TM

155TM Single and 255

Dual

Cartridge Seals

Patented

n Global acceptance and satisfaction across a variety of industrial applications

n Exclusive face design for superior emissions control capability

n Stable, secure sealing under fluctuating conditions

n Patented features assure precision alignment from start-up

n Versatile and cost-effective

ISO 9001

CERTIFIED

Delivering the best value

in cartridge sealing today

CHESTERTON

®

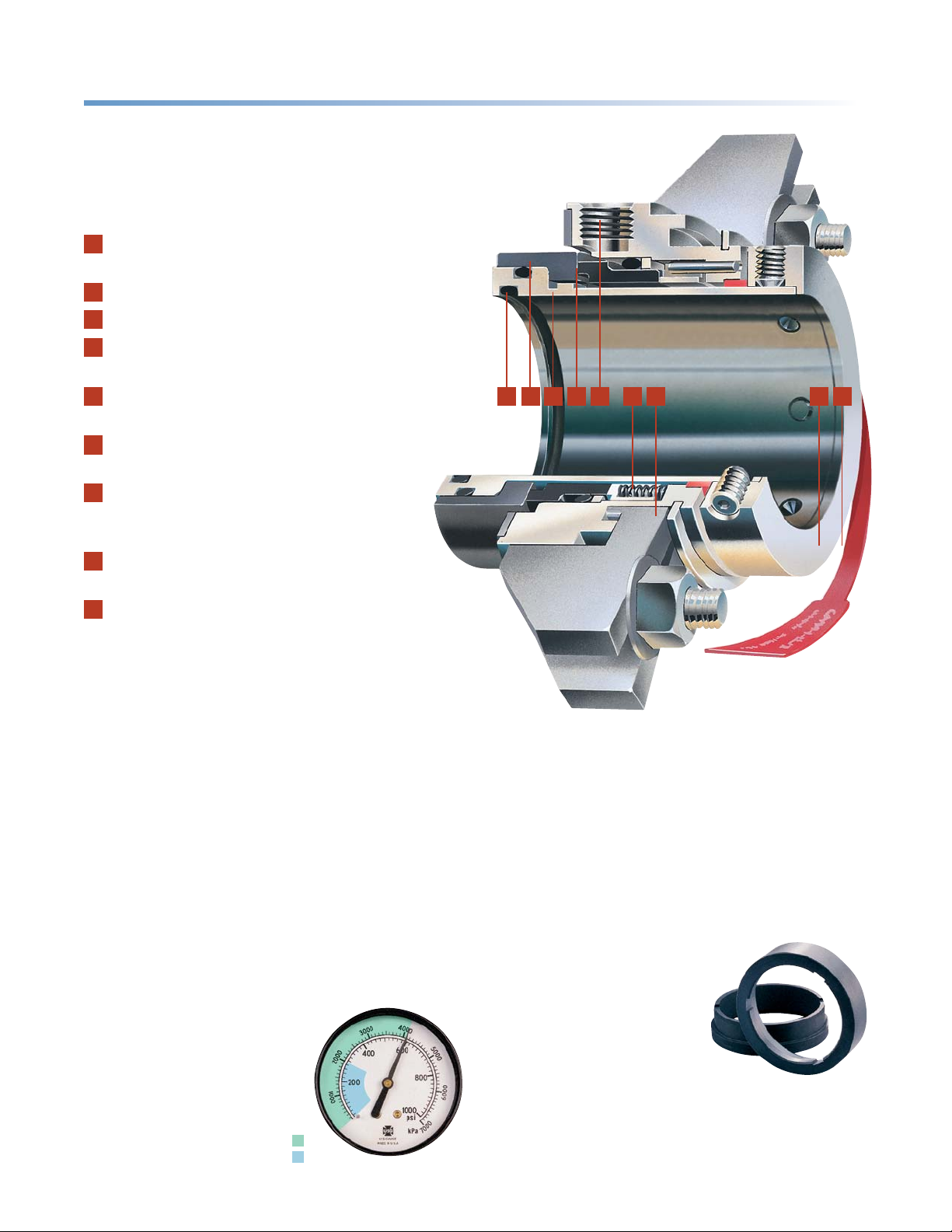

155TM

Cartridge Single Seal

Construction Details

1

All O-rings are either static or move on

non-metallic, non-fretting surfaces.

