Page 1

User Manual

Broadcast Audio Mixing

Console

(Rev. 2.6 ENG)

Page 2

Table

of contents

Main Office BOLOGNA: Via Caduti Di Sabbiuno 6/F

40011 Anzola Emilia - Bologna - Italy

Tel. +39 051 736555 - Fax. +39 051 736170

Regional Office BERGAMO: Via Italia 1 –

24030 Medolago (Bg) – Italy

Tel. +39 051 736555 - Fax. +39 051 736170

e-mail: info@axeltechnology.com - w eb site: www.axeltechnology.com

Page 3

Table of contents

1 Table of contents

1 TABLE OF CONTENTS 3

SAFETY WARNINGS / ISTRUZIONI PER LA SICUREZZA 5

FOREWORD 5

SAFETY WARNINGS 6

CONSIGNES DE SÉCURITÉ IMPORTANTES 7

ISTRUZIONI IMPORTANTI PER LA SICUREZZA 8

WICHTIGE SICHERHEITSHINWEISE 9

INSTRUCCIONES IMPORTANTES DE SEGURIDAD 10

UNPACKING AND INSPECTION 11

FIRST INSTALLATION RECOMMENDATIONS 12

POWER SUPPLY CABLE 12

AC MAINS VOLTAGE SETTING (230 V / 115 V) 12

FUSE REPLACEMENT 13

PROTECTION AGAINST LIGHTNING 14

VENTILATION 14

2 INTRODUCTION 15

3 SYS TEM OVERVIEW 16

3.1 SYSTEM PA RTS 16

3.2 COMMUNICAT ION 18

3.3 FEAT URE S AND HIGHLIGHT S 19

3.4 PRINCIPLE OF OPERATION 20

3.4.1 Oxygen 5 Digital system 20

3.4.2 Mixing console 20

4 CONTROL SURFACES 23

5 OXYGEN 5 DIGITAL ENGINE 24

5.1 IP/CLOCK CONFIGURAT ION 25

5.2 GLOBAL CONFIGURATION 26

5.3 MIX BUSS CONFIGURAT ION 27

5.4 MONIT OR BUSS CONFIGURATION 28

5.5 SOURCE CONFIGURATION 29

5.6 EXT ERN SOURCE CONFIGURATION 31

5.7 DEST INATION CONFIGURATION 32

5.8 TALKBACK CONFIGURAT ION 34

5.9 PROCESSING PRESETS 35

5.9.1 Settings 36

5.10 MODULE ASSIGNMENT 39

5.11 MODULE CONFI GURATION 40

5.11.1 Module configuration page 41

5.12 MIX/MONIT OR BUSS PRESETS 44

5.12.1 Settings 45

5.13 CONSOLE PRESETS 47

5.14 SURFACE CONFIGURAT ION 48

5.15 RACK CONFIGURAT ION 50

5.16 ENGINE FUNCTIONS 52

5.16.1 Modules 52

5.16.2 Busses 58

5.16.3 Monitor busses 59

5.16.4 Global 61

5.16.5 Sources 72

5.16.6 Destinations 73

6 BLOCK DIAGR AMS – NOT AVAIL ABLE 76

7 I/O RACK DESCRIPTION 77

7.1 POWER SUPPLY 78

7.2 ENGINE 78

Page 4

Table of contents

8 AVAILABLE I/O RACK CARDS 81

8.1 MIC INPUT CARD 81

8.2 LINE INPUT CARD 82

8.3 DIGITAL IN/OUTPUT CARD (OPT IONAL SRC) 83

8.4 LINE OUTPUT CARD 84

8.5 CRM OUT PUT CARD 85

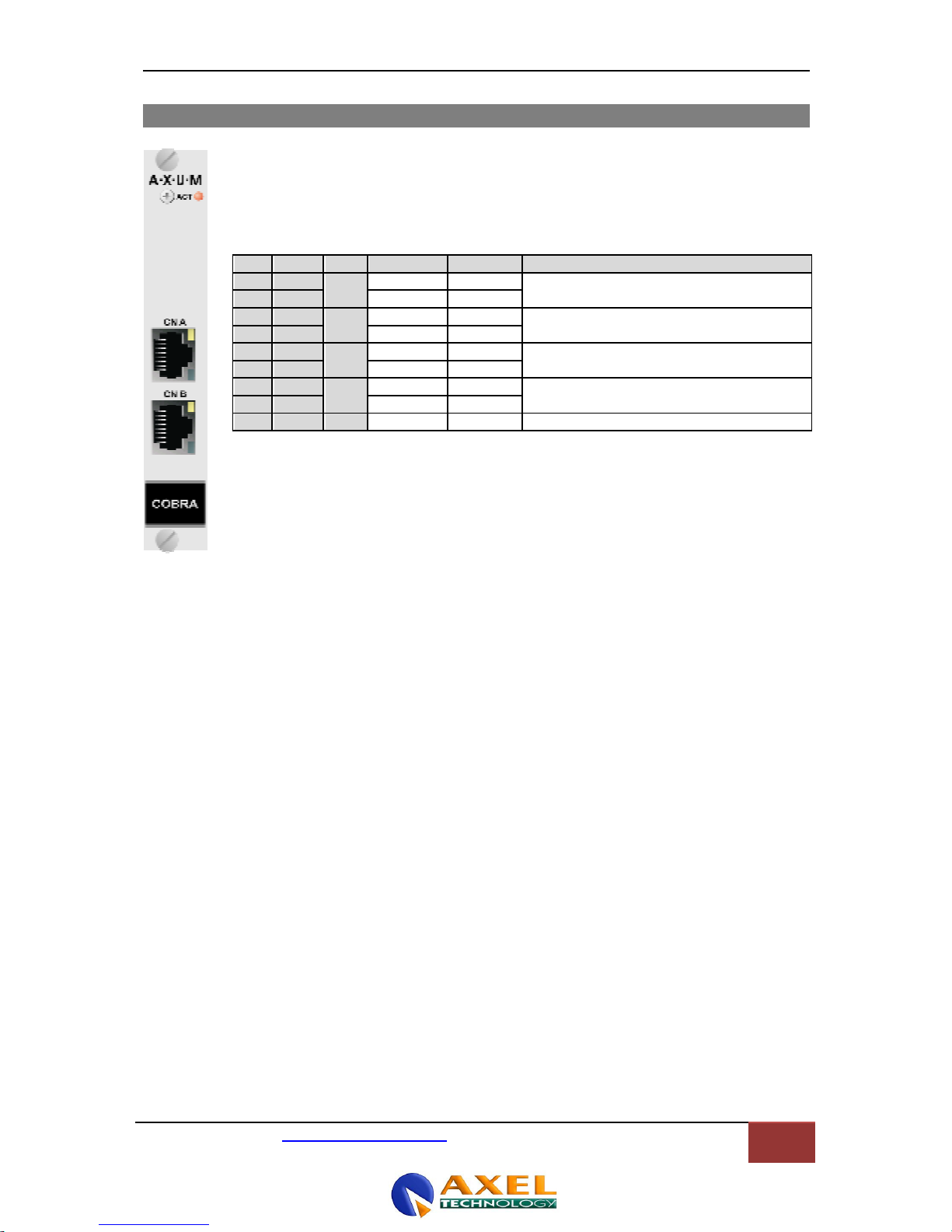

8.6 COBRANET IN/OUTPUT CARD 86

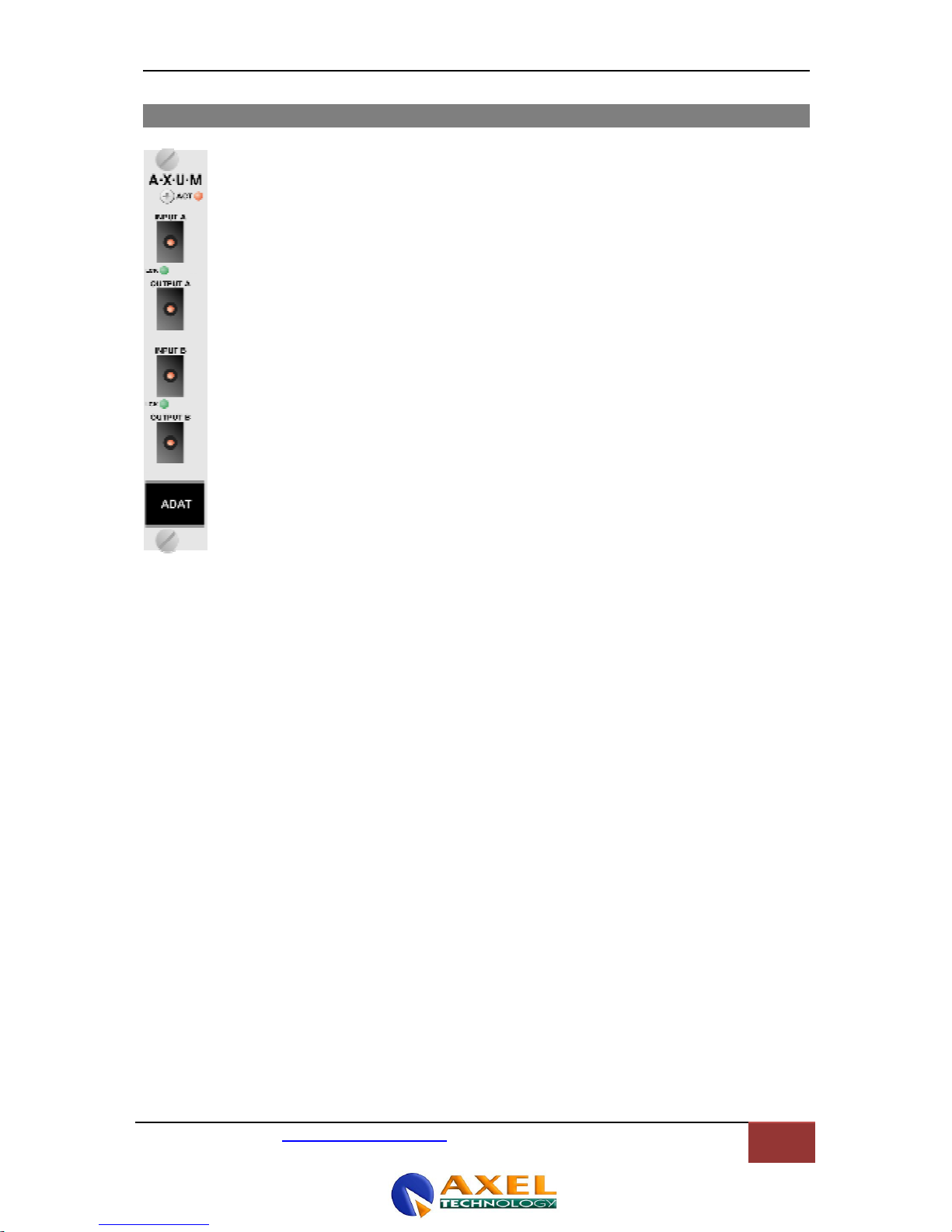

8.7 ADAT IN/OUTPUT CARD 87

8.8 HYBRID IN/OUTPUT CARD – NEEDS T O BE ADDED 88

8.9 FIREWIRE IN/OUTPUT CARD – NEEDS T O BE ADDED 89

8.10 DSP CARD 90

9 PATCH PANELS 91

9.1 19” PAT CH PANELS / BREAKOUT PANELS 91

9.2 WIRING 93

9.2.1 GPIO/Remote 93

9.2.2 MIC 94

9.2.3 Phones 94

9.2.4 Stereo line input and output 95

9.3 STANDARD RJ45 WIRING 95

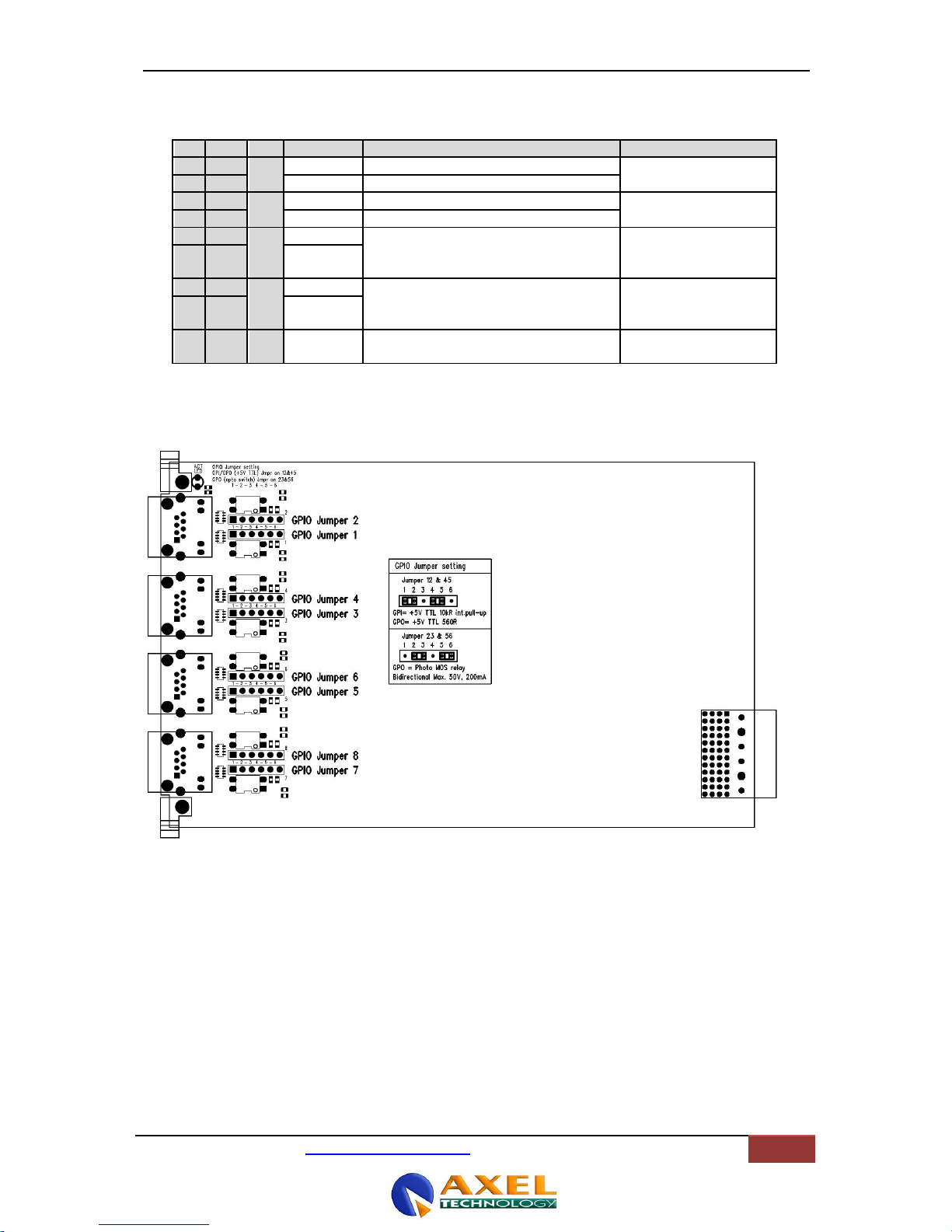

9.3.1 GPIO TTL/Relay selection 95

9.4 SICO BREAKOUT BOX 97

10 SPECIFICATIONS OXYGEN 5 DIGITAL AUDIO SYSTEM 98

10.1 INPUT/OUT PUT CARDS 98

10.2 DSP PROCESSING 98

10.3 OVERALL 99

10.4 DIMENSIONS 99

11 LIST OF FIGURES 100

12 LIST OF TABLES 101

13 DECLAR ATION OF CONFORMITY 102

14 PRODUCT SAFETY 103

15 DISCLAIMER 104

16 APPENDIX A - NETWORK DESIGN FOR OXYGEN 5 DIGITAL 105

16.1 NETWORK LEV ELS 105

16.2 OXYGEN 5 DIGITAL NETWORK IMPLEMENTATION 105

16.3 NETWORK DESIGN 105

16.3.1 Practical solution 1: Physical separated switches and IP router 107

16.3.2 Practical solution 2: single managed level 3 switch/router 108

16.3.3 Practical solution 3: Physical separated switches and PCs if IP router 109

16.4 IP SUBNETS AND IP ROUTES 110

16.5 REMOTE ACCESS 111

17 APPENDIX B – SERVICE 112

17.1 MAMBANET NODE OVERVIEW 114

17.2 TEMPLATES 116

17.3 STORED CONFIGURAT IONS 117

17.4 ENGINE FUNCTIONS 118

17.5 PACKAGE VERSIONS 119

17.6 CHANGE PASSWORD 120

18 WEEE DIRECTIVE – INFORMATIV A RAEE 121

19 WARRANTY 123

20 DECLAR ATION OF ROHS CONFORMITY 123

21 AXEL TECHNOLOGY CONTACTS 124

Page 5

SAFETY WARNINGS / ISTRUZIONI PER LA SICUREZZA

SAFETY WARNINGS / ISTRUZIONI PER LA SICUREZZA

SAFETY WARNINGS

CONSIGNES DE SÉCURITÉ IMPORTANTES

ISTRUZIONI IMPORTANTI PER LA SICUREZZA

WICHTIGE SICHERHEITSHINWEISE

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

(Rel. 1.3)

FOREWORD

For your own safety and to av oid invalidation of the warranty all text marked w ith these Warning

Symbols should be read carefully.

Information in this manual is subject to change without notice and does not represent a commitment on the

part of the vendor.

The manufacturer shall not be liable for any loss or damage whatsoever arising from the use of information

or any error contained in thi s manual, or through any mis-operation or fault in hardware contained in the

product.

It is recommended that all maintenance and service on the product should be carried out by the

manufacturer or its authorised agents. The manufacturer cannot accept any liability whatsoever for any loss

or damage caused by service, maintenance or repair by unauthorised personnel.

Page 6

SAFETY WARNINGS

SAFETY WARNINGS

The installation and servicing instructions in this manual are for use by qualified personnel only.

-

Read All Instructions.

All safety and operating instructions must be read before operating the product.

