Page 1

AWA

W6900S/SF

29”(74 CM) COLOUR TV WITH

INFRARED REMOTE CONTROL

SERVICE MANUAL

Page 2

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION", "SAFETY PRECAUTION" AND "PRODUCT SAFETY

NOTICE" DESCRIBED BELOW.

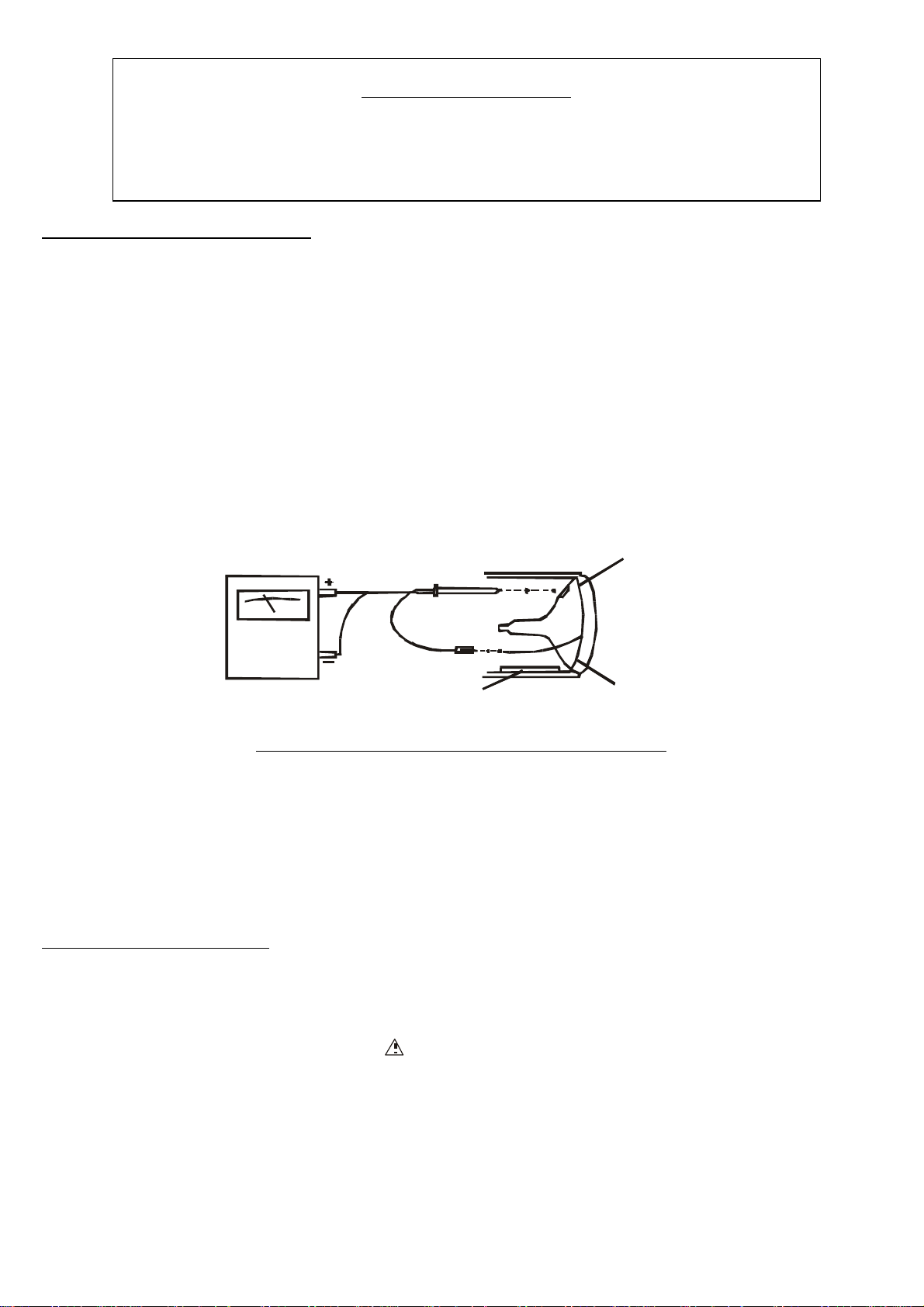

X-RAY RADIATION PRECAUTION

1. Extremely high voltage of the picture tube may result in producing potentially hazardous X-RAY RADIATION.

To avoid such hazards, the high voltage must not be above the specified limit.

The nominal value of the high voltage of this receiver is about 30.4 kV at zero beam current (minimum

brightness) under 175-245V AC power source.

The high voltage must, under any circumstances, not exceed about 36kV.

Each time this receiver requires servicing, the high voltage should be checked according to the HIGH

VOLTAGE CHECK procedure at the back of this manual. it is recommended to record the reading of the high

voltage in the service record each time. Using an accurate and reliable high impedance and high voltage meter

is quite important.

Connect the NEGATIVE and POSITIVE probe of a high voltage meter to the "ground" and the high voltage

anode cap of the picture tube respectively.

Picture tube high voltage anode cap

High impedance and high voltagh meter Chassis

Picture tube ground

HIGH VOLTAGE CHECK CONNECTION DIAGRAM

2. The only source of X-RAY RADIATION in this receiver is the picture tube. For ensuring the intensity of

X-RAY RADIATION from the picture tube being within the specified safety limit, the replacement picture tube

must be exactly the same type specified in the parts list.

3. Some parts in this receiver have special safety-related characteristics which would affect X-RAY

RADIATION protection. For safety, parts replacement should be carried out only after referring to the

"PRODUCT SAFETY NOTICE" below.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this receiver have special safety-related characteristics (directly relate to

high voltage, high temperature or electric shock) which are not easily seen by visual inspection. Whenever

replacing such components, make sure that the replacement parts can provide effective X-RAY RADIATION

protection even though their high voltage and wattage can meet the specification of the original design. Such parts

can be identified by shading and marking with in the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. Using substitute parts which

do not have the same safety characteristics as the ones specified in the parts list may create excessive X-RAY

RADIATION.

2

Page 3

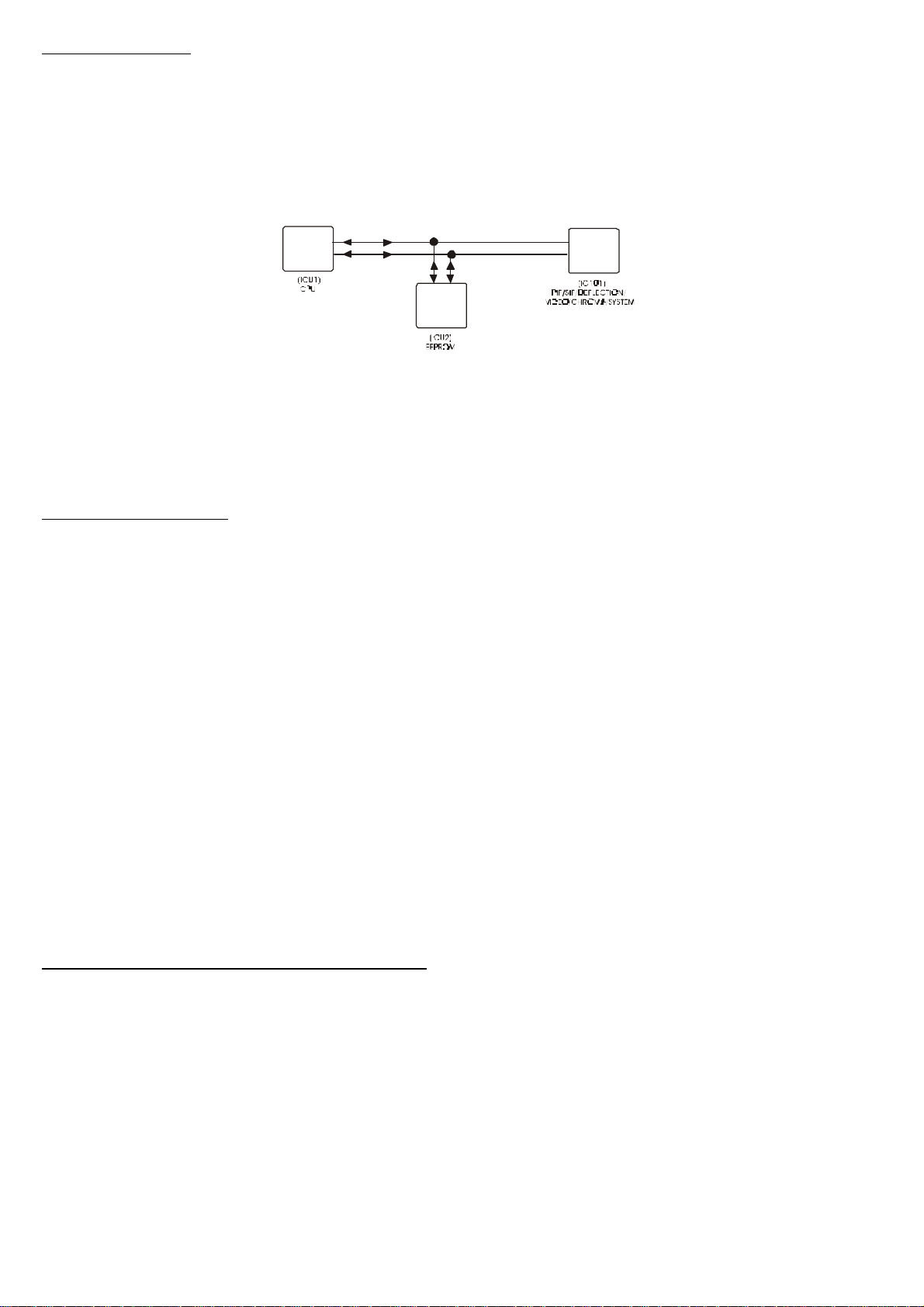

I2C BUS CONCEPT

(1). Characteristics

1.1 I2C Bus consists of clock (SCL) and data (SDA) lines.

1.2 It transmits data among integrated circuits in full duplex mode.

1.3 It is composed of a main IC chip (CPU) and one or more sub-IC chips.

l The CPU mainly operates data transmissions and also generates clock signal.

l The CPU also controls all sub-IC chips, making them work.

(2). I2C Bus Application in this TV unit

SDA

SCL

SDA

SCL

SDA

SCL

In this TV unit, ICU1 is the main chip while ICU2, IC101 and other chips are regarded as sub-chips.

2.1 ICU1 (CPU) controls the functions of IC101 via the I2C bus between them.

2.2 The data of channel positions, BT voltage, band, AFT, clear, volume, power on/off, timer, color, etc. are

written into, stored in and read out from ICU2 via the I2C bus.

SAFETY PRECAUTION

1. High voltage of 27-32kV is always present inside this receiver when it is operating, so be cautious of electric

shock hazard while removing the back cabinet to process adjustment.

(A) Servicing should not be attempted by any person who is not very familiar with the required re-cautions

when working on this high-voltage equipment.

(B) Before removing the anode cap of the picture tube, discharge the high voltage potential from the picture tube

anode several times by short-circuiting the anode together with its ground to keep off electric shock hazard.

(C) Perfectly discharge the high voltage potential of the picture tube before handling the picture tube which is

highly evacuated. When it is broken, danger may be caused because of the violent burst of its glass

fragments.

2. If the fuse in this receiver is blown, replace it with the type specified in the chassis parts list or with the same

specifications (never use other types).

3. Whenever replacing with new components, twist the lead wires of the component together with the concerned

residual leads before soldering.

4. Whenever replacing with a new high wattage resistor (such as oxide metal film resistor) on any of the circuit

boards, keep the body of the resistor 10 mm above the circuit board.

5. Keep all connecting wires away from the components of high voltage or high temperature.

6. This receiver is designed to operate at AC 175-245V~50/60Hz, NEVER connect to DC supply or any other

power sources.

7. The main chassis of this receiver is perfectly isolated.

INSTALLATION AND SERVICE ADJUSTMENTS

GENERAL INFORMATION:

Normally, this receiver have been thoroughly checked and adjusted before leaving the factory; therefore it should

operate normally and produce perfect color and B/W pictures upon installation. However, several minor

adjustments may be required according to the practical situation.

This receiver is packed in a cardboard carton during transportation. Carefully draw it out from the carton and

remove all packing materials.

Plug the receiver's power cord into a convenient 175-245V 50/60Hz AC two pin power outlet.

Check and adjust all the customer controls such as BRIGHTNESS, CONTRAST and COLOUR to obtain natural

color or B/W picture.

3

Page 4

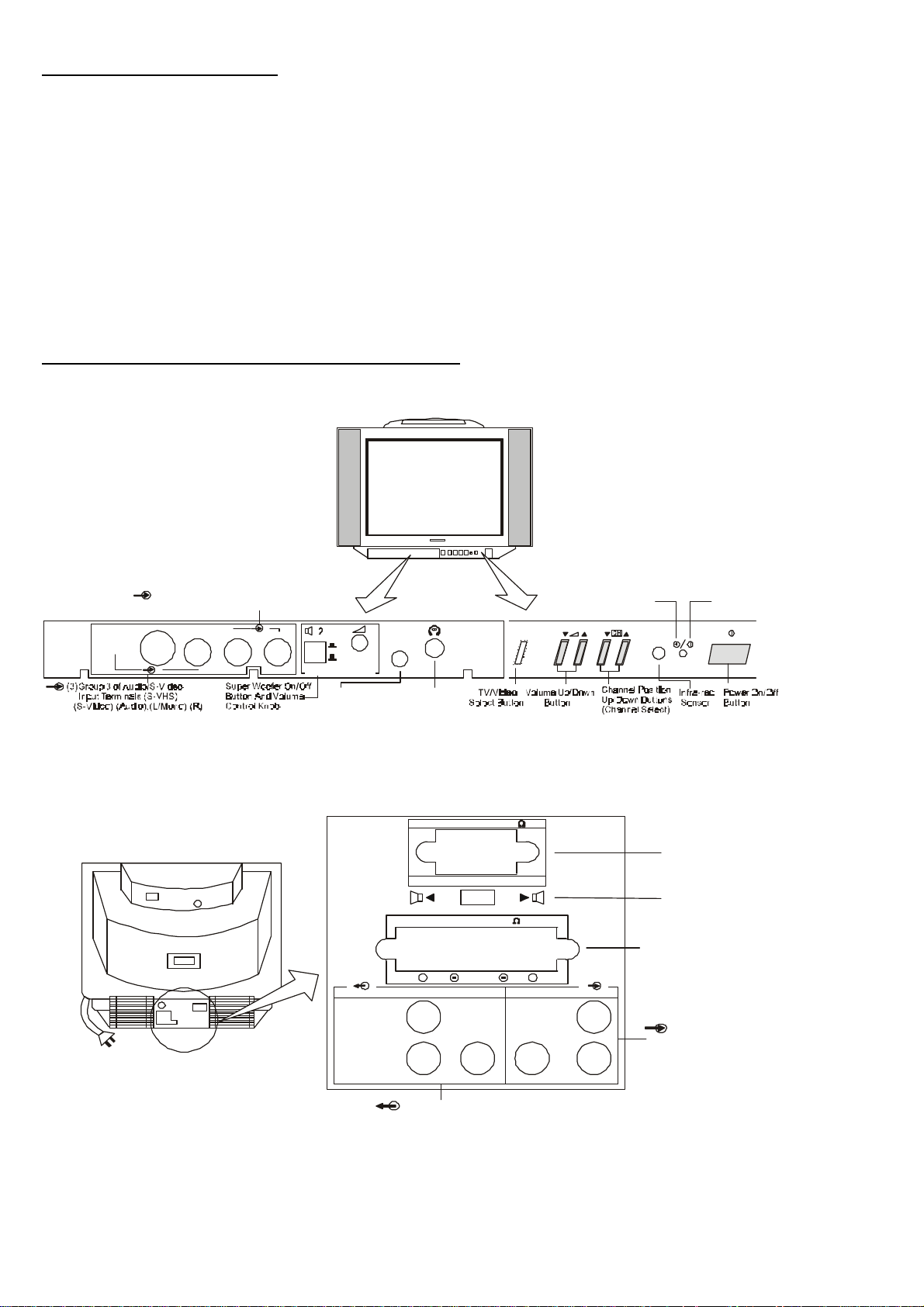

AUTOMATIC DEGAUSSING :

Input Terminals (Video),

A degaussing coil is mounted around the picture tube so that external degaussing after moving the receiver is

normally unnecessary, providing the receiver is properly degaussed upon installation. The degaussing coil

operates for about 1 second after the power to the receiver is switched ON. If the set is moved or faced in a

different direction, the power switch must be switched off at least one hour in order that the automatic degaussing

circuit operates properly. And then the receiver turned it again.

