AWA BBHTN180, MSD306 Schematic

SERVICE MANUAL

LCD TV

Model No. BBHTN180

MSD306

Chassis

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

Service Manual

Model No.:

Chapter 1: General Information

1-1. Table of Contents

1. General Information...........................................................................

1-1. Table of Contents

1-2. General Guidelines

1-3. Important Notice

1-4. How to Read this Service Manual

2. Specifications....................................................................................

3. Location of Controls and Components...........................................

3-1. Board Location

3-2. Main Board

3-3. Power Board

3-4. LCD Panel

4. Disassemble and Assemble..........................................................

4-1 Remove the Pedestal

4-2 Remove the Terminal Bracket

4-3 Remove the Power Module 16

4-4 Remove the Main Board 16

1

1

3

3

6

6

88

8

8

11

12

15

15

16

4-5 Remove the Speaker 17

4-6 Remove the Remote Control Board

5. Installation Instructions..…....………………...........………….........

5-1 External Equipment Connections

5-2 HDMI Connections

6. Operation Instructions....

6-1 Front Panel Controls

6-2 Back Panel Controls

6-3 Universal Remote Control

…....………………...........………….........

7. Electrical Parts…....………………...........………….........................

7-1. Block Diagram

7-2. Circuit Diagram

7-3. Wiring Connection Diagram

8. Measurements and Adjustments........…………............................

17

18

18

21

24

24

24

25

26

26

27

35

39

8-1. How to enter into the factory model

8-2. How to update software

- 01 -

42

43

Service Manual

Model No.:

9. Trouble-shooting…………..............................................................

9-1. Simple Check 44

9-2. Main Board Failure Check

9-3. Panel Failure

44

45

52

- 02 -

Service Manual

Model No.:

1-2. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive

1-3. Important Notice

1-3-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to

open the units and disassemble the units. For example, we need to describe properly

how to avoid the possibility to get electrical shock from the live power supply or charged

electrical parts (even the power is off).

This symbol indicates that high voltage is present inside.It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance.

1-3-2. Be careful to the electrical shock

To prevent damage which might result in electric shock or re, do not expose this TV set

to rain or excessive moisture. This TV must not be exposed to dripping or splashing water,

and objects lled with liquid, such as vases, must not be placed on top of or above the TV.

1-3-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. The following

techniques should be used to help reduce the incidence of component damage caused by

electros static discharge (ESD).

1-3-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repairing of this product.

1-3-5. Use the genewing parts (specied parts)

Special parts which have purposes of fire retardant (resistors), high-quality sound

(capacitors), low noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts

shown in the parts list.

Safety Component

● Components identied by mark have special characteristics important for safety.

- 03 -

Service Manual

Model No.:

1-3-6 Safety Check after Repairment

Conrm that the screws, parts and wiring which were removed in order to service are put

in the original positions, or whether there are the positions which are deteriorated around

the serviced places serviced or not. Check the insulation between the antenna terminal or

external metal and the AC cord plug blades. And be sure the safety of that.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before;

a. Removing or reinstalling any component, circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic

capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage measuring device (DVM, FETVOM, etc) equipped with a suitable high voltage

probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its assemblies.

4. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable non-abrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength).

CAUTION: This is a ammable mixture.

Unless specied otherwise in this service manual, lubrication of contacts is not required.

Capacitors may result in an explosion hazard.

5. Do not defeat any plug/socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

7. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last. Capacitors may result in an explosion

hazard.

8. Use with this receiver only the test xtures specied in this service manual.

CAUTION: Do not connect the test xture ground strap to any heat sink in this receiver.

9. Remove the antenna terminal on TV and turn on the TV.

10. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than Mohm by using the 500V insulation resistance meter.

11. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester. External exposure

metal: Antenna terminal Headphone jack

- 04 -

Service Manual

Model No.:

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect transistors

and semiconductor "chip" components. The following techniques should be used to help

reduce the ncidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist

strap device, which should be removed to prevent potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly

on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static type solder removal device. Some solder removal devices not

classied as "anti-static" can generate electrical charges sufcient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufcient

to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately

before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise harmless motion such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted oor can generate static electricity sufcient to damage

an ES device.)

1-3-7. Ordering Spare Parts

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number, Serial number and Software Version

The model number and Serial number can be found on the back of each product and the

Software Version can be found at the Spare Parts List.

2. Spare Part No. and Description

You can nd them in the Spare Parts List

- 05 -

1-3-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of

products, which may differ from your products in some way.

1-4. How to Read this Service Manual

Using Icons:

Icons are used to attract the attention of the reader to specic information. The meaning of

each icon is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable

to the reader, such as tips and tricks.

Service Manual

Model No.:

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of) a

procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where he/

she will nd additional information on a specic topic.

