggle switches. Each switch is clearly marked with the attenuation

it provides, and the total attenuation in line is the sum of the values switched in. The attenuators that

the switches control are integral to sub-module Bi-Directional Amplifier (17-017301).

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 13 of 28

Page 14

4.4. 5 Watt Tetra Amplifier (12-021601)

The power amplifier fitted to this unit is a multi-stage, solid state power amplifier. Class A circuitry is

employed throughout the device to ensure excellent linearity over a wide dynamic frequency range.

All the semi-conductor devices are very conservatively rated to ensure low device junction

temperatures and a long, trouble free working lifetime.

The power amplifier should require no maintenance over its operating life. Under no circumstances

should the cover be removed or the side adjustments disturbed unless it is certain that the amplifier

has failed; since it is critically aligned during manufacture and any re-alignment will require extensive

test equipment.

The unit housing is an aluminium case (Iridite NCP finish) with SMA connectors for the RF

input/output and a D-Type connector for the power supply and the Current Fault Alarm Function.

12-021601 Specification

PARAMETER SPECIFICATION

Frequency range: 380-470MHz (as required)

Bandwidth: 10-40MHz (typical, tuned to spec.)

Maximum RF output: >5Watts

Gain: >30dB

1dB compression point: +37.5dBm

3rd order intercept point: +50dBm

VSWR: better than 1.5:1

Connectors: SMA female

Supply: 1.9Amps @ 12V DC

Weight: 1kg (excluding heatsink)

operational:

range:

storage:

7-Way Connector Pin-out details

Connector Pin Signal

A1 (large pin) +10-24V DC

A2 (large pin) GND

1 Alarm relay common

2 TTL alarm/0V good

3 Alarm relay contact (bad)

4 Alarm relay contact (good)

5 O/C good/0V bad (TTL)

7-Way Pin-Out Graphical Representation

A1 A2

3 4 5

-10°C to +60°C Temperature

-20°C to +70°C

1 2

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 14 of 28

Page 15

4.5. Linearised Power Amplifier (12-026901)

The power amplifier fitted to (this unit) is a multi-stage, solid state power amplifier. Class A circuitry is

employed throughout the device to ensure excellent linearity over a wide dynamic frequency range.

All the semi-conductor devices are very conservatively rated to ensure low device junction

temperatures and a long, trouble free working lifetime.

The power amplifier should require no maintenance over its operating life. Under no circumstances

should the cover be removed or the side adjustments disturbed unless it is certain that the amplifier

has failed; since it is critically aligned during manufacture and any re-alignment will require extensive

test equipment. The amplifier has a D-Type connector for the power supply and a Current Fault Alarm

Function.

12-026901 Specification

PARAMETER SPECIFICATION

Frequency range: 380-440MHz (tuned to spec.)

Bandwidth: <60MHz (typical)

Maximum RF output: >25Watt

Small signal gain: 37.5dB (typical)

1dB compression point: +44dBm

3rd order intercept point: +61dBm

Noise figure: N/A

Return input loss: >15dB

Return output loss: >15dB

VSWR: better than 1.5:1

RF Connectors: SMA female

Supply: 4.6Amps @ 24V DC

operation:

range:

storage:

Weight: 1.5 kg

12-026901 7-Way Connector Pin-outs

Connector Pin Signal

A1 (large pin) +24V DC

A2 (large pin) GND

1 Alarm relay common

2 TTL alarm/0V good

3 Alarm relay contact (bad)

4 Alarm relay contact (good)

5 O/C good/0V bad (TTL)

7-Way Connector Graphical Representation

A1 A2

3 4 5

-10°C to +60°C Temperature

-20°C to +70°C

1 2

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 15 of 28

Page 16

4.6. Voltage Regulator Board 9.0V (13-001714)

This unit it is used to derive a fixed voltage power supply rail from some higher voltage. In this

instance it is used to derive 9V from a 12V input.

The circuit is based upon a fixed voltage regulator, which is capable of supplying a maximum of 2.0 A

output current. Note that at full output current the dissipation of the device must remain in limits,

bearing in mind the voltage which is being dropped across it. The maximum allowable dissipation will

also depend on the efficiency of the heatsink on which the device is mounted.

