Page 1

SERVICE MANUAL

LCD TV

Model No.

MSDV2413-03-D0

Chassis

MSD306

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

WARNING

Page 2

1-1. Table of Contents

1. General Information...........................................................................

1-1. Table of Contents

1-3. Important Notice

1

Chapter 1: General Information

1

3

1-2. General Guidelines

1-4. How to Read this Service Manual

3

6

2. Specifications....................................................................................

Service Manual

Model No.:

- 01 -

3. Location of Controls and Components...........................................

3-1. Board Location

3-2. Main Board & AV Board

3-3. Power Board

3-4. LCD Panel

4. Disassemble and Assemble..........................................................

4-1 Remove the Pedestal

6

88

8

8

11

12

15

15

4-2 Remove the Back Cover 15

4-3 Remove the Adhesive Tape 15

4-4 Remove the Power Module 16

4-5 Remove the Main Board

16

4-6 Remove the Speaker 17

4-7 Remove the Remote Control Board 17

5. Installation Instructions..…....………………...........………….........

18

5-1 External Equipment Connections

18

5-2 HDMI Connections

21

6. Operation Instructions....

…....………………...........………….........

24

6-1 Front Panel Controls

6-2 Back Panel Controls

6-3 Universal Remote Control

24

24

25

7. Electrical Parts…....………………...........………….........................

26

7-1. Block Diagram

8-1. How to enter into the factory model

8-2. How to update software

7-2. Circuit Diagram

7-3. Wiring Connection Diagram

26

27

42

35

43

8. Measurements and Adjustments........…………............................

39

Page 3

Service Manual

Model No.:

- 02 -

9. Trouble-shooting

…………..............................................................

44

9-1. Simple Check 44

9-2. Main Board Failure Check

9-3. Panel Failure

45

52

10. DVD OPERATION

…………..............................................................

57

11.DVD TROUBLE SHOOTING

…………..............................................................

61

Page 4

1-2. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive

1-3. Important Notice

1-3-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to

open the units and disassemble the units. For example, we need to describe properly

how to avoid the possibility to get electrical shock from the live power supply or charged

electrical parts (even the power is off).

This symbol indicates that high voltage is present inside.It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance.

1-3-2. Be careful to the electrical shock

To prevent damage which might result in electric shock or re, do not expose this TV set

to rain or excessive moisture. This TV must not be exposed to dripping or splashing water,

and objects lled with liquid, such as vases, must not be placed on top of or above the TV.

1-3-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. The following

techniques should be used to help reduce the incidence of component damage caused by

electros static discharge (ESD).

1-3-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repairing of this product.

1-3-5. Use the genewing parts (specied parts)

Special parts which have purposes of fire retardant (resistors), high-quality sound

(capacitors), low noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts

shown in the parts list.

Safety Component

● Components identied by mark have special characteristics important for safety.

Service Manual

Model No.:

- 03 -

Page 5

1-3-6 Safety Check after Repairment

- 04 -

Service Manual

Model No.:

Conrm that the screws, parts and wiring which were removed in order to service are put

in the original positions, or whether there are the positions which are deteriorated around

the serviced places serviced or not. Check the insulation between the antenna terminal or

external metal and the AC cord plug blades. And be sure the safety of that.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before;

a. Removing or reinstalling any component, circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic

capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage measuring device (DVM, FETVOM, etc) equipped with a suitable high voltage

probe.

Do not test high voltage by "drawing an arc".

5. Do not defeat any plug/socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

8. Use with this receiver only the test xtures specied in this service manual.

CAUTION: Do not connect the test xture ground strap to any heat sink in this receiver.

3. Do not spray chemicals on or near this receiver or any of its assemblies.

4. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable non-abrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength).

CAUTION: This is a ammable mixture.

Unless specied otherwise in this service manual, lubrication of contacts is not required.

Capacitors may result in an explosion hazard.

6. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

7. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last. Capacitors may result in an explosion

hazard.

9. Remove the antenna terminal on TV and turn on the TV.

10. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than Mohm by using the 500V insulation resistance meter.

11. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester. External exposure

metal: Antenna terminal Headphone jack

Page 6

Service Manual

Model No.:

- 05 -

Electrostatically Sensitive (ES) Devices

1-3-7. Ordering Spare Parts

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist

strap device, which should be removed to prevent potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly

on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufcient

to damage ES devices.

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

Some semiconductor (solid-state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect transistors

and semiconductor "chip" components. The following techniques should be used to help

reduce the ncidence of component damage caused by static by static electricity.

4. Use only an anti-static type solder removal device. Some solder removal devices not

classied as "anti-static" can generate electrical charges sufcient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately

before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise harmless motion such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted oor can generate static electricity sufcient to damage

an ES device.)

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number, Serial number and Software Version

The model number and Serial number can be found on the back of each product and the

Software Version can be found at the Spare Parts List.

2. Spare Part No. and Description

You can nd them in the Spare Parts List

Page 7

- 06 -

Service Manual

Model No.:

1-3-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of

products, which may differ from your products in some way.

1-4. How to Read this Service Manual

Using Icons:

Icons are used to attract the attention of the reader to specic information. The meaning of

each icon is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable

to the reader, such as tips and tricks.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of) a

procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where he/

she will nd additional information on a specic topic.

Page 8

Service Manual

Model No.:

- 07 -

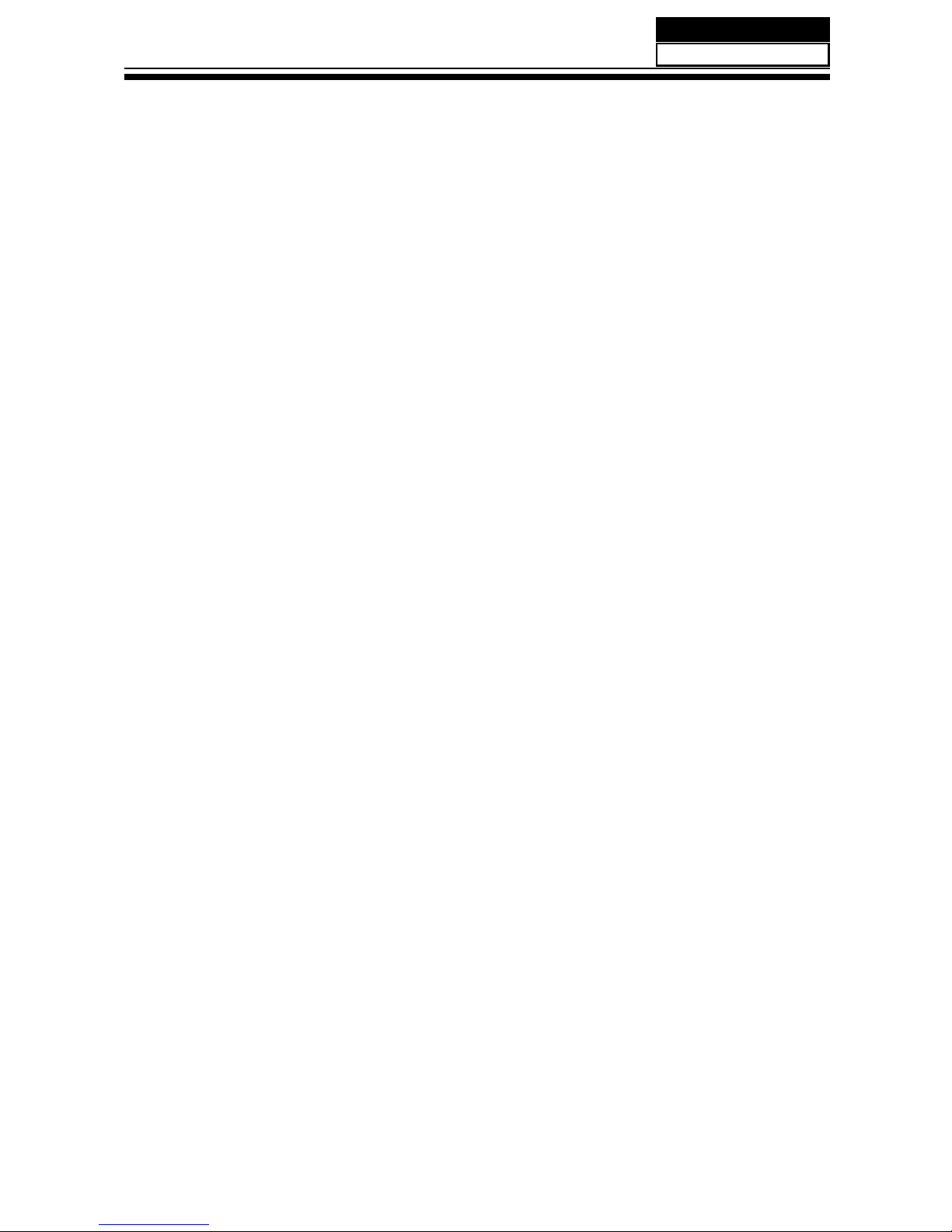

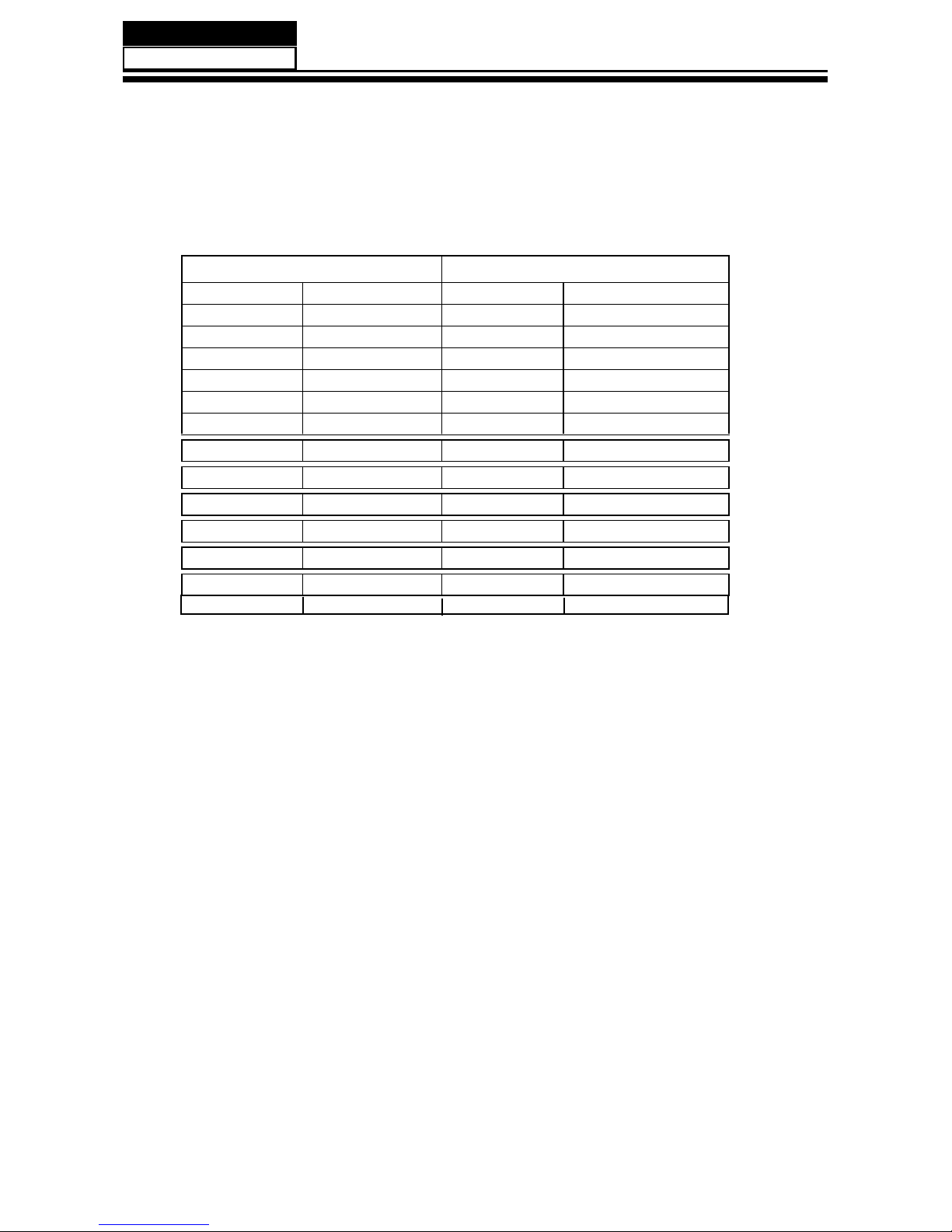

2. Specifications

Model

MSDV2413-03-D0

Screen Size 23.6inch

Aspect Ratio

16:9

Resolution

1920*1080

Response Time (ms)

8 (GRAY TO

GRAY)

