Page 1

- 1 -

IST0638V1/0

MICROWAVE BEAMS

FOR INDOOR AND OUTDOOR USE

BM 60 M

BM 120 M

BM 200 M

BM60M WS

AVS ELECTRONICS

Curtarolo (Padova) Italy

www.avselectronics.com

A COMPANY WITH

CERTIFIED SYSTEM

OF QUALITY

ISO9001

Page 2

- 2 -

The product is in conformity to the CE Directive for electromagnetic compatibility

Supplying must come from a very low security-tension circuit, featuring a limited-power

source protected by fuse.

THE INSTALLATION MUST BE EXECUTED BY QUALIFIED PERSONNEL

Index

Chapter 1: General Description .................................................................................pag. 3

Compatibility with existing models ....................................................................pag. 3

Filter of selection and compensation .................................................................pag. 3

Detection Area ......................................................................................................pag. 3

Chapter 2: Transmitter................................................................................................pag. 3

Chapter 3: receiver of hard-wired systems BM60M, BM120M, BM200M................pag. 4

Chapter 4: Receiver of the wireless system BM60M WS.........................................pag. 5

Chapter 5: Description of working ............................................................................pag. 6

Working.................................................................................................................pag. 6

Chapter 6 : Positioning of the beams........................................................................pag. 7

Chapter 7: Advice for installation ............................................................................pag. 13

Chapter 8: Installation of the transmitter in the hard-wired system.....................pag. 14

Chapter 9: Installation of receiver in the hard-wired system ................................pag. 14

General Warning for the hard-wired system....................................................pag. 14

Chapter 10: Installation of transmitter in the wireless system .............................pag. 14

Chapter 11: Installation of the receiver in the wireless system ............................pag. 14

General Warning for wireless system ..............................................................pag. 14

Chapter 12: Adjustments..........................................................................................pag. 15

Chapter 13: Measurements of the signal by oscilloscope ....................................pag. 16

Chapter 14: Sensitivity Adjustment .........................................................................pag. 17

Chapter 15: Kit TERM (optional) Resistence fo inside heating.............................pag. 18

Chapter 16: Kit AMP (optional) Anti-removal..........................................................pag. 18

Chapter 17: Disqualification (Important Warning) .................................................pag. 19

Chapter 18: Additional supply unit for BM60M WS................................................pag. 19

Chapter 19: BR100 Kit and LCD W (optional) signal remoting-device .................pag. 20

Chapter 20: Optional Brackets.................................................................................pag. 21

Information in conformity to the Directive 1999/5/CEE for model BM_M.............pag. 22

Information in conformity to the Directive 1999/5/CEE for model BM60M WS....pag. 23

Technical Characteristics.........................................................................................pag. 24

Page 3

- 3 -

TAMPER

B A TT

S1

PB1

SW1

LED

LED

OFF

MICROWAVE BEAM

Models BM60M, BM120M, BM200M and BM60M WS are microwave intrusion detection systems,

whose principle of working is the “field-interruption”.Thanks to the microprocessor managing the

signals, they are the ideal instruments for protecting big surfaces, both indoor and outdoor, thus

granting a high security standard.

Chapter 1: General Description

The system is made by a Transmitter and a Receiver which must be installed as a couple,

choosing the same working frequency among the 5 available, in both units (tx and rx) ,

through SW1 (4 dip-switch module) on board.

Compatibility with existing models

In case of replacement, choose the same frequency on the beam to be replaced (F1 by F1, F3 by

F3 etc.). In order to identify the corresponding frequency, use the chart “BEAMS CHANNELS”

Filter of selection and compensation

Any receiver is equipped with a selection filter choosing only the frequency of its channel and

rejecting the others, thus not making possible the elusion of the beam in case of use of a false

transmitter. Special self-adjusting and signal-elaboration circuits have been used in the receiver

for automatic compensation of temperature variations.

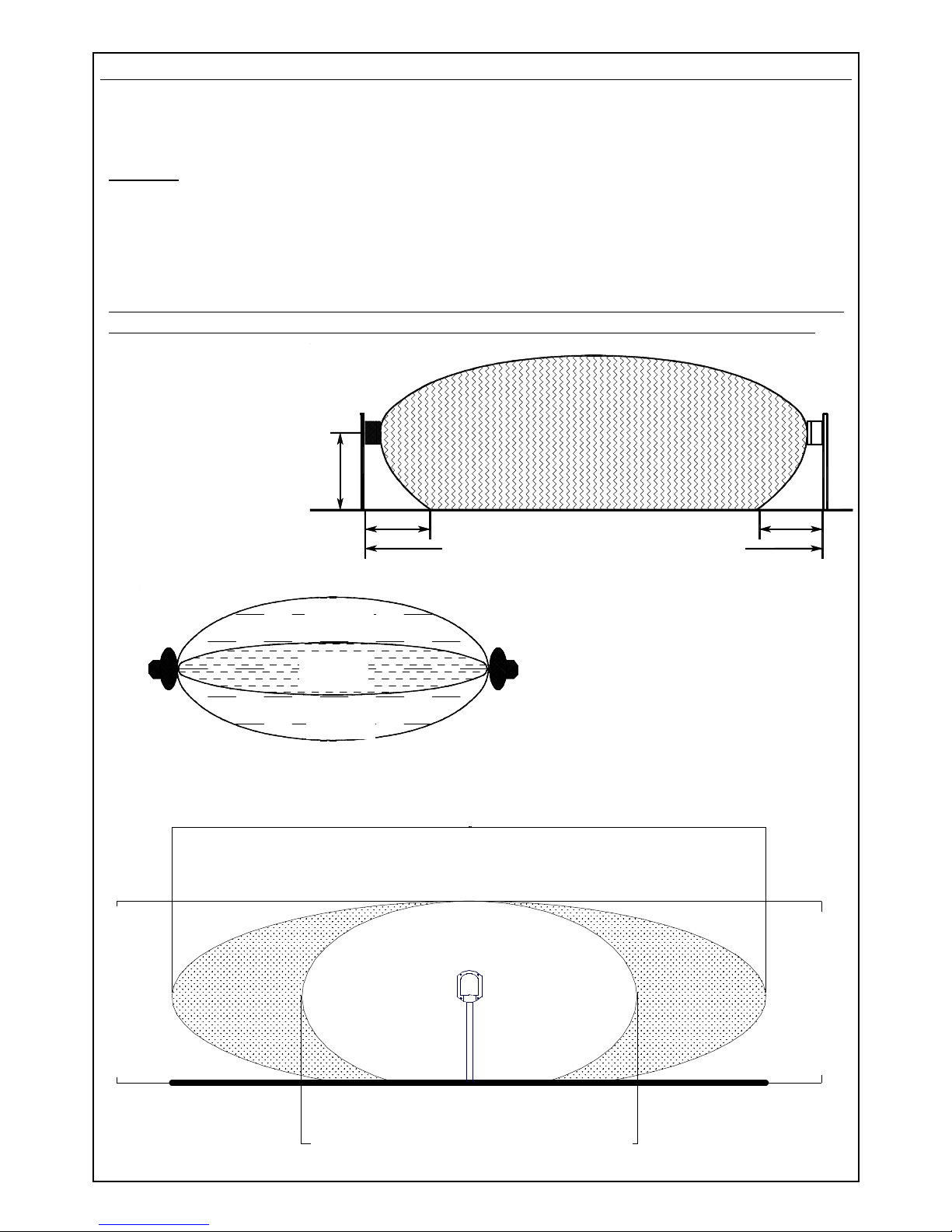

Detection Area

The shape of the irradiation area is very well defined and this allows a higher possibility of

detection and a reduction of false alarms risk.

These beams are manufactured exclusively with solid-state components and are tropicalyzed in

order to obtain a very good seal against weather conditions.

