Page 1

NT132 RFID System

Installation Manual

Page 2

Notices

Notices

Information provided in this manual is a result of the design and

development of AXCESS

without notice. It applies only to current AXCESS

systems.

No part of this manual may be reproduced, translated or transmitted,

in any form or by any means, without the prior written consent of

AXCESS

Responsibilities

• AXCESSTM INC. declines all liability for any damage that might

• AXCESS

• AXCESS

Registered Trademarks

Product names mentioned herein may be trademarks and/or

registered trademarks of their respective companies.

TM

TM

INC. products and is subject to change

INC.

TM

INC. RFID

result from any errors or omissions in this document or from

improper installation.

TM

INC. can only guarantee the correct operation of its

products if they are used with the software programs, systems,

and consumables supplied or authorized in writing by AXCESS

INC.

TM

INC. recommends keeping the original packaging for

transporting the equipment later.

TM

Document Revisions

Number Changes Author Date

700.001.001 Original Issue Jerry Hegdahl Nov 1998

750.001.002 Update Jean Mahoney Mar 1999

750.001.003 Update Jean Mahoney Apr 1999

750.001.003 Update Jean Mahoney July 1999

Customer Service

AXCESSTM INC. toll-free distributor support hotline is1-800-577-

6080. Representatives are available to answer your questions from

7:30 – 6:30 Central Standard Time.

2 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 3

Table of Contents

General Installation Information................................................7

Safety.................................................................................................................................7

Information Flags...............................................................................................................7

Installation Tips..................................................................................................................8

Things to Consider............................................................................................................. 9

Hand Tools, Equipment and Materials.............................................................................10

NT132 System Overview...........................................................13

History..............................................................................................................................13

NT132 System Components............................................................................................ 13

Tags.................................................................................................................................15

Reader.............................................................................................................................16

Antennas..........................................................................................................................17

Antenna Tuning Unit (ATU) .............................................................................................18

Reader Installation....................................................................19

Introduction......................................................................................................................19

Required Materials........................................................................................................... 20

Mounting the Reader - All Types .....................................................................................21

Installation of a Serial Reader..........................................................................................22

Installation of a Wiegand Reader ....................................................................................23

Installation of an FTT Reader System .............................................................................25

Connecting Power to the Reader – All Types..................................................................32

Configuring 3.x Reader Firmware............................................35

Required Materials........................................................................................................... 35

Connecting a Computer to the Reader............................................................................35

Communicating with the Reader via HyperTerminal .......................................................37

Reader Commands ......................................................................................................... 38

Entering a Command.......................................................................................................39

Toggling between reading 3.x Tags and reading 2.0 Tags..............................................40

Changing the Reader ID Number .................................................................................... 41

Toggling Between Default and Diagnostic Modes...........................................................42

Bypass Mode - Enabling Action on 254 Code .................................................................44

Unilon Reset Buttons.......................................................................................................45

Antenna Tuning Unit (ATU) Installation...................................49

Introduction......................................................................................................................49

Installation Considerations...............................................................................................49

Required Materials........................................................................................................... 50

Prerequisite Tasks...........................................................................................................50

Mounting the ATU............................................................................................................51

Cabling the ATU ..............................................................................................................52

Connecting the ATU to the Reader.................................................................................. 53

Connecting the ATU to the Antennas .............................................................................. 53

Page 4

Contents

Dipole Antenna Installation ..................................................... 55

Introduction.......................................................................................................................55

Required Materials...........................................................................................................55

Prerequisite Tasks ...........................................................................................................55

Installing the Dipole Antenna............................................................................................56

Road Loop Antenna Installation .............................................. 59

Introduction.......................................................................................................................59

Required Materials...........................................................................................................60

Prerequisite Tasks ...........................................................................................................60

Road Loop Layout & Connecting to the ATU...................................................................61

Common Layout Problems...............................................................................................63

Installing the Road Loop Antenna....................................................................................64

Bar Antenna System Installation............................................. 67

Introduction.......................................................................................................................67

Required Materials...........................................................................................................68

Prerequisite Tasks ...........................................................................................................68

Installation Considerations ...............................................................................................68

Installing the Bar Antenna ................................................................................................70

Swing Frame Antenna System Installation............................. 71

Introduction.......................................................................................................................71

Required Materials...........................................................................................................71

Prerequisite Tasks ...........................................................................................................71

Installing the Swing Frame Antenna.................................................................................71

Maximizing Antenna Performance w i th the ATU.................... 73

Adjusting Antenna Performance ......................................................................................73

Modifying Antenna Range: Adjusting the Tr ansmi tter Card . 77

Introduction.......................................................................................................................77

Required Materials...........................................................................................................78

Adjusting the Transmission Field.....................................................................................78

Tag Mounting............................................................................ 79

Mounting Tags to Assets..................................................................................................79

Mounting Tags to Vehicles...............................................................................................81

Tags and Personnel.........................................................................................................83

Troubleshooting the System ................................................... 85

Introduction.......................................................................................................................85

Required Materials...........................................................................................................85

Check the Power..............................................................................................................85

Check the Site..................................................................................................................86

Trace the Cables..............................................................................................................86

4 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 5

Contents

Check the Connectors ..................................................................................................... 86

Check the Antennas and Cables for Continuity...............................................................87

Check the ATU ................................................................................................................89

Check the Reception .......................................................................................................90

Check the Output and Connections to Third-Party Devices............................................ 91

Common Problems with NT132 Components.........................93

Cable................................................................................................................................93

Power...............................................................................................................................93

ATU..................................................................................................................................93

Road Loop Antenna.........................................................................................................94

Dipole Antenna ................................................................................................................ 96

Bar Antenna.....................................................................................................................96

Swing Frame Antenna ..................................................................................................... 97

Wiegand Reader..............................................................................................................98

Serial Reader...................................................................................................................98

FTT Reader .....................................................................................................................99

Serial Gateway.................................................................................................................99

Tags.................................................................................................................................99

Appendix A: Coaxial Cable.....................................................101

Required Materials......................................................................................................... 101

Attaching the BNC Connector........................................................................................ 101

Appendix B: Specifications .................................................... 103

Reader...........................................................................................................................103

Serial Gateway...............................................................................................................104

Antenna Tuning Unit (ATU) ...........................................................................................104

Antennas........................................................................................................................105

Tag.................................................................................................................................106

Customer Support Questionnaire..........................................107

Index........................................................................................109

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

5

Page 6

Page 7

General Installation Information

Safety

• Personal safety is of first importance in the performance of any

job.

• Installation and configuration of the NT132 system should only be

performed by experienced installers.

• Where practical or required by code, all wiring should be

enclosed in conduit, or equivalent protection, firmly anchored to

sturdy structural elements and protected from mechanical

damage.

• Hand tools should be of good quality and properly maintained.

• Hand tools should be used in the applications for which they were

intended.

• Always wear eye protection when using power tools.

• When drilling, cutting or drilling, do not damage wires, pipes or

structural components.

• When installing antennas and related equipment above ceiling,

make sure they are properly attached to a structural member and

accessible for maintenance.

Information Flags

Information Flags draw your attention to important information:

IMPORTANT!

These sections provide information you must have to ensure proper

operation of hardware or software. If this advice is not followed,

system recovery can be difficult or time-consuming. ALWAYS READ

THESE ITEMS.

NOTE

These sections provide helpful information that can make the

installation go more smoothly and quickly.

Page 8

General Installation Information

Installation Tips

IMPORTANT! Bench test communications between the

NT132 system and the controller or device to which it will

be connected.

Lay the entire AXCESS NT132 system out and test the

antenna fields before permanently installing any piece of

the system.