Angel of View

Color Display

16.7M

No. of Preset Channels 400

OSD Language English

Color System PAL/SECAM

Audio System

DK, BG, I, M, L, L'

Audio Output Power

(Built-in) (W)

3W×2

Audio Output Power

(outer) (W)

No

Total Power Input (W) 60W

Voltage Range (V)

AC100V-240V

Power Frequency (Hz)

50~60Hz

Net Weight (KG)

5.56

Gross Weight (KG)

7.04

Net Dimension (MM)

577*170*427

Packaged Dimension

(MM)

650*201*494

176(H)/176(V)

Page 9

- 08 -

Service Manual

Model No.:

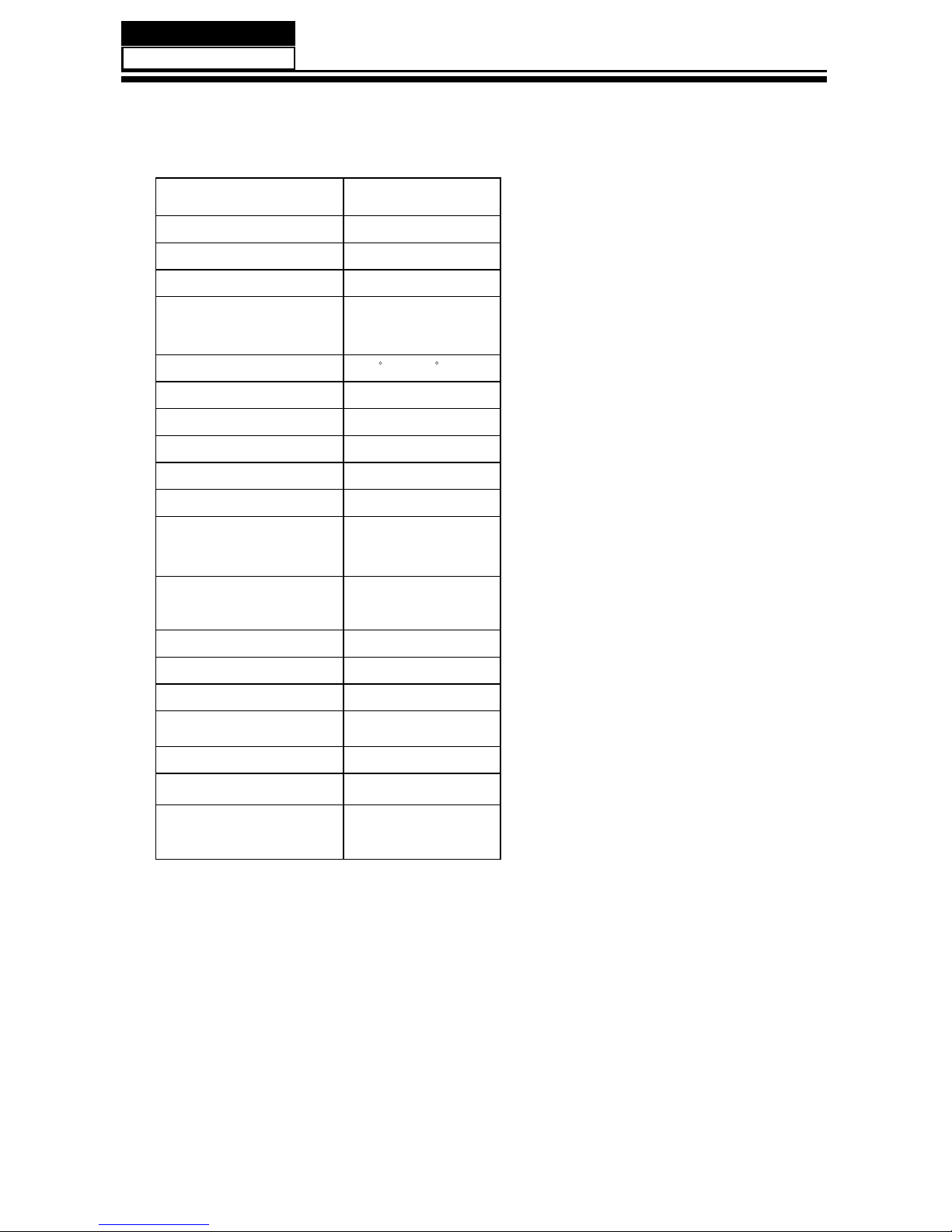

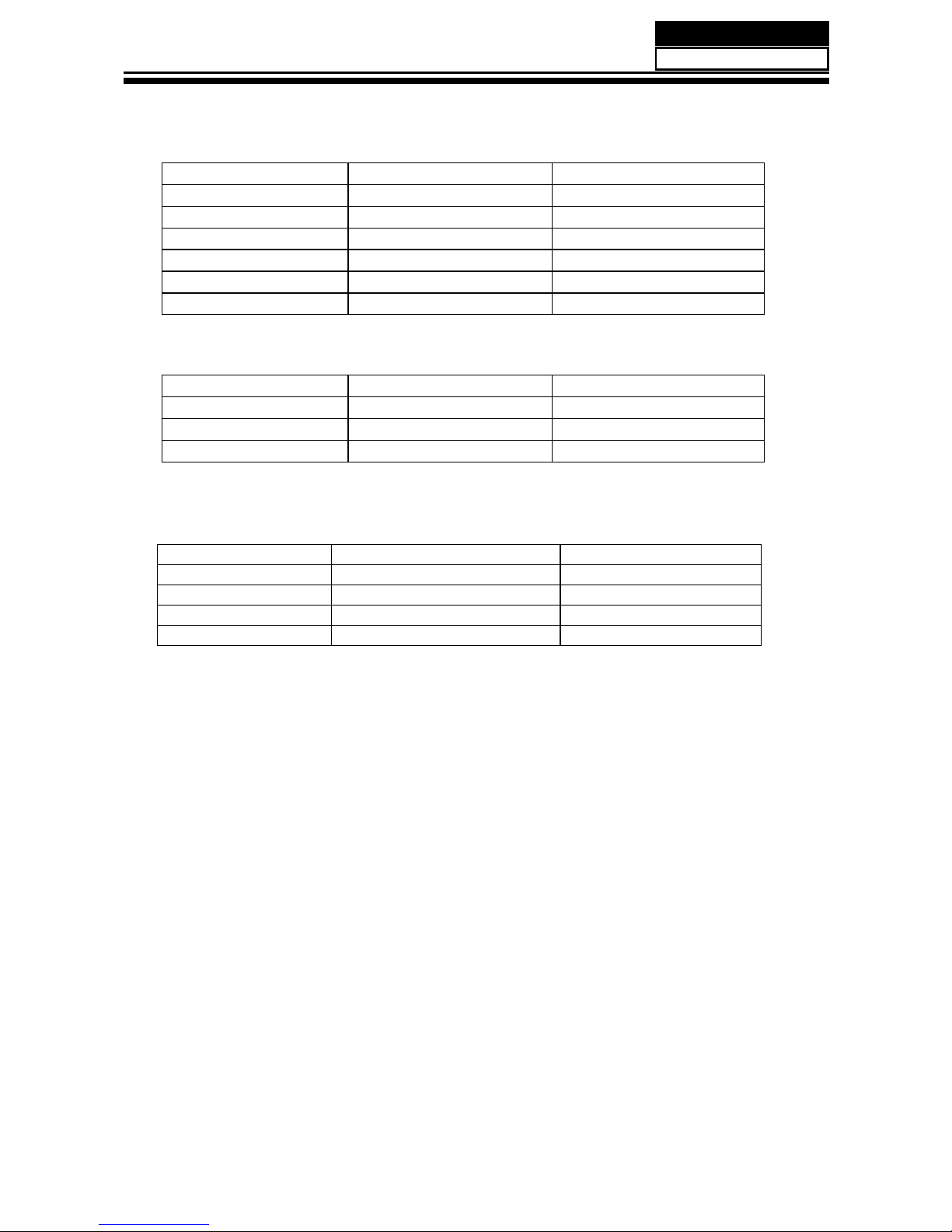

3. Location of Controls and Components

3-1 Board Location

No. Description

A Board Main Board

B Board

Power Board

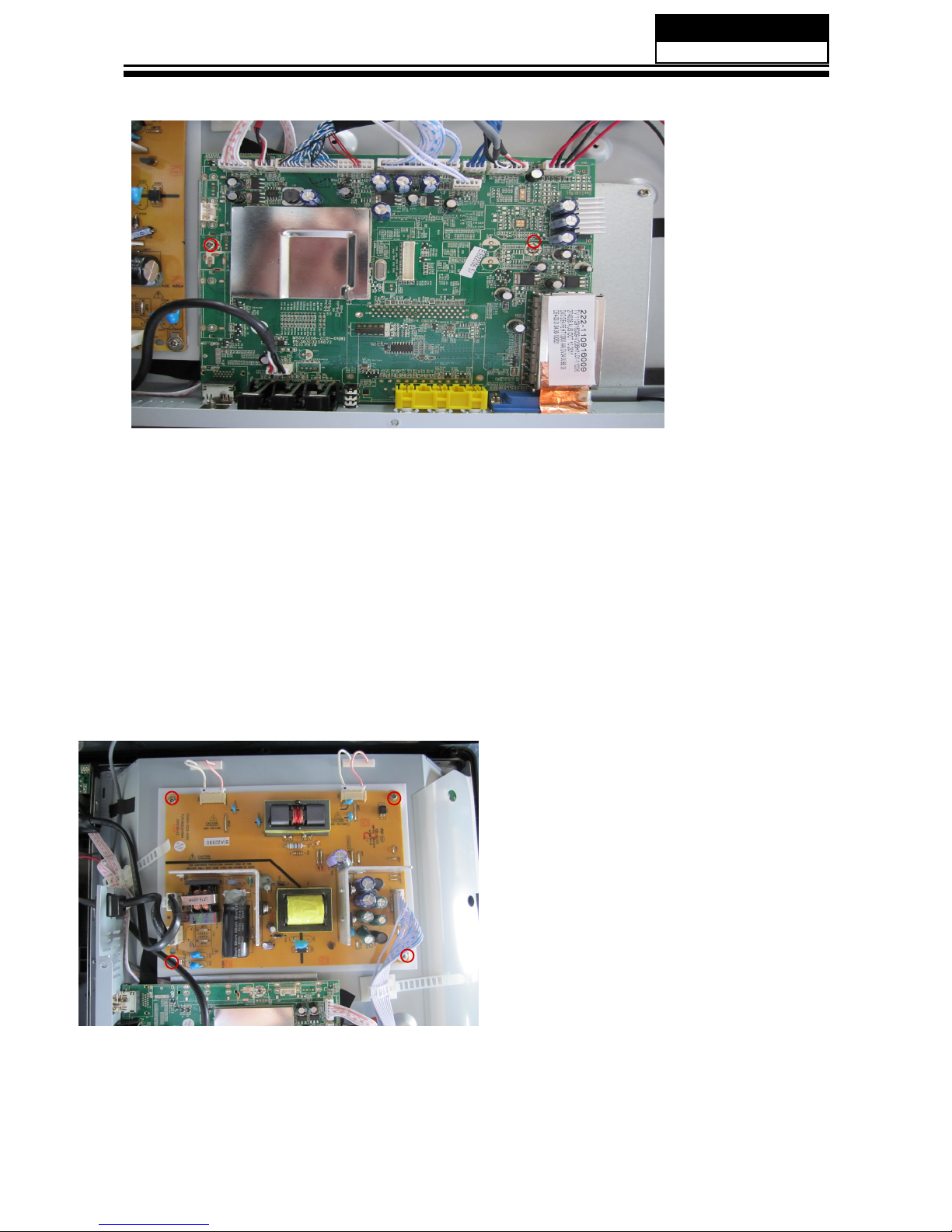

3-2 Main Board

A Board

B Board

C

C

LVDS WIRE

30433920301

514C2411M14

515C3206M57

Page 10

Service Manual

Model No.:

- 09 -

3-2-1 Function Description:

Main Board

Process signal which incept from exterior equipment then translate into signal that panel

can display.

3-2-2 Connector denition

Main board connector

Power connectors (J2,J25)

J2

Pin number Signal name

1 GND

2

ADJ

3 BK ON /OFF

4

+5V

5 POWER ON/OFF

6 +5VSTB

7 +5V

8

+5V

9 GND

10 GND

11 GND

12

+12V

Notes:

J2-Pin 3: Backlight on/off:

The system can turn on or turn off the backlight of TFT LED Panel through the power

supply unit path.

J2-Pin 5: System power on / standby

System board will use this pin to control system power.