13-001714 Specification

PARAMETER SPECIFICATION

Operating voltage: 12V DC

Output voltages: 9.0V

Output current: 2.0A (maximum per o/p)

Connections: Screw Terminal Block

operational: -10°C to +60°C Temperature

range:

storage: -20°C to +70°C

PCB Size: 30.5 x 38.1mm

4.7. DC/DC Converter, 24V in, 12V 8A out (13-003011)

The DC/DC converter fitted is an AFL assembled, high power PCB unit with an 8 amp at 12V output

capability. The circuit is basically an O.E.M semiconductor regulator (one side of which has a heatsink

mounting plate, usually bolted to the casing of a Cell Enhancer) and smoothing components built onto

a printed circuit board with screw block terminations.

In event of failure this unit should not be repaired, only replaced.

13-003011 Specification

PARAMETER SPECIFICATION

Input Voltage range: 18-28V DC

Output voltage: 12V±0.5V

Max. current load: 8.0Amps

operation: -10°C to +60°C Temperature

range:

Size(PCB): 190 x 63mm

Weight (Loaded PCB): 291gms

storage: -20°C to +70°C

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 16 of 28

Page 17

4.8. Bi-Directional Amplifier (17-017301)

This module is a Bi-Directional Amplifier (up-link and down-link). All the amplifier stages are of

balanced type and there is additionally digital attenuation, automatic level control (ALC) in the uplink

path and also Current Fault Alarm Function circuitry, which indicates failure of each RF transistor in

various ways – open collector, closed collector (TTL) and a relay to indicate the failure by voltage free

change over contacts.

The module is housed in an aluminium case (Iridite NCP finish) with SMA connectors for the RF

input/output and a D-type connector for power supply and Current Fault Alarm Function.

Specification 17-017301

PARAMETER SPECIFICATION

Frequency Range MHz 380-430

Gain 64 - 66 dB

Gain Flatness 2.0 dB

ΔGain vs. Temp.

ALC dynamic Range 28 dB Min

ALC o/p power level 29 ± 0.5 dBm Min

Input Return Loss 15 dB Min

Output Return Loss 18 dB Min

P1dB 30 dBm Min

OIP3 41 dBm Min

Noise Figure 1.7 dB Max

DC Supply 9.0V ± 0.5 at 1120 mA Max

Max RF Input +15dBm

Storage temperature -40 to +100 ºC

Operating temperature -20 to +70 ºC

Dimensions 291.0 x 165.6 x 28.5 mm

BDA ‘D’ Connector Pin-out details

Connector pin Signal

1 +ve input (9V)

2 +ve input (9V)

3 GND

4 GND

5 Alarm relay good

6 Alarm relay common

7 Alarm relay O/P bad

8 Attenuator In

9 Detector Out

10 Digital Attenuator Bit 1

11 Digital Attenuator Bit 2

12 Digital Attenuator Bit 3

13 Digital Attenuator Bit 4

14 Not Used

15 Not Used

2.5 dB Max

15-Way Pin-Out Graphical Representation

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 17 of 28

Page 18

4.9. 12V (Single) Relay Board (80-008901)

The General Purpose Relay Board allows the inversion of signals and the isolation of circuits. It is

equipped with a single dual pole change-over relay RL1, with completely isolated wiring, accessed

via a 15 way in-line connector.

The relay is provided with polarity protection diodes and diodes for suppressing the transients caused

by "flywheel effect" which can destroy switching transistors or induce spikes on neighbouring circuits.

It’s common use is to amalgamate all the alarm signals into one, volts-free relay contact pair for the

main alarm system.

Specification 80-008901

PARAMETER SPECIFICATION

Operating voltage: 8 to 30V (floating earth)

Alarm threshold: Vcc - 1.20 volt +15%

Alarm output relay contacts:

Max. switch current: 1.0Amp

Max. switch volts: 120Vdc/60VA

Max. switch power: 24W/60VA

Min. switch load: 10.0µA/10.0mV

Relay isolation: 1.5kV

Mechanical life:

Relay approval: BT type 56

Connector details: Screw terminals

operational: -10°C to +60°C Temperature

range

storage: -20°C to +70°C

>2x107 operations

4.10. 24V Switch-Mode PSU (96-300054)

The power supply unit is a switched-mode type capable of supplying 24V DC at 17.0Amps

continuously. Equipment of this type typically requires approximately 10.0 Amps at 24V DC, so the

PSU will be used conservatively ensuring a long operational lifetime.

