Axcera 79XITS-7045 User Manual

ADC

TELECOMMUNICATIONS

TECHNICAL MANUAL

EXHIBIT IV

(PRELIMINARY)

BTS-7010

FREQUENCY AGILE

QAM UPCONVERTER

REV: 0

102 Rahway Road

McMurray, PA 15317 USA

Phone 412-941-1500

FAX 412-941-9421

SYSTEM DESCRIPTION

The Frequency Agile QAM Upconverter (Wavecom Electronics Inc. MA4040D) is a commercial

quality IF upconverter designed for cable, MMDS and LMDS applications. The MA4040D

upconverter operates from 53 to 857 MHz and maintains a phase noise specification that exceeds

the DOCSIS requirements for 64 QAM. The MA4040D is a modular circuit card and operates in

a card chassis (MA4002D)with a common power/control module (MA4011D) and can contain

up to ten (10) MA4040D independent frequency agile upconverters.

The MA4040D functions as the IF to UHF upconverter component of the BTS-7010 system. The

MA4040D inputs the 44 MHz IF from the WMTS and output a 222 – 408 MHz output signal

that is fed to the input of the BTS-7010.

FREQUENCY AGILE 256 QAM

UPCONVERTER

MA4040D

INSTALLATION AND OPERATION GUIDE FOR

SYSTEM OPERATORS

Proprietary to WaveCom Electronics Inc.

All rights reserved.

No part of this publication may by reproduced in any form or by any means or used to make any derivative work (such as translation, transformation

or adaptation) without written permission from WaveCom Electronics Inc.

WaveCom Electronics Inc. reserves the right to revise this publication and to make changes in content from time to time without obligation on the

part of WaveCom Electronics Inc. to provide notification of such revision or change.

WaveCom Electronics Inc. provides this guide without warranty of any kind, either implied or expressed, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. WaveCom Electronics Inc. may make improvements or changes in the

product(s) described in this manual at any time.

MA4040D Manual; MAN1L0901 REV 13(0104); Approved: D.P.

Specifications subject to change without notice — Printed in Canada

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

ii

Thank-you for purchasing this product

and welcome to WaveCom!

You have chosen an innovative solution from a leading

technology design center in the ongoing TV & data delivery

revolution.

No doubt you’ve been thinking that the future of your television delivery system includes new technologies like

Digital TV, Internet Over Cable, Wireless Cable. By selecting WaveCom, you are benefiting from the same

design powerhouse that since 1988 has created custom RF and digital products for technology leaders like Nortel

Networks, Diva Systems and Cisco Systems.

WaveCom designs and manufactures:

44 Agile CATV Modulators 44 256 QAM Upconverters 44Digital Video Modulators

44 Frequency Translators 44 Spread Spectrum Devices 44 Off-Air Demodulators

44 Video-On-Demand Products 44 Wireless Cable MMDS 44 Wireless Cable LMDS

44 Frequency Stackers 44 MMDS Transceivers 44Satellite Receivers

and more! Designs to fill the market needs of the CATV industry – both foreign and domestic.

For additional product or corporate information, contact us:

On the web at: www.WaveCom.ca

By sending email to: sales@WaveCom.ca

By telephone: (306) 955-7075

By fax: (306) 955-9919

By snail mail: WaveCom Electronics Inc.

222 Cardinal Cres.

Saskatoon, SK Canada S7L 6H8

WaveCom's Corporate Mandate

is to be a leading worldwide designer and manufacturer of state-of-the-

art communications equipment and components. Through the

remarkable success of our customers and business partners,

WaveCom innovations are achieving this goal.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

iii

SAFETY PRECAUTIONS

1. Before installing and operating this equipment, read all Safety, Installation and Operating sections. Retain this

manual for future reference.

2. Follow all instructions — Failure to do so may result in damage to the unit or severe personal injury.

3. Servicing should not be attempted by the user. There are no user serviceable parts inside. Refer all servicing to

factory qualified personnel.

4. Shock Hazard — An electrical shock hazard exists when the chassis cover is removed as is required to set

internal controls. Always disconnect power from the unit before removing the cover.

5. Cleaning — Do not use liquid or aerosol cleaners. Use a damp cloth for cleaning.

6. “CAUTION: The WaveCom MA4000D system with the –48 V dc supply option is intended for use only in

rack mounted or cabinet installations where the dc supply wiring is protected from access by user

personnel and from the outside environment.”

Warning Do not work on the system or connect or disconnect cables during periods of lightning activity.

LES PRÉCAUTIONS DE SÉCURITÉ

1. Avant d'installer ou d'opérer cet équipement, lisez, toutes les sections de sécurités, d'installations et

d'opérations. Gardez ce manuel comme source de référence.

2. Suivez toutes instructions - si non, vous risquez d'endommager la machine ou de vous blesser sérieusement.

3. N'essayez, pas de réparer cet équipement vous même. Référez toutes revisions nécessaire au personnel

qualifié de la manufacture.

4. Risque de choc - Il y a un risque de décharge électrique qui existe quand la couverture du châssis est enlevée,

comme est nécessaire pour ajuster les contrôlcs internes. Il faut toujours couper l'électricité avant d'enlever le

couvercle pour faire aucun ajustage.

5. Le nettoyage - n'utilisez pas de nettoyeurs aérosols ou liquides. Utilisez un tissu humide pour nettoyer.

6. "ATTENTION": Le WaveCom MA4000D system qui peut approvisionner le courant continu -48 V, doit

être employé seulement dans une étagère montée ou installée dans un cabinet où les fils électriques sont

portégés contre les éléments et ne sont pas accessibles aux personnes non-qualifiées.