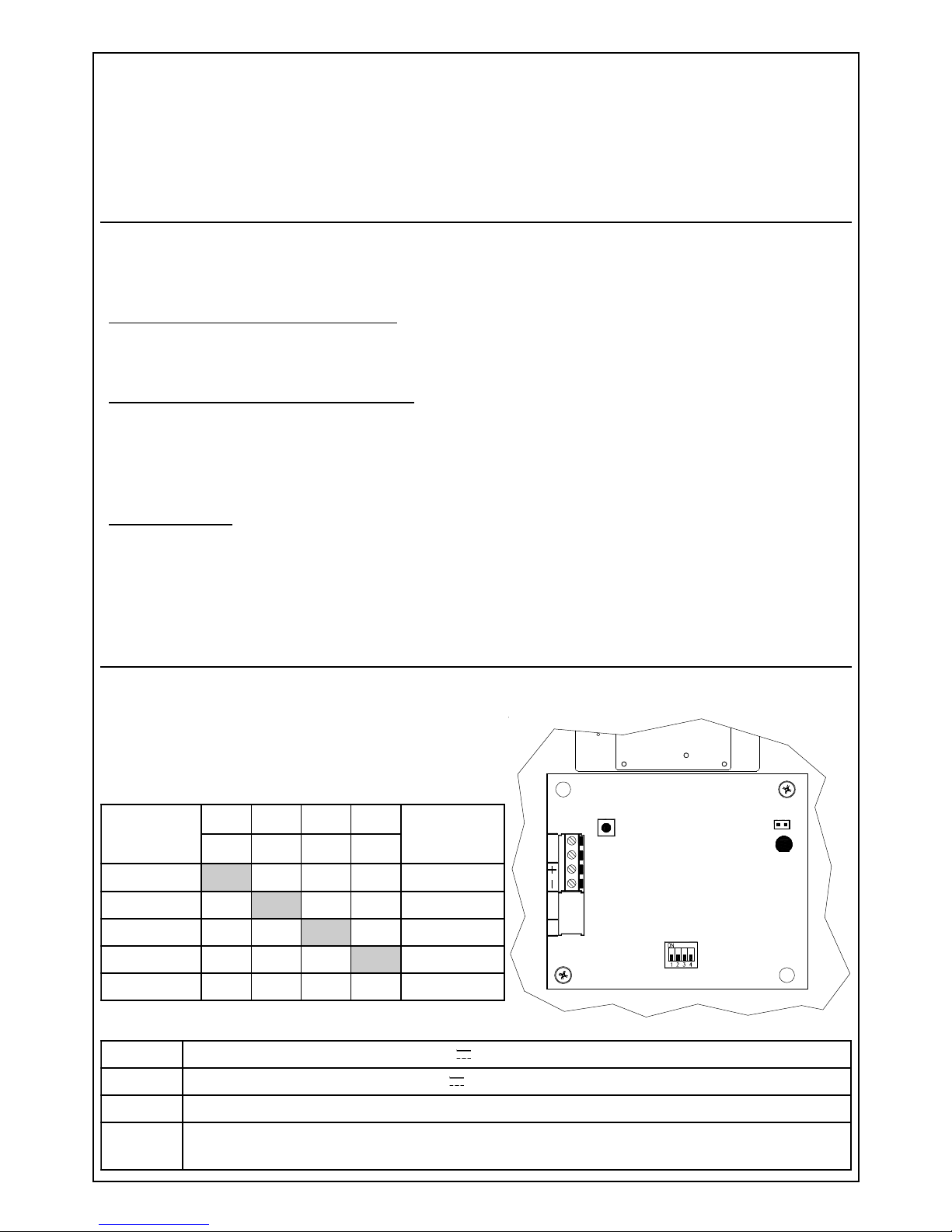

Chapter 2: Transmitter

The transmitter is made of a planar microwave emitting a narrow and directional higly-stable low

power beam.

A 4-dip-switch for setting working frequency is on board.

Check that the transmitter working frequency set is

the same as in the receiver coupled

-

V21evitagengniylppus

+

V21evitisopgniylppus

TT

gnineporotcetedtsiaganoitcetorproftuptuo.c.n

1S

desolc

nepo

delbanedeLgniylppus

delbasiddeLgniylppus

MMB

SLENNAHC

PID PID PID PID

SULPQMB

SLENNAHC

1 2 3 4

1F

NO FFO FFO FFO

DLOG

2F

FFO

NO FFO FFO

EULB

3F

FFO FFO

NO FFO

REVLIS

4F

FFO FFO FFO

NO

WOLLEY

5F

FFO FFO FFO FFO

-

Page 4

- 4 -

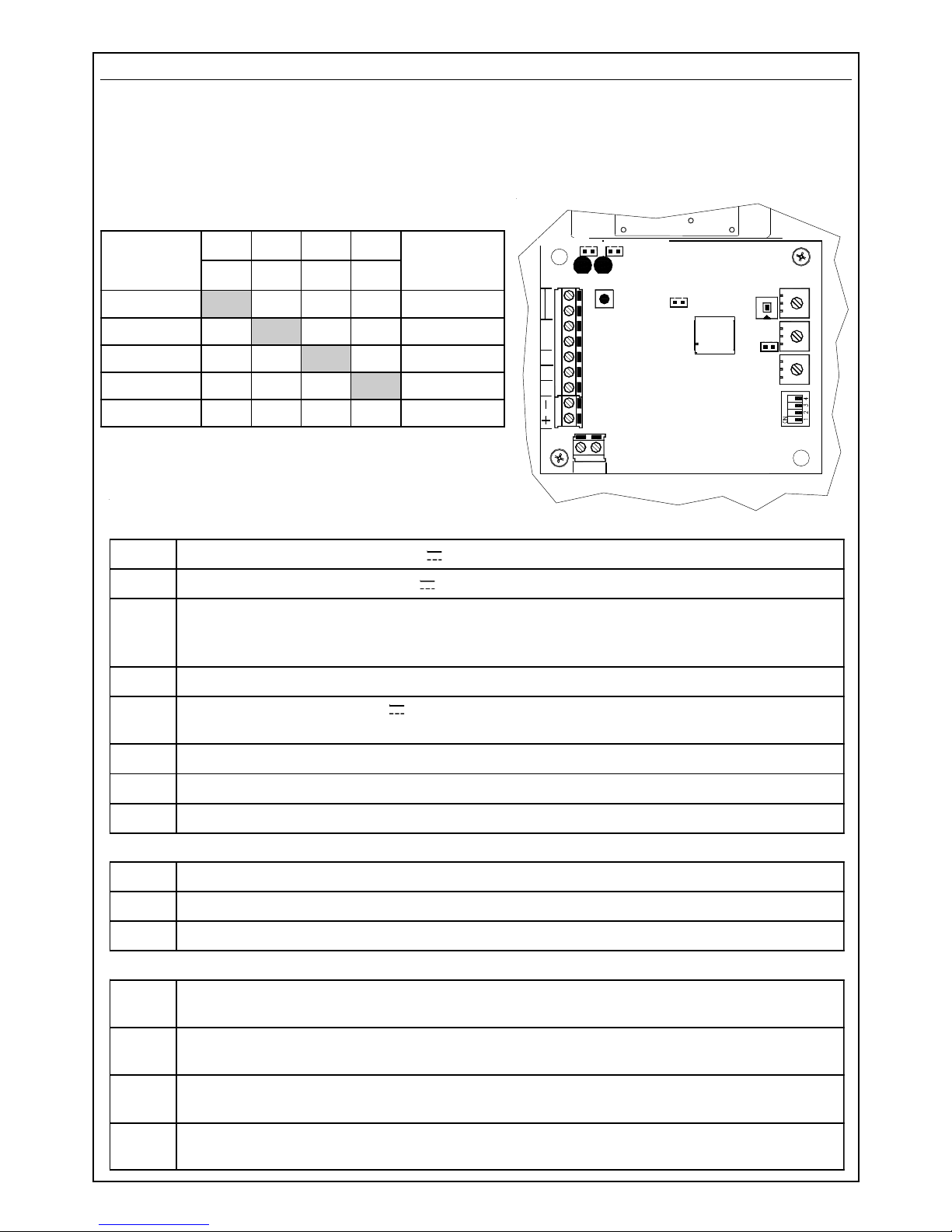

Chapter 3: receiver of hard-wired systems BM60M, BM120M, BM200M

The receiver is made of a high-sensitivity electronic circuit coupled to the antenna; it detects the

signal transmitted in its channel and measures its intensity. Special techniques of signal-elaboration

allow to compensate the variations in the sorroundings and to minimize the effect of possible

perturbations due to small animals or birds.