J2-Pin 2: Control the luminance of backlight

The system can generate the PWN signal to control the strength of TFT LED Panel’s

backlight through this connector

13 +12V

J25

Pin number

Signal name

1

2

3

4

5

+5V

BL ON/OFF

ADJ

+5V

GND

Page 11

- 10 -

Service Manual

Model No.:

3LQQXPEHU 6LJQDOQDPH 'HVFULSWLRQ

/('B5 /$035('

/('B* /$03*5((1

,5 5(027(&21752/

*1' *1'

9 32:(5)255(027(

3LQQXPEHU 6LJQDOQDPH 'HVFULSWLRQ

.(<

.(<

*1'

remote connector (J21)

Keypad and connector (J22)

Speaker connectorJ26

Pin number Signal name Description

1 RSPK+ RSPK+

2 RSPK- RSPK3 LSPK- LSPK4 LSPK+ LSPK+

Page 12

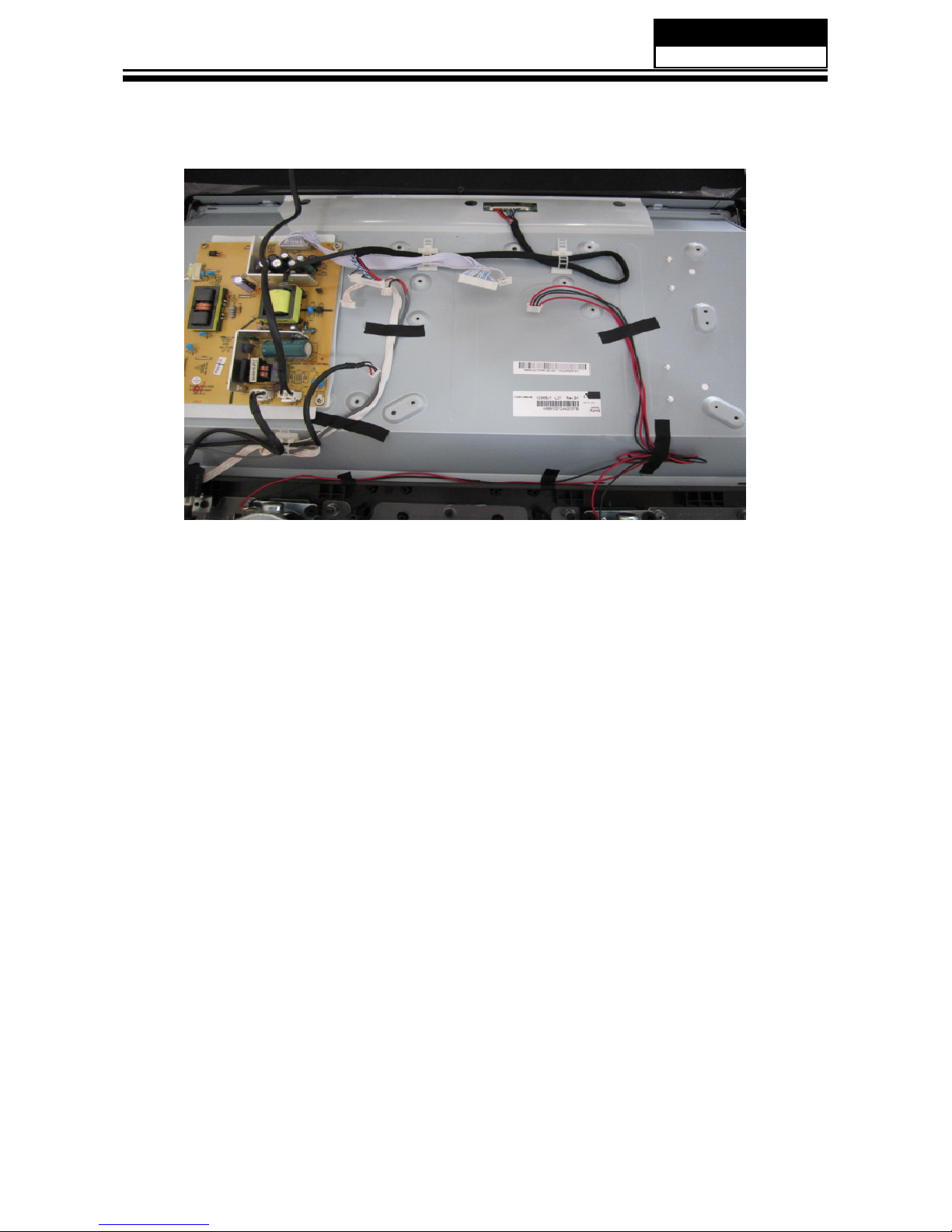

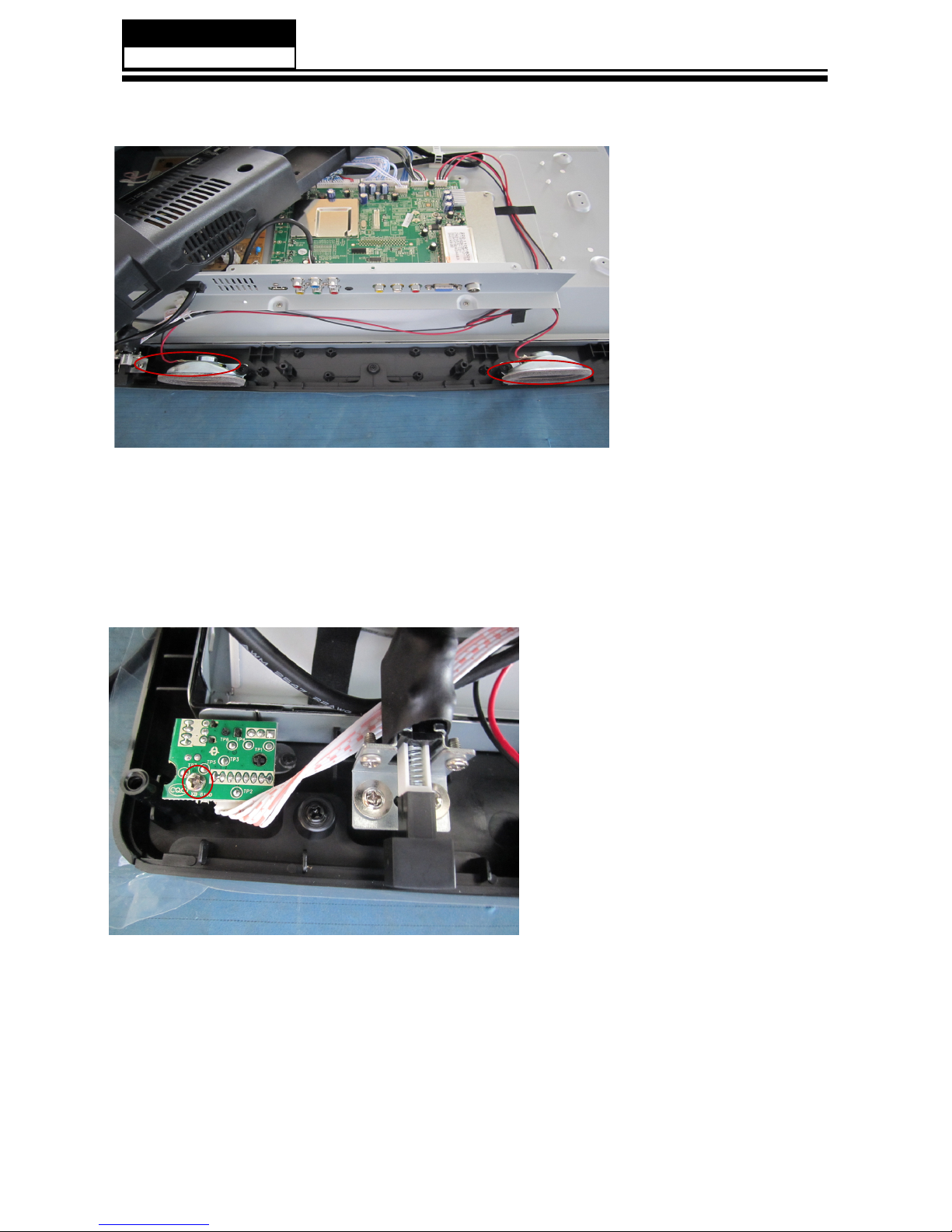

3-3. Power Board

3-3-1 Function Description:

Supply power for Main board, Panel.

3-3-2Connectordefinition

Service Manual

Model No.:

- 11 -

CON5

Pin number Signal name

Pin number Signal name

9

10

11

12

PWR-ON/OFF

GND

GND

DIM

+12V

BL-ON

GND

GND

+12V

+5V

+5V

5V-STBY

Page 13

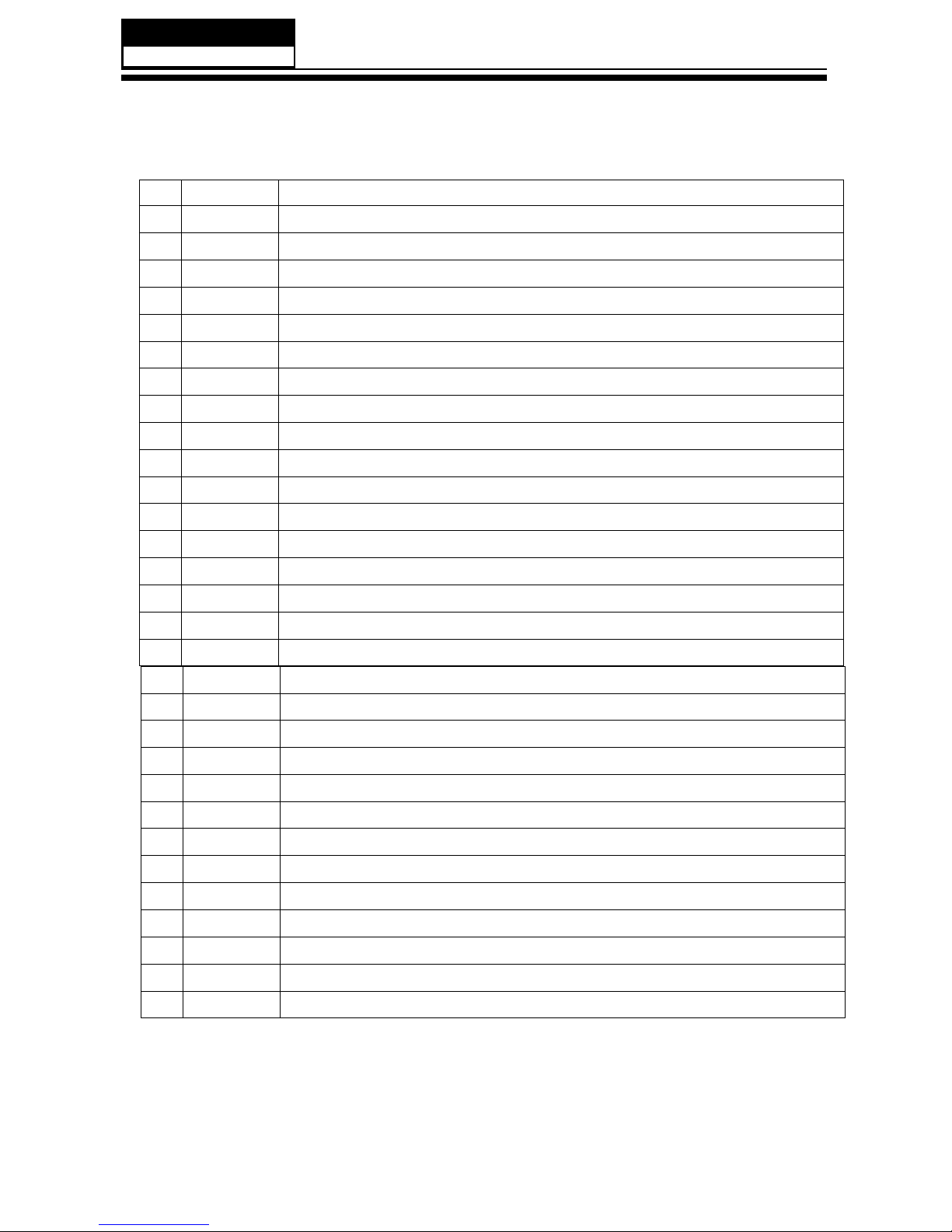

3-4. LED Panel

- 12 -

Service Manual

Model No.:

V236H1-L01

Page 14

Service Manual

Model No.:

- 13 -

3-4- Connector defi

nition.