Attention Ne pas travailler sur le système ni brancher ou débrancher les câbles pendant un orage du foudre.

* Important Installation Instructions

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

iv

INDEX

1.0 GENERAL INFORMATION...............................................................................................................7

1.1 System Overview...................................................................................................................................7

1.2 Functional Overview..............................................................................................................................7

1.3 Module Features....................................................................................................................................7

1.4 System Features.....................................................................................................................................7

1.5 Specifications........................................................................................................................................8

2.0 INSTALLATION................................................................................................................................10

2.1 Unpacking the Unit...............................................................................................................................10

2.2 Operating Environment.........................................................................................................................10

2.3 Power Requirements.............................................................................................................................10

2.4 Rack Mounting ....................................................................................................................................10

2.5 MA4040D Upconverter Module Installation/Replacement.......................................................................10

2.6 MA4012D -48 VDC Redundant Power Supply Module Installation/Replacement .....................................11

2.7 MA4011D 110/240 VAC Redundant Power Supply Module Installation/Replacement..............................12

3.0 OPERATION.......................................................................................................................................13

3.1 Front Panel Description........................................................................................................................13

3.2 Front Panel Operating Modes................................................................................................................15

3.3 Remote Control Operating Instructions .................................................................................................17

3.4 Remote Control Using Terminal Mode...................................................................................................18

3.5 Remote Control Using Terminal Mode over a standard phone modem......................................................18

3.6 Remote Control Via SNMP...................................................................................................................19

3.7 FLASH Upgrade..................................................................................................................................19

3.8 Demonstration Software .......................................................................................................................19

3.9 Procedure for Using the MA4040D Redundancy Feature .......................................................................20

4.0 REAR PANEL CONNECTIONS......................................................................................................22

4.1 MA4040D...........................................................................................................................................22

4.2 MA4011D (and/or MA4012D) Power/Control Module...........................................................................23

5.0 STATUS CODES................................................................................................................................25

5.1 MA4040D Status Codes.......................................................................................................................25

5.2 MA4011D (or MA4012D) Power/Control Module Status Codes.............................................................26

6.0 ERROR CODES.................................................................................................................................27

6.1 MA4040D Error Codes........................................................................................................................27

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

v

6.2 MA4011D (or MA4012D) Power/Control Module Error Codes ..............................................................28

7.0 DETAILED REMOTE CONTROL ...................................................................................................29

7.1 Operation............................................................................................................................................29

7.2 Message Format...................................................................................................................................29

7.3 Command Structure..............................................................................................................................29

7.4 Response Structure ..............................................................................................................................31

7.5 Detailed Command Descriptions and System Responses.........................................................................32

7.6 CRC Calculation..................................................................................................................................36

8.0 WARRANTY AND SERVICE POLICIES.......................................................................................37

8.1 Warranty Statement..............................................................................................................................37

8.2 Service Policies: How to Return an Item for Service...............................................................................37

8.3 Repair Charges and Warranty Exemptions..............................................................................................37

APPENDIX A – CRC – 16 Calculations Table.......................................................................................38

APPENDIX B - MA4040D Redundancy Diagrams ...............................................................................40

APPENDIX C - Remote Access Software Installation & Utility Instructions .....................................41

C1.0 Multi Agile Remote Access Software Installation................................................................................41

C2.0 Multi Agile Remote Access Software Overview..................................................................................42

C3.0 Multi Agile Remote Access Software Utilities.....................................................................................43

C3.1 MA/UC 4040....................................................................................................................................45

C3.2 MA 4050..........................................................................................................................................49

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

vi

1.0 GENERAL INFORMATION

1.1 System Overview

The MA4040D is a modular circuit card, designed for use with the WaveCom MA4000D Series. Each MA4002D

card chassis with common MA4011D (or MA4012D) power/control module can contain up to 10 - MA4040D

independent frequency agile upconverters in a 4U (7”) rack mount configuration. In addition to front panel control,

each MA4002D chassis is also fully remote controllable via a serial RS232 /RS485 Interface or optional integral

SNMP agent.

1.2 Functional Overview

The MA4040D is a fully agile commercial quality IF upconverter for cable, MMDS (Multichannel Multipoint

Distribution System) and LMDS (Local Multipoint Distribution System) applications. The MA4040D also allows

broadband data products to establish an RF channel and create a virtual bus topology on a coaxial backbone.

Advanced design allows a single MA4040D card to cover a frequency band from 53 to 857 MHz, and maintain a

phase noise specification that exceeds the DOCSIS requirements for 64/256 QAM. Remarkably low out of band

noise performance and low spurious are achieved through high level mixing, a microwave frequency IF and multiple

levels of filtering. This advanced, cost effective upconverter offers high performance, flexibility and space efficiency.

Redundancy features make it suitable for the most demanding applications.

1.3 Module Features

•

High level output, +61 dBmV 53 – 857 MHz

•

Front panel selectable output frequency in 12.5 kHz step size

•

Digital slope compensation to achieve <±0.3 dB slope over any channel

•

A range of custom IF input frequencies available

•

Auto IF AGC automatically corrects for input level changes

•

Out-of-band noise performance <-12 dBmV/-30 dBmV/6 MHz

•

Excellent in-band noise performance

•

User defined soft alarms for IF and RF levels can be enabled from remote control

•

RF output mutes when changing output configuration

•

High reliability, state-of-the-art design using microstrip MMIC and surface mount technology

•

Conservative component derating and 100% burn-in help ensure reliable operation

•

Low power consumption

•

All local oscillators are frequency synthesized and locked to a common internal high stability reference

