Page 1

24 Channel 800MHz

& VHF Cell Enhancers

Maintenance Handbook

For

Terry Consulting

AFL Works Order N.: Q111353

AFL product part N’s.: 50-078001 (800 & VHF CE’s)

80-209302 (Battery Back-up)

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

1 of 88

Page 2

Table of Contents

AMENDMENT LIST RECORD SHEET.................................................................................................. 6

INTRODUCTION ....................................................................................................................................... 7

Scope...........................................................................................................................................................................7

Purpose.......................................................................................................................................................................7

Glossary of Terms .....................................................................................................................................................8

Key to AFL RF Module Drawing Symbols.............................................................................................................9

1.

SAFETY CONSIDERATIONS .....................................................................................................10

1.1 Earthing of Equipment ..............................................................................................................................10

1.2 Electric Shock Hazard ...............................................................................................................................10

1.3 RF Radiation Hazard.................................................................................................................................11

1.4 Chemical Hazard........................................................................................................................................12

1.5 Emergency Contact Numbers ...................................................................................................................12

2.

OVERVIEW/SYSTEM DESCRIPTION...................................................................................... 13

3.

SPECIFICATION ..........................................................................................................................14

3.P Photographs..................................................................................................................................................14

3.P.1 800MHz Air I/F Uplink Shelf 50-078002................................................................................................14

3.P.2 Eight Channel Downlink Shelf 50-078003 ..............................................................................................15

3.P.3 Power Amplifier/Driver Shelf 50-078004................................................................................................16

3.P.4 800MHz In-Line Amplifier 50-078017....................................................................................................17

3.P.5 VHF/800MHz Multi-Coupler Shelf 50-078015.......................................................................................18

3.P.6 VHF Simplex Shelf 50-078010................................................................................................................19

3.P.7 VHF Duplex Shelf 50-078011 .................................................................................................................20

3.P.8 VHF Air Interface Shelf 50-078012 ........................................................................................................21

3.P.9 VHF Combiner Shelf 50-078013 .............................................................................................................22

3.P.10 PSU Shelf 50-078014...........................................................................................................................23

3.P.11 Battery Backup 80-209302...................................................................................................................24

3.P.12 Rack Photos..........................................................................................................................................25

3.1 Electrical Specification ..............................................................................................................................29

3.2 Channel Frequency Listing .......................................................................................................................30

3.3 Mechanical Specifications..........................................................................................................................31

3.3.1 Rack Mounted Equipment Mechanical Specifications.............................................................................31

3.3.2 Wall Mounted Equipment (50-078017 & 80-209302).............................................................................31

3.4 Parts Lists ...................................................................................................................................................32

3.4.1 Whole System Parts List (50-078001) .....................................................................................................32

3.4.2 800MHz AIF Uplink Shelf 50-078002 Parts List ....................................................................................33

3.4.3 800MHz 8 Channel, Channel Module Shelf 50-078003 Parts List..........................................................34

3.4.4 800MHz 40W Amplifier Shelf 50-078004 Parts List ..............................................................................35

3.4.5 VHF Simplex Shelf 50-078010/1.............................................................................................................36

3.4.6 VHF Simplex Shelf 50-078010/2 Parts List.............................................................................................37

3.4.7 VHF Duplex Shelf 50-078011/1 Parts List ..............................................................................................38

3.4.8 VHF Duplex Shelf 50-078011/2 Parts List ..............................................................................................39

3.4.9 VHF Duplex Shelf 50-078011/3 Parts List ..............................................................................................40

3.4.10 VHF Duplex Shelf 50-078011/4 Parts List ..........................................................................................41

3.4.11 VHF Air Interface Shelf 50-078012 Parts List ....................................................................................42

3.4.12 VHF Combiner Shelf 50-078013 Parts List .........................................................................................42

3.4.13 VHF PSU Shelf 50-078014 Parts List..................................................................................................43

3.4.14 VHF/800MHz Tx Multi-coupler Shelf 50-078015 Parts List ..............................................................43

3.4.15 800Mhz In-Line Amplifier (Wall-Mount Case) 50-078017 Parts List ................................................44

3.4.16 12V 160Ahour Battery Back-Up 80-209302 Parts List .......................................................................45

4.

SYSTEM DRAWINGS................................................................................................................... 47

4.1 24 Channel 800MHz & VHF Simplex/Duplex Cell Enhancers System Diagram.................................47

4.2 Generic Wall Mounted Cases Outline Drawing (50-078017 & 80-209302) ..........................................48

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

2 of 88

Page 3

5.

SUB-UNIT MODULES .................................................................................................................. 49

5.1 Bandpass Filters (02-007201 & 01-002503)..............................................................................................49

5.1.1 Description ...............................................................................................................................................49

5.1.2 Technical Specification (02-007201) .......................................................................................................49

5.1.3 Technical Specification (01-002503) .......................................................................................................49

5.2 900MHz Splitter/Combiner (05-002602)..................................................................................................50

5.2.1 Description ...............................................................................................................................................50

5.2.2 Technical Specification ............................................................................................................................50

5.3 1 Watt 3dB Broadband Splitter (05-002901) ...........................................................................................51

5.3.1 Description ...............................................................................................................................................51

5.3.2 Technical Specification ............................................................................................................................51

5.4 Four Way Splitter (05-003302) .................................................................................................................52

5.4.1 Description ...............................................................................................................................................52

5.4.2 Technical Specification ............................................................................................................................52

5.5 Four Way Hybrid Splitter (05-003401) ....................................................................................................52

5.5.1 Description ...............................................................................................................................................52

5.5.2 Technical Specification 05-003401..........................................................................................................52

5.6 3 Way Splitter/Combiner (05-003801) .....................................................................................................53

5.6.1 Description ...............................................................................................................................................53

5.6.2 Technical Specification ............................................................................................................................53

5.7 Wideband 3dB Splitter (07-004101) .........................................................................................................54

5.7.1 Description ...............................................................................................................................................54

5.7.2 Technical Specification ............................................................................................................................54

5.8 VHF/UHF 3-Way Splitter (07-005401).....................................................................................................55

5.8.1 Description ...............................................................................................................................................55

5.8.2 Technical Specification ............................................................................................................................55

5.9 3 Port Tx Hybrid Coupler (80-024203) ....................................................................................................56

5.9.1 Description ...............................................................................................................................................56

5.9.2 Technical Specification ............................................................................................................................56

5.10 Crossband Coupler (07-005705) ...............................................................................................................57

5.10.1 Description ...........................................................................................................................................57

5.10.2 Technical Specification ........................................................................................................................57

5.11 6dB Power Monitor (07-014002)...............................................................................................................58

5.11.1 Description ...........................................................................................................................................58

5.11.2 Technical Specification ........................................................................................................................58

5.12 2-Port RF Isolator (08-930002) .................................................................................................................59

5.12.1 Description ...........................................................................................................................................59

5.12.2 Technical Specification ........................................................................................................................59

5.13 ¼Watt 0- -30dB & 0-15dB Variable Attenuators (10-000701 & 10-000901) ........................................60

5.13.1 General Application .............................................................................................................................60

5.13.2 Switched Attenuators ...........................................................................................................................60

5.14 LNA’s (11-001202, 11-005802, 11-005902 11-006002, 11-006702 & 11-004802) ..................................61

5.14.1 Description ...........................................................................................................................................61

5.14.2 Technical Specification (11-001202) ...................................................................................................61

5.14.3 Technical Specification (11-004802) ...................................................................................................61

5.14.4 Technical Specification (11-005802) ...................................................................................................62

5.14.5 Technical Specification (11-005902) ...................................................................................................62

5.14.6 Technical Specification (11-006002) ...................................................................................................63

5.14.7 Technical Specification (11-006702) ...................................................................................................63

5.15 5, 10 & 20W 900MHz Power Amplifiers (12-018601, 12-018001 & 12-018002)...................................64

5.15.1 Description ...........................................................................................................................................64

5.15.2 Technical Specification (12-018601, 5W) ...........................................................................................64

5.15.3 Technical Specification (12-018001, 10W) .........................................................................................64

5.15.4 Technical Specification (12-018002, 20W) .........................................................................................65

5.16 VHF 5Watt Power Amplifier (12-004902) ...............................................................................................65

5.16.1 Description ...........................................................................................................................................65

5.16.2 Technical Specification ........................................................................................................................65

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

3 of 88

Page 4

5.17 3 Stage Alarm PCB & 3 Stage Simplex Alarm PCB(12-002201 & 12-002203) ....................................66

5.17.1

5.17.2

5.17.3 Generic Summary Alarm Wiring Sketch .............................................................................................67

5.18 1 & 3 Stage Alarm/Simplex/Mute PCB (12-002804 & 12-002213) ........................................................68

5.18.1

5.19 Simplex Controller PCB (12-002811) .......................................................................................................68

5.19.1 Description ...........................................................................................................................................68

5.20 Dual DC/DC Converter (13-001803) ........................................................................................................69

5.20.1 Description ...........................................................................................................................................69

5.20.1 Technical Specification ........................................................................................................................69

5.21 Simplex Squelch & AF Module (17-002802)............................................................................................70

5.21.1 Description ...........................................................................................................................................70

5.21.2

5.22 Wide Dynamic Range (Log.) 12V AGC (17-001109, det. & 17-001201, atten.)....................................71

5.22.1 Description ...........................................................................................................................................71

5.22.2 Technical Specification ........................................................................................................................72

5.23 Channel Control Module (17-002101)......................................................................................................73

5.23.1

5.23.2 Technical Specification ........................................................................................................................73

5.23.3 900MHz Programming Procedure........................................................................................................74

5.23.4 900MHz Programming Example..........................................................................................................75

5.24 Channel Selective Modules (17-009127 UHF, & 17-009135 VHF) ........................................................76

5.24.1 Description ...........................................................................................................................................76

5.24.2 Drg. N. 17-003080, Generic Channel Module Block Diagram..........................................................77

5.25 12 & 24V Relay Boards (20-001601 & 20-001602)..................................................................................78

5.25.1 Description ...........................................................................................................................................78

5.25.2 Technical Specification ........................................................................................................................78

5.26 12V Low Voltage Battery Disconnect Module (80-061003)....................................................................79

5.26.1 Description ...........................................................................................................................................79

5.26.2 Technical Specification ........................................................................................................................79

5.27 Crystal Filters (93-980109) ........................................................................................................................79

5.27.1 Description ...........................................................................................................................................79

5.28 IXFN170N10 Power Mos-Fet Module (94-030015).................................................................................79

5.28.1 Description ...........................................................................................................................................79

5.29 STPS12045TV 60A Dual Diode Assembly (94-100004) ..........................................................................80

5.29.1 Description ...........................................................................................................................................80

5.30 15V Switch-Mode PSU (96-300054)..........................................................................................................80

5.30.1 Description ...........................................................................................................................................80

5.30.2 Technical Specification ........................................................................................................................80

6.