Pin

Name Description

1

RXO0- Negative LVDS differential data input. Channel O0 (odd)

2

RXO0+ Positive LVDS differential data input. Channel O0 (odd)

3

RXO1- Negative LVDS differential data input. Channel O1 (odd)

4

RXO1+ Positive LVDS differential data input. Channel O1 (odd)

5

RXO2- Negative LVDS differential data input. Channel O2 (odd)

6

RXO2+ Positive LVDS differential data input. Channel O2 (odd)

7

GND Ground

8

RXOC- Negative LVDS differential clock input. (odd)

9

RXOC+ Positive LVDS differential clock input. (odd)

10

RXO3- Negative LVDS differential data input. Channel O3(odd)

11

RXO3+ Positive LVDS differential data input. Channel O3 (odd)

12

RXE0- Negative LVDS differential data input. Channel E0 (even)

13

RXE0+ Positive LVDS differential data input. Channel E0 (even)

14

GND Ground

15

RXE1- Negative LVDS differential data input. Channel E1 (even)

16

RXE1+ Positive LVDS differential data input. Channel E1 (even)

17

GND Ground

18

RXE2- Negative LVDS differential data input. Channel E2 (even)

19

RXE2+ Positive LVDS differential data input. Channel E2 (even)

20

RXEC- Negative LVDS differential clock input. (even)

21

RXEC+ Positive LVDS differential clock input. (even)

22

RXE3- Negative LVDS differential data input. Channel E3 (even)

23

RXE3+ Positive LVDS differential data input. Channel E3 (even)

24

GND Ground

25

NC For LCD internal use only, Do not connect

26

NC For LCD internal use only, Do not connect

27

NC For LCD internal use only, Do not connect

28

Vcc +5.0V power supply

29

Vcc +5.0V power supply

30

Vcc +5.0V power supply

Note (1) Connector Part No.: STM MSAKT2407P30HA or Equivalent

Note (2) Mating Wire Cable Connector Part No.: FI-X30H(JAE) or FI-X30HL(JAE)

Note (3) Mating FFC Cable Connector Part No.: 217007-013001 (P-TWO) or JF05X030-1 (JAE)

Note (4) The first pixel is odd.

Note (5) Input signal of even and odd clock should be the same timing.

Page 15

4. Disassemble and assemble

Remove the front frame on the

gure above

① Lay down the unit so that rear cover

faces upward

① Remove the three screw from the

rear cover indicated with ○

① Then remove the pedestal

4-2Remove the Back Cover

① Remove the these screw indicated on

gure above by ○

① Then remove the back cover from the

unit.

Service Manual

Model No.:

- 15 -

4-1 Remove the Pedestal

4-3. Remove the adhesive tape

Page 16

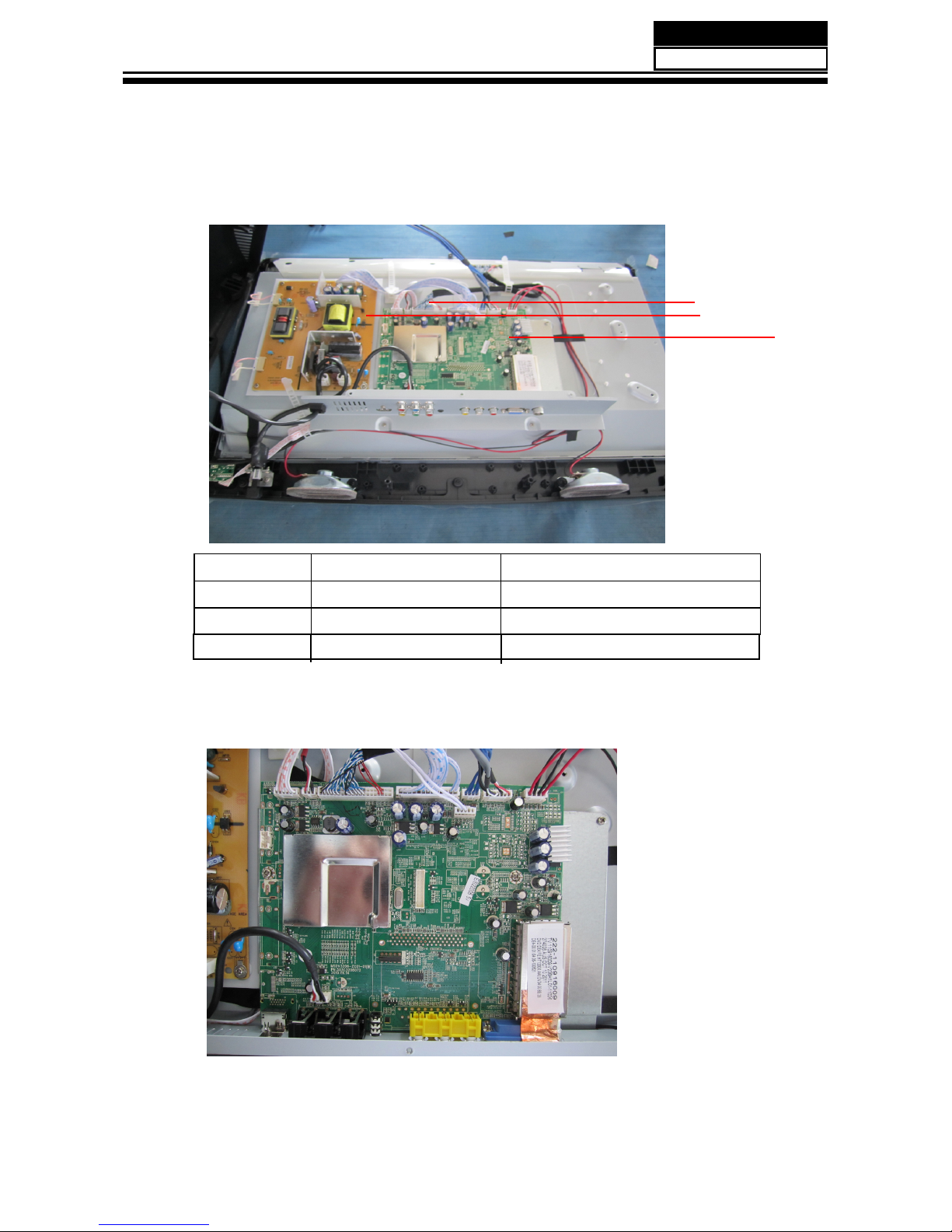

4-4 Remove the main board

① Remove the two screw indicated on

the gure above by ○

①

Then put the terminal bracket to the side

4-5 Remove the power module

① Remove the four screw indicated on the

gure above by ○

①

Then remove the power module

① Disconnected the coupler ① ①

①

①

Remove the Main board

Service Manual

Model No.:

- 16 -

J21 J22 J20 J2 J25

J10 J11 J26 J17

J21 J22 J20 J2 J25

J10 J11 J26 J17

Page 17

4-6 Remove the speaker

Take out the speaker

4-7 Remove the remote control

take out the remote control

board

Service Manual

Model No.:

- 17 -

Page 18

5. Installation Instructions

5-1 External Equipment Connections

Accessories

Remote Control

User GUIDE

Battery

Antenna Connection

Connect one end of a coaxial cable (not included) to the ANT IN jack on the back of

your TV/DVD combo, then connect the other end of the cable into the antenna or cable

TV wall outlet.

To improve picture quality from an antenna in a poor signal area, install a signal

amplier.

If you need to split the antenna signal to connect two TVs, install a two-way splitter.

Service Manual

Model No.:

- 18 -

Page 19

Service Manual

Model No.:

- 19 -

CONNECTING TO AV EQUIPMENT

It can be connected to the following appliances: VCR, multi disc player, DVD, camcorder, video

game or stereo system, etc.....

YPbPr can support these video formats: 480i,576i,480p,576p,720p,1080i.(component video)

This TV provides one group of AV, one group of YPbPr (component video) inputs for

convenient connection to VCR, DVD or other video equipment. Please refer to the owner's

manual of the equipment to be connected as well.

You can use the input terminals on TV set rear as follows.

W

R

To audio outputs

VIDEO EQUIPMENT

TO VIDEO output

W R

W R

G

B

R

G

B

R

Yellow (video)

White(audio L)

Red(audio R or Pr)

Y

W

R

Blue(Pb)

Green(Y)

B

G

HDMI

VIDEO EQUIPMENT with YPbPr

W

R

HDMI INPUT

PC

AUDIO INPUT

L

RAVPrY

Pb

AV L R

AV OUTP UT

RF INPUT

W

R

W R

TO AUDIO INPUTS

TO VIDEO

INPUTS

Page 20

Service Manual

Model No.:

- 20 -

PRESET M

ODE

HDMIINPUT

PC

AUDIO INPUT

L

RAVPrY

Pb

AV L R

AV OUTPU T

RF INPUT

STEPS:

CONNECTING TO PC

Be sure both the TV and computer are set to Power off.

1.Connect VGA and audio cable.

2.Connect the power cord.

3.Power on the TV, switch the input source to VGA mode.

4.Power on the PC.

This sequence is very important.

1

2

3

4

5

6

7

720*400

640*480

800*600

800*600

800*600

1024*768

1024*768

70

60

56

60

72

60

70

31.47

31.47

35.156

37.88

48.08

48.36

56.48

RESOLUTION

V.Freq.(Hz) H.Freq.(KHz)

Page 21

5-2 HDMI Connections

When the source device(DVD player or Set Top Box) supports HDM

How To Connect

1. Connect the source device to HDMI port of this TV with an HDMI cable(not supplied

with this product).

2. No separated audio connection is necessary.

How To Use

If the source device supports Auto HDMI function, the output resolution of the source

device will be automatically

set to 1280x720p.

If the source device does not support Auto HDMI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution of the source device to

1280x720p.

Select HDMI input source in input source option of Select Main source menu.

When the source device(DVD player or Set Top Box) supports DVI

How To Connect

1. Connect the source device to HDMI port of this TV with a HDMI-to-DVI cable(not

supplied with this product).

2. A separated audio connection is necessary.

3. If the source device has an analog audio output connector, connect the source device

audio output to DVI Audio In port located on the PC port.

How To Use

If the source device supports Auto DVI function, the output resolution of the source device

will be automatically

set to 1280x720p.

If the source device does not support Auto DVI, you need to set the output resolution

appropriately.

To get the best picture quality, adjust the output resolution of the source device to

1280x720p.

Press the INPUT button to select HDMI input source in input source option of Select Main

source menu.

Installation

Service Manual

Model No.:

- 21 -

Page 22

Cable sample

HDMI Cable

(not supplied with the product)

HDMI to DVI Cable

( not supplied with the product)

Analog Audio Cable

(Stereo to RCA type)

(not supplied with the product)

Service Manual

Model No.:

- 22 -

Page 23

Power source

TO USE AC POWER SOURCE

Use the AC polarized line cord provided for operation on AC.

Insert the AC cord plug into a standard polarized AC outlet.

NOTES:

■ Never connect the AC line cord plug to other than the specied voltage.

Use the attached power cord only.

■ If the polarized AC cord does not t into a non-polarized AC outlet,

do not attempt to le or cut the blade. It is the user`s responsibility to have an

electrician replace the obsolete outlet.

■ If you cause a static discharge when touching the unit and the unit fails to function,

simply unplug the unit from the AC outlet and plug it back in. The unit should return to

normal operation.

Service Manual

Model No.:

- 23 -

Page 24

6. Operation Instructions

6.2 Back panel controls

Service Manual

Model No.:

- 24 -

KEY BOARD

1. SOURCE:

2. MENU:

3. CH+/CH-

4. VOL+/VOL-

5.

Displays the input source Menu.

Displays the main MENU.

In TV mode, press "CH+" or "CH-" to change the

channel up and down.

In MENU mode, press "CH+" or "CH-" to select items.

Adjusts the sound level.

In MENU mode, press "VOL+" or "VOL-" to adjust the

item that you have selected.

Once the TV's main power switch has been activated,

press this button to turn the unit ON from STANDBY

mode.

STANDBY

6. USB

Press it again to turn the set back to STANDBY.

The USB memory stick should be plugged into the

unit directly. USB extension cables should not

be used to avoid failing of data transferring

and interference caused.

To access or play the files on your USB memory

stick using this USB socket on your TV, please

refer to use of the Applications Menu on page 17

of this manual.

SOURCE

MENU

CH+

CH-

VOL+

VOL-

STANDBY

USB

All the terminals are (from left to right):

AC Power input, HDMI input, YPbPr , AV composite video input,

Audio input, PC Audio input, AV output , VGA input,

Antenna socket.

.

(component video) input

(composite video and audio)

Note: 1. AV and YPbPr inputs share the Rear Audio input channel.

2. When the HDMI port receives a DVI signal, the matching audio signal is received

by the PC Audio input.

HDMI INPUT

PC

AUDIO INPUT

L

RAVPrY

Pb

AV L R

AV OUTP UT

RF INPUT

Page 25

6-3 Setting Up Your Remote Control

Service Manual

Model No.:

- 25 -

Remote control

03

REMOTE CONTROL

1

2

3

4

5

6

7

8

9

10

11

13

12

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1:

POWER

:To

set the TV

to standby or

power on.

2: :In USB

mode, used as

reverse key,

in teletext

mode used as

subpage key.

3: : In

USB mode, used as forword key

, in teletext

mode used as reveal key.

4: :

Press the Play

Button in USB

Mode to begin

or continue

Playback.