1.4 System Features

•

Local control via LCD and 4 soft touch push buttons

•

Remote control via RS232/RS485/Terminal or optional SNMP

•

FLASH memory for easy software updates

•

Front panel displays IF and RF power levels

•

International internal switching power supply (100 – 240 VAC) (Optional –48 VDC power supply)

•

Internal high reliability fan ensures cool operation for long product life

•

1-to-1 Redundancy

•

Durable design is reflected in the stainless steel chassis and lexan labels

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

7

1.5 Specifications

IF INPUT

IF Frequency (center of the band) 44.00 MHz (optional 36.125 MHz or 43.75 MHz)

Bandwidth Passband 6 MHz (optional 8 MHz)

Input Level +25 to +35 dBmV (total power)

Impedance 75 ohm

Return Loss 20 dB

Connector F type (female)

IF Detector Accuracy 1 dB

IF attenuator Step Size 0.05 dB typical

IF AGC (for carrier/digital input) enable/disable

RF OUTPUT

Frequency Range 53 to 857 MHz (band center)

Frequency Step Size 12.5 kHz

Frequency Accuracy 2 ppm

Frequency Response (any 5 MHz band) ±0.3 dB

Frequency Response (any 7 MHz band) ±0.4 dB (for wide band options)

Group Delay (any 5 MHz band) 15 nsec p-p max (8 nsec typ)

Output Level +61 dBmV max.

Output Level Step Size 0.05 dB typical

RF Detector Accuracy ±1.0 dB typical

Gain Control Range +45 to +61 dBmV

Impedance 75 ohm

Return Loss (inband) 16 dB

Connector F type

RF Monitor Point (calibrated) 20 dB ± 0.5 dB

Spurious (50 MHz to 950 MHz) -60 dBc (70 dBc typ)

Phase Noise

Broadband Noise

(average noise all Channels outside ± 18 MHz) -12 dBmV/6 MHz (-15 dBmV/6 MHz typ)

Modulated Adjacent Noise (6 MHz channel)

Modulated Adjacent Noise (8 MHz channel option)

Carrier Mute Automatic upon frequency change

Redundancy switching speed (1 to 1) 50 ms

1 to 10 kHz (double side band noise power) -37 dBc (-40 dBc typ)

10 to 50 kHz (double side band noise power) -54 dBc (-57 dBc typ)

50 kHz to 3 MHz (double side band noise power) -53 dBc (-55 dBc typ)

10 kHz Offset (SSB) -95 dBc/Hz @ 10 kHz (99 dBc/Hz typical)

-11 dBmV/8 MHz (8 MHz option)

-30 dBmV/6 MHz at twice RF frequency

± 3 to 3.75 MHz -58 dBc min (>60 typ)

± 3.75 to 9 MHz -62 dBc min (>64 typ)

± 9 to 15 MHz -65 dBc min

± 4 to 5 MHz -58 dBc min

± 5 to 12 MHz -61 dBc min

± 12 to 20 MHz -64 dBc min

ELECTRICAL AND MECHANICAL

Remote Control Serial Interface RS232 or RS485 (software selectable)

Connector Dual RJ45

Power Requirement 100 to 240 VAC, 50 to 60 Hz (MA4011D)

Power Consumption 400 VA maximum

Operating Temp 10 to 40°C (50 to 104°F)

Mounting Standard 19” (48.3 cm), 4U (7”) rack space

Dimensions (MA4002D Chassis) 19” (w) x 14.25” (d) x 7” (h) (48.3 x 36.2 x 13.2cm)

Shipping Weight

MA4002D Chassis with MA4011D P/C Module 18 lbs. (8.2 kg)

MA4040D Upconverter card (each) 1.2 lb. (0.6 kg)

F Connectors ANSI SP 406-1998

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

(Optional SNMP over IEEE802.3 10-Base-T Ethernet)

Optional –48 VDC (MA4012D)

Approved: D.P.

8

INTERFACE

Power +10.3 V @ < 1A

Communication I2C

+5V @ < 200 mA

+24V @ < 400mA

POWER/CONTROL MODULE (MA4011D AND/OR MA4012D)

Internal Output Power +12V/+5V/+24V

Internal Communication Bus I2C

Internal Reference (10 MHz) 2 ppm

Remote Control RS232 or RS485 (software selectable)

Connector Dual RJ45

Power Requirements 100 to 240 VAC, 50 to 60 Hz (MA4011D)

Power Consumption 400 VA max.

Operating Temperature 10 to 40oC (50 to 104oF)

Mounting Standard 19” (48.3 cm) - 4U (7”) rack space

Shipping Weight 5 lbs.

(Optional SNMP)

-48VDC (MA4012D)

ACCESSORIES

RS232/485 Serial Interface Adapter

MA4000 COMKIT

SNMP Manual (with Option 2S1 only)

OPTIONS

MA4040D Power/Control Module (MA4011D and/or MA4012D)

1P1 - Input-Digital 44.00 MHz with 8 MHz Passband 2S1 - SNMP Proxy Agent and Interface

1P2 - Input-Digital 36.125 MHz with 8 MHz Passband 2R1 - Additional PS4011D (100 to 240 VAC) Power Supply Module

1P4 - 43.75 MHz IF with 8 MHz Passband 2R2 - Additional PS4012D (-48 VDC) Power Supply Module

1P5 - 44.00 MHz IF with 18 MHz Passband

2H1 - +63 dBmV RF Output

Chassis

8F1 - Front Intake - Fan Tray

Specifications subject to change without notice.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

9

2.0 INSTALLATION

2.1 Unpacking the Unit

Carefully remove the equipment from its packing material and set it on a solid surface, such as a table or desk. If it

appears damaged in any way, notify the carrier, and keep all packing materials for inspection by the carrier’s

agent.