They also must be retained for future reference, as it contains a number of useful hints for determining

the best combination of equipment settings for Yr particular application.

-

Heed All Warnings

. All warnings on the product and those listed in the operating instructions must be

adhered to.

-

Heat

. This product must be situated away from any heat sources such as radiators or other products

(including power amplifiers or transmitters) that produce heat.

-

Power Sources.

This product must be operated from the type of power s

ource indicated on the marking

label and in the installation instructions. If you are not sure of the type of power supplied to your facility,

consult your local power company. Make sure the AC main voltage corresponds to that indicated in the

technical specifications. If a different voltage (ex. 110/115 VAC) is avail able, open the equipment closure

and set the voltage switch on the main supply circuit, located behind the AC socket

-

Power Cord Protection.

Power supply cords must be routed so that they

are not likely to be walked on

nor pinched by items placed upon or against them. Pay particular attention to the cords at AC wall plugs

and convenience receptacles, and at the point where the cord plugs into the product

-

Use only w ith a cart,

stand, t

ripod, bracket, or table specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when moving the cart/apparatus combination to avoid injury

from tip-over.

-

Lightning

. For added protection for this product duri ng a

lightning storm, or when it is left unattended and

unused for long periods of time, unplug it from the AC wall outlet and the audio connections. This will

prevent damage to the product due to lightning and power line surges

-

Installation

.

Configuration and installation should only be carried out by a competent installation engineer

-

Cabling

. Using high quality wires, well protected. Make sure the cable integrity.

This symbol alerts you to the presence of dangerous voltage inside the closure – voltage

which may be sufficient to constitute a risk of shock. Do not perform any servicing other

than that contained in the operating instructions. Refer all serv icing to qualified

personnel

The exclamation point w ithin an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (serv icing) instructions in the

literature accompanying the appliance.

Do not change the voltage setting or replace the mains fuse without first t

urning the

unit off and unplugging the mains cord

Make sure the AC main voltage corresponds to that indicated in the technical

specifications.

THIS APPARATUS MUST BE EARTHED !

To avoid risk of fire use the correct value fuse, as indicated on

the label stuck on the

right side of the unit.

This apparatus uses a single pole mains sw itch and does therefore not separate the

unit completely from the mains power. To completely separate from mains power

(f.i. in the event of danger) unplug mains power cord. As the MAINS plug is the

disconnect dev ice, the disconnect dev ice shall remain readily operable.

Page 7

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSIGNES DE SÉCURITÉ IMPORTANTES

-

Lire ces consignes

-

Conserver ces consignes

-

Observer tous les avertissements

-

Suivre toutes

les consignes

-

Ne pas utiliser cet appareil à proximité de l’eau

-

Ne pas obstruer les ouvertures de ventilatio

n. Installer en respectant les consignes du fabricant

-

N

e pas installer à proximité d'une source de chaleur

telle qu'un radiateur, une bouche de chaleur, un

poêle ou d'autres appareils (dont les amplificateurs) produisant de la chaleur.

-

Ne pas annuler la sécurité de la fiche de terre

, la troisième branche est destinée à la sécurité. Si la

fiche fournie ne s'adapte pas à la prise électrique, demander à un électricien de remplacer la prise hors

normes.

-

Protéger le cordon d'alimentation

afin que personne ne marche dessus et que rien ne le pince, en

particulier aux fiches, aux prises de courant et au poi nt de sortie de l’appareil

-

Utiliser uniquement les accessoires spécifiés par le fabricant

-

Utiliser uniquement avec un chariot

, un support ou une table spécifié par le fabricant ou vendu avec

l’appareil. Si un chariot est utilisé, déplacer l’ensemble chariot–appareil avec précaution afin de ne pas le

renverser, ce qui pourrait entraîner des blessures

-

Débrancher l’appareil

pendant les orages ou quand il ne sera pas utilisé pendant longtemps.

-

Confier toute réparation à du personnel

qualifié.

Des réparations sont nécessaires si l’appareil est

endommagé d’une façon quelconque, par exemple: cordon ou prise d’alimentation endommagé, liquide

renversé ou objet tombé à l’intérieur de l’appareil, exposition de l’appareil à la pluie ou à l’humidité,

appareil qui ne marche pas normalement ou que l’on a fait tomber.

-

NE PAS exposer cet appareil aux égouttures et aux éclaboussements

. Ne pas poser des objets

contenant de l'eau, comme des vases, sur l'appareil

Ce symbole indique la présence d'une tension dangereuse dans l'appareil constituant un

risque de choc électrique.