Should the chassis or parts of the cabinet become magnetized to cause poor colour purity, use an external

degaussing coil. Slowly move the degaussing coil around the faceplate of the picture tube, the sides and front of

the receiver and slowly withdraw the coil to a distance of about 2 meters before disconnecting it from AC source.

If colour shading still persists, perform the “COLOUR PURITY ADJUSTMENT” and “CONVERGENCE

ADJUSTMENTS” procedures as mentioned later.

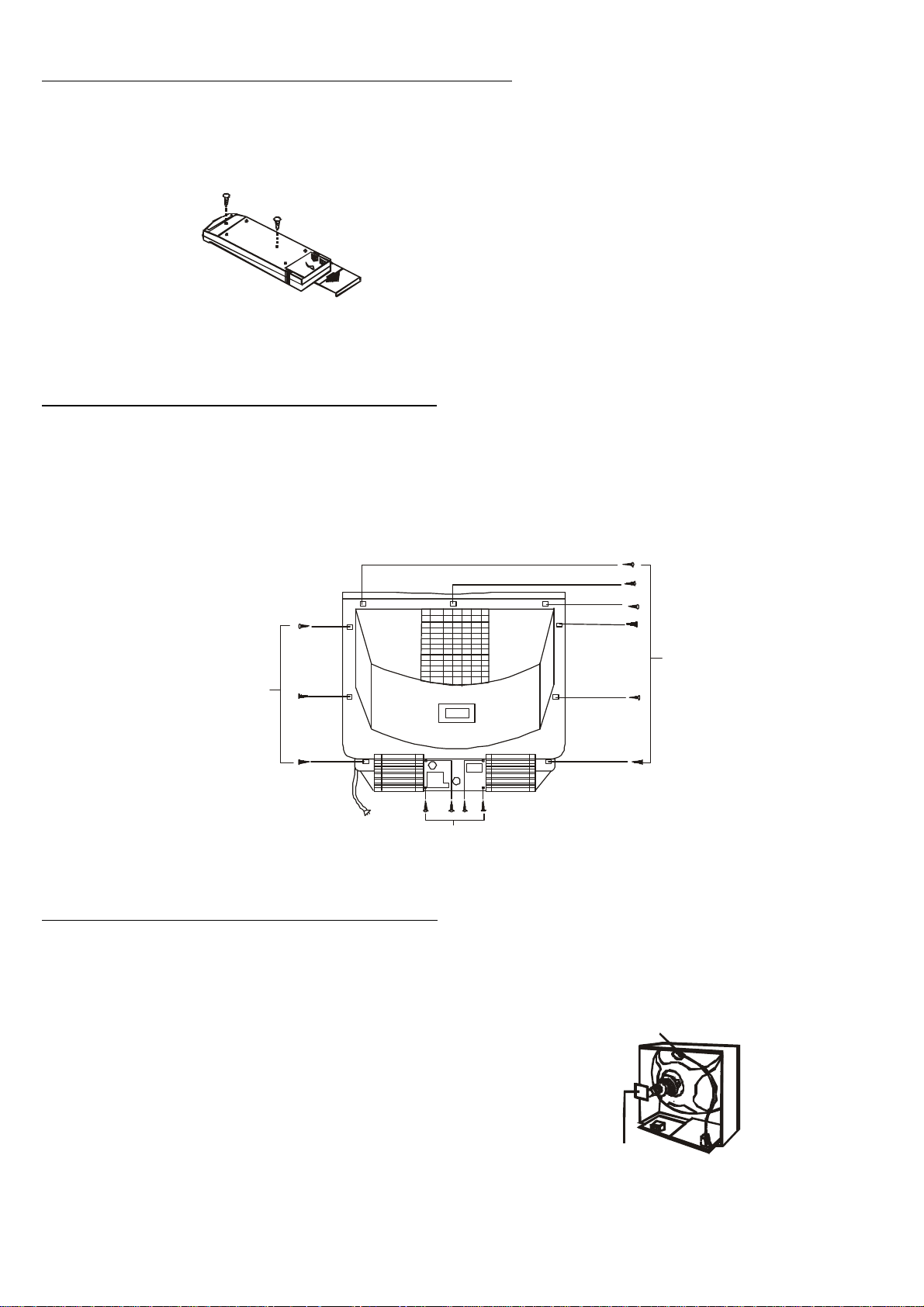

LOCATION OF CONTROLS AND SWITCHES

Front View (Front Configuration)

(2)Groups 2 of Audio/Video Input

Terminals (Video), (Audio), (L/Mono),

S-VIDEO

AUDIO

R

3

AUDIO

2

VIDEOL/MONO

:

SUPER WOOFER

MENU

Button

Rear View (Back Configuration)

ON

OFF

Headphone Jack

(3.5mm Dia, 16ohm)

MENU

SUPER WOOFER 8

EXT. SPEAKER 8

+

R

AUDIO(MONITOR) AUDIOVIDEOVIDEO

R

INT.

EXT.

MENU

L

Standby

(Red)

Super Woofer Out Terminals

Main Speakers Output Terminals

+

L/MONOL/MONO

R

Power

(Green)

Speaker Switch (EXT/INT)

(1)Group of Audio/Video

(Audio), (L/Mono),(R)

(Monition) Tv Out Terminals

(Video), (Audio), (L/Mono),(R)

4

Page 5

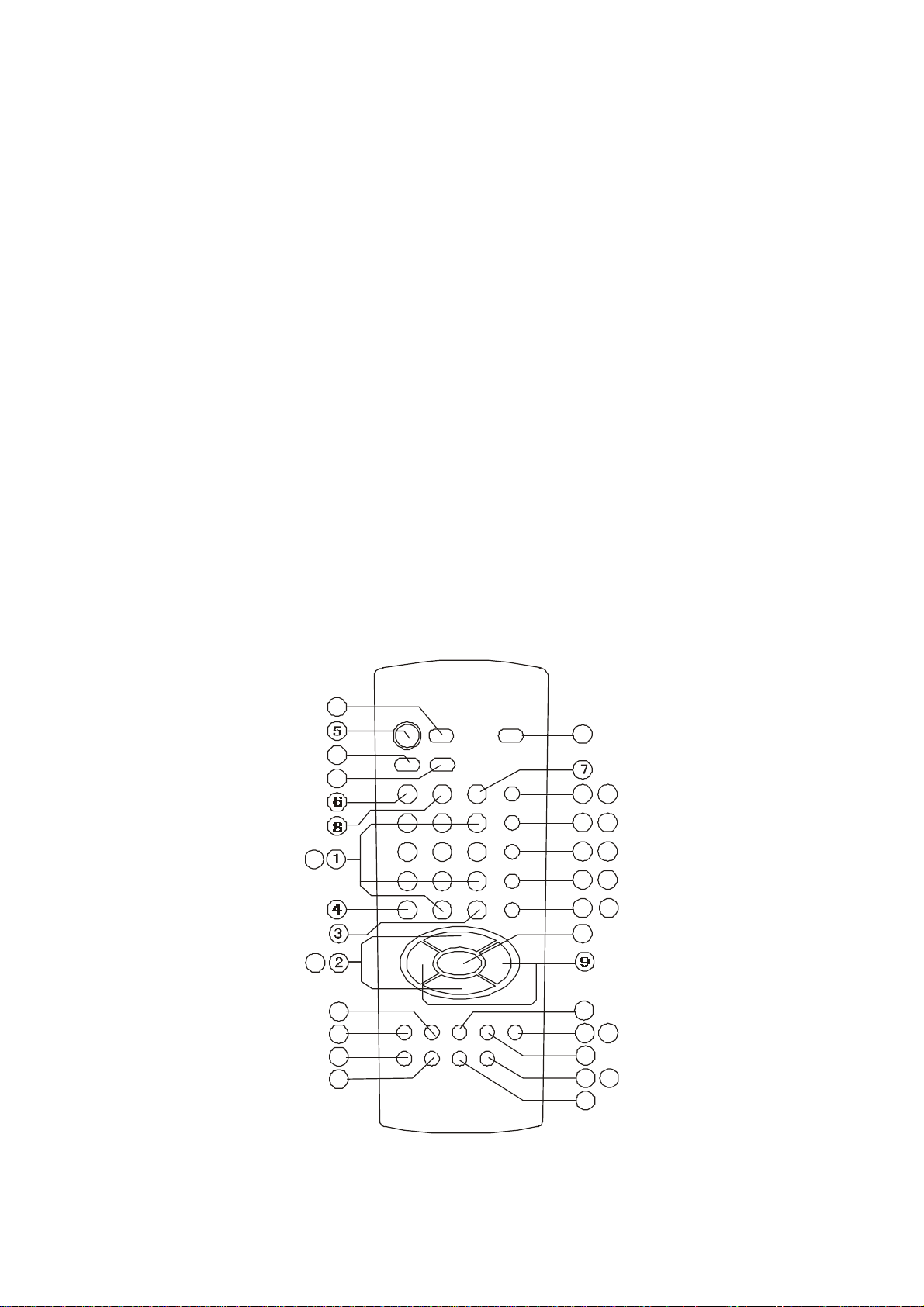

Remote Control Unit

There are 38 buttons on the remote control. It operates with infra-red beam which is not affected by noise or other

interferences. Make sure strong light never strikes on the infra-red receiver; otherwise, it would obstruct the

remote control working normally with the TV unit.

Do not drop or expose it to high temperature.

*16-17 (FOR GERMAN STEREO ONLY)

*19-36 (FOR TELETEXT ONLY)

1. NUMBER (0-9) BUTTONS

2. PROGRAM (UP/DOWN) BUTTONS

3. AV BUTTON

4. TV BUTTON

5. STANDBY BUTTON

6. PERSONAL PREFERENCE BUTTON (PP)

7. SOUND MUTING BUTTON

8. STATUS BUTTON

9. VOLUME (UP/DOWN) BUTTONS

10. MENU BUTTON

11. RED (PICTURE MENU) BUTTON

12. GREEN (SOUND MENU) BUTTON

13. YELLOW (OTHER MENU) BUTTON

14. CYAN (INSTALL MENU) BUTTON

15. WHITE (TIME MENU) BUTTON

16. STEREO/MONO & DUAL I/II BUTTON

17. EFFECT BUTTON

18. SWAP BUTTON

19. SUBTITLE BUTTON

20. TXT. BUTTON

21. MIX. BUTTON

22. CANCEL BUTTON

23. HOLD BUTTONSIZE BUTTON

24. SIZE BUTTON

25. REVEAL BUTTON

26. TIME BUTTON

27. SUBCODE BUTTON

28. DIGIT ENTRY (0-9) BUTTONS

29. PAGE NUMBER UP / DOWN BUTTONS

30. PREVIOUS BUTTON

31. TOP/FLOP/SIMPLE BUTTON

32-35. COLOR BUTTONS

36. WHITE (INDEX) BUTTON

37. SERVICE BUTTON

28

29

37

16

17

21

20

24

23

19

11

12

13

14

15

10

22

18 31

30

26 27

25

32

33

34

35

36

5

Page 6

HOW TO DISASSEMBLE REMOTE CONTROL HAND UNIT (see Fig. 1)

1. Remove the battery cover and loosen the screws.

2. Open one side of the back cabinet to take it away from the front cabinet.

Fig. 1

METHOD OF REMOVING BACK CABINET (see Fig. 2)

Attn.: Before disassembling the back cabinet, first draw the power cord plug of the receiver from AC outlet.

1. Disconnect the antenna cable from the antenna terminal.

2. Loosen the 5 pieces of screw (A) used in fixing the antenna jack plate on the back cabinet.

3. Loosen the 9 pieces of screw (B) used in fixing the back cabinet to the front cabinet; then remove the back

cabinet.