2.2 Operating Environment

The MA4002D chassis includes an active cooling fan tray which forces cooling air from the bottom through to the

top of the chassis. (See options (p 8) for selection of front air intake – rear air intake is factory default). For

adequate ventilation, a space of 1U (1.75”) should be left in the rack, directly above the MA4002D chassis for

warm air exhaust. It is designed to operate at temperatures ranging from 10 to 40oC (50 to 104oF). As with all

electrical equipment, operation at excessive temperature accelerates the deterioration of components. For this

reason, measures should be taken to prevent the build up of excessive heat in the rack.

2.3 Power Requirements

The equipment has an international auto-ranging internal power supply which allows it to be powered from any 100

- 240 VAC; 50 - 60 Hz source. The power source should be capable of delivering a minimum of 400 watts per unit.

Check the total current consumption of all equipment on the same line before applying power to the MA4000D

system. Avoid sharing an AC source that feeds heavy motors or other equipment, which require large current

drains.

2.4 Rack Mounting

The MA4000D system is designed for standard rack mounting in a 19” equipment rack. It requires 4U (7.00”) of

vertical rack space. It should be installed in a rack allowing access to the back of the unit. The upconverter should

be isolated from strong RF radiation emanating from local equipment in the rack. Power line transients that may

cause damage to the unit should be avoided.

2.5 MA4040D Upconverter Module Installation/Replacement

1. Power off the chassis using the rear panel AC switch

2. Disconnect the RF cables from the rear of the corresponding module

3. Using a screwdriver, loosen the corresponding front panel captive screws until the module is free to pull forward

4. Insert the replacement module and retighten the front panel captive screws

5. Turn on the AC power switch

6. Reconnect the rear panel RF cables

7. Configure the output frequency, IF level, and RF level

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

10

2.6 MA4012D -48 VDC Redundant Power Supply Module Installation/Replacement

Caution! To avoid energy hazard from arcing, etc. from the 48v supply lines, the module being

“hot swapped” must be powered down before removal. Separate switches for each module supply

line are recommended.

Attention! Il est fortement recommande d’installer un interrupteur pour chaque fil electrique de 48v

qui se rend aux modules afin d’eviter la formation d’une etincelle pendant le replacement d’un

module

Achtung! zu vermeidet Energie Gefahr von Elektrodenüberschlag, usw. von die 48 Volt Versorgung

Linien, der Modul wird ersetzt muß geschaltet werden ab vor Ersetzen. Getrennte Schalter für jede

Modul Versorgung Linie werden für Sicherheit empfohlen.

1. Lift the tabs on the -48Vdc input connector to release the power wires. Then pull the power wires out of

the connector.

2. Using a flat head screwdriver, disconnect the PS4012D module from the power supply chassis by

unscrewing the captive screw on the back of the module.

3. Grip the handle of the PS4012D module and pull it out of the power supply chassis using your other hand

to support the middle of the module as it slides out.