6.1 Initial Installation Record .........................................................................................................................81

6.1.1 Rack Mounted Equipment........................................................................................................................81

6.1.2 Wall Mounted Equipment ........................................................................................................................81

6.1.3 Electrical Connections..............................................................................................................................81

6.1.4 RF Connections ........................................................................................................................................82

6.2 Commissioning ...........................................................................................................................................82

6.3 Quick Fault Checklist ................................................................................................................................82

7.

7.1 General Procedures....................................................................................................................................83

7.1.1 Basic Fault Finding ..................................................................................................................................83

7.1.2 Downlink..................................................................................................................................................84

7.1.3 Uplink.......................................................................................................................................................84

7.1.4 Fault repair ...............................................................................................................................................84

7.1.5 Checking service ......................................................................................................................................85

7.1.6 Service Support ........................................................................................................................................85

7.2 Tools & Test Equipment............................................................................................................................85

Description ...........................................................................................................................................66

Technical Specification ........................................................................................................................67

Description ...........................................................................................................................................68

Technical Specification ........................................................................................................................70

Description ...........................................................................................................................................73

INSTALLATION............................................................................................................................ 81

MAINTENANCE............................................................................................................................ 83

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

4 of 88

Page 5

7.3 Care of Modules .........................................................................................................................................86

7.3.1 General Comments...................................................................................................................................86

7.3.2 Module Removal (LNA’s, general procedure): .......................................................................................86

7.3.3 Module Replacement (general): ...............................................................................................................86

7.3.4 Power Amplifiers .....................................................................................................................................86

7.3.5 Low Power Amplifier Replacement.........................................................................................................87

7.3.6 Module Transportation:............................................................................................................................87

APPENDIX A INITIAL EQUIPMENT SET-UP CALCULATIONS ............................................... 88

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

5 of 88

Page 6

AMENDMENT LIST RECORD SHEET

Issue

Nō.

Date Incorporated

by

Page No.’s

Amended

Reason for new issue

A 14/09/2004 CMH 1st Draft

Document Ref:-50-078001HBKM

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

6 of 88

Page 7

INTRODUCTION

Scope

This handbook is for use solely with the equipment identified by the AFL Part Number

shown on the front cover. It is not to be used with any other equipment unless specifically

authorised by Aerial Facilities Limited. This is a controlled release document and, as such,

becomes a part of Aerial Facilities’ Total Quality Management System. Alterations and

modification may therefore only be performed by Aerial Facilities Ltd.

Purpose

AFL recommends that the installer of this equipment familiarise his/herself with the safety

and installation procedures contained within this document before installation commences.

The purpose of this handbook is to provide the user/maintainer with sufficient information

to service and repair the equipment to the level agreed. Maintenance and adjustments to any

deeper level must be performed by AFL, normally at the company’s repair facility in

Chesham, England.

This handbook has been prepared in accordance with BS 4884, and AFL’s Quality

procedures, which maintain the company’s registration to ISO 9001: 1994 and to the

R&TTE Directive of the European Parliament. Copies of the relevant certificates and the

company Quality Manual can be supplied on application to the Quality Manager.

This document fulfils the relevant requirements of Article 6 of the R&TTE Directive.

Limitation of Information Notice

This manual is written for the use of technically competent operators/service persons. No

liability is accepted by AFL for use or misuse of this manual, the information contained

therein, or the consequences of any actions resulting from the use of the said information,

including, but not limited to, descriptive, procedural, typographical, arithmetical, or listing

errors.

Furthermore, AFL does not warrant the absolute accuracy of the information contained

within this manual, or it’s completeness, fitness for purpose, or scope.

AFL has a policy of continuous product development and enhancement, and as such,

reserves the right to amend, alter, update and generally change the contents, appearance and

pertinence of this document without notice.

All AFL products carry a twelve month warranty from date of shipment. The warranty is

expressly on a return to base repair or exchange basis and the warranty cover does not

extend to on-site repair or complete unit exchange.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

7 of 88

Page 8

Glossary of Terms

Repeater or

Cell Enhancer A Radio Frequency (RF) amplifier which can simultaneously

amplify and re-broadcast Mobile Station (MS) and Base

Transceiver Station (BTS) signals.

Band Selective Repeater A Cell Enhancer designed for operation on a range of channels

within a specified frequency band.

Channel Selective

Repeater A Cell Enhancer, designed for operation on specified channel(s)

within a specified frequency band. Channel frequencies may be

factory set, remotely set by computer, or on-site programmable.

