MECHANICAL SEAL

INSTALLATION INSTRUCTIONS

15 5™

CARTRIDGE SINGLE SEAL

SEAL INSTALLATION

Preparation

Determine if the pump is in

good condition.

A. Check the shaft or sleeve.

1. Remove all burrs and sharp corners,

especially in areas where the O-ring

has to slide. Cover threads and

keyway slots with a thin tape to

prevent cutting the O-ring. The

distance from the face of the stuffing

box to the center of the O-ring

groove is .47" (12 mm). For shaft

sizes larger than 2.5" (60 mm),

this distance is .68" (17 mm).

2. The shaft finish should be no rougher

than 32 microinches (0,8 microns)

AA. It should feel smooth if you run

your fingernail along the shaft in the

axial direction.

3. Make sure the shaft or sleeve

diameter is within tolerance

(no more than +/- .002"

[0,05 mm] from nominal).

Example: 1.750" (50 mm) shaft

should not be larger than 1.752"

(50,05 mm) or smaller than 1.748"

(49,95 mm).

4. Use a dial indicator to measure the

shaft runout in the area where the

seal is to be installed. Readings

should not exceed .001" TIR per

inch (0,001 mm TIR per millimeter)

of shaft diameter.

5. Place the dial indicator on the end

of the shaft and alternately push and

pull the shaft in the axial direction to

measure end play. If the bearings are

in a good condition, end play should

not exceed .005" (0,13 mm) TIR.

6. Protect the sleeve O-ring by

lubricating the shaft with a clean

silicone based lubricant. A sufficient

quantity is provided with the seal.

B. Check the stuffing box face.

1. The stuffing box face must be

smooth enough for a gasket to

seal; maximum 125 microinches

(3,2 microns) AA.

2. Split case pumps will sometimes

cause a step (misalignment) to

occur on the stuffing box face.

This step must be machined flat.

3. Make sure the stuffing box is clean

and clear along its entire length.

4. If possible, attach the base of a

dial indicator to shaft and rotate

shaft and indicator slowly while

reading the runout of the stuffing box

face. Misalignment of the stuffing

box relative to the shaft should

not exceed .005" TIR per inch

(0,005 mm TIR per millimeter)

of shaft diameter.

Installation

1. Check the chemical listing to determine

if the FKM O-rings installed in this seal

are compatible with the fluid being

sealed. If it is necessary to change

the O-ring material, disassemble the

seal as shown in the instructions and

replace it with suitable O-rings. A spare

set of Ethylene Propylene O-rings is

supplied with the seal.

2. For 155 Small Seal (1" to 2.5"

[25 mm to 60 mm] shaft/sleeve):

The flat head socket screws (covered

with yellow dots) hold the lock ring

in place. These socket screws go

through the smaller holes on the

sleeve. Do not loosen the flat head

socket screws when positioning

the seal. The three cup point screws

next to the flat head socket screws

press on the sleeve. Their loading

configuration assists in centering the

sleeve on the shaft. The three cup

point screws further away from the

flat head socket screws go through

the larger holes on the sleeve. Make

sure these are engaged through the

sleeve but do not protrude into the

sleeve I.D. bore.

For 155 Large Seal (larger than

2.5" [60 mm] shaft/sleeve): The

flat head socket screws (covered

with yellow dots) hold the lock ring

in place. These socket screws go

through the smaller holes on the

sleeve. Do not loosen the flat head

socket screws when positioning

the seal. The three hybrid dog/cup

point screws press on the sleeve.

Their loading configuration assists

in centering the sleeve on the shaft.

The six cup point screws go through

the larger holes on the sleeve. Make

sure these are engaged through the

sleeve but do not protrude into

the sleeve I.D. bore.

3. CAUTION: If the 155 seal is

operating at a stuffing box

pressure of over 300 psig (20 Bar)

or if the shaft is case hardened,

replace the three 316 stainless

steel set screws that go through

the larger holes on the sleeve

with the hardened steel set

screws supplied with the seal.

SEAL INSTALLATION

4. For 155 Small Seal (1" to 2.5"

[25 mm to 60 mm] shaft/sleeve):

Attaching the 478 or any other

gland or re-attaching the tabs.

A. When using the 478 or any other

gland instead of the tabs, remove

the tabs by removing the tab

retaining snap ring and pressing the

tabs towards the center of the hub

gland and then sliding them out.

Slide the 478 or other gland over

the hub gland until it bottoms out.

B. If the tabs need to be re-attached:

UÊ *>ViÊÌiÊÃi>]ÊVÊÀ}ÊÃ`iÊ

up, on a flat surface.

UÊ 7iÊÃÌ>}Ê>ÊÌ>LÊëÀ}ÊÊ

a tab, apply a small amount of

silicone grease to the bottom

of the spring. This will help the

spring stay in the hole. To install

a tab, compress the tab spring

by pressing the tab against the

hub gland surface and slide the

tab till it bottoms out on the hub

gland. Place the desired number

of tabs, in pairs, at the required

orientation. As a minimum two

pairs of tabs must be used.

When the 155 seal is operating

at a stuffing box pressure of

over 300 psig (20 Bar), four

pairs of tabs must be used.

UÊ ÃiÀÌÊÌiÊÃ>«ÊÀ}ÊÊÌiÊÕLÊ

gland groove. The snap ring

will prevent the tabs from falling

off, but can be removed at

any time without affecting the

performance of the seal. Make

sure that the gap between the

ends of the snap ring is aligned

with the slot in the hub gland

for the centering strap.

5. Slide the seal onto the shaft,

by pushing on the lock ring.

6. Reassemble the pump and make

necessary shaft alignments and

impeller adjustments.

7. Orientate the flush connection to the

location required. The port is plugged

prior to shipping. Removal of the

plug will require 25 lbs.-ft. (33,9 Nm)

of torque.

8. Piping connections should not

be made prior to tightening the

gland bolts.

9. Tighten the gland nuts evenly.

IMPORTANT: The gland nuts must

be tightened before tightening

set screws onto the shaft.