A 4 dip-switch is on board for setting working frequency

Check that the working frequency of the receiver is

the same as set in the transmitter coupled.

draoBlanimreT

-

V21evitagengniylppus

+

V21evitisopgniylppus

D Am05(evitagendezirotsisnartasevigti;langisnoitacifilauqsiDfotuptuo

rettimsnartehtfolangisehtesacnisliafevitagensihT.noitidnocteiuqgnirud).xam

ces03nihtiwdeviecertonsi

PT

deviecerlangisehtfonoitazilausivroftnioPtseTfotuptuoevitisop

B

mralaeht,lanimretsihtotevitisopagnivig;yb-dnatsrofV21:tupnievitisop

noitidnocteiuqniskcolbyaler

CN/C

yalermralafoegnahcxe..c.n

TT

gnineporotcetedtsniaganoitcetorproftuptuo.c.n

BA

lenapetomerfonoitcennocrofroodlaires

remmirT

LEVEL

deviecerlangisehtgnitsujdarofremmirt

.SNES

esiwkcolcgninrutybsesaercniti;ytivitisnesgnitsujdarofremmirt

.PMOC

esiwkcolc-retnuocgninrutybsesaercniti;noitasnepmocgnitsujdarofremmirt

srepmuJ

1S

desolc

nepo

delbane,evaworcimfoytilauq-langisfodeLneerg

delbasid,evaworcimfoytilauq-langisfodeLneerg

tluafed

2S

desolc

nepo

delbane,gnillangismralafodeLder

delbasid,gnillangismralafodeLder

tluafed

FFO

PMOC

desolc

nepo

dedulcnitiucricnoitasnepmoc

dedulcxetiucricnoitasnepmoc

tluafed

GAC

desolc

desolcniamertsumrepmujsiht

BCA

TPB D

LED

VERDE

TAMPER

T

NC

T

TAMPER

S1 : OFF LED VERDE

LED

ROSSO

S2 : OFF LED ROSSO

CAG

SENS.

OFF COMP.

SW1 COMP.

TEST

CAG

LEVEL

MMB

SLENNAHC

PID PID PID PID

SULPQMB

SLENNAHC

1 2 3 4

1F

NO FFO FFO FFO

DLOG

2F

FFO

NO FFO FFO

EULB

3F

FFO FFO

NO FFO

REVLIS

4F

FFO FFO FFO

NO

WOLLEY

5F

FFO FFO FFO FFO

-

S1: OFF GREEN LED S2: OFF RED LED

GREEN LED

RED LED

Page 5

- 5 -

M_MB

SLENNAHC

PID PID PID PID

SSERDDA

1 2 3 4

1F

NO FFO FFO FFO

1

2F

FFO

NO FFO FFO

2

3F

FFO FFO

NO FFO

3

4F

FFO FFO FFO

NO

4

5F

FFO FFO FFO FFO

5

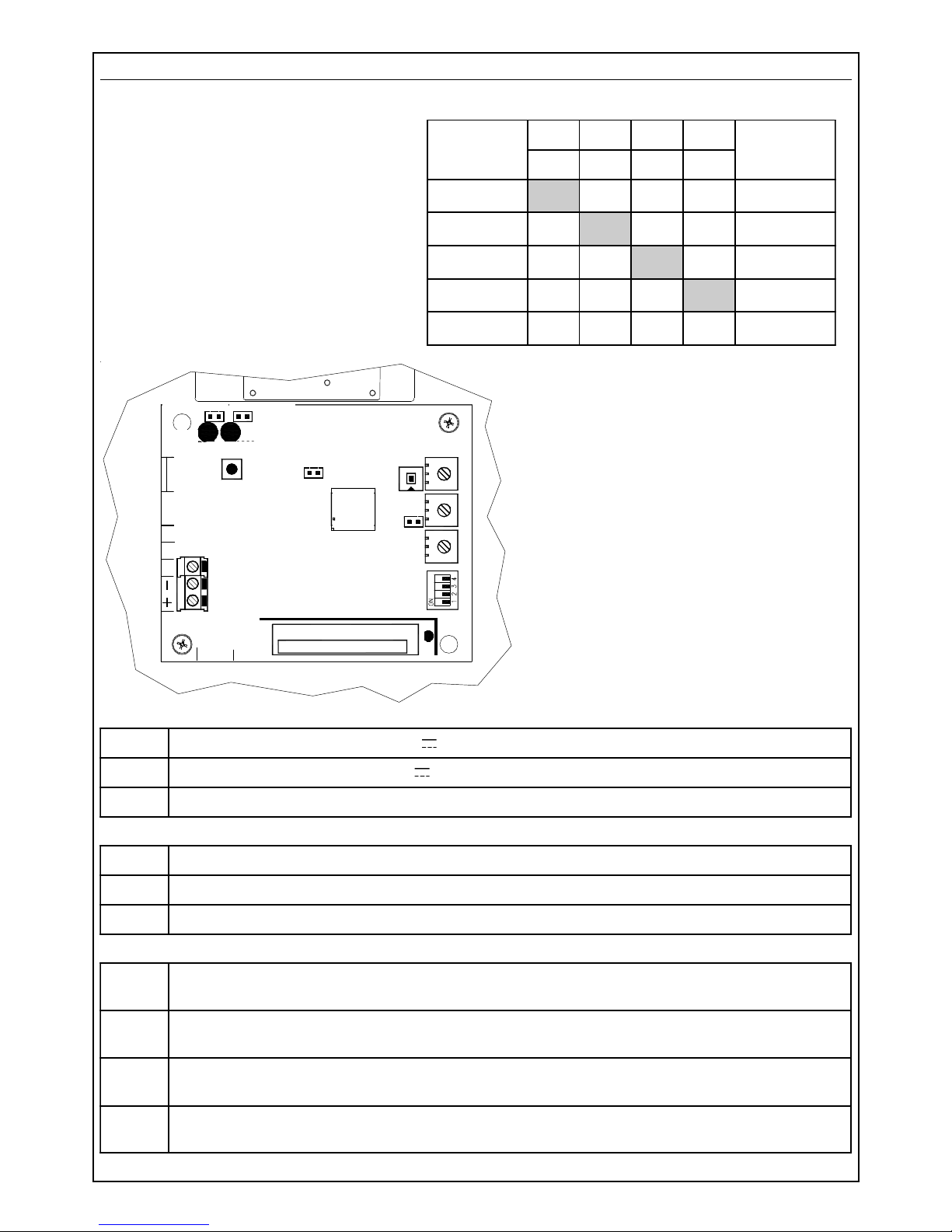

Chapter 4: Receiver of the wireless system BM60M WS

The receiver has the same characteristics as the hard-wired models, with a few differences:

• the 4-ways dip-switch on board

adjusts both working frequency

and the zone address set. If, e.g.,

the beam is addressed on

frequency F2 (dip 1,3,4 in OFF and

dip 2 in ON), it is automatically

acquired as detector 2. It is not

possible to select the working

frequency and the zone address

in the control panel, in a separate way.

•the terminals on board are the supplying

(+ and -) an the signal reading (TP)

•the alarm transmission occurs for both

movement detection inside a pattern and

protracted absence of the signal

received (disqualification): the restore

transmission occurs a few seconds after

the signal is restored in the limits preset.

Check that the working frequency of

the receiver is the same as the

frequency set on the transmitter

coupled.

BCA

TPB D

LED

VERDE

TAMPER

T

NC

T

TAMPER

OFF LED VERDE

LED

ROSSO

OFF LED ROSSO

CAG

SENS.

OFF COMP .

SW1 COMP.