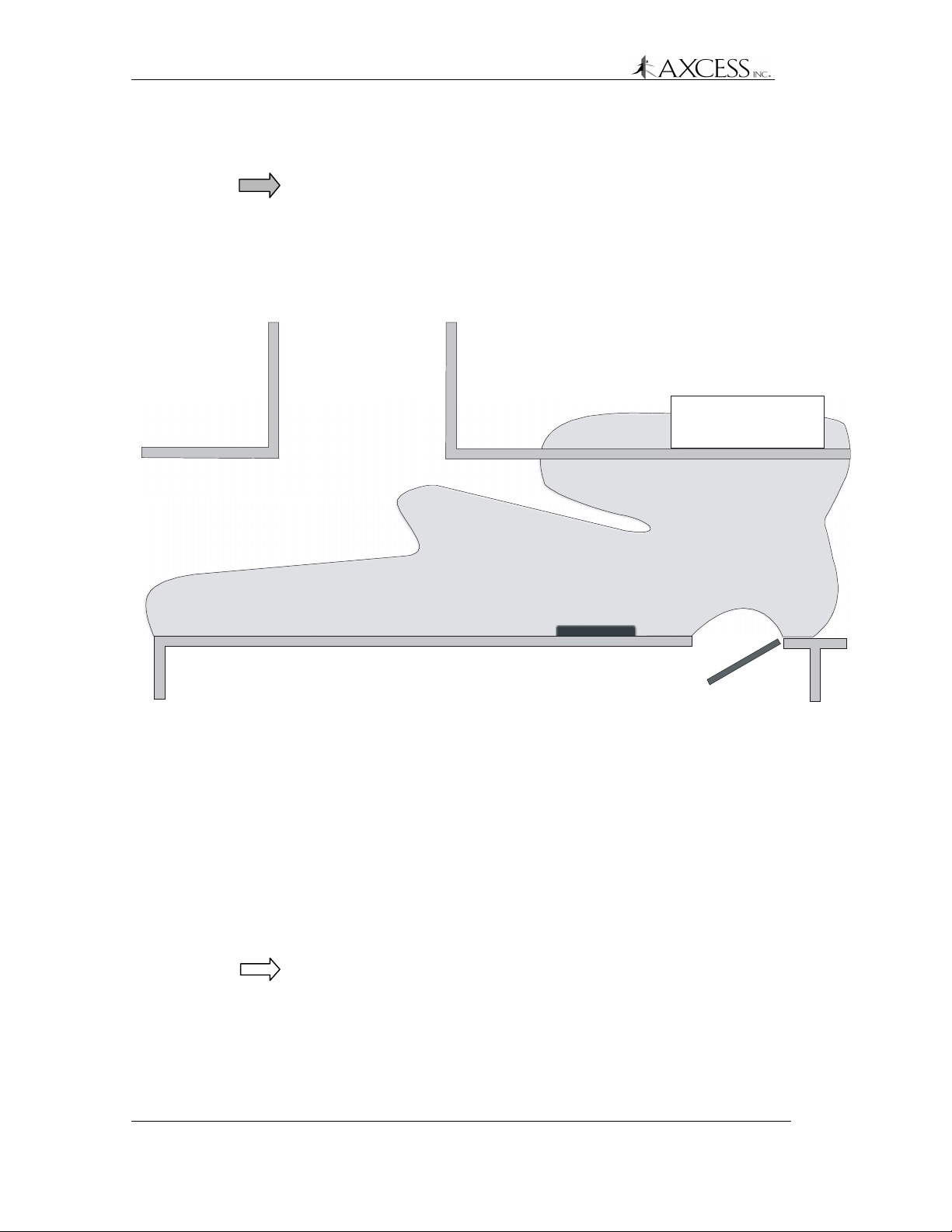

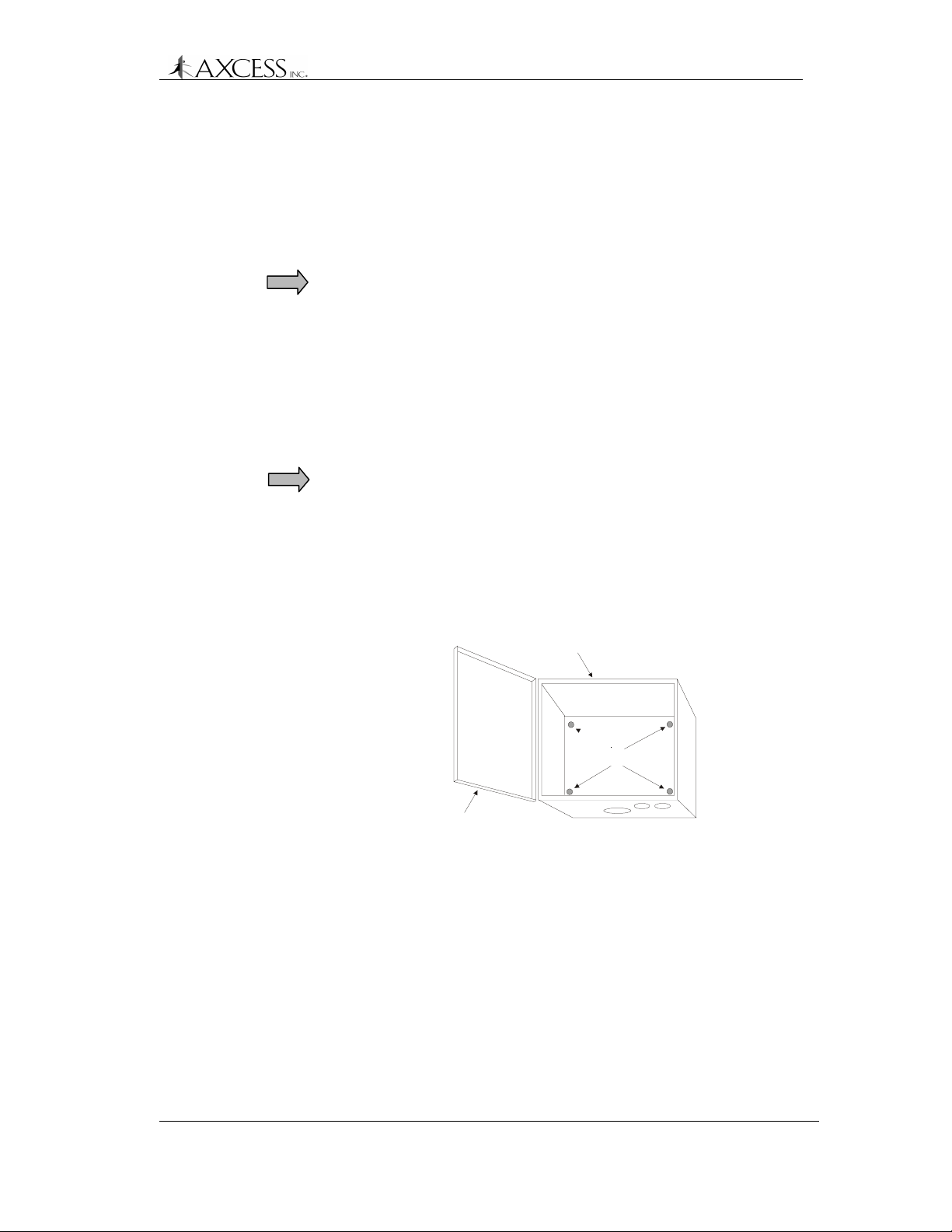

Supply Cabinet

Swing Frame Antenna

Figure 1 A real-life example of an antenna field. The gray area is

the field of a Swing Frame Antenna mounted in a hall. Always

test your field to ensure that you get the coverage you want.

Waterproofing

Any parts of the system exposed to the elements must be

waterproofed using sealing tape, waterproof boxes, sealant spray,

etc.

RTV rubber silicone sealant can be used on outside connections to

protect them from the weather.

Note: The silicone seal can be broken by just pulling on a cable, and

the sealant would then need to be reapplied.

8 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 9

Things to Consider

General Installation Information

IMPORTANT! The Reader must be installed in a moisture-free

environment at approximately room temperature and a minimum of

36 inches above the floor. Installation at eye height is recommended.

If possible, position the Reader and the ATU where they are not

readily accessible to help prevent tampering or accidental damage.

Cabling

• Use only RG-58/U coaxial cable with 50-ohm impedance

(nominal), solid copper center conductor, 55% tinned copper

braid or better, 100% foil shield coverage (for example, Belden

9310).

• The maximum recommended cable length between the Reader

and ATU is 80 feet.

• The maximum recommended cable length between the ATU and

the antennas is 20 feet.

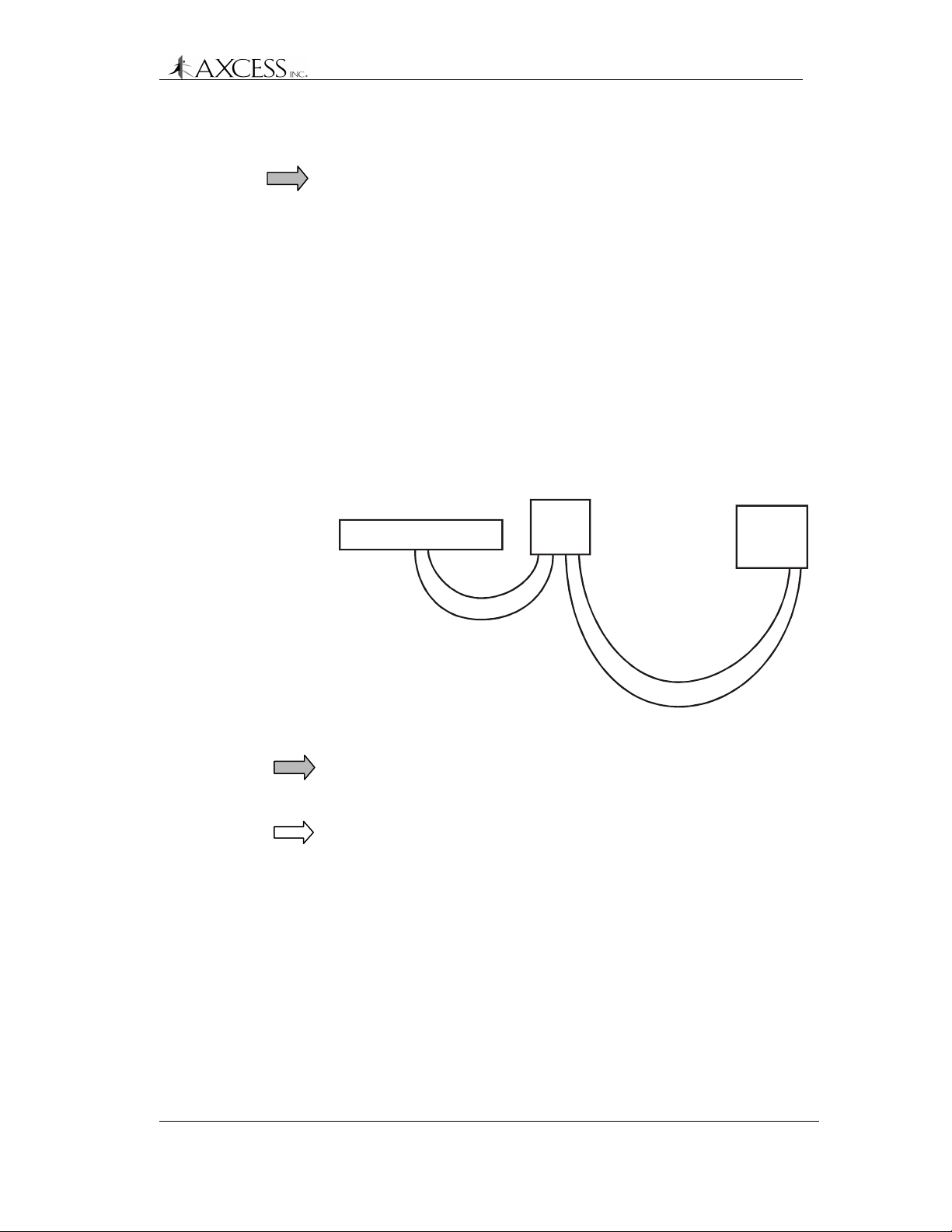

Bar Antenna

20 feet

ATU

Reader

80 feet

Figure 2 Maximum recommended cable lengths

IMPORTANT! System performance may be adversely affected if a

different cable is used, the cable lengths exceed recommendations,

or if the cable is kinked.

NOTE: All distances are by cable run unless specified otherwise.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

9

Page 10

General Installation Information

Hand Tools, Equipment and Materials

IMPORTANT! You need to have the following materials on hand to

ensure successful installation of the NT132 system.

These items are not supplied with the NT132 System.

Required

• RG-58/U coaxial cable with 50-ohm impedance (nominal), solid

copper center conductor, 55% tinned copper braid or better,

100% foil shield coverage (for example, Belden 9310). The

length required for your installation will vary.

• Eight 3-Piece Crimp Type Male BNC Connectors (for example,

Amphenol 31-320). Connectors can be damaged during

crimping. Having more than eight on hand is recommended.

• Tape measure

• Power drill and bits

• Diagonal cutters

• Phillips and flathead screwdrivers, including a very small flathead

screwdriver

• 4 # 10 Anchors, Plastic (for mounting the Reader in drywall or

mortar)

• 4 # 10 Self threading screws

• 4 # 10 Washers

• 4 Screws for mounting the ATU

• Wire strippers

• Three blade rotary coaxial cable stripper

• BNC crimpers

• Multimeter

• Wire to connect to third-party devices (i.e., camera, door strike,

etc.) as specified by the manufacturers.

• A computer to configure the Reader ID numbers

• A terminal communication program

• A straight-through (one-to-one) DB9 male to female serial cable.

DO NOT use a null-modem cable or a null-modem adapter.

10 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 11

General Installation Information

Required for Road Loop Antenna Installation

• Saw for cutting the road surface (e.g., a walk-behind concrete

saw)

• Two 1/8” saw blades with spacer – abrasive blades for asphalt or

diamond blades for concrete

• Vacuum or compressed air to clean the cut

• Mounting or burying hardware – concrete nails, thin dowel for

pushing wire into cut, etc.

• Road Sealant – For example, Bondo Flexible Embedding Sealer

(P-606), 3M Detector Loop Sealant or Q-Seal sealant. It takes

about a gallon of “Bondo” to seal the cuts for a 4x16-foot

antenna.

Required for Wiegand Reader Installation

• AXCESS Wiegand Readers are standard SIA 26-bit. The Reader

accepts Data Zero, Data One and Ground. Wires between the

Reader and the Wiegand control panel should be 18 AWG, no

longer than 500 feet. The wires should be green for Data Zero,

white for Data One and black for Common Ground.

Required for FTT Reader Installation

• Unshielded, twisted-pair wire to connect Readers to each other.

For details on network lengths, see Network Specifications, page

27

• Sensitive trigger, TTL relays to drive door strikes or other devices

(for example, Altronix RBSN-TTL or Alarm Saf RBKS-124P)

• 22 AWG wire, maximum four feet in length, to connect the FTT

Readers to the relays.

• Additional wire as specified by device manufacturer(s) to connect

to external control devices (i.e., camera, door strike, etc.)

• A straight-through (one to one) RS-232 cable of sufficient length

to connect the Serial Gateway to the System PC. It is

recommended that the cable not exceed 50 feet in length. One

end of the cable should be a male DB9 connector.

Required for Serial Reader Installation

• A straight-through (one to one) RS-232 cable of sufficient length

to connect the Reader to the System PC. It is recommended that

the cable not exceed 50 feet in length. One end of the cable

should be a male DB9 connector.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

11

Page 12

General Installation Information

Recommended

• Ladder for Bar Antenna mounting

• Chalk for marking Road Loop Antenna placement

• Fishing line – 15 lb. test for pulling cable

• Tie wraps and anchors

• Battery powered screwdriver

• Duct tape

• A pair of walkie-talkies if more than one installer will be on site

• Laptop computer to connect to Readers easily

• Wiegand wedge for Wiegand system troubleshooting

• Instructions for all third party devices

12 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 13

NT132 System Overview

History

Radio Frequency Identification (RFID) systems have existed for

many years. Initially, systems were developed so that military aircraft

and ships could be quickly identified by electronic methods. Radio

equipment (transponder) on a plane or vessel would broadcast a

coded signal to identify it as a friend to an appropriate receiving

station. A plane or vessel not able to transmit the correct

identification would be considered a possible enemy. Similar

technology is employed today for air traffic control as well as vessel

identification in shipping lanes and ports – and the RF device is still

called a transponder.

Other present-day applications include “tagging” vehicles, assets or

people for identification within a designated area – or as they pass

through portals. For example, a transmitting device can be placed on

a laptop computer so it can be identified if carried out of a building.

Further, if people in that building also carry transmitting devices, it is

easy to ascertain not only that the computer left the building – but

that it was not carried by the person to whom it was assigned!

Obviously, such technology has quickly found its way into disciplines

such as vehicle entry, fleet management, inventory control, and

controlled access to buildings or other areas.