No routine maintenance of the PSU is required. If a fault is suspected, then the output voltage from

the power supply may be measured on its output terminals. This is typically set to 24.5V using the

multi-turn potentiometer mounted close to the DC output studs on the PSU PCB.

All the PSUs used in AFL Cell Enhancers are capable of operation from either 110 or 220V nominal

AC supplies. The line voltage is sensed automatically, so no adjustment or link setting is needed by

the operator.

96-300054 Specification

AC Input Supply

Voltages:

Frequency: 47 to 63Hz

DC Output Supply:

Voltage:

Maximum current: 17A

110 or 220V nominal

90 to 132 or 180 to 264V (absolute limits)

24V DC (nominal)

20 to 28V (absolute limits)

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 18 of 28

Page 19

5. INSTALLATION & COMMISIONING

5.1. Antenna Installation & Gain Calculations

1 Most Cell Enhancer require two antennas, one a highly directional Yagi or similar directed

towards the donor cell base station, and one a leaky feeder, omni-directional antenna or Yagi to cover

the area in which the mobiles are to be served.

2 The maximum gain at which the Cell Enhancer can be set is limited by the isolation that can

be achieved between these two antennas. Therefore when the antennas have been installed, inject a

signal (at a known power level) into one of them and measure the signal level received by the other

antenna on a spectrum analyser. The isolation can then be calculated as the difference between

these two figures. The gain in each path of the Cell Enhancer should be set at least 10 dB below this

figure, using attenuators as described below in paragraph 5.

3 Also measure the received signal from the donor cell at the input to the Cell Enhancer (base

port). The gain of the Cell Enhancer downlink path should be set such the donor site will not overload

the Cell Enhancer amplifiers. It is recommended that the input level should be less than -50dBm at

the input of the Cell Enhancer (Base Port). (This figure is assuming maximum gain, and may be

increased by the value of the attenuator fitted in the downlink path.)

4 Ensure that the mobile facing antenna has at least 70 dB isolation from the nearest mobile.

(This is usually easily achieved when using a leaky feeder.)

5 The Cell Enhancer gain is set by setting the attenuation in each path (uplink and downlink)

between the first two amplifier stages (see markings within the Cell Enhancer or layout drawings for

the exact attenuator locations). Note that the uplink (mobile to base) and downlink (base to mobile)

path gains are set independently. This allows the paths to have different gains if required to set the

correct output power levels.

6 It is recommended that the gains are set such that the Downlink output levels from the Cell

Enhancer are typically +44dBm. (Input level + Gain = Output level).

5.2. Initial Installation Record

When this equipment is initially commissioned, please use the equipment set-up record sheet in

Appendix B This will help both the installation personnel and AFL should these figures be needed for

future reference or diagnosis.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 19 of 28

Page 20

6. FAULT FINDING / MAINTENANCE

6.1. Tools & Test Equipment

The minimum tools and test equipment needed to successfully service this AFL product are as

follows:-

Spectrum analyser: 100kHz to 2GHz (Dynamic range = 90dB).

Signal Generator: 30MHz to 2GHz (-120dBm to 0dBm o/p level).

Attenuator: 20dB, 10W, DC-2GHz, (N male – N female).

Test Antenna: Yagi or dipole for operating frequency.

Digital multi-meter: Universal Volt-Ohm-Amp meter.

Test cable x 2: N male – N male, 2M long RG214.

Test cable x 2: SMA male – N male, 1m long RG223.

Hand tools: Philips #1&2 tip screwdriver.

3mm flat bladed screwdriver.

SMA spanner and torque setter.

6.2. Basic Fault Finding

In the event that the performance of the system is suspect, a methodical and logical approach to the

problem will reveal the cause of the difficulty. The System consists of modules in a wall-mounted

enclosure.

Transmissions from the main base stations are passed though the system to the mobile radio

equipment; this could be a handheld radio or a transceiver in a vehicle. This path is referred to as the

downlink. The return signal path from mobile radio equipment to the base station is referred to as the

uplink.