BTS Base Transceiver Station

C/NR Carrier-to-Noise Ratio

Downlink (D.L.) RF signals transmitted from the BTS and to the MS

Uplink (U.L.) RF signals transmitted from the MS to the BTS

EMC Electromagnetic Compatibility

GND Ground

DC Direct Current

AC Alternating Current

ID Identification Number

OIP3 Output Third Order Intercept Point = RF

+(C/I)/2

out

LED Light Emitting Diode

M.S. Mobile Station

N/A Not Applicable

N/C No Connection

NF Noise Figure

RF Radio Frequency

Rx Receiver

Tx Transmitter

S/N Serial Number

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

8 of 88

Page 9

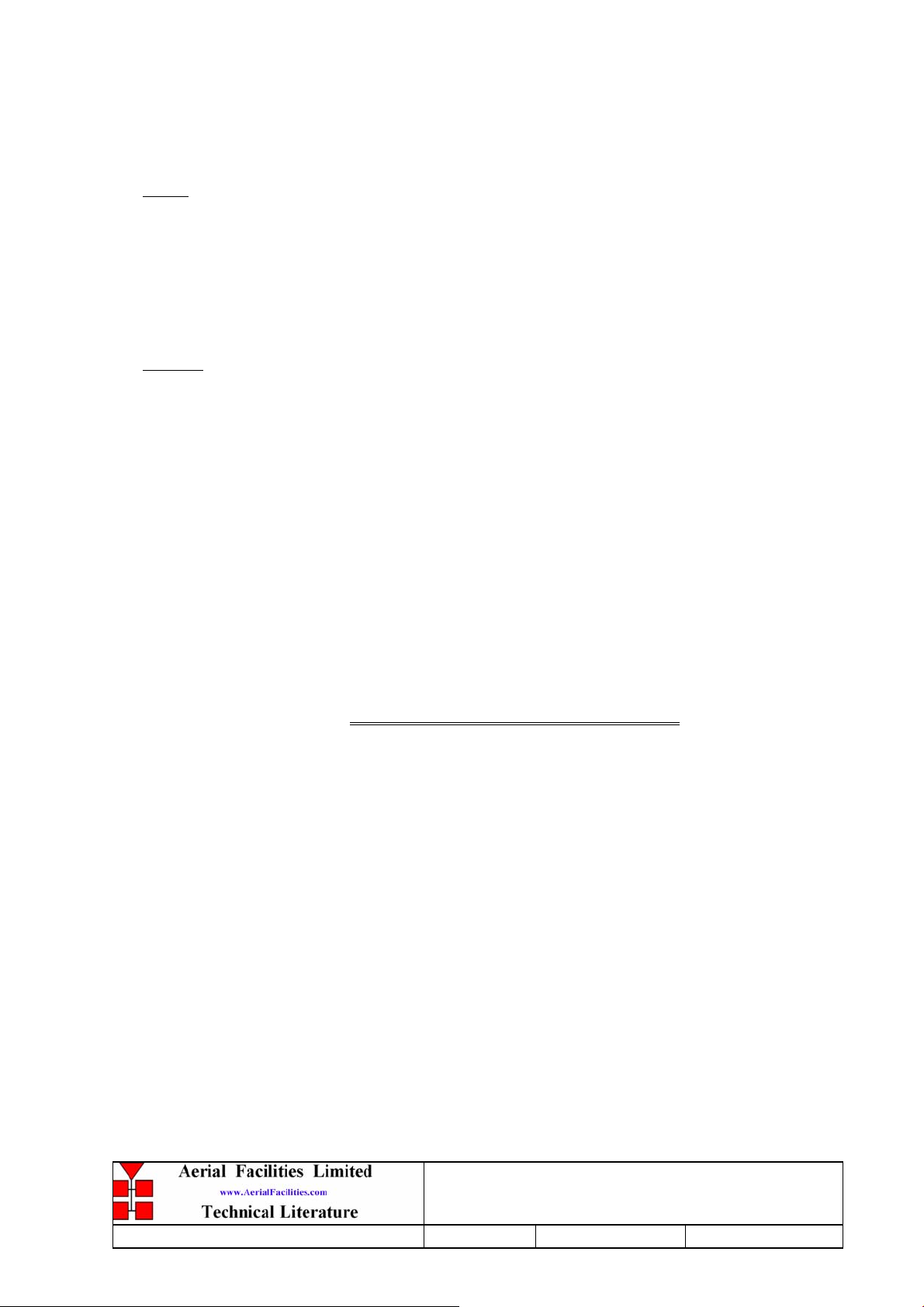

Key to AFL RF Module Drawing Symbols

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

9 of 88

Page 10

1. SAFETY CONSIDERATIONS

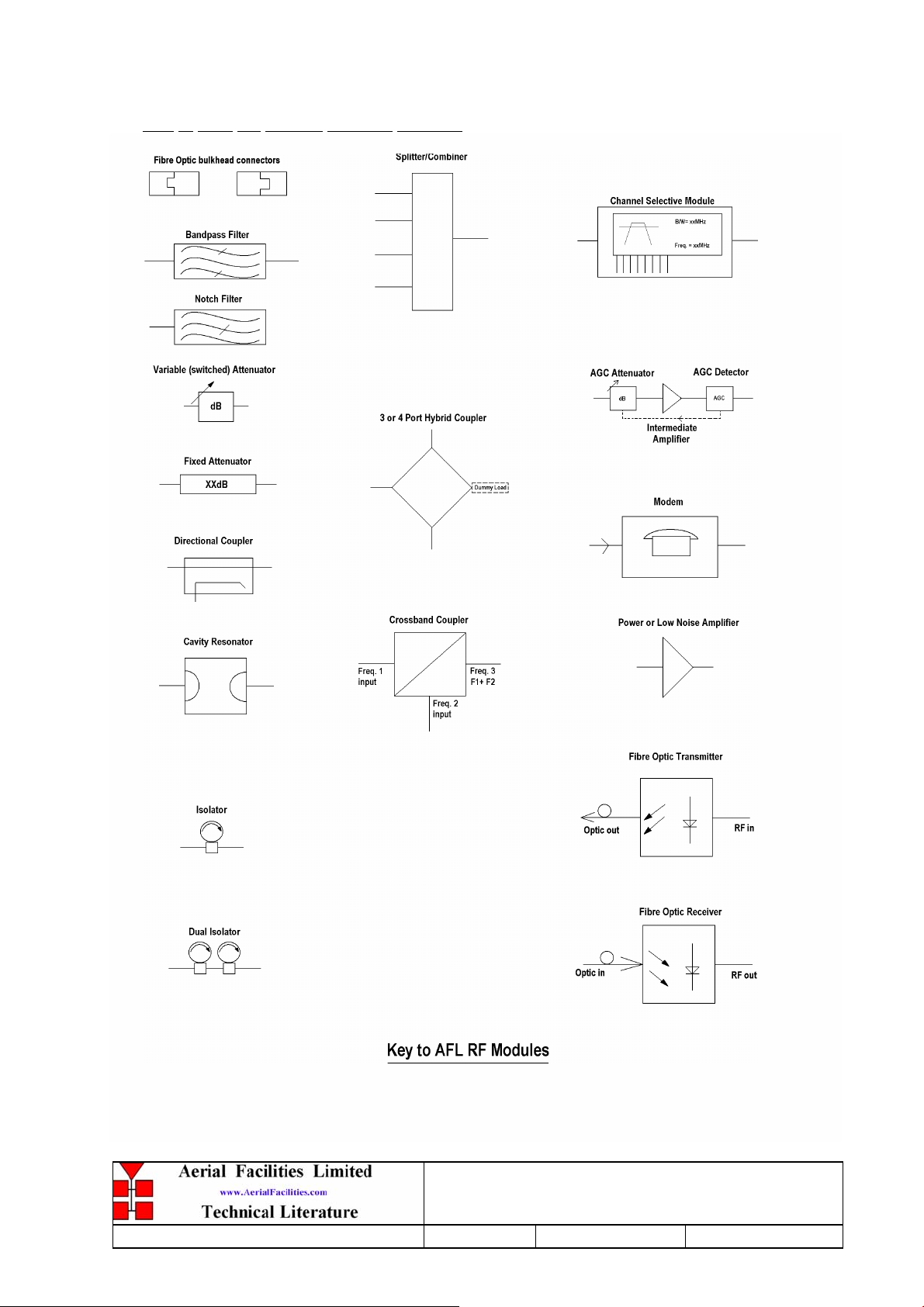

1.1 Earthing of Equipment

Cell Enhancers supplied from the mains must be connected to grounded outlets and earthed

in conformity with appropriate local, national and international electricity supply and safety

regulations.

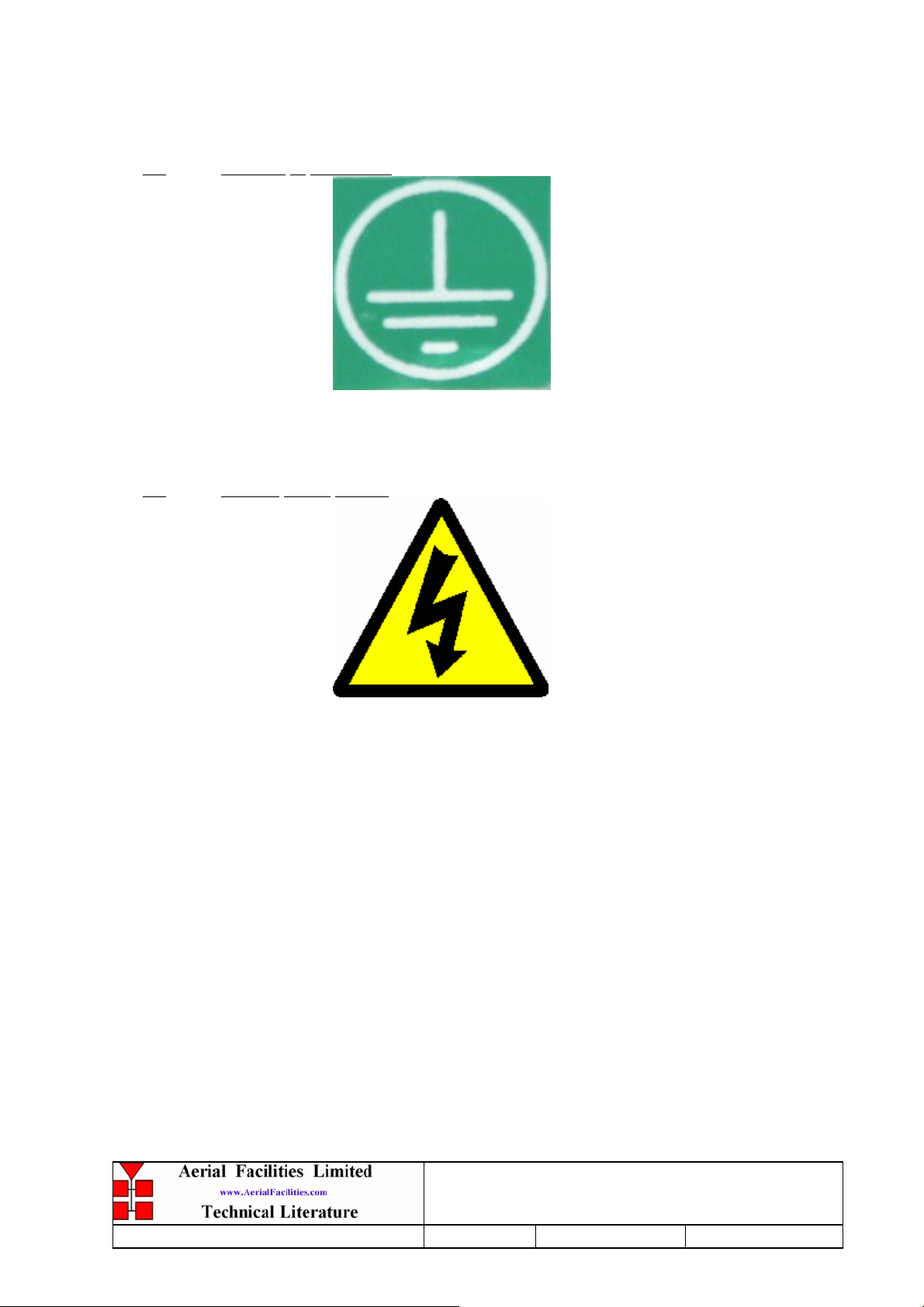

1.2 Electric Shock Hazard

Electrical shocks due to faulty mains driven power supplies.

Whilst ever potentially present in any electrical equipment, such a condition would be

minimised by quality installation practice and thorough testing at:

a) Original assembly

b) Commissioning

c) Regular intervals, thereafter.

All test equipment to be in good working order prior to its use. High current power supplies

can be dangerous because of the possibility of substantial arcing. Always switch off during

disconnection and reconnection.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

10 of 88

Page 11

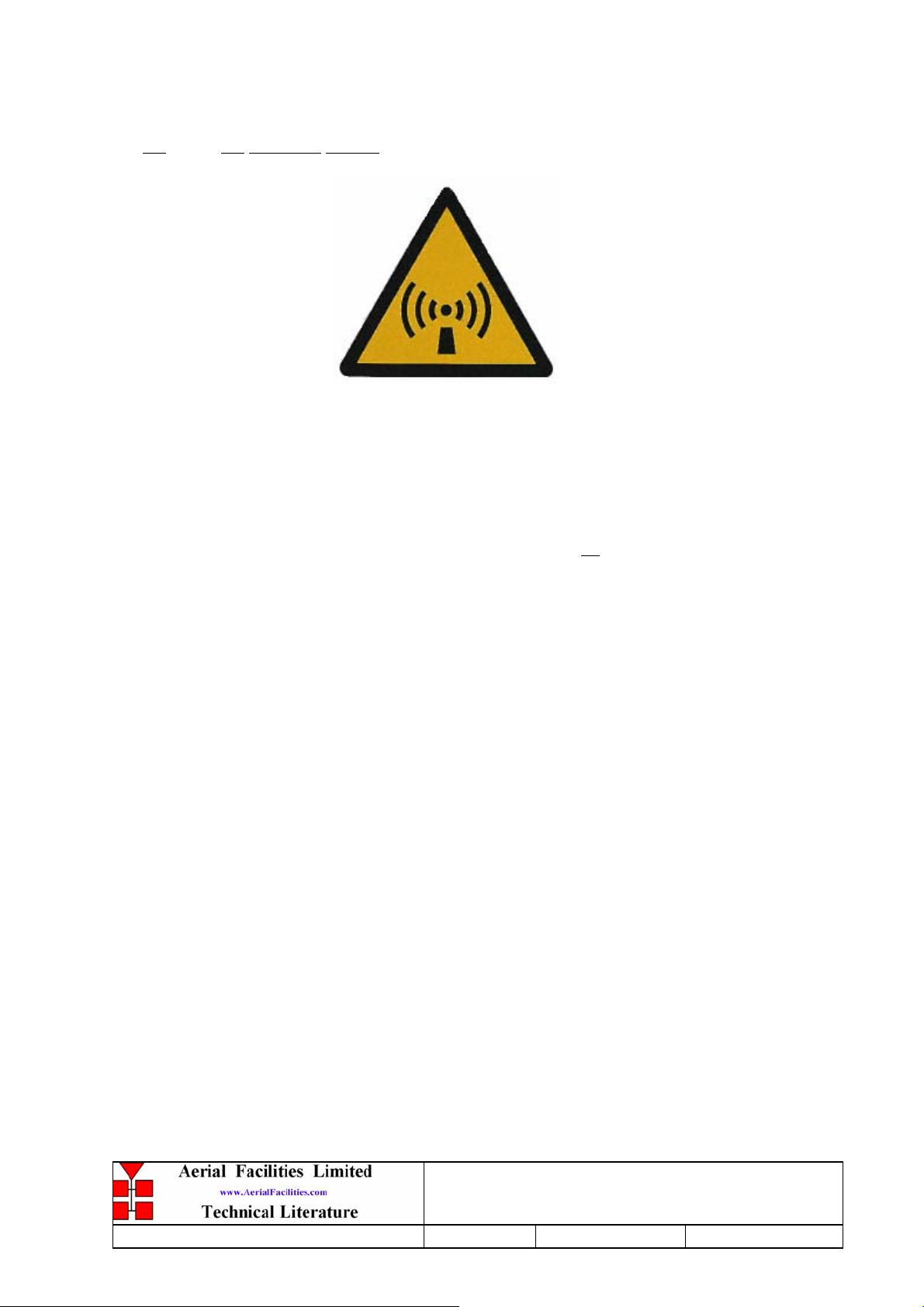

1.3 RF Radiation Hazard

RF radiation, (especially at UHF frequencies) arising from transmitter outputs connected to

AFL’s equipment, must be considered a safety hazard.

This condition might only occur in the event of cable disconnection, or because a ‘spare’

output has been left unterminated. Either of these conditions would impair the system’s

efficiency. No investigation should be carried out until all RF power sources have been

removed. This would always be a wise precaution, despite the severe mismatch between the

impedance of an N type connector at 50, and that of free space at 377, which would

severely mitigate against the efficient radiation of RF power. Radio frequency burns could

also be a hazard, if any RF power carrying components were to be carelessly touched!

Antenna positions should be chosen to comply with requirements (both local & statutory)

regarding exposure of personnel to RF radiation. When connected to an antenna, the unit is

capable of producing RF field strengths, which may exceed guideline safe values especially if

used with antennas having appreciable gain. In this regard the use of directional antennas

with backscreens and a strict site rule that personnel must remain behind the screen while the

RF power is on, is strongly recommended.