NT132 System Components

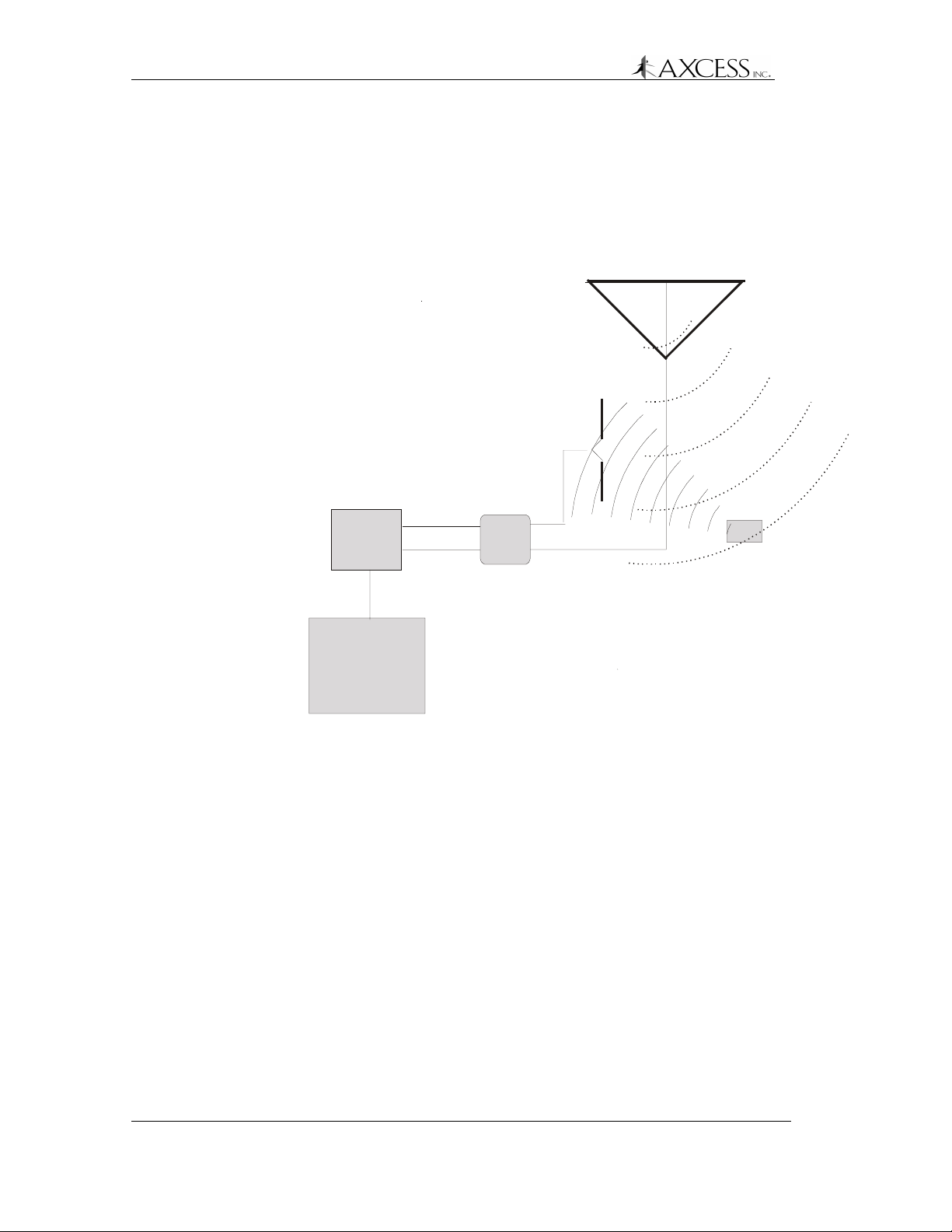

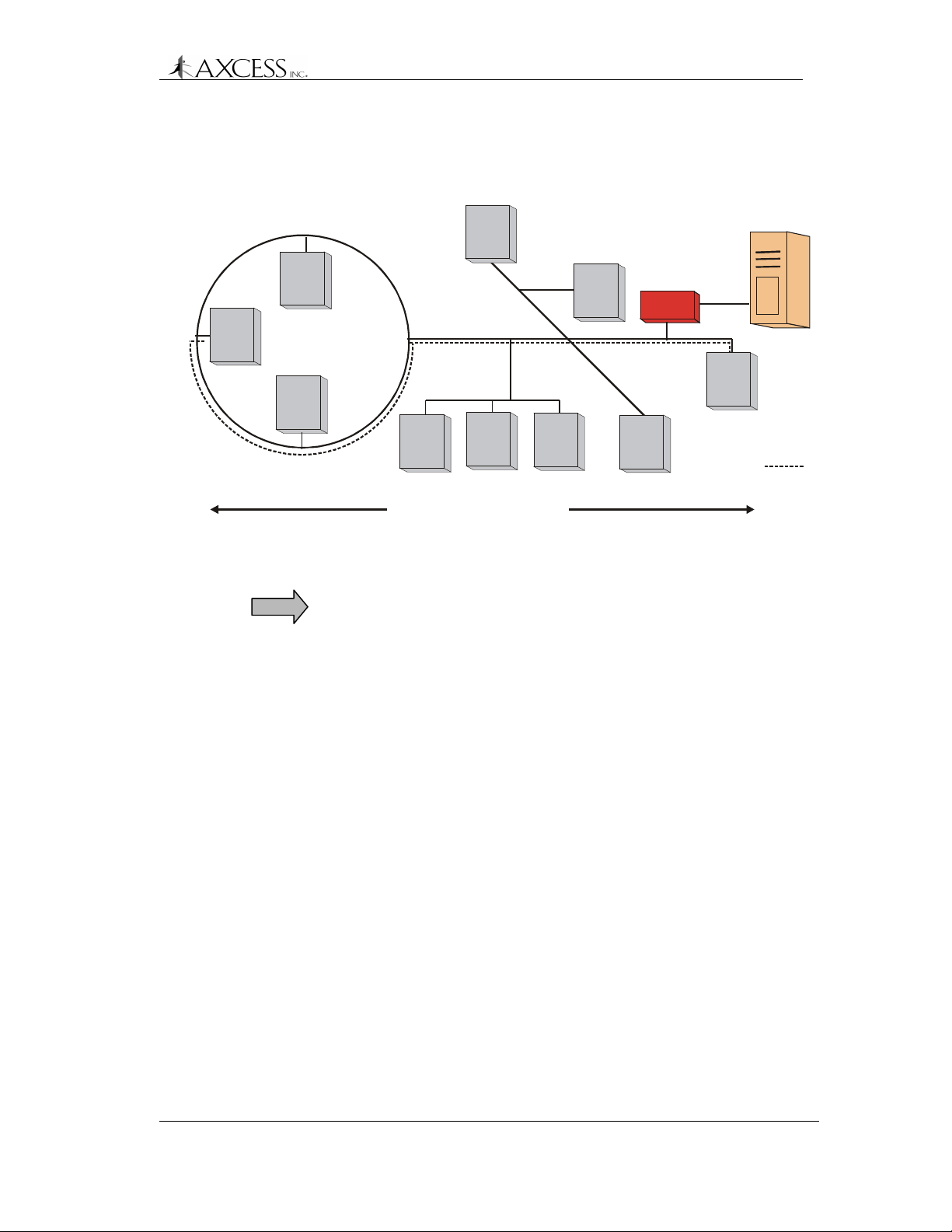

The following diagram (Figure 3) shows a very basic AXCESS NT132

system. The system has the following components:

• A Reader to send radio signals to a transmitting antenna,

receives radio signals from a receiving antenna and outputs the

data to some device – a computer or a Wiegand control panel,

for instance.

• A transmitting antenna to “wake up” any Tags in the area.

• An Antenna Tuning Unit (ATU) placed between the Reader and

the Antennas to properly tune the transmitting antenna to its

surrounding environment.

• Tags to receive wake-up radio signals and broadcast their IDs to

the receiving antenna. Tags can be carried by individuals, placed

on equipment or in vehicles.

• A receiving antenna to intercept radio signals from the Tags and

to pass the signals to the Reader.

• One or more of the following: a computer for data storage, a

peripheral device such as a light, buzzer, door strike, gate

Page 14

NT132 System Overview

controller, camera, etc., and/or a control panel that accesses a

computer or a device.

An NT132 system may be as simple as a single Reader and Bar

Antenna controlling the front door of a small office or it may comprise

a network of interconnected devices and Readers controlled by a

computer.

Transmitting Antenna

U

Low Frequenc y Wakeup Signal

Receiving

Antenna

H

F

T

a

g

R

e

s

p

o

n

s

e

Reader

Device

(Computer, controller

door strike, camera

etc.)

Figure 3 A simple AXCESS NT132 System

RX

TX

ATU

Tag

14 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 15

Tags

NT132 System Overview

A Tag is a very small transponder (transmitter + responder) that

remains in a sleep state (off) until awakened. When the Tag receives

a special wake-up signal from the Reader, the Tag will wake up (turn

on) and emit a radio signal of its own. The signal emitted by the Tag

is typically its pre-programmed identification number – but could

include other data as well. The signal is generally used for detection,

identification and location of people or objects.

An AXCESS Tag, encased in black or beige plastic, is about the size

of a credit card and is approximately 200 mils thick. Some Tags have

slots to attach personnel ID pictures to them. Other Tags may be

attached permanently to vehicles or assets such as computers.

Types of Tags

The typical types of Tags are:

Passive Tags

A passive tag does not have an on-board power source (battery). It is

powered from the antenna radiation field of the transmitter that is

trying to wake the tag up. It uses the same antenna for transmitting

and receiving.

Active Tags

An active tag has its own battery and is capable of a greater transmit

distance (range) than the passive tag. An active tag only has a

transmitting antenna. It is common for active tags to continually

transmit and the system will only report those tags in the reception

field.

AXCESS Tags

AXCESS Tags, based on AXCESS NeuroTag technology, are a

hybrid of active/passive and do not respond until awakened. The tag

is in a “sleep” state that requires almost no power until the tag is

activated. AXCESS Tags receive on a low frequency and transmit on

an ultra high frequency.

The Tag checks the wakeup signal for proper modulation and a

Reader ID code, then transmits its own ID number along with the

Reader ID that woke it up.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

15

Page 16

NT132 System Overview

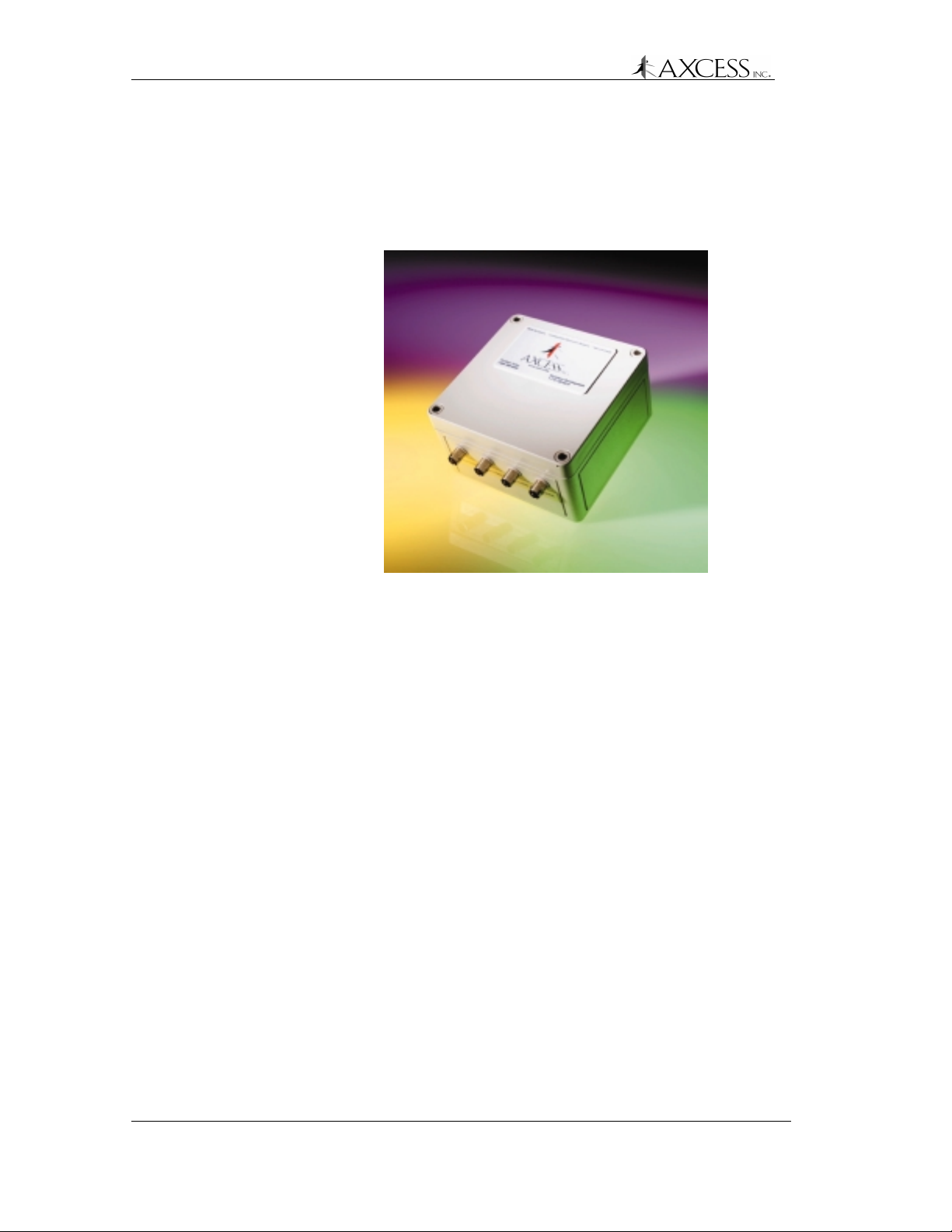

Reader

The Reader (Figure 4) originates the signal that is broadcast to wake

the Tag. The Reader has the following purposes:

• Encode a transmission wake-up signal and transmit it via the

antenna to the sleeping Tag.