5: :

Press the Pause

Button to pause

play in USB

Mode.

6:

TEXT

:To

enter or TELETEXT

.

7:

SUBTITLE

: T

o turn on

subtitles press the

subtitle button

in DTV mode.

8 : :

Displays the main

on-screen menu.

9 :

CURSOR

:

To

move within the

menu.

10:

OK

: Confirms selection.

11:

EPG

: T

o display information

about the program

being viewed

and what's on

next in DTV

mode.

12:

FAV

: T

o access your

favourite channels list

in TV or

DTV mode.

13:

VOL+/-

: T

o adjust sound

level.

14:

NUMERIC KEY

: For direct

access to channels.

15:

AUDIO

: T

o select the

available audio language

of TV programs

.

16:

MUTE

: T

o disable or

enable the sound

output.

17: : In

USB mode, used

as next key

, in teletext

mode used as

list key.

18: : In

USB mode, used

as previous key

, in teletext

mode used

as hold key

.

19: :In teletext

mode used as

index.

20:

: Press to

stop play in

USB mode.

21:

INFO

: T

o display the

program information of

the show you

are watching, press the info button.

22:

FREEZE:

Press to freeze

the picture you

are watching.

23: : Press

to display and

select the available

video sources.

24:

EXIT

: T

o return to

the previous menu

or exit menu.

25:

CH+/CH-

: T

o access the

next or previous

channels.

26:

REP

: In USB

mode,select Repeat mode.

27:

RECALL

: DTV Mode:RECALL:Jumps

to last channel

viewed.

VO

L

CH

RE

P

FREEZE

Page 26

Service Manual

Model No.:

TELETEXT

T

EXT

SELECTING A P

AGE

DIRECT ACCESS

TO THE ITEMS

INDEX

SUB PAGE

HOLD

REVEAL

P

r

ess

:

Y

ou

will obtain

:

LIST

Enter the number

of the page

required using the

0 to 9

up/down.

Example: page 120,

enter 120. The

number is displayed

top left, the

counter turns and

then the page

is displayed. Repeat

this operation to

view another page.

If the counter

continues to search,

this means

that the page

is not transmitted.

Select another number

.

Coloured buttons correspond

to the colours

at the bottom

of the

screen. The 4

coloured keys are

used to access

the items or

corresponding pages. The coloured areas flash when the item or the

page is not

yet available.

This returns to

the contents page (usually page 100).

Certain pages contain

sub-pages which are

automatically

displayed successively.

This key is

used to stop

or resume subpage acquisition. The

indication appears top

left.

To freeze the page.

To display or hide the concealed information (games solutions).

The user can

set four favourite

pages to be

directly linked to

the four

color keys. While list mode is activated, it is not possibility to use TOP

or FLOF navigation

with the colourkeys.

The favourite page

numbers

should be stored

and restored to/from

nonvolatile memory for

each

channel by the

system software.

This is used

to call or

exit teletext modes.

The summary appears

with

a list of

items that can

be accessed. Each

item has a

corresponding

3 digit page

number. If

the channel selected

does not broadcast

teletext, the indication

100 will be

displayed and the

screen will

remain blank (in

this case, exit

teletext and select

another channel).

Teletext

is an information

system broadcast by

certain channels which

can be

consulted like a

newspaper. It

also offers

access to subtitles

for viewers with

hearing

problems or who

are not familiar

with the transmission

language (cable networks,

satellite channels, etc.)

Page 27

7. Electrical parts

7-1. Block diagram

Service Manual

Model No.:

- 26 -

MSD306

1517

12

Page 28

7-2. Circuit Diagram

Service Manual

Model No.:

- 27 -

5

4

3

2

D D

C C

B B

RX3B0P

RX3B0N

RX3B1P

RX3B1N

RX3B2P

RX3B2N

RX3BCLKP

RX3BCLKN

DDC3BSDA

DDC3BSCL

HOTPLUG3

RX2B0P

RX2B0N

RX2B1P

RX2B1N

RX2B2P

RX2B2N

RX2BCLKP

RX2BCLKN

DDC2BSDA

DDC2BSCL

HOTPLUG2

RX1B0P

RX1B0N

RX1B1N

RX1B2P

RX1B2N

RX1BCLKP

RX1BCLKN

DDC1BSDA

RX1B1P

DDC1BSCL

HOTPLUG1

HDMI_E_CEC

RGB0_RIN+

RGB0_RIN-

RGB0_GIN+

RGB0_GIN-

RGB0_BIN+

RGB0_BIN-

RGB0-SOG

SC1_FS

SC1_FB

AV1-Rin

AV1-Lin

VGA_AR

VGA_AL

SCART_AV

SIDE_AV

SPDIF_O

CVBS_OUT

IRIN

YINO+

PBINO+

PRINO+

SOY

RAIN+

GAIN+

BAIN+

SOG

VSYNC

HSYNC

MUX_AR

MUX_AL

HD1R

HD1L

REAR_AV

DVD_AV

ASEL0

ISP-RXD

ISP-TXD

DVD-ON/OFF

MIUA_DQS0

MIUA_DQS0B

MIUA_DQS1

MIUA_DQS1B

MIUA_DQM1

MIUA_DQM0

MIUA_DQ[0:15]

MIUA_A[0:12]

MIUA_MCLK

MIUA_MCLKZ

MIUA_ODT

MIUA_WEZ

MIUA_MCKE

MIUA_BA1

MIUA_BA0

MIUA_BA2

MIUA_RASZ

MIUA_CASZ

OTG_DM

OTG_DP

OTG_DP1

OTG_DM1

USB_DETEC1

ON_USB1

TSSTART

TSVALID

TSCLK

TS_CLK

TS_MDI[7:0]

TS_D[7:3]

PCM_D[7:0]

TS_MOSTART

TS_MOVAL

PCM_IRQA_N

PCM_CE_N

PCM_IOWR_N

PCM_IORD_N

PCM_WE_N

PCM_A[14:0]

PCM_OE_N

PCM_REG_N

PCM_WAIT_N

PCM_RESET

PCM_CD_N

POWERON/OFF

BKLON

ADJ-PWM

LCDON

RF_AGC_SELO

#IF_OUT

IF_OUT

IF_AGC

RF_AGC

VIFP

VIFM

TV-SIFP

TV-SIFM

SIF_CTL

T_SDA

T_SCL

AV1_AL

AV1_AR

ON_USB2

CLASS_EN

AUOUTL1

AUOUTR1

AMP-Lout

AMP-Rout

HP_DET SC_AROUT

SC_ALOUT

HP_SMUTE

HP_SL

HP_SR

TS_MDO0

TS_MDO1

TS_MDO2

Page 6

06_TUNER

RF_AGC_SELO

IF_OUT

#IF_OUT

RF_AGC

IF_AGC

T_SCL

T_SDA

SIF_CTL

TV-SIFP

VIFM

VIFP

TV-SIFM

Page 10

10_MST_POWER

Page 11

11_AUDIO

HP_DET

AMP-Rout

HP_SR

HP_SL

HP_SMUTEAMP-Lout

AUOUTR1

AUOUTL1

SC_AROUT

CLASS_EN

SC_ALOUT

Page 3

03_AVIN&OUT

SPDIF_O

HP_SMUTE

HP_SL

HP_SR

SIDE_AV

CVBS_OUT

VGA_AL

VGA_AR

AV1_AL

AV1_AR

SC1_FB

SC1_FS

SC_ALOUT

SC_AROUT

SCART_AV

AV1-Lin

AV1-Rin

RGB0-SOG

RGB0_GIN+

RGB0_BIN+

RGB0_RIN+

RGB0_BIN-

RGB0_GIN-

RGB0_RIN-

Page 5

05_HDMI

RX2B1P

RX2B1N

RX1B1P

RX1B1N

RX1B0P

RX1B0N

RX1BCLKP

RX1BCLKN

DDC1BSCL

DDC1BSDA

RX2B0P

HOTPLUG1

RX1B2P

RX1B2N

RX2B0N

RX2BCLKP

RX2BCLKN

DDC2BSCL

DDC2BSDA

HDMI_E_CEC

RX3B2P

RX3B2N

RX3B1P

HOTPLUG2

RX3B1N

RX3B0P

HOTPLUG3

RX3B0N

RX3BCLKP

RX3BCLKN

RX2B2P

DDC3BSDA

RX2B2N

DDC3BSCL

Page 7

07_PCMCIA

OTG_DM

OTG_DP

OTG_DP1

OTG_DM1

USB_DETEC1

ON_USB1

TSSTART

TSVALID

TSCLK

TS_MDI[7:0]

TS_D[7:3]

TS_CLK

TS_MOSTART

TS_MOVAL

PCM_D[7:0]

PCM_A[14:0]

PCM_IRQA_N

PCM_CE_N

PCM_IOWR_N

PCM_IORD_N

PCM_WE_N

PCM_OE_N

PCM_REG_N

PCM_WAIT_N

PCM_RESET

PCM_CD_N

ON_USB2

TS_MDO0

TS_MDO1

TS_MDO2

Page 2

02_SYS_POWER

POWERON/OFF

BKLON

ADJ-PWM

LCDON

Page 9

09_MEMORT

MIUA_DQS0

MIUA_DQS0B

MIUA_DQS1

MIUA_DQS1B

MIUA_DQM1

MIUA_DQM0

MIUA_DQ[0:15]

MIUA_MCLK

MIUA_MCLKZ

MIUA_ODT

MIUA_WEZ

MIUA_MCKE

MIUA_BA1

MIUA_BA0

MIUA_A[0:12]

MIUA_BA2

MIUA_RASZ

MIUA_CASZ

Page 4

04_HD&VGA

YINO+

PBINO+

PRINO+

DVD_AV

DVD-ON/OFF

IRIN

HD1L

HD1R

REAR_AV

ISP-RXD

VSYNC

ISP-TXD

HSYNC

SOG

GAIN+

RAIN+

BAIN+

SOY

ASEL0

MUX_AR

MUX_AL

AV1_AR

AV1_AL

Page 8

08_MSD306

RX2B1P

HOTPLUG2

RX2B1N

RX2BCLKP

RX2B2P

RX2BCLKN

RX2B2N

RX2B0P

RX2B0N

DDC2BSDA

DDC2BSCL

RX3B1P

HOTPLUG3

RX3B1N

RX3BCLKP

RX3B2P

RX3BCLKN

RX3B2N

RX3B0P

RX3B0N

DDC3BSDA

DDC3BSCL

RX1B1P

HOTPLUG1

RX1B1N

RX1BCLKP

RX1B2P

RX1BCLKN

RX1B2N

RX1B0P

RX1B0N

DDC1BSDA

DDC1BSCL

HDMI_E_CEC

RAIN+

GAIN+

BAIN+

SOG

HSYNC

VSYNC

RGB0_RIN-

RGB0_RIN+

RGB0_GIN-

RGB0_GIN+

RGB0_BIN-

RGB0_BIN+

RGB0-SOG

SC1_FS

SC1_FB

PRINO+

SOY

YINO+

PBINO+

ADJ-PWM

OTG_DP

OTG_DM

OTG_DP1

OTG_DM1

IRIN

ISP-TXD

ISP-RXD

AV1-Rin

AV1-Lin

HD1L

HD1R

VGA_AR

VGA_AL

MUX_AR

MUX_AL

AMP-Rout

AMP-Lout

AUOUTL1

AUOUTR1

SPDIF_O

SCART_AV

DVD_AV

SIDE_AV

REAR_AV

CVBS_OUT

POWERON/OFF

CLASS_EN

PCM_RESET

PCM_CE_N

PCM_WE_N

PCM_CD_N

PCM_WAIT_N

PCM_IOWR_N

PCM_REG_N

LCDON

BKLON

PCM_OE_N

PCM_IORD_N

PCM_IRQA_N

TSCLK

TSVALID

TSSTART

TS_D[7:3]

TS_CLK

TS_MOVAL

TS_MOSTART

#IF_OUT

IF_OUT

IF_AGC

RF_AGC

VIFP

VIFM

TV-SIFP

TV-SIFM

SIF_CTL

T_SDA

T_SCL

MIUA_A[0:12]

MIUA_DQ[0:15]

MIUA_DQS0

MIUA_DQS0B

MIUA_DQS1

MIUA_DQS1B

MIUA_DQM0

MIUA_DQM1

MIUA_MCLK

MIUA_MCLKZ

MIUA_WEZ

MIUA_RASZ

MIUA_MCKE

MIUA_CASZ

MIUA_BA0

MIUA_BA1

MIUA_BA2

MIUA_ODT

TS_MDI[7:0]

PCM_A[14:0]

PCM_D[7:0]

RF_AGC_SELO

DVD-ON/OFF

ASEL0

ON_USB1

USB_DETEC1

HP_DET

ON_USB2

TS_MDO0

TS_MDO1

TS_MDO2

Page 29

Service Manual

Model No.:

- 28 -

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A

A

V8ADJ

V8ADJ

V8ADJ

V8ADJ

1.32V5VA

GND

GND

+12V +8V

GND

1.8VA

1.8VA

3.3VU5Vstb

3.3VA

5VA

2.5VA

1.32V

2.5VA

5VA

3.3VA

1.8VA

3.3VU

3.3VA

SHEN ZHEN MTC MULTIMEDIA CO.,LTD

DESIGN:YANXUEWU

MODEL: MSDV3205-L2 TITLE:MST_POWER

CHECKED: PART NO.: DWG NO.:

APPRD: SHEET: 10 OF 12 VER:1.0

MSD306 POWER SUPPLY

8.12V

1.27V

1.02A

+1.2V FOR MST CORE

U37靠近CA16

放置

230mA(DDR2/PCS)

3.29V/380mA

1.31V/1100mA

3.29V/150mA

2.54V/230mA

1.84V/110mA

1.31V

C154

15nF

C154

15nF

ADJ

OUT

IN

U12

AMS1117-3.3

ADJ

OUT

IN

U12

AMS1117-3.3

321

4

C132

NC/0.1u

C132

NC/0.1u

R279

470R

R279

470R

C127

0.1u

C127

0.1u

C165

10uF

C165

10uF

C140

0.1u

C140

0.1u

C128

NC/0.1u

C128

NC/0.1u

R280 2KR280 2K

U16

MP1482

U16

MP1482

EN

7

FB

5

VCC2BS

1

SW

3

AGND

4

SS

8

COMP

6

R2731kR273

1k

C162 15nFC162 15nF

R281

6.8K

R281

6.8K

C141

0.1u

C141

0.1u

C123

0.1u

C123

0.1u

C142

0.1u

C142

0.1u

ADJ

OUT

IN

U11

AMS1117-3.3

ADJ

OUT

IN

U11

AMS1117-3.3

321

4

C137

0.1u

C137

0.1u

C135

0.1u

C135

0.1u

C158

0.1u

C158

0.1u

+

C163 470uF/16V+C163 470uF/16V

C152

100uF/16V

C152

100uF/16V

C134

NC/0.1u

C134

NC/0.1u

C159 1nFC159 1nF

R2741KR274

1K

+

C131

220uF/16V

+

C131

220uF/16V

C143

0.1u

C143

0.1u

C121

0.1u

C121

0.1u

R282

4.7K

R282

4.7K

C138

0.1u

C138

0.1u

C151

0.1uF

C151

0.1uF

+

C150

100uF/16V

+

C150

100uF/16V

C148

0.1u

C148

0.1u

R278

100K

R278

100K

+

C126

100uF/16V

+

C126

100uF/16V

C124

0.1u

C124

0.1u

C133

0.1u

C133

0.1u

C144

0.1u

C144

0.1u

+

C136

100uF/16V

+

C136

100uF/16V

R269NCR269

NC

C157

0.1u

C157

0.1u

C139

NC/0.1u

C139

NC/0.1u

R277

2.49K/%1

R277

2.49K/%1

C153

0.1uF

C153

0.1uF

R2700RR270

0R

R271NCR271

NC

C125

NC/0.1u

C125

NC/0.1u

C122

0.1u

C122

0.1u

R275

470R

R275

470R

C164 0.1uC164 0.1u

C146

0.1u

C146

0.1u

L80

15H_2A

L80

15H_2A

C156

0.1u

C156

0.1u

C160

10uF

C160

10uF

ADJ

OUT

IN

U14

AMS1117-ADJ

ADJ

OUT

IN

U14

AMS1117-ADJ

321

4

ADJ

OUT

IN

U13

AMS1117-ADJ

ADJ

OUT

IN

U13

AMS1117-ADJ

321

4

U15

AMS1084-SO263

TO-252-4

U15

AMS1084-SO263

TO-252-4

Adjust

1

VIN3VOUT

2

TAB

4

R2720RR272

0R

C130

0.1u

C130

0.1u

C147

0.1u

C147

0.1u

+

C129

100uF/16V

+

C129

100uF/16V

C155

0.1u

C155

0.1u

C145

0.1u

C145

0.1u

C149

0.1u

C149

0.1u

R276

220R

R276

220R

C161 0.1uC161 0.1u

Page 30

Service Manual

Model No.:

- 29 -

5

4

3

2

D

C

B

HP_LINP

ROUT+

LOUT+

ROUT#

HP_RINP#

ROUT#

HP_LINP#

SVRR

LOUT#

SC_AROUT

ROUT-

ROUT-

ROUT-

ROUT-

HP_LIN

HP_RINAMP-Rout

AMP-Lout

AUOUTR1

AUOUTL1

SC_ALOUT

HP_LIN

HP_RIN

HP_LINP#

HP_LINP#

HP_LINN#

HP_LINN#

LOUT+

LOUT+

LOUT+

LOUT+

LOUT-

HP_RINP#

HP_RINN#

ROUT-

LOUT-

ROUT+

MUTEn

VCC-OP2

VCC-OP2

HP_RINP

LOUT#

LOUT#

SVRR

MUTEO

MUTETI

ROUT-

ROUT+

LOUT1+#

LOUT1-#

GAIN1

GAIN0

LOUT-GAIN0

GAIN1

VOLUME

AMP1_R-

AMP1_R+

LOUT1-#

LOUT1+#

SUB_AL+ AMP1_L+

AMP1_L-

SD

VOLUME

LOUT2-#

FADE

LOUT2+#

+12V

SD

FADE

HP_RINP

HP_LINP

SUB_AL+

SUB_AL-

LOUT+

LOUT-

LOUT+

HP_LINP#

HP_LINN# AMP1_L-

HP_RINP#

HP_RINN# AMP1_R-

AMP1_R+

AMP1_L+

AMP2_L-

AMP2_L+HP_LINP#

HP_LINN#

SUB_AL-

AMP2_L+

AMP2_L-

AMP2_R+

AMP2_R-HP_RINN#

HP_RINP#

AMP2_R-

AMP2_R+

LOUT2-#

LOUT2+#

SUB_LOUT-

SUB_LOUT+

ROUT+

LOUT+

MUTEO

MUTEPAM

MUTEO

ROUT-

MUTEPAM

CLASS_EN

MUTEPAM

MUTEPAM

HP_RIN

HP_LIN

HP_DETHP_DET HP_SMUTE

HP_SL

HP_SR

AMP-Rout

AMP-Lout

AUOUTR1

AUOUTL1

SC_AROUT

CLASS_EN

SC_ALOUT

HP_DET

HP_SR

HP_SL

HP_SMUTE

+8V

PVCC

+8V

PVCC

+12V

PVCC

PVCC

+5V

PVCC

3.3VA

+8V

3.3VA

+12V

+12V

+12V+12V

+12V

+12V

+12V

+8V

+8V

+8V

+8V

+12V

PVCC

3.3VA

GND

GND GND

+5V

+5V

GND GND GND

GND

GND

5VA

GND

GND

GAIN=1K/470R

Location Near

IC Pin.

Location Near

IC Pin.