10. The seal has been designed to

promote self-centering of the sleeve

on the shaft. Following the set screw

tightening procedure outlined

below will lead to the maximum

self-centering possible.

For 155 Small Seal (1" to 2.5"

[25 mm to 60 mm] shaft/sleeve):

Tighten the three cup point set

screws, that are closer to the flat

head screws, evenly. If necessary,

tighten the three flat head socket

screws with the hex keys provided.

Then tighten the three cup point set

screws, that are further away from

the flat head screws, evenly. After

these three cup point screws have

been tightened with the hex key,

tighten them again with a torque

wrench to 50-60 lbs.-in. (5,7-6,

8 Nm). Pull out the centering strap,

and save the strap. If the strap is

lost after seal installation, a standard

wire wrap, .054" thick by .187" wide

(1,37 mm thick by 4,75 mm) can

be used.

For 155 Large Seal (larger than 2.5"

[60 mm] shaft/sleeve): Tighten the

three hybrid dog/cup point set screws

evenly. If necessary, tighten the three

flat head socket screws with the hex

keys provided. Then tighten the six

cup point set screws evenly. After

these three cup point screws have

been tightened with the hex key,

tighten them again with a torque

wrench to 50-60 lbs.-in. (5,7-6,8 Nm).

Pull out the centering strap, and save

the strap. If the strap is lost after seal

installation, a standard wire wrap,

.068" thick by .300" wide (1,73 mm

thick by 7,62 mm) can be used.

11. IMPORTANT: It is important to

make sure that the gland is properly

centered over the sleeve. To do this,

turn the shaft by hand to make sure

the seal turns freely. If you hear metal

to metal contact within the seal, it

was improperly centered.

For 155 Seal:

UÊ -Ì>ÀÌÊÌiÊViÌiÀ}ÊÃÌÀ>«ÊÌÀÕ}Ê

the slot in the hub gland.

UÊ ÃiÊÌiÊ}>`ÊLÌðÊ

UÊ ÃiÊÌiÊÃiÌÊÃVÀiÜðÊ

(Do not loosen the flat head

socket screws as this will allow

the lock ring to come off).

UÊ *ÕÃÊÌiÊÃÌÀ>«ÊÊÕÌÊÌÊV«iÌiÞÊ

surrounds the seal sleeve. It will

pilot between the hub gland, seal

sleeve and lock ring.

UÊ ,iÌ}ÌiÊÌiÊ}>`ÊLÌð

UÊ ,iÌ}ÌiÊÌiÊÃiÌÊÃVÀiÜð

UÊ ,iÛiÊÌiÊViÌiÀ}ÊÃÌÀ>«°

If metal to metal contact still exists

check the centering of the stuffing box.

Take all necessary precautions and

follow normal safety procedures

before starting equipment.

CAUTIONS

These instructions are general in nature. It is assumed that the installer is familiar with seals

and certainly with the requirements of their plant for the successful use of mechanical seals.

If in doubt, get assistance from someone in the plant who is familiar with seals or delay the

installation until a seal representative is available. All necessary auxiliary arrangements for

successful operation (heating, cooling, flushing) as well as safety devices must be employed.

These decisions are to be made by the user. The chemical listing is intended as a general

reference for this seal only. The decision to use this seal or any other Chesterton seal in a

particular service is the customer's responsibility.