• Decode the signal from the Tag via the receiving antenna. The

Reader will convert the data to a format usable by a computer or

Wiegand control panel for further processing of the information.

• Output data to a control device or a computer.

Figure 4 AXCESS Reader – external view

Types of Readers

Serial

This Reader communicates using the EIA-232 standard, more

commonly known as RS-232C. It can connect to a communications

port on a computer or any device that can accept RS-232C data.

Wiegand

Wiegand Readers output Security Industry Association (SIA) 26-bit

data to Wiegand control panels. It connects to the Wiegand control

panel by three wires – Data One, Data Zero and Ground.

Free Topology Transceiver (FTT)

FTT Readers can be used to create networks of Readers. They

communicate with a computer using Echelon LonWorks

control external devices via TTL controls.

TM

and can

16 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 17

Antennas

NT132 System Overview

Because the Tags receive and transmit at different frequencies,

different antennas are used for each leg of the communication.

Antenna construction is related to the wavelength (or fraction thereof)

of its design frequency. Antennas designed for the Ultra High

Frequency spectrum (to receive the transmit signal from the Tag) can

be quite short. Antennas designed for Very Low Frequencies (to

transmit the wake-up signal to the Tags) must be quite long. The

transmitting antenna is a loop and the receiving antenna is a dipole.

Types of Ant ennas

For interior use, antennas can be inconspicuously mounted – for

example, hidden in a false ceiling or disguised as a common picture

frame. Also, depending on type of installation, the transmitting

antenna and receiving antenna may be combined into a single

enclosure or may be built as separate units.

Road Loop and Dipole Antennas

The Road Loop and Dipole Antennas are used for identifying Tags in

vehicles. The Road Loop Antenna is installed in the road surface and

sends out wake-up signals. The Dipole Antenna is separate from the

Road Loop Antenna and is mounted so that it can receive

transmissions from the Tags.

Bar Antenna

The Bar Antenna has both transmitting and receiving antennas

enclosed in a box that is approximately 2 feet long, 5 inches wide and

1 inch thick. It can be inconspicuously mounted above or next to a

door or above the ceiling tiles.

Swing Frame Antenna

The Swing Frame Antenna has both transmitting and receiving

antennas built into its frame. The antenna enclosure is designed as a

picture frame so that it may be mounted unobtrusively on walls.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

17

Page 18

NT132 System Overview

Antenna Tuning Unit (ATU)

An Antenna Tuning Unit or ATU (Figure 5) maximizes the signal

transmission from the Reader. It is installed between the Reader and

the transmitting and receiving antennas.

Figure 5 AXCESS ATU – external view

On the bottom of the ATU, there are two jacks to connect to the

transmitting and receiving antennas and two jacks to connect to the

Reader.

Types of ATUs

There are two kinds of ATUs currently provided. Although they

require different methods of optimizing performance, they perform

the same function.

Toggle Switch ATU

This ATU has a toggle switch, a rotary switch and a voltmeter. The

antenna performance is tuned by toggling one switch between three

positions and turning the other switch among ten positions. The

voltmeter indicates when the optimal setting has been reached.

Jumper ATU

This ATU has eleven 3-pin headers and five LEDs. The antenna

performance is tuned by moving jumpers on the headers. Optimal

performance is indicated by the strength of the LEDs.

18 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 19

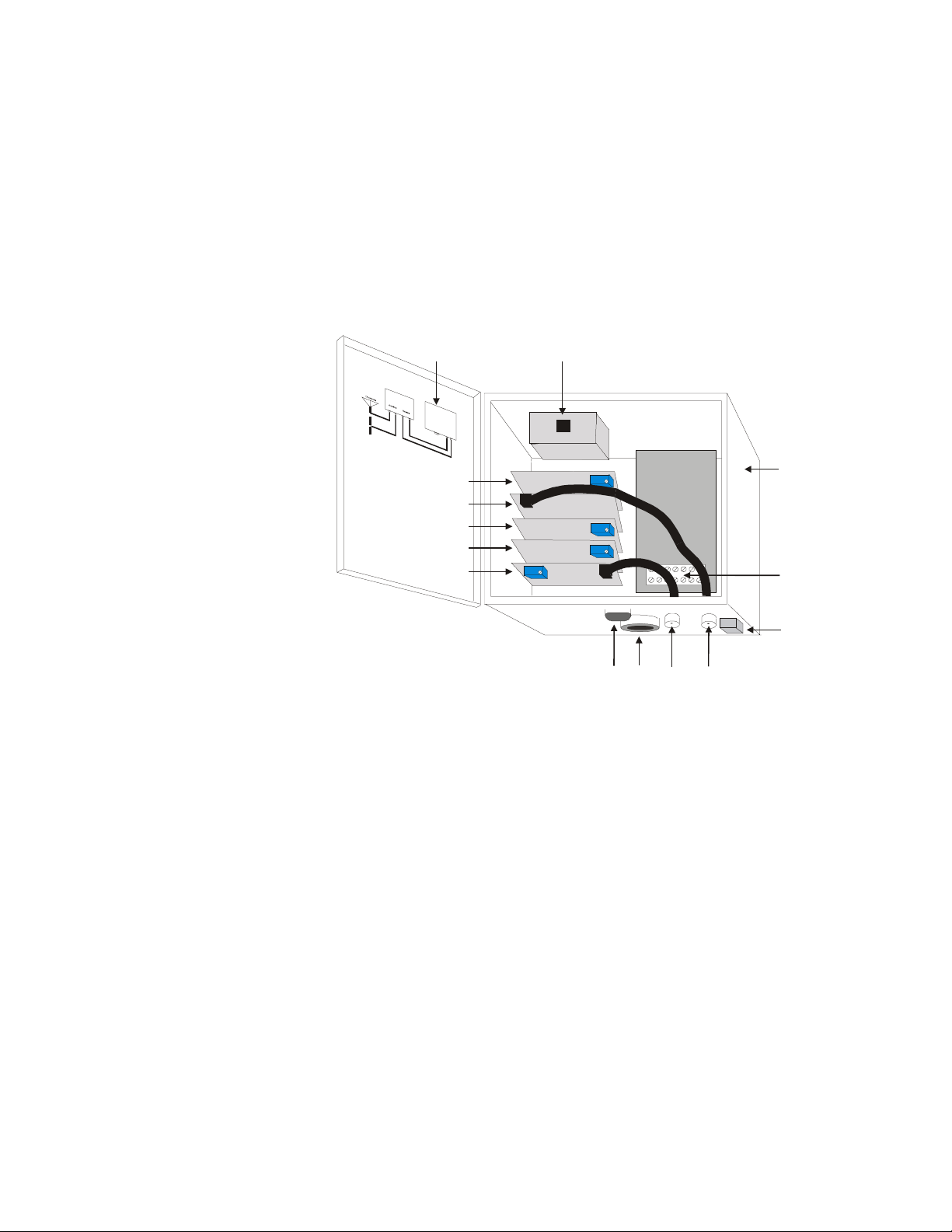

Reader Installation

Introduction

The Reader is the brain of the NT132 system. Its functions include

sending wakeup signals, receiving Tag signals, processing Tag data,

and routing Tag data.

Cabling Label

Unilon RX Card

RF Card

Unilon Output Card

Unilon TX Card

Transmitter Card

RJ-45

Conduit

Chase

TX

RXRS-232

Figure 6 Reader – internal view

The Reader (Figure 6) in a typical AXCESS system consists of the

following:

Reader Case

Terminal Block (TB1)

Ground Lug

• A stack of sub-controller Printed Circuit Board (PCB) cards:

Unilon RX Card – decodes the signal sent from the receiving

antenna through the RF card

RF Card – receives the signal from the receiving antenna

Unilon Output Card – sends the data to a controller or

computer

Unilon TX Card – encodes the transmission signal

Transmitter Card – sends the signal to the transmitting

antenna

• Two external female BNC connectors to connect to the Antenna

Tuning Unit (ATU)

Page 20

Reader Installation

• External DB9 RS-232 female connector to connect to a computer

or device

• Conduit chase for wiring access through the Reader case

• White terminal block with connections for Wiegand ground, Data

One and Data Zero, and connections for 24V power and ground

• RJ45 connector used by AXCESS for programming the Reader’s

firmware

Reader Types

Serial Reader

This type of Reader can interface directly with the communications

port of a computer or another control device that process standard

EIA-232 serial data.

Wiegand Reader

This is type of Reader outputs standard SIA 26-bit Wiegand data and

is used when interfacing with a standard Wiegand controller.

Required Materials

For each Tag read, the Reader outputs data every 750 milliseconds.

Duplicate Tag information is stored in the Reader’s buffer for 12

seconds so that redundant Tag reads are ignored during the this time

interval.

FTT Readers

FTT (Free Topology Transceiver) Readers are for installations

involving a network of Readers connected to one another. This is

accomplished via twisted-pair wiring over a total distance of up to

8,800 feet. FTT Readers can also control devices according to data

sent over the network by the host computer.

The following materials are necessary for a successful installation:

• Power drill and bits

• Screwdrivers – Phillips and flathead

• 4 # 10 Anchors, Plastic (for mounting in drywall or mortar)

• 4 # 10 Self threading screws

• 4 # 10 Washers

• Depending on the surface that the Reader will be mounted on,

you may need #10 molly bolts.

20 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 21

• Each Reader type has it own required materials for connecting to

third-party devices. Please see the specific section for the

Reader that you are installing.

Mounting the Reader - All Types

All Readers have the same mounting requirements.

IMPORTANT! Before permanently mounting any piece of the

AXCESS NT132 System, first lay out and test the entire system.