2

Seal face support shoulder is precisely square.

3

Integral drive pads cannot fall out.

4

Hydraulically balanced faces

for low frictional heat.

5

Flush port can be rotated 360° for ease

of piping as required.

6

Stationary springs, isolated from fluid

to prevent clogging.

7

Patented Adjustable Gland™

fits common bolt arrangements

without modification.

8

Self- Centering Lock Ring™

for superior concentricity.

9

Centering strap for simple installation.

1•2•3•4•5•6•7

8•9

•

•

Self-Centering Lock Ring™

ensures reliability

The patented Self-Centering Lock Ring

makes installation precise for correct face mating

and sustainable sealing. Cloverleaf 3- point

contact ensures concentricity to the shaft.

Faces start out square and stay square to prevent

the intrusion of contaminants or abrasives.

Also, constant face squareness reduces

opportunities for fluid leakage and uneven wear.

Superior reliability

during system variations

Pressure surges at start-up and

shut- down can create seal reliability

problems. The 155 seal can handle

50% to 100% greater transient

pressure than conventional seals

and provides a “margin of safety”

during normal surges.

CHESTERTON 155 Seal

Conventional Seal

Dynamic stress relief keeps faces closed

Variances in temperature or pressure, fluid phase changes,

or water hammer can create dynamically changing

stresses on the seal faces. Common face geometries

distort at the mating surface under such conditions

and create drastic wear. Chesterton face geometry

compensates for stresses in the body of the seal ring,

away from the critical face mating surfaces.

Face material

interchangeability

With the 155, the interchanging is

a fast and easy process, with seal

function and reliability assured.

Standard face materials are

silicon carbide or carbon.

The carbon can be swapped for

silicon carbide, tungsten carbide or

Duplex Carbide™, which provides the utility

of two hard faces but with lower frictional heat.

All faces are interchangeable with the

225 and 255 dual seals.