Screws(B)

Screws(A)

Fig.2

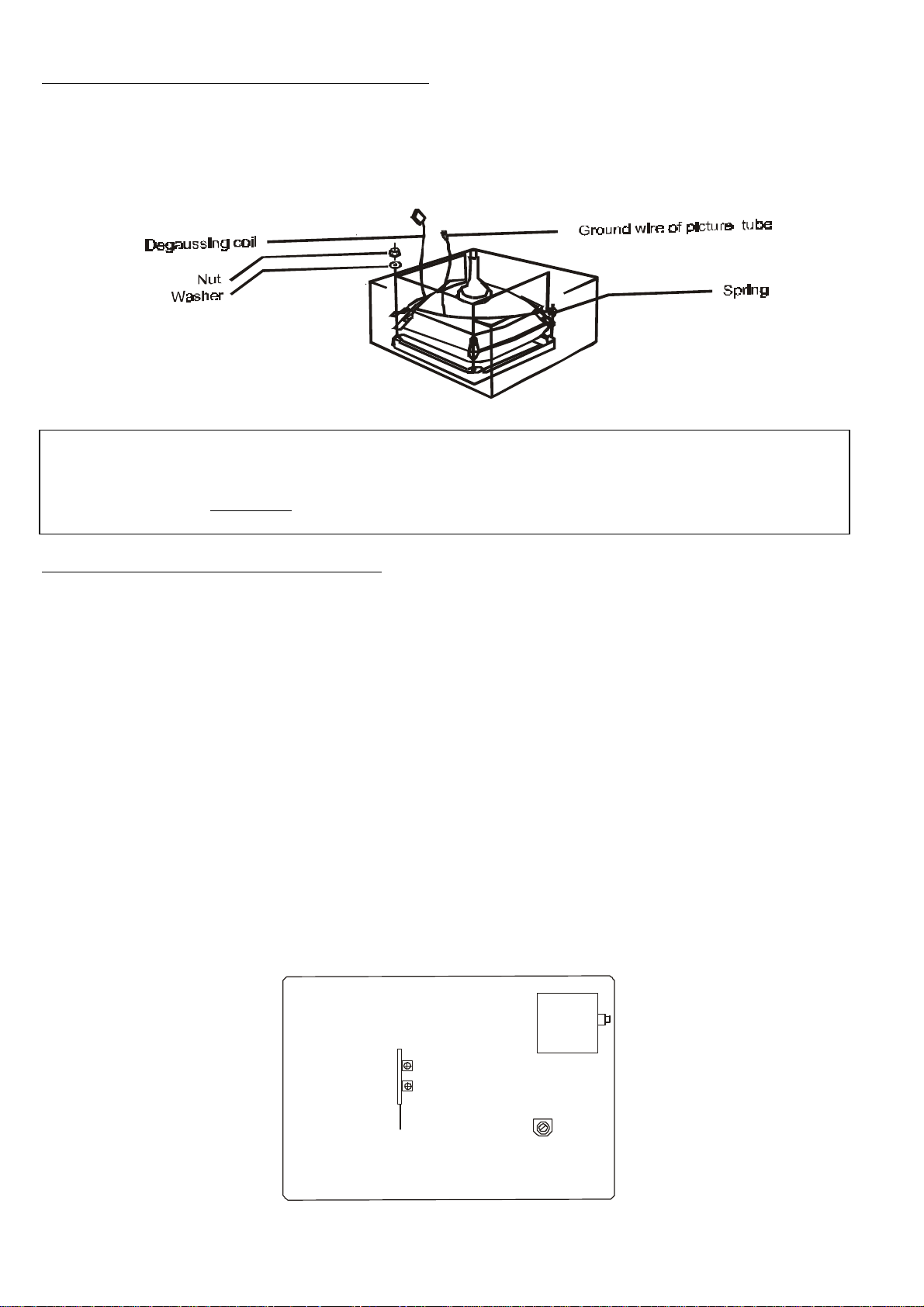

METHOD OF REMOVING MAIN CHASSIS (see Fig. 3 & 4)

After removing the back cabinet, proceed the following procedures accordingly.

1. To avoid electric shock hazard, discharge the high Fig.3

voltage potential from the picture tube anode

several times by short-circuiting the positive anode

of the picture tube with its ground before detaching

the high-voltage anode cap.

2. Unsolder and detach the ground wire of the picture

tube from the picture tube socket board.

3. Detach the picture tube socket board.

4. Detach the high-voltage anode cap.

5. Unplug Socket F, U, V, A, B, K or X and P.

6. Take out the chassis from the chassis holder.

High-volotage anode cap

Picture tube socket board

Screws(B)

6

Page 7

METHOD OF REMOVING PICTURE TUBE (see Fig. 4)

MAIN CHASSIS PC BOARD

After taking out the chassis holder (main chassis), proceed the following procedures accordingly:

1. Turn the receiver down and let the screen of the picture tube face downward, and put it on a soft cushion.

2. Loosen the 4 pieces of nut used in fixing the picture tube on the front cabinet, remove the degaussing coil; then

use two hands to hold the edges of the picture tube tightly and draw it out.

3. Detach the ground wire of the picture tube which is attached to the lugs of the picture tube with springs.

Fig.4

SUGGESTION: Before servicing the chassis, please read through “X-RAY RADIATION

PRECAUTION", "SAFETY PRECAUTION" and "PRODUCT SAFETY NOTICE" at

Page 2 & 3 of this manual.

GENERAL ADJUSTMENT INSTRUCTIONS

This receiver is transistorized and special care should be taken when servicing. If not necessary, do not attempt

any adjustments because the requirements of the procedures are very stringent. Read the following matters before

attempting any adjustments.

An isolation transformer should be used during any dynamic service to avoid possible electric shock hazard.

The test equipment specified or their equivalent is required in having proper alignment. Using unsuitable

equipment, which do not meet these requirements, may result in improper alignment.

Correct matching of the equipment is essential. Failure of using proper matching will result in responses which

cannot show the true operation of the receiver.

Excessive signal by using a sweep generator can cause the receiver circuit overloaded. Overloading should be

avoided to obtain a true response curve. Insertion of markers by using the marker generator should not cause the

response curve distorted.

The AC power line voltage should be accurately kept during alignment.

During the process of alignment, the AC voltage should be kept in the range from 215V to 225V (50Hz).

Do not attempt to connect or disconnect any wire while the receiver is in operation. Make sure the power cord is

unplugged before replacing any parts in the receiver.

Unless specified, start adjustments after the receiver is turned on for at least 30 seconds.

CHASSIS'S TOP VIEW

VRC2

VRC1

E-W CORRECTION PC BOARD

7

T902

VR 501

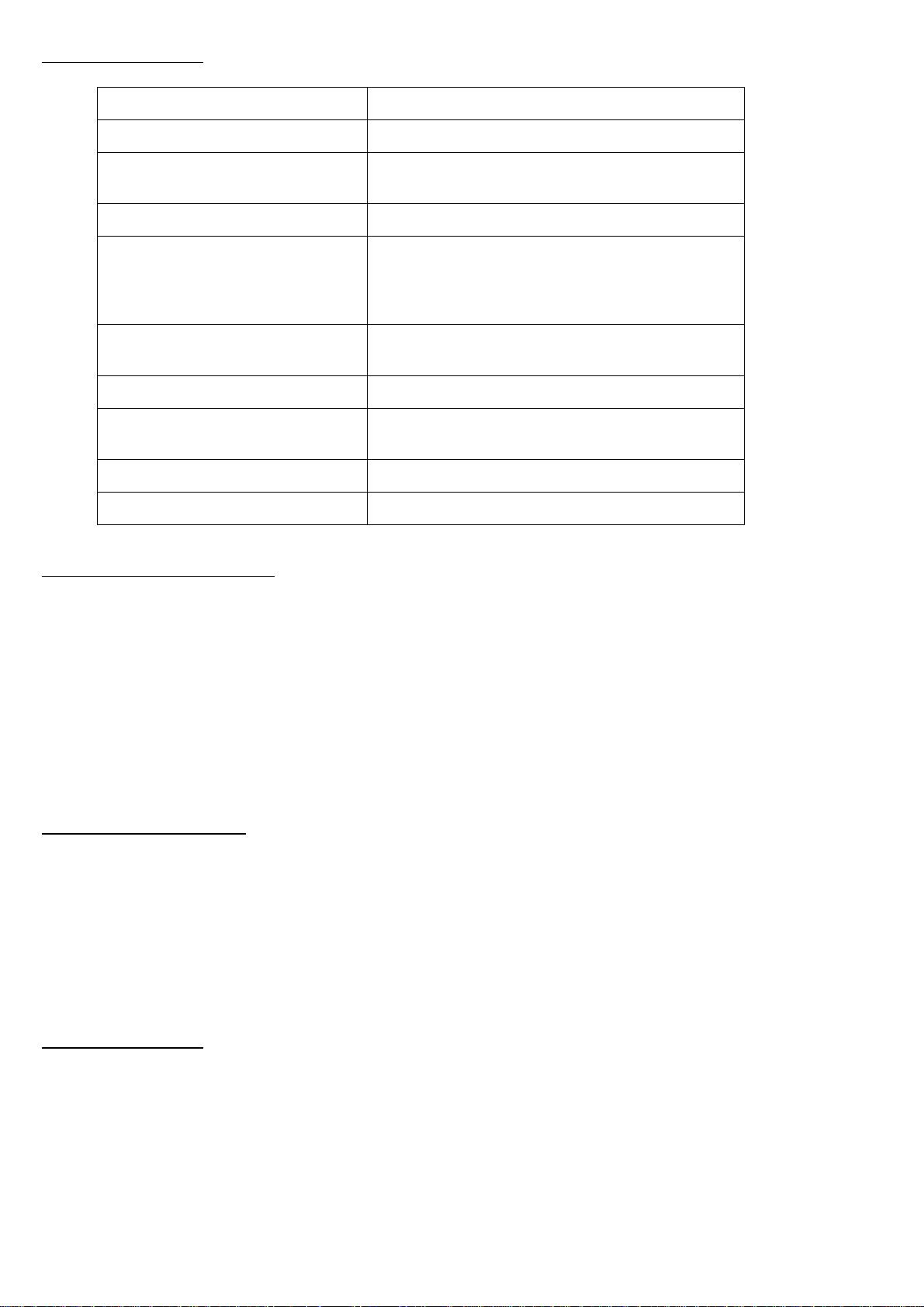

Page 8

NOTICE:

1. Resistor

All resistors are of 1/8W Carbon Film type except those listed below. The unit of measure for resistor is OHM

(K = 1,000 ohm, M = 1,000,000 ohm).

CARBON FILM RESISTOR

CARBON COMPOSITION RESISTOR

METAL OXIDE RESISTOR +5%

METAL OXIDE RESISTOR +2%

FUSIBLE RESISTOR

NON-INFLAMMABLE RESISTOR

PTC THERMISTOR

VARIABLE RESISTOR

2. Capacitor

All capacitors are of 50V Ceramic type except those listed below. The unit of measure for capacitor is

FARAD (F) (UF = 0.000001 F, PF = UUF = 0.000001 UF)

CERAMIC CAPACITOR

TANTALUM CAPACITOR

POLYESTER FILM CAPACITOR

POLYPROPYLENE FILM CAPACITOR

ELECTROLYTIC CAPACITOR

TRIMMER CAPACITOR

METAL POLYESTER FILM CAPACITOR

3. Unit of Measure: UH

4. Test Point

5. Marking of Ground Wire

: Ground wire of chassis (COLD)

: Ground wire of external wire (HOT)

6. Voltage Measurement

The voltages at all points should be measured with a digital multi-meter, and the measuring conditions are as

follows:

Power Source: AC220V 50Hz

Receiving Signal: Color Bar Signal

All Control Buttons: in Normal Position

7. Waveform

The numeral in the small circle represents the number of waveform, refer to the waveform table.

8. It is easy to locate a connection point in the direction as indicated by arrow (↗).

9. The schematic diagram in this manual is drawn according to the original design. It may be slightly different from

the actual circuit of the receiver because of any change in the circuit subject to no prior notice.

Notice: This circuit has a transformer to isolate the power supply circuit from the majority of the other

circuit, and they can be identified in the schematic diagram by marking with "HOT" and "COLD”.

Please note the followings .All circuits are "COLD" except power supply circuit.

(1) To avoid electric shock hazard, never touch the "HOT" and "COLD" circuit simultaneously.

(2) Never short-circuit the "HOT" and "COLD" circuit to prevent the fuse or other components from burning.

(3) Never connect any measuring equipment such as oscilloscope to both the "HOT" and "COLD" circuit at the

same time to prevent the fuse from burning. Also, connect the ground of the measuring equipment to the ground

of the circuit being tested.

(4) Never fail to unplug the power cord of the receiver before taking out the chassis.

8

Page 9

TEST EQUIPMENT :

EQUIPMENT SPECIFICATION

High Impedance Voltmeter Having an impedance of at least 100 Kohm.

Oscilloscope Volt sensitivity over 10mV input impedance over 1

Sweep/Marker Generator Output adjustable to at least 0.1 volts rms.

Colour Bar Generator With functions: BAR/DOT/SQUARE/SYSTEM

Power Supply

AC/DC Voltmeter High sensitive (better use digital voltmeter)

Isolation Transformer

Probe Low-capacitance / High impedance.

Mohm, below 10PF.

SELECT/VIDEO OUTPUT TERMINAL/CROSS-

HATCH/S-VIDEO OUTPUT TERMINAL functions and

green or red purity signal.

Source such as a battery or a well regulated and isolated

DC bias supply. (Adjust 0-20V)

Voltage adjustable type having capacity of more than

200 watts.

FM/AM Signal Generator National ; MODEL : VP8177A

B+ VOLTAGE ADJUSTMENT

Notice: (A) B+ voltage closely relates to the picture tube's positive high voltage.

(B) To prevent it from producing excessive hazardous X- RAY RADIATION, ensure that B+ voltage must

be adjusted to at the 125V (CE-6401/6418/6409/7405)/ 124V(or)140V (CE-7406)/ 145V (CE-8608)/

115V (CE-8616) POSITIONS.

1. Check the AC line voltage supplied is AC220V +-5% 50 Hz.

2. Turn in an active channel, adjust BRIGHTNESS and CONTRAST controls to obtain a normal picture.

3. Connect test point (C523) on the MAIN CHASSIS PCB with high impedance DC voltmeter.

4. Adjust VR501 (on the MAIN PCB) for B+ 125V +/-0.3V (CE-6401/6418/6409/7405)/ 124V(or)140V +/-

0.3V(CE-7406)/ 145V +/-0.3V(CE-8608)/ 115V +/-0.3V(CE-8616) voltage reading.

HIGH VOLTAGE CHECK:

CAUTION : There is no HIGH VOLTAGE ADJUSTMENT on this chassis.

a. Connect an accurate high voltage meter to the second anode of the picture tube.

b. Turn on the receiver and set the BRIGHTNESS, COLOUR and CONTRAST Controls to the minimum

(zero beam current).

c. High voltage will be measured below 35KV.

d. Adjust the BRIGHTNESS Control to both extremes to ensure the high voltage does not

exceed the limit of 34Kv under any circumstances.