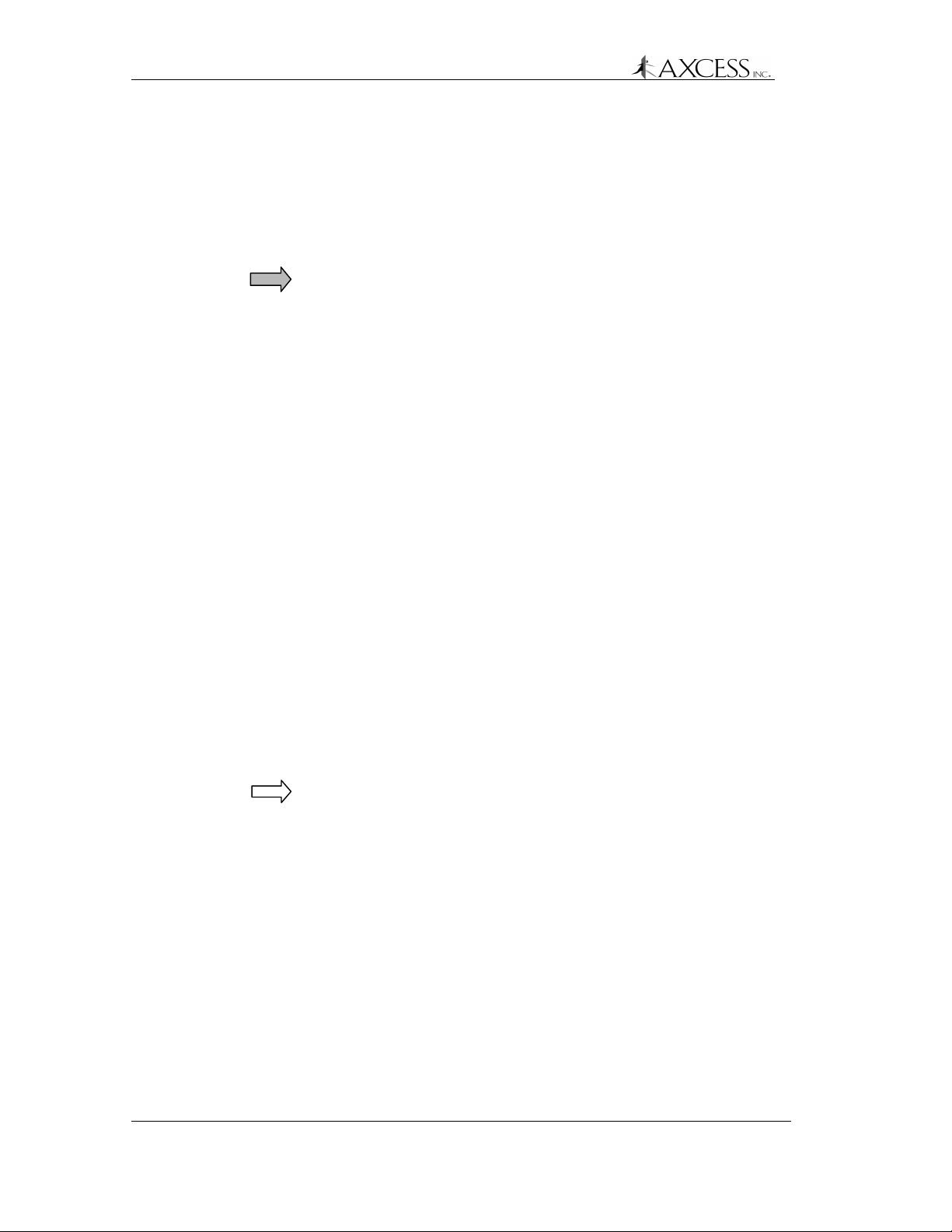

Step 1: Select a Reader location consistent with the type of

antenna being installed. The Reader should be a minimum

of 36 inches off the ground, preferably at eye-height.

Step 2: Mount the Reader securely with the cover hinge on the left

and external connectors on the bottom (Figure 6). Screw

holes are provided inside the cabinet for mounting to a wall

(Figure 7).

IMPORTANT! When you mount the Reader, be careful not

to damage the electronic components. A manual

screwdriver is recommended for tightening the screws.

Reader Installation

Other installation techniques may better satisfy specific

site conditions - L-brackets or double-sided tape to mount

the Reader, or placement of the Reader inside an

enclosure on a shelf.

Reader Cabinet

Mounting Holes

Hinged Cover

Figure 7 Reader mounting holes

Step 3: Go to the following sections for the type of Reader that you

are installing:

Serial Reader – Installation of a Serial Reader, page 22.

Wiegand Reader – Installation of a Wiegand Reader, page

23.

FTT Reader – Installation of an FTT Reader System, page

25.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

21

Page 22

Reader Installation

Installation of a Serial Reader

Required Materials

• A standard one-to-one connection RS-232 cable (computer

modem cable) of sufficient length to connect the Reader to any

device that accepts RS-232 as input. The length required for your

installation will vary. One end needs to be a DB9 male connector.

IMPORTANT! DO NOT use a null-modem cable or a null-modem

adapter.

Connecting the Serial Reader to a Computer or Device

Step 1: Attach the female end (it can be either DB25 or DB9

according to the device serial connector) of the cable to

the third-party device. Connect the DB9 male end to DB9

female connector on the Reader.

Step 2: For the third-party device, configure the communications

port settings to the following:

Baud Rate 4800

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

The Reader is a DCE (Data Circuit-terminating Equipment)

device, and data is output through a DB9 female RS-232

connector. Only the following pin assignments are used:

• Transmitted Data (pin 2)

• Received Data (pin 3)

• Signal Ground (pin 5)

Note: Although the Serial Reader has a terminal block

labeled with Wiegand Data Zero, Data One and Ground, it

cannot be used to connect to a Wiegand control panel.

Step 3: Apply power to the Reader. See section Connecting Power

to the Reader – All Types, page 32.

22 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 23

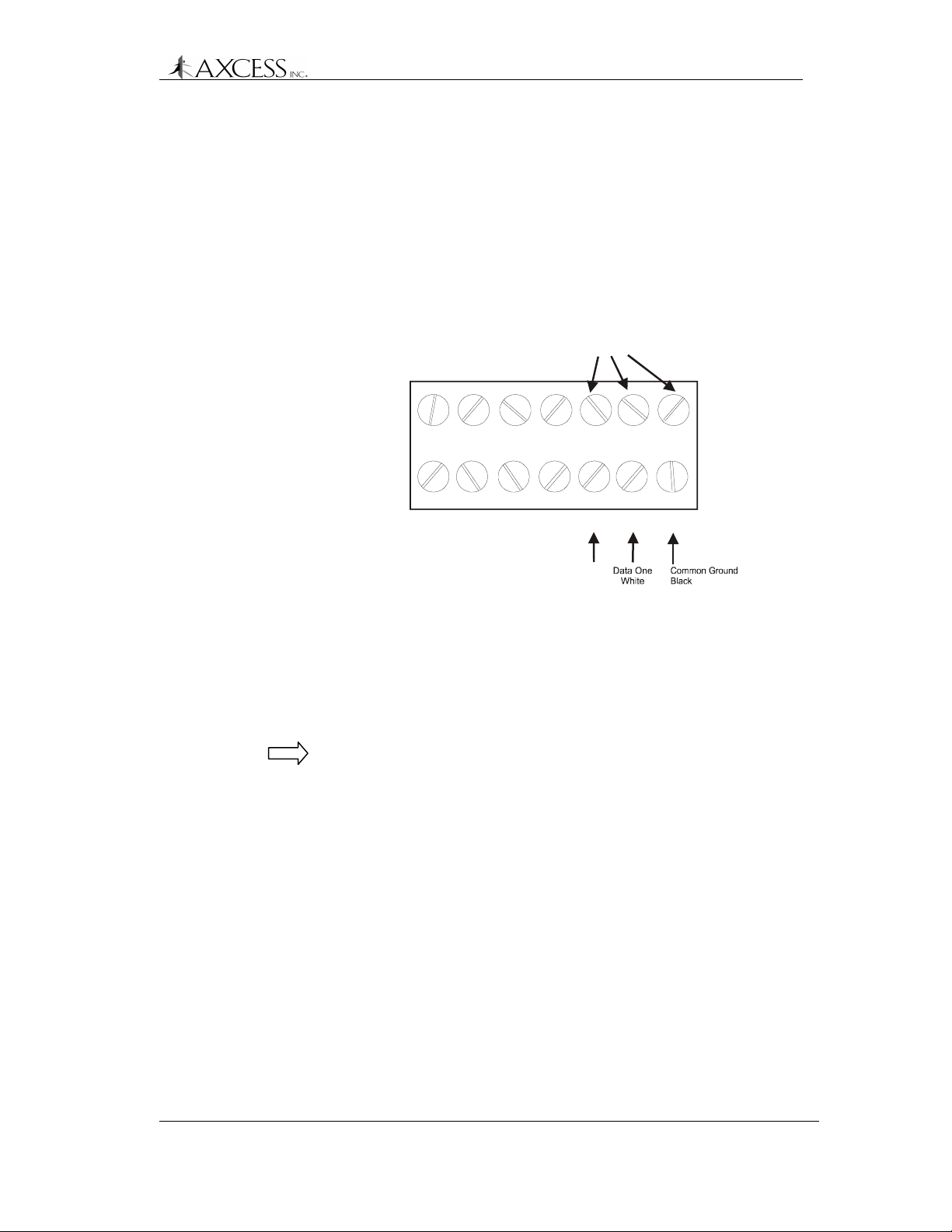

Installation of a Wiegand Reader

Required Materials

• Black, white and green wire of sufficient length to connect the

Reader to the Wiegand control panel. With 22-gauge wire, 200

feet of wire can be run. With 18 gauge, 500 feet can be run.

• A very small flathead screwdriver

Reader Installation

Ribbon-cabled to UniLon Output

Card in PCB stack

GD0

24V

Data Zero

Green

Wires from Wiegand

Control Panel

D1

G

Figure 8 Wiegand Reader connections

Connecting the Wiegand Reader to a Wiegand Control

Panel

Note: Although the Wiegand Reader has a serial output, it cannot be

converted to a Serial Reader. The serial output can only be used for

Reader configuration and diagnostics.

Step 1: Install the Wiegand control panel according to the

instructions provided with that unit.

Step 2: Open the Reader case and disconnect the BNC connector

running from the Transmitter card at the TX connector

(Figure 6). This will give you access to the terminal block

underneath.

Step 3: Loosen the white terminal block by unscrewing it. This will

give you access to the terminals.

Step 4: The ground connection protects against any differential in

voltage potential at each ground plane that may cause

current to flow between the external panel and the Reader.

Such a condition could damage and/or impact the

performance of either or both units.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

23

Page 24

Reader Installation

Run the ground wire from the Ground connection at the

Wiegand control panel to the G terminal on the Terminal

Block (TB1, see Figure 8) in the Reader. For standard

Wiegand control panels, the Ground wire is black. Ensure

that the termination is secure, but not over-tight. Route

cables through the conduit chase at the bottom of the

Reader.

Step 5: Run the Data One wire from the Wiegand control panel to

D1 on the Terminal Block. For standard Wiegand control

panels, the Data One wire is white.

Step 6: Run the Data Zero wire from the Wiegand control panel to

D0 on the Terminal Block. For standard Wiegand control

panels, the Data Zero wire is green.

Note: If Data One and Data Zero are connected

backwards, the data will be garbled.

Step 7: Screw the white terminal block down.

Step 8: Reconnect the TX cable connector.

Step 9: Ensure the Wiegand control panel is wired correctly.

Step 10: Enter the Tag numbers into the panel’s database

according to the panel manufacturer’s instructions.

Step 11: Apply power to the Reader. See section Connecting Power

to the Reader – All Types, page 32.

24 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 25

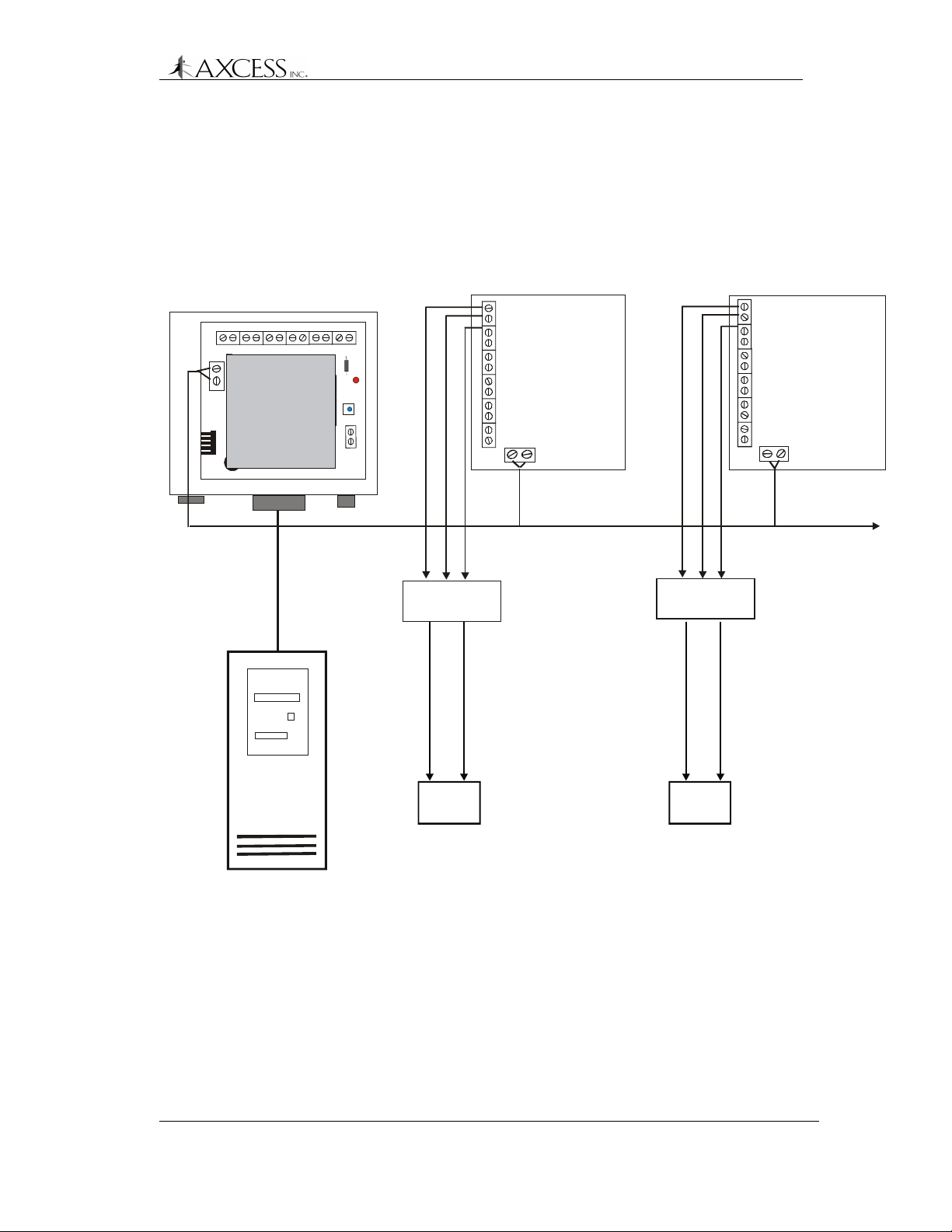

Installation of an FTT Reader System

Introduction

The AXCESS Free Topology Transceiver (FTT) Reader System is

for network applications involving multiple, interconnected Readers

(Figure 9).