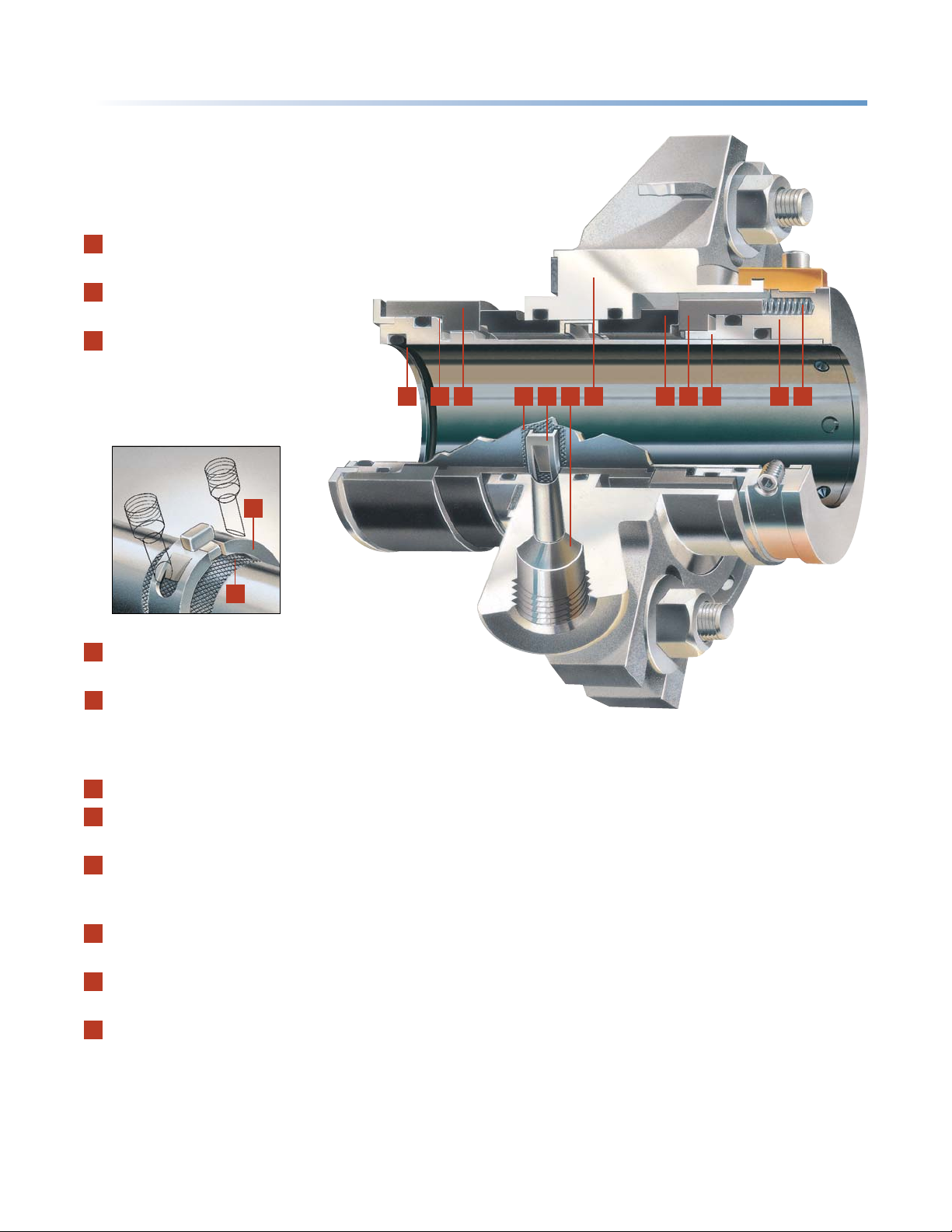

255TM

Cartridge Dual Seal

Construction Details

1

Every O-ring is either static or moves on

a non-fretting, non-metallic surface.

2

Precision seal ring support shoulder

maintains rotary alignment.

3

Inboard rotary and stationary faces.

Dynamic stress-relieving seal rings,

mated over a narrow cross-section

for low heat generation.

5

1•2•3

CHESTERTON

®

•

•

•

•

4•5•6

7

8•8• 9

10• 11

•

•

4

4

Profiled sleeve provides positive

pumping of barrier fluid.

5

Patented shuttle slides within gland to

decouple faces from gland misalignment,

channel barrier fluid, and provide anti-rotation

for stationary seal rings.

6

Barrier fluid ports provide high capacity cooling.

7

Universal gland fits majority of pumps.

ANSI oversize and API glands available.

8

Outboard stationary and rotary faces,

identical to inboard set for simple assembly,

low replacement inventory.

9

Inboard and outboard integral drive pads

cannot loosen or fall out.

10

Patented Self-Centering Lock Ring™

for superior concentricity.

11

Revolutionary Unified Seal Alignment™

requires only one set of springs to provide

constant loading of all four faces.

Springs are isolated from process and

barrier fluids.

•

Built for the future of emissions control

The Chesterton 255 seal is designed to meet

environmental regulations for emissions control.

Advanced technology for applications flexibility

The exclusive design of the 255 enables it to operate

in double-mode (barrier fluid pressure higher than

stuffing box pressure) or tandem-mode (barrier fluid

pressure lower than stuffing box pressure).

Staying cool in operation and under pressure

The 255 handles 50% to 100% more pressure than

typical seals, providing users with a “margin of safety”

at start-up and shut-down when transient surges

often occur. The 255 features an internal positive

barrier fluid pumping system with wide flow channels

for efficient removal of heat. To test the 255’s cool

running, the 255 and a widely used competitive double

seal were run under identical conditions with repeated

shutoffs. Test conditions: 1.875” (48 mm) shaft, water

barrier fluid room temperature, 1750 RPM, closed

convection system. Results: 255 ran cool and steady

while the conventional seal overheated and flashed.