Where the equipment is used near power lines, or in association with temporary masts not

having lightning protection, the use of a safety earth connected to the case-earthing bolt is

strongly advised.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

11 of 88

Page 12

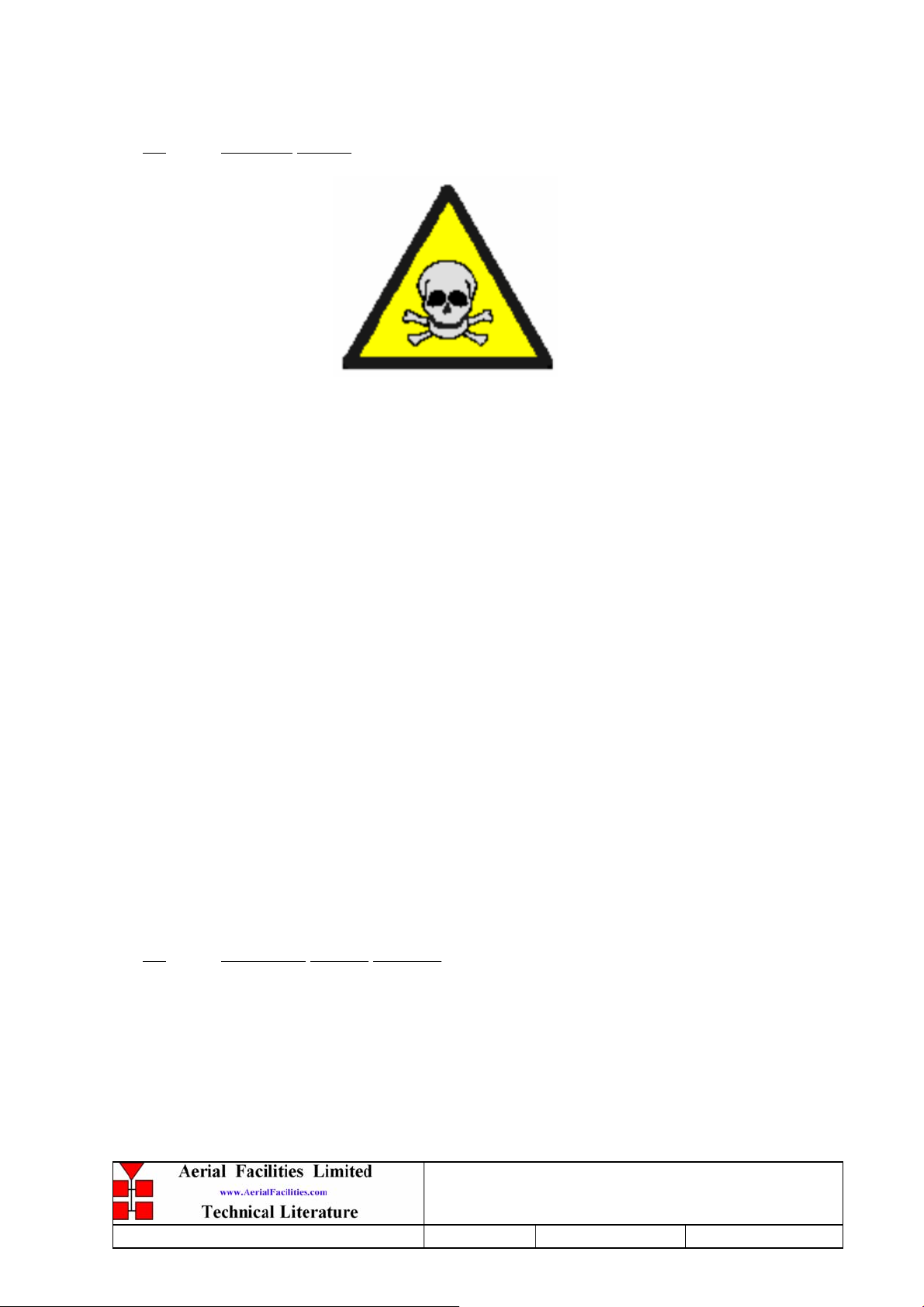

1.4 Chemical Hazard

Beryllium Oxide, also known as Beryllium Monoxide, or Thermalox™, is sometimes used

in devices within equipment produced by Aerial Facilities Ltd. Beryllium oxide dust can be

toxic if inhaled, leading to chronic respiratory problems. It is harmless if ingested or by

contact.

Products that contain beryllium are load terminations (dummy loads) and some power

amplifiers. These products can be identified by a yellow and black “skull and crossbones”

danger symbol (shown above). They are marked as hazardous in line with international

regulations, but pose no threat under normal circumstances. Only if a component containing

beryllium oxide has suffered catastrophic failure, or exploded, will there be any danger of the

formation of dust. Any dust that has been created will be contained within the equipment

module as long as the module remains sealed. For this reason, any module carrying the

yellow and black danger sign should not be opened. If the equipment is suspected of failure,

or is at the end of its life-cycle, it must be returned to Aerial Facilities Ltd for disposal.

To return such equipment, please contact the Quality Department, who will give you a

Returned Materials Authorisation (RMA) number. Please quote this number on the packing

documents, and on all correspondence relating to the shipment.

PolyTetraFluoroEthylene, (P.T.F.E.) and P.T.F.E. Composite Materials

Many modules/components in AFL equipment contain P.T.F.E. as part of the RF insulation

barrier.

This material should never be heated to the point where smoke or fumes are evolved. Any

person feeling drowsy after coming into contact with P.T.F.E. especially dust or fumes

should seek medical attention.

1.5 Emergency Contact Numbers

The AFL Quality Department can be contacted on:

Telephone +44 (0)1494 777000

Fax +44 (0)1494 777002

e-mail qa@aerial.co.uk

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

12 of 88

Page 13

2. OVERVIEW/SYSTEM DESCRIPTION

The AFL Channel and/or Band Selective Cell Enhancers are 2-way on-band repeaters.

Various models are available to cover frequency bands from 50MHz to 3000MHz. The

principle sphere of applications is in urban areas where the topology is such that shadows

occur in the propagation pattern (for example within large buildings, conference centres,

road and rail tunnels, etc.)

The frequency bands that are passed by the Cell Enhancer are set as per the specific

customer requirements.

AFL manufacture a wide range of Cell Enhancers, configured for each customer's specific

requirements. Two basic physical variants are available, a rack mounted version to fit in a

standard 19" rack and an environmentally sealed wall mounted version which requires no

further enclosure.

This system provides 800MHz Channelised (x 24) & VHF Simplex/Duplex coverage for the

various concourses platforms and tunnels with a 12V battery backup service (for the

800MHz line amplifier) that will guarantee limited continued coverage in case of mains

power failure.

Each active module is alarm monitored with each shelf/ wall-case having a summary alarm

with a visual ‘alarm active’ indication and a door intrusion alarm included for the wall cases.

All alarms are volt-free, relay contact pairs which may be easily configured into an

RS232/modem system such that automatic remote monitoring by computer may be

achieved.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

13 of 88

Page 14

3. SPECIFICATION

3.P Photographs

3.P.1 800MHz Air I/F Uplink Shelf 50-078002

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

14 of 88

Page 15

3.P.2 Eight Channel Downlink Shelf 50-078003

Photos of this shelf are unavailable

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

15 of 88

Page 16

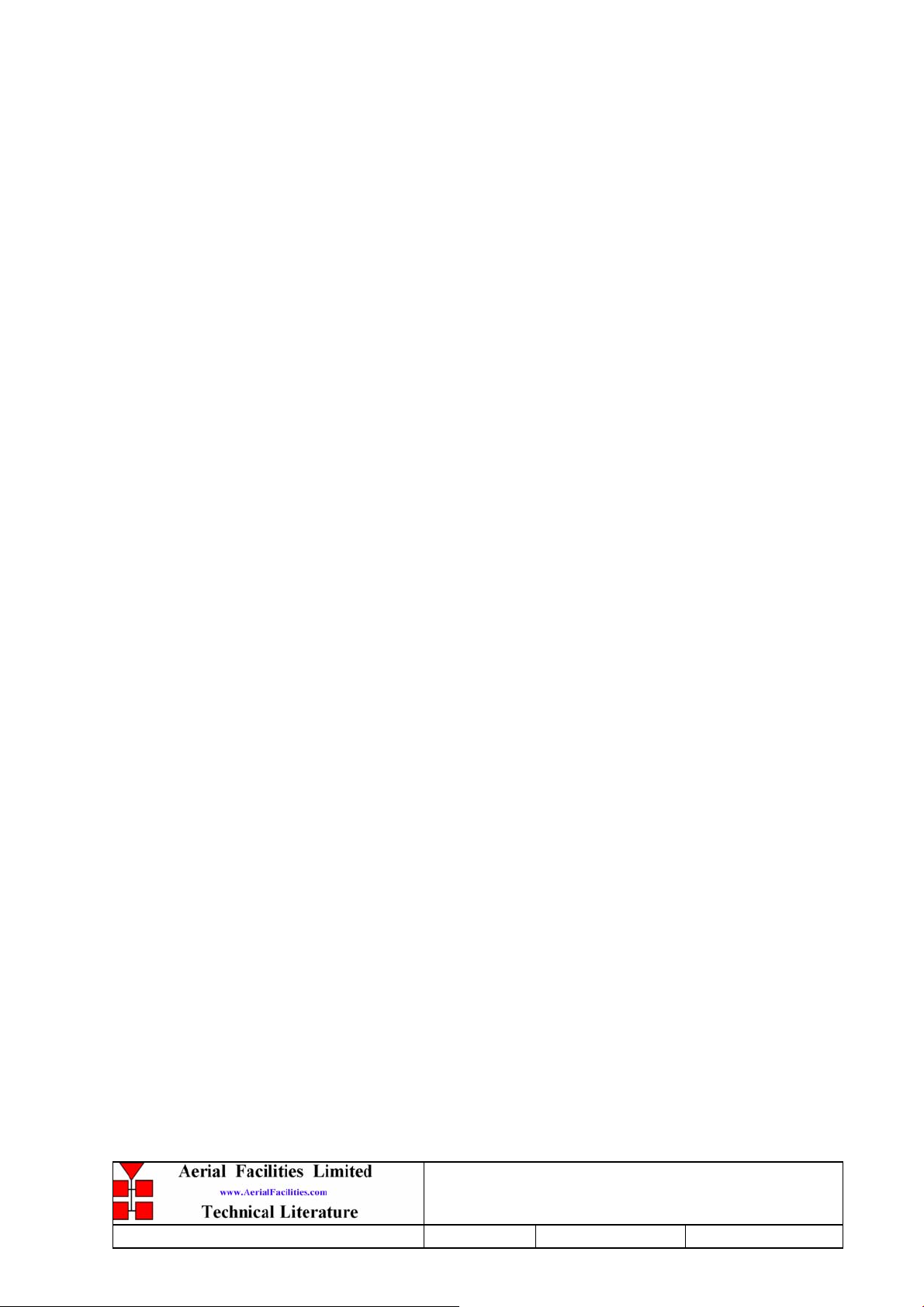

3.P.3 Power Amplifier/Driver Shelf 50-078004

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

16 of 88

Page 17

3.P.4 800MHz In-Line Amplifier 50-078017

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

17 of 88

Page 18

3.P.5 VHF/800MHz Multi-Coupler Shelf 50-078015

Photos of this shelf are unavailable

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

18 of 88

Page 19

3.P.6 VHF Simplex Shelf 50-078010

There are two different types of simplex shelves 50-078010/1 & 50-078010/2, they differ

only in the frequencies they process.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