The first fault finding operation is to check the alarms of each of the active units and determine that

the power supplies to the equipment are connected and active. This can be achieved remotely (via

CEMS, the RS232

panel LEDs. The green LED on the front panel should be illuminated, while the red alarm indicator

should be off. Note that passive only shelves will have no DC power or alarm indicators. If an Alarm is

on, then that individual shelf must be isolated and individually tested against the original test

specification. The individual amplifier units within any shelf have a green LED showing through a hole

in their cover, which is illuminated if the unit is working correctly. (Without active power supplies there

can be no alarm LED indicators, however without DC power, the fail-safe summary alarm system

[normally closed relay contacts] will be an open circuit, thereby activating any externally connected

system.)

If an amplifier is suspect, check the DC power supply to the unit. If no other fault is apparent use a

spectrum analyser to measure the incoming signal level at the input and then after reconnecting the

amplifier input, measure the output level. Consult with the system diagram to determine the expected

gain and compare result.

In the event that there are no alarms on and all units appear to be functioning it will be necessary to

test the system in a systematic manner to confirm correct operation.

Coverage Enhancement Management System, if fitted), or locally with the front

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 20 of 28

Page 21

6.3. Quick Fault Checklist

All AFL equipment is individually tested to specification prior to despatch. Failure of this type of

equipment is not common. Experience has shown that a large number of fault conditions relating to

installations result from simple causes often occurring as result of transportation, unpacking and

installation. Below are listed some common problems which have resulted in poor performance or an

indicated non-functioning of the equipment.

Mains power not connected or not switched on.

External connectors not fitted or incorrectly fitted.

Internal connectors/ports becoming loose due to transport vibration.

Wiring becoming detached as a result of heavy handling.

Input signals not present due to faults in the aerial or feeder system.

Base transmissions not present due to faults at the base station.

Modems fitted with incorrect software configuration/and or PIN Nos.

Changes to channel frequencies and inhibiting channels.

Hand held radio equipment not correctly set to repeater channels.

Hand held radio equipment not correctly configured to base station.

6.4. Downlink

C

onfirm that there is a signal at the expected frequency and strength from the base station(s). If this is

not present then the fault may lay outside the system. To confirm this, inject a downlink frequency

signal from a known source at the BTS input and check for output at the antenna output port.

If a signal is not received at the output it will be necessary to follow the downlink path through the

system to find a point at which the signal is lost.

6.5. Uplink

T

esting etc. of the uplink paths is similar to the downlink paths, except for the frequencies involved.

6.6. Fault repair

O

nce a faulty component has been identified, a decision must be made on the appropriate course to

carry out a repair. A competent engineer can quickly remedy typical faults such as faulty connections

or cables. The exceptions to this are cable assemblies connecting bandpass filter assemblies

(duplexers) that are manufactured to critical lengths to maintain a 50-ohm system.

Care should be taken when replacing cables or connectors to ensure that items are of the correct

specification. The repair of component modules such as amplifiers and bandpass filters will not

usually be possible in the field, as they frequently require specialist knowledge and test equipment to

ensure correct operation. It is recommended that items of this type are replaced with a spare unit and

the faulty unit returned to AFL for repair.

Following the repair of any part of the system it is recommended that a full end-to-end test is carried

out in accordance with the test specification and that the coverage is checked by survey.

It is important to bear in mind that the system includes antennas and base stations that m

or may have been damaged.

ay be faulty

6.7. Service Support

A

dvice and assistance with maintaining and servicing this system are available by contacting Aerial

Facilities Ltd. see section 2.7.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 21 of 28

Page 22

6.8. Care of Modules

Many of the active modules contain semiconductor devices utilising MOS technology, which can be

damaged by electrostatic discharge. Correct handling of such modules is mandatory to ensure their

long-term reliability. Good engineering practices should be observed at all times.

To prevent damage to a module, it must be withdrawn/inserted with care.

6.9. Module Removal (LNAs, general procedure):

The following general rules should be followed to remove a module:

1) Remove power to the unit

2) Remove all connectors (RF, DC/alarm)

3) Release module retaining screws.

4) Slowly but firmly, pull the module straight out of its position. Take care not to twist/turn the

module during withdrawal.

6.10. Module Replacement (general):

1) Carefully align the module into its location then slowly push the module directly straight into its

position, taking care not to twist/turn it during insertion.