CHESTERTON

®

155 STANDARD – Dimensional Data/Inch

SHAFT

SIZE

1.000 4.65 1.75 2.00 0.63 1.89 2.88 3.01 3.13 –

1.125 4.69 1.88 2.03 0.63 1.89 2.92 3.05 3.17 –

1.125*** 4.69 1.88 2.03 0.63 1.89 2.92 3.05 3.17 –

1.250 4.90 2.00 2.26 0.63 1.89 3.13 3.26 3.38 –

1.375 5.04 2.13 2.42 0.63 1.89 3.27 3.40 3.52 –

1.375*** 5.04 2.00 2.42 0.63 1.89 3.27 3.40 3.52 –

1.500 5.23 2.25 2.62 0.63 1.89 3.46 3.59 3.71 –

1.625 5.29 2.38 2.68 0.63 1.89 3.52 3.65 3.77 –

1.750 5.41 2.50 2.80 0.63 1.89 3.64 3.77 3.89 –

1.875 5.53 2.63 2.93 0.63 1.89 3.76 3.89 4.01 –

2.000 5.74 2.75 3.18 0.63 1.89 3.97 4.10 4.22 –

2.125 6.04 2.88 3.43 0.63 1.89 4.27 4.40 4.53 –

2.250 6.14 3.00 3.55 0.63 1.89 4.38 4.51 4.63 –

2.375 6.29 3.13 3.59 0.63 1.89 4.52 4.65 4.77 –

2.500 6.41 3.25 3.80 0.63 1.89 4.65 4.78 4.90 –

2.625 7.63 3.63 4.00 0.88 2.50 – 5.35 5.48 5.60

2.750 7.76 3.75 4.13 0.88 2.50 – 5.48 5.60 5.73

2.875 7.88 3.88 4.25 0.88 2.50 – 5.60 5.73 5.85

3.000 8.01 4.00 4.44 0.88 2.50 – 5.73 5.85 5.98

3.125 8.13 4.13 4.55 0.88 2.50 – 5.85 5.98 6.10

3.250 8.26 4.25 4.69 0.88 2.50 – 5.98 6.10 6.23

3.375 8.38 4.38 4.80 0.88 2.50 – 6.10 6.23 6.35

3.500 8.51 4.50 4.94 0.88 2.50 – 6.23 6.35 6.48

3.625 8.63 4.63 5.05 0.88 2.50 – 6.35 6.48 6.60

3.750 8.76 4.75 5.14 0.88 2.50 – 6.48 6.60 6.73

3.875 8.88 4.88 5.26 0.88 2.50 – 6.60 6.73 6.85

4.000 9.01 5.00 5.44 0.88 2.50 – 6.73 6.85 6.98

4.125 9.13 5.13 5.55 0.88 2.50 – 6.85 6.98 7.10

4.250 9.18 5.25 5.69 0.88 2.50 – 6.89 7.02 7.14

4.375 9.30 5.38 5.81 0.88 2.50 – 7.02 7.14 7.27

4.500 9.43 5.50 5.94 0.88 2.50 – 7.14 7.27 7.39

4.625 9.56 5.63 6.06 0.88 2.50 – 7.27 7.39 7.52

4.750 9.76 5.75 6.22 0.88 2.50 – 7.47 7.60 7.72

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

MAX

C

SB

DEPTHOBLENGTH

MIN

E

F G/ MIN

BOLT CIRCLE

BY BOLT SIZE

3/8” 1/2” 5/8” 3/4”