- 06 -

Service Manual

Model No.:

2. Specifications

Model

Screen Size 18.5 inch

Aspect Ratio 16:9

Resolution 1366x768

Response Time (ms)

Angel of View

Color Display 170 (H)/160 (V)

No. of Preset Channels 400

OSD Language English

Color System PAL/SECAM

Audio System DK, BG, I, M, L, L'

Audio Output Power

(Built-in) (W)

Audio Output Power

(outer) (W)

BBHTN180

5 (GRAY TO

GRAY)

0

176

0

3W×2

No

0

Total Power Input (W) 30W

Voltage Range (V)

Power Frequency (Hz)

Net Weight (KG)

Gross Weight (KG)

Net Dimension (MM)

Packaged Dimension

(MM)

AC100V-240V

50~60Hz

3.6

3.8

460*140*346

541*171*408

- 07 -

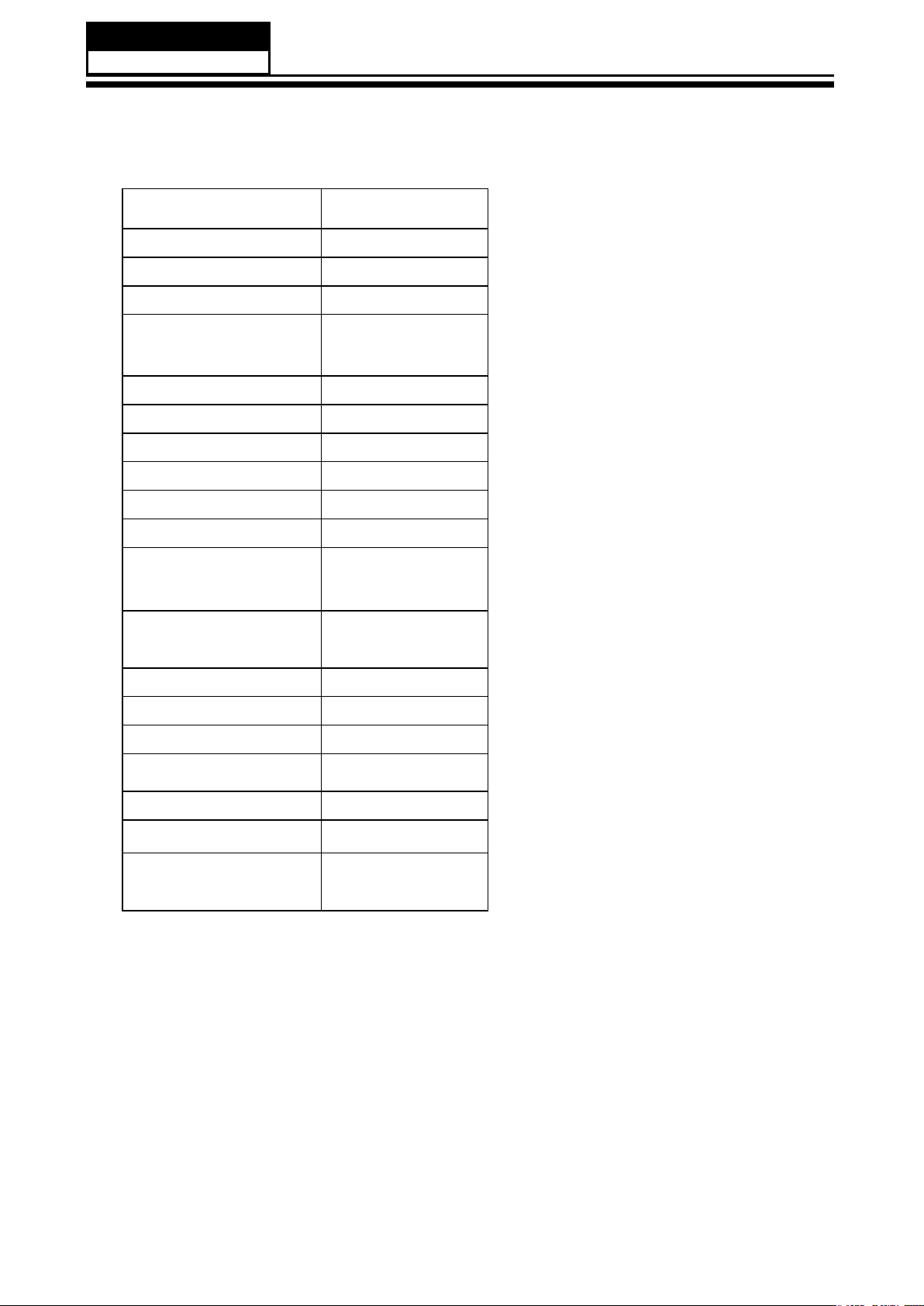

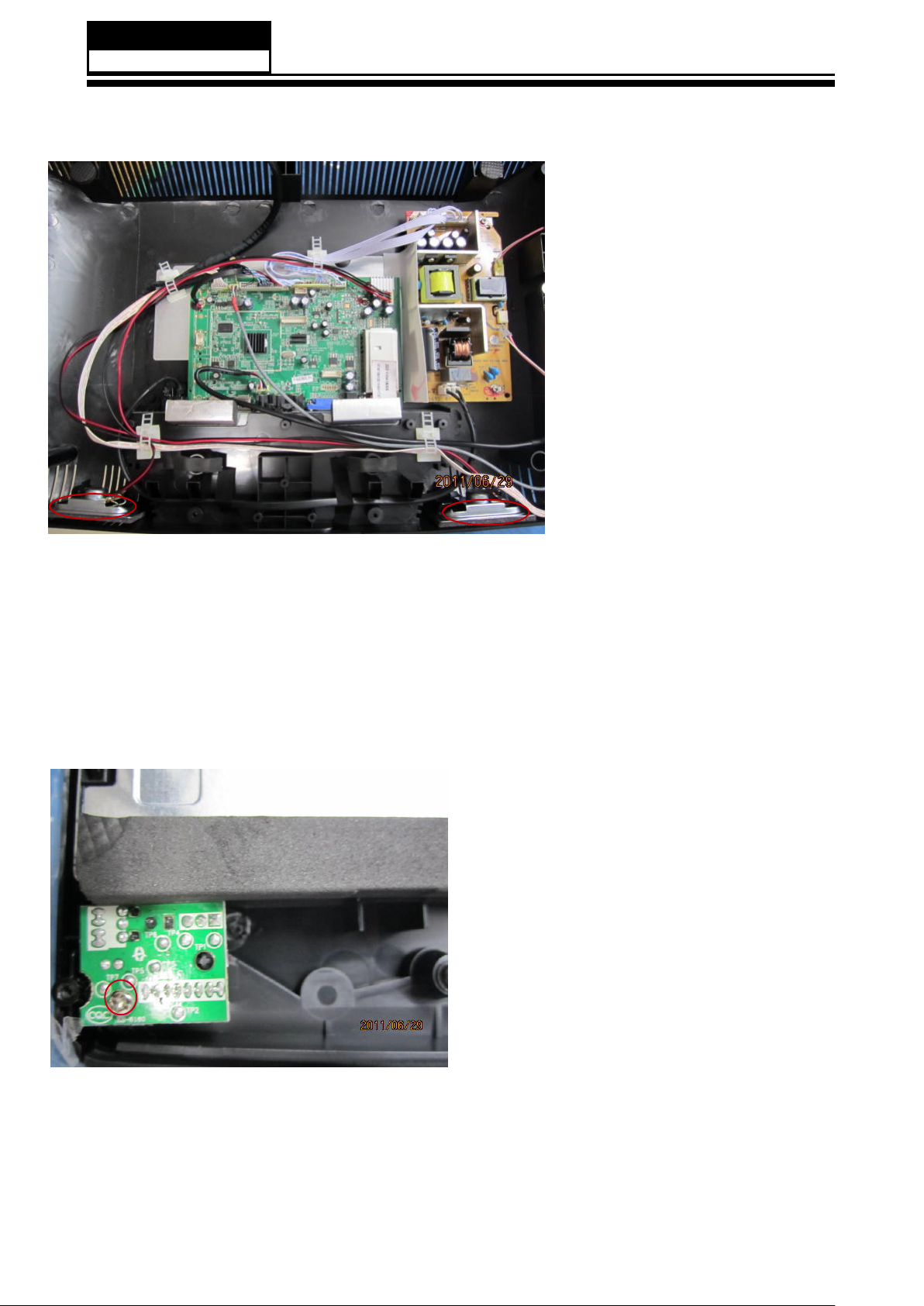

3. Location of Controls and Components

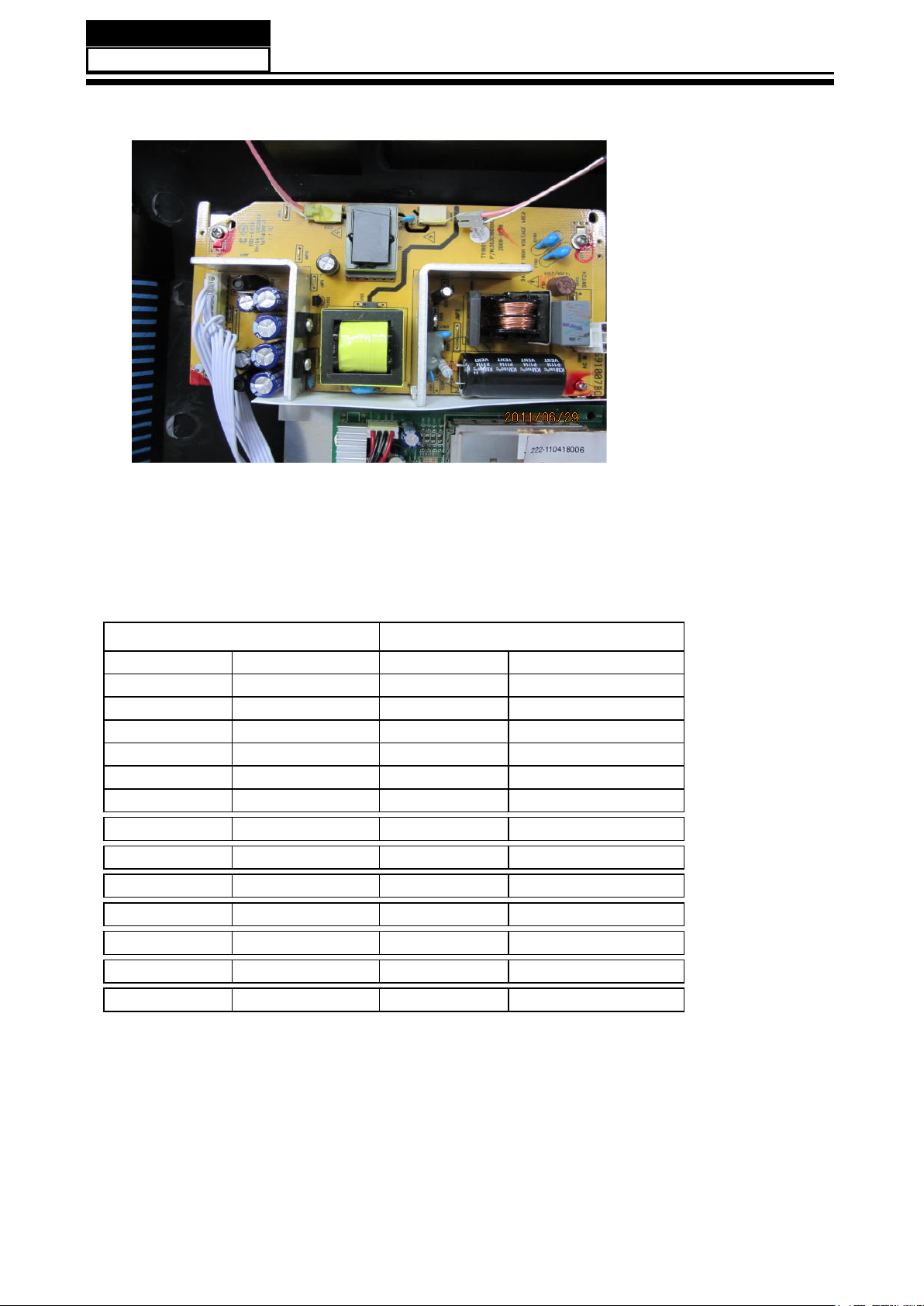

3-1 Board Location

Service Manual

Model No.:

B Board

A Board

No. Description

A Board Main Board

B Board

Power Board

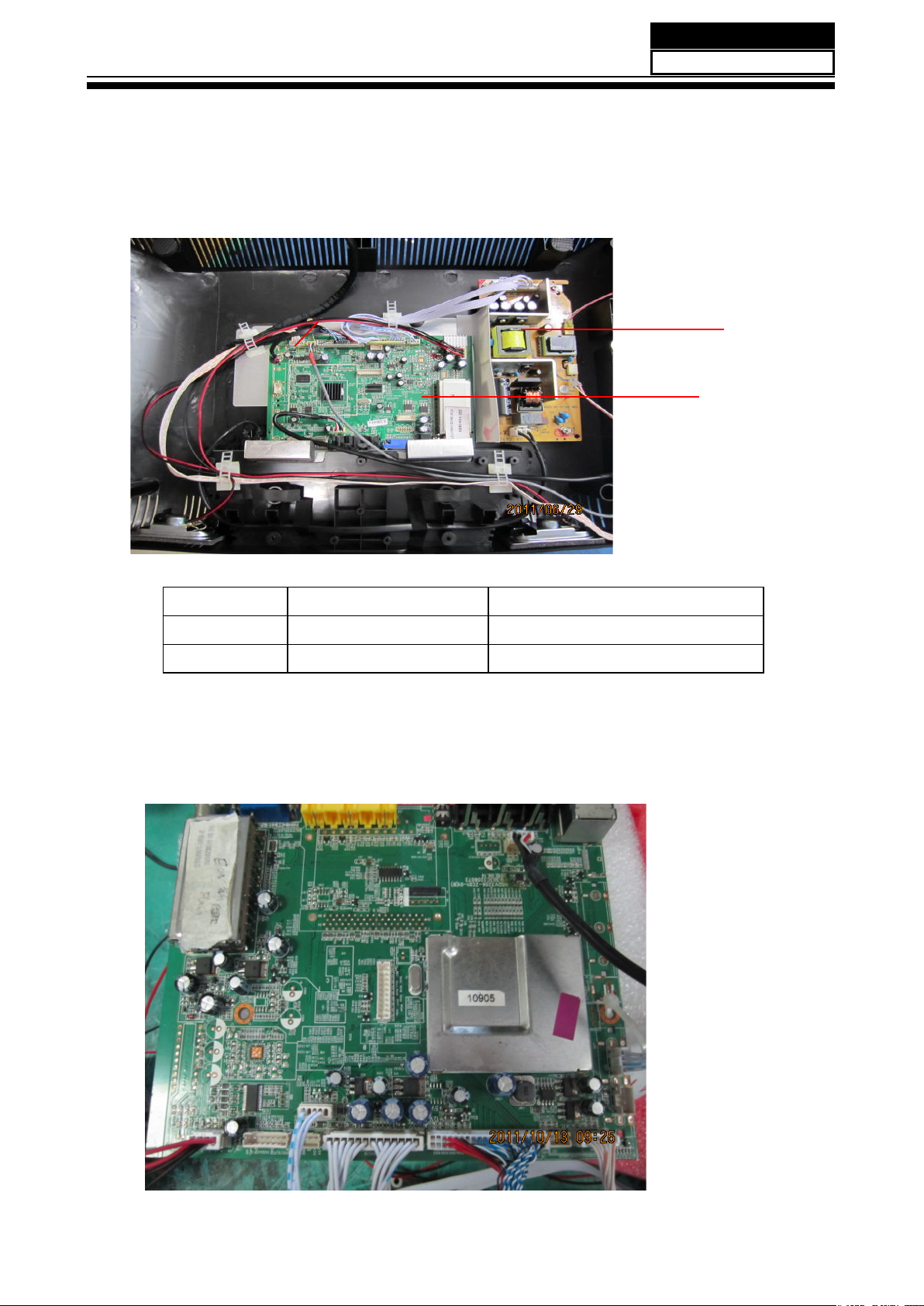

3-2 Main Board

515C3206M60

514C1901M03

- 08 -

Service Manual

Model No.:

3-2-1 Function Description:

Main Board

Process signal which incept from exterior equipment then translate into signal that panel

can display.

3-2-2 Connector denition

Main board connector

Power connectors (J25, J2)

J25

J2

Pin number Signal name Pin number Signal name

1 +5V 1 GND

2 2 GND

3 3 +5V

4 4 +5V

BL-ON

BL-ADJUST

+5V

5 GND 5 POWER ON/OFF

6 +5VSTB

7 +5V

8 +5V

9 GND

10 GND

11 GND

12 +12V

13 +12V

Notes:

J25-Pin 2: Backlight on/off:

The system can turn on or turn off the backlight of TFT LCD Panel through the power

supply unit path.

J2-Pin 5: System power on / standby

System board will use this pin to control system power.

J25 T-Pin 3: Control the luminance of backlight

The system can generate the PWN signal to control the strength of TFT LCD Panel’s

backlight through this connector

- 09 -

Service Manual

Model No.:

remote connector (J21)

Pin number Signal name Description

1 LED_R LAMP RED

2

3

4 IR REMOTE CONTROL

5 GND GND

6 5V POWER FOR REMOTE

Keypad and connector (J22)

Pin number Signal name Description

1 KEY1

2 KEY0

3 GND

LED_G LAMP GREEN

Speaker connectorJ26

Pin number

1

2 RSPK3

4

Signal name Description

RSPK+ RSPK+

LSPK- LSPKLSPK+ LSPK+

RSPK-

- 10 -

Service Manual

Model No.:

3-3. Power Board

3-3-1 Function Description:

Supply power for Main board, Panel.

3-3-2Connectorde

fi

nition

CON5

Pin number Signal name

1

2

3

4

5

6

7

8

9

10

POEWR ON/OFF

12V

12V

GND

GND

5V

5V STB

5V

GND

GND

11

12

13

ON-PBACK

BK ON/OFF

NC

- 11 -

3-4. LCD Panel

Service Manual

Model No.:

MTC185TVM-C07H(CPT:CLAA185WA04 V4)

MTC185TVM-C07H(CPT:CLAA185WA04 V4)

MTC185TVM-C07H(CPT:CLAA185WA04 V4)

- 12 -

Service Manual

Model No.:

3-4-1 Function Description: Display the signal.