19 of 88

Page 20

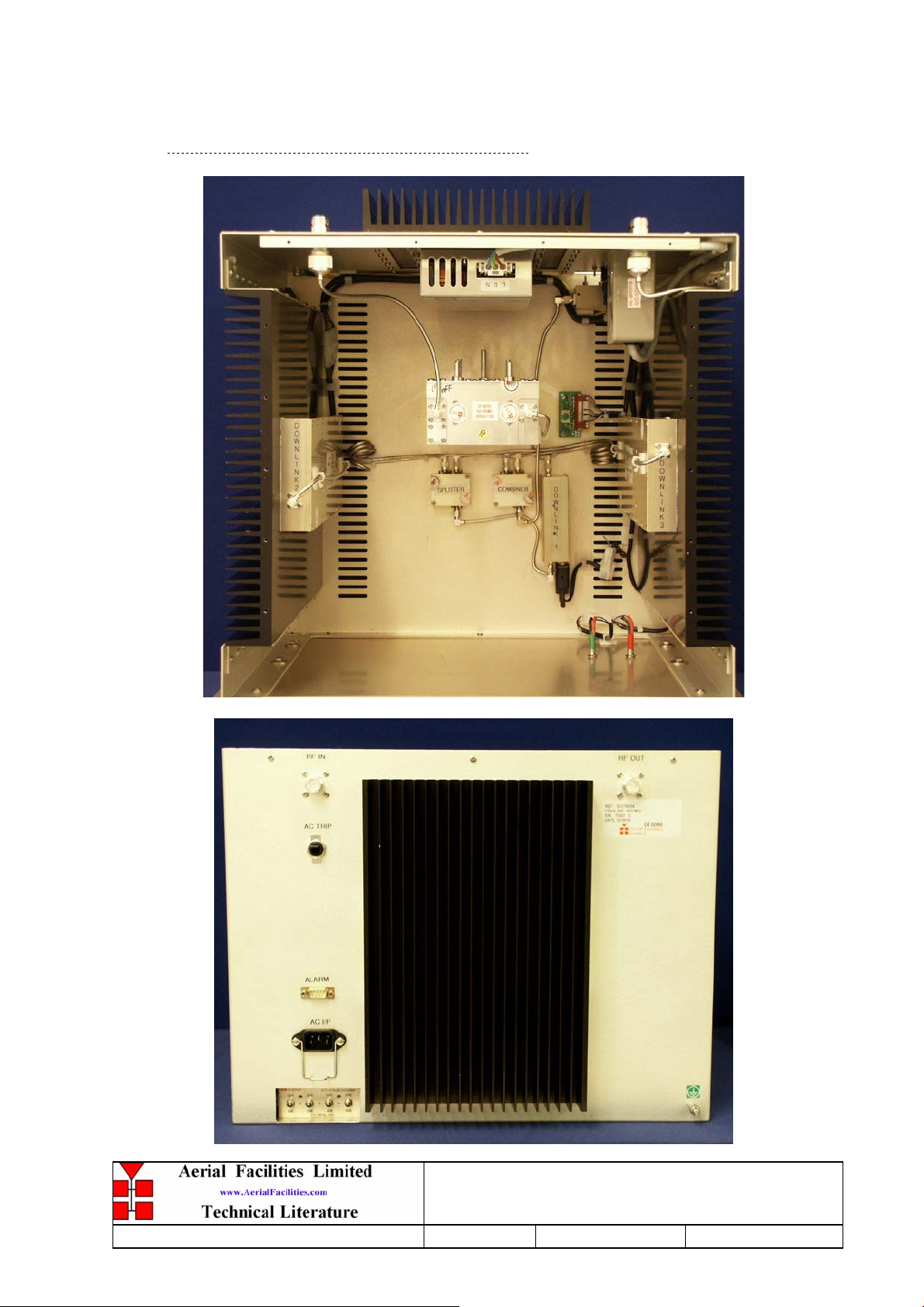

3.P.7 VHF Duplex Shelf 50-078011

There are four different types of duplex shelves 50-078011/1,2,3 & 4 they differ only in

the frequencies they process.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

20 of 88

Page 21

3.P.8 VHF Air Interface Shelf 50-078012

Photos of this shelf are unavailable.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

21 of 88

Page 22

3.P.9 VHF Combiner Shelf 50-078013

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

22 of 88

Page 23

3.P.10 PSU Shelf 50-078014

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

23 of 88

Page 24

3.P.11 Battery Backup 80-209302

800MHz & VHF Cell Enhancers

Maintenance Handbook

H/book Number:-50-078001HBKM

Issue No:-A

Date:-02/09/2004

Page:-

24 of 88

Page 25

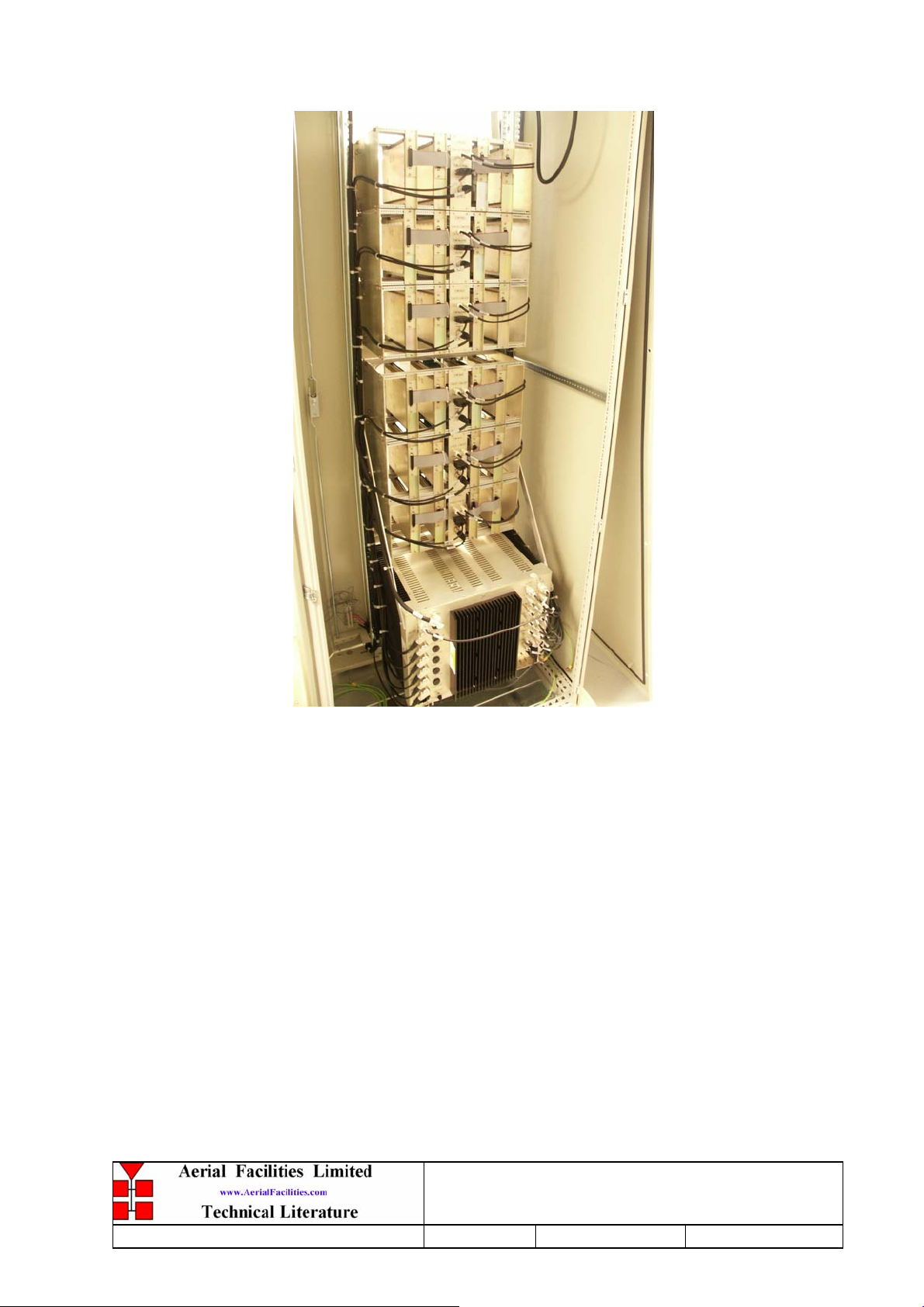

3.P.12 Rack Photos

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

25 of 88

Page 26

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

26 of 88

Page 27

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

27 of 88

Page 28

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

28 of 88

Page 29

)

3.1 Electrical Specification

PARAMETER SPECIFICATION

Frequency range:

Gain Adjustment: 0 - 30dB (in 2dB steps)

IP3:

Temperature range

(non-latching, volt-free relay

851-869MHz (Downlink)

806-824MHz (Uplink)

160.2-161.8MHz (Simplex/Duplex)

Bandwidth:

Gain:

Uplink Power:

Downlink Power

18MHz (UHF)

1.6MHz (VHF)

>100dB (Uplink)

>90dB (Downlink)

>5.0Watts (UHF)

>5.0Watts (VHF)

>40.0Watts (UHF)

>5.0Watts (VHF)

Uplink +43dBm

Downlink +50dBm

Noise Figure: <6dB

AGC: -25dBm (factory set in channel module

VSWR: better than 1.5:1

RF Connectors: N type, female

operational:

storage:

Alarms Fitted:

contacts/TTL)

-10°C to +55°C

-40°C to +70°C

1 PSU’s

2 Amplifiers

3 Channel modules

4 Door (Wall mount cases)

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

29 of 88

Page 30

3.2 Channel Frequency Listing

User

No.