155 STANDARD – Dimensional Data/Metric

SHAFT

SIZE

25 118 44 51 16 48 70 72 74 –

28 118 47 52 16 48 70 72 74 –

30 124 49 57 16 48 76 78 80 –

32 124 51 58 16 48 77 79 81 –

33 124 52 59 16 48 76 78 80 –

35 128 54 62 16 48 80 82 84 –

38 133 57 67 16 48 85 87 89 –

40 134 59 68 16 48 86 88 90 –

43 134 62 69 16 48 86 88 90 –

45 140 64 73 16 48 92 94 96 –

48 139 67 74 16 48 91 93 95 –

50 145 69 78 16 48 97 99 101 –

55 150 74 83 16 48 102 104 106 –

60 160 79 91 16 48 112 114 116 –

65 194 92 102 22 64 – 132 134 138

70 197 95 105 22 64 – 135 137 141

75 203 100 113 22 64 – 141 143 147

80 207 105 116 22 64 – 144 146 150

85 213 110 122 22 64 – 151 153 157

90 216 115 125 22 64 – 154 156 160

95 222 120 131 22 64 – 160 162 166

100 229 127 138 22 64 – 167 169 173

110 236 136 148 22 64 – 174 176 180

120 248 145 158 22 64 – 186 188 192

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

MAX

C

SB

DEPTHOBLENGTH

MIN

E

F G/ MIN

BOLT CIRCLE

BY BOLT SIZE

8 mm 10 mm 12 mm 16 mm

G

B

155 – Standard Version

C

E

F

STANDARD MATERIALS**

Rotary Faces:

n

Silicon Carbide

n Tungsten Carbide

Stationary Faces:

n Duplex Carbide™

n Carbon

n Silicon Carbide

n Tungsten Carbide

All Metal Parts:

n

316SS

Springs:

n Hastelloy C*

O-Rings:

n Fluorocarbon installed;

EPR included

n FEPM installed;

No spares

OPERATING LIMITS

Speed Limits:

n To 4000 fpm

Temperature Limits:

n To 300°F

Ethylene Propylene

n To 400°F (205°C

Fluorocarbon, FEPM

n To 500°F

Perfluoroelastomer

Pressure Limits:

n To 600 psig

* Haynes International, Inc

Registered Trademark.

** Other materials available upon request.

*** 155T Sizes.

(

150°C

(

260°C

(

(

20 mps

)

)

)

40 bar g

)

)

155 CAST – Dimensional Data/Inch

SHAFT

SIZE

1.000 4.13 1.75 2.00 0.47 1.98 2.88 3.01 –

1.125 4.13 1.88 2.03 0.47 1.98 3.01 3.13 –

1.250 4.13 2.00 2.26 0.47 1.98 3.13 3.26 –

1.500 5.01 2.25 2.62 0.47 1.98 3.38 3.51 –

1.625 5.01 2.38 2.66 0.47 1.98 3.51 3.64 –

1.750 5.51 2.50 2.80 0.47 1.98 3.63 3.76 –

1.875 5.51 2.63 2.93 0.47 1.98 3.76 3.88 –

2.000 5.51 2.75 3.18 0.47 1.98 4.01 4.13 –

2.125 6.01 2.88 3.28 0.47 1.98 4.26 4.38 4.51

2.250 6.01 3.00 3.55 0.47 1.98 4.38 4.51 4.63

2.375 6.01 3.13 3.59 0.47 1.98 4.42 4.55 4.67

2.500 6.52 3.25 3.80 0.47 1.98 4.64 4.76 4.89

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

1/2”3/8” 5/8”