Ce symbole indique que la documentation fournie avec l'appareil contient des instructions

d'utilisation et d'entretien importantes.

Avant de modifier le commutateur de changement de tension ou replacer le fusible il

faut débrancher l’appareil de la prise électrique. Pendant son usage, l’appareil doit etre

branchee à la prise de terre

Utiliser le fusible principal AC avec le

valeur qui est indiquée sur l'étiquette collée sur le

coffret.

Assurez

-

vous que la tension principale AC correspond à celle indiquée dans les

spécifications techniques.

L’interrupteur d’alimentation interrompt un pôle du réseau d’alimentation excepté le

conducteur de terre de protection. En cas de danger, debrancher le cordon

d'alimentation. Parce que la prise du réseau de alimentation est utilisée comme

dispositif de déconnexion, ce dispositif doit demeuré aisément accessible

Page 8

ISTRUZIONI IMPORTANTI PER LA SICUREZZA

ISTRUZIONI IMPORTANTI PER LA SICUREZZA

-

Leggere le presenti istruzioni

-

Conservare queste istruzioni

-

Osservare tutte le avvertenze

-

Seguire scrupolosamente tutte le istruzioni

-

Non usare questo apparecchio in prossimità di acqua

-

Non ostruire alcuna apertura per il raffreddamento

. Installare l’apparecchio seguendo le istruzioni

-

Non installare l'apparecchio accanto a fonti di calore

quali radiatori, aperture per

l'afflusso di aria

calda, forni o altri apparecchi (amplificatori inclusi) che generino calore

-

Non rimuovere il terminale di connessione a terra sul cordone di alimentazione

: esso ha lo scopo di

tutelare l’incolumità dell’utilizzatore. Se la spina in dotazione non si adatta alla presa di corrente, rivolgersi

ad un elettricista per far eseguire le modifiche necessarie.

-

Evitare di calpestare il cavo di alimentazione o di comprimerlo

, specialmente in corrispondenza della

spina e del punto di inserzione sull’apparato.

-

Utilizzare solo dispositivi di collegamento e gli accessori specificati dal produttore.

-

Utilizzare l’apparecchio

solo con un carrello, un sostegno, una staffa o un tavolo di tipo specificato dal

produttore o venduto insieme all’apparecchio. Se si utilizza un carrello, fare attenzione negli spostamenti

per evitare infortuni causati da ribaltamenti del carrello stesso.

-

Scollegare l’apparecchio dalla presa di corrente

durante i temporali o quando inutilizzato a lungo

-

Per qualsiasi intervento

, rivolgersi a personale di assistenza qualificato. È’ necessario intervenire

sull’apparecchio ogni qualvolta si verificano danneggiamenti di qualsiasi natura. Ad esempio, la spina o il

cavo di alimentazione sono danneggiati, è entrato liquido nell’apparecchio o sono caduti oggetti su di

esso, l’apparecchio è stato esposto alla pioggia o all’umidità, non funziona normalmente o è caduto.

-

Non esporre a sgocciolamenti o spruzzi

. Non appoggiare sull'apparecchio oggetti pieni di liquidi, ad

esempio vasi da fiori .

Questo simbolo indica la presenza di alta tensione all'interno dell'apparecchio, che

comporta rischi di scossa elettrica.

Questo simbolo indica la presenza di istruzioni importanti per l'uso e la manutenzione nella

documentazione in dotazione all'apparecchio.

Non sostituire il fusibile o cambiare la tensione di alimentazione senza aver prima

scollegato il cordone di alimentazione. L’APPARATO DEVE ESSERE CONNESSO A

TERRA.

Sostituire il fusibile generale con uno di identico v alore, come indicato sulla

etichetta

applicata sul mobile dell’apparato

Assicurarsi che la tensione di rete corrisponda a quella per la quale è configurato

l’apparecchio

Questo apparato utilizza un interruttore di alimentazione di tipo unipolare e

l’isolamento dalla rete elettrica non è pertanto completo. Per ottenere un isolamento

totale (ad esempio in caso di pericolo), scollegare il cordone di alimentazione. Inoltre,

poichè la spina di alimentazione è utilizzata come dispositiv o di sezionamento, essa

deve restare facilmente raggiungibile

Page 9

WICHTIGE SICHERHEITSHINWEISE

WICHTIGE SICHERHEITSHINWEISE

-

Diese Hinw eise LESEN

-

Diese Hinw eise AUFHEBEN

-

Alle Warnhinweise BEACHTEN

-

Alle Anweisungen BEFOLGEN

-

Dieses Gerät NICHT in der Nähe von Wasser v erw enden

-

KEINE

Lüftungsöffnungen verdecken

. Gemäß den Anwei sungen des Herstellers einbauen

-

Nicht in der Nähe von Wärmequellen

, wie Heizkörpern, Raumheizungen, Herden oder anderen

Geräten (einschließlich Verstärkern) installieren, die Wärme erzeugen

-

Die Schutzfunktion des Schukosteckers NICHT umgehen

. Bei Steckern für die USA gibt es

polarisierte Stecker, bei denen ein Leiter breiter als der andere ist; US-Stecker mit Erdung verfügen über

einen dritten Schutzlei ter. Bei diesen Steckerausführungen dient der breitere Leiter bzw. der Schutzleiter

Ihrer Sicherheit. Wenn der mitgelieferte Stecker nicht in die Steckdose passt, einen Elektriker mit dem

Austauschen der veralteten Steckdose beauftragen

-

VERHINDERN, dass das Netzkabel gequetscht oder darauf

getreten wird

, insbesondere im Bereich

der Stecker, Netzsteckdosen und an der Austrittsstelle vom Gerät

- N

UR das vom Hersteller angegebene Zubehör

und entsprechende Zusatzgeräte verwenden.

-

NUR in Verbindung

mit einem vom Hersteller angegebenen oder mit dem Gerät verkauften

Transportwagen, Stand, Stativ, Träger oder Tisch verwenden. Wenn ein Transportwagen verwendet wird,

beim Verschieben der Transportwagen-Geräte- Einheit vorsichtig vorgehen, um Verletzungen durch

Umkippen

-

Das Netzkabel dieses Geräts

während Gewittern oder bei längeren Stillstandszeiten aus der Steckdose

ABZIEHEN.

-

Alle Reparatur

- und Wartungsarbeiten

von qualifiziertem Kundendienstpersonal DURCHFÜHREN

LASSEN. Kundendienst ist erforderlich, wenn das Gerät auf i rgendwelche Weise beschädigt wurde, z.B.

wenn das Netzkabel oder der Netzstecker beschädigt wurden, wenn Flüssigkei ten in das Gerät

verschüttet wurden oder Fremdkörper hineinfielen, wenn das Gerät Regen oder Feuchtigkeit ausgesetzt

war, nicht normal funktioniert oder fallen gelassen wurde.

-

Dieses Gerät v or Tropf

- und Spritzwasser SCHÜTZEN

. KEINE mit Wasser gefüllten Gegenstände wie

zum Beispiel Vasen auf das Gerät STELLEN.

Dieses Symbol zeigt an, dass gefährliche Spannungswerte, die ein Stromschlagrisiko

darstellen, innerhalb dieses Geräts auftreten.

Dieses Symbol zeigt an, dass das diesem Gerät beiliegende Handbuch wichtige Betriebs- und

Wartungsanweisungen enthält.

Vor Änderung der Netzspannung oder Sicherungsw echsel Netzkabel trennen.

Das Gerät muss für den Betrieb geerdet werden.

Hauptsicherung nur mit einer gleichwertigen austauschen

(s. entsprechende Etikette).

Vor Einschalten Netzspannungseinstellung am Gerät überprüfen bzw . anpassen

.

Inpoliger Netzschalter. In Notfälle oder für Wartungsarbeiten Netzkabel trennen.

Der

Netzstecker fungiert auch als Trennelement muss deshalb zugänglich bleiben

Page 10

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

-

LEA estas instrucciones

-

CONSERVE estas instrucciones

-

PRESTE ATENCION a todas las advertencias.

-

SIGA todas las instrucciones

-

NO utilice este aparato cerca del agua

-

NO obstruya ninguna de las aberturas de ventilación.

Instálese según lo indicado en las

instrucciones del fabricante

-

No instale el aparato cerca de fuentes de calor

tales como radiadores, regi stros de calefacción,

estufas u otros aparatos (incluyendo amplificadores) que produzcan calor

-

NO anule la función de seguridad del enchufe polarizado

o con clavija de puesta a tierra. Un enchufe

polarizado tiene dos patas, una más ancha que la otra. Un enchufe con puesta a tierra tiene dos patas y

una tercera clavija con puesta a tierra. La pata más ancha o la tercera clavij a se proporciona para su

seguridad. Si el toma corriente no es del tipo apropiado para el enchufe, consulte a un electricista para

que sustituya el toma corriente de estilo anticuado

-

PROTEJA el cable eléctrico

para evitar que personas lo pisen o estrujen, particularmente en sus

enchufes, en los toma corrientes y en el punto en el cual sale del aparato

-

UTILICE únicamente los accesorios especificados por el fabricante

-

UTILICESE únicamente

con un carro, pedestal, escuadra o mesa del tipo especificado por el fabricante

o vendido con el aparato. Si se usa un carro, el mismo debe moverse con sumo cuidado para evitar que

se vuelque con el aparato

-

DESENCHUFE el

aparato

durante las tormentas eléctricas, o si no va a ser utilizado por un lapso

prolongado.

-

TODA reparación

debe ser llevada a cabo por técnicos calificados. El aparato requiere reparación si ha

sufrido cualquier tipo de daño, incluyendo los daños al cordón o enchufe eléctrico, si se derrama líquido

sobre el aparato o si caen objetos en su interior, si ha sido expuesto a la lluvia o l a humedad, si no

funciona de modo normal, o si se ha caído.

-

NO exponga

este aparato a chorros o salpicaduras

de líquidos. NO coloque objetos llenos con líquido,

tales como floreros, sobre el aparato .

Este símbolo indica que la unidad contiene niveles de voltaje peligrosos que representan un

riesgo de choques eléctricos.

Este símbolo indica que la literatura que acompaña a esta unidad conti ene instrucciones

importantes de funcionamiento y mantenimiento.

Antes de cambiar la alimentacion de voltaje o de cambiar el fusible, desconecte el

cable de alimentacion. Para reducir el riesgo de descargas electricas, esta unidad

debe ser conectada a tierra.

Remplaze el fusible con lo mismo, que corresponde a lo indicado en el panel del

equipo.

Antes de encender, controlar que la linea de alimentacion de voltaje corresponda a la

indicada

El interruptor de alimentación es unipolar. En el caso de peligro, desconecte el cable

de alimentación. Porque la clavija de conexion a red sirve por la desconection de la

unidad, la clav ija debe ser ubicada en proximidad de la unidad

Page 11

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnol ogy.com

|

UNPACKING

AND INSPECTION

11

UNPACKING AND INSPECTION

Your equipment was packed carefully at the factory in a container designed to protect the unit during

shipment. Nevertheless, we recommend making a careful inspection of the shipping carton and the

contents for any signs of physical damage.

Damage & Claims

If damage is evident, do not discard the container or packing material. Contact your carrier

immediately to file a claim for damages. Customarily, the carrier requires you, the consignee, to make

all damage claims. It will be helpful to retain the shipping documents and the waybill number.