FS CIRCUIT CHECK:

a. Push the Power Switch on and adjust all controls for normal operation.

b. Temporarily connect a 18Kohm resistor across R908 on the Main Chassis PC Board. Raster and sound

will disappear.

c. The receiver must remain in this state even after removing the resistor. This is the evidence that the

Fail Safe circuit is functioning properly.

d. To obtain a picture again, temporarily push the power switch off and allow the Fail Safe circuit move

than 30 seconds to reset. Then push the power switch on to produce a normal.

9

Page 10

FOCUS ALIGNMENT :

Tune in an active channel or Phillips Pattern. Adjust the Focus control on the FLYBACK

TRANSFORMER (T902) for well defined scanning lines in the center area on the screen.

SCREEN VOLTAGE (VG2) ADJUSTMENT

Apply a FULL BLACK signal with a colour bar signal generator.

Connect oscilloscope to measure pin of R132, R133 or R134 (Vbcmp) on the main board. Vbcmp means

DC-level of the black current measurement pulse.

Turn the CONTRAST and BRIGHTNESS controls to normal positions.

Turn the SCREEN VR anti-clockwise to get the minimum value.

Then turn the SCREEN VR clockwise slowly to get the reading of the DC-level at the RGB-output is 3.3V.

ATTN.: CE-7407 of SCREEN VOLTAGE adjustment reading of the DC-level at the RGB-output is 3.3V or

Screen Voltage is about DC 400V.

HORIZONTAL POSITION ADJUSTMENT

a. Receive the Phillips Pattern. Apply a crosshatch signal.

b. Set the contrast and colour to their minimum, and the brightness to its maximum.

c. Adjust (H-SHIFT) to move the picture at the center.

ATTN.: These settings should be done with separate test signals with a 50 Hz and a 60 Hz field frequency. These

parameters are stored in separate groups for 50 Hz and 60 Hz and are recalled or set, depending on the

field frequency of the currently received program.

VERTICAL ADJUSTMENT

Apply a crosshatch signal.

Adjust (V-SLOPE) to obtain half picture.

Adjust (V-S.CORR) to obtain a linear picture.

Adjust (V-SHIFT) to move the picture at the center.

Adjust (V-AMPL) to obtain rightful high picture.

ATTN.: These settings should be done with separate test signals with a 50 Hz and a 60 Hz field frequency. These

parameters are stored in separate groups for 50 Hz and 60 Hz and are recalled or set, depending on the

field frequency of the currently received program.

PICTURE WIDTH AND PINCUSHION DISTORTION ADJUSTMENT :

a. Perform this adjustment after the B+ volts and the Hor. CENTER adjustment are completed.

b. Receive a Phillips Pattern.

c. Set the contrast and colour to the minimum, and the brightness to the maximum.

d. Adjust the H. WIDTH Control (VRC2) for the horizontal width so that the white flags on the left and

right of the pattern just hide.

e. Adjust the DPC Control (VRC1) to correct the vertical line on left and right straight.

f. Readjust the WIDTH Control (VRC2) for the precision.

DELAY AGC ADJUSTMENT :

Apply a 60dbu level with standard colour bar signal to the antenna input.

Connect the probes of the high impedance DC voltmeter to C156.

Adjust (AGC-ADJ) to get the reading of 4 - 5V till obtaining a clear picture.

10

Page 11

CRT GREY SCALE ADJUSTMENT (WHITE BALANCE ADJUSTMENT):

Apply a white balance alignment signal with the white balance checker.

Adjust brightness and contrast suitable for the adjustment.

Adjust (R-GAIN), (G-GAIN) and (B-GAIN) to obtain a 9300 K colour temperature.

SAFETY PRECAUTION :

Dielectric voltage withstand test :

The following accessible parts should be stressed for a period of one second on each complete appliance

before it leaves the factory.

The test potential voltage not less than 3500V, 50Hz should be applied for 1 second between both blades of

the attachment plug cap. and the following parts :

Name of part Locations

1. Antenna Terminal Back Cabinet

2. AV input Terminals Front / Back Cabinet

3. AV output Terminals Back Cabinet

3. Enclosure Screws Back Cabinet

4. S-Video Sockets Front Cabinet

5. Ext. Speaker Terminals Back Cabinet

SOUND IF ALIGNMENT (BG-38.9MHz)

a. Apply IF signal (38.9 MHz, 10mV) to Pin 1 of D socket.

b. Set a signal generator to colour bar and dual transmission with internal modulation of 3 KHz on channel

1 and 1 KHz on channel 2.

c. Connect oscilloscope to pin 15 of ICF1 (TDA3857).

d. Align the 38.9MHz coil (LF4) for minimum picture contents.

STEREO SOUND AND DUAL SIF ALIGNMENT (BG - 5.5MHZ, DK - 6.5 MHz)

a. Set transmitter to dual sound mode and off the main sound modulation.

b. Adjust (LF5) 5.74MHz tank coil to minimum THD.

c. Set transmitter to BG mono sound mode, connect the dual vertical input of the oscilloscope to RF17

(MAIN SOUND) 5.5MHz and RF15 (SUB SOUND) 5.74MHz.

d. Adjust (LF6) 5.5MHz tank coil to minimum THD.

e. Change the sound to D/K system, adjust (LF7) 6.5MHz tank coil to minimum THD.

f. Re-align LF6 and LF7 to minimum THD both.

GERMAN STEREO FILTER COIL (LF8)

a. Set a signal generator to colour bar, stereo sound mode and off the main sound modulation (5.5 MHz

signal).

b. Connect the oscilloscope to Pin 5 of ICF2.

c. Adjust FILTER COIL (LF8) for the maximum reading on the oscilloscope (envelope waveform) with

the minimum distortion.

11

Page 12

COLOUR PURITY ADJUSTMENT

Note: Before attempting any color purity adjustments, the receiver should be turned on for at least 30

minutes. (see Figure 8). A few rubber wedges should be available for use whenever necessary

during the process of color purity adjustment.

a. Demagnetize the picture tube and cabinet using an external degaussing coil.

b. Turn the CONTRAST and BRIGHTNESS controls to maximum.

c. Adjust RED and BULE bias controls (R-GAIN) and (B-GAIN) to provide only a green raster.

Advance the GREEN bias control (G-GAIN) is necessary.

d. Loosen the clamp screw holding the yoke and slide the yoke and slide the yoke backward to provide

vertical green belt (zone) in the picture screen.

e. Remove the rubber wedges.

f. Rotate and spread the tabs of the purity magnet (See Fig. 9 around the neck of the picture tube until

the green belt is in the center of the screen. At the same time center the raster vertically.

g. Move the yoke slowly forward or backward until a uniform green screen is obtained. Tighten the

clamp screw of the yoke temporarily.

h. Check the purity of the red and blue raster by adjusting the bias controls.

i. Obtain a white raster, referring to "CRT GREY SCALE ADJUSTMENT (White Balance

Adjustment).

j. Proceed with convergence adjustment.

CENTER CONVERGENCE ADJUSTMENT :

Note : Before attempting any convergence adjustments, the receiver should have operated for at least fifteen

minutes.

a. Receive crosshatch pattern with a colour bar signal generator.

b. Adjust the BRIGHTNESS and CONTRAST controls for a well defined pattern.

c. Adjust two tabs of the 4-Pole magnets to change the angle between them (See Fig.9) and superimpose red

and blue vertical lines in the center area of the picture screen (See Fig. 10).

d. Turn both tabs at the same time , keeping their angles constant to superimpose red and blue horizontal lines

at the center of the screen (See Fig. 10).

e. Adjust two tabs of 6-Pole magnets to superimpose red and blue line with green one. Adjusting the angle

affects the vertical lines and rotating both magnets affects the horizontal lines.

f. Repeat adjustments c,d,e, keeping in mind red, green and blue movements because 4-Pole magnets and 6-

Pole magnets mutual affection and make dot movement complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT :

a. Loosen the clamping screw of the deflection yoke to allow the yoke to tilt.

b. Put a wedge as shown in Fig.8 temporarily. (Do not remove the cover paper on the adhesive part of the

wedge).

c. Tilt front of the deflection yoke up or down to obtain better convergence in circumference. (See Fig.10).

Push the mounted wedge into the space between the picture tube and the yoke to hold the yoke temporarily.

d. Put another wedge into bottom space and remove the cover paper to stick.

e. Tilt front of the yoke right or left to obtain better convergence in circumference. (See Fig. 10).

f. Keep the yoke position and put another wedge in either upper space. Remove the cover paper and stick the

wedge on picture tube to hold the yoke.

g. Detach the temporarily mounted wedge and put it in another upper space. Stick it on the picture tube to fix

the yoke. After fixing three wedges, recheck overall convergence.

h. Tighten the screw firmly to hold the yoke tightly in place. Stick 3 adhesive tapes on wedges as shown in

Fig. 8.

12

Page 13

DEFLECTION YOKE

RUBBER

WEDGES

PURIIY AND

CONVERGENCE

MAGNET ASS Y

33 mm

(1-5/16 )

TEMPORARY

MOUNTING

30

30

RUBBER WEDGES

LOCATION

Figure 8

30

DEF.YOKE

RUBBER WEDGE

ADHESIVE

4-POLE MAGNETS

PURITY MAGNETS

6-POLE

MAGNETS

CONVERGE MAGNET ASSEMBLY

BLU RED

BLU

RED

4-Pole Magnets Movement

Center Convergence by Convergence Magnets

R

G

B

R

G

B

ADJUST THE ANGLE

(VERTICAL LINES)

ADJUSTMENT OF MAGNETS

Figure 9

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

BLU

RED

/

RED

BLU

/

6-Pole Magnets Movement

FIXED

GRN

Incline the Yoke up (or down) Incline the Yoke right (or left)

Circumference Convergence by DEF Yoke

Fig .10 Dot movement Pattern

13

Page 14

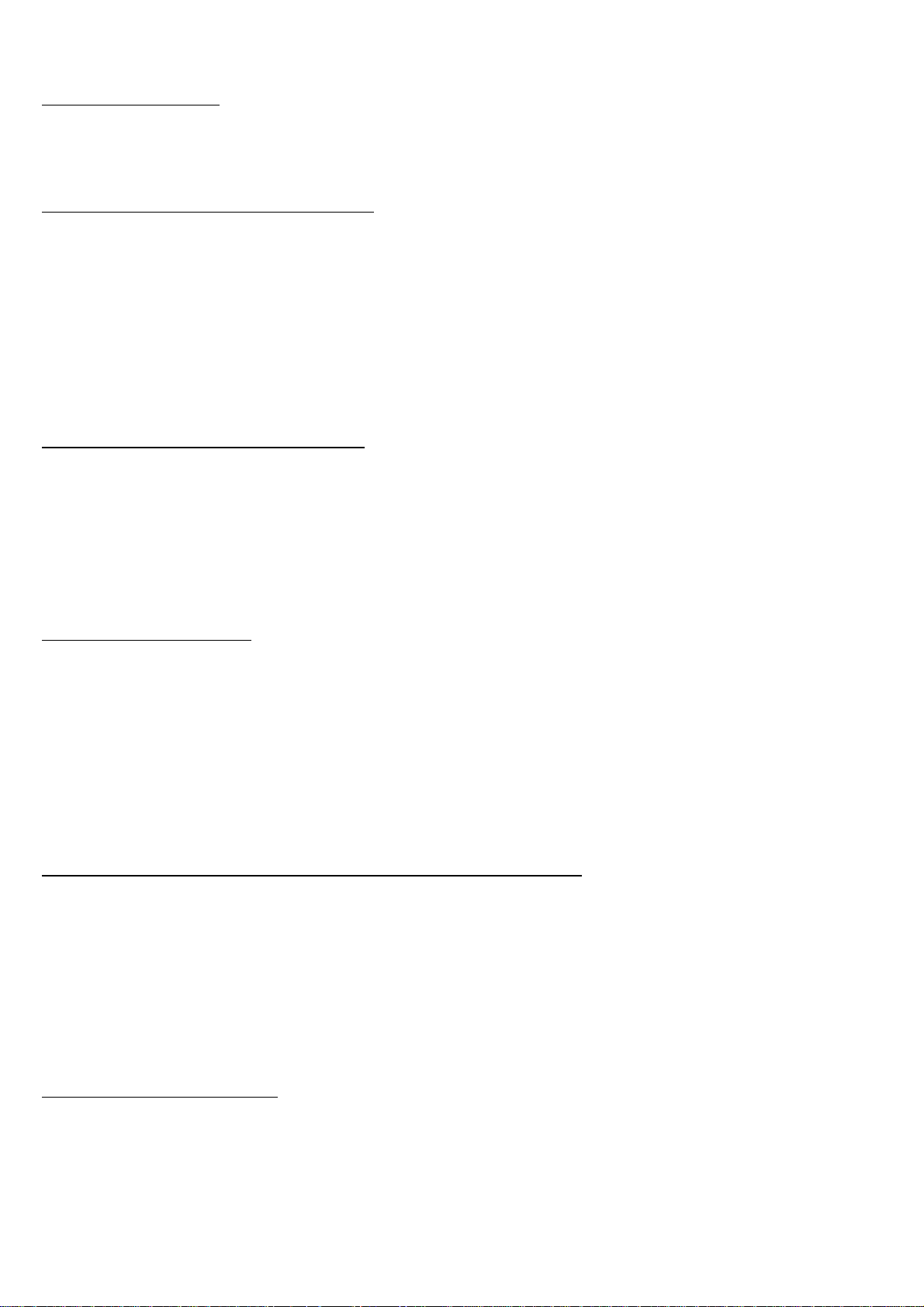

FACTORY ADJUSTMENT MODE:

General

All available options are devided over 4 option bytes, which can be set in the service menu. To activate

the service menu, RC-5 code 58 with system address 7 should be transmitted to the system. When the

Service menu is activated, pressing the Status-key will bring up option byte 0. The menu left/right keys

will change the value of the option byte down or up respectively. Pressing the Menu Up key will bring up

the next option byte, option byte 1.

Note, that the four option bytes are not part of the overall service menu carrousel or even part of an own,

“option byte” carrousel. When the last option byte has been entered and menu up is pressed, the first item of

the service menu will be activated again. Pressing menu-down, when any of the option bytes 1..3 is active

will bring up the previous option byte. Pressing menu-down when option byte 0 is present, will bring up the

last item in the service menu carrousel.

Note, that the option bytes are represented in binary notation and that the Least Significant Bit (LSB, bit 0)

is the most right-hand bit.

Note, that bits marked as reserved are used by other members of the

CTV27X family of TV control systems.

In case the user should forget the password that has been entered, there is a “built-in” password,

that will always work: 759.