CHESTERTON

G

B

®

155 CAST – Dimensional Data/Metric

SHAFT

SIZE

25 105 44 51 12 50 72 74 76

28 105 47 52 12 50 75 77 79

30 105 49 57 12 50 76 78 80

32 105 51 58 12 50 78 80 82

33 114 52 59 12 50 79 81 83

38 127 57 67 12 50 84 86 88

40 127 59 68 12 50 86 88 90

43 127 62 69 12 50 89 91 93

45 140 64 73 12 50 90 92 94

48 140 67 74 12 50 93 95 97

50 140 69 78 12 50 95 97 99

55 153 74 83 12 50 100 102 104

60 153 79 91 12 50 111 113 115

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F

BOLT CIRCLE

BY BOLT SIZE

G/MIN

10 mm8 mm 12 mm

155 OVERSIZE – Dimensional Data/Inch

SIZE

GLAND

OD

MAXCMIN

SHAFT

1.125 5.29 2.50 2.75 0.63 1.89 3.59 3.72 3.84 – –

1.375 5.57 2.68 3.00 0.63 1.89 3.86 3.99 4.11 – –

1.750 6.64 3.37 3.75 0.63 1.89 4.93 5.06 5.18 – –

1.875 6.58 3.42 3.81 0.63 1.89 4.88 5.01 5.13 – –

2.125 7.31 3.75 4.25 0.63 1.89 5.60 5.73 5.85 – –

2.500 8.14 4.37 4.75 0.63 1.89 6.43 6.56 6.68 – –

2.625 8.04 4.38 4.78 0.88 2.50 – 5.83 5.96 6.08 6.21

2.750 8.04 4.28 4.78 0.88 2.50 – 5.83 5.96 6.08 6.21

3.000 8.65 4.75 5.39 0.88 2.50 – 6.44 6.57 6.69 6.82

3.375 8.54 4.78 5.27 0.88 2.50 – 6.33 6.46 6.58 6.71

3.750 9.63 5.78 6.40 0.88 2.50 – 7.41 7.54 7.66 7.79

4.125 9.54 5.78 6.27 0.88 2.50 – 7.33 7.46 7.58 7.71

4.750 11.25 7.03 7.65 0.88 2.50 – 9.04 9.17 9.29 9.42

B

STUFFING BOX

BORE

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

5/8”3/8” 1/2” 3/4” 7/8”

155 – Cast Version

C

E

G

B

155 – Oversize Version

F

CONFIGURATIONS TO FIT YOUR APPLICATION NEEDS

155T:

All of 155 features in a compact

configuration suited for Duriron Mark II

Group I, Goulds 319ST and similar pumps.

CPI Gland:

Quench and drain ports,

plus floating throttle bushing,

in a slotted, universal gland.

ANSI Oversized Gland:

Patented Adjustable Gland™

available for large bore seal

chambers.

155A API:

155 with factory installed glands

having piloting, quench, drain

and floating carbon throttle

bushing to meet API 610.

155V:

Specially designed to fit Viking Pumps.

155P:

Specially designed for flushless

sealing of paper stock up to 3%.

C

E

F

CHESTERTON

®

255 STANDARD – Dimensional Data/Inch

SHAFT

SIZE

1.000 4.12 1.75 1.81 1.36 2.16 2.81 2.94 –

1.125 4.12 1.88 1.94 1.36 2.16 2.95 3.08 –

1.250 4.12 2.00 2.06 1.36 2.16 3.08 3.21 –

1.375 4.37 2.13 2.31 1.36 2.16 3.21 3.34 –

1.500 4.50 2.25 2.44 1.36 2.16 3.33 3.46 –

1.625 5.00 2.38 2.56 1.36 2.16 3.45 3.58 –

1.750 5.50 2.50 2.81 1.36 2.16 3.66 3.79 –

1.875 5.50 2.63 2.94 1.36 2.16 3.78 3.91 –

2.000 5.50 2.75 3.19 1.36 2.16 4.03 4.16 –

2.125 6.01 2.88 3.44 1.36 2.16 4.29 4.42 4.54

2.250 6.01 3.00 3.56 1.36 2.16 4.41 4.54 4.66

2.375 6.01 3.13 3.59 1.36 2.16 4.44 4.57 4.69

2.500 6.51 3.25 3.81 1.36 2.16 4.66 4.79 4.91

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

1/2”3/8” 5/8”