Save all packing materials! If You should ever have to ship the unti (e.g. for servicing), it is best to ship

it in the original carton with its packing materials because both the carton and packing material have

been carefully designed to protect the unit.

Under normal conditions no user maintenance or calibration are required. Internal links and preset

controls may be set to configure the unit during installation. Any service w ork required should be

carried out by qualified service personnel only.

We are able to offer further product support through our worldwide network of approved dealers and

service agents.

To help us prov ide the most efficient service please would you keep a record of

the unit serial number, and date and place of purchase to be quoted in any

communication regarding this product.

The actual equipment Serial Number is indicated on the silver label stuck on the rear panel of the

equipment closure.

Tools And Equipment Needed

Onl y standard technician’s tools are required to install this equipment.

Page 12

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnol ogy.com

|

FIRST

INSTALLATION RECOMMENDATIONS

12

FIRST INSTALLATION RECOMMENDATIONS

POWER SUPPLY CABLE

A power supply cable of approx. 2 mt length is supplied with the device, which has a moulded IEC

plug attached – this is a legal requirement.

The type of plug for the power supply depends on the country in which i t is delivered.

If for any reason, you need to use this appliance with a different plug, you should use the following

wiring guidelines in replacing the exsisting plug with the new one:

Earth

Green, or green and yellow

Neutral (N)

Blue

Liv e (L)

Brown

Supply cables should be laid in such a manner that one does not step or walk on them. They should

not be squashed by any objects.

THIS EQUIPMENT MUST BE EARTHED.

The chassis is always connected to mains earth to ensure your safety: check your mains wiring and

earthing before switching on.

AC MAINS VOLTAGE SETTING (230 V / 115 V)

BE SURE THAT THE UNIT IS SET TO THE CORRECT MAINS/LINE VOLTAGE

FOR YOUR COUNTRY BEFORE PLUGGING IT INTO THE WALL OUTLET !

The actual Mains voltage is indicated on the label stuck on the equipment closure. Should the type of

power at the operation location not be known, please contact your dealer or electrici ty company.

If, for some reason, the unit is to be operated at a mains input voltage which is different to that as

supplied, you need to switch the voltage selector on the right side of the unit. You also need to replace

the AC main fuse, according to information provided on the external label or on the Technical

Specifications table at the end of this user manual.

CAUTION: TO REDUCE THE RISK OF ELECTRICAL SHOCK, ALWAYS

DISCONNECT THE AC MAINS CABLE BEFORE ALTERING THE CHANGE-OVER

SWITCH. NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

Page 13

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnol ogy.com

|

FIRST

INSTALLATION RECOMMENDATIONS

13

FUSE REPLACEMENT

The power supply socket has an integral fuse drawer containing the AC power fuse and a spare, both

of the same value.

BEFORE REPLACING THE POWER FUSE, MAKE SURE YOU HAVE THE RIGHT TYPE

OF FUSE FOR THE VOLTAGE TO BE PROTECT ED.

USING WRONG FUSE TYPE WILL RESULT IN INSUFFICIENT PROTECTION.

Make sure that the power is sw itched off and the power cable is disconnected from

the

equipment.

a.

Open the fuse drawe r using a small blade screwdrive r.

b.

Replace the fuse located at the internal position

c.

Push the fuse socket back into the original position (a.)

Perform the set

-

up under static control conditions. Static charges are likely to

completely destroy one or more of the CMOS semiconductors employed in the unit.

Static damage will not be covered under warranty.

Basic damage prevention consists of minimizing generation, discharging any

accumulated static charge on your body and preventing that discharge from being sent

to or through any electronic component.

Uninsulated dangerous voltage are inside the enclosure, voltage that may be sufficient

to constitute a risk of shock.

Always disconnect to AC Mains before removing the top cover

Page 14

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

FIRST

INSTALLATION RECOMMENDATIONS

14

PROTECTION AGAINST LIGHTNING

Should the device be put out of action due to being struck by lightning or excess

voltage, disconnect it from the power supply wi thout delay. Do not reconnect until the

device has been checked. If in doubt contact the technical support service.

Make sure there is sui table lightning protection to protect the device.

Alternatively you should disconnect all connectors from the device during a storm or

when the device is going to be unsupervised or not used for a longer period of time.

These measures will protect against damage by lightning or excess voltage.

VENTILATION

The equipment will operate as a free-standing unit without requiring any special cooling arrangement.

However, slots and openings in the product are provided for ventilation. They ensure reliable operation

of the product, keeping it from overheating. These openings must not be blocked nor covered during

operation.

YOU MUST LEAVE AT A MINIMUM ONE RACK UNIT OF EMPTY SPACE ABOVE THE

EQUIPMENT TO ENHANCE VENTILATION AND TO GET A LONGER EQUIPMENT LIFE.

Page 15

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Introduction

15

2 Introduction

This manual will give you an overview of the functionality of the Oxygen 5 Digital audio system and all

its features. It is advisable to read this manual at least once before touching any control, or even

thinking about hooking up the system. We know that this is actually the fi rst thing you want to do, but

please do not and discipline yourself to read the manual first.

The manual gives all sorts of valuable information before getting started and it saves you from getting

all sorts of questions. After installing this manual can be used as a reference.

In the first chapter, we shall give you an overview of the Oxygen 5 Digital and its features.

This way, you have an impression on how to implement the system in your applicati on.

The next chapters will deal with interconnecting the various parts of the system and its external

interfacing with your equipment

When installing and wiring the Oxygen 5 Digital, you can finali ze its interfacing with the instructions in

the following chapters.

After installation, you will have a very complete mixer with a human interface that is very logical and

intuitive.

Page 16

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

System over view

16

3 System overview

The Oxygen 5 Digital is a digital modular audio system that can solve your digital mi xing/routing

requirements in your broadcast studio or in your complete broadcast facility. The modular system can

be used in all your mixing/routing applications like on-air broadcast, self-op, production and voice

tracking.

3.1 System parts

To make a functional mixing console you require at least a 19” rack with a DSP card (32 stereo

channels), the desired I/O cards and a control surface that can control all the mixing power. T he

connection between the 19” rack(s) and control surface(s) rely on a network protocol that is been

called MambaNet.

MambaNet works on Ethernet layer 2, there for no IP-addresse s have to be setup for the ‘real-time’

functionality.

WARNING: Do not connect multiple Oxygen 5 Digital engines/racks in the same Ethernet

network (Layer 2)

To connect surface(s) and 19” rack(s) you can built on this known Ethernet standard with common

switches till advanced managed switches with all the security soluti ons as there are ST P (spanning

tree protocol), Trunking etc.

For (remote) configuration the well known webbrowser is used to access the consoles webserver. Of

course this happens on a IP-based level of communication, which makes it possible to configure

system over the internet.

The defaults IP-addresses for configuration pages are:

http://192.168.0.200 for the configuration in main menu

http://192.168.0.23x for the controller surface configuration. (for the fi rst surface set x to 4, for a

second surface set x to 5, etc).

To prevent other people to access the Oxygen 5 Digital configuration pages you need to logon.

The default logon is:

Username: service

Password: service

This account may change, which is explained in Appendix B.

Network specialists can find some more information in chapter 16 (Appendix A).

Page 17

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnol ogy.com

|

System over view

17

Figure 1: Basic system layout

Page 18

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnol ogy.com

|

System over view

18

3.2 Communication

All control communication takes place with MambaNet and gives the surface flexibility and power to

the Oxygen 5 Digital digital audio system. To understand the Oxygen 5 Digital audio system it would

help to know some principles of MambaNet.

MambaNet definitions:

- Objects

a fader, switch will have to tri gger an action in the Oxygen 5 Digital digital audio system. In

MambaNet, we call these faders and switches ‘objects’.

- Nodes

In hardware the faders and switches are grouped on modular blocks (think of a single PCB),

such blocks are represented as ‘nodes’ in MambaNet.

- Engine

In the Oxygen 5 Digital digital system the engine is in fact your mixing console. The functions

available in the ‘engine’ can connect to one or more objects found in your network.

In practice, this means you can connect any surface element like switches and faders to any function

of your mixing console(s). From now on, you can design your own functionality at the control surface.

Information for manufacturers and developers is located at http://www.mambanet.org, its possible to

make your own communication with the mixing system; we have a MambaNet library available for

Windows (DLL) and Linux (lib).

For professional developers it is possi ble to buy a Manufacture ID from Axel Technology so you are

able to make your own equipment compatible with the MambaNet protocol. Secondly, local radio

stations can use manufacturer ID 0xFFFF for some custom implementations.

(Al manufacturer IDs are unique except the 0xFFFF, which is free for ‘in-house’ implementation)

Figure 2: MambaNet logo

Page 19

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

System over view

19

3.3 Features and highlights

Because the Oxygen 5 Digital audio system is highly flexible, you can make many solutions for your

mi xing and routing. T o have an overview on the power of the Oxygen 5 Digital digital audio system we

made a list of the most important features and highl ights:

• I/O Matri x of 1280x1280 with opti onal I/O Cards:

- MIC inputs and GPIO’s

- Line inputs and GPIO’s

- Digital in/outputs and GPIO’s

- Line outputs and GPIO’s

- CRM/Phones outputs and GPIO’s

- ADAT in/outputs

- CobraNet in/outputs

- Firewire in/outputs

- Hybrid in/outputs

• 32 stereo modules per DSP card.

- Gain

- Low cut

- 6 band full parametric EQ

- Voice processi ng

- one free FX DSP for future use.

• 32 busse s, default configured if:

console 1 and 2 with each a:

- Stereo Program buss

- Stereo Sub buss

- 4x Stereo Aux buss

- Stereo Dump buss

- Stereo PFL buss

• Up to 4 DSP cards

- up to 128 stereo modules

- up to 16 monitor busses.

(for example it is possible to make 4 studios with one I/O rack, or even 2 studios of 16 stereo

modules and 2 stereo monitor busses with a single DSP card in your I/O rack…)

• Advanced preset system.

• Object oriented control protocol, MambaNet

• Configuration of the Oxygen 5 Digital nodes using one web server

• Multiple redundancy solutions

• Remote configuration via HTTP and TCP/IP

• Remote control via MambaNet over TCP/IP

• Standardized cabling with RJ45 (shielded for audio connections)

Page 20

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

System over view

20

3.4 Principle of operation

3.4.1 Oxygen 5 Digital system

The Oxygen 5 Digital system will be build up around the matrix/router that gives a lot of routing

flexibility. Up to 4 DSP cards can be inserted to create mixing power as requested. For example, you

can create with one Oxygen 5 Digital system (equipped with one DSP card):

- A single mixing console with 32 stereo modules and 16 stereo busse s

- Multiple mixing consoles (maximal 4), 3 consoles are used in our example:

1 consoles with 16 stereo modules and 6 stereo busses

1 consoles with 12 stereo modules and 6 stereo busses

1 console 4 stereo modules and 4 stereo busses

This makes clear we do not talk over a ‘mixing console’, the Oxygen 5 Digital is an audio-platform!

Depending on the configuration, you can make your own studio console(s)/surface funcionality. Al this

power is controlled and configured by the Oxygen 5 Digital engine. This engine configuration is

described in detail later on.

3.4.2 Mixing console

As mentioned before the configuration is done within the Oxygen 5 Digital engine, now we will give a

short overview/introduction on the structure of the mixing console(s) platform solution of the engine.

For the configuration of the busses, monitor busses and modules you can setup to which console it

should belong (1-4). Final ly the engine will extract a ‘assignment’ picture from thi s information which

shows clearly the console blocks.