TEST

CAG

LEVEL

LED

TX

S1: OFF LED VERDE

S2: OFF LED ROSSO

S1: OFF GREEN LED S2: OFF RED LED

GREEN LED

RED LED

draoBlanimreT

-

V21evitagengniylppus

+

V21evitisopgniylppus

PT

deviecerlangisehtfonoitazilausivroftnioPtseTfotuptuoevitisop

remmirT

LEVEL

deviecerlangisehtgnitsujdarofremmirt

.SNES

esiwkcolcgninrutybsesaercniti;ytivitisnesgnitsujdarofremmirt

.PMOC

esiwkcolc-retnuocgninrutybsesaercniti;noitasnepmocgnitsujdarofremmirt

srepmuJ

1S

desolc

nepo

delbane,evaworcimfoytilauq-langisfodeLneerg

delbasid,evaworcimfoytilauq-langisfodeLneerg

tluafed

2S

desolc

nepo

delbane,gnillangismralafodeLder

delbasid,gnillangismralafodeLder

tluafed

FFO

PMOC

desolc

nepo

dedulcnitiucricnoitasnepmoc

dedulcxetiucricnoitasnepmoc

tluafed

GAC

desolc

desolcniamertsumrepmujsiht

Page 6

- 6 -

1 - 1,2 mt

BM60M e BM60M WS : max 60 meters

BM120M : max 120 meters

BM200M : max 200 meters

3 meters

3 meters

The sensitive zone shown in the drawings is to

be taken into consideration, as a big target.

Overpassing this area might cause the

same perturbations as a small body

passing the alarm area, that’s to say might

cause false alarms.

BM60M - BM60M WS

6,5 meters

BM120M

10 meters

BM200M

16 meters

BM60M - BM60M WS

2 meters

BM120M - BM200M

3 meters

BM60M - BM60M WS 1,2 meters

BM120M 3 meters

BM200M 4 meters

Alarm zone

Sensitive zone

Sensitive zone

Chapter 5: Description of working

The two units (transmitter: TX and receiver: RX) must be positioned facing each other at the two

ends of the distance to protect. Be aware that the nature of the ground underneath, or special

weather conditions might affect the real range.

Working

The transmitter emits a modulated microwave signal (10,525 GHz), which is received by the

receiver and whose amplitude is compared with the programmed alarm threshold.

When an intruder crosses the microwave area, it causes a signal-intensity decrease under a

minimum level fixed; the receiver shows the alarm condition, lighting up a red Led indicator and

opening the contat of the alarm relay.

If the signal of the transmitter is not received for over 30 seconds, the alarm relay could go back

to quiet condition and the negative to terminal D (disqualification) fails until signal restoring.

For this reason, in the hard-wired system, it is

suggested to make the connection

described in the chapter

concerning disqualification.

The drawings identify the

natural shadow areas

in the immediate

sorroundings of the

two units, which extend

for about 3 meters, in a

typical installation at 1 - 1,2 m

height.

Note: the diagrams of the patterns shown in the drawings are an indication and a guide

during installation. They do not represent the real radiation diagram of the antennas as

they may be subject to variations due to environmental context.