255 STANDARD – Dimensional Data/Metric

SHAFT

SIZE

25 105 44 46 35 55 70 72 74

28 105 47 49 35 55 73 75 77

30 105 49 51 35 55 76 78 80

32 105 51 52 35 55 77 79 81

33 114 54 58 35 55 78 80 82

35 111 54 59 35 55 80 82 84

38 114 57 62 35 55 83 85 87

40 127 59 61 35 55 86 88 90

43 127 64 69 35 55 89 91 93

45 140 64 66 35 55 93 95 97

48 140 69 74 35 55 94 96 98

50 140 69 71 35 55 98 100 102

55 153 74 76 35 55 – 103 105

60 153 79 85 35 55 – 113 115

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

10 mm8 mm 12 mm

G

255 – Standard Version

E

C

B

F

255 ADAPTER VERSION – Dimensional Data/Inch

SHAFT

SIZE

1.000 4.12 1.75 1.81 1.18 2.35 2.81 2.94 –

1.125 4.12 1.88 1.94 1.18 2.35 2.95 3.08 –

1.250 4.12 2.00 2.06 1.18 2.35 3.08 3.21 –

1.375 4.37 2.13 2.31 1.18 2.35 3.21 3.34 –

1.500 4.50 2.25 2.44 1.18 2.35 3.33 3.46 –

1.625 5.00 2.38 2.56 1.18 2.35 3.45 3.58 –

1.750 5.50 2.50 2.81 1.18 2.35 3.66 3.79 –

1.875 5.50 2.63 2.94 1.18 2.35 3.78 3.91 –

2.000 5.50 2.75 3.19 1.18 2.35 4.03 4.16 –

2.125 6.01 2.88 3.44 1.18 2.35 4.29 4.42 4.55

2.250 6.01 3.00 3.56 1.18 2.35 4.41 4.54 4.67

2.375 6.01 3.13 3.59 1.18 2.35 4.44 4.57 4.70

2.500 6.51 3.25 3.81 1.18 2.35 4.66 4.79 4.92

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

MIN

E

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

1/2”3/8” 5/8”