Page 21

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

System over view

21

3.4.2.1 Sources

Each module can receive audio from the matrix using so called ‘sources’. A source is given a name,

left/right physical input and some additional settings (think of phantom, pad, redlight settings). For

example if we make source ‘MIC1’ with phantom on we can route this to module 1 and/or module 13.

So the MIC 1 i s used at console 1 but also at console 2 (or 3).

3.4.2.2 Destinations

Audio is sent to physical outputs by so called ‘destinations’. A destinations given a name, left/right

physical outpus and some additional settings (default audio-source, N-1 etc). For examples we make

destinations ‘Line out 1’ and ‘Dig out 1’ which both get the audio from ‘Prog A’.

3.4.2.3 Console/Surface functionality

After the consoles are set-up/configured and the inputs and outputs are set-up with the correct

settings if sources/destinati ons you can start using the console functionality. Which functi onality is

available depends on the configuration of the system.

It is important to make the required ‘real-time’ functionality available via de surface and rack

configuration menu’s. Actually here you define the ‘knob functions’.

3.4.2.4 Console startup/Presets

If the console start up it will load the last backup or the programmed defaults, this depends on a

setting in global configuration.

The programmed defaults are:

- The information set within the webbrowser pages

- For the modules ‘module preset 1A’ is selected by default.

Further in live use of the console(s) you can make use of presets:

- Processing presets

- Module presets

- Console presets

processing preset:

A processing preset contains module-settings (think of EQ, Dynamics etc. etc).

When a source is sel ected by the control surface encoder, the assigned default processing preset is

loaded.

Module preset:

The module preset 1A t/m 4B defines a combination of: Source, Processing preset and Routing

preset.

In this case if module preset 1B is recalled:

- The configured ‘preset 1B source’ is set on the module

- The corresponding processing preset is set on the module. Processing preset field that not

override the module will set according to the module configuration settings (if ‘Use at source

select’ is active).

- The routi ng as given by ‘module preset 1B’ is restored.

Console preset:

The console preset consists of two main parameters:

- It loads Module preset 1A, 1B, 2A, 2B, 3A, 3B, 4A or 4B.

- It loads a buss/monitor buss preset.

Here also you can define if a separate buss is used within the preset (the configuration setting ‘Use’ –

Yes/No).

In general you can say:

- The console will startup in the defaults like given in the webpage.

Page 22

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

System over view

22

- When a source is selected (can also be in the startup-defaults) the corresponding processing

preset is loaded.

- When a module preset is loaded, the complete module settings can be preset.

- With the console preset you are able to change: module-settings , buss master en monitor

buss settings.

Page 23

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Control Surf aces

23

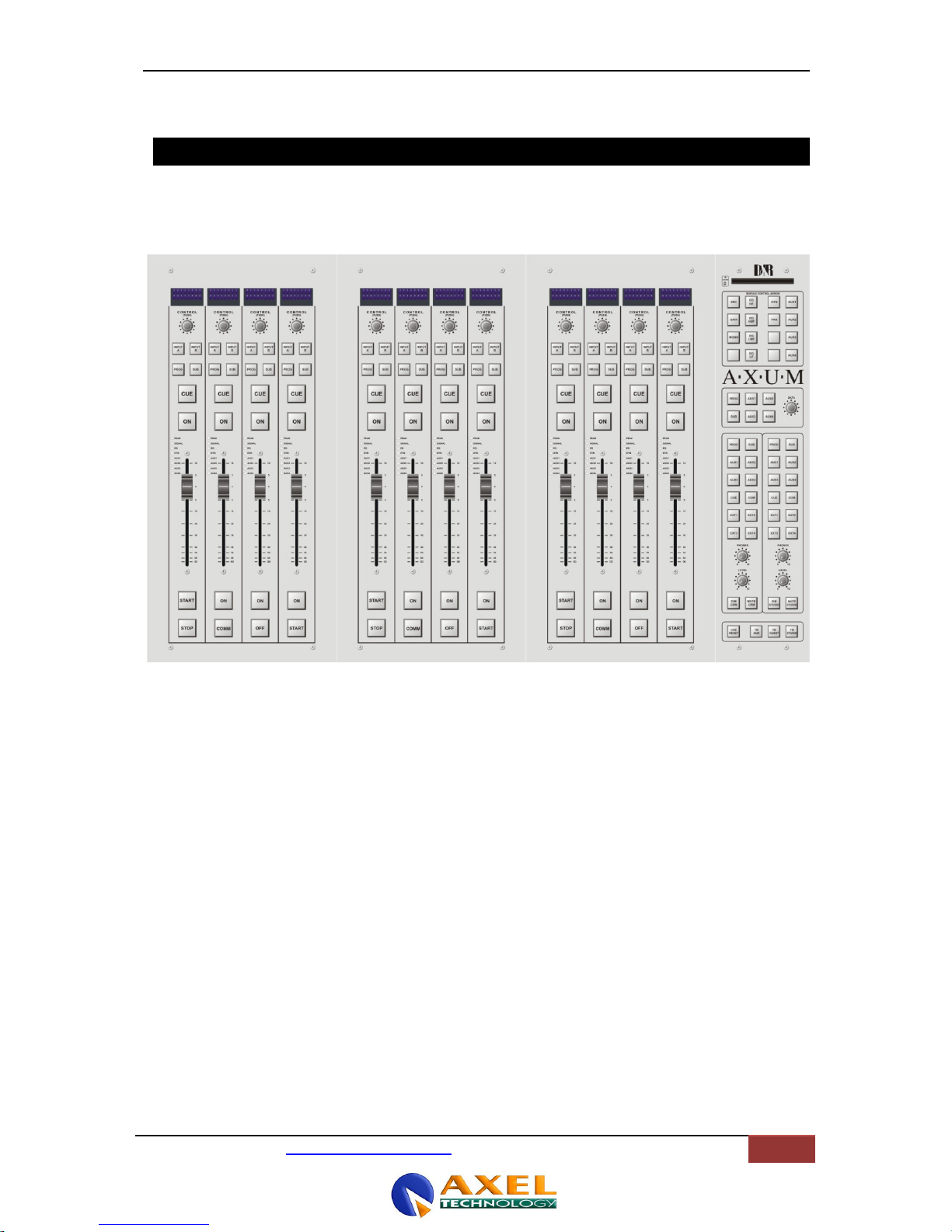

4 Control Surfaces

The engine will recognize the control surfaces of the Oxygen 5 Digital audio system as ‘nodes with

objects’. Each object can connect to an engine (mixing console) function.

Below you see an example of a control surface and a short description of the node/object structure.

Figure 3: 12 fader control surface

This control surface holds 4 user interfaces nodes:

- 3x four fader panel node

- 1x monitor buss panel node

The ‘four fader panel node’ holds 84 obj ects:

- 4x Display upper line

- 4x Display lower line

- 4x Encoder

- 4x Encoder-push

- 32x LEDs

- 32x switches with LEDs (16 small, 16 large)

- 4x fader

The ‘monitor buss panel node’ holds 61 objects:

- 1 chip card

- 54 switches with LED’s

- 1 encoder

- 1 encoder push

- 4 potentiometers

Page 24

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

24

5 Oxygen 5 Digital Engine

The engine of the Oxygen 5 Digital drives all audio processi ng/routing and from the surfaces and

remote locations, it can be controlled using MambaNet. Therefore it is required that you setup the

engine/system with your settings before it will work according your requirements. Of course, we deliver

the system in a default confi guration that will cover 90% of the functionality you wish.

Setting up the engi ne (your mixing console) is done using your web browser.

Simply enter the IP address of the 19” rack in your browser and log-on to the configuration pages.

By default the IP Address is: http://192.168.0.200

(at first time startup you can use a network or cross wire with a static IP given to your network

interface, e.g. 192.168.0.10).

On the Oxygen 5 Digital website, you find all necessary options to configure your system as full

functioning mixing console(s), it’s the most easy to step from up to down through the main menu:

Figure 4: Oxygen 5 Digital web server

Page 25

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

25

5.1 IP/Clock configuration

Figure 5: IP/Clock configuration

Here you can setup the network settings to be compatible with the required settings in your si tuation

and you can set the time zone to where you are.

It’s possible to change the IP, subnet, gateway and DNS server address by clicking on the address.

For more information on IP addressing:

http://en.wikipedia.org/wiki/IP_address

To change the time zone, click on the used time zone (in our example ‘Europe/Amsterdam’). You can

select the desired time zone in the list box.

The Oxygen 5 Digital uses the NTP protocol for accurate clock synchronization. In the section ‘current’

you find the IP address of the used ‘clock master’ and its ‘stratum’. For more information on NTP:

http://en.wikipedia.org/wiki/Network_Time_Protocol

When IP and DNS settings are setup correct, the Oxygen 5 Digital will automatically synchronize to a

pool of time servers. The Oxygen 5 Digital is also able to use a GPS receiver via USB for time

synchronization. At this moment to Oxygen 5 Digital may function if a NTP server for the surfaces.

On the webserver of the control surfaces you now can click on 'optional ntp server' to fill in the IP

address of the ntp server (e.g. 192.168.0.200).

Remember that all changes will become effective after reboot.

Page 26

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

26

5.2 Global configuration

Some overall system settings can be filled in on this webpage.

Figure 6: Global configuration

• Sample rate

You can select a sampl e rate of 32 kHz, 44.1 kHz en 48kHz. According to this setting, the

filters are setup so you have to make sure to select the sample rate you work with. Also when

using external clock.

• Extern(al) clock

If you want to use the external clock (Frame clock in) you can turn it on here.

• Headroom

The internal headroom is fixed at 20 dB, to adjust the headroom on a local input/output you

can give an offset level to the sources/destinations or at the rack configuration.

• Fader top level

You can make the fader work with or without 10 dB fader reserve. In the last situation the

faders will be 0 dB (unity gain) when the fader is fully up (maximum position).

• Auto momentary

Most switch functions can work in a auto-momentary mode. When set to yes a knob will

function latching when pressed shortly. But with a long press (>750 mS) the knob reacts like a

momentary switch (function active while pressed).

• Startup state

Here you can select to use a known startup state which is the ‘programmed defaul ts’ or use a

‘backup of the last situation’.

Programmed defaults are the defaults as setup in the web-configuration. An backup of the

console is saved once a minute, which means you will return to (almost) the last situation.

Page 27

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

27

5.3 Mix buss configuration

You have to setup the busses to create the names, console assignment and functionality of the

Busse s. Here we see the setup for a single console buss setup:

Figure 7: Buss configuration

• Label

The name given to this buss.

• 2 Mono busses

It is possible to make 2 mono busse s from one stereo buss. All buss-sends, to this buss, on

the module’s will now include stereo to mono summing.

• Master pre/post

You can choose the buss to be pre or post ON, level (comparable with pre/post fader) and

balance (could be your pan-pot).

• Master level/state

This setting is used as programmed startup level, so the buss masters are in a known state.

• Interlock

If you make a buss interlock, only 1 module can be assigned at the same time.

• Exclusive

When routing to an exclusive buss is made, the routing to all other busses on that module will

be disabled. This is usefull for a so called ‘dump buss’.

• Buss reset

This setting can be used to create a CUE/PFL buss with auto-reset (CUE Reset).

If you have multiple studi os and CUE/PFL busses you may assign reset to multiple busses.