4. Replace with a new PS4012D module by reversing steps 3 through 1.

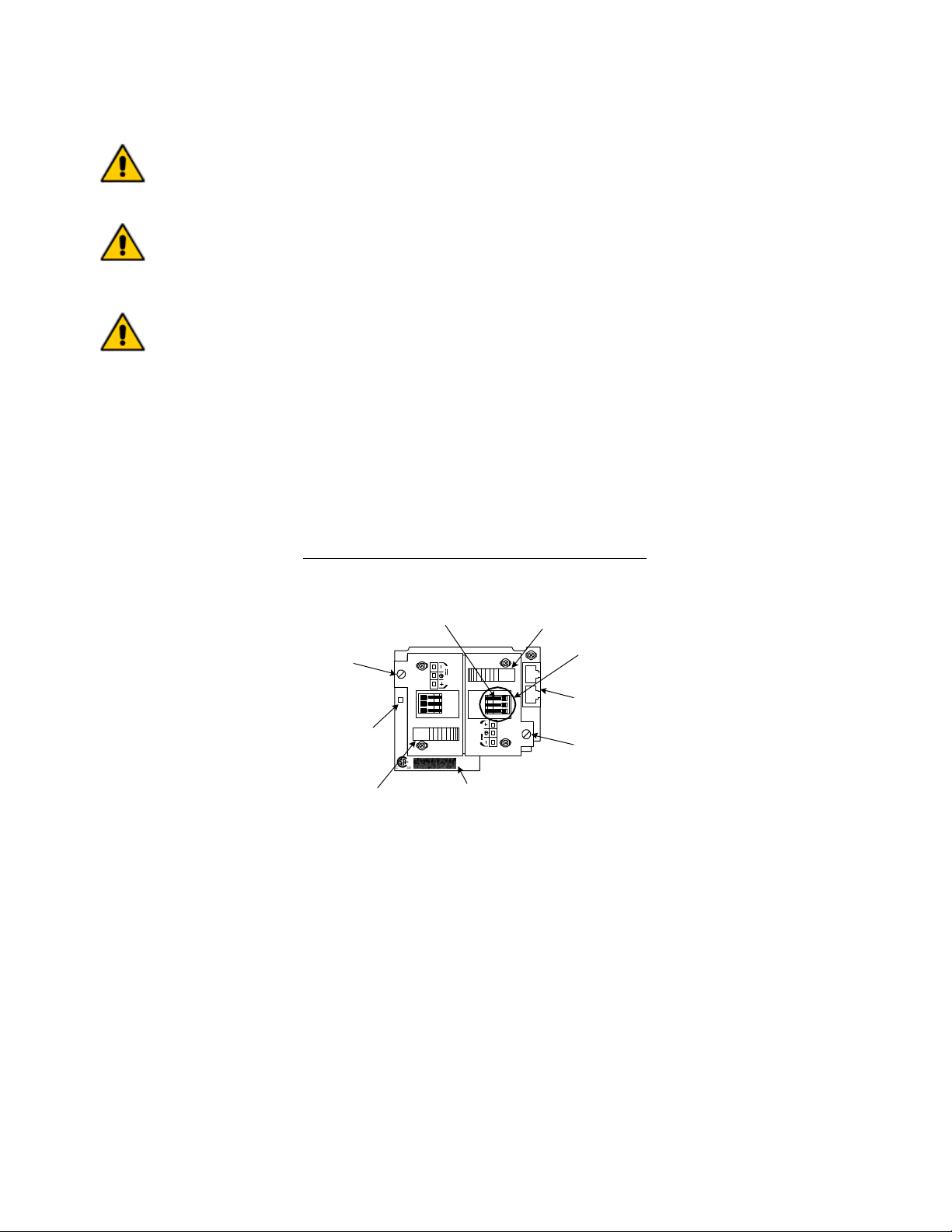

DD IAGRAM IAGRAM 2.62.6AA : MA4012D – D: MA4012D – DETAILED ETAILED RR EAR EAR PP ANELANEL

Captive

Screw

Ethernet Port

Activity LED

(SNMP Option)

PS4012D

Pull Handle

-48 VDC Input

Connector Tabs

PS4012D

Pull Handle

-48 VDC Input

Connector

7A MAX.

48V

36 - 75VDC

PS4012D

PS4012D

REMOTE

36 - 75VDC

7A MAX.

INTERFACE

48V

RJ45 Ports for

Remote Control

Captive

MADE IN

CANADA

Screw

CH401xD

Power Supply

Chassis

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

11

2.7 MA4011D 110/240 VAC Redundant Power Supply Module Installation/Replacement

Caution!

To avoid electrical shock hazard, disconnect power to the module being “hot swapped” before

removal.

Do not reach into the open bay when module is removed.

Replacement of power supply modules must be performed by qualified service personnel only.

Attention!

Le remplacement de modules de l’alimentation électrique doit être réservé au personnel de

l’entretien qualifié.

Pour éviter le danger du choc électrique, veuillez couper le courant du module à échanger avant

de l’enlever.

Ne touchez pas le renforcement ouvert lorsque le module est enlevé.

Vorsicht!

Die Netzgerätbaugruppe darf nur von qualifiziertem Service-Personal ausgetauscht werden.

Zur Vermeidung eines Elektroschocks muß die Stromzuführung immer abgeschaltet werden, bevor

die Netzgerätbaugruppe herausgenommen wird.

Nach der Herausnahme der Netzgerätbaugruppe nicht in den Hohlraum greifen.

1. Pull the ac line cord out of the power entry module on the PS4011D module to be swapped.

2. Using a flat head screwdriver, disconnect the PS4011D module from the power supply chassis by

unscrewing the captive screw on the back of the module.

3. Grip the handle of the PS4011D module and pull it out of the power supply chassis using your other hand

to support the middle of the module as it slides out.

4. Replace with a new PS4011D module by reversing steps 3 through 1.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