2

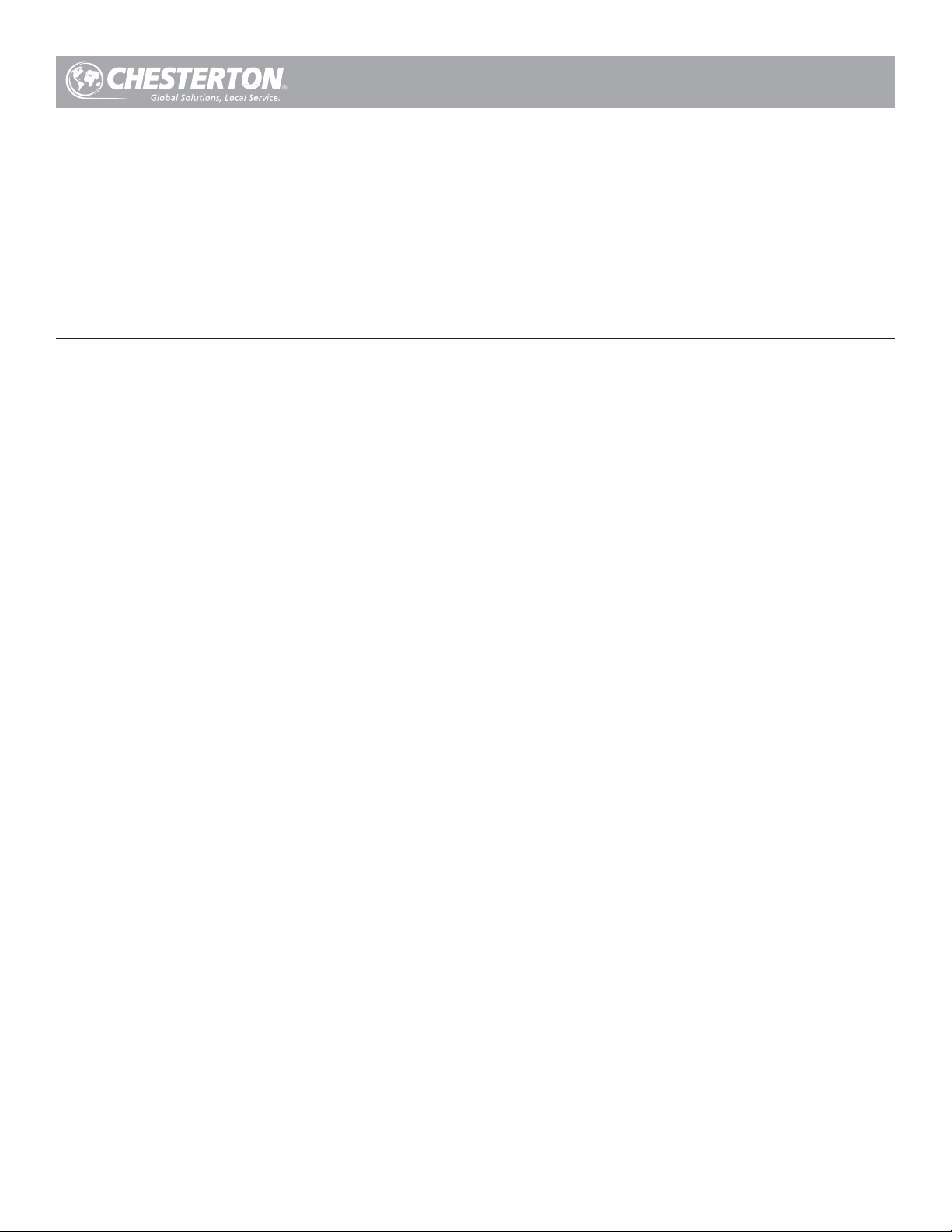

DISASSEMBLY (1-6) – SMALL (1" to 2.5" [25 mm to 60 mm] shaft/sleeve)

For 155 seal, remove the tabs or the 478

or other gland before disassembling the

seal. Remove the tabs by removing the

tab retaining snap ring and pressing the

tabs towards the center of the hub gland

and then sliding them out. To remove

the 478 or other gland just pull the gland

away from the hub gland.

3

1

You will need the hex keys provided with

the seal, and an O-ring extractor or paper

clip to disassemble the seal.

4

2

Place the seal, lock ring side up, on a flat

surface. Back out all the screws from the

sleeve. Remove the lock ring. Remove the

centering strap.

5

While holding the sleeve and gland together,

turn the seal assembly over and lift out

the rotary and the sleeve, separating the

stationary face from the rotary face with your

fingers. Turn the faces in opposite directions

if it becomes difficult to separate them.

6

Remove the back-up washer and

stationary drive with the springs. Remove

the springs from the stationary drive.

Remove the rotary, rotary O-ring and

shaft O-ring from the sleeve.

Place the rotary and the sleeve next to

the gland assembly.

vÌÊÕÌÊÌiÊÃÌ>Ì>ÀÞÊ>`ÊÀiÛiÊÌiÊ

dynamic O-ring.

3

ASSEMBLY (7-14) – SMALL (1" to 2.5" [25 mm to 60 mm] shaft/sleeve)

7

ÕLÀV>ÌiÊÌiÊÃiiÛiÊ°°Ê"À}ÊÜÌÊÌiÊ

silicone grease provided and install it in

ÌiÊÃiiÛiÊ°°Ê}ÀÛi°ÊÕLÀV>ÌiÊÌiÊ

rotary O-ring and install it in the sleeve

O.D. groove.

10

8

Slide the rotary onto the sleeve, aligning

the drive tabs with the rotary slots. Slide

the rotary over the O-ring until the rotary

bottoms out. Check to make sure the

drive tabs are properly engaged.

11

9

Place a spring in each hole in the stationary

drive. A small amount of silicone grease can

be applied to the bottom of each spring.

This will help the springs stay in the holes.

12

Place the hub gland assembly with the

gasket side up, on a flat surface. Align the

slots in the stationary drive with the tabs

in the hub gland. Slide the stationary drive

in until the springs touch the hub gland.

Place the back-up washer in the hub

gland. It will rest on the stationary drive

until the seal is compressed.

13

ÕLÀV>ÌiÊÌiÊ`Þ>VÊ"À}ÊvÀÊÌiÊ

stationary. Slide the O-ring onto the

stationary. Slide the stationary into the

hub gland until it engages the stationary

drive. Be sure to line-up the drive tabs

with the stationary slots.

Turn the assembly over and place with

the lock ring side of the sleeve up, on

a flat surface. Place the lock ring over

the sleeve, lining up the flat head socket

screws with the smaller holes and the cup

point set screws with the larger holes.

Press down on the lock ring and tighten

the flat head socket screws and the cup

point set screws. Check to ensure that

the sleeve is not deformed while tightening

the set screws. Make sure the screws do

not protrude into the sleeve I.D. bore.

Wipe the stationary and rotary faces clean

with a lint free cloth. Place the hub gland,

with the stationary installed, stationary side

up on a flat surface. Place the stuffing box

face gasket in the hub gland. Slide the

sleeve, with the rotary installed, downwards

into the hub gland. Pick up the hub gland

and sleeve and continue to push them

together until the faces contact each other.

14

Press down on the hub gland and push

the centering strap through the slot in

the hub gland. Push the strap in until it

completely surrounds the seal sleeve.

It will pilot between the hub gland, seal

sleeve and lock ring.

4

DISASSEMBLY (1-8) – LARGE (larger than 2.5" [60 mm] shaft/sleeve)

1

You will need the hex keys provided with

the seal, and an O-ring extractor or paper

clip to disassemble the seal.

4

2

For 155 large seal, remove the tabs or the

478 or other gland before disassembling

the seal. Remove the tabs by removing the

tab retaining snap ring and pressing the

tabs towards the center of the hub gland

and then sliding them out. To remove the

478 or other gland just pull the gland away

from the hub gland.

5

3

Place the seal, lock ring side up, on a flat

surface. Back out all the screws from the

sleeve. Remove the lock ring. Remove the

centering strap.

6

While holding the sleeve and gland

together, turn the seal assembly over

and lift out the rotary and the sleeve,

separating the stationary face from the

rotary face with your fingers.

7

Remove the stationary and the adapter

together. Separate them and remove the

dynamic O-ring.

Place the rotary and the sleeve next to the

gland assembly.

8

Remove the stationary drive with the

springs. Remove the static O-ring from

inside the hub gland. Remove the springs

from the stationary drive.

Remove the rotary, rotary O-ring and shaft

O-ring from the sleeve.