2) Reconnect all connectors, RF, alarm, power etc.

3) Replace retaining screws (if any).

4) Double-check all connections before applying power.

6.11. Power Amplifiers

1) Remove power to the unit. (Switch off at mains/battery)

2) Disconnect multi-way alarm ‘D’ type connector

3) Carefully disconnect the RF input and output coaxial connectors (usually SMA)

4) If the amplifier to be removed has a heatsink attached, there may be several different ways it

can have been assembled. The most commonly used method, is screws through the front of the

heatsink to threaded screw holes (or nuts and bolts), into the amplifier within the main case. If the

heatsink is mounted on the rear of the main case (e.g., against a wall in the case of wall mounted

enclosures), then the fixing method for the heatsink will be from within the case, (otherwise the

enclosure would have to be removed from the wall in order to remove the heatsink).

When the heatsink has been removed, the amplifier may be unscrewed from the main casing by its

four corner fixings and gently withdrawn.

Fitting a new power amplifier module will be the exact reverse of the above.

Note: Do not forget to apply fresh heatsink compound to the heatsink/main case joint and

also between the amplifier and the main case.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 22 of 28

Page 23

5) If the amplifier to be removed has a heatsink attached, there may be several different ways it

can have been assembled. The most commonly used method, is screws through the front of the

heatsink to threaded screw holes (or nuts and bolts), into the amplifier within the main case. If the

heatsink is mounted on the rear of the main case (e.g., against a wall in the case of wall mounted

enclosures), then the fixing method for the heatsink will be from within the case, (otherwise the

enclosure would have to be removed from the wall in order to remove the heatsink).

When the heatsink has been removed, the amplifier may be unscrewed from the main casing by its

four corner fixings and gently withdrawn.

Fitting a new power amplifier module will be the exact reverse of the above.

Note: Do not forget to apply fresh heatsink compound to the heatsink/main case joint and also

between the amplifier and the main case.

6.12. Low Power Amplifier Replacement

Disconnect the mains power supply and disconnect the 24V dc supply connector for the LPA.

Disconnect the RF input and output cables from the LPA.

Disconnect the alarm connector.

Remove the alarm monitoring wires from (D type connector) pins 9 and 10.

Remove the LPA module by removing the four retaining screws, replace with a new LPA module and

secure it with the screws.

Connect the RF cables to the LPA input and output connectors. Reconnect the wires to the alarm

board connector pins 9 and 10.

Reconnect the DC supply connector and turn the mains switch on.

Note: Tighten SMA connectors using only a dedicated SMA torque spanner. If SMA connectors are

over-tightened, irreparable damage will occur. .

connectors.

Also take care not to drop or knock the module as this can damage (or misalign in the case of tuned

passive modules) sensitive internal components. Always store the modules in an environmentally

friendly location

Test equipment should always be used to verify the performance of any new module fitted to

the system before broadcasting in the public domain.

Do not use adjustable pliers to loosen/tighten SMA

6.13. Module Transportation:

To maintain the operation, performance and reliability of any module it must be stored and

transported correctly. Any module not installed in a whole system must be kept in an anti-static bag or

container. Any module sent back to AFL for investigation/repair must be so protected. Please contact

AFL’s quality department before returning a module, see section 2.7.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 23 of 28

Page 24

APPENDIX A

A.1. Glossary of Terms used in this document

Repeater or

Cell Enhancer

Band Selective

Repeater

Channel Selective

Repeater

AC Alternating Current

AGC Automatic Gain Control

BBU Battery Backup Unit

BTS Base Transceiver Station

CEMS Coverage Enhanced Management System

C/NR Carrier-to-Noise Ratio

DC Direct Current

Downlink (D/L) RF signals TX from the BTS to the Master Site

FO Fibre Optic

GND Ground

ID Identification Number

LED Light Emitting Diode

LNA Low Noise Amplifier

LPA Low Power Amplifier

MOU Master Optical Unit

M.S. Mobile Station

MTBF Mean Time Between Failures

N/A Not Applicable

N/C No Connection

OFR On Frequency Repeater

OIP3 Output Third Order Intercept Point

P1dB 1dB Compression Point

PA Power Amplifier

RF Radio Frequency

RSA Receiver/Splitter Amplifier

RX Receiver

S/N Serial Number

TX Transmitter

Uplink (U/L) RF signals transmitted from the MS to the BTS

VSWR Voltage Standing Wave Ratio

WDM Wave division multiplex

A Radio Frequency (RF) amplifier which can simultaneously

amplify and re-broadcast Mobile Station (MS) and Base

Transceiver Station (BTS) signals.