sensitive

zone

sensitive

zone

alarme

zone

Page 7

- 7 -

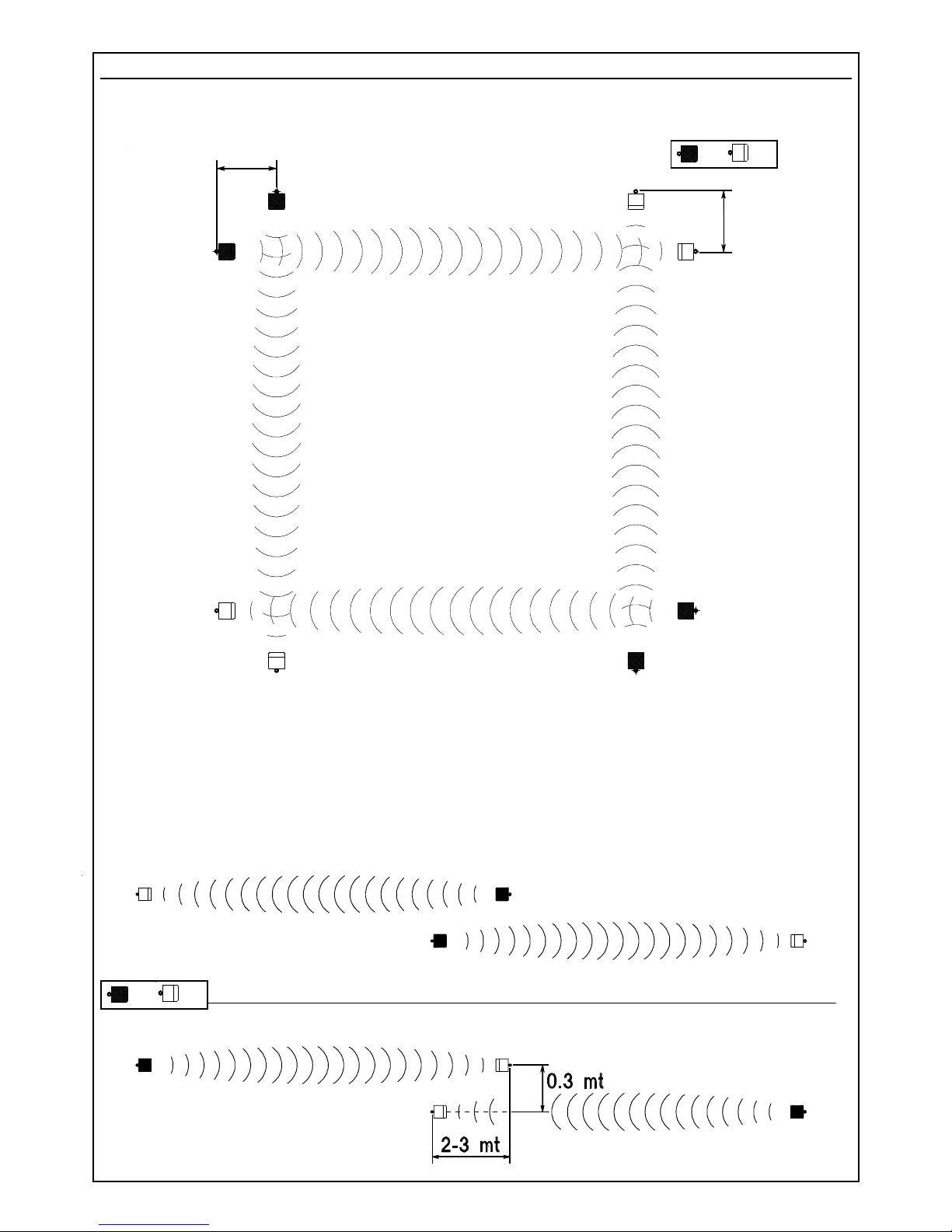

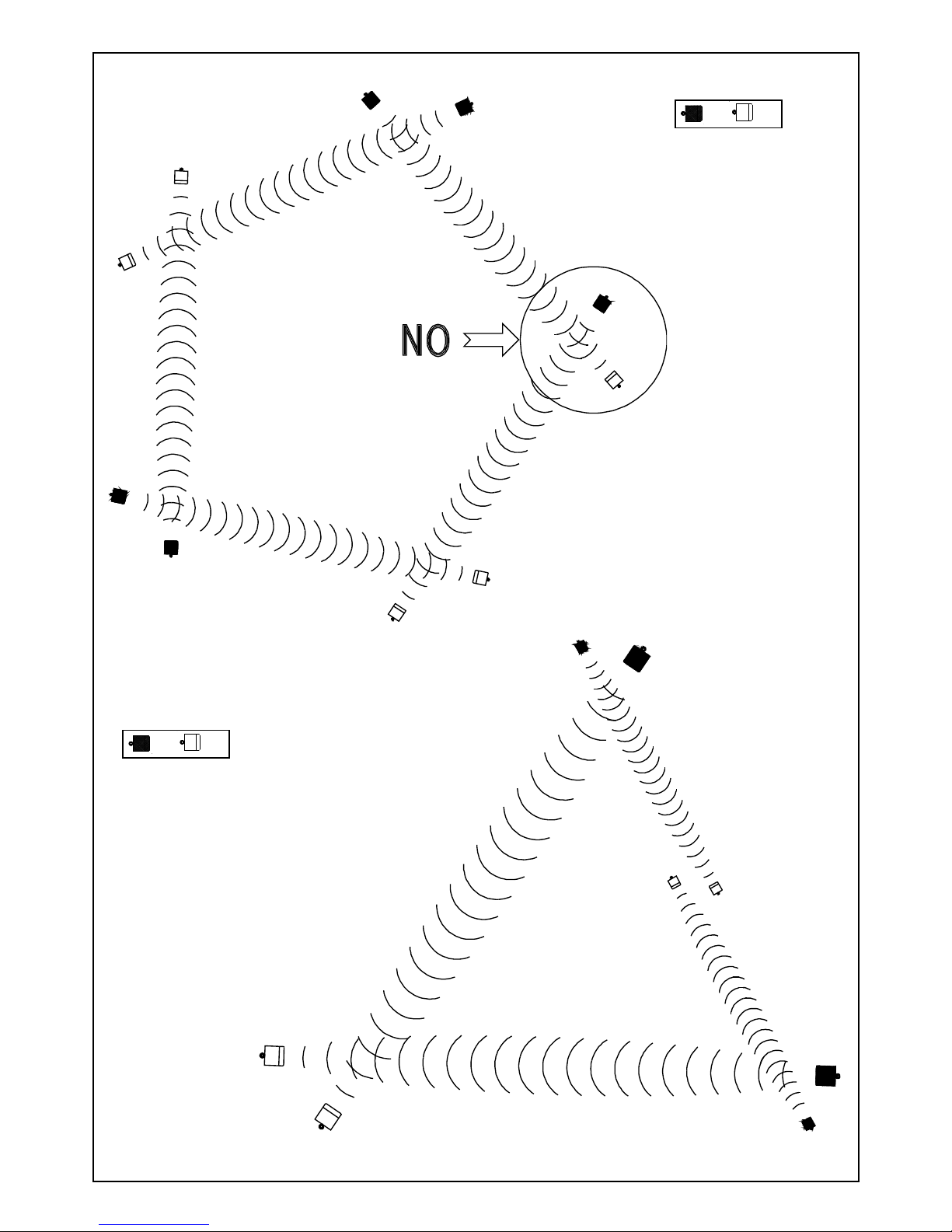

Chapter 6 : Positioning of the beams

For a correct installation of the system, choose carefully the positioning of the two units, according

to following advice:

Drawings identify the correct positioning of transmitters and receivers, in order to eliminate any

possible shadow area.

The drawings here below show how one or more couples of beams have to be positioned for

reaching the distance required.

BE CAREFUL: only elements with different frequencies (F1, F2, F3, F4, F5) and of the

same type (TX/TX or RX/RX) can be installed in proximity one to the other; in order to

avoid interferences between transmitters and receivers belonging to different couples.

The typical installation of

BM M system consists in

sorrounding the area to be

protected by use of more

beams couples in order to

obtain a proper perimetric

fence

3 mt

3 mt

TX RX

TX

RX

Page 8

- 8 -

If, in a perimetric installation, the

beams cross the patterns, they

must always be installed in

pair (2, 4, 6 etc.)

It is absolutely

necessary to

avoid installing a

transmitter near a

receiver belonging

to another couple

TX

RX

TX RX

Page 9

- 9 -

In order to extend the height of the protection, two couples of beams

can be installed as shown in the picture. In this case, it is

suggested to use couples of beams having

close working frequency (two couples

with frequency F1 and F2 or F3 and

F4)

BM60M : 1 meter

BM60M WS : 1 meter

BM120M : 10 meters

BM200M : 10 meters

If the fence is made of bushes or metal fences

subject to possible movement, the minimum

distance must be 1 meter for BM60M

and BM60M WS and 10 meters

for BM120M and

BM200M.

Page 10

- 10 -

BM60M : 1 meter

BM60M WS : 1 meter

BM120M : 5 meters

BM200M : 5 meters

If a couple must be installed

near a building or a fix fence, a

minimum distance of 1 meter for

BM60M and BM60M WS and 5 meters for

BM120M and BM200M must be kept.

This is required in order to avoid false alarms

caused by reflection of microwave

beam.

BM60M : 0,6 meters

BM60M WS : 0,6 meters

BM120M : 2 meters

BM200M : 2 meters

A corridor large not less than 0,6 meters for BM60M and

BM60M WS and not less than 2 meters for BM120M

and BM200M, must be left free from obstacles

between transmitter and receiver; a clear

visual must always be granted in this

area

The suggested height for the installation is

between 1 and 1,2 meters.

Page 11

- 11 -

It is possible to install the system BM60M and BM60M WS

also to protect walls. In this case, the system of

installation shown in the drawing can be used,

in order to avoid false alarms caused by

cats or birds. In this case also, the

height from ground must be

between 1 and 1,2 meters.

Because of ground

characteristics, it may

happen to have a very high

sensitivity in the centre of the

protected area and near the ground,

because of special reflection of the ray.

BM60M : 4 meters

BM60M WS : 4 meters

BM120M : 10 meters

BM200M : 10 meters

It is also possible

to install the system

BM M along a transited

street with transit; in this case,

it is necessary to keep a minimum

distance of 4 meters (for BM60M

and BM60M WS) or 10 meters (for

BM120M and BM200M) between the

sight-line of the couple and the area of transit

of the cars.

In case a metal fence is placed between the transit

area and the area to be protected, detectors must be kept

at a minimum distance of 1 meter (for BM60M and BM60M

WS) or 5 meters (or BM120M and BM200M) from the fence.

BM60M : 1 meter

BM60M WS : 1 meter

BM120M : 5 meters

BM200 : 5 meters

Page 12

- 12 -

• Should any pet be present and free in the installation area, it is suggested to carefully adjust

sensitivity, in order to avoid the risk of false alarms due to the passage of these small targets

in the areas which are very sensitive at the ground. To further decrease this risk, the height

of installation of the couple can be increased a little bit.

• Should trees or bushes affect the protection corridor because of the wind, false alarms

might occur. In the same way, if the system is installed near a hedge, this one must be

carefully attended to avoid darkening the protected area.

• High grass ad bushes decrease sensitivity at groud level.

• Any obstacle or important difference of level in the ground in the protected area, create

shadow-areas and very sensitive zones.

The BM M system has a good tolerance against bad weather conditions and temperature

variations; nevertheless it is necessary to care for following situations:

• RAIN: strong rain only causes a decrease of signal power whilst water puddles may increase

sensitivity at ground level

• SNOW: snow fall does not affect beams sensitivity, but the system cannot work if it is entirely

covered by the snow; so take care in areas with frequent and abundant snow

• FOG: a very thick fog can decrease the signal for 1/3. Because of the limits of compensation

of the gain automatic control (C.A.G.) , it is suggested to install the beams couple at a

distance not exceeding 85% of max range,in the regions where a thick fog is frequent.

The temperature working concditions are between - 20°C and + 55°C; if the use is required in

areas where temperature goes lower than 0°C, it is necessary the permanent installation of the

heating kit, which requires an alternate current at 12 V for a consumption of 150 mA for any

element of the beam (see chapter 15 for installation of heating kit).

Page 13

- 13 -

Chapter 7: Advice for installation

• Use special care for the

cables entry, in order to avoid

moisture and rain penetrating

inside the box.

• For cable entry inside the

covers of board protection, use the

cable-loops given within (as shown in the

drawing)

• In the hard-wired system use anti-fire shielded cable (2 x 0,75 mm² + 8 x 0,22 mm²)

In the wireless system, connect the support pole to ground and use an additional

shield for the supplying cable 220 V ~ inside the pole, in order to create a double

isolation.