Option byte 0

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Opt StoreUp Opt

Auto store

up

(1..99)

1=Auto

store

starts at

program 1

0=Autostore

starts at

program 99

Table 5.1 Option byte 0 definitions

The setmaker’s logo can only be displayed if memory bank 1 is present. If this bank is present, displaying

the logo can disabled by setting bit 1 low. If the memory bank is present and bit 1 is set, then the logo will

be displayed for 15 seconds, after a cold start only.

NOTE: If no text is defined for the logo in memory bank 1, this option should always be 0

Option Byte 0 adjustment setting are 10000001.

The following options are available in option byte 0.

Opt Standby Opt Tuner Opt

FColorOn

Forced

Color

on

1=Auto

Color killing

disabled

0=Auto

Color killing

enabled

reserv. Standby after

power on

- 1=Al. ways

goto standby

after power

on

0=power on

mode depends

on last status

UV1316tuner

type

1=UV1316M

K2

0=Old

UV1316

Logo

reserv. Display

Logo

- 1=displ

ay

0=don’t

display

Opt

Stereo

Simple

Stereo

1=prese

nt

0=not

present

14

Page 15

Option byte 1

bit 7

bit 0

Opt SChannels

Op Chan Table

used

Video Chip

reserved

not used

not used

Channel Table

bit 5

Opt Pall

Opt PalDK

NTSC-BG

NTSC-M

SECAM-DK

SECAM-BG

PAL-I

PAL-DK

PAL-BG

The following options are available in option byte 1:

not

bit 6 bit 5 bit 4 bit 3 bit 2 bit 1

Opt

TDA884X

S-channels

- 1=TDA884X - 1= S-channels

- -

included

0= S-channels

not included

Table 5.2 Option byte 1 definitions

In option byte 1, the bits 0 and 1 form a number between 0 and 3.

bit 1 bit 0

Op Chan Table

Not used for VST tuners

0 0 CCIR

0 1 UK

1 0 OIRT

1 1 Illegal

Table 5.3 Option byte 1, bits 0 and 1 determine channel table

Note, that when a VST tuner is installed, the option bits for

Channel Table have no meaning.

Option Byte 1 adjustment setting are 01010000.

Option byte 2

Option byte 2 is used entirely to set the available color and sound standards.

Note, that the available systems set here must match the installed Xtal’s for the video one-chip and sound

traps.

bit 7 bit 6

Opt

NtscBG

Opt

NtscM

bit 4 bit 3 bit 2 bit 1 bit 0

Opt

SecamDK

Opt

SecamBG

Opt

PalBG

Not

used

1=present

0=not

present

1=presen

t

0=not

present

- 1=present

0=not

present

1=present

0=not

present

1=presen

t

0=not

present

1present

0=not

present

1=present

0=not

present

Table 5.4 Option byte 2 definitions

Option Byte 2: 1. Adjustment setting are 01000001 for PAL-BG and NTSC-M.

2. Adjustment setting are 01000011 for PAL-BG/DK and NTSC-M.

3. Adjustment setting are 01011011 for PAL/SECAM-BG/DK and NTSC-M.

15

Page 16

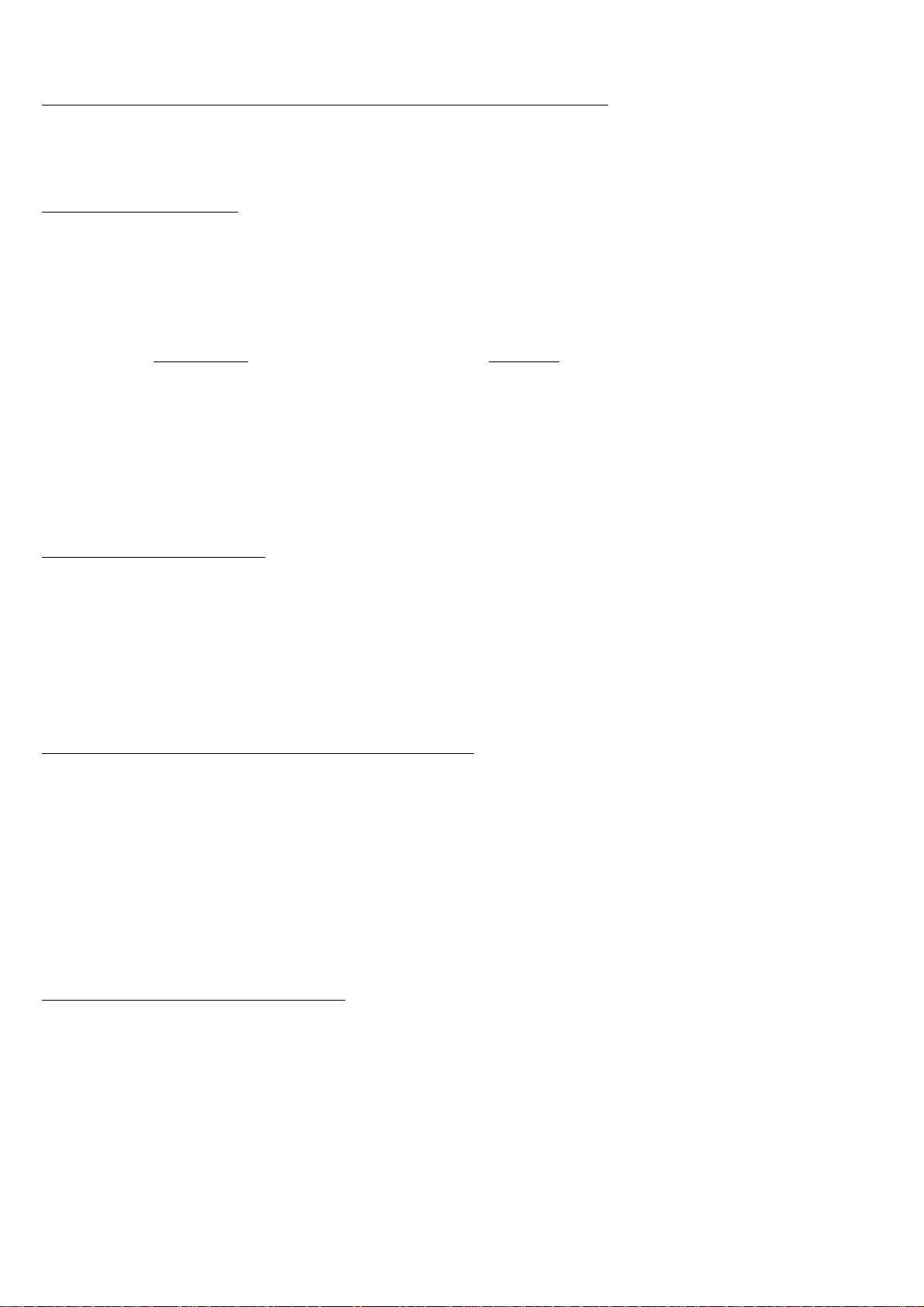

Option byte 3

bit 7

bit 6

bit 5

Opt Nr Of AV

Opt Blueback

Opt VhfH

Opt 24Hr

VHF-L band

The following tables show the options in the last of the option bytes.

reserve

d

-

Bits 5 and 6 form a pair to indicate the number of available AV (external) sources.

bit 4 bit 3 bit 2 bit 1 bit 0

Opt VhfL Opt Vid

Mute

Blue

background

VHF-H

band

Video mute

if

Chan.

change

1=blue

background

0=no blue

1=present

0=not

present

1=present

0=not

present

1=mute

0=no mute

background

Table 5.5 Option byte 3 definitions

bit 6 bit 5

24 hr

clock

1=24 hour

0=AM/PM

OptNrOfAV

0 0 No external source

0 1 AV-1 only

1 0 AV-1 and AV-2

1 1 AV-1 and AV-2 and S-VHS

Table 5.6 Option byte 3, Number of AV sources

Option Byte 3 adjustment setting are 01111111 for AV-1 and AV-2 and S-VHS.

Option Byte 3 adjustment setting are 01011111 for AV-1 and AV-2.

Cathode drive level adjust (CL-ADJ)

For variation of the cathode drive level at he CRT three IIC bits CL2, 1,0 are added. The table below gives a

survey of the cathode drive levels:

CL-ADJ

Variation Cathode Drive

0 57V

1 63V

2 70V

3 77V

4 84V

5 91V

6 99V

7 107V

Measuring conditions:

Brightness are set to their nominal value. As test signal is used a black field with white block. The measured

cathode drive voltages have a tolerance of +/- 3V.

16

Page 17

7 Service and Factory mode

Factory mode

When the service contact (pin 35) of the microprocessor is shorted to ground for 250 ms but not longer

than 500 ms, CTV272V2 will show the service menu. In the service menu, configuration and geometry

parameters can be modified (service alignment), using the remote or local keyboard. In service mode, the

EVG-bit of the video one-chip is cleared to 0, to avoid RGBOUT blanking when the vertical deflection fails,

for easier repair. To indicate that the service menu is active, CTV272V2 will display the following OSD

message:

CTV272V2

VERSION XX.YY

H-PARAB. 33 09-63

Figure 7.1 Service menu OSD

The OSD shows the identification of the TV system CTV272V2 and it’s version number in XX.YY

format. An example of a version number is 00.04.The lowest line shows one of the alignment parameters.

This is also the position on which the parameters will be shown when the service menu is active. There

will only be one alignment parameter active at any given time. The alignment parameter consists of it’s

name (refer to chapter on the service menu for details), it’s current value and the range in which the value

can be altered.

When the short circuit lasts longer than 500 ms, CTV272V2 will enter Factory mode. The continuous

update via the I2C bus and OSD’ s are suppressed. A factory computer can then write to the non-volatile

memory. When a command from the local or remote keyboard is received, all devices are updated and the

processor stops again. In this way, all non I2C bus controlled outputs of the microprocessor can still be

controlled.

In factory mode, the setmaker’ s logo can be set, if the optional memory bank 1 is present. In this memory

bank 40 bytes are available for the logo text. The characters for the logo text are NOT packed, like the

characters for the program names. Any of the characters as described in the chapter on the user interface

can be used. The logo text will be printed in two lines, the first line has a maximum of 20 characters, the

second line has a maximum of 16 characters. If both lines are to be used, the upper line has to be filled out

with ‘ Space’ characters. There is no New Line character available, this will be inserted automatically

after 20 characters have been read from the non-volatile memory.

The logo text can be ‘ ended’ by either filling the remainder of the 40 bytes with spaces, or by inserting

an EOL (End-Of-Logo) character. When the software reads an EOL character, the logo text will be

regarded as finished.

The service line of the microprocessor is also used as a “ write protect” line for the non- volatile

memory. Any of the non-volatile memory IC’s used can either be connected to this line or have their write

protect pin (if applicable) fixed to ground. Prior to any write access to the non-volatile memory, the

microprocessor will pull the service pin low.

17

Page 18

Service Alignment

The service menu can also be activated by sending RC-5 code 58 with system address 7. When the

service menu is activated, the Menu Up/Down keys will select the next item, while the Menu Left/Right

keys will change the value of the item currently on screen. The following alignments can be set.

RC-5 key Function OSD Range

Status option byte 0 OPTION 0 10000001

I/II option byte 1 OPTION 1 01010000

EFFECT option byte 2 OPTION 2 01000001

HOLD option byte 3 OPTION 3 01111111

- Hotel Mode :Maximum Volume HM VOL setting is 00 0-63

- Hotel Mode :Initial Program HM INI-P setting is 00 0-99

3 Horizontal shift 1) H-SHIFT setting is 34 0-63

2 E-W width 1) H-WIDTH setting is 31 0-63

1 E-W parabola 1) H-PARAB setting is 31 0-63

8 E-W corner 1) H-CORNER setting is 31 0-63

9 E-W trapezium 1) H-TRAP setting is 31 0-63

5 Vertical slope 1) V-SLOPE setting is 25 0-63

6 Vertical amplitude 1) V-AMPL setting is 41 0-63

4 Vertical S-correction 1) V-S.CORR setting is 12 0-63

7 Vertical shift 1) V-SHIFT setting is 36 0-63

Red Red gain R-GAIN setting is 31 0-63

Green Green gain G-GAIN setting is 31 0-63

Blue Blue gain B-GAIN setting is 31 0-63

White Cathode drive level adjust CL-ADJ setting is 02-04 0-7

Size IF-PLL adjust 2) IF-PLL/AFC setting is 02 0-3

Reveal AGC adjust ) AGC-ADJ setting is 02-07 0-63

Time Y-delay system 3) Y-DELAY setting is 04 0-8

CANCEL VSD alignment 5) VSD setting is 00 0-1

PP Stereo balance STER BAL setting is 24 0-49

- VHF-L step size A4) VHFL A setting is 78 0-128

- VHF-L step size B4) VHFL B setting is 18 0-128

- VH F L step size C4) VHFL C setting is 06 0-128

- VHF H step size A4) VHFH A setting is 39 0-128

- VHF H step size B4) VHFH B setting is 09 0-128

- VHF H step size C4) VHFH C setting is 03 0-128

- UHF step size A4) UHF A setting is 26 0-128

- UHF step size B4) UHF B setting is 06 0-128

- UHF step size C4) UHF C setting is 02 0-128

- VHF-L delay time A4) VHFL A DL setting is 40 0-128

- VHF-L delay time B4) VHFL B DL setting is 40 0-128

- VHF-L delay time C4) VHFL C DL setting is 40 0-128

- VHF-H delay time A4) VHFH A DL setting is 40 0-128

- VHF-H delay time B4) VHFH B DL setting is 40 0-128

- VHF-H delay time C4) VHFH C DL setting is 40 0-128

- UHF delay time A4) UHF A DL setting is 40 0-128

- UHF delay time B4) UHF B DL setting is 40 0-128

Mute UHF delay time C4) UHF C DL setting is 40 0-128

1) These settings should be done with separate test signals with a 50 Hz and a 60 Hz field frequency.

These parameters are stored in separate groups for 50 Hz and 60 Hz and are recalled or set, depending

on the field frequency of the currently received program.

18

Page 19

2) The TDA884x supports an alignment free IF-PLL.

The required IF- frequency can be set by adjusting the IF- PLL value according the table below:

IF-PLL value IF- Frequency

0 58.75 MHz

1 45.75 MHz

2 38.90 MHz

3 38.00 MHz

3) This setting should be repeated for any of the possible color standards in the TV – system, since this

parameter is recalled or set, depending on the currently selected color standard.

4) VST tuners only.

5) VSD alignment, when there is no vertical deflection, the remaining horizontal line can be used for

simplified Vg2 alignment

0: Vertical scan active (normal operation)

1: Vertical scan disabled

6) Stereo balance (STER BAL) setting is adjusted separation of German Stereo.

a. Set a signal generator to colour bar, stereo sound mode and off the main sound modulation (5.5

MHz signal).

b. Connect the high impedance voltmeter to L speaker output.

c. Adjust STER BAL for the maximum reading (unit of dB) on the voltmeter of the stereo separation.