AMP

AUDIO OP

MUTE Control

HOLE

Ground in the middle of the L/R

Gain=R295/R298+1

Gain=R285/R291+1

SUBWOOFER SCH

F=Q/

∏

RC

LOW PASS

PH_Drive

R351

100R

R351

100R

L90

NC/FB/1206

L90

NC/FB/1206

R307

NC/0R

R307

NC/0R

L50

FB_56OHM_500MA

L50

FB_56OHM_500MA

C231

NC/220nF

C231

NC/220nF

Q30

NC/BT3904

Q30

NC/BT3904

-

+

U20B

NC/4558

-

+

U20B

NC/4558

5

6

7

8 4

R320

NC/0R

R320

NC/0R

R369

NC/1uF

R369

NC/1uF

C250

NC/1u

C250

NC/1u

R321

NC/4.7K

R321

NC/4.7K

C230

NC/10uF

C230

NC/10uF

C213

1000pF

C213

1000pF

R383

NC/100K

R383

NC/100K

C214

NC/10uF

C214

NC/10uF

R319 NC/0RR319 NC/0R

C221

200pF

C221

200pF

R291

10K

R291

10K

R367

NC/100

R367

NC/100

R327 NC/0RR327 NC/0R

R299

30K

R299

30K

R328

NC/0R

R328

NC/0R

Q29

NC/2N3904

Q29

NC/2N3904

312

+

C236

470uF/16V

+

C236

470uF/16V

1 2

R322

NC/100R

R322

NC/100R

R303

NC/0R

R303

NC/0R

R305 NC/10KR305 NC/10K

R292 3KR292 3K

C238

NC/10uF

C238

NC/10uF

C174

10uF

C174

10uF

R336

10R

R336

10R

C251

NC/100n

C251

NC/100n

C191

200pF

C191

200pF

C227

NC/1uF

C227

NC/1uF

R339

470R

R339

470R

D8 IN4148D8 IN4148

C228

NC/1uF

C228

NC/1uF

C170

0.1uF

C170

0.1uF

C302

NC/2.2uF

C302

NC/2.2uF

R338

10R/0.22uF

R338

10R/0.22uF

C176

220uF/16V

C176

220uF/16V

C222

2.2uF

C222

2.2uF

R362

10R

R362

10R

C243

0.22uF

C243

0.22uF

C200

NC/4.7uF

C200

NC/4.7uF

R345 NC/0RR345 NC/0R

R314

100K

R314

100K

R371

NC/15K

R371

NC/15K

R365

NC/100K

R365

NC/100K

R289

NC/0R

R289

NC/0R

U25

NC/DF3544

U25

NC/DF3544

IN1

3

BIAS

6

OUTA1MUTE

2

VDD

8

GND

4

IN2

5

OUTB

7

C189

NC/1000P

C189

NC/1000P

NC/0R

R370

NC/0R

R370

C209

2.2uF

C209

2.2uF

R388

NC/100

R388

NC/100

+

C241

470uF/16V+C241

470uF/16V

1 2

R352

NC/0R

R352

NC/0R

H1

10-2.54MMH110-2.54MM

123

4

R288

NC/0R

R288

NC/0R

C195

NC/220nF

C195

NC/220nF

C296

NC/10UF

C296

NC/10UF

C212

1uF

C212

1uF

C178 NC/0.22uFC178 NC/0.22uF

R3080RR308

0R

C2030RC203

0R

R373

NC/1M

R373

NC/1M

R346 150RR346 150R

C202

200pF

C202

200pF

R296

NC/0R

R296

NC/0R

R390

NC/100K

R390

NC/100K

R301 220RR301 220R

C169

0.1uF

C169

0.1uF

C190

NC/1000P

C190

NC/1000P

R337

NC/0R

R337

NC/0R

C196

NC/1uF

C196

NC/1uF

C295 NC/2.2uFC295 NC/2.2uF

U18

NC/PAM8610

U18

NC/PAM8610

AVDD3VREF4RINN1RINP

2

FADE8AGND17VOLUME5REFGND

6

PVCCL

12

PGNDL

11

LINN10LINP

9

BSLP

16

BSLN

15

LOUTN

14

LOUTN

13

LOUTP

17

LOUTP

18

PVCCL

19

PGNDL

20

VCLAMPL

21

COSC22ROSC23AGND

24

MUTE

25

AVCC

26

V2P5

27

VCLAMPR

30

PGNDR

31

PVCCR

32

ROUTP

33

ROUTP

34

BSRP

35

BSRN

36

ROUTN

37

ROUTN

38

PVCCR

39

PGNDR

40

AGND

28

SD

29

thermal

41

C232

NC/10uF

C232

NC/10uF

C244

0.22uF

C244

0.22uF

+

C210

100uF/16V+C210

100uF/16V

R335 NC/0RR335 NC/0R

C2080RC208

0R

R286

NC/0R

R286

NC/0R

R306 10KR306 10K

R313 100RR313 100R

Q32

3906

Q32

3906

C179 NC/0.22uFC179 NC/0.22uF

R325

100K

R325

100K

C182

NC/1000P

C182

NC/1000P

Q33

2N3904

Q33

2N3904

312

C187

NC/10uF

C187

NC/10uF

R315

NC/100K

R315

NC/100K

Q31

2N3904

Q31

2N3904

312

L86

NC/FB/1206

L86

NC/FB/1206

R415

NC/100K

R415

NC/100K

R386

NC/15K

R386

NC/15K

U19

TPA1517

U19

TPA1517

IN11SGND2SVRR3OUT14PGND5OUT26VCC7M/SB8IN29GND/HS

10

GND/HS11GND/HS12GND/HS13GND/HS14GND/HS15GND/HS16GND/HS17GND/HS18GND/HS19GND/HS

20

L81

NC/FB/1206

L81

NC/FB/1206

R355

NC/0R

R355

NC/0R

C217

NC/1000pF

C217

NC/1000pF

C242

NC/100n

C242

NC/100n

C197

NC/1uF

C197

NC/1uF

C225

NC/1000P

C225

NC/1000P

+

C248

220uF/16V

+

C248

220uF/16V

-

+

U20A

NC/4558

-

+

U20A

NC/4558

3

2

1

8 4

C207 NC/1uFC207 NC/1uF

R374

NC/100K

R374

NC/100K

R309

NC/0R

R309

NC/0R

L85

NC/FB/1206

L85

NC/FB/1206

R343

330R

R343

330R

C205

NC/220uF/16V

C205

NC/220uF/16V

R317

NC/10K

R317

NC/10K

R295

NC/10R

R295

NC/10R

C299

NC/10UF

C299

NC/10UF

U17

NC/TPA3110D2

U17

NC/TPA3110D2

SD1FAULT2LINP3LINN

4

AGND8AVCC7GAIN16GAIN0

5

GVDD9PLIMIT10RINN11RINP

12

BSPR

17

OUTPR

18

PGND

19

OUTNR

20

BSNR

21

BSNL

22

OUTNL

23

PGND

24

OUTPL

25

BSPL

26

PVCCL27PVCCL

28

PVCCR

16

NC13PBTL

14

PVCCR

15

GND

29

R368

NC/15K

R368

NC/15K

R311

NC/0R

R311

NC/0R

R304

NC/10K

R304

NC/10K

C183 NC/1uFC183 NC/1uF

C224

NC/1000P

C224

NC/1000P

R298

NC/10K

R298

NC/10K

R3120RR312

0R

R3341KR334

1K

C215

NC/100nF

C215

NC/100nF

C188

0.1uF

C188

0.1uF

C211 NC/1uFC211 NC/1uF

R341

NC/0.22uF

R341

NC/0.22uF

C223

1000pF

C223

1000pF

R375

NC/22K

R375

NC/22K

T1

10-2.54MMT110-2.54MM

1234567

8

R347

NC/120K

R347

NC/120K

C186 NC/0.22uFC186 NC/0.22uF

Q28

3906

Q28

3906

R342

100K

R342

100K

C204

NC/2200uF/16V

C204

NC/2200uF/16V

C300

NC/10UF

C300

NC/10UF

R357

10R/0.22uF

R357

10R/0.22uF

L88

NC/FB/1206

L88

NC/FB/1206

R354

NC/0R

R354

NC/0R

Q26

2N3904

Q26

2N3904

312

R349

75R

R349

75R

L98

NC/FB_56_OHM_4A

L98

NC/FB_56_OHM_4A

L51NCL51

NC

R382

NC/1M

R382

NC/1M

R366

NC/1.5K

R366

NC/1.5K

C216

200pF

C216

200pF

C172

NC/1000P

C172

NC/1000P

R3481KR348

1K

L82 NC/FB/1206L82 NC/FB/1206

T2

10-2.54MMT210-2.54MM

1234567

8

C206 NC/1uFC206 NC/1uF

L53

NC/FB

L53

NC/FB

RX56

NC/V800AA

RX56

NC/V800AA

R387

NC/15K

R387

NC/15K

L89

NC/FB/1206

L89

NC/FB/1206

C181 NC/1uFC181 NC/1uF

C246

NC/220n

C246

NC/220n

C301

NC/0.1uF

C301

NC/0.1uF

R324 100RR324 100R

NC/0R

R385

NC/0R

R385

R333

NC/0R

R333

NC/0R

C226

NC/1000pF

C226

NC/1000pF

R293

NC/10K

R293

NC/10K

R363 150RR363 150R

C247

NC/10uF

C247

NC/10uF

+

C180

10uF/16V/220uF/16V

+

C180

10uF/16V/220uF/16V

R377

NC/1uF

R377

NC/1uF

R340 100RR340 100R

R361

NC/0.22uF

R361

NC/0.22uF

C192

NC/10uF

C192

NC/10uF

C219 NC/220pFC219 NC/220pF

C237

NC/10uF

C237

NC/10uF

C298

NC/0.1uF

C298

NC/0.1uF

L49

NC/10K

L49

NC/10K

R356

330R

R356

330R

R331 NC/0RR331 NC/0R

C184

NC/1000P

C184

NC/1000P

J24

NC/2Pin 2.0MM

J24

NC/2Pin 2.0MM

1

2

L97

NC/FB_56_OHM_4A

L97

NC/FB_56_OHM_4A

R381

2R2

R381

2R2

R329

NC/1K

R329

NC/1K

Q34

2N3904

Q34

2N3904

312

C245

NC/47P

C245

NC/47P

C233

NC/1000P

C233

NC/1000P

C240

NC/47P

C240

NC/47P

R359

NC/0R

R359

NC/0R

L83 NC/FB/1206L83 NC/FB/1206

L52

FB_120_OHM_500MA

L52

FB_120_OHM_500MA

J26

SPEAKER

J26

SPEAKER

123

4

C185

NC/1uF

C185

NC/1uF

Q36

2N3904

Q36

2N3904

312

C220 NC/1uFC220 NC/1uF

C235

NC/220n

C235

NC/220n

C218

1uF

C218

1uF

R316

NC/0R

R316

NC/0R

C194

NC/10uF

C194

NC/10uF

+

C167

100uF/16V+C167

100uF/16V

R384

NC/1.5K

R384

NC/1.5K

C229

NC/220nF

C229

NC/220nF

C249

NC/10uF

C249

NC/10uF

C173

0.1uF

C173

0.1uF

C166 NC/0.22uFC166 NC/0.22uF

R3782KR378

2K

R294

NC/10K

R294

NC/10K

R364

75R

R364

75R

R323 NC/0RR323 NC/0R

C168

0.001uF

C168

0.001uF

R353

100K

R353

100K

R414

NC/100K

R414

NC/100K

RX57

NC/V800AA

RX57

NC/V800AA

C234

NC/1000P

C234

NC/1000P

R332

NC/1K

R332

NC/1K

R326

NC/10K

R326

NC/10K

Q27

2N3904

Q27

2N3904

312

R3762KR376

2K

C177 NC/1uFC177 NC/1uF

R300 4.7KR300 4.7K

C201

NC/0.1uF

C201

NC/0.1uF

R372

NC/33K

R372

NC/33K

C297

NC/0.1uF

C297

NC/0.1uF

L91

NC/FB/1206

L91

NC/FB/1206

R360

NC/0R

R360

NC/0R

R389

NC/33K

R389

NC/33K

R318 NC/0RR318 NC/0R

L84

NC/FB/1206

L84

NC/FB/1206

R344 10RR344 10R

R302 10KR302 10K

C239

NC/1u

C239

NC/1u

C193

NC/220nF

C193

NC/220nF

R285 270KR285 270K

R330

NC/0R

R330

NC/0R

R380

2R2

R380

2R2

R350

NC/0R

R350

NC/0R

Q35

3906

Q35

3906

R416

NC/100K

R416

NC/100K

R283

NC/0R

R283

NC/0R

R297

NC/10K

R297

NC/10K

R310

NC/10K

R310

NC/10K

R358

470R

R358

470R

C175

NC/1000P

C175

NC/1000P

R3792KR379

2K

Page 31

Service Manual

Model No.:

- 30 -

5

4

3

2

1

D

C

B

POWERON/OFF#

POWERON/OFF

BKLONBKLON

BKLON

BKLON

BKLONBKLON

ADJ-PWM

POWERON/OFF#POWERON/OFF#POWERON/OFF#POWERON/OFF#

BL_ON

BKLON

BL-ADJUST

LCDON

BL-ADJUST

BL_ON

POWERON/OFF

BKLON

ADJ-PWM

LCDON

5Vstb

5Vstb

+12V

+5V

5Vstb

VCCLCDVCCLCDFN

+12V VCCLCDFN

5Vstb

+5V

+5V

3.3VA

+5V

+5V

5VSTB#

5VA

+5V

H:ON

L:OFF

H:ON

L:OFF

552mA,V315B3_L01

1.42A

1.14A

112mA

12.21V

5.12V

PANEL POWER

TO INVERTER

5.15V

12.23V

5.12V

5.14V

R407 NC/0RR407 NC/0R

C9100pF C9100pF

Q3

2N3904Q32N3904

32

1

+

C1

470uF/16V

+

C1

470uF/16V

C3

1nFC31nF

C12

0.1uF

C12

0.1uF

J2

MAINPOWER

J2

MAINPOWER

12345678910111213

CON2

CON4-2.0mm

CON2

CON4-2.0mm

123

4

R16 1KR16 1K

Q1 AO3407Q1 AO3407

1

32

+

C17

100uF/16V

+

C17

100uF/16V

Q4

NC/2N3904Q4NC/2N3904

32

1

C22

0.1uF

C22

0.1uF

R15

4.7K

R15

4.7K

R210RR21

0R

R17 4.7KR17 4.7K

C20

0.1uF

C20

0.1uF

L57 FB_56_OHM_4AL57 FB_56_OHM_4A

+

C5

470uF/16V

+

C5

470uF/16V

R5 NCR5 NC

C6

0.1uFC60.1uF

C11

0.01uF

C11

0.01uF

R7

10KR710K

R11

10K

R11

10K

R408 NC/0RR408 NC/0R

C23

0.1uF

C23

0.1uF

R22

10k

R22

10k

C7

1nFC71nF

J25

NC/INVERTER

J25

NC/INVERTER

112233445

5

R10

10K

R10

10K

R14

4.7K

R14

4.7K

C14

0.1u

C14

0.1u

J37

DCJACK

J37

DCJACK

1

2

3

L56

FB_56_OHM_4A

L56

FB_56_OHM_4A

+

C21

470uF/16V+C21

470uF/16V

R18

4.7K

R18

4.7K

C16

0.1uF

C16

0.1uF

Q2

2N3904Q22N3904

312

Q5

2N3904Q52N3904

32

1

C25

10n

C25

10n

R13

4.7K

R13

4.7K

C15

0.1u

C15

0.1u

C18

100pF

C18

100pF

R9

4.7KR94.7K

R19 0RR19 0R

C8

4.7nFC84.7nF

C24

10n

C24

10n

R409 0RR409 0R

C2

0.1uFC20.1uF

C4 0.1uFC4 0.1uF

C13

10uF

C13

10uF

C19

100pF

C19

100pF

R4100RR410

0R

R6 0RR6 0R

R20

10k

R20

10k

R8

100KR8100K

Q6

2N3904Q62N3904

32

1

R23NCR23

NC

R12

10K

R12

10K

C10NCC10

NC

CON1

DCJACK

CON1

DCJACK

1

2

3

Page 32

Service Manual

Model No.:

- 31 -

5

4

3

2

1

D D

C C

B B

A A

SPDIF_O

SPDIFOUT

VGA_ARI

VGA_ALI

HP_SR

SIDE_AVIN

SIDE_AULIN

SIDE_AURIN

SPDIFOUT

HP_SMUTE

HP_SL

VGA_ALI

VGA_ARI

SIDE_AV

CVBS_OUT

VOUT

VGA_AL

VGA_AR

AV1_AL

AV1_AR

RGB0_GIN-

RGB0_BIN-

RGB0_RIN-

SC1_FB

Pb

Y

Y

Pb

Pr

SCART_AV

VOUT

AV1-V

Pr

AV1-L

SC1_FSO

SC_AROUT

AV1-R

SC_ALOUT

RGB0_BIN+

RGB0_GIN+

RGB0_RIN+

RGB0-SOG

AV1-L

AV1-R

AV1-Lin

AV1-Rin

SC_ALOUT

SC_AROUT

AV1-V

SIDE_AVIN

SIDE_AULIN

SIDE_AURIN

SC_AROUT

AV1-R

SC_ALOUT

AV1-L

Pb

SC1_FSOYPr

SC1_FB

VOUT

AV1-V VOUT

SC_ALOUT

SC_AROUT

SPDIF_O

HP_SMUTE

HP_SL

HP_SR

SIDE_AV

CVBS_OUT

VGA_AL

VGA_AR

AV1_AL

AV1_AR

SC1_FB

SC1_FS

SC_ALOUT

SC_AROUT

SCART_AV

AV1-Lin

AV1-Rin

RGB0-SOG

RGB0_GIN+

RGB0_BIN+

RGB0_RIN+

RGB0_BIN-

RGB0_GIN-

RGB0_RIN-

5V-IF

+8V

AGND

AGND AGND

SPDIF Output

SIDE CVBS Input

C:1uF Location near MST.IC

R:10ohm,C:1uF 47nF Location near MST.IC

Keep spacing for L/R

Keep AGND trace with signal

Keep trace width(12mil+)

AV Output

Keep spacing for L/R

Keep AGND trace with signal

Keep trace width(12mil+)