• Before installing the support poles in a definitve way, it is suggested to make a trail installation

in order to find out the best position of alignement for the best effective detection:

1 Position the beams couple in the centre of a free area, respecting the minimum distances

for beams positioning and the installation height

2 Supply the transmitter and the receiver with two batteries and orientate TX and RX one

towards the other

3 Check the signal on TP and adjust it at 7,3 V .

4 Move the two beams towards RIGHT/LEFT within 30 - 50 cm and Up/Downwards

checking the variations of signal of TP and identifying the signal max point.

5 Once identified the best position, fix the brackets.

• During positioning and adjusting of the Receiver, take care not to have big bodies inside the

sensitive zone, which will then be moved when the system is in use, such as lorries or cars;

the adjustment could be highly affected.

The fixing bracket

is pre-arranged

for the

installation

on a steel

pipe, whose

external

diameter is

40 millimeters

Thanks to the two slides on the sides of

the fixing bracket, it is possible to adjust

the inclination (max 5° upwards

and 5° downwards) in both

transmitter and

receiver.

Two

notches on

the slides indicate the

max inclination

Page 14

- 14 -

Chapter 8: Installation of the transmitter in the hard-wired system

1) Choose the position of the transmitter, fix it at the height desired and orientate it as much

precisely as you can towards the direction where the receiver will be installed

2) Position the 4 dip-switches according to the working frequency chosen

3) Connect the supplying (from 11,5 V to 15 V ) and check the transmitter working by the

lighting-up of the Red Led inside; taking off the jumper S1 (Off Led), it is possible to

disable the Led for reducing consumption

4) Connect the TT terminals of tamper board to tamper line of control panel.

Chapter 9: Installation of receiver in the hard-wired system

1) Install the receiver in the support at the same height of the transmitter

2) Position the 4 dip-switches according to the working frequency chosen

3) Connect the supplying (from 11,5 V to 15 V ) to the positive + and negative - terminals

4) Connect the C and NC alarm outputs and the disqualification output D to the detection

line of the control panel and the TT terminals to anti-tamper line of the control panel

General Warning for the hard-wired system

It is suggested to reach the two units by use of a plastic flexible and waterproof pipe and

to make the connections by use of shielded cables.

The choice of the section of the wires to be used for connections must be made according

to the distance from supplying source, in order to grant a minimum continuous tension of

12 V on both units. Should the supplying tension get lower than this value, bad-functioning

might occur.

Chapter 10: Installation of transmitter in the wireless system

1) Choose the position of the transmitter, fix it at the height desired and orientate it at sight as

much precisely as you can towards the direction where the receiver will be installed.

2) Position the 4 dip-switches according to the working frequency chosen

3) Connect the 230 V ~ supplying to the input of the supply unit given within

4) Connect the support pole to the ground

5) Connect the terminals + and - to the output of the 13,8 V /300 mA supply unit, given within

and check the functioning of the transmitter by the inside red Led (taking off jumper S1 Off

Led it is possible to disable the Led to decrease consumption)

6) Connect the batteries poles to terminals + and - of the supply unit given within

7) In order to have an alarm indication in case of opening of the cover, it is suggested to

connect the TT terminals in series to supplying positive

Chapter 11: Installation of the receiver in the wireless system

1) Install the receiver in the proper support, at the same height of the transmiter

2) Position the 4 dip-switches according to the working frequency chosen

3) Connect the 230V ~ supplying to the input of the supply unit given within

4) Connect the support pole to the ground

5) Connect the terminals + and - to the output of the 13,8 V /300 mA supply unit given within

6) Connect the back-up battery poles to terminals + and - of the supply unit given within

General Warning for wireless system

Create a double isolation for the passing of the mains cable at 220 V ~, inside a

pole, by using an additional shield.

Page 15

- 15 -

LED

VERDE

OFF LED VERDE

PTP1

LED

ROSSO

Chapter 12: Adjustments

1) Orientate at sight the device in the direction of the transmitter and connect a voltmeter

betwen the negative (-) and TP

terminal (Test Point) on board

2) Orientate the device in horizontal

way, looking for the position

giving the max reading; in case

it is over 7,3 Volt tthe signal level

must be reduced by use of

LEVEL trimmer, in such a way

as to bring the signal to the best

point of working, that’s to say 7,3

Volt

• It is possible to have a high value

also with receiver not aligned to

transmitter; in this case it could be a reflection of the beam transmitted, which must most be

taken into consideration.

• In case the signal does not reach 6,8 V having LEVEL trimmer at max, move the device in

vertical way within a limit of 10-20 cm.

• Shouldn’t it be possible to reach the min. value, it will be necessary to decrease the distance

between receiver and transmitter or look for a better alignement position

3) Check the quality of the signal received, keeping in mind that in absence of seeming

movements inside the protected area:

• Green Led on fix: there is no signal noise

• Green Led quick or slow flashing: the signal noise is low but is

anyway detected by the beam

• Green Led slow flashing (off for about 1 second) , the signal

noise is more important and it is near to the intervention

threshold of the beam

In order to have a more precise indication of noise quantity, it is suggested to make

mesurements with an oscilloscope, as specified in chapter 13 (Measurements of the signal

by oscilloscope) on the following page

4) Once reached the best condition of working, make a test through the pushbutton TEST

C.A.G. placed on the receiver board.

Keeping the pushbutton pressed , the red alarm led will light up for about 10 seconds, then

the green led will light up again to show normal working; now the pushbutton can be released

5) At the end of all tests, for a reduced consumption of the receiver, it is possible to take off the

jumpers S1 and S2 (Led OFF) which disable the green led and the red led respectively.

LED

ROSSO

SW1 COMP. SENS. LEVEL

OFF COMP.

TEST

CAG

CAG

TAMPER

LED

VERDE

OFF LED VERDE

OFF LED ROS S O

A

B

TPDB

CNC

TAMPER

T T

LED TX

7,3 Volt

OFF GREEN

LED

GREEN LED RED LED

Page 16

- 16 -

PTP1

PTP2

PTP3

Chapter 13: Measurements of the signal by oscilloscope

In the drawing below, the points where to connect the oscilloscope are shown:

Point B shows the quality of

the signal received

In the graphic here below the wave shapes concerning the signal quality are shown:

1- the beam is in quiet condition and there is no passage of people or any perturbation due to

moving objects, the level is fix . Check that the quiet condition is as described.

2- the beam is disturbed or we are crossing a sensitive area (partial darkening)

3- the beam has been darkened and there is an alarm situation

Point C shows the alarm

threshold (trimmer sens.).

In this case the sensitivity

is adjusted at the half

Point A

(PTP1)

it shows the amplitude

of the signal received

Point C

(PTP3)

it shows the alarm

threshold

Point B

(PTP2)

it shows the quality of

the signal received

C

B

.2 s

0.5 V

.2 s

0.5 V

.2 s

2 .1 V DC

x

10

3 .1 V DC

x

10

0 V

Sensitivity

range

Page 17

- 17 -

Chapter 14: Sensitivity Adjustment

1) Turn trimmer SENS clockwise in the position of minimum sensitivity and make a trial

walking in the central point of the distance covered (point of minimum sensitivity of the

system) and check the behaviour of the green led.

2) If necessary, increase the sensitivity progressively until obtining the answer desired

3) After any sensitivity and orientation adjustment, it is necessary to wait about 20 seconds in

order to have all signals set and make a new trial

Caution: a high sensitivity can cause false alarms in critical conditions (such as strong rain

or snow fall)

4) In the BM M system a special compensation circuit has been included, which can be

adjusted by means of trimmer COMP (turning it clockwise the compensation increases); this

circuit records the perturbations resulting in the microwave area when the target approaches

or moves away crosswise to the pattern and it automatically increases the receiver sensitivity

in order to make easier detection of the target when it crosses the central line of the pattern.

The compensation circuit can be completely excluded taking off the jumper OFF COMP. A

high compensation can cause a false alarm of the beam when there are moving objects

near the pattern.

CAUTION

(BM120M and BM200M ONLY)

Due to larger pattern and to compensation circuit, BM M beams are more sensitive to

perturbations caused by moving objects in the areas near the corridor protected.