G

255 – Adapter Version

C

B

E

F

CHESTERTON

255 LARGE – Dimensional Data/Inch

SHAFT

SIZE

2.625 6.45 3.63 3.69 1.64 2.52 5.02 5.15 –

2.750 7.71 3.75 4.19 1.64 2.52 5.42 5.55 –

2.875 7.83 3.88 4.32 1.64 2.52 5.50 5.63 –

3.000 7.94 4.00 4.44 1.64 2.52 5.65 5.78 –

3.125 7.99 4.13 4.57 1.64 2.52 5.80 5.93 –

3.250 8.19 4.25 4.69 1.64 2.52 5.93 6.06 –

3.375 8.31 4.38 4.82 1.64 2.52 6.00 6.13 6.26

3.500 8.44 4.50 4.94 1.64 2.52 6.16 6.29 6.42

3.625 8.49 4.63 5.07 1.64 2.52 6.29 6.42 6.55

3.750 8.72 4.75 5.19 1.64 2.52 6.36 6.49 6.62

3.875 8.84 4.88 5.32 1.64 2.52 6.50 6.63 6.76

4.000 8.96 5.00 5.44 1.64 2.52 6.64 6.77 6.90

4.125 8.99 5.13 5.57 1.64 2.52 6.76 6.89 7.02

4.250 8.99 5.25 5.69 1.64 2.52 6.89 7.02 7.15

4.375 9.34 5.38 5.82 1.64 2.52 7.01 7.14 7.27

4.500 9.49 5.50 5.94 1.64 2.52 7.16 7.29 7.42

4.625 9.49 5.63 6.07 1.64 2.52 7.26 7.39 7.52

4.750 10.49 5.75 6.19 1.64 2.52 7.38 7.51 7.64

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

255 LARGE – Dimensional Data/Metric

SHAFT

SIZE

65 164 92 93 42 64 127 131 –

70 196 95 105 42 64 137 141 –

75 202 102 112 42 64 143 147 –

80 203 105 115 42 64 147 151 –

85 211 111 121 42 64 152 156 160

90 214 114 124 42 64 156 160 164

95 221 121 131 42 64 161 165 169

100 228 127 137 42 64 168 172 176

110 237 137 147 42 64 177 181 185

120 266 146 156 42 64 187 191 195

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

255 OVERSIZE – Dimensional Data/Inch

SHAFT

SIZE

1.125 4.49 2.63 2.94 1.48 1.98 3.77 – –

1.375 5.40 2.82 2.99 1.48 1.98 4.02 – –

1.750 6.64 3.51 3.74 1.30 2.16 5.21 5.34 5.46

1.875 5.99 3.57 3.80 1.30 2.16 – 4.94 –

2.125 6.99 3.89 4.24 1.30 2.16 – – 5.89

2.500 7.77 4.51 4.74 1.30 2.16 – – 6.70

GLAND

OD

B

MAX

STUFFING BOX

BORE

C

MIN

C

MAX

SB

DEPTHOBLENGTH

E

MIN

SB

DEPTHOBLENGTH

E

MIN

SB

DEPTHOBLENGTH

E

MIN

F G/MIN

F G/MIN

F G/MIN

BOLT CIRCLE

BY BOLT SIZE

1/2”3/8” 5/8”

BOLT CIRCLE

BY BOLT SIZE

16 mm12 mm 20 mm

BOLT CIRCLE

BY BOLT SIZE

1/2”3/8” 5/8”

G

255 – Large Version

E

C

G

®

B

F

B

STANDARD MATERIALS **

Rotary Faces:

n

Silicon Carbide

n Tungsten Carbide

Stationary Faces:

n Duplex Carbide™

n Carbon

n Silicon Carbide

n Tungsten Carbide

All Metal Parts:

n

316SS

Springs:

n Hastelloy C*

O-Rings:

n Fluorocarbon installed;

EPR included

n FEPM installed;

No spares

OPERATING LIMITS

Speed Limits:

n To 4000 fpm

Temperature Limits:

n To 300°F

Ethylene Propylene

n To 400°F (205°C

Fluorocarbon, FEPM

n To 500°F

Perfluoroelastomer

Pressure Limits:

n To 600 psig

n To 250 psig

* Haynes International, Inc

Registered Trademark.

** Other materials available upon request.

*** 155T Sizes.

(

)

20 mps

(

)

150°C

)

(

)

260°C

(

40 bar g) inboard

(

17 bar g) outboard

255 – Oversize Version

E

C

F

CHESTERTON

®

155TM Single and 255

Cartridge Seals

TM

Dual

155

Highly effective

emissions control

The advanced design of the 155 and the ability

to keep faces square and flat ensures superior

emissions control capability.

The 155 has been proven in

independent tests to meet or

exceed the most stringent

USA emissions standards.

Of course, for total emissions

control or hazardous fluids,

use Chesterton new generation

dual seals.

Ancillary Products

Seal Support System

Mechanical seal support systems

are the lifeline to dual,

liquid-lubricated mechanical

seals. By providing a dedicated

lubrication system, mechanical

seal performance will be

optimized. Other, less efficient

systems will compromise seal

performance and reliability goals.

ASME Section VIII DIV. 1 and

Section IX. PED 97/23/EC.

Fluid Flow Control

Chesterton DualFlow™ is the

advanced regulator for dual

seal barrier fluid arrangements.

Exclusive, no-maintenance,

non- clog design and two -way

flow rate detection increase

reliability. Ideal for reducing

unnecessary water consumption

in flow through barrier systems.

Contact your local CHESTERTON Sealing

Specialist for precise system recommendations

Let us help you identify opportunities for cost- savings and greater

efficiency at your plant. Distributors can be found at our distributor

locator on our website (www.chesterton.com).

The following are trademarks of A.W.Chesterton Company: 155, 255, Self-Centering Lock Ring,

Adjustable Gland, Duplex Carbide, Unified Seal Alignment, and DualFlow.

Chesterton ISO certificates available on www.chesterton.com/corporate/iso

DISTRIBUTED BY:

860 Salem Street

Groveland, MA 01834 USA

Telephone: 781-438-7000

Fax: 978-469-6528

www.chesterton.com

© A.W. Chesterton Company, 2012. All rights reserved.

Registered trademark owned and licensed by A.W. Chesterton Company

®

in USA and other countries, unless otherwise noted.

FORM NO. 073018 PRINTE D 10/12

Loading...

Loading...