1 SD Trolley 160.6650 160.9350 Duplex

2 SD Trolley 160.3800 160.9050 Duplex (Note1)

3 SD Trolley 160.7100 161.4150 Duplex

4 SD Trolley 161.2950 161.2950 Simplex

5 SD Trolley 161.5650 160.7550 Duplex

6 SD Trolley 160.5300 160.5300 Simplex

1 SD City (PD/FD) 860.0500 815.0500 Duplex

2 SD City (PD/FD) 860.0250 815.0250 Duplex

3 SD City (PD/FD) 859.0500 814.0500 Duplex

4 SD City (PD/FD) 859.0250 814.0250 Duplex

5 SD City (PD/FD) 858.0500 813.0500 Duplex (Note 2)

6 SD City (PD/FD) 858.0250 813.0250 Duplex (Note 2)

7 SD City (PD/FD) 857.0500 812.0500 Duplex

8 SD City (PD/FD) 860.0000 815.0000 Duplex

9 SD City (PD/FD) 859.0000 814.0000 Duplex

10 SD City (PD/FD) 858.0000 813.0000 Duplex (Note 2)

11 SD City (PD/FD) 857.0250 812.0250 Duplex

12 SD City (PD/FD) 857.0000 812.0000 Duplex

13 SD City (PD/FD) 856.0500 811.0500 Duplex

14 SD City (PD/FD) 856.0250 811.0250 Duplex

15 SD City (PD/FD) 862.0500 817.0500 Duplex

16 SD City (PD/FD) 862.1000 817.1000 Duplex

17 SD City (PD/FD) 863.0500 818.0500 Duplex

18 SD City (PD/FD) 864.0500 819.0500 Duplex

19 SD City (PD/FD) 865.5000 820.0500 Duplex

20 SDSU Security 868.5750 823.5750 Duplex (Note 4)

21 SDSU Security 866.3875 821.3875 Duplex (Note 4)

22 SD City (PD/FD) 00 811.1500 Duplex (Note 3)

23 TBD TBD TBD TBD

24 TBD TBD TBD TBD

Group

Frequencies (MHz) Channel

Downlink Uplink

800 MHz Band

Status

Note 1: Channel 2 uplink frequency was changed to 160.9050 MHz from 161.9050MHz as

required by the Authority.

Note 2: Channel 4, 5 & 10 uplink frequency changed to 813.0500 MHz, 813.0250MHz, &

813.0000MHz from 816.050 MHz, 816.0250MHz & 816.000MHz respectively.

Note 3: Channel 22 is new frequency pair for SD City with 25KHz channel spacing.

Note 4: Channel 20 & 21 are analogue radio system with digital modulation (3600bps) and the

donor site for these channels has azimuth of 150 degree. The Azimuth of CH 1 to Ch 19

and the new CH 22 is 40 degree.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

30 of 88

Page 31

3.3 Mechanical Specifications

3.3.1 Rack Mounted Equipment Mechanical Specifications

PARAMETER SPECIFICATION

Rack

Shelves:

Temperature

operational: -10°C to +55°C

Range:

RF Connectors: N type female

Environmental Protection: IP54

Finish:

Heatsinks: Matt black

Supply Cable:

* Note: Individual shelf weight not specified.

3.3.2 Wall Mounted Equipment (50-078017 & 80-209302)

PARAMETER SPECIFICATION

Case size

(excluding heatsinks, connectors, handles and feet)

operational:

Range:

RF Connectors:

Environmental Protection:

Finish:

Heatsinks:

Supply Cable:

Height: 40U Standard Eurorack

Width: 19" (482.6mm)

Depth: 600mm (800 optional)

Height: See parts lists

Width: 19" (482.6mm)

Depth: <400mm(excluding heatsinks, connectors,

handles and feet)

storage: -40°C to +70°C

Weight: >5-15*kg

Humidity: 5 – 95% non-condensing

Case: Alocrom

Handles: Alloy

Fascias Painted to RAL7032

Unit supplied with suitable supply input

leads, connector and specified length of

cable (where appropriate)

Height:

Width:

Depth:

Fixings:

620mm

420mm

250mm

4 holes on 470(w) x 500(h)mm

-10°C to +60°C Temperature

storage:

Weight:

-40°C to +70°C

>30kg

N type female

IP65 (with door closed and all ports terminated)

Case:

To RAL 7032/5

Matt black (where fitted)

Handles:

Black Technopolymer

Unit supplied with suitable supply input leads

with connector and appropriate length of cable.

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

31 of 88

Page 32

3.4 Parts Lists

3.4.1 Whole System Parts List (50-078001)

AFL Part Nō. Part Description Qty.

50-078002 800MHz AIR I/F + BSCE UPLINK SHELF 1

50-078003 800MHz 8CH CHANNEL MOD. SHELF 3

50-078004 800MHz 40W HPA / DRIVER SHELF 2

50-078010/1 VHF SIMPLEX SHELF 1

50-078010/2 VHF SIMPLEX SHELF 1

50-078011/1 VHF DUPLEX SHELF 1

50-078011/2 VHF DUPLEX SHELF 1

50-078011/3 VHF DUPLEX SHELF 1

50-078011/4 VHF DUPLEX SHELF 1

50-078012 VHF AIR I/F SHELF 1

50-078013 VHF COMBINER SHELF 1

50-078014 VHF PSU SHELF 1

50-078015 VHF/ 800 Tx MULTICOUPLER 1

50-078017 800MHz IN LINE AMPLIFIER 2

60-020608 40U SWING FRAME CABINET Q104362 3

80-209302 12V 160Ah BATTERY BACK UP STANDARD 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

32 of 88

Page 33

3.4.2 800MHz AIF Uplink Shelf 50-078002 Parts List

AFL Part Nō. Part Description Qty.

02-007201 900MHz 8POLE 10-20MHz B/W SMA 4

05-002602 900MHz SPLITTER/COMBINER, 20W 5

05-003801 3WAY GEN.SPLIT 900MHz GEN.ASS 4

10-000701 1/4W0-30dB SWITCHED ATTENUATOR 2

11-005902 900MHz LOW NOISE AMP WITH RELAY ASS 3

11-006702 GA 800-1000MHz LNA 29dB (WITH RELAY 4

12-018001 PA 800-960MHz 10W 30dB 2

14-000225 CASE RAIL LONG R.S.A./R.F.A. 4

17-001109 CE AGC UNIT LOG DET/AMP ASSY (12v) 1

17-001201 C/E AGC UNIT ATTENUATOR ASSY 1

20-001601 12V RELAY BOARD 1

50-012820 CCE RACK MOUNTED 8U CHASSIS 1

50-012822 CCE RACK MOUNTED LID 1

50-012825 CCE RACK MOUNTED HEATSINK BRACKET 4

50-027720 RACK MTD CHAN C.E. MODIFIED HEATSIN 2

80-090822 C/E 8U FRONT PANEL, AFL (RAL7035) 1

80-310420 BCC 400W POWER SUPPLY HEATSINK 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-130005 SMA BULKHEAD ADAPTOR F/F 12

91-500025 3 PIN RIGHT ANGLE FREE PLUG NC-X 3

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 3

91-510004 3 PIN PNL.MOUNT SOCKET NC-X 3

91-510032 20A SOCKET CONTACT PIN 4

91-520001 PWR MAINS INL FIXED/SOLD.TERMS 1

91-520005 MAINS LEAD (KETTLE, IEC) 1

91-520010 MAINS RETAINING CLIP 1

91-600007 'D' 9 WAY BLACK SHELL 8

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 7

91-600015 'D' 9 WAY PLUG S/B (NON FILTERED) 1

91-660001 2W5 MIXED D TYPE SOCKET (7 WAY) 2

96-110034 FUSE HOLDER 16-30A, 32mm BODY 3

96-300057 15V 27A PSU 400W (XP BCC) 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

96-900018 AC TRIP SWITCH (5 AMP M.C.B.) 2

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

99-200008 DANGER HIGH VOLTAGE LABEL 2x2' 1

99-200017 CAUTION HEAVY LABEL 75x55mm 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

33 of 88

Page 34

3.4.3 800MHz 8 Channel, Channel Module Shelf 50-078003 Parts List

AFL Part Nō. Part Description Qty.

05-003302 4 WAY SPLITTER GSM 900MHz 4

17-002101 CHANNEL CONTROL MODULE 2

17-002103 26WAY RIBBON CABLE LEAD 8

17-003022 MODULE PATTERNED LEAVE 8

17-003023 SUBRACK SIDE PANEL 4

17-003024 SUBRACK REAR BRACKET 8

17-003025 BOTTOM MODULE GUIDE 8

17-003028 MODULE SQUARE LEAVE 8

17-003029 TOP MODULE GUIDE 8

17-009127 CHAN MOD 810-860MHz 30KHz 8p TCXO 8

91-100004 SMA PLUG ELBOW UT-85/RG405 32

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 2

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 2

91-600007 'D' 9 WAY BLACK SHELL 4

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 2

91-600015 'D' 9 WAY PLUG S/B (NON FILTERED) 2

92-280033 Captive Screw 16

96-110001 FUSE HOLDER 20 x 5mm6.3A 2

96-110007 T 1.6A A.SURGE FUSE 20mm 4

97-000002 BLACK MODULE CAGE RUNNER 16

97-600001 SUBRACK FRONT HORIZ 4

97-600002 SUBRACK M2.5 STD TAP 4

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

34 of 88

Page 35

3.4.4 800MHz 40W Amplifier Shelf 50-078004 Parts List

AFL Part Nō. Part Description Qty.

02-007201 900MHz 8POLE 10-20MHz B/W SMA 1

05-002602 900MHz SPLITTER/COMBINER, 20W 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 1

11-005802 900MHz DRIVER STAGE WITH RELAY 1

12-018002 PA 800-960MHz 20W CLASS A 2

14-000225 CASE RAIL LONG R.S.A./R.F.A. 2

50-012820 CCE RACK MOUNTED 8U CHASSIS 1

50-012822 CCE RACK MOUNTED LID 1

50-012825 CCE RACK MOUNTED HEATSINK BRACKET 4

50-027720 RACK MTD CHAN C.E. MODIFIED HEATSIN 2

80-090822 C/E 8U FRONT PANEL, AFL (RAL7035) 1

80-310420 BCC 400W POWER SUPPLY HEATSINK 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 2

91-510032 20A SOCKET CONTACT PIN 4

91-520001 PWR MAINS INL FIXED/SOLD.TERMS 1

91-520005 MAINS LEAD (KETTLE, IEC) 1

91-520010 MAINS RETAINING CLIP 1

91-600007 'D' 9 WAY BLACK SHELL 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 1

91-600015 'D' 9 WAY PLUG S/B (NON FILTERED) 1

91-660001 2W5 MIXED D TYPE SOCKET (7 WAY) 2

96-300057 15V 27A PSU 400W (XP BCC) 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

96-900018 AC TRIP SWITCH (5 AMP M.C.B.) 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

99-200008 DANGER HIGH VOLTAGE LABEL 2x2' 1

99-200017 CAUTION HEAVY LABEL 75x55mm 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

35 of 88

Page 36

3.4.5 VHF Simplex Shelf 50-078010/1

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-001202 10/600MHz LNA 24v SMA Alarm 7

12-002213 3 STAGE ALARM/SIMPLEXMUTE PCB SUB-ASS 2

12-002220 3 STAGE ALARM PCB COVER 2

12-002804 SINGLE CH. ALARM/SIMPLEX MUTE BOARD 7

12-002820 SINGLE CHANNEL ALARM COVER 7

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 1

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002811 SIMPLEX CONTROLLER PCB ASSEMBLY 2