12

3.0 OPERATION

UPCONVERTER

3.1 Front Panel Description

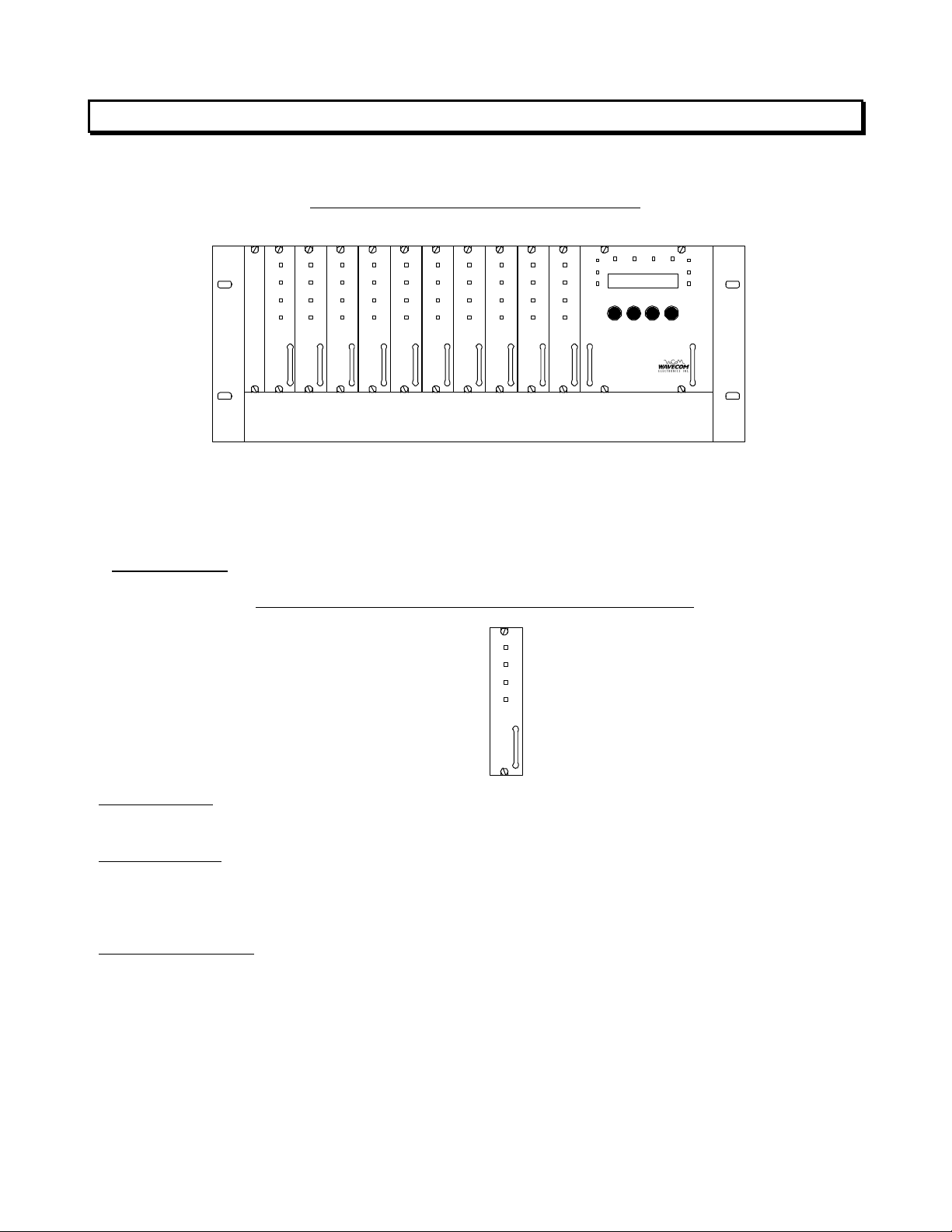

DD IAGRAM IAGRAM 3.13.1AA :F:FRONT RONT PP ANEL ANEL - MA4000D S- MA4000D SYSTEMYSTEM

A B C D E F G H I J K

24V

POWER ALARM MODULE

5V

10V

STATUS STATUS

DOWN UP

SYSTEM 4000

POWER SUPPLY

WaveCom MA4011D

RF ENABLED

UPCONVERTER

WaveCom

MA4040D

POWER

MODULE

SELECT

ALARM

RF ENABLED

UPCONVERTER

WaveCom

MA4040D

POWER

MODULE

SELECT

RF ENABLED

UPCONVERTER

WaveCom

MA4040D

MODULE

SELECT

ALARM

POWER

POWER

RF ENABLED

MODULE

SELECT

ALARM

UPCONVERTER

WaveCom

MA4040D

POWER

POWER

POWER

POWER

POWER

POWER

RF ENABLED

RF ENABLED

RF ENABLED

RF ENABLED

RF ENABLED

RF ENABLED

MODULE

MODULE

MODULE

MODULE

MODULE

UPCONVERTER

WaveCom

MA4040D

SELECT

MODULE

SELECT

ALARM

ALARM

UPCONVERTER

WaveCom

MA4040D

SELECT

SELECT

SELECT

UPCONVERTER

WaveCom

MA4040D

SELECT

ALARM

ALARM

UPCONVERTER

WaveCom

MA4040D

ALARM

ALARM

ALARM

UPCONVERTER

UPCONVERTER

WaveCom

WaveCom

MA4040D

MA4040D

As shown in Diagram 3.1A, the power/control module front panel has an LCD display, four soft touch push buttons,

and 4 indicator LEDs. All other modules have 4 indicator LEDs. Modules are configured using both the LCD display

and push buttons on the power supply module, or via the remote interface. If no configuration adjustments are being

made via the front panel controls, the display back light will shut off after a five minute time out. Pressing any of the

front panel buttons will re-enable the back light.