Table 7.1 Basic service alignments

When a VST tuner is used, the search tuning algorithm uses three different step-sizes when

searching a transmitter (refer to VST tuning for details). These step-sizes are called Step A, Step B and

Step C. Step A is the largest step (approximately 1 MHz), Step C is the smallest step (approximately

62.5 kHz). Measured in frequency, these steps should be approximately equal for all three bands.

However, the tuning voltage applied to the tuner results in different frequencies for each band.

Therefore, the step-sizes should be set for each step in each band individually. Note, that the software

will not set default values, after a new non-volatile memory is installed. If a UV1315 VST tuner is used,

the following values for the step-sizes will give good tuning results:

Step Value

VHF-L A 78

VHF-L B 18

VHF-L C 06

VHF-H A 39

VHF-H B 09

VHF-H C 03

UHF A 26

UHF B 06

UHF C 02

Table 7.2 Possible step-sizes for UV1315 VST tuner

19

Page 20

For different tuners it may be necessary to obtain different values. In order to stabilize the tuner, the

tuning algorithm will wait for a certain time after each step. This time is the tuning delay time, which

can be set for each step-size in each band. The delay time set in the non-volatile memory is directly

measured in milliseconds. The tuning algorithm itself has an update time of 40 ms, so it is useless to set

the delay times to less than 40 ms. Also, for the UV1315 tuner, 40 ms is a value, which will produce

good search tuning results. For different tuners it may be necessary to obtain different values.

The four option bytes can also be changed via the service menu. These are however not part of the

service parameter carrousel, as shown in the previous table. The following table shows the OSD for the

four option bytes.

RC-5 key Function OSD Range

Status Option byte 0 OPTION 01) 0 - 256

Sound channel Option byte 1 OPTION 11) 0 - 256

Spatial Option byte 2 OPTION 21) 0 - 256

Hold Option byte 3 OPTION 31) 0 - 256

Notation is in binary format, so that it is easy to see which option bits are set. Refer to the option

section for a detailed description of the option bytes.

Table 7.3 Option bytes

Each of the option bytes can also be “ stepped to” by means of the Menu Up key, provided the first

option byte is at that moment on screen. Pressing Menu Up when the last option byte is active, will step

to “ Horizontal shift”. Using Menu down is also possible when the option bytes are on screen, to step

back through the option bytes. If option byte 0 is active when Menu Down is pressed, will step back to

UHF delay time C.

When a new non-volatile memory is installed, it’s contents may have random values, which do not

fit in the range, as set by table 7.1. The software will also not check on this situation and set

appropriate default values. It is up to the service engineer or the factory to bring the service

alignment values into range. Once the values have been set to a proper, in range value, it is no

longer possible to set a value out of range. The software will check on ranges, when the alignment

values are changed.

Hotel Mode

Hotel mode can only be set from within the service menu. The reason for this is that a separate

menu with a security code is never safe enough. It is always possible, that either willingly or by

accident hotel customers activate the Hotel Mode Menu and change any of the settings. The service

menu however can only be activated by a special remote control device or by activating the service

pin of the micro-controller.

The parameters that set Hotel Mode are always the first two items in the service menu. Therefore,

a hotel technician, setting hotel mode in the service menu does not need to know all the details about

the TV alignments. The hotel technician only needs to know that the first two parameters can safely

be set and that the service menu should be left after the necessary settings have been made.

When Hotel Mode is active, the micro-controller will not be able to write any of the settings in the

system into the non-volatile memory. The only settings that can be written are the Maximum

Volume and the Initial Program of hotel mode. The Installation menu is not available in hotel mode.

This also means, that programs that have been cleared, prior to setting hotel mode, can not be

returned. The lock status of programs will be ignored. Also, in the Others menu, the Password item

is not available when hotel mode is ON. Effectively, this means that locked programs are unlocked

when hotel mode is on.

20

Page 21

Any of the analog settings (volume, balance, brightness, contrast etc.,) can be changed, but these

changes will only have effect as long as the TV is switched on. After going to standby, or powering

down and up, the settings from the non-volatile memory will be recalled. Therefore, analog settings

that the system should start up with should be set and stored as Personal Preset prior to setting

hotel mode itself.

Hotel mode will be activated, as soon as the value for the maximum volume (HMVOL) is set to a

value unequal to 0. The maximum value the analog volume can have is 63, which in normal

operating conditions is visualized by a bargraph, in the most right position. Every dash in the

bargraph corresponds to 4 increments in volume. The value for the maximum volume can be set

from 0 to 63 and is wrapped around from 0 to 63 with the Menu Left key or wrapped around from

63 to 0 with the Menu Right key. This feature can be used to help setting the maximum volume to an

acceptable value.

First, make sure the maximum volume is set to 0, which also means hotel mode is off. Set the

volume level to an acceptable maximum value, by means of the Sound menu or the Volume + local

or remote key. The activate the service menu and start setting the maximum volume by using the

Menu Left key. The will start the maximum value at the value of 63 and sets hotel mode active.

Continue decrementing the maximum volume, until the volume at the loudspeakers starts to

decrease. This is then the maximum level that can be set by the hotel customer. Another way of

setting the maximum volume is just by setting a value, without the help of any audible effects.

The initial program is the number of the program. That the TV set will power up with, either from

power down or standby. For all versions of the CTV27xxx package, the maximum number that can

be set here is 99, also for versions that have less than 99 programs. Care should be taken to select

an existing program at this location, because the system will bring value in range if necessary. The

initial program in that case is then unequal to the one set at Initial Program.

When factory alignment is performed, this can either be done by a factory computer or by hand by a

factory technician. In the first case, the microprocessor will have to be put in factory mode, so the

factory computer will be able to write to the non-volatile memory without any problems. Make

sure however, to write 0 in the HM VOL service parameter to allow analog setting to be written

into the non-volatile memory.

In the second case, the factory technician must make sure, that the service parameter HM VOL

(Hotel Mode maximum Volume) is set to 0. If this is not the case, also the alignment parameters

will NOT be written into non-volatile memory, even though the new setting are written the

corresponding components (e.g. video one-chip) of the system! If alignment parameter are changed

while the hotel mode is active, powering the system down and up will restore the previous

parameters as recalled from non-volatile memory.

21

Page 22

8

1

2

6

3

5

8

3

2

6

3

3

4

3

4

2

3

C

Y

7

22

9

0

1

Page 23

CIRCUIT DIAGRAM (REMOTE CONTROL)

CAUTION:

The international hazard symbols and shaded area in the schematic diagram and parts list

designate component which have special characteristics important for safety and should

be replaced only with the types identical to those in the original circuit or specified in the

parts list. The mounting position of replacement parts should be identical to the originals.

Before replacing any of these components, read carefully the "PRODUCT SAFETY

NOTICE" at Page 2. Do not degrade the safety of the receiver through improper servicing.

Notice: The part number must be used when ordering spare parts In order to facilitate order

processing, be sure to include the model number and description.

*

mark are for 'THOMSON' 29" SUPERFLAT CRT - A68EGD049X70 WORLD WIDE.

*

mark are for 'TOSHIBA' 29" PERFECTLY FLAT CRT - A68LQP356X03(Z).

*

mark are for 'FORTUNE' 29" SUPERFLAT CRT - 73SX732Y22-DC01

ELECTRICAL COMPENONTS LIST

23

Page 24

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

C0101 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0306 54-A54700DM1-AN 4.7 UF 25V ELECTROLYTIC CAPACITOR

C0102 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR C0308 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR

C0103 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR C0310 54-C44700GK1-BF 0.47 UF 100V POLYESTER FILM CAPACITOR

C0105 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR C0311 54-A63300VM1-A 33 UF 63V ELECTROLYTIC CAPACITOR

C0109 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR C0313 54-L35600GJ1-BP 0.056 UF 100V POLYESTER FILM CAPACITOR

C0110 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR C0402 54-B22200LM1-E 2200 PF 500V CERAMIC CAPACITOR

C0111 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR C0403 54-E31000XJ1-Q 0.01 UF 630V POLYPROPYLENE FILM CAPACITOR

C0112 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR C0404 54-A54700JM1-AD 4.7 UF 250V ELECTROLYTIC CAPACITOR

C0113 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0405 54-B21000PK1-E 1000 PF 2KV CERAMIC CAPACITOR

C0114 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR C0501 54-B21500PK1-E 1500 PF 2KV CERAMIC CAPACITOR

C0115 54-A71000CM1-O 100 UF 16V ELECTROLYTIC CAPACITOR C0502 54-B13300PK1-E 330 PF 2KV CERAMIC CAPACITOR

C0116 54-54703-96 0.047 UF 100V POLYESER CAPACITOR C0503 54-A71000DM1-A 100 UF 25V (105) ELECTROLYTIC CAPACITOR

C0117 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR C0504 54-C41000GK1-BP 0.1 UF 100V POLYESTER FILM CAPACITOR

C0119 54-C42200GJ1-BF 0.22 UF 100V POLYESTER FILM CAPACITOR C0505 54-C41000GK1-BP 0.1 UF 100V POLYESTER FILM CAPACITOR

C0120 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR C0506 54-B24700LM11E 4700 PF 500V CERAMIC CAPACITOR

C0123 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR C0507 54-P22200KM11BA 2200 PF 400VAC CERAMIC CAPACITOR (VDE)

C0124 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR C0508 54-T41000JK1-BX 0.1 UF 275VAC POLYESTER FILM CAPACITOR

C0125 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR C0509 54-T41000JK1-BX 0.1 UF 275VAC POLYESTER FILM CAPACITOR

C0126 54-C23300GJ1-BP 3300 PF 100V POLYESTER FILM CAPACITOR C0511 54-B24700NM1-E 4700 PF 1KV CERAMIC CAPACITOR

C0127 54-B32200FZ1-BN 0.022 UF 50V CERAMIC CAPACITOR C0512 54-B24700NM1-E 4700 PF 1KV CERAMIC CAPACITOR

C0128 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR C0513 54-B24700NM1-E 4700 PF 1KV CERAMIC CAPACITOR

C0129 54-C41000GJ1-BF 0.1 UF 100V POLYESTER FILM CAPACITOR C0514 54-B24700NM1-E 4700 PF 1KV CERAMIC CAPACITOR

C0130 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR C0515 54-A61000FM1-AN 10 UF 50V ELECTROLYTIC CAPACITOR

C0131 54-A54700DM1-AN 4.7 UF 25V ELECTROLYTIC CAPACITOR C0516 54-A72200CM1-AN 220 UF 16V ELECTROLYTIC CAPACITOR

C0132 54-B24700FK2-AA 4700 PF 50V CERAMIC CAPACITOR C0519 54-B24700PZ1-E 4700 PF 2KV CERAMIC CAPACITOR

C0133 54-A51000FM1-O 1 UF 50V ELECTROLYTIC CAPACITOR C0520 54-B24700LM11E 4700 PF 500V CERAMIC CAPACITOR

C0134 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR C0521 54-B13900LK1-AT 390 PF 500V CERAMIC CAPACITOR

C0136 54-C42200GJ1-BF 0.22 UF 100V POLYESTER FILM CAPACITOR C0525 54-A74700EM1-AF 470 UF 35V ELECTROLYTIC CAPACITOR

C0137 54-A61000CM1-AN 10 UF 16V ELECTROLYTIC CAPACITOR C0526 54-A73300HM1-AF 330 UF 160V ELECTROLYTIC CAPACITOR

C0138 54-B23300LK1-E 3300 PF 500V CERAMIC CAPACITOR C0527 54-A73300KM1-AP 330 UF 400V ELECTROLYTIC CAPACITOR

C0139 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR C0528 54-T41000JK1-BX 0.1 UF 275VAC POLYESTER FILM CAPACITOR

C0140 54-B32200FZ1-BN 0.022 UF 50V CERAMIC CAPACITOR C0529 54-C41000GK1-BP 0.1 UF 100V POLYESTER FILM CAPACITOR

C0141 54-A71000BM1-A 100 UF 10V ELECTROLYTIC CAPACITOR C0530 54-A72200CM1-AN 220 UF 16V ELECTROLYTIC CAPACITOR

C0142 54-B01800FJ2-AA 18 PF 50V CERAMIC CAPACITOR C0532 54-A72200BM1-AF 220 UF 10V ELECTROLYTIC CAPACITOR

C0145 54-B01500FJ1-E 15 PF 50V CERAMIC CAPACITOR C0533 54-B13900LK1-AT 390 PF 500V CERAMIC CAPACITOR

C0148 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0534 54-A74700FM1-AF 470 UF 50V ELECTROLYTIC CAPACITOR

C0149 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0536 54-P14700KK11BA 470 PF 400VAC CERAMIC CAPACITOR (VDE)

C0150 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0537 54-A64700CM1-AN 47 UF 16V ELECTROLYTIC CAPACITOR

C0151 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR C0538 54-B13900LK1-AT 390 PF 500V CERAMIC CAPACITOR

C0152 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0539 54-P14700KK11BA 470 PF 400VAC CERAMIC CAPACITOR (VDE)

C0153 54-A74700BM1-AF 470 UF 10V ELECTROLYTIC CAPACITOR C0540 54-A73300CM1-AF 330 UF 16V ELECTROLYTIC CAPACITOR

C0155 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0701 54-A64700BM1-AF 47 UF 10V ELECTROLYTIC CAPACITOR

C0156 54-A72200BM1-AF 220 UF 10V ELECTROLYTIC CAPACITOR C0702 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR

C0159 54-A74700BM1-AF 470 UF 10V ELECTROLYTIC CAPACITOR C0901 54-B16800LK1-E 680 PF 500V CERAMIC CAPACITOR

C0160 54-A74700BM1-AF 470 UF 10V ELECTROLYTIC CAPACITOR C0902 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR

C0161 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR C0903 54-C32200FK1-E 0.022 UF 50V POLYESTER FILM CAPACITOR

C0303 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR C0904 54-L21500FJ1-BP 1500 PF 50V POLYESTER FILM CAPACITOR

C0304 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR C0905 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR

24

Page 25

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

C0305 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR C0908 54-B21000PK1-BN 1000 PF 2KV CERAMIC CAPACITOR