17-001201 C/E AGC UNIT ATTENUATOR ASSY 4

17-002802 SIMPLEX C.E Rx/SQUELCH & AF (SMD) 2

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 2

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 9

93-540035 1K3 0.25W 1% RES MRS25 M:F 2

93-980109 161.295MHz CRYSTAL FILT FAN4M52500 4

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-300014 PSU VOLTS ADJUSTER 2

96-700017 LED AMBER 5mm SEALED IP66 2

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

36 of 88

Page 37

3.4.6 VHF Simplex Shelf 50-078010/2 Parts List

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-001202 10/600MHz LNA 24v SMA Alarm 7

12-002213 3 STAGE ALM/SIMPLEXMUTE PCB SUB-ASS 2

12-002220 3 STAGE ALARM PCB COVER 2

12-002804 SINGLE CH. ALARM/SIMPLEX MUTE BOARD 7

12-002820 SINGLE CHANNEL ALARM COVER 7

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 1

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002811 SIMPLEX CONTROLLER PCB ASSEMBLY 2

17-001201 C/E AGC UNIT ATTENUATOR ASSY 4

17-002802 SIMPLEX C.E Rx/SQUELCH & AF (SMD) 2

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 2

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 9

93-540035 1K3 0.25W 1% RES MRS25 M:F 2

93-980112 160.530MHz CRYSTAL FILT FAN4M52500 4

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-300014 PSU VOLTS ADJUSTER 2

96-700017 LED AMBER 5MM SEALED IP66 2

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

37 of 88

Page 38

3.4.7 VHF Duplex Shelf 50-078011/1 Parts List

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-006002 LNA VHF 70-500MHz WITH RELAY 7

12-002201 3 STAGE AMPLIFIER ALARM BOARD 1

12-002203 3 STAGE ALARM BOARD SIMPLEX 1

12-002220 3 STAGE ALARM PCB COVER 2

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 2

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002812 SWITCH VERSION OF SIMPLEX CONT. 1

17-001105 CE AGC UNIT LOG DET/AMP ASSY (24v) 1

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 7

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 2

93-980103 160.665MHz CRYSTAL FILT FAN4M52500 2

93-980104 160.935MHz CRYSTAL FILT FAN4M52500 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

38 of 88

Page 39

3.4.8 VHF Duplex Shelf 50-078011/2 Parts List

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-006002 LNA VHF 70-500MHz WITH RELAY 7

12-002201 3 STAGE AMPLIFIER ALARM BOARD 1

12-002203 3 STAGE ALARM BOARD SIMPLEX 1

12-002220 3 STAGE ALARM PCB COVER 2

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 2

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002812 SWITCH VERSION OF SIMPLEX CONT. 1

17-001105 CE AGC UNIT LOG DET/AMP ASSY (24v) 1

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 7

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 2

93-980105 160.380MHz CRYSTAL FILT FAN4M52500 2

93-980106 160.905MHz CRYSTAL FILT FAN4M52500 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

39 of 88

Page 40

3.4.9 VHF Duplex Shelf 50-078011/3 Parts List

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-006002 LNA VHF 70-500MHz WITH RELAY 7

12-002201 3 STAGE AMPLIFIER ALARM BOARD 1

12-002203 3 STAGE ALARM BOARD SIMPLEX 1

12-002220 3 STAGE ALARM PCB COVER 2

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 2

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002812 SWITCH VERSION OF SIMPLEX CONT. 1

17-001105 CE AGC UNIT LOG DET/AMP ASSY (24v) 1

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 7

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 2

93-980107 160.710MHz CRYSTAL FILT FAN4M52500 2

93-980108 161.415MHz CRYSTAL FILT FAN4M52500 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

40 of 88

Page 41

3.4.10 VHF Duplex Shelf 50-078011/4 Parts List

AFL Part Nō. Part Description Qty.

08-930002 2 PORT ISOLATOR 150-300MHz SMA 2

10-000901 SW. ATTENUATOR 0.25W 0-15dB 4

11-006002 LNA VHF 70-500MHz WITH RELAY 7

12-002201 3 STAGE AMPLIFIER ALARM BOARD 1

12-002203 3 STAGE ALARM BOARD SIMPLEX 1

12-002220 3 STAGE ALARM PCB COVER 2

12-004902 POWER AMP VHF 5W CLASS AB 2

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 2

13-001822 DC-DC CON 24V-5V/15V COVER 1

13-002812 SWITCH VERSION OF SIMPLEX CONT. 1

17-001105 CE AGC UNIT LOG DET/AMP ASSY (24v) 1

17-009135 VHF 15Kstep CH MOD 15kHz 8p BW+IFRX 2

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

19-000924 3U 19" UNIT FRONT PANEL FAB 1

80-063920 HEATSINK 2U ASS140 (5W) MILCHBUCK 2

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-600001 'D'TYPE 9 WAY PLUG S/B TERM 1

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 7

91-620001 'D' 25 WAY SOCKET S/B TERM 2

91-700017 ICD 15 WAY 0.1' CONNECTOR 2

93-980110 161.565MHz CRYSTAL FILT FAN4M52500 2

93-980111 160.755MHz CRYSTAL FILT FAN4M52500 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

41 of 88

Page 42

3.4.11 VHF Air Interface Shelf 50-078012 Parts List

AFL Part Nō. Part Description Qty.

01-002503 FILTER VHF H/B 6 SMA S 100W 2

05-002901 3dB BROADBAND SPLITTER SMA 1WATT 2

05-003401 4 WAY SPLITTER LOW POWER 1

07-005401 160-470MHz 3 WAY SPLITTER 2

11-004802 450MHz (10dB GAIN) LNA 12V. 1

12-002801 SINGLE CHANNEL ALARM BOARD STD 1

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 1

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

80-024203 TRANSMITTER HYBD COUPL.3 PORT 1

80-063627 3U FRONT PANEL FOR H/S 80-063920 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 15

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

91-700017 ICD 15 WAY 0.1' CONNECTOR 6

93-540035 1K3 0.25W 1% RES MRS25 M:F 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

3.4.12 VHF Combiner Shelf 50-078013 Parts List

01-002503 FILTER VHF H/B 6 SMA S 100W 2

05-002901 3dB BROADBAND SPLITTER SMA 1WATT 1

07-005401 160-470MHz 3 WAY SPLITTER 4

11-006002 LNA VHF 70-500MHz WITH RELAY 1

13-001803 DUAL DC/DC CONVERTER 24V-12V 1A 1

19-000826 2U,3U,4U 19" UNIT 400 DEEP LID 1

19-000921 3U 19" UNIT 400 DEEP CHASSIS + BKT 1

80-024203 TRANSMITTER HYBD COUPL.3 PORT 2

80-063627 3U FRONT PANEL FOR H/S 80-063920 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 15

91-500001 POWER PLG 3 PIN PNL.MOUNT NC-X 1

91-510003 3 PIN R.ANGLE FREE SOC.NC-X. 1

93-540035 1K3 0.25W 1% RES MRS25 M:F 2

96-110001 FUSE HOLDER 20 x 5mm6.3A 1

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400005 HANDLE TYPE H6802 3U [ALLOY] 2

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

42 of 88

Page 43

3.4.13 VHF PSU Shelf 50-078014 Parts List

AFL Part Nō. Part Description Qty.

13-003301 MAINS FILTER 8AMP ASSEMBLY 1

20-001602 24V RELAY BOARD 1

80-008920 DUAL PSU HEATSINK 2

80-008921 DUAL PSU CASE 1

80-008922 DUAL PSU LID 1

80-008925 DUAL PSU FRONT PANEL 1

80-020632 2U CHASSIS LID FIXING RAIL 4

91-500025 3 PIN RIGHT ANGLE FREE PLUG NC-X 6

91-510004 3 PIN PNL.MOUNT SOCKET NC-X 6

91-510035 3 WAY MATE N LOK PLUG HOUSING 2

91-520001 PWR MAINS INL FIXED/SOLD.TERMS 1

91-520005 MAINS LEAD (KETTLE, IEC) 1

91-520010 MAINS RETAINING CLIP 1

91-520032 MATE N LOK SOCKET CONTACT 20/14 AWG 6

91-600015 'D' 9 WAY PLUG S/B (NON FILTERED) 1

91-800014 3 WAY TERMINAL BLOCK 1

94-100004 STPS12045TV 60A DUAL DIODE 1

96-100001 20x5mm,10A FUSE HOLDER/CARRIER 6

96-300054 24V 17A PSU 400W (XP BCC) 2

96-600001 INSULATING BOOT LARGE 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 2

96-900017 AC TRIP SWITCH (3 AMP M.C.B.) 2

97-400002 HANDLE TYPE H6803 4U.[ALLOY] 2

3.4.14 VHF/800MHz Tx Multi-coupler Shelf 50-078015 Parts List

AFL Part Nō. Part Description Qty.

05-002602 900MHz SPLITTER/COMBINER, 20W 1

05-002901 3dB BROADBAND SPLITTER SMA 1WATT 3

05-003401 4 WAY SPLITTER LOW POWER 1

05-003801 3WAY GEN.SPLIT 900MHz GEN.ASS 1

07-004101 70-1000MHz 3dB SPLITTER/COMBINER 1

07-005401 160-470MHz 3 WAY SPLITTER 2

07-005705 CROSSBAND CPLR XC 250/380 SMA 6

07-014002 6dB 170-2200MHz DIRECTIONAL COUPLE 2

19-001122K 5U CHASSIS KIT (450mm deep) 1

80-024203 TRANSMITTER HYBD COUPL.3 PORT 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 15

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

43 of 88

Page 44

3.4.15 800Mhz In-Line Amplifier (Wall-Mount Case) 50-078017 Parts List

AFL Part Nō. Part Description Qty.

02-007201 900MHz 8POLE 10-20MHz B/W SMA 4

07-005705 CROSSBAND CPLR XC 250/380 SMA 4

10-000701 1/4W0-30dB SWITCHED ATTENUATOR 2

11-005902 900MHz LOW NOISE AMP WITH RELAY ASS 2

12-018002 PA 800-960MHz 20W CLASS A 1

12-018601 POWER AMPLIFIER 900MHz 5W 1

17-000126 CELL ENHANCER LABEL 6 DIGIT 1

17-000526 CE 10/20W HEATSINK THERMAL GASKET 2

17-001109 CE AGC UNIT LOG DET/AMP ASSY (12v) 1

17-001201 C/E AGC UNIT ATTENUATOR ASSY 1

17-009020 ENCLOSURE 620 x 420 x 250 (3 H/S) ALU 1

20-001601 12V RELAY BOARD 1

80-031820 20W PA HEATSINK (NEEDS 17-000526) 1

80-032320 10W PA HEATSINK (NEEDS 17-000526) 1

91-030002 N ADAPTOR PANEL FEMALE:FEMALE 4

91-500011 PWR 3POLE PNL PLUG SEALED IP68 1

91-500015 PWR CON CAP SEALED with INT. THREAD 2

91-500016 PWR 6POLE PNL PLUG SEALED IP68 1

91-510032 20A SOCKET CONTACT PIN 4

91-600007 'D' 9 WAY BLACK SHELL 4

91-600014 'D' 9 WAY SOCKET S/B (NON FILTERED) 4

91-660001 2W5 MIXED D TYPE SOCKET (7 WAY) 2

96-700034 LED RED 5mm IP67 INTEGRAL RES. 24V 1

96-700035 LED GREEN 5mm IP67 INTEGRAL RES 24V 1

97-400010 BLACK PLASTIC HANDLE 50mm HIGH 2

97-900003 RUBBER FOOT 1 1:2' DIA. 4

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

44 of 88

Page 45

3.4.16 12V 160Ahour Battery Back-Up 80-209302 Parts List

AFL Part Nō. Part Description Qty.