Reader Installation

Serial Gateway

FTT

Jp1

Jp4

Reader 1

24V

Ground

Door Stri k e

FTT Motherboard

Jp3

Jp5

Jp6

FTT

Reader 2

24V

Ground

Door Strike

FTT Motherboard

FTT

Tw is ted Pair

LonWorks Network

+ Trigger

Sensit iv e Trig ge r

Serial Data

Relay

Sensitive Trigger

Relay

To more Readers

+ Trigger

Common Ground

NC (normally closed)

or NO (normally open)

Computer

Device

Figure 9 FTT Reader system

The FTT Reader System has at least one of each of the following:

• An FTT Reader that can connect to several external devices and

to other FTT Readers.

• A computer to drive the system. The computer collects data from

the tags. The computer may also send commands via the

Readers to other devices that control doors, send alarms, turn on

lights, etc.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

Common Ground

Device

NC (normally c losed)

or NO (normally open)

25

Page 26

Reader Installation

• A Serial Gateway that coverts the computer’s RS-232 data to

LonWorks data and vice versa. LonWorks is the protocol used to

communicate with the FTT Readers. The Serial Gateway

transmits data from the computer to the Readers via twisted pair

wire. Up to thirty-one FTT Readers can be connected to the

Serial Gateway.

Note: Although the Serial Gateway has a terminal block, it cannot

directly control any access devices. Do not wire access devices to

the Serial Gateway.

Required Materials

• Unshielded twisted pair wire to run between Readers. The type of

cable chosen affects the cable distances allowed in the FTT

network. The recommended cable lengths are given in the next

section.

• Belden 85102, 16 AWG, single twisted pair, stranded 9/29,

unshielded, plenum

• Belden 8471, 16 AWG, single twisted pair, stranded 9/29,

unshielded, non-plenum

• Level IV, 22 AWG, twisted pair, typically solid and unshielded

• TIA 568A Category 5, 24 AWG, twisted pair, unshielded. This

cable type is recommended because it allows for upgrades.

• Sensitive trigger, TTL relays to drive door strikes or other devices

(for example, Altronix RBSN-TTL or Alarm Saf RBKS-124P)

• 22 AWG wire, max four feet in length, to connect the FTT

Readers to the relays.

• Wire as specified by device manufacturers to connect the

devices to the relays.

• An RS-232C straight-through cable with a DB9 male connector to

connect the Serial Gateway to a computer.

26 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 27

Reader Installation

Network Specifications

An FTT network can be comprised of a loop, star, bus or a mixture of

wiring topologies (Figure 10).

PC

Serial

Gateway

Max node to node

distance:

Up to 32 FTT R e aders

Figure 10 Example FTT network – a mixture of bus, star and ring

wiring topologies

IMPORTANT! Both of the following specifications must be met for

proper system operation:

Cable Type Max node to node

distance

Max total wire

length

Belden 85102 1640 feet (500 m) 1640 feet (500 m)

Belden 8471 1312 feet (400 m) 1640 feet (500 m)

Level IV 1312 feet (400 m) 1640 feet (500 m)

Category 5 820 feet (250 m) 1475 feet (450 m)

Max Node to Node Distance

The distance from each Reader to all other Readers on the network

must not exceed the maximum node-to-node distance. If multiple

paths exist, e.g., a loop topology, then the longest path should be

used for calculations (Figure 10).

Max Total Wire Length

Maximum total wire length is the total amount of wire connected per

network.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

27

Page 28

Reader Installation

Connecting the Serial Gateway to the PC

Step 1: Connect the male DB9 end of the straight-through serial

cable to the female DB9 connector at the bottom of the

Reader.

Step 2: Connect the other end of the serial cable to the PC.

Step 3: The Serial Gateway has pads so that it can be placed on

top of or next to the PC.

Step 4: Configure the communications port settings on the PC as

follows:

Baud 2400

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

The Serial Gateway is a DCE (Data Circuit-terminating

Equipment) device, and data is output through a DB9

female RS-232 connector. Only the following pin

assignments are used:

• Transmitted Data (pin 2)

• Received Data (pin 3)

• Signal Ground (pin 5)

Connecting the Serial Gateway to an FTT Reader

Step 1: Prepare a sufficient length of twisted pair wire to connect

the first Reader to the Serial Gateway.

Step 2: Insert the twisted pair wire into the terminal block labeled

FTT in Figure 11 in the Serial Gateway and run it out the

conduit chase.

Step 3: Run the twisted pair through the conduit chase of the

Reader and insert the twisted pair wire into the FTT

terminal block. You can connect up to four Readers by the

FTT terminal block in the Serial Gateway; however, we

recommend connecting only one or two. You can network

up to thirty-one Readers together by twisted pair wire.

Connecting FTT Readers to Each Other

Step 1: Prepare a sufficient length of twisted pair wire to connect

the two Readers.

28 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 29

Reader Installation

Power

Grnd 24V

Power for relay

24V

Grnd

FTT terminal block

1

Jp3

Jp5

Jp6

Jp4

Jp1

FTT

Figure 11 FTT Motherboard. Gray area notes location of the

LonWorks daughterboard.

Step 2: Insert the twisted-pair wire into the terminal block labeled

FTT (Figure 11) in the first Reader and run it out the

conduit chase.

Step 3: Run the twisted pair through the conduit chase of the

second Reader and insert the twisted pair wire into the

FTT terminal block. Each terminal in the FTT terminal

block can hold up to four wires, depending on gauge.

Note: When connecting Readers to each other, remember that

shorter cabling makes for a better network because it improves

transmission.

Connecting an FTT Reader to a Device

The FTT Reader has two outputs to control devices. These outputs

can be found on the FTT Terminal block (Figure 11).

The terminals in the FTT terminal block are for the following:

Label Purpose

24V 24V for powering the TTL relay

Gnd Ground for the TTL relay

Door Strike Trigger output with a 20 mA source/sink

capability for triggering sensitive trigger relays.

Secondary

Output

Trigger output with a 20 mA source/sink

capability for triggering sensitive trigger relays.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

29

Page 30

Reader Installation

24V

Ground

Door Strike

Secondary

Output

FTT ter mi nal block

IMPORTANT! Do not use the Door Strike and Secondary Output

terminals to drive relay modules directly. Such relays require 100 mA

or more, well in excess of the FTT module’s source power capacity.

The FTT card can burn up. Using sensitive trigger, TTL relays (for

example, Altronix RBSN-TTL or Alarm Saf RBKS-124P) is

recommended.

NOTE: The rolled-up serial cable connected to the RS-232 connector

is for configuration and diagnostics. The FTT Reader cannot be

converted to a Serial Reader.

Trig -

Pos +

C

NC

NO

TTL Relay

Trig +

Neg -

C

NC

NO

Device can be wired to either:

Device can be wired to either:

NC - Normally Closed

NC - Normally Closed

NO - Normally Open

NO - Normally Open

Device

Power Supply

for Device

+V

G

Figure 12 Wiring details for driving a device

Step 1: Run 22 AWG wire (max length two feet) from the terminal

labeled GND on the FTT terminal block through the

conduit chase to the relay terminal labeled Neg -.

Step 2: Run 22 AWG wire (max length four feet) from the terminal

labeled either Door Strike or Secondary Output on the

FTT terminal block through the conduit chase to the relay

terminal labeled Trig +.

Step 3: Run 22 AWG wire (max length four feet) from terminal

labeled 24 V on the FTT terminal block through the conduit

chase to the relay terminal labeled Pos +.

Step 4: Connect the Common (C) terminal on the relay to +V on

the device’s power supply with manufacturer

recommended wire.

Step 5: Connect Ground from the device’s power supply to the

device using manufacturer recommended wire.

30 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 31

Reader Installation

Step 6: Connect either the Normally Open (NO) or Normally

Closed (NC) terminal on the relay to the device with

manufacturer recommended wire.

Applying Power to the Serial Gateway

Step 1: Ensure that the 110V AC outlet is close by and easily

accessible.

Step 2: Plug the AC adapter into the connector at the bottom of

the Serial Gateway.

Step 3: Plug the adapter into 110 AC wall outlet or UPS.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