• Console

You can select to which console a buss belongs.

Page 28

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

28

5.4 Monitor buss configuration

Per DSP card, you have 4 stereo monitor busses that can be used. They need a name, console

assignment and configuration so they can work properly:

Figure 8: Monitor buss configuration

• Label

Here you give a name to this monitor buss

• Interlock

Yes means only one source is active at the same time, on this monitor buss.

• Default selection

If the last selected source is turned off it will always go to the default selection.

This selection is also your startup default.

• Automatic switching.

You can tell the Engine that a monitor buss switches automatically when the ‘source buss’ is

activated. Also known as ‘PFL to CRM’. If you have two separate studios’ you can have

multiple automatically switched busse s (e.g. PFL 1 and PFL 2).

When to mix buss is an exclusive buss, the monitor buss will also switch ‘exclusive’; normally

automatic switching will be summing wi th the set up ‘Dim level’.

• Dim level

When you have set the monitor buss to swi tch automatically, the source signal is dimmed by

the filled in level and the buss that is switched on to the Monitor buss is at unity gain (0 dB).

• Console

You can select to which console a monitor buss belongs.

Page 29

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

29

5.5 Source configuration

The 19” rack unit can accept various I/O cards. These inserted I/O cards can accept audio in various

formats. This is because the audio connected to the I/O cards can have di fferent channel relations

(mono, stereo). To create a user readable label you have to configure sources.

Such a source is the entity you can select to be the input of your module in the mixing console.

See below for a simple source list example:

Figure 9: Source configuration

• Nr

Here you can reposition the destination to make the list in a convenient order.

• Label

Name of the source you are creating.

• Input 1/2

Here you select the physical slot and input of the card you want to assign to this source.

For mono sources you selected the same input for left and right.

• Phantom

The phantom power for this source is turned on/off at startup.

(this field is only avail able w hen the source-phantom function is al so assigned to an object;

e.g. via rack configuration)

• Pad

The PAD for this source is turned on/off at startup.

(thi s field is only available when the source-phantom function is al so assigned to an object;

e.g. via rack configuration)

• Gain

The source gain for this source is at startup set to this level.

(this field is only avail able w hen the source-phantom function is al so assigned to an object;

e.g. via rack configuration)

• Processing preset

If this source is selected on a module, by the ‘source select’ function (not via module or

Page 30

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

30

console preset), this processing preset is ‘set’ on the module.

• Trigger start

Here you can confi gure how the source start/stop change is triggered:

- Dedicated, the module fader and on are not triggering start/stop only the dedicated start/stop

controllers.

- Module fader on, the fader on will trigger the start as well.

- Module on, the on swi tch will trigger the start as well.

- Module fader on & on, the fader must be open and on active then the start is triggered.

For all modes the start/stop may at the same time controlled by the dedicated controllers

• Trigger stop

Here you can confi gure how the source start/stop change is triggered:

- Dedicated, the module fader and on are not triggering start/stop only the dedicated start/stop

controllers.

- Module fader off, the fader off will trigger the stop as well.

- Module off, the on swi tch will trigger the stop as well.

- Module fader off & off, the fader must be closed or on inactive then the stop is triggered.

For all modes the start/stop may at the same time controlled by the dedicated controllers

• Red-light.

When this source becomes active on a module, the corresponding Red-light buss becomes

active.

• Monitor destination mute

When this source becomes active on a module, the corresponding monitor buss will be muted.

• Delete

When you click on this column the source will be deleted (and also all references are deleted).

• Create a new source

By clicking on this link a popup will appear where you have to setup the physical inputs and

label for the new source.

Page 31

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

31

5.6 Extern source configuration

Each DSP card can handle four stereo monitor busses (with 4 DSP cards a max of 16 stereo monitor

busses is possible). For each DSP card you can configure 8 external stereo sources, beyond the 16

stereo mixing busses which are fixed available in the monitor section.

Figure 10: External source configuration

• Safe

Extern source can be confi gured to be ‘i nterlock safe’.

Normally only one buss or external input can be active on the monitor buss if configured to be

‘interlock’. But sometimes it is important your signal will not disappear if another CRM-source

is selected, in that case you can set the external source to be ‘safe’.

• Source

Here you can select which signal routes to this ‘external input’.

You can choose:

- Input sources (Mic, line, dig etc. etc.)

- Mix busses

- Monitor busses

- Insert outs (of modules)

- N-1 signals (for a single module)

Page 32

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

32

5.7 Destination configuration

The 19” rack unit can accept various I/O cards. With these cards, you can send audio from the

Oxygen 5 Digital digital audio system to the audio format you require. Because the audio connected

to the I/O cards can have different channel relations (mono, stereo) a combination has to be made. A

user readable label has to be created to configure destinations. Such destination is the entity you can

select to be the output of a mixing buss of the mixing console. See an example destination list:

Figure 11: Destination configuration

• Nr

Here you can reposition the destination to make the list in a convenient order.

• Label

Name of the desti nation you are setting up.

• Output 1/2

Here you select the physical slot and output of the card you want to assign to this destination.

For a mono output you have to select only one of the l eft or right outputs to a physical slot/ch.

• Level

The destination l evel for this source is at startup set to this level; for example to adjust

headroom for a single output.

(this field is only avail able w hen the destination-level function is al so assigned to an object;

e.g. via rack configuration)

• Default signal from

This destination/output will send audio from the default selected source (except if a N-1 is

active, then automatically the N-1 signal is selected).

You can choose:

Page 33

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

33

- Input sources (Mic, line, dig etc. etc.)

- Mix busses

- Monitor busses

- Insert outs (of modules)

• Default signal routing

Here you can choose which signal feeds the physical outputs:

Stereo (if no mix minus source is assigned):

Output left and right received their corresponding signal

Left:

Output left and right both receive the left signal.

Right:

Output left and right both receive the right signal.

Mono (only i f a mix minus source i s assigned):

The mix minus signal is always a mono signal.

• N-1 from/mix minus source

When the selected source is assigned to a module, this destination automatically creates an

N-1 using the selected source.

• Delete

When you click on this column the destination will be deleted (and also all references are

deleted).

• Create a new destination

By clicking on this link a popup will appear where you have to setup the physical outputs and

label for the new destination. When you select the same output for both channels, the system

will use it on the left output and set the right to none.

Page 34

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

34

5.8 Talkback configuration

This pages makes it possible to select the sources for the 16 talkback busse s available in the Oxygen

5 Digital.

Figure 12: Talkback configuration

• Source

Here you can select which signal routes to a talkback buss.

You can choose:

- Input sources (Mic, line, dig etc. etc.)

- Mix busses

- Monitor busses

- Insert outs (of modules)

- N-1 signals (for a single module)

Page 35

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

35

5.9 Processing presets

It is possible to set the module processing when a source is selected (via ‘source select’ or a module

preset) , the i nformation for this functionality is stored in the processing presets.

Figure 13: Processing presets

• Nr

Here you can reposition the preset to make the list in a convenient order.

• Label

Name of the preset.

• Settings.

Shows a new page where you can confi gure the preset.

• Delete

When you click on this column the preset will be deleted (and also all references are del eted).

• Copy to new preset

This function can be used to get the current settings copied in a new preset.

A popup will appear where you have to setup the label for the new preset.

• Create new preset

By clicking on this link a popup will appear where you have to setup the label for the new

preset.

Page 36

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

36

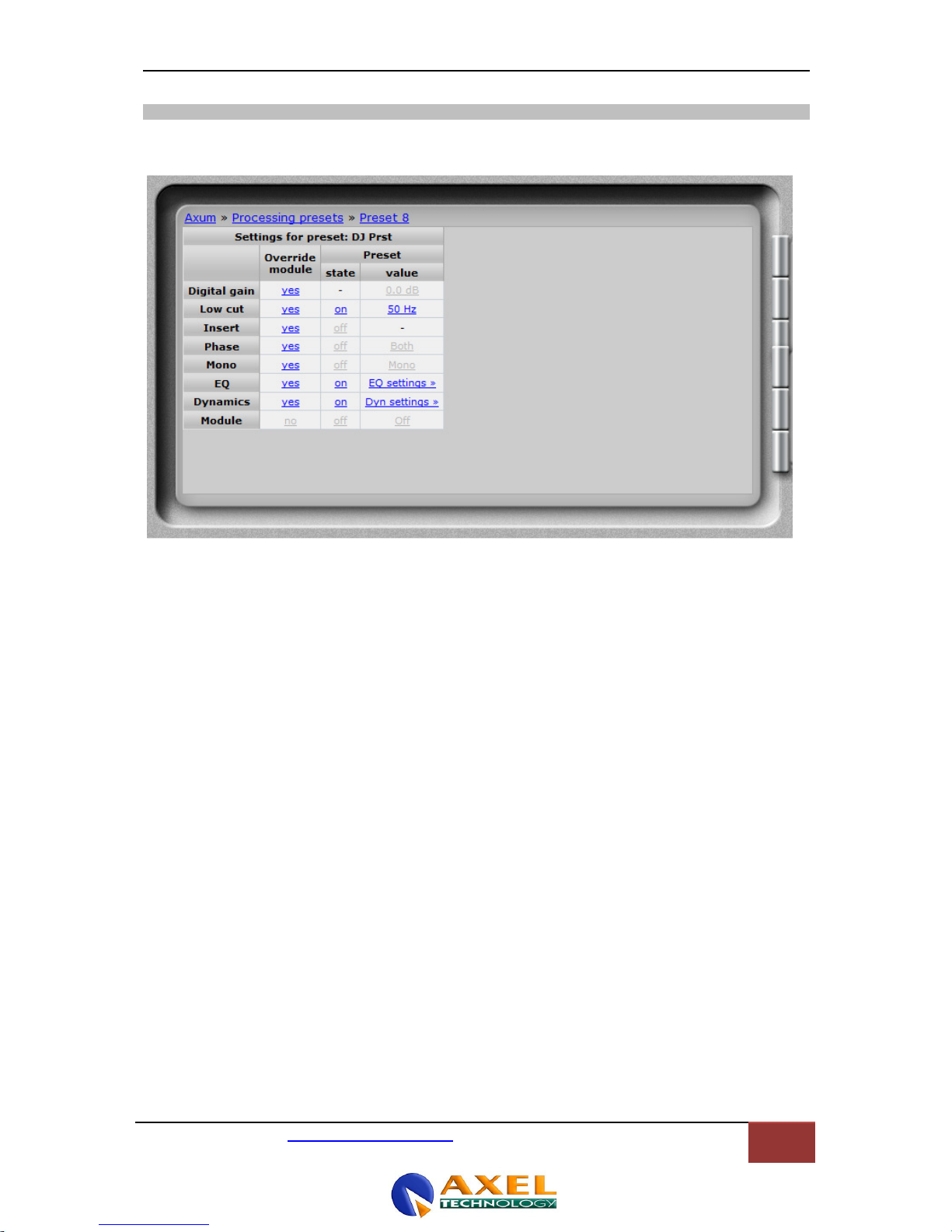

5.9.1 Settings

All processi ng parameters can be configured in the processing preset settings webpage

Figure 14: Processing preset settings

Page 37

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

37

• Override module

If set to no, the module setting will not be affected by this preset.

If set to yes, this preset will change the settings of the module for the corresponding

processing section (Digital gain, Low cut etc. etc.)