3-4-2 Connector de

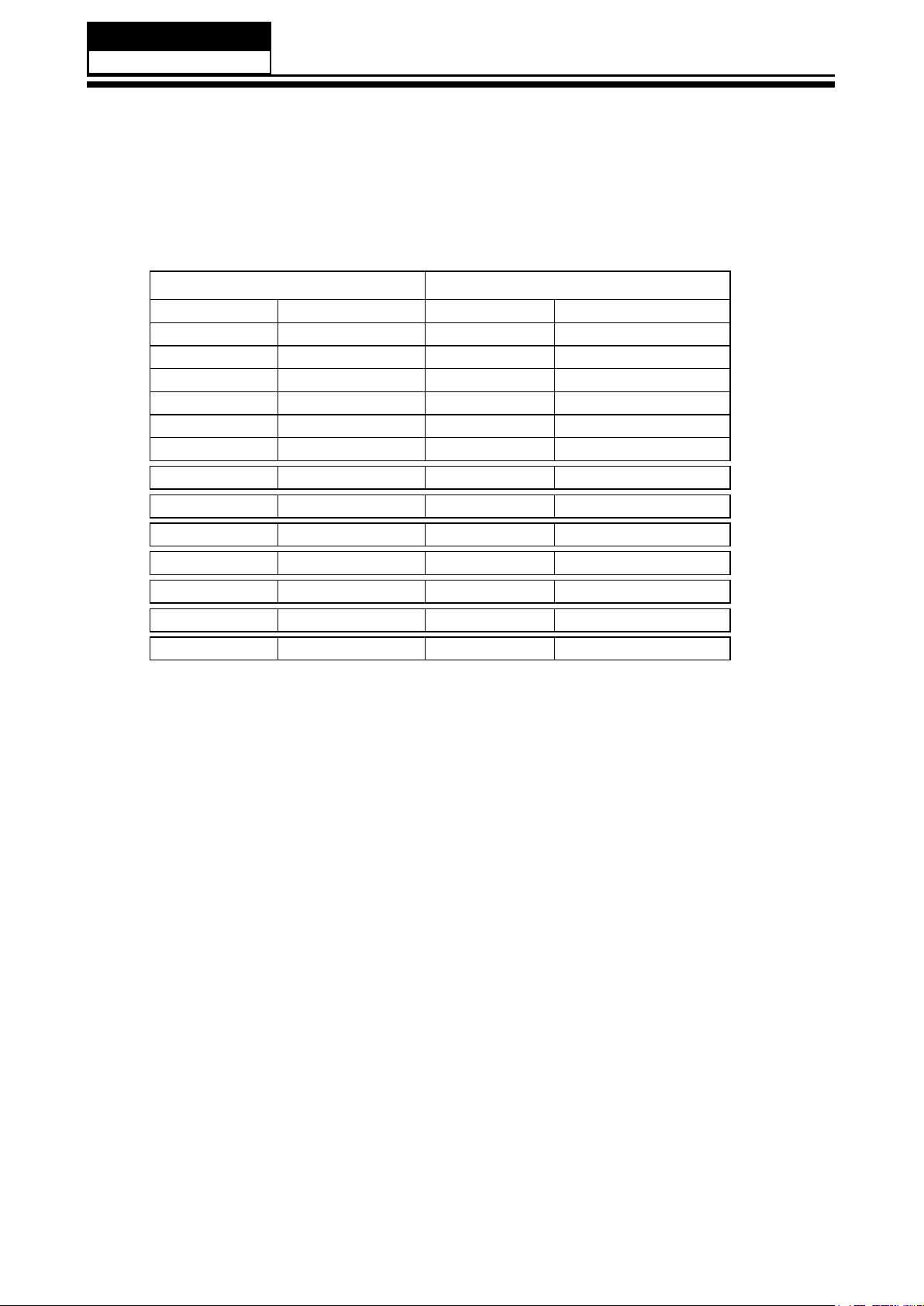

CN1(Data Signal and Power Supply)

PIN NO. SYMOBL FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

NC NC

NC NC

NC NC

GND Power ground

RXIN0- Negative LVDS differential data input(0)

RXIN0+ Positive LVDS differential data input(0)

GND Power ground

RXIN1- Negative LVDS differential data input(1)

RXIN1+ Positive LVDS differential data input(1)

GND Power ground

RXIN2- Negative LVDS differential data input(2)

RXIN2+ Positive LVDS differential data input(2)

GND Power ground

RXCLKIN- Negative LVDS differential clock input(clock)

RXCLKIN+ Positive LVDS differential clock input(clock)

GND Power ground

RXIN3- Negative LVDS differential data input(3)

RXIN3+ Positive LVDS differential data input(3)

GND Power ground

NC NC

NC NC

NC NC

GND Power ground

GND Power ground

GND Power ground

VCC Power supply input voltage(5.0 V)

VCC Power supply input voltage(5.0 V)

VCC Power supply input voltage(5.0 V)

VCC Power supply input voltage(5.0 V)

VCC Power supply input voltage(5.0 V)

fi

nition.