5

ASSEMBLY (9-19) – LARGE (larger than 2.5" [60 mm] shaft/sleeve)

9

ÕLÀV>ÌiÊÌiÊÃiiÛiÊ°°Ê"À}ÊÜÌÊ

the silicone grease provided and install

ÌÊÊÌiÊÃiiÛiÊ°°Ê}ÀÛi°ÊÕLÀV>ÌiÊÌiÊ

rotary O-ring and install it in the sleeve

O.D. groove.

12

10

Slide the rotary onto the sleeve, aligning the

drive tabs with the rotary slots. Slide the

rotary over the O-ring until the rotary bottoms

out. Check to make sure the drive tabs are

properly engaged.

13

11

Place a spring in each hole in the stationary

drive. A small amount of silicone grease can

be applied to the bottom of each spring.

This will help the springs stay in the holes.

14

Place the hub gland assembly with the

}>ГiМКГ`iКХ«]КК>Кv>МКГХАv>Vi°КХLАV>МiК

the static O-ring and install it in the hub

gland. Align the slots in the stationary drive

with the tabs in the hub gland. Slide the

stationary drive in until the springs touch

the hub gland. Place the back-up washer

in the hub gland.

ÕLÀV>ÌiÊÌiÊ`Þ>VÊ"À}ÊvÀÊÌiÊ

stationary and slide it in the adapter I.D.

groove. Place the stationary face down

on a flat surface and press the adapter

onto the stationary.

Slide the stationary and adapter assembly

into the hub gland until it engages the

stationary drive. Be sure to line-up the drive

tabs with the stationary slots.

6

ASSEMBLY (9-19

) –

LARGE (larger than 2.5" [60 mm] shaft/sleeve)

15

Wipe the stationary and rotary faces clean

with a lint free cloth. Place the hub gland,

with the stationary installed, stationary side

up on a flat surface. Place the stuffing box

face gasket in the hub gland.

18

16

Slide the sleeve, with the rotary installed,

downwards into the hub gland. Pick up

the hub gland and sleeve and continue

to push them together until the faces

contact each other.

19

17

Press down on the hub gland and push the

centering strap through the slot in the hub

gland. Push the strap in until it completely

surrounds the seal sleeve. It will pilot

between the hub gland, seal sleeve and

lock ring.

Turn the assembly over and place with

the lock ring side of the sleeve up, on a flat

surface. Place the lock ring over the sleeve,

lining up the flat head socket screws and

hybrid dog/cup point set screws with the

smaller holes. Also, line up the cup point

set screws with the larger holes. Press

down on the lock ring and tighten the flat

head socket screws, hybrid dog/cup point

set screws and the cup point set screws.

Check to ensure that the sleeve is not

deformed while tightening the set screws.

Make sure the screws do not protrude

into the sleeve I.D. bore.

Replace the tabs by pressing the tabs

toward the center of the hub gland and

then sliding them in. Reinstall the tab

retaining snap ring. The assembly is

now complete.