Consequently, the security distance to be kept in the installation, especially in respect to

the transit of vehicles, trains, or presence of big trees or bushes, must be increased. In the

special case of a street with vehicles transit, parallel to the protected area, it is suggested

to keep a minimum security distance of 10 meters.

Signal

Signal

Alarm

thresold

ALARM

Extreme Compensation

ALARM

Correct Compensation

Alarm

thresold

Page 18

- 18 -

Chapter 15: Kit TERM (optional) Resistence fo inside heating

• For installation in an indoor or outdoor place

where temperature can go lower than 0°C, it

is necessary to use the heating kit Term

1 in both Receiver ad Transmitter. This has

to be done in order to avoid formation of

condensation which might affect the good

working of the electronic circuit.

• The optional heating kit, is made of a circuit

where an electromechanical thermostat, a

heating resistence and a terminal board

for connection to supplying, are placed.

• Supplying must be given by means of an

external trasnformer with output at alternate 12V ; the consumption of any heating

resistence is 150 mA at the tension of alternate 12 V.

• The thermostate intervention occurs taking

off supplying to the resistence when the temperature of 30° C is reached inside the box.

Chapter 16: Kit AMP (optional) Anti-removal

The anti-removal kit AMP is made of two bulbs, whose

function is sending an alarm in case of tampering or

removal of the beam from its support.

This kit must be positioned in such a way that one of the

bulbs is installed in vertical position compared to the

device and the other one in horizontal position as shown

in the picture.

This system allows a complete protection against any

attempt of :

- removal of the beam from the support

- removal of the supports from fixing points

The horizontal bulb must be positioned in such a way that

the contact opens as soon as there is an attempt of moving

the beam.

Before connecting the tamper line to the control panel,

check that the contact of single bulbs as well as tamper line is closed .

:gniylppuS V21etanretla

:noitpmusnoC xamAm051

:remrofsnarT ~V022:tupni

~V21:tuptuo

rewopW02:smaebfoselpuoc4rof

Example: RX BEAM

CTPB

D

TAMPER

TNCT

Page 19

- 19 -

SUPPLY UNIT

BATTERY

Chapter 17: Disqualification (Important Warning)

In order to prevent and show

disalignements caused by any

obstacle placed in the active

beam of the barriers at system

off, it is necessary to connect

the disqualifiation output

(terminal D) in series to the

exchange of the alarm relay or

alternatively, use it to control an

additional relay, whose

exchange has to be put in series

to the alarm line.

NOTE

The output D gives a

transistorized negative (max. 50

mA) which fails when the signal

level goes under a minimum

level for over 30 seconds.

Chapter 18: Additional supply unit for BM60M WS

In both transmitter and receiver, the supply

unit is fixed inside the cover on the top,

whilst a back-up battery 12V 0,8 Ah is

located in the bottom (to be fixed

with the strip given within), and

not exceeding the following

size: height 65 mm, length 96

mm, depth 25 mm.

Make the supplying

cables pass behind the

supply unit and the

backup battery, in order

not to affect the cover

closing.

Two protection fuses are

available in the supply

unit: F1 for mains

supplying and F2 of

battery input.

F1

F2

-

~ ~

+

+

-

Battery

input

Output

beam

supplying

Mains

supplying

input

1F V052-LAm005

2F V052-LAm005

Balance

Resistence

AVS CONTROL PANEL OTHER CONTROL PANEL

Page 20

- 20 -

A

+

-

B

BR100 is an accessory accepting up to

4 LCD W boards.

Chapter 19: BR100 Kit and LCD W (optional) signal remoting-device

LCD W is a Led and

display module

allowing the

constant

monitoring of

the BM M

signal to

which it is

associated.

This system of remoting the signal levels of the beams, is made of a Led/display module (LCD

W) for any couple of beams, to be contained into the BR100 housing.

Thanks to this system, it is possible to monitor constantly from 1 up to 4 couples of BM M.

On the front of BR100 module, for any couple of beams to monitor, there are:

• the LCD W module for vizualising the signal

quantity received, expressed in Volt (the

display visualizes the units, the Led bar

visualizes the decimals). The value

shown is the same given by the TP

terminal (Test Point) of the receiver to

which it is coupled

• a yellow Led (FAIL) is especially

appointed to the Disqualification

indication

• a red Led (ALARM) indicating the alarm

condition (it follows the condition of the

receiver red Led)

• a green Led (STATUS) visualizing the

signal quality (it follows the condition of the

receiver green Led)

There also is a key-block which must not be

connected (for future uses)

DRAOBLANIMRET

+

V21evitisopgniylppuS

-

evitagengniylppuS

BA

ehtotlaires-eugolaidehtfotupnI

smaebdetaicossa

SCITSIRETCARAHCLACINHCET

noisnetlanimoN V8,31-5,11

noitpmusnoC Am011xam

esuF V052LA5.0F

The supplying of the BR100 panel must be separate from the beams supplying in order to

avoid that a possible short-circuit in the supplying line of the panel can cause the break of

the supplying to the beams. To this purpose, use the fuse-holder with its 500 mA fuse

given within BR100 panel.

Page 21

- 21 -

SB60

GNIKROWNEEWTEBECNEDNOPSERROC

TINUNOITAZILAUSIVDNAYCNEUQERF

MAEB

LENNAHC

PID PID PID PID

TINU

1 2 3 4

1F

NO FFO FFO FFO

1

2F

FFO

NO FFO FFO

2

3F

FFO FFO

NO FFO

3

4F

FFO FFO FFO

NO

4

5F

FFO FFO FFO FFO

1

NOITUAC

1TINUotnosesserddasi5FhtiwtesmaebehT

TEST

CAG

LEVEL

B D TP

PTP2

TT

NC

TAMPER

TAMPER

LED

VERDE

OFF LED VERDE

PTP1

LED

ROSSO

CAG

OFF LED ROSSO

OFF CO M P.

SENS.

LED TX

PTP3

SW1 COMP.

C

B

A

TEST

CAG

LEVEL

B D TP

PTP2

TT

NC

TAMPER

TAMPER

LED

VERDE

OFF LED VERDE

PTP1

LED

ROSSO

CAG

OFF LED ROSSO

OFF CO M P.

SENS.

LED TX

PTP3

SW1 COMP.

C

B

A

TEST

CAG

LEVEL

B D TP

PTP2

TT

NC

TAMPER

TAMPER

LED

VERDE

OFF LED VERDE

PTP1

LED

ROSSO

CAG

OFF LED ROSSO

OFF CO M P.

SENS.

LED TX

PTP3

SW1 COMP.

C

B

A

TEST

CAG

LEVEL

B D TP

PTP2

TT

NC

TAMPER

TAMPER

LED

VERDE

OFF LED VERDE

PTP1

LED

ROSSO

CAG

OFF LED ROSSO

OFF CO M P.

SENS.

LED TX

PTP3

SW1 COMP.