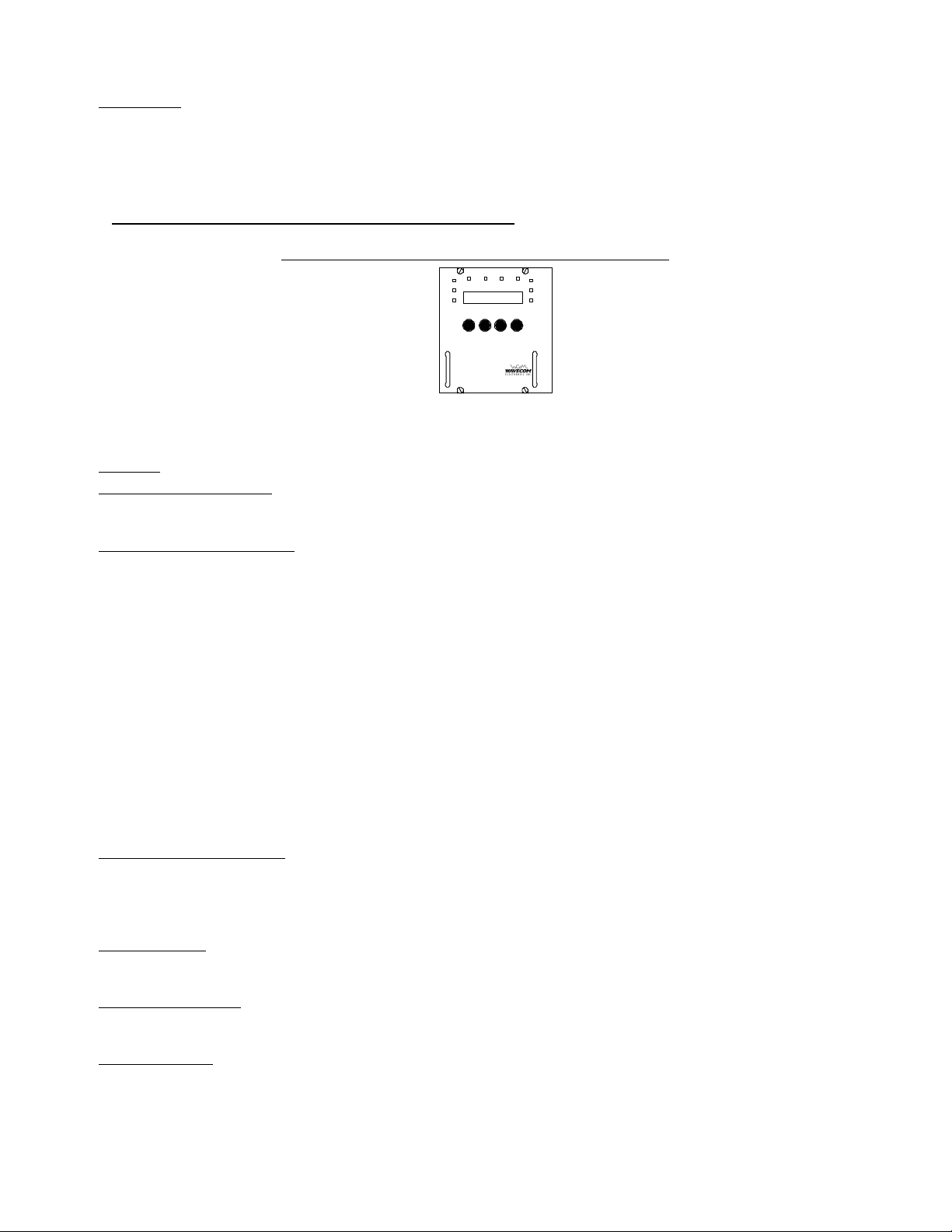

3.1.1 MA4040D

SELECT

MODE MODULE

SELECT

24V

AUX

5V

10V

DD IAGRAM IAGRAM 3.13.1BB : F: FRONT RONT PP ANEL ANEL - MA4040D U- MA4040D UPCONVERTER PCONVERTER MM ODULEODULE

POWER

RF ENABLED

MODULE

SELECT

ALARM

WaveCom

MA4040D

POWER ON LED

When the green POWER ON indicator is illuminated, the module has been correctly installed and powered on.

RF ENABLED LED

When the green RF ENABLED indicator is illuminated, the internal output circuitry is enabled to provide an RF

output. The RF ENABLED indicator does not necessarily indicate the presence of an output, it only reflects that the

module is capable of an RF output if an IF input is applied and the levels configured.

MODULE SELECT LED

When the green MODULE SELECT indicator is illuminated, it indicates that the corresponding module has been

selected from the front panel or via the remote control interface.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

13

ALARM LED

The red MA4040D ALARM indicator has two modes. A flashing Alarm LED indicates a non-critical alarm condition

(i.e. soft alarm). A constant Alarm LED indicates a critical alarm condition (i.e. hard alarm). Detailed alarm

information is available by selecting the corresponding module from the front panel and observing the status and

error codes on the LCD display.