(AV+SPDIF) Output

SC1_FSO

0-2v: TV Mode

5-8v: 16:9 AV

9.5-12v: 4:3 AV

SCART

Keep AGND trace with signal

Keep spacing for L/R

R:10ohm,C:1uF 47nF Location near MST.IC

R:10ohm,C:1uF 47nF Location near MST.IC

R:10ohm,C:1uF 47nF Location near MST.IC

R44 68RR44 68R

C56 47nC56 47n

J6

NC/HeadphotoJ6NC/Headphoto

1122334

4

R57 10KR57 10K

C31

1000pF

C31

1000pF

RX2

NC/V800AA

RX2

NC/V800AA

RX5

NC/V800AA

RX5

NC/V800AA

R31 10KR31 10K

R45 68RR45 68R

RX9

NC/V800AA

RX9

NC/V800AA

RX4

NC/V800AA

RX4

NC/V800AA

R38 33RR38 33R

R50

75R

R50

75R

C28

NC/0.1uF

C28

NC/0.1uF

L58

FB_11_OHM_500MA

L58

FB_11_OHM_500MA

C30

NC/0.1uF

C30

NC/0.1uF

C34

NC/33pF

C34

NC/33pF

R48

330R

R48

330R

C54

100pF

C54

100pF

R34

10K

R34

10K

J27

SCART_24

J27

SCART_24

11223344556677889

9

1010111112121313141415151616171718181919202021212323222224

24

25

25

26

26

R30

10K

R30

10K

C41 47nC41 47n

J5

PC Audio Input

J5

PC Audio Input

12345

6

7

8

Q9

2N3904Q92N3904

32

1

RX7

NC/V800AA

RX7

NC/V800AA

C50

100pF

C50

100pF

C51

1uF

C51

1uF

C57

100pF

C57

100pF

C37

100p

C37

100p

Q7

NC/3906Q7NC/3906

1

3 2

C27

100p

C27

100p

L59

NC/FB_11_OHM_500MA

L59

NC/FB_11_OHM_500MA

R47

22K

R47

22K

R26

75R

R26

75R

C55

100pF

C55

100pF

L60

FB_11_OHM_500MA

L60

FB_11_OHM_500MA

C33 1uFC33 1uF

RX1

NC/V800AA

RX1

NC/V800AA

R40 33RR40 33R

R29

NC/220R

R29

NC/220R

C42 47nC42 47n

C38 1nC38 1n

R59 10KR59 10K

R28

NC/1K

R28

NC/1K

R56

10K

R56

10K

C48 1uFC48 1uF

RX3

NC/V800AA

RX3

NC/V800AA

R25

75R

R25

75R

R53 10KR53 10K

R36

10K

R36

10K

J34

AV-JACK-3/AV

J34

AV-JACK-3/AV

112233445

5

7

7

6

6

8

8

R33

2.2K

R33

2.2K

R55 10KR55 10K

R61

47R

R61

47R

R39 33RR39 33R

R52

75R

R52

75R

R27

NC/150R

R27

NC/150R

J33

NC/Side_AV

J33

NC/Side_AV

1122334

4

R37 0RR37 0R

J7

AV-JACK-3/AVJ7AV-JACK-3/AV

112233445

5

7

7

6

6

8

8

R35 10KR35 10K

R62

75R

R62

75R

R60

10K

R60

10K

R24 33RR24 33R

R42

75R

R42

75R

RX6

NC/V800AA

RX6

NC/V800AA

C32

1000pF

C32

1000pF

C49

100pF

C49

100pF

C36 1uFC36 1uF

C43 47nC43 47n

C47

100pF

C47

100pF

C39 47nC39 47n

C29

NC/1uF

C29

NC/1uF

R54 10KR54 10K

C52 1uFC52 1uF

J4

NC/OUTPUTJ4NC/OUTPUT

112

2

J32

NC/AV-JACK-3/AVOUT

J32

NC/AV-JACK-3/AVOUT

112233445

5

7

7

6

6

8

8

R49

75R

R49

75R

Q8

3906Q83906

1

3 2

R43

75R

R43

75R

C44 47nC44 47n

R58 10KR58 10K

C35

100p

C35

100p

R46 68RR46 68R

P1

NC/SCARTP1NC/SCART

24681012141618

20

13579111315171921

24

25

RX8

NC/V800AA

RX8

NC/V800AA

C40 47nC40 47n

R51

10K

R51

10K

C45

4.7uF/1206

C45

4.7uF/1206

C53 1uFC53 1uF

R32

NC/150R

R32

NC/150R

C26 47nC26 47n

R41

75R

R41

75R

Page 33

Service Manual

Model No.:

- 32 -

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

PBINO

PBIN

PBIN

PBIN

PBIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YIN

YINO

PRINO

DVD_AVIN

IRIN

VSYNC

HD1RIN

HD1LIN

DVD_AR

DVD_AL

DVD-ON/OFF

PBIN

YIN

DVD_AVIN

HD1RIN

PRIN

PRIN

BAIN+

AV1

GAIN+

RAIN+

DVD_AV

GRED

GRED

GRED

GREDGRED

GRED

GGRN

GGRN

GGRN

GGRNGGRN

GGRN

REAR_AV

GBLUGBLU

GBLU

GBLU

GBLUGBLU

AV1

HD1LIN

ISP-RXD GSCL

GSDA ISP-TXD

GSDA

GSDA

GSDA

GSDAGSDA

GSDA

GSDA

GSDAGSDA

GSDA

GSDAGSDA

GSDA

GSDA

GSDAGSDA

GSDA

GSDA

IHS

GSCL

GSCL

HSYNC

HSYNC

HSYNC

HSYNCHSYNC

HSYNC

HSYNC

HSYNCHSYNC

HSYNC

GSDA

GSDA

GSDA

GSDAGSDA

GSDA

GSDA

GSDAGSDA

GSDA

GSDAGSDA

SOG

IVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVSIVS

SOY

YINO+

PRINO

PBINO+

PRINO+

PBINO

YINO

DVD_AL

ASEL0

AV1_AR

AV1_AL

DVD_AR

MUX_AR

MUX_AL

YIN

PBIN

PRIN

YINO+

PBINO+

PRINO+

DVD_AV

DVD-ON/OFF

IRIN

HD1L

HD1R

REAR_AV

ISP-RXD

VSYNC

ISP-TXD

HSYNC

SOG

GAIN+

RAIN+

BAIN+

SOY

ASEL0

MUX_AR

MUX_AL

AV1_AR

AV1_AL

AGND

+5V

VCC1

VCC1

VCC1

+8V

R & C Location near MST.IC

AV1/YPbPr/DVD INPUT

VGA INPUT

SHEN ZHEN MTC MULTIMEDIA CO.,LTD

DESIGN:YANXUEWU

MODEL: MSDV3205-L2 TITLE:HD&VGA

CHECKED: PART NO.:

DWG NO.:

APPRD: SHEET: 4 OF 12 VER:1.0

R:10ohm C:47n Location near MST.IC

C71

10uF

C71

10uFJ9

AV-JACK-3/YPbPr

J9

AV-JACK-3/YPbPr

112233445

5

7

7

6

6

8

8

R92 100KR92 100K

R83 10RR83 10R

J11

CON7

J11

CON7

1122334455667

7

R101

10K

R101

10K

C73 47nC73 47n

R103

4.7K

R103

4.7K

R76

47R

R76

47R

C821uC82

1u

C75 1uFC75 1uF

J12

PC_DB15HD_MIDDLE

J12

PC_DB15HD_MIDDLE

1

2

3

4

5

6

7

8

9

10

11

121314

15

1617

C72

0.1uF

C72

0.1uF

C76

100pF

C76

100pF

R100

10K

R100

10K

C74 1uFC74 1uF

C87

47nF

C87

47nF

R93 100KR93 100K

RX15

NC/V800AA

RX15

NC/V800AA

L66

FB_11_OHM_500MA

L66

FB_11_OHM_500MA

C80

10uF

C80

10uF

RX19NC/V800AARX19NC/V800AA

L64

FB_11_OHM_500MA

L64

FB_11_OHM_500MA

R65

10K

R65

10K

R98 33RR98 33R

R66 33RR66 33R

J8

NC/AudioJ8NC/Audio

112

2

993

3

8

8

4

4

5

5

7

7

6

6

RX18

NC/V800AA

RX18

NC/V800AA

R78 NCR78 NC

C65 1nFC65 1nF

R67

10K

R67

10K

C63 47nFC63 47nF

C79

0.1uF

C79

0.1uF

R89 100KR89 100K

R77 NCR77 NC

R107 0RR107 0R

R71

75R

R71

75R

L69

FB_11_OHM_500MA

L69

FB_11_OHM_500MA

R82 100RR82 100R

R102 0RR102 0R

R70 0RR70 0R

R68 33RR68 33R

J10

CON4

J10

CON4

1122334

4

L70

FB_11_OHM_500MA

L70

FB_11_OHM_500MA

Q10

2N3904

Q10

2N3904

312

L61

FB_11_OHM_500MA

L61

FB_11_OHM_500MA

R94 100RR94 100R

C69 47nC69 47n

C64 47nFC64 47nF

R72

75R

R72

75R

R97 33RR97 33R

RX14

NC/V800AA

RX14

NC/V800AA

L71

FB_11_OHM_500MA

L71

FB_11_OHM_500MA

C58

1uF

C58

1uF

R85 100KR85 100K

C88

1nF

C88

1nF

L67

FB_11_OHM_500MA

L67

FB_11_OHM_500MA

C6833pF C6833pF

R69 33RR69 33R

R73

75R

R73

75R

C62

100pF

C62

100pF

R104

75R

R104

75R

R86 100KR86 100K

R75

75R

R75

75R

L62

FB_11_OHM_500MA

L62

FB_11_OHM_500MA

J35

AV-JACK-3/YPbPr

J35

AV-JACK-3/YPbPr

112233445

5

7

7

6

6

8

8

C851uC85

1u

R64

10K

R64

10K

R106

75R

R106

75R

C67

33pF

C67

33pF

R74 47RR74 47R

R81

75R

R81

75R

R99

4.7K

R99

4.7K

R95 100RR95 100R

L63

FB_11_OHM_500MA

L63

FB_11_OHM_500MA

C70

100pF

C70

100pF

R105

75R

R105

75R

R87 100KR87 100K

L65

FB_56_OHM_4A

L65

FB_56_OHM_4A

R63

10K

R63

10K

C86

47nF

C86

47nF

C60 47nFC60 47nF

RX10

NC/V800AA

RX10

NC/V800AA

R79 100RR79 100R

R88 100KR88 100K

R96 33RR96 33R

C61

100pf

C61

100pf

C66

33pF

C66

33pF

RX17

NC/V800AA

RX17

NC/V800AA

RX11

NC/V800AA

RX11

NC/V800AA

R80 100RR80 100R

C59 1uFC59 1uF

U1

4052SWU14052SW

15246109

7

121415

11

13

3

168

RX13

NC/V800AA

RX13

NC/V800AA

C83

47nF

C83

47nF

RX12NC/V800AA RX12NC/V800AA

RX20

NC/V800AA

RX20

NC/V800AA

R91 100KR91 100K

R108 0RR108 0R

RX16

NC/V800AA

RX16

NC/V800AA

Page 34

- 33 -

5

4

3

2

1

D D

C C

B B

RX1B1N

RX1B1P

RX1B0N

RX1B0P

RX1B2N

RX1B2P

RX1BCLKP

RX1BCLKN

HDMI_CEC

DDC1BSDA

DDC1BSCL

RX1B1P

RX1B1N

RX1B2N

RX1B0P

RX1B0N

RX1BCLKP

RX1BCLKN

HDMI1/5V

RX1B2P

HOTPLUG2

HDMI_E_CEC

RX2B1N

RX2B1P

RX2B0N

RX2B0P

RX2B2N

RX2B2P

RX2BCLKP

RX2BCLKN

RX3B1N

RX3B1P

RX3B0N

RX3B0P

RX3B2N

RX3B2P

RX3BCLKP

RX3BCLKN

HDMI2/5V

HOTPLUG_2

DDC3BSCL

DDC3BSDA

RX3B2P

RX3B2N

RX3B1P

RX3B1N

RX3B0P

RX3B0N

RX3BCLKP

RX3BCLKN

HOTPLUG_3

HDMI3/5V

DDC2BSDA

DDC2BSCL

RX2B1P

RX2B1N

RX2B2N

RX2B0P

RX2B0N

RX2BCLKP

RX2BCLKN

RX2B2P

HOTPLUG_3

HDMI3/5V

HDMI_CEC

RX2B2P

DDC2BSCL

DDC2BSDA

RX2B2N

RX2B1P

RX2B1N

RX2B0P

RX2B0N

RX2BCLKP

RX2BCLKN

HOTPLUG_2

HDMI2/5V

HDMI_CEC

RX3B2P

DDC3BSCL

DDC3BSDA

RX3B2N

RX3B1P

RX3B1N

RX3B0P