31

Page 32

Reader Installation

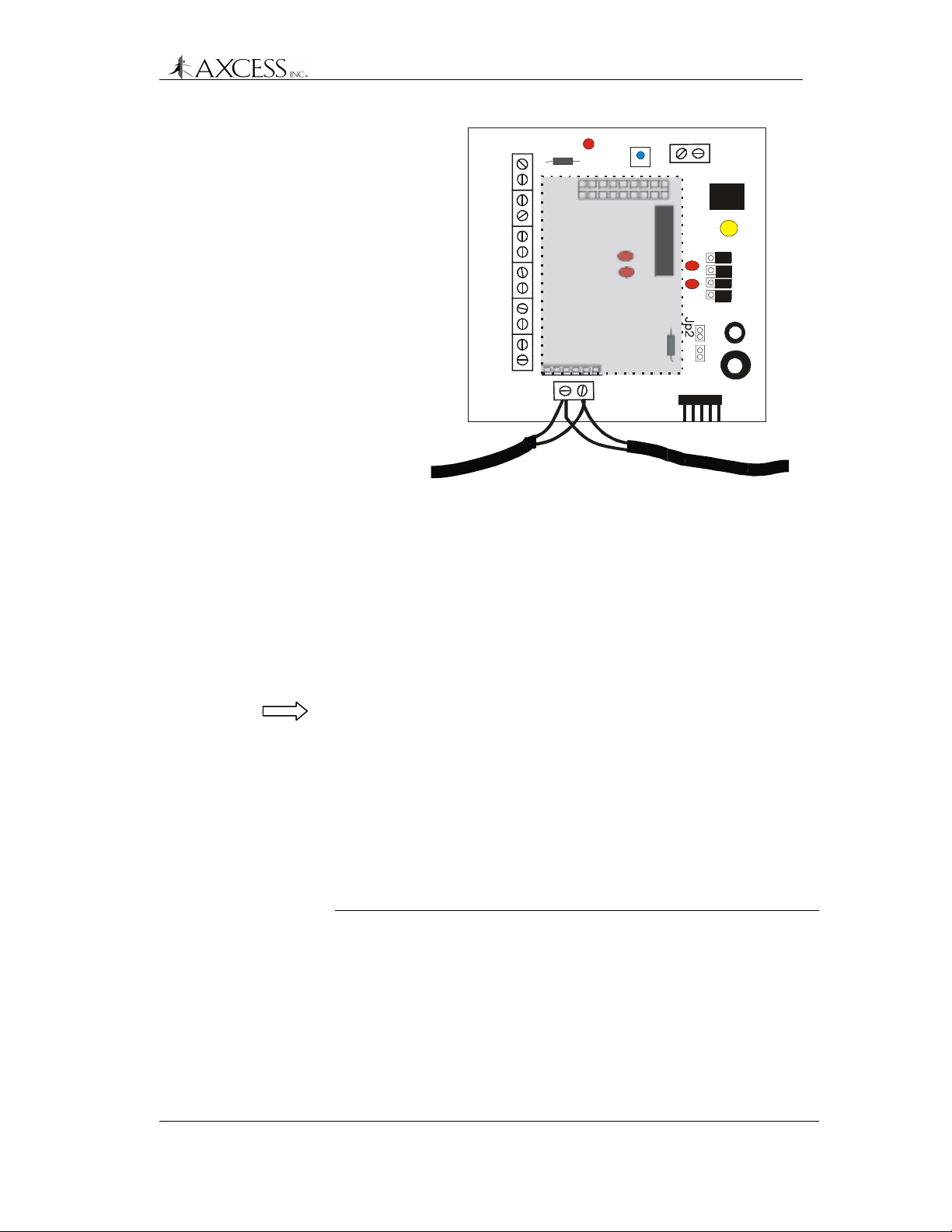

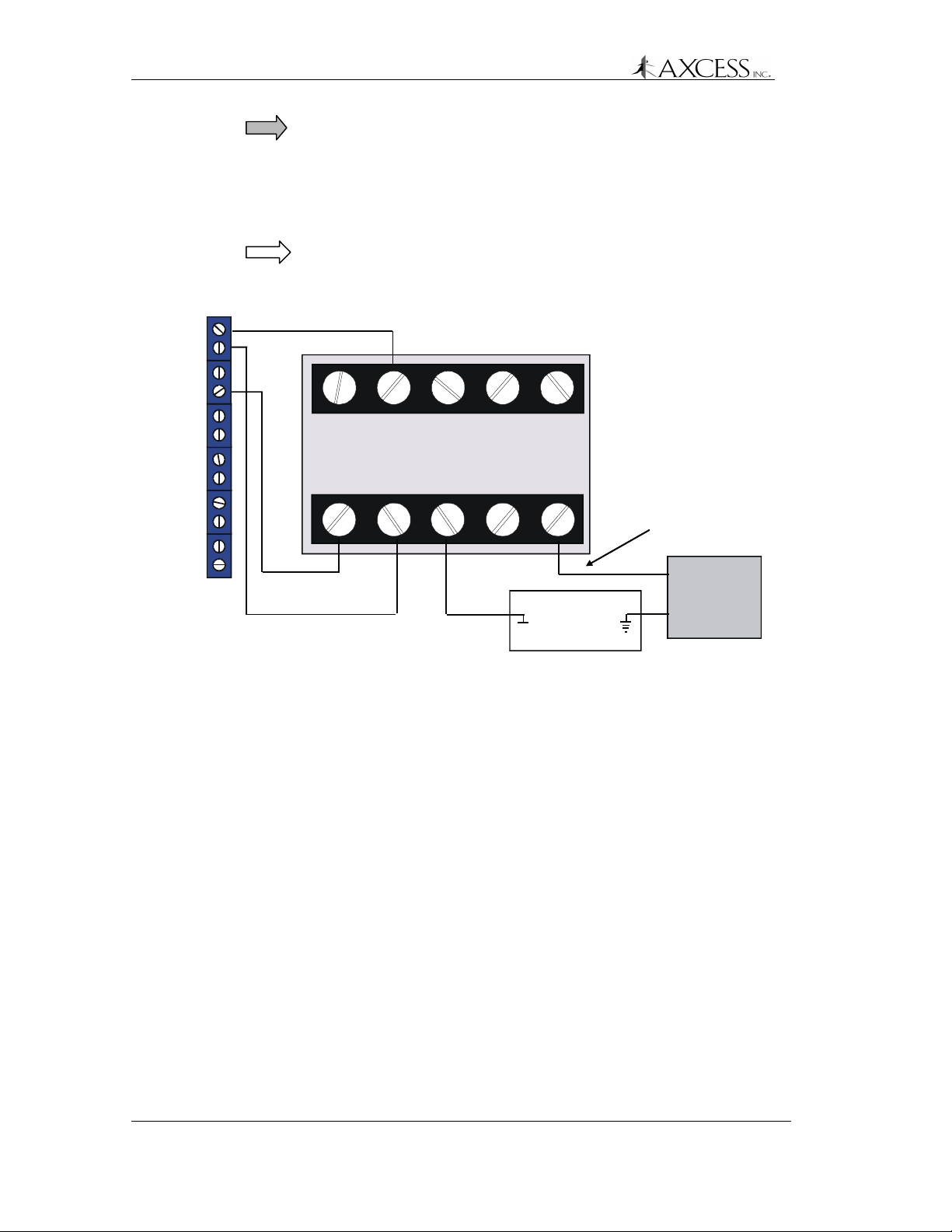

Connecting Power to the Reader – All Types

IMPORTANT! Finish installing the Reader before applying power.

All Readers come with a 24V, 700 mA wall adapter that plugs into a

110 outlet. If uninterruptible power is an issue, a UPS can be used.

Wires to

Reader

24V

Wires from

AC adapter

GD0

D1

G

Figure 13 Power terminals for the Reader

Grounding the Reader

The Reader needs to be properly grounded. Failure to ground the

Reader will result in erratic performance.

Step 1: Run 14 AWG wire from a solid earth ground to the ground

lug on the outside of the Reader case (Figure 6).

Step 2: If the Reader is connected to a Wiegand control panel,

ensure that the Wiegand control panel is similarly

grounded.

AC Adap ter

The AC adapter wires (Figure 14) are labeled as follows:

Power

80 C VW - 1 22 AWG X 2C

Ground

Figure 14 AC adapter wires

Power is marked with the dashed white line.

Ground is black and has the gauge information printed on it.

32 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 33

Reader Installation

Step 1: Ensure that the 110 AC outlet is near the Reader and is

easily accessible.

Step 2: Open the Reader case and disconnect the BNC connector

running from the Transmitter card at the TX connector

(Figure 6). This will give you access to the terminal block

underneath.

Step 3: Loosen the white terminal block by unscrewing it. This will

give you access to the terminals.

Step 4: Run the power wires through the conduit chase.

Step 5: Insert the positive 24V wire into the terminal labeled 24V

(Figure 13).

Step 6: Insert the ground wire into the terminal labeled G.

Step 7: Screw the white terminal block down.

Step 8: Reconnect the TX cable connector.

Step 9: Plug the AC adapter into a 110 outlet.

When power is supplied to the Reader, the LEDs on the card stack

will light up.

Note: The open terminals on TB1 are for future enhancements.

IMPORTANT! The Reader comes with a factory-default ID number

that needs to be changed to eliminate the possibility of cross talk.

See the section Configuring 3.x Reader Firmware, page 35.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

33

Page 34

Page 35

Configuring 3.x Reader Firmware

A 3.x Reader can be configured by a terminal application to do the

following:

• Set modes for reading either 2.0 Tags or 3.x Tags.

• Change the Reader ID number to eliminate the possibility of

cross talk in multi-Reader applications.

• Place the Reader in diagnostics mode so that Reader and Tag

performance can be monitored.

HyperTerminal is a convenient terminal application for

communicating with a Reader since it is standard with the

Windows

programs, such as ProCom, etc., can be used.

Required Materials

• A computer with a terminal program and a free communications

• A standard one-to-one computer modem RS-232 cable with a

TM

operating system. Although other terminal emulation

port. A laptop running Windows is recommended for

convenience.

DB9 male connector.

IMPORTANT! DO NOT use a null-modem cable or null-modem

adapter.

Connecting a Computer to the Reader

Serial and Wiegand Readers

Step 1: Attach the DB9 male connector of the RS-232 cable to the

RS-232 port on the Reader

Step 2: Attach the other end of the RS-232 cable to the computer.

FTT Reader

Step 1: Open the Reader case. There is a 9-wire ribbon cable

connected to the RS-232 port. The other end is

unconnected and tied. There is a 10-wire ribbon cable

connecting the output card to the FTT motherboard

(Figure 15).

Step 2: Disconnect the 10-wire ribbon cable from the output card.

Step 3: Connect the free end of the 9-wire ribbon cable to the

output card (Figure 15). The red wire should be closest to

the Reader case’s hinges.

Page 36

Configuring 3.x Reader Firmware

RS-232 cable

attached to the

output card.

The red wire is

closest to the

Reader case.

Figure 15 FTT Reader with the output card disconnected from

the FTT motherboard and connected to the RS-232 port.

RS-232

Step 4: Attach the DB9 male connector of the RS-232 cable to the

external RS-232 port on the Reader.

Step 5: Attach the other end of the RS-232 cable to the computer.

Remember: When you have finished communicating with

the Reader, detach the 9-wire ribbon cable from the output

card, reattach the 10-wire ribbon cable from the FTT

motherboard to the output card and detach the computer

from the Reader.

36 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 37

Configuring 3.x Reader Firmware

Communicating with the Reader via HyperTerminal

Step 1: On the computer’s desktop, click the Start button. The

Start menu will appear (Figure 16).

Step 2: From the Start menu, select Programs, Accessories,

Communications, HyperTerminal.

Figure 16 Accessing HyperTerminal from the Start Menu

Step 3: In the Explorer window that appears, double-click the

Hypertrm.exe icon. This launches the HyperTerminal

application.

Step 4: In the Connection Description dialog box that appears,

enter any name for the connection in the Name field, and

select the first icon in the Icon selection box. Click the OK

button.

Step 5: In the Connect To dialog box that appears, select the com

port to which the Reader is connected from the Connect

Using drop-down list. The other options will gray out. Click

the OK button.

Step 6: In the Com Properties dialog box that appears, enter the

following information depending on the Reader type to

which you are connecting:

Serial Reader and Wiegand Reader:

Bits per second (Baud) 4800

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

FTT Reader:

Bits per second (Baud) 2400

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

37

Page 38

Configuring 3.x Reader Firmware

Step 7: Click the OK button. If you are connecting to a Serial

Reader Commands

The following is a list of commands that can be sent to the Reader

via the terminal application.

Code Action

* Changes the Tag version that the Reader reads.

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Reader, the HyperTerminal’s main window will display the

five-digit ID numbers for any Tags in the field. Wiegand

and FTT Readers will not output anything to the screen

unless they are placed in diagnostics mode (See the

section Toggling Between Default and Diagnostic Modes,

page 42.)

This should be checked to ensure that the Reader is

reading the correct version of Tag. A Reader can only read

2.0 Tags or 3.x Tags; it cannot read both.

# Changes the Reader ID to eliminate the potential of cross

talk.

& Turns on/off diagnostic mode.

$ Allows the Reader to act on a 254 code in addition to its

own ID number. This is only available for Wiegand

Readers.

38 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 39

Entering a Command

Step 1: In HyperTerminal’s main window, press the Spacebar until

Step 2: Type one of the above commands at the “Enter:” prompt.

Configuring 3.x Reader Firmware

the Reader responds with “Enter:” on the terminal screen.

The Reader will now wait for input.

Note: When the Reader is waiting for input, it is paying

attention only to the serial cable and is not receiving

information from the antennas.

For example,

Enter: &

Places the Reader into diagnostics mode.

IMPORTANT! Do not press the Enter key after you have

typed the command; it is not necessary.

If the Reader receives no input after a few seconds, it

displays the message, “Timed out.” If you are

communicating with an FTT Reader, the Reader displays

the firmware version, jumper settings and Reader ID.

All outputs from the Reader are preceded by an indent to

indicate that the string is not a Tag ID.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

39

Page 40

Configuring 3.x Reader Firmware

Toggling between reading 3.x Tags and reading 2.0 Tags

Readers can receive information from either 2.0 Tags or 3.x Tags,

but not both. The toggle command lets you to switch between them.

IMPORTANT! Ensure that the Tag version the Reader is receiving

matches the version stamped on the edge of the Tag case. If the

Reader and Tags are mismatched, no Tag information will be output.

The Tag version information is stored so that the Reader will continue

to read the same Tag version even if it has been powered off and

powered back up.

Step 1: Type an asterisk (

Do not press Enter.

The Reader will respond with, “Reading 2.0 tags.”

For example:

Enter: *

Reading 2.0 tags.

Step 2: To switch back to reading 3.x Tags, press the Spacebar

until the “Enter:” prompt appears, then type an asterisk at

the “Enter:” prompt.

The Reader will respond with “Reading 3.x tags.”

* ) at the “Enter:” prompt.

40 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 41

Changing the Reader ID Number

IMPORTANT! All Readers are given the same ID number (127) at

the factory. Each Reader needs to be set with a unique ID number to

eliminate the possibility of cross talk (i.e., a Tag broadcasting to an

incorrect Reader) in multi-Reader applications.

Step 1: At the “Enter:” prompt, type a pound sign ( # ) followed by

a two-number code (01-32). See Table 1 for codes and

their corresponding Reader ID numbers.

Do not press Enter.

The Reader will respond with “Selected Value: #NN”

where NN is the code that you entered, and “Reader

ID=XXXXX” where XXXXX is the new Reader ID number

corresponding to the code entered.