A Cell Enhancer designed for operation on a range of channels

within a specified frequency band.

A Cell Enhancer, designed for operation on specified channel(s)

within a specified frequency band. Channel frequencies may be

factory set or on-site programmable.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 24 of 28

Page 25

A.2. Key to Drawing Symbols used in this document

A

89

ANTENNAS

OMNI ANTENNA

YAGI ANTENNA

FLAT PLATE ANTENNA

(MOUNTED AT HIGH LEVEL)

DIRECTIONAL ANTENNA

ANTENNA

REMOTE ANTENNA UNIT

RAU

SPLITTERS

HYBRID SPLITTER

OUT

OUT

IN

CABLES

8/FIBRE OPTIC CABLE /LINK

4 6

CABLE 1/2"

RADIATING CABLE

1/2" DIA

C0-AX CABLE

CAT 5 CABLE

JUMPER

24/FIBRE OPTIC C ABLE/LINK

J

3 5 7

COUPLERS

6 dB DIRECTIONAL COUPLER

10dB COUPLER

10dB DIRECTIONA L COUPLER

DIRECTIONAL COUPLER

6dB DIRECTIONAL COUPLER

C10

C6

OUTIN

C10

COUPLED

2

HUBS

FIBRE MAIN HUB

1

FMH

TAPPER/COUPLER

EXPANSION HUB

E

EH

A

B

Outputs

C0-AX CABLE

CROSS BAND COUPLER

HI COM

B

C

STANDARD EXCEPT

LEVEL (dBm)

IDENTITY CODE)

BSIC (BASIC SITE

BCCH (BROADCAST

= READING POSITION

CONTROL CHANNEL)

22 =

602 =

AC TO DC PSU

-82 = ACCEPTABLE SIGNAL

DC TO DC

CONVERTER

DC

PANEL ANTENNA

SPLITTER

(up to

16 way)

SIGNAL KEY

BLADE ANTENNA

MISC

DC

MISC

AMPLIFIER

7/8" DIA

MISC

LOW

MISC

ATTENUATOR (VARIAB LE)

dB

BAND PASS FILTER

CAVITY RESONATOR

STATION

BASE TRANSCEIVER

B/W=30 to 200kHz

BTS

CHANNEL MODULE

A.G.C

ATTENUATOR (FI XED)

dB

AGC dB

NOTCH FILTER

ISOLATOR

IN

FIBRE-OPTIC

MODULATOR

FREQUENCY PROGRAMMING

RF

DATA

C

D

FOR AIRPORTS

(SEE BELOW)

SIGNAL LEVEL(dBm)

-83 = BELOW ACCEPTABLE

FUSE

MONITORING CONTROLLER

MONITORING

CONTROLLER

HYBRID COMBINER

OUT

IN

FIBRE-OPTIC

DEMODULATOR

RF

D

-72 = ACCEPTABLE SIGNAL

STANDARD FOR

N.O. (CLEAR CONTACT)

MODEM

EARTH STUD

PL

E

BYDATEDESCRIPTIONNo

PL

PLBLADE ANTENNA ADDED1A

PL

F

3

A

9

23/05/00

21/06/00

26/01/04

28/07/04

ALL AIRPORTS

ISSUE

90-000001

8

LEVEL (dBm)

SIGNAL LEVEL(dBm)

-73 = BELOW ACCEPTABLE

2B TEXT CORRECTION

2A ECN3165

ORIGINAL

ISSUE

AA

7

AFL - STANDARD SYMBOLS

TITLE

RELAY

N.C. (FILLED CONTACT)

COM

THIRD ANGLE PROJECTION

(CELL ENHANCER)

DUMMY LOAD

BI-DIRECTIONAL AMPLIFIER

MODEM

LOCAL OSCILLATOR

LOCAL OSCILLATOR

CUSTOMER DRAWING.No

England

Aerial Facilities Limited

56

Tel : 01494 777000

Fax : 01494 777002

4

NTS

LEEKY FEEDER

R.S.A

Outputs to receivers

SCALE

23

THIS IS A PROPRIETARY DESIGN OF AERIAL FACILITIES LTD.