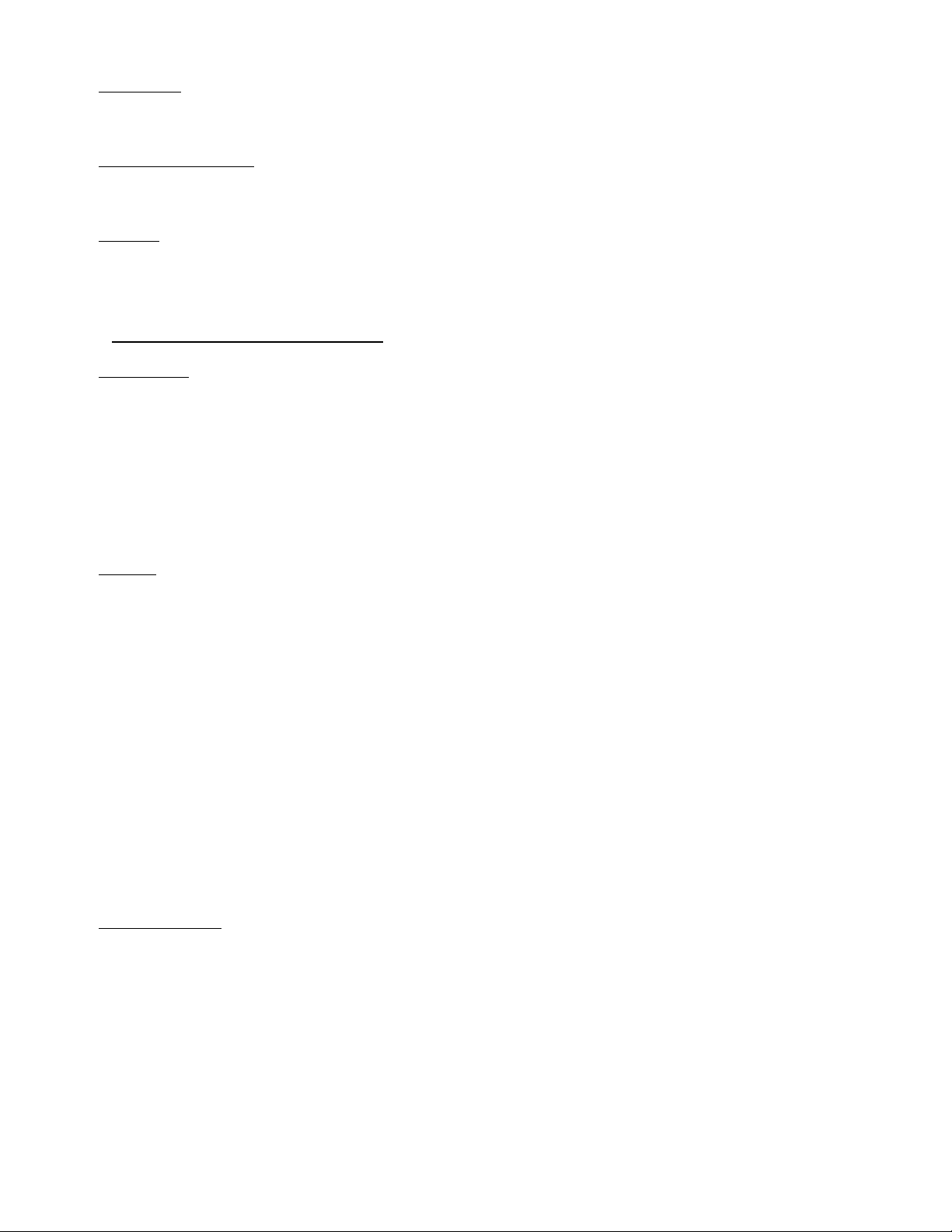

3.1.2 MA4011D (or MA4012D) Power/Control Module

DD IAGRAM IAGRAM 3.13.1C C :: FF RONT RONT PP ANEL ANEL - MA4011D P- MA4011D POWER OWER SS UPPLYUPPLY

24V

POWERALARMMODULE

5V

10V

STATUS STATUS

24V

AUX

SELECT

5V

10V

DOWN UP MODEMODULE

SYSTEM 4000

POWER SUPPLY

WaveCom MA4011D

SELECT

* The MA4011D and the MA4012D power supplies have the same front panel functions and

displays. Diagram 3.1C represents both the MA4011D and the MA4012D.

DISPLAY

The first line on the display is the Mode Information Line. It shows the settings for the currently selected mode. The

possible operating modes depend upon the currently selected module. (See Section 3.2, Front Panel Operating

Modes (pp 14, 15) for a detailed description of the available modes).

The second line on the display is the Status Information Line. The Status Line is divided as follows:

The two leftmost characters are “mX” where X is replaced by the currently selected module address. Looking at

the front of the MA4000D system, the module addresses are assigned starting with module A in the leftmost slot in

the chassis and module K in the Power Supply. The modules in between are lettered B through J. (As shown in

Diagram 3.1A (p 12)). Modules can be installed in any open slot, and not all slots need to be filled.

The next two characters are “sXX” where “XX” indicate the status code for the currently selected module. Refer to

Section 5.0, Status Codes (pp 23, 24) for a list of current status codes.

The next two characters are “eXX” where “XX” indicates the error code for the currently selected module. (This

code is only displayed when it is non-zero). Refer to Section 6.0, Error Codes (pp 25, 26) for the list of current

error codes.

The final three or four characters of the second line can display the following information:

•

When under Remote Control and local control is disabled, it will read “RMT”

•

When under Local Control and a MA4040x card is selected, it will display the current firmware revision of the MA4040x

card (ex “r118”)

•

When under Local Control and a module other than a MA4040x is selected, this area will be blank

MODULE SELECT BUTTON

The MODULE SELECT button allows the user to select the module to display and/or control (the MODULE

SELECT LED will be lit on the selected module, and the LCD display will indicate the module address in the status

line).

MODE BUTTON

The MODE button allows the user to cycle through each of the various modes for the selected module.

UP/DOWN BUTTONS

The UP/DOWN arrow buttons adjust the settings for the currently selected mode.

POWER ON LED

When the green POWER ON indicator is illuminated, the module has been correctly installed and powered on.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

14

ALARM LED

A constant Alarm LED on the MA4011D indicates a critical alarm condition. Detailed alarm information is available

by selecting the module from the front panel and observing the status and error codes on the LCD display.

MODULE SELECT LED

When the green MODULE SELECT indicator is illuminated, it indicates that the corresponding module has been

selected from the front panel or via the remote control interface.

AUX LED

This LED is reserved for future use.

3.2 Front Panel Operating Modes

3.2.1 MA4040D Upconverter Modes

FREQUENCY

When this mode is selected, the display will read : Frq XXX.XXXX MHz

The displayed frequency is the current configured Output Frequency. To adjust the output frequency, use the

UP/DOWN arrow buttons. Single stepping will allow 12.5 kHz adjustment, while holding the buttons depressed will

change the frequency more quickly.

* The displayed frequency represents the center of the band.

* During frequency change, the output is muted and the RF ENABLED indicator is turned off for

5 seconds to avoid undesirable interference.

AUTO IF

When this mode is selected, the display will read: IF AGC Enabled

or

IF AGC Disabled

Pressing the UP/DOWN buttons will toggle the display between Enabled and Disabled. When enabled, the

MA4040D will automatically optimize the IF level and ensure it is within a pre-set threshold range (default ±0.5 dB).

When disabled, the IF level can be manually adjusted as described in the next section.

* The Auto IF mode should only be used for continuous IF inputs (non-bursty).

* The Auto IF mode should be used for proper operation in redundant mode.

* If the IF level is not within ±4.0 dBmV of the optimum level during Auto IF mode, the output will

be muted to avoid undesirable interference, and the Alarm LED will be on.

* At the time of shipping, the AUTO IF is enabled.

* Because the IF AGC has been optimized for digital QAM signals, it is recommended that

AUTO IF is disabled for analog signals.

IF LEVEL ADJUST

When this mode is selected, the display will read: IFPwr ±±XX.X dB

The display indicates the approximate IF power level measured at the internal IF power detector. To adjust the IF

level, use the UP/DOWN arrow buttons. To configure the MA4040D Upconverter for optimum performance, the IF

level should be adjusted to read approximately 0.0 dB (-0.5 to +0.5). An IF level less than 0 dB will degrade noise

performance and a level above 0 dB will promote intermodulation products.

* The IF level can only be adjusted if the Auto IF mode is disabled.

WaveCom Electronics Inc

MA4040D Manual; MAN1L0901 REV 13(0104)

Approved: D.P.

15

Loading...

Loading...