For example, if you type:

The Reader will respond with

Configuring 3.x Reader Firmware

Enter: #10

Selected Value: #10

Reader ID=00106

The new Reader ID number will be kept even after a

power off/on cycle.

Code to

Enter

00 00000 16 00080

01 00033 17 00113

02 00034 18 00114

03 00003 19 00083

04 00100 20 00052

05 00069 21 00021

06 00070 22 00022

07 00103 23 00055

08 00072 24 00024

09 00105 25 00057

10 00106 26 00058

11 00075 27 00027

12 00044 28 00124

13 00013 29 00093

14 00014 30 00094

15 00047 31 00127

Table 1 Reader ID codes and numbers

Reader

ID #

Code to

Enter

Reader

ID #

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

41

Page 42

Configuring 3.x Reader Firmware

Toggling Between Default and Diagnostic Modes

Diagnostic mode allows you to troubleshoot the NT132 system. It

displays information that the Tag broadcasts to the Reader – the

Reader ID, Site Code and Tag ID number.

Step 1: At the “Enter:” prompt, enter an ampersand ( & ).

Do not press Enter.

The Reader will respond with “Diagnostics ON”

A Reader reporting 3.x Tag information will output 15 digits

to the terminal screen:

R R R R R S S S S S T T T T T

Where:

R – The 5-digit Reader ID as returned by the Tag

S – The 5-digit Site Code of the Tag

T – The 5-digit Tag ID number

A Reader reporting 2.0 Tag information will output 10 digits

to the terminal screen:

S S S S S T T T T T

Where:

S – The 5-digit Site Code of the Tag

T – The 5-digit Tag ID number

For example, turning on the diagnostics mode for Reader

reporting 3.x Tags looks like this:

Enter: &

The Reader will respond with

Diagnostics ON

001060002401234

001060002423235

001060002467843

00106 is the Reader ID; 00024 is the Site Code and

01234, 23235 and 67843 are the IDs of the Tags that are

in the field.

Code 254

When the Tag determines that a Reader signal is present but cannot

determine the Reader ID number, the Tag returns 254 for Reader ID

as a code indicating that it could not pick up the Reader ID number.

When the Reader is in default mode, it will not report the 254 code as

it would with a regular Tag read.

42 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 43

Configuring 3.x Reader Firmware

Wiegand Output

Although a Wiegand Reader will output Tag data to HyperTerminal

as rapidly as it receives it, it will still buffer the data being sent to the

Wiegand control panel. The Reader will output data to the control

panel for one Tag read every 750 milliseconds. Duplicate Tag

information is stored in the Reader’s buffer for 12 seconds so that

duplicate Tag reads are ignored during this time interval. When a

Wiegand Reader is in diagnostics mode, all Tag information is sent

to the control panel including the 254 code.

Turning off the Diagnostics Mode

Step 1: Turn off the diagnostics mode by pressing the Spacebar

until the “Enter:” prompt appears and then typing an

ampersand ( & ).

The Reader will respond with “Diagnostics OFF.”

IMPORTANT! Always turn off diagnostics mode when finished.

Failure to do so can result in cross talk, garbled output and erratic

control device performance.

The diagnostics mode is not stored permanently, and when the

Reader is powered on again it will start in default mode, in which the

diagnostics are turned off.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

43

Page 44

Configuring 3.x Reader Firmware

Bypass Mode - Enabling Action on 254 Code

When 3.x Tags cannot determine the Reader ID, they transmit back

a 254 code in place of a Reader ID. In default mode, the Reader will

not report or act on this code. It will only report Tag messages which

include its own ID number. A Wiegand Reader can be set to report

messages with both its ID number and code 254. This is useful at

sites where vehicles travel quickly over a Road Loop Antenna and

the Tags may not have time to resolve the Reader ID number.

Step 1: At the “Enter:” prompt, type a dollar sign ( $ )

The Wiegand Reader will respond with “ReaderID 254

ON”

IMPORTANT! Do not turn on the bypass mode on a

Reader that is within the range of another Reader. This will

cause crosstalk.

Step 2: Turn off the bypass mode by pressing the Spacebar until

the “Enter:” prompt appears and then typing the dollar sign

( $ ).

The Wiegand Reader will respond with “ReaderID 254

OFF”

The bypass mode is stored so that the Reader will continue to report

254 messages even if it has been powered off and powered back up.

44 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 45

Unilon Reset Buttons

Each Unilon card in the Reader’s PCB stack (Figure 17) has a reset

button that provides revision numbers and jumper configurations for

the card.

The reset buttons can also be pressed when the Reader has been

subjected to static discharge or power glitches.

Configuring 3.x Reader Firmware

Cabli ng Label

Unilon RX Card

RF Card

Unilon Output Card

Unilon TX Card

Transmitter Card

RJ-45

Conduit

Chase

TX

Reader Case

Terminal Block (TB1)

Ground Lug

RXRS-232

Figure 17 PCB stack cards

The cards perform the following functions:

Unilon RX Card – decodes the signal sent from the receiving

antenna via the RF Card.

RF Card – receives the signal from the receiving antenna

Unilon Output Card – sends the data to a controller or

computer

Unilon TX Card – encodes the signal to transmit

Transmitter Card – sends the signal to the transmitting

antenna

The RX, TX and Output Unilon Cards (Figure 18) appear to be

physically the same with the exception of jumper placement, which

configures them for their respective tasks.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

45

Page 46

Configuring 3.x Reader Firmware

Serial/FTT Connector

Reset Button

Service Pin

Jp4

Jp3

Jp1

1

Jp2

1

1

Jp7

Figure 18 Unilon card

Wiegand Connector

Jp6

Depending on how the card is set up, there may be a serial cable

connected to the top of the card and the jumper shunts may be in

different places.

IMPORTANT! Do not press the Service Pin. If the Service Pin is

accidently pressed, cycle the power off and on to put the Reader into

a known state.

Viewing Unilon Card I nf ormat ion

Step 1: Connect the Reader to a PC and access the Reader with a

terminal application. See the section Configuring 3.x

Reader Firmware, page 35, for instructions.

Step 2: Press the reset button on the Unilon RX Card. The Reader

will display to the screen the firmware name, its revision

number and the jumper settings separated by dollar signs

( $ ).

For example, when pressing the reset button on a Unilon

RX Card, the following information may be seen on the

terminal screen:

200rx $Revision: 1.6 $Receive JP1=2-3 JP2=2-3

Step 3: Press the reset button on the Unilon TX Card. The Reader

will display to the screen the firmware name, its revision

number and the jumper settings separated by dollar signs

( $ ).

For example:

200ltx $Revision: 1.5 $Transmit JP1=2-3 JP2 1-2

46 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 47

Configuring 3.x Reader Firmware

Step 4: Press the reset button on the Unilon Output Card. The

Reader will display to the screen the firmware name, its

revision number, the jumper settings and its ID number

separated by dollar signs ( $ ).

For example:

200sera $Revision: 1.5 $Serial JP1=2-3 JP2 1-2

ID=033

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

47

Page 48

Page 49

Antenna Tuning Unit (ATU) Installation

Introduction

Each access control point (e.g. door, roadway, etc.) has at least two

antennas:

• A Low Frequency (LF) loop antenna that broadcasts a wakeup

signal at 132 kHz to any Tags that may be within the antenna

field of radiation.

• A dipole antenna designed for the Ultra-High Frequency (UHF)

range for receiving a response signal (315 MHz) from each Tag.

For road-loop sites, the two antennas are separate to accommodate

unique installation and distance requirements.

For interior installations, the two antennas are packaged in a single

housing that can be inconspicuously mounted near the access

monitoring point.

An ATU optimizes the performance of one antenna pair to its

environment.

Installation Considerations

When selecting a location for each ATU, keep in mind that it should

be mounted:

• within 20 feet cable length of its antennas

• within 80 feet cable length of the Reader

Review the appropriate antenna section in this manual prior to

installing each ATU. The ATU should be mounted in a location that

provides protection from the elements and easy access for cabling

and system tuning.

IMPORTANT! Place the ATU in a waterproof box if it is mounted

outside.

In some installations, it may be desirable to install the ATU out of

sight (e.g. above ceiling tiles).

Page 50

Antenna Tuning Unit (ATU) Installation

Required Materials

The following materials are necessary for successful installation:

• RG-58/U coaxial cable with 50-ohm impedance (nominal), solid

copper center conductor, 55% tinned copper braid or better,

100% foil shield coverage (for example, Belden 9310). The

length required for your installation will vary. The maximum

length recommended is 80 feet between the Reader and ATU

and 20 feet between the ATU and each antenna. AXCESS

cannot guarantee performance if these parameters are

exceeded.

• Four 3-piece crimp type male BNC connectors (for example,

Amphenol 31-320). Note: extras are recommended in case of

damage during crimping.

• Power drill and bits

• Four mounting screws

• Diagonal cutters

Prerequisite Tasks

• Phillips and flathead screwdrivers

• Three blade rotary coaxial cable stripper

• BNC crimpers

• Multimeter

It is assumed that the following task has already been completed.

The Reader has been installed. If not, refer to the appropriate

section in this document and install the Reader before

continuing.

50 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 51

Mounting the ATU

Antenna Tuning Unit (ATU) Installation

IMPORTANT! Lay out and test the entire NT132 System before

permanently mounting any piece of the system.

Figure 19 Mounting screw channels for the ATU

Step 1: The ATU should be mounted a minimum of 36 inches off

the ground, preferably at eye height. Mark and drill the

holes for mounting the ATU.

Step 2: Mount the ATU with the connectors pointing down. There

are screw channels at each corner of the ATU for

mounting purposes (Figure 19).

IMPORTANT! If the ATU has a voltmeter, install the ATU with the

connectors pointing down. This orients the voltmeter so that it reads

accurately. For more information on voltmeters and toggle switch

ATUs, see the section Adjusting Performance with a Toggle Switch

ATU, page 74.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

51

Page 52

Antenna Tuning Unit (ATU) Installation

Cabling the ATU

Figure 20 shows the cabling between the ATU and the Reader – and

between the ATU and the associated antennas.

READER

RXTX

TX Antenna

RX Antenna

Antenna

TX

ATU

RX RX

Reader

TX

Figure 20 ATU connections

IMPORTANT! All coaxial cable between the ATU and the Reader

must be RG-58/U with 50-ohm impedance (nominal), solid copper

center conductor, 55% tinned copper braid or better, 100% foil shield

coverage (for example, Belden 9310). Cable must be terminated at

both ends with 3-piece crimp type male BNC connectors. See

Appendix A: Coaxial Cable, page 101, for directions on how to

prepare the cable.

52 750.001.003

Revised June 1999

© 1999 AXCESSTM Inc.

Page 53

Connecting the ATU to the Reader

Step 1: Measure the length between the ATU and the Reader for

the connecting cable run. The cable length should not

exceed 80 feet.

Step 2: Cut two lengths of coaxial cable. Each length should equal

the measured cable distance from the ATU to the Reader.

Ensure that you give yourself some slack in the cable

length.

Step 3: Attach a male BNC connector to each end of each cable.

Step 4: Run one cable from the Reader’s connector labeled TX to

the connector labeled Reader TX on the ATU.

Step 5: Run the other cable from the Reader’s connector labeled

RX to the connector labeled Reader RX on the ATU.

Connecting the ATU to the Antennas

See the following sections for each antenna type:

Antenna Tuning Unit (ATU) Installation

To connect the ATU to a Bar Antenna –Installing the Bar Antenna,

page 70.

To connect the ATU to a Road Loop Antenna – Road Loop Layout &

Connecting to the ATU, page 61

To connect the ATU to a Dipole Antenna - Installing the Dipole

Antenna, page 56

To connect the ATU to a Swing Frame Antenna -Installing the Swing

Frame Antenna, page 71

Note: Do not dress (tie-wrap) the cables until the installation is

complete and tested. Once the system is operating properly, finish

the cabling.

© 1999, AXCESSTM Inc. 750.001.003

Revised June 1999

53

Page 54

Page 55

Dipole Antenna Inst allation

Introduction

The Dipole Antenna receives signals transmitted by the Tags and

works in association with the Road Loop Antenna.

IMPORTANT! To ensure proper system operation, do not substitute

antenna kit components.

Required Materials

The following materials must be on hand in order to successfully

install the Dipole Antenna:

• RG-58/U coaxial cable with 50-ohm impedance (nominal), solid

copper center conductor, 55% tinned copper braid or better,

100% foil shield coverage (for example, Belden 9310) to connect

the Dipole Antenna to the ATU. The length required varies by