7

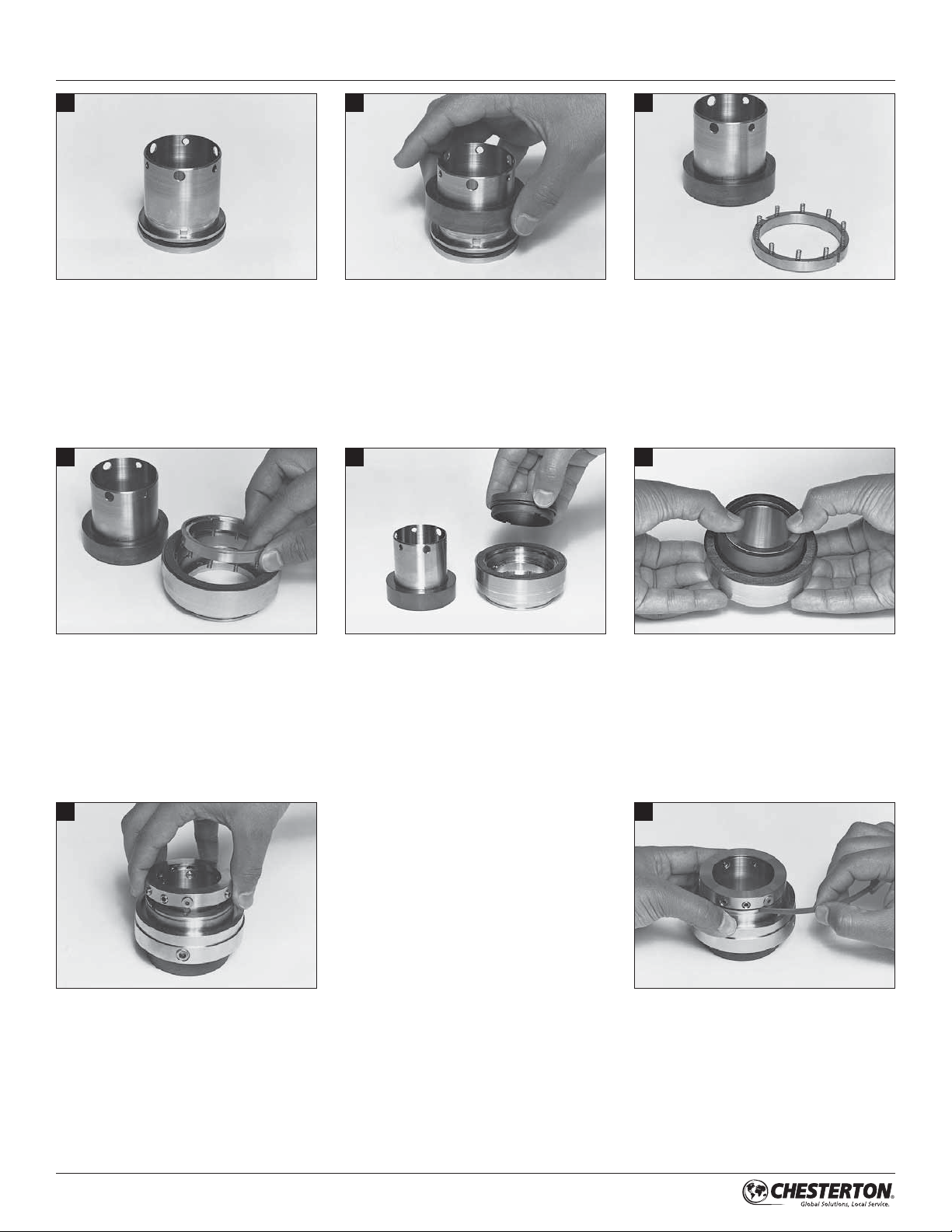

DIMENSIONAL DATA (DRAWINGS) – SMALL

E MIN

F

V

UTS

D A

N M

1/16" Spring Gap

(Typical)

K

L P RC

J

478 GLAND TABS

H

CAUTION:

REMOVE BEFORE OPERATING

G MIN

B MAX

CAUTION:

REMOVE BEFORE OPERATING

G MIN

B MAX

8

DIMENSIONAL DATA (INCH) – SMALL

STUFFING

SHAFT BOX BORE

SIZE DASH B MAX B MAX C C E

A SIZE TABS 478 MIN MAX D MIN F

1.000 8 4.65 4.24 1.75 2.00 1.69 0.63 1.89

1.125 9 4.69 4.24 1.88 2.03 1.82 0.63 1.89

1.250 10 4.90 4.49 2.00 2.26 1.94 0.63 1.89

1.375 11 5.04 4.99 2.13 2.42 2.07 0.63 1.89

1.500 12 5.23 4.99 2.25 2.62 2.19 0.63 1.89

1.625 13 5.29 4.99 2.38 2.68 2.32 0.63 1.89

1.750 14 5.41 5.49 2.50 2.80 2.44 0.63 1.89

1.875 15 5.53 5.49 2.63 2.93 2.57 0.63 1.89

2.000 16 5.74 5.99 2.75 3.18 2.69 0.63 1.89

2.125 17 6.04 5.99 2.88 3.43 2.82 0.63 1.89

2.250 18 6.14 6.24 3.00 3.55 2.94 0.63 1.89

2.375 19 6.29 6.24 3.13 3.59 3.07 0.63 1.89

2.500 20 6.41 6.49 3.25 3.80 3.19 0.63 1.89

G MIN G MIN

TABS 478

3/8" 1/2" 5/8" 3/8" 1/2" 5/8"

BOLTS BOLTS BOLTS BOLTS BOLTS BOLTS

2.88 3.01 3.13 2.90 – –

2.92 3.05 3.17 2.90 – –

3.13 3.26 3.38 3.21 – –

3.27 3.40 3.52 3.52 – –

3.46 3.59 3.71 3.52 – –

3.52 3.65 3.77 3.51 3.63 –

3.64 3.77 3.89 3.74 3.86 –

3.76 3.89 4.01 3.90 4.02 –

3.97 4.10 4.22 4.15 4.27 –

4.27 4.40 4.52 4.53 4.66 4.78

4.38 4.51 4.63 4.56 4.69 4.81

4.52 4.65 4.77 4.56 4.69 4.81

4.65 4.78 4.90 4.79 4.92 5.04

DIMENSIONAL DATA (METRIC) – SMALL

STUFFING

SHAFT BOX BORE

SIZE B MAX B MAX C C E

A TABS 478 MIN MAX D MIN F

25 118 108 44 51 43 16 48

28 118 108 47 52 46 16 48

30 124 111 49 57 48 16 48

32 124 114 51 58 50 16 48

33 124 114 52 59 51 16 48

35 128 127 54 62 52 16 48

38 133 127 57 67 56 16 48

40 134 127 59 68 58 16 48

43 134 127 62 69 61 16 48

45 140 139 64 73 63 16 48

48 139 139 67 74 66 16 48

50 145 139 69 78 68 16 48

55 150 158 74 83 73 16 48

60 160 158 79 91 78 16 48

G MIN G MIN

TABS 478

8 mm 10 mm 12 mm 8 mm 10 mm 12 mm

BOLTS BOLTS BOLTS BOLTS BOLTS BOLTS

70 72 74 71 73 –

70 72 74 71 73 –

76 78 80 77 79 –

77 79 81 78 80 –

76 78 80 78 80 –

80 82 84 86 88 –

85 87 89 86 88 –

86 88 90 86 88 90

86 88 90 86 88 90

92 94 96 92 94 96

91 93 95 92 94 96

97 99 101 96 98 100

102 104 106 112 114 116

112 114 116 113 115 117

NPT

478 SIZE

H J K L M N P R S T U GLAND V

0.44 0.93 0.37 1.76 1.58 0.47 2.25 2.45 120 124 126 9 1/8"

0.44 0.93 0.37 1.89 1.58 0.47 2.25 2.48 122 126 128 9 1/8"

0.44 0.93 0.37 2.01 1.58 0.47 2.43 2.70 124 128 130 11 1/8"

0.44 0.93 0.37 2.14 1.58 0.47 2.75 2.84 126 130 132 12 1/8"

0.44 0.93 0.37 2.26 1.58 0.47 2.75 3.03 128 132 134 12 1/8"

0.58 0.93 0.37 2.39 1.58 0.47 2.87 3.08 130 134 136 13 1/8"

0.58 0.93 0.37 2.51 1.58 0.47 3.12 3.21 132 136 138 14 1/8"

0.58 0.93 0.37 2.64 1.58 0.47 3.25 3.33 134 138 140 15 1/8"

0.58 0.93 0.37 2.76 1.58 0.47 3.50 3.54 136 140 142 16 1/8"

0.69 0.93 0.37 2.89 1.58 0.47 3.75 3.84 138 142 144 18 1/8"

0.69 0.93 0.37 3.01 1.58 0.47 3.87 3.94 140 144 146 19 1/8"