• State

if the override is turned to yes, you can set the processing section to ‘on’ or ‘off’.

for example:

- Microphones will often have the state EQ on

- CD players will often have the state EQ off

• Value

if the override is turned to yes, this value is set for the corresponding processing section.

For EQ and dynamics, a popup window is shown. Here you can set multiple values.

Figure 15: Processing preset EQ/Dynamics settings

EQ Range

Maximal adjustment you may generate with this band.

EQ Level

Level of the band that this preset will set.

The value must be within the EQ Range

EQ Frequency

Frequency of the band that this preset will set.

The frequency range is 20-20000 Hz.

EQ Bandwidth

Bandwidth of the band that this preset will set.

The bandwidth range is 0.1 – 10

EQ type

Type of the band that this preset will set.

You can choose:

- Off

- High pass filter (6 dB/Oct)

- Low shelf

- Peaking (is the normal EQ curve)

- High shelf

- Low pass filter

- Band pass fil ter

- notch filter

Downward expander threshold

Page 38

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

38

Threshold of the downward expander (to reduce ambient sound) that this preset will set.

The threshold range is -50 dB till 0 dB.

AGC ratio

The ratio for this automatic gain control is given in 0-100%.

AGC threshold

Threshold of the AGC, above the threshold the AGC tries to hold the signal 0 dB.

the threshold range is -30 till 0 dB.

(Be aware with a l ow threshold, you may generate a lot of gain)

Page 39

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

39

5.10 Module assignment

Modules can be assi gned to one of the 4 consoles, after this and a correct assignment of the busses

to the consoles you may click ‘generate’ to make a correct assi gnment configuration.

Afterwards you can overri de the generate assi gnments by clicking the ‘y’/’n’ fields. For example you

can create a buss that is available to all consoles.

Figure 16: Module assignment

Page 40

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

40

5.11 Module configuration

The module configuration makes it possible to give modules a default setting (after powering on) and

you can also configure module presets 1A/1B, 2A/2B, 3A/3B, 4A/4B.

Figure 17: Input module configuration

• Console

Shows to which console the module is assigned.

• Preset 1A/1B, 2A/2B, 3A/3B, 4A/4B

Shows the source and processing preset selected for corresponding module preset. If the ‘#’

symbol appears there is an active routing preset.

(cli ck on the link to go to the configuration page for the module)

• Processing

Here you can see if there is any processi ng done.

(cli ck on the link to go to the configuration page for the module)

• Routing

(cli ck on the link to go to the configuration page for the module)

Page 41

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

41

5.11.1 Module configuration page

On this page you can setup the defaul t module configuration, used at startup if programmed default.

If you have made your settings and you would like to copy them to all modules in this console (for

example if you want to use the same EQ center frequencies) you can simply hit ‘To all console x

modules’ after you made and checked the settings on the current module.

Figure 18: Module configuration page

Page 42

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

42

5.11.1.1 Module preset 1A/1B, 2A/2B, 3A/3B, 4A/4B

Here you select the source, processing preset and routing preset that is used when module preset

1A/1B, 2A/2B, 3A/3B, 4A/4B is selected. After a click on ‘routing’ a popup appears with the routing

possibilities (this depends on the consol e assignment).

• Routing Preset

Figure 19: Module routing preset

Ov erride module

If set to no, the module setting will not be affected by this preset. If set to yes, this preset will

change the settings of the module for the corresponding buss.

Level

If the override is turned to yes, this will set the send level to the buss for this module when

current preset is selected.

State

If the override is turned to yes, this will set the buss state to ‘on’ or ‘off’ for this module when

this module preset is select.

Pre/Post

If the override is turned to yes, this will set the buss pre or post for this module when this

module preset i s select.

Balance

If the override is turned to yes, this will set the buss balance for this module when this module

preset is select.

To all console 1-4 module

With this link you can copy the current settings to the same routing preset (1A/1B, 2A/2B,

3A/3B, 4A/4B) at all modules of the console where this module is assigned to.

• Ignore module state

When presets are recalled, it checks the module state to prevent recalling ‘onair’ signals. The

preset will wait till the module is switched off air.

If the ignore module state function is switched to yes, the presets will not check the module

state and forces the recall to be done always!

Page 43

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

43

5.11.1.2 Processing

This are the programmed processing defaults for the modules. Depending on the startup settings

these processing defaults will be used at startup.

The field ‘Use at source select’ determines if the processing section also is used when there is no

processing preset assigned to the source/module preset, or the processing section in the processing

preset is not overriding the module settings.

The following processing sections are available:

• Digital Gain level

You can enter a default gain level for each module.

• Low cut frequency

You can enter a default frequency of the low cut filter.

• Phase

Set the phase to default settings.

• Mono

Give the mono settings default values.

• EQ

By clicking on EQ you can set the default equalizer settings.

• Dynamics

This setting is used as default

• Module level

Set the level to default value at startup.

• Module state

Set the module to on or off at startup.

5.11.1.3 Routing

• Buss level

You may predefine the send level of a module to the busse s (e.g. Aux send).

• Buss status

You have to setup the startup status for the busse s. With this setting you set the buss routing

(e.g. Program on/off or CUE on/off).

• Buss Pre/Post

It’s possible to have pre/post selection per module, the startup setting can be configured here.

• Balance

You can select the bal ance of the buss sent.

Page 44

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

44

5.12 Mix/monitor buss presets

It is possible to make mix/monitor buss presets to make sure for different programs the correct buss

master states and levels are set. Also you can make sure the required monitor buss selection is made.

Figure 20: Mix/monitor buss presets

• Nr

Here you can reposition the preset to make the list in a convenient order.

• Label

Name of the preset.

• Settings.

Shows a new page where you can confi gure the preset.

• Delete

When you click on this column the preset will be deleted (and also all references are del eted).

• Create new buss preset

By clicking on this link a popup will appear where you have to setup the label for the new

preset.

Page 45

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

45

5.12.1 Settings

On this page you can set the required levels and state for all busses and monitor busse s which are

used in the mix/monitor buss preset.

Figure 21: Mix/monitor buss preset settings

5.12.1.1 Mix buss settings

• Console

Displays the console where this mix buss is assigned to.

• Use

When set to ‘yes’ the settings for this mix buss overrides the current mix settings if the preset

is loaded.

• Master level

Here you can give the preset master level of the corresponding mix buss.

• Master state

Here you can give the preset master state of the corresponding mix buss.

5.12.1.2 Monitor buss settings

• Console

Displays the console where this monitor buss is assigned to.

• Use

When set to ‘yes’ the settings for this monitor buss overrides the current monitor settings if the

Page 46

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

46

preset is loaded.

• State

This must be set to ‘yes’ if you want that this preset makes this monitor-buss routing.

Page 47

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

47

5.13 Console presets

To recall a complete console you use the console presets, what exactly is recalled is depending on the

underlying configuration of:

- Source configuration

- Processing presets

- Module configuration

- Mix/monitor buss presets

When a console preset is recalled it will set all modules to the module preset ‘A’-‘H’ as configured.

Secondly it will load the Mix/monitor preset as given in the console preset.

Figure 22: Console presets

• Nr

Here you can reposition the preset to make the list in a convenient order.

• Label

Name of the preset.

• Console

Select to which console or consoles this preset i s active.

• Select module preset

Here you can select to use module preset 1A/1B, 2A/2B, 3A/3B, 4A/4B.

• Mix/monitor buss preset

Here you can select on of the mix/monitor buss presets to use in this console preset.

• Recall time

A console preset can be recalled onair safe, so active channels are not recalled. Default you

have to press the preset button for 1 second before an ‘safe’ recall is done. After pressing 3

seconds the active channels are recalled as well (forced).

You can setup the delay time for the safe and forced console presets, when you give 0

seconds the recall will be done ‘direct’ when the button is pressed.

• Delete

When you click on this column the preset will be deleted (and also all references are del eted).

• Create new console preset

By clicking on this link a popup will appear where you have to setup the label for the new

preset.

Page 48

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

48

5.14 Surface configuration

You can see an overview of the boards in the surface(s) on this page. These are grouped together,

like their physical layout.

Figure 23: Surface configuration

• MambaNet Address

Show information on the internal used MambaNet addresses

• Node name

Logical name of the node

• Default

Number of objects that have a default value set.

• Config

Number of objects that are configured to an engine function.

• Import/Export

Once you have configured the defaults and used engine functions you can export and import

these settings. With export the current configuration is stored in the database, where you have

to give a logical name (e.g. Module 5-8). With i mport you can restore a configuration to the

same or a different node (of the same type). When you import Module 5-8 with an offset of -4

the configuration wil l be as you expect Module 1-4.

Page 49

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

49

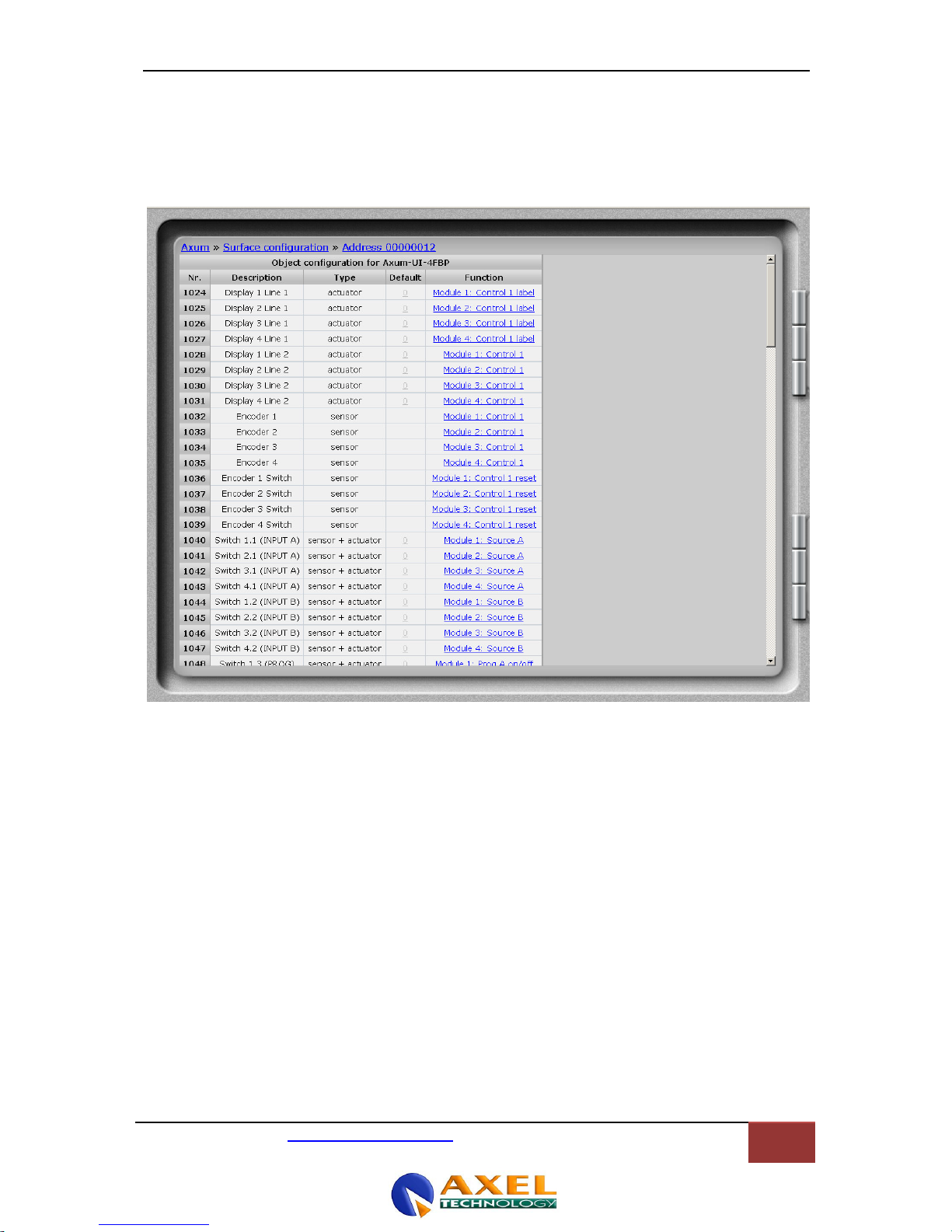

• Configure

When you fol low the link configure, you are able to setup the functi onality for the different

objects on the node. The sensor and actuator data types determine which functi on is able to

connect to the object. For a complete list of the functions, you can go to chapter 5.16 Engine

function.

