A.W. Chesterton 155, 255 User Manual

TM

155TM Single and 255

Dual

Cartridge Seals

Patented

n Global acceptance and satisfaction across a variety of industrial applications

n Exclusive face design for superior emissions control capability

n Stable, secure sealing under fluctuating conditions

n Patented features assure precision alignment from start-up

n Versatile and cost-effective

ISO 9001

CERTIFIED

Delivering the best value

in cartridge sealing today

CHESTERTON

®

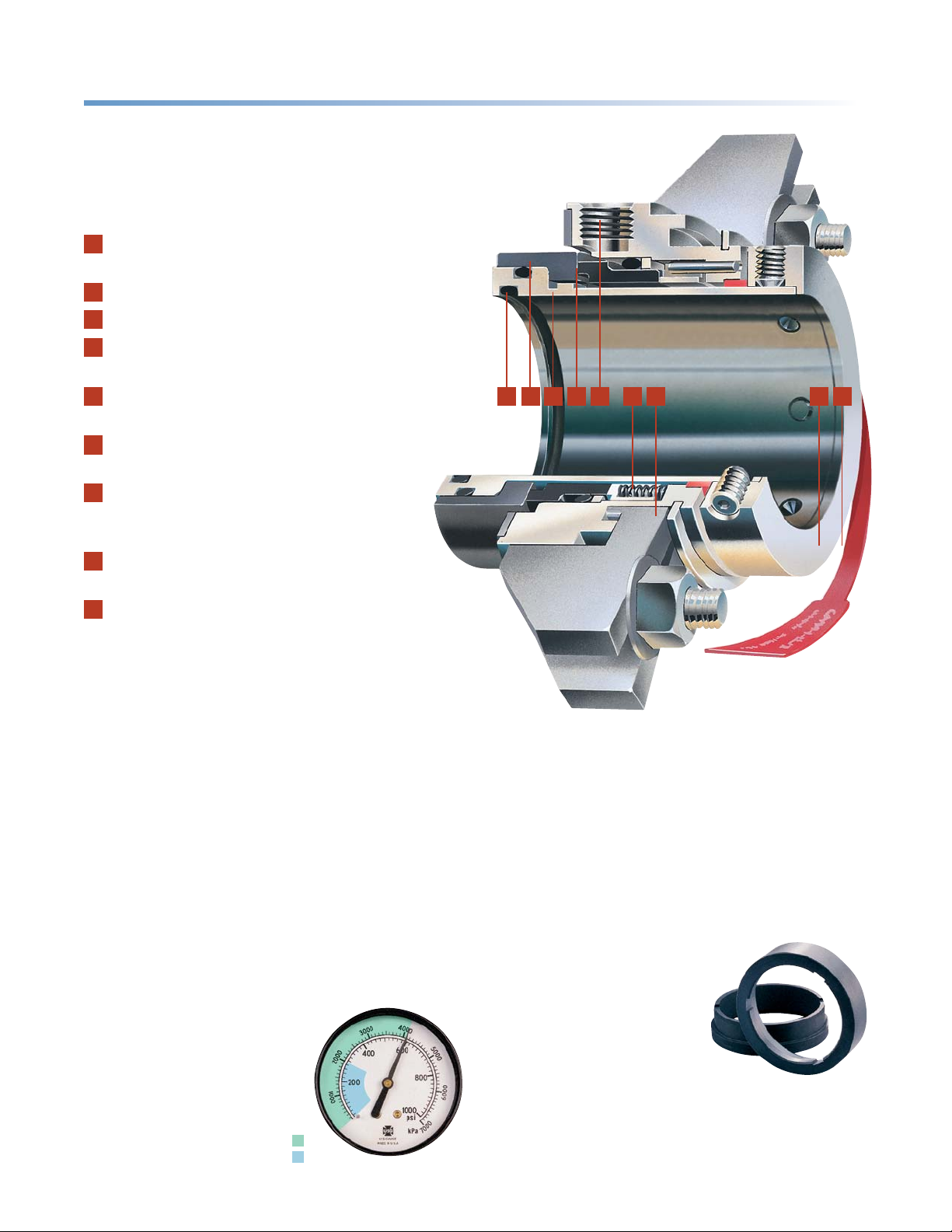

155TM

Cartridge Single Seal

Construction Details

1

All O-rings are either static or move on

non-metallic, non-fretting surfaces.