0.69 0.93 0.37 3.14 1.58 0.47 3.90 4.08 142 146 148 19 1/8"

0.69 0.93 0.37 3.26 1.58 0.47 4.12 4.21 144 148 150 20 1/8"

NPT

478 SIZE

H J K L M N P R S T U GLAND V

11 24 9 44 40 12 57 62 120 124 126 9 1/8"

11 24 9 47 40 12 57 62 121 126 128 9 1/8"

11 24 9 49 40 12 60 68 123 127 129 10 1/8"

11 24 9 51 40 12 62 69 124 128 130 11 1/8"

11 24 9 52 40 12 62 69 125 129 131 11 1/8"

11 24 9 54 40 12 70 72 126 130 132 12 1/8"

11 24 9 57 40 12 70 77 128 132 134 12 1/8"

15 24 9 59 40 12 73 78 129 134 135 13 1/8”

15 24 9 62 40 12 73 78 131 135 137 13 1/8"

15 24 9 64 40 12 79 84 132 136 138 14 1/8"

15 24 9 67 40 12 79 84 134 139 140 14 1/8"

15 24 9 69 40 12 82 89 136 140 142 15 1/8"

17 24 9 74 40 12 94 94 139 143 145 18 1/8"

17 24 9 80 40 12 99 104 142 146 148 19 1/8"

KEY (drawings & charts)

A – Shaft Size

B – Maximum Gland Tab Diameter

C – Stuffing Box Inside Diameter

D – Seal Diameter in Stuffing Box

E – Minimum Stuffing Box Depth

Ê qÊ "ÕÌL>À`Ê-i>Êi}Ì

G – Minimum Bolt Circle by Bolt Size

H – Slot Width

J – Hub Gland Flange Width

K – Hub Gland Sot Width

Ê qÊ VÊ,}Ê>iÌiÀ

M – Distance from Stuffing Box Face to Set Screws

N – Distance from Stuffing Box Face to Shaft O-Ring

P – Hub Gland Slot Diameter

R – Hub Gland Diameter

S – Shaft O-Ring

T – Rotary O-Ring

U – Stationary O-Ring

V – NPT Size

9

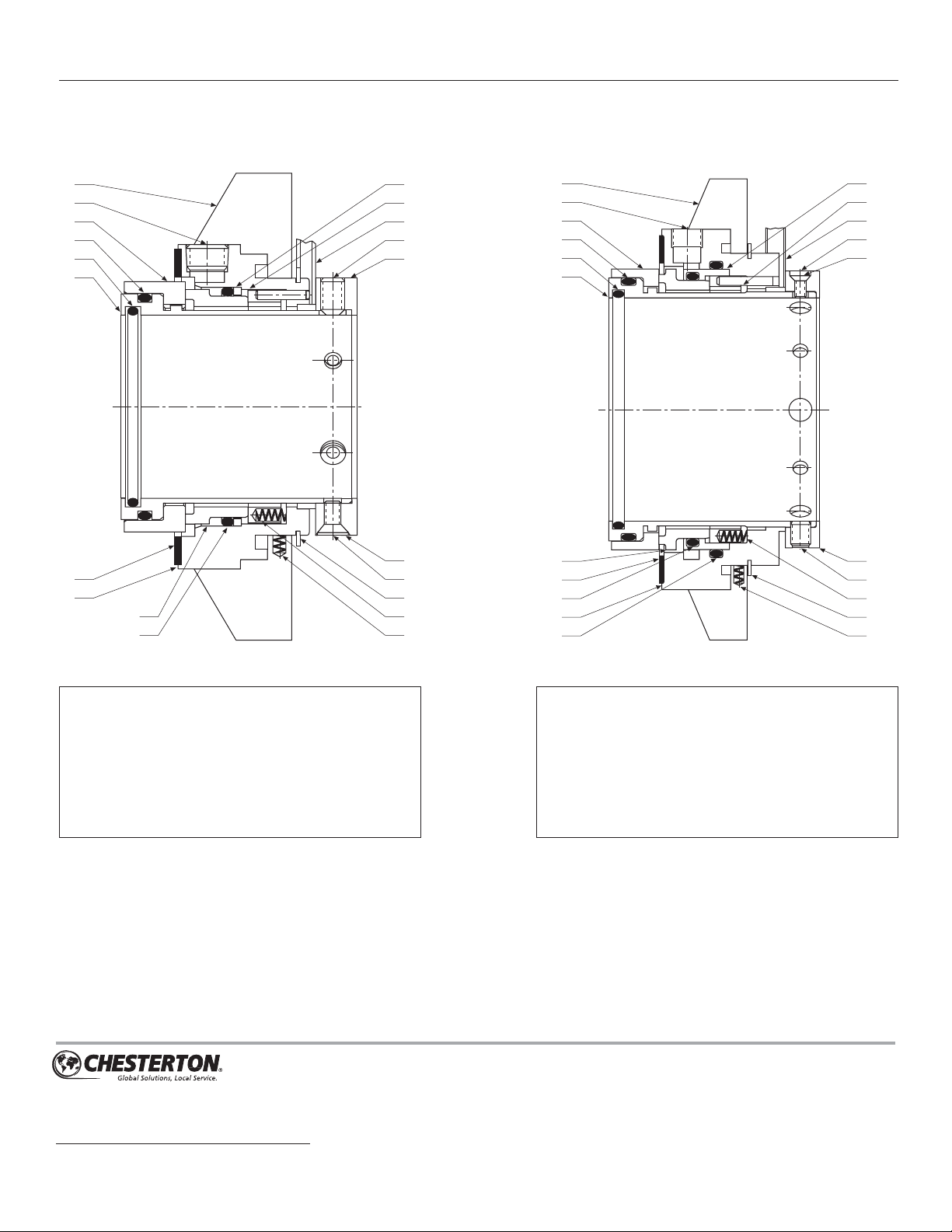

DIMENSIONAL DATA (DRAWINGS) – LARGE & OVERSIZE

LARGE

E

MIN

D A

N M

F

W

3/32" Spring Gap

(Typical)