17-000526 CE 10/20W HEATSINK THERMAL GASKET 2

17-004833 BATTERY BACK UP LABEL 1

20-001601 12V RELAY BOARD 1

50-046922 HEATSINK COVER (A) FOR DIODES 1

50-046923 DOOR VENT MESH 2

50-046924 BATTERY BACK UP UNIT DIODE HEATSINK 1

50-046926 BATTERY BACK UP UNIT BACK PANEL 1

50-046927 HEATSINK COVER (B) FOR DIODES 1

50-046928 COVERS A & B FIXING STRIP 1

50-046929 BATTERY BACK UP CASE 1

50-046930 BBU BATTERY REAR BRACKET 3

50-046931 BBU BATTERY CLAMPING BRACKET 1

50-046932 BBU TOP BATTERY LOCATION PLATE 1

50-046933 BBU BATTERY BASE TRAY 1

50-046934 BBU BATTERY CLAMPING STUD 6

50-046935 BBU LOWER BATTERY CLAMPING BAR 1

50-046936 BBU TOP BAT LOCATION PLATE SPACER 1

50-046937 CHARG'R AL'M INDIC'R PL'T&SILK SC'N 1

80-061003 LOW VOLTAGE 12v BATT DISC PCB PARTS 1

80-160020 AC TRIP SWITCH BOX-TWIN MTG BKT 1

80-310420 BCC 400W POWER SUPPLY HEATSINK 1

90-100003 MAINS LEAD '6 AMP' 1

90-300045 BATT.BACKUP LEADS (2 1

90-400013 CE/BBU ALARM LINK LEAD 4 CORE 1

90-600026 HEATSHRINK SLEEVE 4.8mm BLACK% 0

91-500011 PWR 3POLE PNL PLUG SEALED IP68 1

91-500015 PWR CON CAP SEALED with INT. THREAD 2

91-500016 PWR 6POLE PNL PLUG SEALED IP68 1

91-510013 PWR CON CAP SEALED with Ext. THREAD 3

91-510035 3 WAY MATE N LOK PLUG HOUSING 1

91-520032 MATE N LOK SOCKET CONTACT 20/14 AWG 3

91-800015 TRIPLE DECK TERMINAL BLOCK 3

91-800016 TRIPLE DECK TERMINAL JUMPER 3

91-800017 TRIPLE DECK TERMINAL END 1

91-800027 DIN RAIL NON-FUSED TERMINAL BLOCK 7

91-800028 DIN RAIL END-STOP 6

91-800029 DIN RAIL TERMINAL BLOCK PARTITION 4

91-800031 SYMETRIC 35x7.5mm DIN RAIL 1

91-800066 DIN RAIL END COVER 2

93-510081 0R05 50W RESISTOR ALUMINIUM CLAD 2

93-540035 1K3 0.25W 1% RES MRS25 M:F 3

94-030015 IXFN170N10 PWR MOSFET (MINI-BLOC) 1

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

45 of 88

Page 46

94-100004 STPS12045TV 60A DUAL DIODE 5

96-000004 38AH 12V S.L.A. BATTERY 4

96-100004 32mm 20A FUSE HOLDER 1

96-100006 FUSE HOLDER ATO IN-LINE 4

96-110015 T 15A A/SURGE FUSE 1.25' 1

96-110042 15A ATO FUSE 4

96-300057 15V 27A PSU 400W (XP BCC) 1

96-700002 LED.GREEN 5mm SEALED IP66 3

96-700005 LED.RED 5mm SEALED IP66 1

96-900018 AC TRIP SWITCH (5 AMP M.C.B.) 2

96-920002 DPDT MINI TOGGLE SWITCH 1

96-920008 PUSH BUTTON SWITCH RED (SPNO) 1

96-920011 PROXIMITY SWITCH 1

96-920012 PROXIMITY SWITCH MAGNET 1

97-100047 LOUVRE VENT PANEL 70mm RAL7035 2

97-300010 C/E SUPPLY INPUT COVER 1

97-400010 BLACK PLASTIC HANDLE 50mm HIGH 2

97-900004 RUBBER FOOT FOR CELL ENHANCERS 4

99-200003 WARNING LABELS DISCONNECT MAINS 2

99-200008 DANGER HIGH VOLTAGE LABEL 2x2' 1

99-200017 CAUTION HEAVY LABEL 75x55mm 1

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

46 of 88

Page 47

4. SYSTEM DRAWINGS

24 Channel 800MHz & VHF Simplex/Duplex Cell Enhancers System Diagram

4.1

West Tunnel 'A'

Fir e Exit Stair 1

West Tunnel 'B'

Fir e Exit Stair 2

Sta ir s (P103)

Sto r e Ro o m (M 210)

Sta ir s (P101)

Sta ir s (P104)

Co r r id or (M 211)

Stair s 2 (P 102)

dBdB

dB

ALC

DET

800MHz T UNNEL IN L INE AM PL IFIER

800MHz T UNNEL IN L INE AM PL IFIER

West Tunnel 'A'

-64d Bm

(+LONGDITUDE LOSS )

dBdB

dB

ALC

DET

Exit Stairs

West Tunnel 'B'

Space Antenna (Platform South Side)

Sp ace An ten n a (Pla tfor m No r th Si d e)

18d Bm

17d Bm

6dB

M ech an ical Ro o m

(M 204)

6dB

6dB

Nor th M ezzanin e

6dB

West M ez zan in e-DL

6dB

6dB

6dB

West M ez zan in e-UL

14d Bm

Power Room (M 238)

East M ech . (M235)

6dB

6dB

6dB

East Tunnel 'A'

East Tunnel 'B'

East M ezzan in e-DL

East M ezzan in e-UL

DOWNLINK

UPLINK

Q110730

VHF LEVEL S IN ITALICS

-65d Bm

Mission Valley

-71d Bm -65d Bm

-79d Bm

-71d Bm

-74d Bm

24d Bm

21d Bm

800M Hz LE VEL S NORMAL

20d Bm

-75d Bm-77d Bm

UPL INK & DOWNLINK

DIST RIBUTION CABINET

17d Bm 12d Bm 11d Bm

18d Bm

-12d Bm

-26d Bm

dB

800M Hz HIGH POWER AM PLIF IER

50-078004

dB

-25d Bm

-22d Bm

-19d Bm

-39d Bm

-33d Bm

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

0dB

-27d Bm

17-009127

17-009127

-37d Bm

-31d Bm

-25d Bm

17-009127

8 CHN M ODU LE 50-078003

0dB

17-009127

17-009127

17-009127

17-009127

17-009127

17-009127

17-009127

8 CHN M ODU LE 50-078003

0dB

17-009127

17-009127

17-009127

17-009127

17-009127

17-009127

8 CHN M ODU LE 50-078003

0dB

17-009127

17-009127

17-009127

17-009127

17-009127

-22d Bm

-52d Bm

dB

-36d Bm

800M Hz OFF AIR REPEA TER 800MHz HIGH POWE R AMPL IFIER

50-078002 50-078004

-66d Bm

-65d Bm

27d Bm

28d Bm

VHF COMBINER

50-078013

31d Bm

37d Bm

37d Bm

-80d Bm

dB

50-078011

dB

-81d Bm

-51d Bm

dBdB

0dB

17-009127

0dB

-52d Bm

-22d Bm

dB

-24d Bm

-25d Bm

VH F B I-DIRE CT IONAL AM P 50-078011

-5d Bm

+26d Bm

ALC

DET

0dB

0dB

dB dB

0dB

dB

dB dB

VH F B I-DIRE CT IONAL AM P 50-078011

VHF BI-DIRECT IONAL AM P

+25d Bm

VHF AIR INTERF ACE

+24d Bm

50-078012

0d Bm

dB

-20d Bm

-19d Bm

-11d Bm

0dB

-32d Bm

0dB

dB

-57d Bm

dB dB

-56d Bm

-77d Bm

-98d Bm

VH F B I-DIRE CT IONAL AM P 50-078011

50-078010

dB

0dB

dB

dBdB

0dB

SQL

0dB

dB

dB dB

dB

VHF BI-DIRECTIONAL AMP(SIMPLEX)

dBdB

dB dB

0dB

SQL

SQL

0dB

dB

dB

dB

VHF BI-DIRECTIONAL AMP(SIMPLEX) 50-078010

-90d Bm

-82d Bm

-92d Bm

-90d Bm

-57d Bm

-60d Bm

-66d Bm

-72d Bm

-51d Bm

-52d Bm

-55d Bm

-35d Bm

SQL

0dB

-15d Bm

dB dB dB

-21d Bm

-22d Bm

-2d Bm

37d Bm

36.5d Bm

31d Bm

26d Bm 28dB m

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

47 of 88

Page 48

4.2 Generic Wall Mounted Cases Outline Drawing (50-078017 & 80-209302)

H/book Number:-50-078001HBKM

800MHz & VHF Cell Enhancers

Maintenance Handbook

Issue No:-A

Date:-02/09/2004

Page:-

48 of 88

Page 49

5. SUB-UNIT MODULES

5.1 Bandpass Filters (02-007201 & 01-002503)

5.1.1 Description

The bandpass filters are multi-section designs with a bandwidth dependent upon the

passband frequencies, (both tuned to customer requirements). The response shape is

basically Chebyshev with a passband design ripple of 0.1dB. The filters are of slot coupled,

folded combline design, and are carefully aligned during manufacture in order to optimise

the insertion loss, VSWR and intermodulation characteristics of the unit. The tuned elements

are silver-plated to reduce surface ohmic losses and maintain a good VSWR figure and 50

load at the input and output ports.

Being passive devices, the bandpass filters should have an extremely long operational life

and require no maintenance. Should a filter be suspect, it is usually most time efficient to

replace the module rather than attempt repair or re-tuning.

5.1.2 Technical Specification (02-007201)

PARAMETER SPECIFICATION

Response Type Chebyshev

Frequency Range: 800 - 950MHz (tuned to spec.)

Bandwidth: 10-25MHz (tuned to spec.)