C0912 54-A72200DM1-BY 220 UF 25V ELECTROLYTIC CAPACITOR CF0015 54-A54700CM1-AN 4.7 UF 16V ELECTROLYTIC CAPACITOR

C0914 54-B21500LM1-BN 1500 PF 500V CERAMIC CAPACITOR CF0016 54-E18200GJ1-Q 820 PF 100V POLYPROPYLENE FILM CAPACITOR

C0915 54-A61000JM1-AF 10 UF 250V ELECTROLYTIC CAPACITOR CF0017 54-B21000FK1-BN 1000 PF 50V CERAMIC CAPACITOR

C0916 54-B12200LK2-AA 220 PF 500V CERAMIC CAPACITOR CF0018 54-B21000FK1-BN 1000 PF 50V CERAMIC CAPACITOR

C0917 54-A64700HM1-AS 47 UF 160V ELECTROLYTIC CAPACITOR CF0019 54-E16800GJ1-Q 680 PF 100V POLYPROPYLENE FILM CAPACITOR

C0918 54-E35600IK1-BP 0.056 UF 200V POLYPROPYLENE FILM CAPACITOR CF0021 54-A71000BM1-AF 100 UF 10V ELECTROLYTIC CAPACITOR

C0919 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR CF0022 54-A61000CM1-AN 10 UF 16V ELECTROLYTIC CAPACITOR

C0920 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR CF0023 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR

C0921 54-A61000FM1-AN 10 UF 50V ELECTROLYTIC CAPACITOR CF0024 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR

C0922 54-A63300CM1-AF 33 UF 16V ELECTROLYTIC CAPACITOR CF0025 54-S23300FJ1-BY 3300 PF 50V CERAMIC CAPACITOR (NPO)

C0923 54-B22200LK2-AA 2200 PF 500V CERAMIC CAPACITOR CF0026 54-B04700FJ2-AA 47 PF 50V CERAMIC CAPACITOR

C0925 54-M32200KJ1-BS 0.022 UF 400V POLYPROP. FILM CAPACITOR CF0027 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

C0926 54-B15600PK1-AA 560 PF 2KV CERAMIC CAPACITOR CF0028 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

C0929 54-E43300IJ1-BE 0.33 UF 200V POLYPROPYLENE FILM CAPACITOR CF0029 54-C31000GJ1-BF 0.01 UF 100V POLYESTER FILM CAPACITOR

C0930 54-M28200WJ11BL 8200 PF 2.5KV POLYPROPYLENE FILM CAPACITOR CF0030 54-A62200CM1-AF 22 UF 16V ELECTROLYTIC CAPACITOR

C0931 54-M28200WJ11BL 8200 PF 2.5KV POLYPROPYLENE FILM CAPACITOR CF0031 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR

C0932 54-E43900IK1-BP 0.39 UF 200V POLYPROPYLENE FILM CAPACITOR CF0032 54-C31000GJ1-BF 0.01 UF 100V POLYESTER FILM CAPACITOR

C0934 54-B11000LK1-BN 100 PF 500V CERAMIC CAPACITOR (T. P.) CF0033 54-A61000CM1-AN 10 UF 16V ELECTROLYTIC CAPACITOR

C0935 54-L26800GJ1-AH 6800 PF 100V POLYPROPYLENE FILM CAPACITOR CF0034 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR

CA0010 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR CF0035 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR

CA0011 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR CF0036 54-A64700CM1-AN 47 UF 16V ELECTROLYTIC CAPACITOR

CC0001 54-A51000FM1-O 1 UF 50V ELECTROLYTIC CAPACITOR CF0037 54-A61000CM1-AN 10 UF 16V ELECTROLYTIC CAPACITOR

CC0002 54-A71000CM1-O 100 UF 16V ELECTROLYTIC CAPACITOR CF0038 54-A61000CM1-AN 10 UF 16V ELECTROLYTIC CAPACITOR

CC0003 54-C41000GJ1-BF 0.1 UF 100V POLYESTER FILM CAPACITOR CF0039 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0004 54-L36800GJ1-AH 0.068 UF 100V POLYESTER FILM CAPACITOR CF0040 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0005 54-A64700FM1-AF 47 UF 50V ELECTROLYTIC CAPACITOR CF0041 54-A71000BM1-AF 100 UF 10V ELECTROLYTIC CAPACITOR

CC0006 54-A74700BM1-AF 470 UF 10V ELECTROLYTIC CAPACITOR CF0042 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0008 54-C41000GJ1-BF 0.1 UF 100V POLYESTER FILM CAPACITOR CF0043 54-C36800GJ1-BP 0.068 UF 100V POLYESTER FILM CAPACITOR

CC0009 54-A71000FM1-AF 100 UF 50V ELECTROLYTIC CAPACITOR CF0044 54-C41500GK1-BP 0.15 UF 100V POLYESTER FILM CAPACITOR

CC0010 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR CF0045 54-E25600GJ1-Q 5600 PF 100V POLYPROPYLENE FILM CAPACITOR

CC0011 54-G54700FM1-BS 4.7 UF 50VAC ELECTROLYTIC CAPACITOR CF0046 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0012 54-A64700CM1-AN 47 UF 16V ELECTROLYTIC CAPACITOR CF0047 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0013 54-A63300CM1-AF 33 UF 16V ELECTROLYTIC CAPACITOR CF0048 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CC0014 54-L36800GJ1-AH 0.068 UF 100V POLYESTER FILM CAPACITOR CF0049 54-C41500GK1-BP 0.15 UF 100V POLYESTER FILM CAPACITOR

CC0015 54-L32200FJ1-AH 0.022 UF 50V POLYESTER FILM CAPACITOR CF0050 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CF0001 54-B21000FK1-BN 1000 PF 50V CERAMIC CAPACITOR CF0051 54-C41500GK1-BP 0.15 UF 100V POLYESTER FILM CAPACITOR

CF0002 54-B24700FK2-AA 4700 PF 50V CERAMIC CAPACITOR CF0052 54-C36800GJ1-BP 0.068 UF 100V POLYESTER FILM CAPACITOR

CF0003 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR CF0053 54-C41500GK1-BP 0.15 UF 100V POLYESTER FILM CAPACITOR

CF0004 54-B21000FK1-BN 1000 PF 50V CERAMIC CAPACITOR CF0054 54-E25600GJ1-Q 5600 PF 100V POLYPROPYLENE FILM CAPACITOR

CF0005 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR CF0055 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CF0006 54-B21000FK1-BN 1000 PF 50V CERAMIC CAPACITOR CF0056 54-A71000BM1-AF 100 UF 10V ELECTROLYTIC CAPACITOR

CF0007 54-A62200CM1-AF 22 UF 16V ELECTROLYTIC CAPACITOR CF0057 54-A44700FM1-AF 0.47 UF 50V ELECTROLYTIC CAPACITOR

CF0008 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR CF0058 54-A51000FM1-AF 1 UF 50V ELECTROLYTIC CAPACITOR

CF0009 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR CF0059 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR

CF0010 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR CF0060 54-C24700FK1-E 4700 PF 50V POLYESTER FILM CAPACITOR

CF0011 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR CF0061 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CF0012 54-B04700FJ2-AA 47 PF 50V CERAMIC CAPACITOR CF0062 54-C24700FK1-E 4700 PF 50V POLYESTER FILM CAPACITOR

25

Page 26

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

CF0013 54-K06800FJ1-E 68 PF 50V T. P. CERAMIC CAPACITOR (N150) CF0063 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR

CF0014 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR CF0064 54-A72200FM1-AF 220 UF 50V ELECTROLYTIC CAPACITOR

CF0065 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR D0401 51-03062-05 DIODE BAV21

CF0066 54-C32200GK1-BP 0.022 UF 100V POLYESTER FILM CAPACITOR D0402 51-03062-05 DIODE BAV21

CF0067 54-A74700DM1-AN 470 UF 25V ELECTROLYTIC CAPACITOR D0403 51-03062-05 DIODE BAV21

CF0068 54-A74700DM1-AN 470 UF 25V ELECTROLYTIC CAPACITOR D0501 51-03021-41 DIODE SJ5295J

CF0069 54-A82200EM1-AN 2200 UF 35V ELECTROLYTIC CAPACITOR D0502 51-03021-41 DIODE SJ5295J

CF0070 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR D0503 51-02027-40 ZENER DIODE CH05W9.1 - 9.1V 0.5W

CF0102 66-55001-03 CERAMIC TRAP 5.5MHZ (TPS5.5MB) D0504 51-03021-41 DIODE SJ5295J

CK0001 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR D0505 51-03005-48 DIODE FR104

CK0002 54-A64700BM1-AF 47 UF 10V ELECTROLYTIC CAPACITOR D0506 51-03058-41 DIODE 1N4007

CK0006 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR D0507 51-03058-41 DIODE 1N4007

CK0007 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR D0508 51-03058-41 DIODE 1N4007

CK0008 54-B21000FK2-BN 1000 PF 50V CERAMIC CAPACITOR D0509 51-03058-41 DIODE 1N4007

CT0002 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR D0510 51-03051-05 RECTIFIER DIODE BYD33D

CT0003 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR D0512 51-03053-05 RECTIFIER DIODE BYW95C

CT0004 54-A52200FM1-AF 2.2 UF 50V ELECTROLYTIC CAPACITOR D0513 51-02001-40 ZENER DIODE - GZA6.2Y (6.00 - 6.35V)

CT0005 54-42200-75 22 PF 50V CERAMIC CAPACITOR D0515 51-03051-05 RECTIFIER DIODE BYD33D

CT0006 54-42200-75 22 PF 50V CERAMIC CAPACITOR D0516 51-02007-40 DIODE CH05W5.6

CT0007 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR D0517 51-08001-23 DIODE 1N4148

CU0001 54-A71000BM1-A 100 UF 10V ELECTROLYTIC CAPACITOR D0901 51-02002-40 ZENER DIODE - GZA7.5Y (7.34 - 7.70V)

CU0002 54-A74700BM1-AF 470 UF 10V ELECTROLYTIC CAPACITOR D0902 51-03018-41 DIODE 1S2775

CU0003 54-B02200FJ2-AA 22 PF 50V CERAMIC CAPACITOR D0903 51-03018-41 DIODE 1S2775

CU0007 54-A51000FM1-O 1 UF 50V ELECTROLYTIC CAPACITOR D0904 51-03048-05 HIGH-SPEED SILICON DIODE BAW62

CU0008 54-C41000GK1-BP 0.1 UF 100V POLYESTER FILM CAPACITOR D0905 51-02023-40 ZENER DIODE CH05W5.1 - 5.1V 0.5W

CU0009 54-A61000FM1-AN 10 UF 50V ELECTROLYTIC CAPACITOR D0907 51-03005-48 DIODE FR104

CU0010 54-C41000GK1-BP 0.1 UF 100V POLYESTER FILM CAPACITOR D0908 51-03005-48 DIODE FR104

CU0011 54-B01800FJ2-AA 18 PF 50V CERAMIC CAPACITOR D0909 51-03001-48 RECTIFIER DIODE FR155

CU0012 54-B01800FJ2-AA 18 PF 50V CERAMIC CAPACITOR D0910 51-03001-48 RECTIFIER DIODE FR155

CU0013 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR D0913 51-03057-05 RECTIFIER DIODE BY228

CU0014 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR DF0001 51-08001-23 DIODE 1N4148

CU0015 54-L22700GJ1-BP 2700 PF 100V POLYESTER FILM CAPACITOR DF0002 51-08001-23 DIODE 1N4148

CU0016 54-L22700GJ1-BP 2700 PF 100V POLYESTER FILM CAPACITOR DF0003 51-08001-23 DIODE 1N4148

CU0017 54-B04700FJ2-AA 47 PF 50V CERAMIC CAPACITOR DU0002 51-08001-23 DIODE 1N4148

CU0018 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR DU0005 51-02060-56 ZENER DIODE 4A2 (3.6V, 0.5W)

CU0019 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR DU0006 51-08001-23 DIODE 1N4148

CU0020 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR F0501 72-01100-01 CERAMIC FUSE T5A/250V

CU0021 54-B02700FJ1-AA 27 PF 50V CERAMIC CAPACITOR FB0001 65-03003-32 **FERRITE BEAD 4B1 "PHILIPS"

CU0022 54-A64700CM1-AN 47 UF 16V ELECTROLYTIC CAPACITOR FB0002 65-03003-32 **FERRITE BEAD 4B1 "PHILIPS"

CU0023 54-B41000FZ1-BN 0.1 UF 50V CERAMIC CAPACITOR IC0101 67-AF008838-01 I.C. OM8838PS

CU0024 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR IC0102 67-32705-02 I.C. - TC74HC241AP

CU0025 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR IC0301 67-AF08359J-01 I.C. TDA8359J

CU0026 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR IC0401 67-AF006107-01 I.C. TDA6107Q

CU0027 54-B31000FZ1-BN 0.01 UF 50V CERAMIC CAPACITOR IC0501 69-02006-04 PHOTOCOUPLER - LTV817C

CU0028 54-A61000CM1-AE 10 UF 16V ELECTROLYTIC CAPACITOR IC0502 67-CJ007805-01 I.C. MC7805CT

D0101 51-02003-40 ZENER DIODE - GZA8.2X (7.70 - 8.10V) IC0503 67-CJ007808-01 I.C. MC7808CT

D0102 51-08001-23 DIODE 1N4148 IC0701 67-AF008521-01 I.C. PCA8521BT/040,SO20

D0301 51-02028-40 DIODE CH05W15V (14.25-15.75) ICC0001 67-AL007950-01 I.C. LA 7950

26

Page 27

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

D0302 51-03048-05 HIGH-SPEED SILICON DIODE BAW62 ICF0001 67-AF003857-01 I.C. TDA3857

D0303 51-02055-01 ZENER DIODE HZ24 (3) 25V ICF0002 67-AF009840-01 I.C. TDA9840

D0304 51-02055-01 ZENER DIODE HZ24 (3) 25V ICF0003 67-AF009860-01 I.C. TDA9860

ICF0004 67-00120-01 I.C. TDA2616 PLUG I 73-6EEF601M-01C 6-POLE MODULAR WIRE (L=600MM)

ICK0001 69-02015-09 INFRARED DETECTING UNIT (GP1U281Q) PLUG K 73-3DFF421M-01C 3-POLE MODULAR WIRE (L=420MM)

ICT0001 67-AF005261-01 I.C. SAA5261PS/117 PLUG M 73-2AEF301F-01C 2-POLE MODULAR WIRE (L=300MM)

ICU0001 67-AFP83C05-01 CPU P83C055BBP/314 (W/CTV272SV2V1.03) PLUG P 61-W0001-02H 2-POLE WAFER - (TYPE NO.: TJC1-2A)

ICU0002 67-BA024C04-01 EEPROM I.C. BR24C04-W PLUG SP 73-4AEF421M-03C 4-POLE MODULAR WIRE (L=420MM)