U VTS

J

TABS

CAUTION:

REMOVE BEFORE OPERATING

L RC

B MAX

G MIN

K

OVERSIZE – SMALL

(1.13" to 2.50" shaft/sleeve)

E

MIN

D A

N M

F

W

UTS

OVERSIZE – LARGE

(2.63" to 4.75" shaft/sleeve)

E MIN

L RC

D A

N M

F

W

U VTS

L RC

10

1/16" Spring Gap

J

(Typical)

K

J

K

3/32" Spring Gap

(Typical)

DIMENSIONAL DATA (INCH) – LARGE

STUFFING

SHAFT BOX BORE G MIN

SIZE DASH B C C E 1/2" 5/8" 3/4"

A SIZE MAX MIN MAX D MIN F BOLTS BOLTS BOLTS

2.625 21 7.63 3.63 4.00 3.54 0.88 2.50 5.35 5.48 5.60

2.750 22 7.76 3.75 4.13 3.67 0.88 2.50 5.48 5.60 5.73

2.875 23 7.88 3.88 4.25 3.79 0.88 2.50 5.60 5.73 5.85

3.000 24 8.01 4.00 4.44 3.92 0.88 2.50 5.73 5.85 5.98

3.125 25 8.13 4.13 4.55 4.04 0.88 2.50 5.85 5.98 6.10

3.250 26 8.26 4.25 4.69 4.17 0.88 2.50 5.98 6.10 6.23

3.375 27 8.38 4.38 4.80 4.29 0.88 2.50 6.10 6.23 6.35

3.500 28 8.51 4.50 4.94 4.42 0.88 2.50 6.23 6.35 6.48

3.625 29 8.63 4.63 5.05 4.54 0.88 2.50 6.35 6.48 6.60

3.750 30 8.76 4.75 5.14 4.67 0.88 2.50 6.48 6.60 6.73

3.875 31 8.88 4.88 5.26 4.79 0.88 2.50 6.60 6.73 6.85

4.000 32 9.01 5.00 5.44 4.92 0.88 2.50 6.73 6.85 6.98

4.125 33 9.13 5.13 5.55 5.04 0.88 2.50 6.85 6.98 7.10

4.250 34 9.18 5.25 5.69 5.17 0.88 2.50 6.89 7.02 7.14

4.375 35 9.30 5.38 5.81 5.29 0.88 2.50 7.02 7.14 7.27

4.500 36 9.43 5.50 5.94 5.42 0.88 2.50 7.14 7.27 7.39

4.625 37 9.56 5.63 6.06 5.54 0.88 2.50 7.27 7.39 7.52

4.750 38 9.76 5.75 6.22 5.67 0.88 2.50 7.47 7.60 7.72

DIMENSIONAL DATA (METRIC) – LARGE

STUFFING

SHAFT BOX BORE G MIN

SIZE B C C E 10 mm 12 mm 16 mm

A MAX MIN MAX D MIN F BOLTS BOLTS BOLTS

65 194 92 102 90 22 64 132 134 138

70 197 95 105 93 22 64 135 137 141

75 203 100 113 99 22 64 141 143 147

80 207 105 116 103 22 64 144 146 150

85 213 110 122 109 22 64 151 153 157

90 216 115 125 113 22 64 154 156 160

95 222 120 131 118 22 64 160 162 166

100 229 127 138 125 22 64 167 169 173

110 236 136 148 134 22 64 174 176 180

120 248 145 158 144 22 64 186 188 192

O-RINGS NPT

SIZE

J K L M N R S T U V W

1.08 1.33 3.49 2.22 0.68 4.79 231 234 236 239 1/4"

1.08 1.33 3.61 2.22 0.68 4.92 232 235 237 240 1/4"

1.08 1.33 3.74 2.22 0.68 5.04 233 236 238 241 1/4"

1.08 1.33 3.86 2.22 0.68 5.17 234 237 239 242 1/4"

1.08 1.33 3.99 2.22 0.68 5.29 235 238 240 243 1/4"

1.08 1.33 4.11 2.22 0.68 5.42 236 239 241 244 1/4'

1.08 1.33 4.24 2.22 0.68 5.54 237 240 242 245 1/4"

1.08 1.33 4.36 2.22 0.68 5.67 238 241 243 246 1/4"

1.08 1.33 4.49 2.22 0.68 5.79 239 242 244 247 1/4"

1.08 1.33 4.61 2.22 0.68 5.92 240 243 245 248 1/4"

1.08 1.33 4.74 2.22 0.68 6.04 241 244 246 249 1/4"

1.08 1.33 4.86 2.22 0.68 6.17 242 245 247 250 1/4"

1.08 1.33 4.99 2.22 0.68 6.29 243 246 248 251 1/4"

1.08 1.33 5.11 2.22 0.68 6.33 244 247 249 252 1/4"

1.08 1.33 5.24 2.22 0.68 6.46 245 248 250 253 1/4"

1.08 1.33 5.36 2.22 0.68 6.58 246 249 251 254 1/4”

1.08 1.33 5.49 2.22 0.68 6.71 247 250 252 255 1/4"

1.08 1.33 5.61 2.22 0.68 6.91 248 251 253 256 1/4"

O-RINGS NPT

SIZE

J K L M N R S T U V W

34 89 56 17 122 231 234 236 239 1/4"

27

27 34 92 56 17 125 232 235 237 240 1/4"

27 34 98 56 17 131 234 237 239 242 1/4"

27 34 102 56 17 134 236 238 240 243 1/4"

27 34 108 56 17 141 237 240 242 245 1/4"

27 34 112 56 17 144 239 241 243 246 1/4"

27 34 117 56 17 150 240 243 245 248 1/4"

27 34 123 56 17 157 242 245 247 250 1/4"

27 34 133 56 17 164 245 248 250 253 1/4"

27 34 142 56 17 176 248 251 253 256 1/4"