REPRODUCTION OR USE OF THI S DESIGN BY OTHERS IS

PERMISSIBLE ONLY IF EXPRESSLY AUTHORISED IN WRITING

BY AERIAL FACILITIES LTD.

NO DECIMAL PLACE ± 1mm

ONE DECIMAL PLACE ± 0.3mm

TWO DECIMAL PLACES ± 0.1mm

FIBRE OPTIC

CONNECTOR

SOCKET

PLUG & SOCKET

FC/APC

PLUG

DATE

TOLERANCES

10/05/00

APPD

1

PL

MB GD

ALL DIMENSIONS ARE IN mm

CHKD

DRAWN

E

UNLESS OTHERWISE STATED

F

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 25 of 28

Page 26

A.3. EC Declaration of Conformity

In accordance with BS EN ISO/IEC 17050-1&-2:2004

Aerial Facilities Limited

Aerial House

Asheridge Road

Chesham

Buckinghamshire HP5 2QD

United Kingdom

DECLARES, UNDER OUR SOLE RESPONSIBILITY THAT THE FOLLOWING PRODUCT:

PRODUCT PART NO[S] 55-199102

PRODUCT DESCRIPTION UHF Bandselective Bi-Directional Amplifier

IN ACCORDANCE WITH THE FOLLOWING DIRECTIVES:

1999/5/EC The Radio & Telecommunications Terminal Equipment Directive Annex V

and its amending directives

HAS BEEN DESIGNED AND MANUFACTURED TO THE FOLLOWING STANDARD[S] OR

OTHER NORMATIVE DOCUMENT[S]:

BS EN 60950 Information technology equipment.

Safety. General requirements

ETS EN 301 489-1 EMC standard for radio equipment and services.

Part 1. Common technical requirements

I hereby declare that the equipment named above has been designed to comply with the relevant

sections of the above referenced specifications. The unit complies with all essential requirements

of the Directives.

SIGNED

B S BARTON

TECHNICAL DIRECTOR DATE: 01/10/2007

Registered Office: Aerial House, Asheridge Road, Chesham, Buckinghamshire, HP5 2QD England Registered No. 4042808 (England)

Aerial Facilities Limited

www.aerialfacilities.com

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 26 of 28

Page 27

A.4. Amendment List Record Sheet

Issue

No.

A 26/09/2007 AJS Draft

1 05/10/2007 AJS First Issue

Document Ref. 55-199102HBKM

Date Incorporated

by

Page Nos.

Amended

Reason for new issue

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 27 of 28

Page 28

APPENDIX B

Initial Equipment Set-Up Calculations

General Information

Site Name:

Date:

Antenna Systems

Model Gain Azimuth Comments

A - Service Antenna

B – Donor Antenna

Type Loss Length Comments

C – Service Feeder

D – Donor Feeder

Initial Parameters

E – CE Output Power dBm

F – Antenna Isolation dB

G – Input signal level from donor BTS dBm

Operating Voltage V

Downlink Calculations

Parameter Comments Value

Input signal level (G) dBm

CE max. o/p power (E) dBm

Gain setting E - G dB

Isolation required (Gain + 10dB) dB

Service antenna gain (A) dB

Service antenna feeder loss (C) dB

Effective radiated power (ERP) E+A-C dBm

Attenuator setting CE gain-gain setting dB

If the input signal level in the uplink path is known and steady, use the following calculation table to

determine the gain setting. If the CE features Automatic Gain Control the attenuator should be set to

zero and if not, then the attenuation setting for both uplink and downlink should be similar.

Uplink Calculations

Parameter Comments Value

Input signal level dBm

CE max. o/p power (E) dBm

Gain setting dB

Required isolation dB

Donor antenna gain (B) dB

Donor antenna feeder loss (D) dB

Effective radiated power (ERP) E+B-D dBm

Attenuator setting (CE gain-gain setting) dB

Client Name:

AFL Equip. Model No.

UHF Bandselective BDA

90dB 40/5W

Document Number 55-199102HBKM Issue No. 1 Page 28 of 28

Loading...

Loading...