Figure 24: Node object configuration (to Oxygen 5 Digital functions)

• Default

The gray value is the startup defaul t, this may be changed by assigning a custom value.

When you submit an empty box the object returns to the startup default value.

• Function

Here you may select which engine function is connected to the object

Page 50

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

50

5.15 Rack configuration

You can see an overview of the cards in the rack on this page. You can find informati on like the slot

number, MambaNet address, card name, number of inputs and outputs.

The link Configure wi ll go to a page for connecting objects of the card to Oxygen 5 Digital engine’s

functions.

You can consider this as the remote control configuration. For example you can connect:

• Start/stop functionality to remote outputs

• Source gain functionality to MIC gain

• Speaker level to CRM output level

• etc. etc.

Figure 25: Rack configuration

• Slot

Slot number where the I/O card i s located.

• MambaNet Address

Show information on the internal used MambaNet addresses

• Node name

Logical name of the node

• Inputs

Number of mono input channels

• Outputs

Number of mono output channels

• Default

Number of objects that have a default value set.

• Config

Number of objects that are configured to an engine function.

• Import/Export

Once you have configured the defaults and used engine functions you can export and import

these settings. With export the current configuration is stored in the database, where you have

to give a logical name (e.g. Module 5-8). With i mport you can restore a configuration to the

same or a different node (of the same type). When you import Module 5-8 with an offset of -4

the configuration wil l be as you expect Module 1-4.

Page 51

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

51

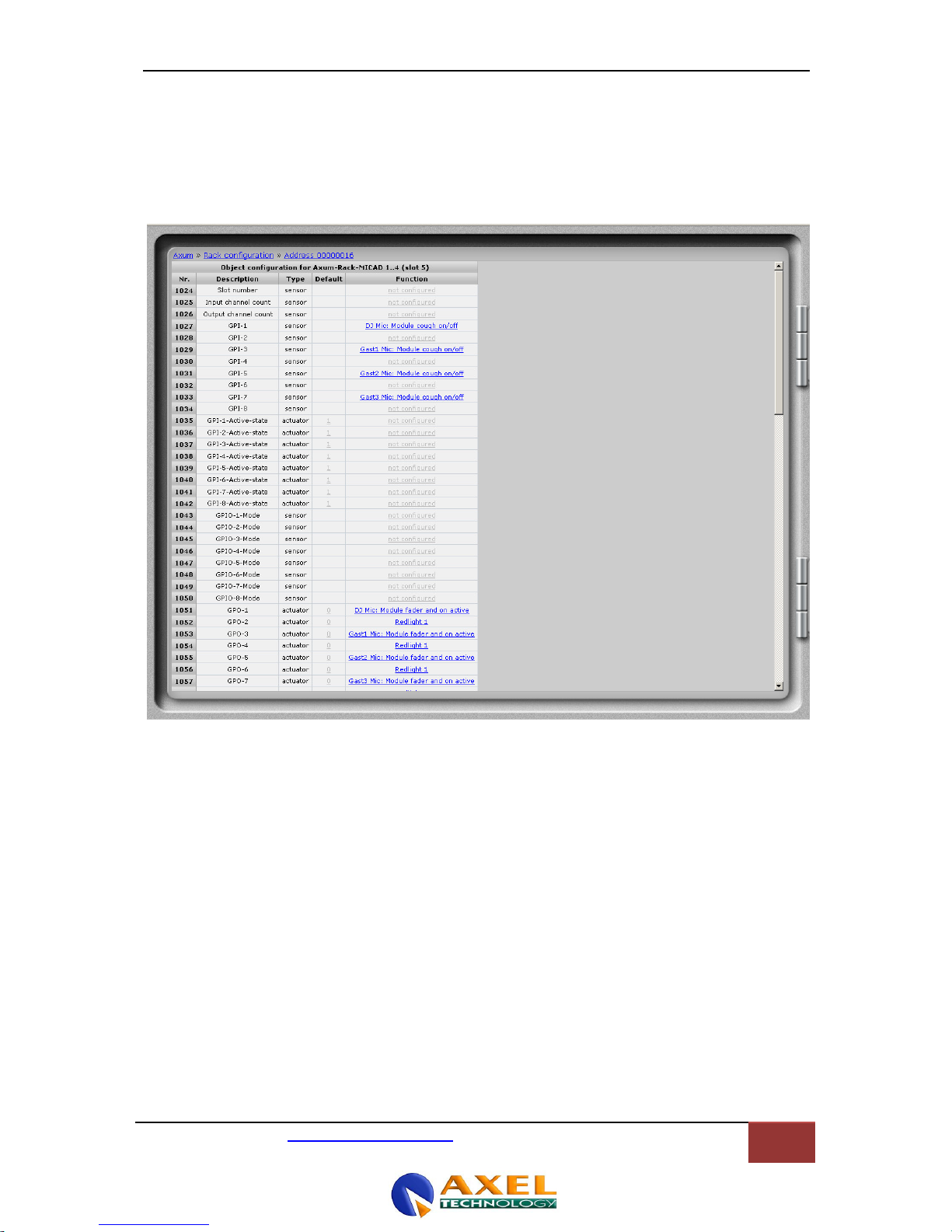

• Configure

The page shown below gives an indi cation how the CRM output level objects connect to the

Speaker level engine functi ons. By following the links, you can reconfigure the functions that

connect to the objects. The sensor and actuator data types determine which functi on assigns

to the object.

For a complete list of the functions, you can look up chapter 5.16 Engine function.

Figure 26: Node object configuration (to Oxygen 5 Digital functions)

Page 52

Oxygen 5 Digital - User Manual Version 2.5 - 12/22/2010

Axel Technology srl

www.axeltechnology.com

|

Oxyg en 5 Digital

Eng ine

52

5.16 Engine functions

The engine houses all mixing console functions and is able to connect various objects to its function

as has been described in the previous chapters. Below we gi ve a list of all availabl e functions within

the engine.

5.16.1 Modules

If four DSP cards are i nserted, it is possi ble to have 128 modules (32 stereo modules per DSP card).

For each module, you are able to connect objects to the following functions:

Function name

comments

Example object to connect to

Version

Label Label of the module

Display

2.0 Source

Steps through the source list at the current module

Enco der, Display

2.0 Module preset A

Select the pre con figured module preset 1A, 2A, 3A

or 4A. (Which of the 4 depends on the last console

preset used).

Switc h

2.2 Module preset B

Select the

pre configured module preset 1B, 2B, 3B

or 4B. (Which of the 4 depends on the last console

preset used).

Switc h

2.2 Module preset A/ B

Toggle

the pre configured modul e preset 1A

/1B

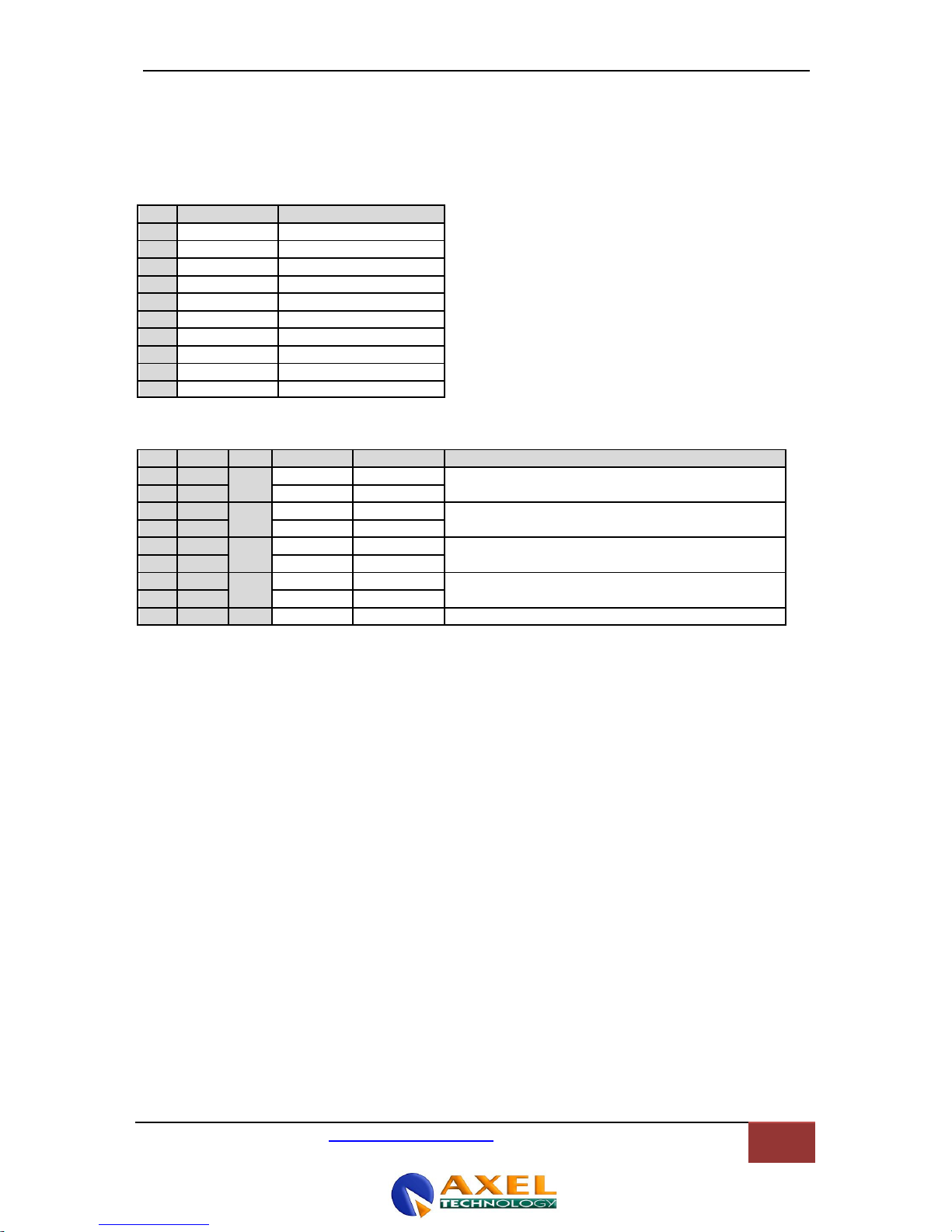

,