2

Seal face support shoulder is precisely square.

3

Integral drive pads cannot fall out.

4

Hydraulically balanced faces

for low frictional heat.

5

Flush port can be rotated 360° for ease

of piping as required.

6

Stationary springs, isolated from fluid

to prevent clogging.

7

Patented Adjustable Gland™

fits common bolt arrangements

without modification.

8

Self- Centering Lock Ring™

for superior concentricity.

9

Centering strap for simple installation.

1•2•3•4•5•6•7

8•9

•

•

Self-Centering Lock Ring™

ensures reliability

The patented Self-Centering Lock Ring

makes installation precise for correct face mating

and sustainable sealing. Cloverleaf 3- point

contact ensures concentricity to the shaft.

Faces start out square and stay square to prevent

the intrusion of contaminants or abrasives.

Also, constant face squareness reduces

opportunities for fluid leakage and uneven wear.

Superior reliability

during system variations

Pressure surges at start-up and

shut- down can create seal reliability

problems. The 155 seal can handle

50% to 100% greater transient

pressure than conventional seals

and provides a “margin of safety”

during normal surges.

CHESTERTON 155 Seal

Conventional Seal

Dynamic stress relief keeps faces closed

Variances in temperature or pressure, fluid phase changes,

or water hammer can create dynamically changing

stresses on the seal faces. Common face geometries

distort at the mating surface under such conditions

and create drastic wear. Chesterton face geometry

compensates for stresses in the body of the seal ring,

away from the critical face mating surfaces.

Face material

interchangeability

With the 155, the interchanging is

a fast and easy process, with seal

function and reliability assured.

Standard face materials are

silicon carbide or carbon.

The carbon can be swapped for

silicon carbide, tungsten carbide or

Duplex Carbide™, which provides the utility

of two hard faces but with lower frictional heat.

All faces are interchangeable with the

225 and 255 dual seals.