ICU0003 67-90430-01 I.C. UPC574J PLUG SV 73-4EEF341M-01C 4-POLE MODULAR WIRE (L=340MM)

L0101 59-06411-01 0.56 UH PEAKING COIL PLUG T 61-W0001-02H 2-POLE WAFER - (TYPE NO.: TJC1-2A)

L0105 59-72916-01 4.7 UH PEAKING COIL PLUG T 73-2GDF241N-01C 2-POLE MODULAR WIRE (L=240MM)

L0106 59-72917-01 10 UH PEAKING COIL PLUG V 73-3AEF481M-01C 3-POLE MODULAR WIRE (L=480MM)

L0107 59-08001-02 10 UH PEAKING COIL PSF0101 68-18001-33 SAW FILTER TSF5315 -38.9MHZ (VIDEO CHANNEL)

L0108 59-08001-02 10 UH PEAKING COIL Q0101 50-40725-06 TRANSISTOR 2SC2717

L0109 59-06411-01 0.56 UH PEAKING COIL Q0103 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0501 65-03005-32 FERRITE BEAD FB02 Q0105 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0502 65-03005-32 FERRITE BEAD FB02 Q0106 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0504 59-06412-01 1 UH CHOKE COIL Q0107 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0505 59-03401-02 100 UH INDUCTOR COIL Q0112 50-AG002369-01 TRANSISTOR PH2369

L0506 65-03005-32 FERRITE BEAD FB02 Q0113 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0507 65-03005-32 FERRITE BEAD FB02 Q0115 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0508 58-77492-02 LINE FILTER ET-28 - 85MH +-15% (LB01120B) Q0117 50-AI001815-01 TRANSISTOR 2SC1815-Y

L0509 58-78676-02 LINE FILTER - 8MH - (JLF-29-UF16) Q0301 50-AI001015-02 TRANSISTOR 2SA1015-Y

L0902 59-08001-39 CHOKE COIL Q0501 50-AP004237-01 TRANSISTOR 2SC4237

L0903 59-08001-47 10 MH PEAKING COIL Q0502 50-32237-07 TRANSISTOR 3CG1013-Y

*L0904 59-03001-14 LINEARITY COIL (LS-14C-07) Q0503 50-40750-06 TRANSISTOR 2SC2655-Y

LD0001 69-01014-53 LED - LTL-58EFJ (DUAL COLOR: GREEN/ RED) Q0504 50-AI001015-02 TRANSISTOR 2SA1015-Y

LD0701 69-01014-52 LED TL-IR503C Q0505 50-AI001015-02 TRANSISTOR 2SA1015-Y

LF0001 59-06401-06 10 UH PEAKING COIL Q0506 50-30737-08 TRANSISTOR 2SA1013-O

LF0002 59-06411-02 1 UH PEAKING COIL Q0508 50-AI001815-01 TRANSISTOR 2SC1815-Y

LF0003 59-06401-06 10 UH PEAKING COIL Q0509 50-40750-06 TRANSISTOR 2SC2655-Y

LF0004 59-08701-02 COIL (7 MM) KS1705N Q0701 50-AG032740-01 TRANSISTOR BC32740

LF0005 59-06505-05 SOUND DEMODULATOR COIL (7 MM) KS1727N Q0901 50-40756-05 TRANSISTOR 2SC1569

LF0006 59-06505-05 SOUND DEMODULATOR COIL (7 MM) KS1727N Q0902 50-40223-01 TRANSISTOR BU2520AX

LF0008 59-X3250J001-L 2.5 MH (7.5X7.5)MM IFT FILTER COIL (7M1A1859N) Q0903 50-AI001815-01 TRANSISTOR 2SC1815-Y

LF0010 59-06401-06 10 UH PEAKING COIL Q0904 50-AI001015-02 TRANSISTOR 2SA1015-Y

LF0011 59-06401-06 10 UH PEAKING COIL Q0905 50-AI001015-02 TRANSISTOR 2SA1015-Y

LF0012 59-08001-29 8.2 UH PEAKING COIL QC0001 50-AI001815-01 TRANSISTOR 2SC1815-Y

LF0013 59-08001-29 8.2 UH PEAKING COIL QC0002 50-AI001815-01 TRANSISTOR 2SC1815-Y

LF0014 59-08001-17 160 UH CHOKE COIL QC0003 50-AI001815-01 TRANSISTOR 2SC1815-Y

LK0001 59-08001-03 12 UH PEAKING COIL QC0005 50-AI001815-01 TRANSISTOR 2SC1815-Y

LK0002 59-08001-05 68 UH PEAKING COIL QC0006 50-50704-11 TRANSISTOR 2SK30ATM-GR

LT0001 65-03005-32 FERRITE BEAD FB02 QC0007 50-AI001015-02 TRANSISTOR 2SA1015-Y

LU0001 65-03005-32 FERRITE BEAD FB02 QC0008 50-40755-07 TRANSISTOR 2SD880-Y

LU0002 59-72910-01 22 UH PEAKING COIL QF0001 50-AI001815-01 TRANSISTOR 2SC1815-Y

LU0003 59-06401-06 10 UH PEAKING COIL QF0002 50-40725-06 TRANSISTOR 2SC2717

PLUG A 73-5AEF321M-01C 5-POLE MODULAR WIRE (L=320MM) QF0003 50-AI001815-01 TRANSISTOR 2SC1815-Y

PLUG B 73-3EEF461M-01C 3-POLE MODULAR WIRE (L=460MM) QF0004 50-AI001815-01 TRANSISTOR 2SC1815-Y

27

Page 28

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

PLUG D 73-2EEF181M-01C 2-POLE MODULAR WIRE (L=180MM) QF0005 50-AI001815-01 TRANSISTOR 2SC1815-Y

PLUG E 73-5AEF161M-03C 5-POLE MODULAR WIRE (L=160MM) QF0006 50-AI001815-01 TRANSISTOR 2SC1815-Y

PLUG G 73-6DFF141M-01C 6-POLE MODULAR WIRE (L=140MM) QF0007 50-AI001015-02 TRANSISTOR 2SA1015-Y

PLUG H 73-4AEM501M-02C 4-POLE MODULAR WIRE (L=500MM) QF0008 50-40763-02 TRANSISTOR 2SC2878B

QK0001 50-AI001815-01 TRANSISTOR 2SC1815-Y R0155 52-A3470EJ12-AP 4.7 KOHM 1/6W CARBON FILM RESISTOR

QK0002 50-AI001815-01 TRANSISTOR 2SC1815-Y R0156 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

QK0003 50-AI001815-01 TRANSISTOR 2SC1815-Y R0157 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

QK0004 50-AI001815-01 TRANSISTOR 2SC1815-Y R0158 52-A2330EJ12-AP 330 OHM 1/6W CARBON FILM RESISTOR

QU0001 50-AG002369-01 TRANSISTOR PH2369 R0159 52-A4470EJ12-AP 47 KOHM 1/6W CARBON FILM RESISTOR

QU0002 50-AI001015-02 TRANSISTOR 2SA1015-Y R0160 52-A5100EJ12-AP 100 KOHM 1/6W CARBON FILM RESISTOR

QU0003 50-AI001015-02 TRANSISTOR 2SA1015-Y R0169 52-A1820EJ12-AP 82 OHM 1/6W CARBON FILM RESISTOR

QU0004 50-AI001815-01 TRANSISTOR 2SC1815-Y R0170 52-A2470EJ12-AP 470 OHM 1/6W CARBON FILM RESISTOR

QU0005 50-AI001815-01 TRANSISTOR 2SC1815-Y R0171 52-A1820EJ12-AP 82 OHM 1/6W CARBON FILM RESISTOR

QU0006 50-AI001815-01 TRANSISTOR 2SC1815-Y R0172 52-A2470EJ12-AP 470 OHM 1/6W CARBON FILM RESISTOR

QU0009 50-AI001815-01 TRANSISTOR 2SC1815-Y R0173 52-A1820EJ12-AP 82 OHM 1/6W CARBON FILM RESISTOR

R0101 52-A2180EJ12-AP 180 OHM 1/6W CARBON FILM RESISTOR R0174 52-A2470EJ12-AP 470 OHM 1/6W CARBON FILM RESISTOR

R0102 52-A3120EJ12-AP 1.2 KOHM 1/6W CARBON FILM RESISTOR R0175 52-A2470EJ12-AP 470 OHM 1/6W CARBON FILM RESISTOR

R0103 52-A3470EJ12-AP 4.7 KOHM 1/6W CARBON FILM RESISTOR R0176 52-A1820EJ12-AP 82 OHM 1/6W CARBON FILM RESISTOR

R0104 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR R0177 52-A2560EJ12-AP 560 OHM 1/6W CARBON FILM RESISTOR

R0107 52-A1270EJ12-AP 27 OHM 1/6W CARBON FILM RESISTOR R0178 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0108 52-A1100GJ12-AP 10 OHM 1/2W CARBON FILM RESISTOR R0179 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0112 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0180 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0113 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0181 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0114 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR R0182 52-A2560EJ12-AP 560 OHM 1/6W CARBON FILM RESISTOR

R0115 52-A1470EJ12-AP 47 OHM 1/6W CARBON FILM RESISTOR R0194 52-B2390GJ11-B 390 OHM 1/2W METAL OXIDE RESISTOR

R0118 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0195 52-A1820EJ12-AP 82 OHM 1/6W CARBON FILM RESISTOR

R0119 52-A2180EJ12-AP 180 OHM 1/6W CARBON FILM RESISTOR R0196 52-A4330EJ12-AP 33 KOHM 1/6W CARBON FILM RESISTOR

R0120 52-A0470EJ12-AP 4.7 OHM 1/6W CARBON FILM RESISTOR R0197 52-A4220EJ12-AP 22 KOHM 1/6W CARBON FILM RESISTOR

R0125 52-A2390EJ12-AP 390 OHM 1/6W CARBON FILM RESISTOR R0301 52-A1100EJ12-AP 10 OHM 1/6W CARBON FILM RESISTOR

R0126 52-A2330EJ12-AP 330 OHM 1/6W CARBON FILM RESISTOR R0302 52-A1100EJ12-AP 10 OHM 1/6W CARBON FILM RESISTOR

R0127 52-A2330EJ12-AP 330 OHM 1/6W CARBON FILM RESISTOR R0303 52-A3220EJ12-AP 2.2 KOHM 1/6W CARBON FILM RESISTOR

R0128 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR R0304 52-A3220EJ12-AP 2.2 KOHM 1/6W CARBON FILM RESISTOR

R0130 52-A3220EJ12-AP 2.2 KOHM 1/6W CARBON FILM RESISTOR R0306 52-A5750EJ12-AP 750 KOHM 1/6W CARBON FILM RESISTOR

R0131 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR R0307 52-A1220GJ12-AI 22 OHM 1/2W CARBON FILM RESISTOR

R0132 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0308 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0133 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

R0134 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

R0138 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR R0311 52-A4100EJ12-AP 10 KOHM 1/6W CARBON FILM RESISTOR

R0139 52-A3120EJ12-AP 1.2 KOHM 1/6W CARBON FILM RESISTOR R0313 52-A3100EJ12-AP 1 KOHM 1/6W CARBON FILM RESISTOR

R0140 52-A3120EJ12-AP 1.2 KOHM 1/6W CARBON FILM RESISTOR R0314 52-A2220GJ12-AP 220 OHM 1/2W CARBON FILM RESISTOR

R0141 52-A3680EJ12-AP 6.8 KOHM 1/6W CARBON FILM RESISTOR

R0142 52-A2680EJ12-AP 680 OHM 1/6W CARBON FILM RESISTOR R0316 52-A3270EJ12-AP 2.7 KOHM 1/6W CARBON FILM RESISTOR

R0143 52-A4390EJ12-AP 39 KOHM 1/6W CARBON FILM RESISTOR R0401 52-D0150IJ11-AQ 1.5 OHM 1W FUSIBLE RESISTOR

R0144 52-A6220EJ12-AP 2.2 MOHM 1/6W CARBON FILM RESISTOR R0402 52-B3150GJB1-AI 1.5 KOHM 1/2W METAL OXIDE RESISTOR

R0145 52-A6470EJ12-AP 4.7 MOHM 1/6W CARBON FILM RESISTOR R0403 52-B3150GJB1-AI 1.5 KOHM 1/2W METAL OXIDE RESISTOR

R0146 52-A5100EJ12-AP 100 KOHM 1/6W CARBON FILM RESISTOR R0404 52-B3150GJB1-AI 1.5 KOHM 1/2W METAL OXIDE RESISTOR

R0147 52-A4270EJ12-AP 27 KOHM 1/6W CARBON FILM RESISTOR R0405 52-B3150GJB1-AI 1.5 KOHM 1/2W METAL OXIDE RESISTOR

R0149 52-A4150EJ12-AP 15 KOHM 1/6W CARBON FILM RESISTOR R0406 52-B1470GJB1-AI 47 OHM 1/2W METAL OXIDE FIXED RESISTOR

*

*

*

R0309 52-B0150JJ11-AP 1.5 OHM 2W METAL OXIDE FILM RESISTOR

R0310 52-B0270JJD1-AI 2.7 OHM 2W METAL OXIDE RESISTOR

R0315 52-B2270JJE1-AQ 270 OHM 2W METAL OXIDE FILM RESISTOR

28

Page 29

SYMBOL NO. PART NUMBER PART DESCRIPTION SYMBOL NO. PART NUMBER PART DESCRIPTION

R0150 52-A4100EJ12-AP 10 KOHM 1/6W CARBON FILM RESISTOR R0408 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

R0151 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0409 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

R0152 52-A3330EJ12-AP 3.3 KOHM 1/6W CARBON FILM RESISTOR R0410 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR

R0153 52-A2100EJ12-AP 100 OHM 1/6W CARBON FILM RESISTOR R0500 52-C0180NJ11-B 1.8 OHM 5W WIRE WOUND RESISTOR (CEMENT )

R0154 52-A3330EJ12-AP 3.3 KOHM 1/6W CARBON FILM RESISTOR R0501 52-Q6560GJ12-BF 5.6 MOHM 1/2W METAL GLAZE FILM RESISTOR

R0502 52-B4820LJE1-B 82 KOHM 3W METAL OXIDE RESISTOR R0925 52-B2150JJE1-AQ 150 OHM 2W METAL OXIDE FILM RESISTOR

R0503 52-B4820LJE1-B 82 KOHM 3W METAL OXIDE RESISTOR R0926 52-B3100IJD1-AP 1 KOHM 1W METAL OXIDE RESISTOR