1) Keep the NC Pin and don’t connect it to GND or other signals.

2) GND Pin must connect to the ground, don’t let it be a vacant pin.

- 13 -

Service Manual

Model No.:

4. Disassemble and assemble

4-1 Remove the Pedestal

① Lay down the unit so that rear cover

faces upward

① Remove the three screw from the

rear cover indicated with ○

Then remove the pedestal

①

4-2Remove the Back Cover

① Remove the these screw indicated on

gure above by ○

Then remove the back cover from the

①

unit.

- 15 -

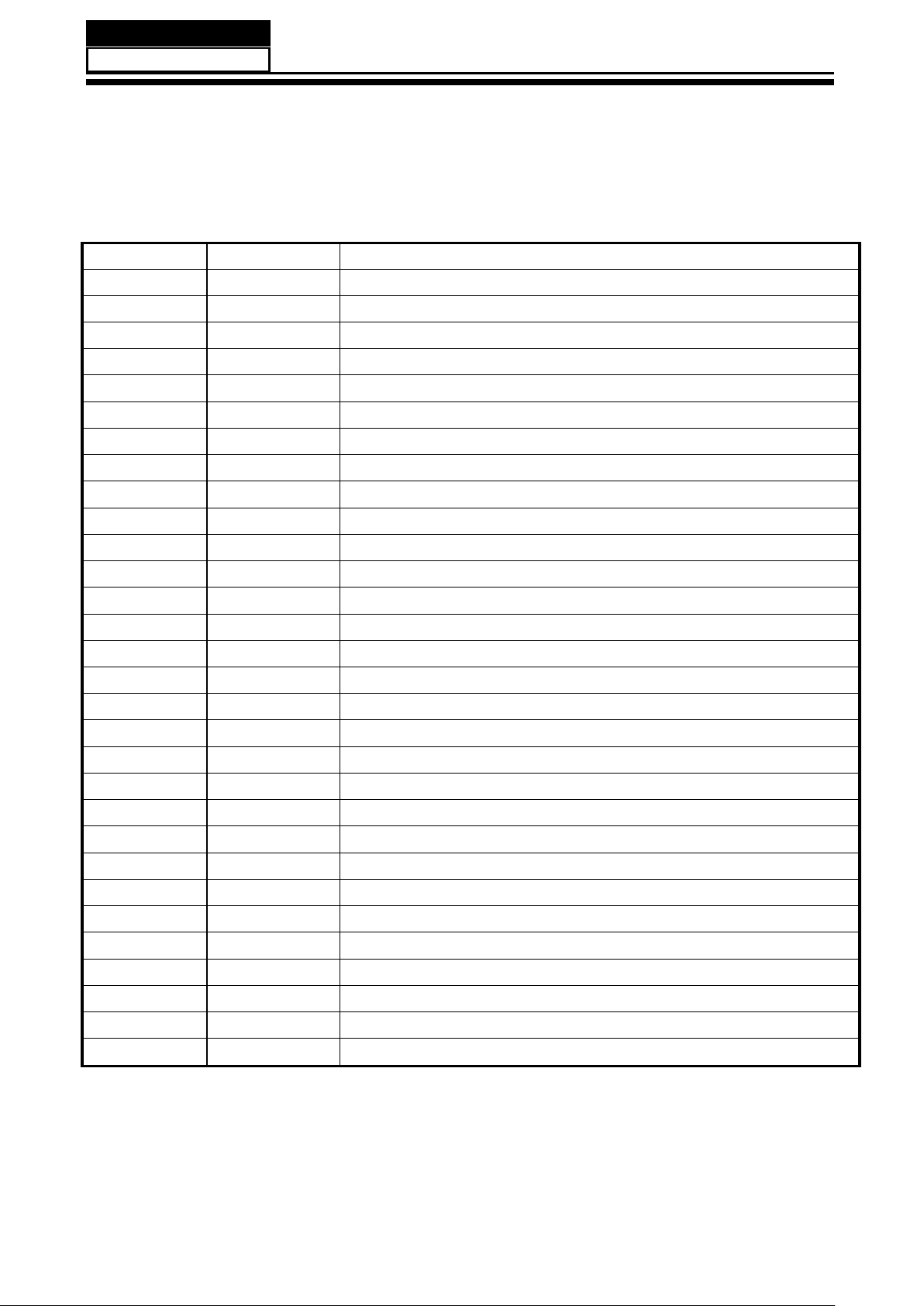

4-3 Remove the power module

Service Manual

Model No.:

① Remove the four screw indicated on the

gure above by ○

① Then remove the power module

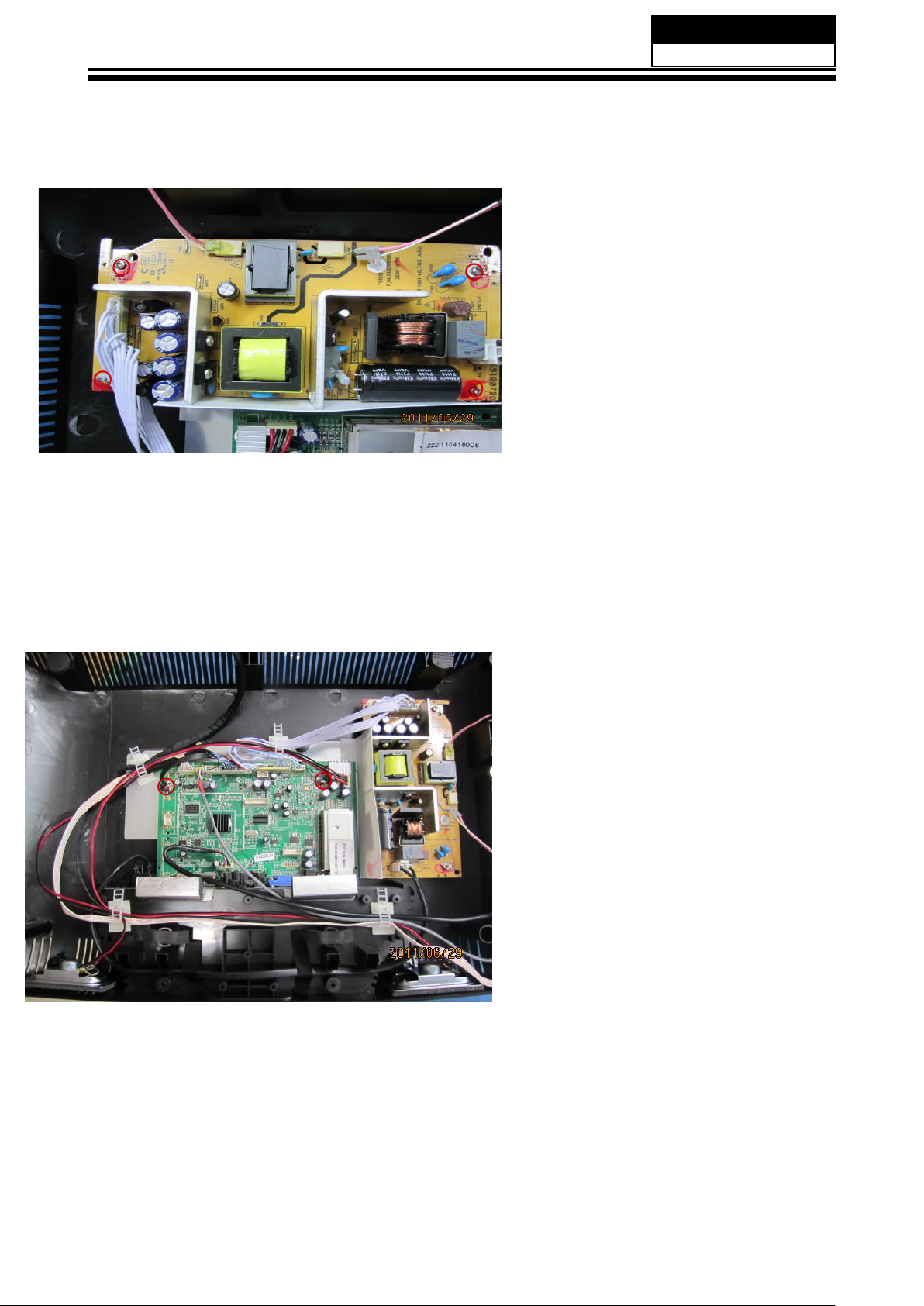

4-4 Remove the Main board

① Remove the two screw indicated

on the gure above by ○

①

J2

①

① Remove the Main board

Disconnected the coupler J20

①

J21

①

J22

①

J25

①

J26

①

J17

①

- 16 -

Service Manual

Model No.:

4-7 Remove the speaker

Take out the speaker

4-8 Remove the remote control

Remove the screw, take out the remote control

board

- 17 -

5. Installation Instructions

5-1 External Equipment Connections

Accessories

Service Manual

Model No.:

Remote Control

Antenna Connection

Connect one end of a coaxial cable (not included) to the ANT IN jack on the back of

your TV/DVD combo, then connect the other end of the cable into the antenna or cable

TV wall outlet.

User GUIDE

Battery

To improve picture quality from an antenna in a poor signal area, install a signal

amplier.

If you need to split the antenna signal to connect two TVs, install a two-way splitter.

- 18 -

Loading...

Loading...