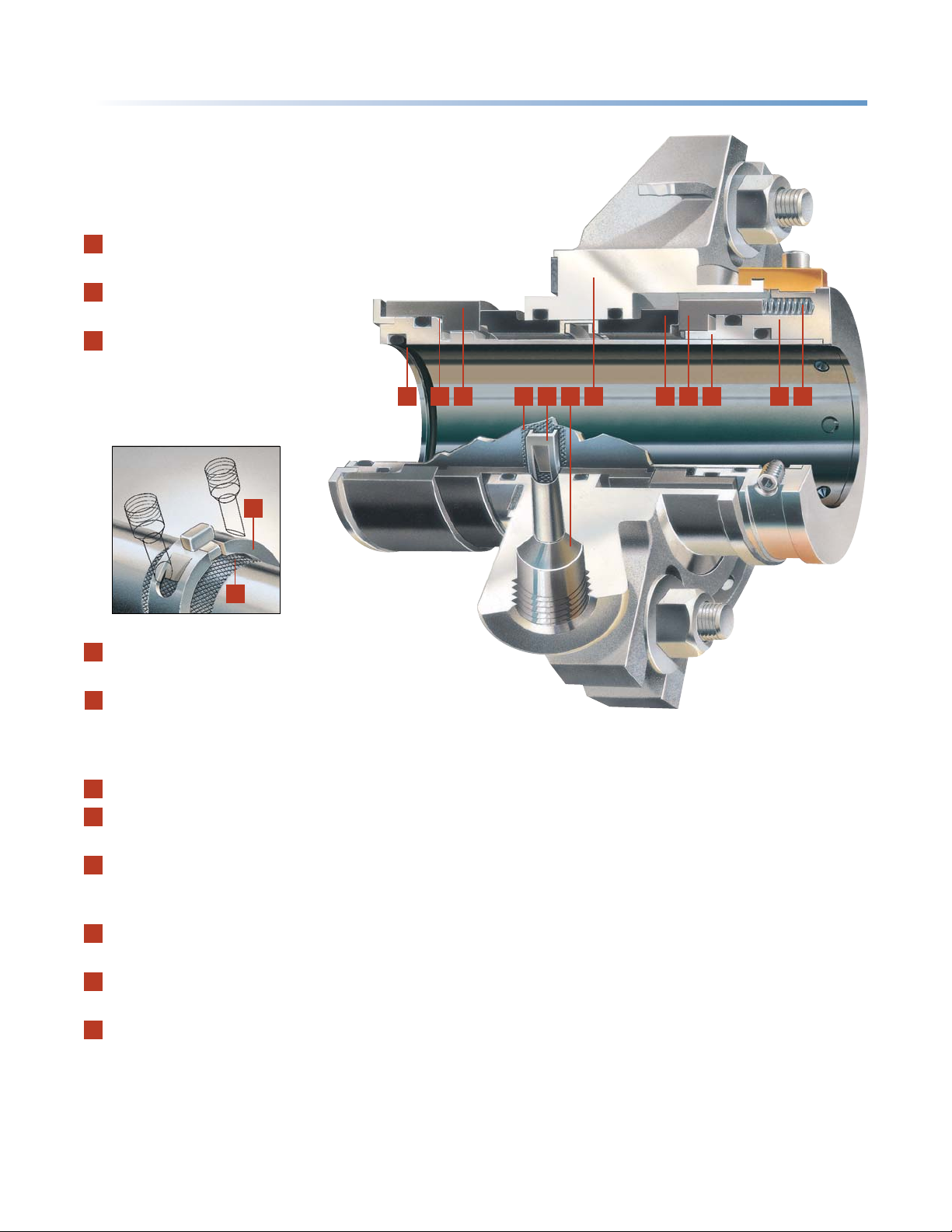

255TM

Cartridge Dual Seal

Construction Details

1

Every O-ring is either static or moves on

a non-fretting, non-metallic surface.

2

Precision seal ring support shoulder

maintains rotary alignment.

3

Inboard rotary and stationary faces.

Dynamic stress-relieving seal rings,

mated over a narrow cross-section

for low heat generation.

5

1•2•3

CHESTERTON

®

•

•

•

•

4•5•6

7

8•8• 9

10• 11

•

•

4

4

Profiled sleeve provides positive

pumping of barrier fluid.

5

Patented shuttle slides within gland to

decouple faces from gland misalignment,

channel barrier fluid, and provide anti-rotation

for stationary seal rings.

6

Barrier fluid ports provide high capacity cooling.

7

Universal gland fits majority of pumps.

ANSI oversize and API glands available.

8

Outboard stationary and rotary faces,

identical to inboard set for simple assembly,

low replacement inventory.

9

Inboard and outboard integral drive pads

cannot loosen or fall out.

10

Patented Self-Centering Lock Ring™

for superior concentricity.

11

Revolutionary Unified Seal Alignment™

requires only one set of springs to provide

constant loading of all four faces.

Springs are isolated from process and

barrier fluids.

•

Built for the future of emissions control

The Chesterton 255 seal is designed to meet

environmental regulations for emissions control.

Advanced technology for applications flexibility

The exclusive design of the 255 enables it to operate

in double-mode (barrier fluid pressure higher than

stuffing box pressure) or tandem-mode (barrier fluid

pressure lower than stuffing box pressure).

Staying cool in operation and under pressure

The 255 handles 50% to 100% more pressure than

typical seals, providing users with a “margin of safety”

at start-up and shut-down when transient surges

often occur. The 255 features an internal positive

barrier fluid pumping system with wide flow channels

for efficient removal of heat. To test the 255’s cool

running, the 255 and a widely used competitive double

seal were run under identical conditions with repeated

shutoffs. Test conditions: 1.875” (48 mm) shaft, water

barrier fluid room temperature, 1750 RPM, closed

convection system. Results: 255 ran cool and steady

while the conventional seal overheated and flashed.

Loading...

Loading...