DIMENSIONAL DATA (INCH) – OVERSIZE

STUFFING

SHAFT BOX BORE G MIN

SIZE DASH B C C E 3/8" 1/2" 5/8" 3/4" 7/8"

A SIZE MAX MIN MAX D MIN F BOLTS BOLTS BOLTS BOLTS BOLTS

1.125 9 5.29 2.50 2.75 1.82 0.63 1.89 3.59 3.72 3.84 – –

1.375 11 5.57 2.68 3.00 2.07 0.63 1.89 3.86 3.99 4.11 – –

1.750 14 6.64 3.37 3.75 2.44 0.63 1.89 4.93 5.06 5.18 – –

1.875 15 6.58 3.42 3.81 2.57 0.63 1.89 4.88 5.01 5.13 – –

2.125 17 7.31 3.75 4.25 2.82 0.63 1.89 5.60 5.73 5.85 – –

2.500 20 8.14 4.37 4.75 3.19 0.63 1.89 6.43 6.56 6.68 – –

2.625 21 8.04 4.38 4.78 3.54 0.88 2.50 – 5.83 5.96 6.08 6.21

2.750 22 8.04 4.28 4.78 3.67 0.88 2.50 – 5.83 5.96 6.08 6.21

3.000 24 8.65 4.75 5.39 3.92 0.88 2.50 – 6.44 6.57 6.69 6.82

3.375 27 8.54 4.78 5.27 4.29 0.88 2.50 – 6.33 6.46 6.58 6.71

3.750 30 9.63 5.78 6.40 4.67 0.88 2.50 – 7.41 7.54 7.66 7.79

4.125 33 9.54 5.78 6.27 5.04 0.88 2.50 – 7.33 7.46 7.58 7.71

4.750 38 11.25 7.03 7.65 5.67 0.88 2.50 – 9.04 9.17 9.29 9.42

KEY (drawings & charts)

A – Shaft Size

B – Maximum Gland Tab Diameter

C – Stuffing Box Inside Diameter

D – Seal Diameter in Stuffing Box

E – Minimum Stuffing Box Depth

Ê qÊ "ÕÌL>À`Ê-i>Êi}Ì

G – Minimum Bolt Circle by Bolt Size

J – Hub Gland Flange Width

K – Distance from Stuffing Box Face to Back of Tab

Ê qÊ VÊ,}Ê>iÌiÀ

M – Distance from Stuffing Box Face to Set Screws

N – Distance from Stuffing Box Face to Shaft O-Ring

R – Hub Gland Diameter

S – Shaft O-Ring

T – Rotary O-Ring

U – Stationary O-Ring

V – Gland O-Ring

(applies only to large size and large oversize seal)

W – NPT Size

O-RINGS NPT

SIZE

J K L M N R S T U V W

0.93 1.18 1.89 1.58 0.47 3.15 122 126 128 – 1/4"

0.93 1.18 2.14 1.58 0.47 3.43 126 130 132 – 1/4"

0.93 1.18 2.51 1.58 0.47 4.49 132 136 138 – 1/4"

0.93 1.18 2.64 1.58 0.47 4.44 134 138 140 – 1/4"

0.93 1.18 2.89 1.58 0.47 5.17 138 142 144 – 1/4"

0.93 1.18 3.26 1.58 0.47 6.00 144 148 150 – 1/4”

1.08 1.33 3.49 2.22 0.68 5.27 231 234 236 239 1/4"

1.08 1.33 3.61 2.22 0.68 5.27 232 235 237 240 1/4"

1.08 1.33 3.86 2.22 0.68 5.88 234 237 239 242 1/4"

1.08 1.33 4.24 2.22 0.68 5.77 237 240 242 245 1/4"

1.08 1.33 4.61 2.22 0.68 6.86 240 243 245 248 1/4"

1.08 1.33 4.99 2.22 0.68 6.77 243 246 248 251 1/4"

1.08 1.33 5.61 2.22 0.68 8.48 248 251 253 256 1/4"

11

PARTS IDENTIFICATION

(1" to 2.5" [25 mm to 60 mm] shaft/sleeve)

1

2

3

4

4

5

6

7

8

4

9

10

11

12

13

14

15

16

17

18

1

2

3

4

4

5

6

7

4

8

4

(larger than 2.5" [60 mm] shaft/sleeve)

SMALL

LARGE

9

10

11

12

13

14

15

16

17

18

KEY

1 – Bolt Tab

2 – Pipe Plug

3 – Rotary Seal Ring

4 – O-Ring

5 – Sleeve

6 – Gasket

7 – Hub Gland Assembly

8 – Stationary Seal Ring

9 – Back-up Washer

155 is a trademark of A.W. Chesterton Company.

860 Salem Street

Groveland, MA 01834 USA

Telephone: 781-438 -7000 Fax: 978-469- 6528

www.chesterton.com

© A.W.Chesterton Company, 2014. All rights reserved.

® Registered trademark owned and licensed by

A.W. Chesterton Company in USA and other countries.

10 – Stationary Drive

11 – Centering Strap

12 – Cup Point Set Screw

£ÎÊqÊ VÊ,}

14 – Dot

15 – Flat HD Socket Screw

16 – Snap Ring

17 – Spring

18 – Bolt Tab Spring

KEY

1 – Bolt Tab

2 – Pipe Plug

3 – Rotary Seal Ring

4 – O-Ring

5 – Sleeve

6 – Stationary Seal Ring

7 – Gasket

8 – Hub Gland Assembly

9 – Adapter

Chesterton ISO certificates available on www.chesterton.com/corporate/iso

FORM NO. 071379 REV. 5 PRINTED IN USA 04/14

10 – Stationary Drive

11 – Centering Strap

12 – Flat HD Socket Screw

13 – Dot

£{ÊqÊ VÊ,}

15 – Cup Point Set Screw

1/4 Dog Point Set Screw (not shown)

16 – Spring

17 – Snap Ring

18 – Bolt Tab Spring

Loading...

Loading...