C

B

A

SW1

SW1

SW1

SW1

A

B

RX 1

ABABA

B

RX 2

RX 3

RX 4

+

-

Fuse

Chapter 20: Optional Brackets

SB120

Optional

bracket SB60

can be used

with BM60M

and BM60M WS

only

SB20

The optional

bracket

SB20 and

SB60 can

be used for

installation

to the wall

SB130

Optional brackets SB120 and SB130 can

be used for installation to the floor

Page 22

- 22 -

Information in conformity to the Directive 1999/5/CEE for model BM_M

The product here described is in conformity to the essential prescriptions of the Directive 1999/

5/CEE (R&TTE) on the radio-transmitting devices of low power and on the use of frequencies of

the radioelectrical spectrum, in accordance with CEPT 70-03 recommandation.

kramedarT SCINORTCELESVA

ledoM M002MB-M021MB-M06MB

ycneuqerfgnikroW zhG525,01

gniylppusfoepyT tnerrucsuounitnoc

noisnetlanimoN V21

)XRdnaXT(tnerruclanimoN Am101

ytinummoCnaeporuEehtniesufoseirtnuoC snoitcirtserlacolfonoitpecxeehthtiwreverehW

etaD 6002lirpAht5

DICHIARAZIONE DI CONFORMITA

(MANUFACTURERS DECLARATION OF CONFORMITY)

DICHIARA CHE LA SEGUENTE APPARECCHIATURA

(DECLARES THAT THE FOLLOWING EQUIPMENT)

RISULTA CONFORME CON QUANTO PREVISTO DALLE SEGUENTI DIRETTIVE COMUNITARIE:

(IS IN ACCORDANCE WITH THE FOLLOWING COMMUNITY DIRECTIVES)

E CHE SONO STATE APPLICATE LE SEGUENTI NORMATIVE

(APPLYING THE FOLLOWING NORMS OR STANDARDS)

IDENTIFICATORE DI CLASSE DEL DISPOSITIVO (per apparati RF regolamentati dalla direttiva R&TTE)

(Equipment class identifier (RF products falling under the scope of R&TTE))

Il costruttore dichiara sotto la propria responsabilità che questo prodotto é conforme alla direttiva

93/68/EEC (marcatura) e soddisfa i requisiti essenziali e altre prescrizioni rilevanti della direttiva

1999/5/EC (R&TTE) in base ai risultati dei test condotti usando le normative (non) armonizzate in

accordo con le Direttive sopracitate.

(We declare under our sole responsibility that this product is in conformity with directive 93/68/EEC (Marking)

and/or complies to the essential requirements and all other relevant provisions of the 1999/5/EC (R&TTE)

based on test results using (non)harmonized standards in accordance with the Directives mentioned)

Luogo (Place) : Curtarolo

Data (Date) : April 2006

Firma (Signature)

Nome (Name) : G. BARO

Amministratore

(Managing Director)

erotturtsoC

)rerutcafunaM(

APSSCINORTCELESVA

ozziridnI

)sserddA(

YLATI-)DP(oloratruC01053-36,anaguslaVaiV

:arutaihccerappA’lledemoN

)emaNtnempiuqE(

:

M002MB-M021MB-M06MB

arutaihccerappAidopiT

)tnempiuqEfoepyT(

: ONRETSEREPEDNOORCIMAEREIRRABIROTALEVIR

)METSYSMRALANAPSEVAWORCIMROODTUO(

olledoM

)ledoM(

:

enoizurtsoCidonnA

)erutcafunaMforaeY(

:

6002

)CME(CE/633/98

)ETTR&R(CE/50/99

)DVL(CE/32/37

044003NE

3-984103NE

4-03105NE

05906NE

elbacilppAtoN )tcudorp1ssalc(enoN

X

)tcudorp2ssalc(

Page 23

- 23 -

Information in conformity to the Directive 1999/5/CEE for model BM60M WS

The product here described is in conformity to the essential prescriptions of the Directive 1999/

5/CEE (R&TTE) on the radio-transmitting devices of low power and on the use of frequencies of

the radioelectrical spectrum, in accordance with CEPT 70-03 recommandation.

DICHIARAZIONE DI CONFORMITA

(MANUFACTURERS DECLARATION OF CONFORMITY)

DICHIARA CHE LA SEGUENTE APPARECCHIATURA

(DECLARES THAT THE FOLLOWING EQUIPMENT)

RISULTA CONFORME CON QUANTO PREVISTO DALLE SEGUENTI DIRETTIVE COMUNITARIE:

(IS IN ACCORDANCE WITH THE FOLLOWING COMMUNITY DIRECTIVES)

E CHE SONO STATE APPLICATE LE SEGUENTI NORMATIVE

(APPLYING THE FOLLOWING NORMS OR STANDARDS)

IDENTIFICATORE DI CLASSE DEL DISPOSITIVO (per apparati RF regolamentati dalla direttiva R&TTE)

(Equipment class identifier (RF products falling under the scope of R&TTE))

Il costruttore dichiara sotto la propria responsabilità che questo prodotto é conforme alla direttiva

93/68/EEC (marcatura) e soddisfa i requisiti essenziali e altre prescrizioni rilevanti della direttiva

1999/5/EC (R&TTE) in base ai risultati dei test condotti usando le normative (non) armonizzate in

accordo con le Direttive sopracitate.

(We declare under our sole responsibility that this product is in conformity with directive 93/68/EEC (Marking)

and/or complies to the essential requirements and all other relevant provisions of the 1999/5/EC (R&TTE)

based on test results using (non)harmonized standards in accordance with the Directives mentioned)

Luogo (Place) : Curtarolo

Data (Date) : April 2006

Firma (Signature)

Nome (Name) : G. BARO

Amministratore

(Managing Director)

erotturtsoC

)rerutcafunaM(

APSSCINORTCELESVA

ozziridnI

)sserddA(

YLATI-)DP(oloratruC01053-36,anaguslaVaiV

:arutaihccerappA’lledemoN

)emaNtnempiuqE(

:

SWM06MB

arutaihccerappAidopiT

)tnempiuqEfoepyT(

: ONRETSEREPEDNOORCIMAAREIRRABEROTALEVIR

)METSYSMRALANAPSEVAWORCIMROODTUO(

olledoM

)ledoM(

:

enoizurtsoCidonnA

)erutcafunaMforaeY(

:

6002

)CME(CE/633/98

)ETTR&R(CE/50/99

)DVL(CE/32/37

044003NE

3-022003NE

3-984103NE

4-03105NE

05906NE

elbacilppAtoN )tcudorp1ssalc(enoN

X

)tcudorp2ssalc(

kramedarT SCINORTCELESVA

ledoM SWM06MB

ycneuqerfgnikroW )ycneuqerfgnikrowevaworciM(zhG525,01

)ycneuqerfnoissimsnarT(zHM053,868

gniylppusfoepyT yrettabpu-kcabV21+tnerrucetanretla

noisnetlanimoN Am003~V032

)XRdnaXT(tnerruclanimoN noitidnocteiuqniAm101

noissimsnartgnirudAm131

ytinummoCnaeporuEehtniesufoseirtnuoC snoitcirtserlacolfonoitpecxeehthtiwreverehW

etaD 6002lirpAht5

Page 24

- 24 -

Technical

Characteristics

AVS ELECTRONICS S.p.A.

Via Valsugana, 63

35010 (Padova) ITALY

Tel. 049 9698 411 / Fax. 049 9698 407

avs@avselectronics.com

www.avselectronics.com

Assistenza Tecnica: 049 9698 444

support@avselectronics.com

AVS ELECTRONICS S.p.A. reserves the right to modify the technical and esthetical characteristic of the products at any time.

M06MB M021MB M002MB SWM06MB

egnarxaM sretem06 sretem021 sretem002 sretem06

noisnetlanimoN V21 V21 V21 V21

noisnetniM V5.11 V5.11 V5.11 V5.11

noisnetxaM V51 V51 V51 V51

nihtiwnevigtinu-ylppuS

- - -

~V032:.snettupnI

Am003:tnerruC

AV6:rewoP

V8.31:.snettuO

etacolotyrettaB

- - -

hA8,0-V21

21-8,0PN.doM

teiuqgnirudnoitpmusnoC Am13:XT

Am07:XR

Am13:XT

Am07:XR

Am13:XT

Am07:XR

Am13:XT

Am07:XR

mralagnirudnoitpmusnoC Am13:XT

Am07:XR

Am13:XT

Am07:XR

Am13:XT

Am07:XR

Am13:XT

Am001:XR

)HxLxP(:eziS 591x501x051 522x522x631 522x522x631 522x522x631

ycneuqerfnoissimsnarT - zHM868MF

noitacidnilavivruS on sey

yalerrotcetedfokcolB Blanimretdetnioppayb -

tuptuomralA V21taegnarAm005htiwegnahcxe.c.n -

tuptuorepmaT hctiws-orcim -

)PMA(lavomer-itnaroftiklanoitpO on sey sey on

lairesroftuptuO lenapetomerfonoitcennocrofroodlaires -

QMIenoizatserP QMIolleviLII

tiKnocM002MBeM021MBrepQMIolleviLIII

enoizomiritnA

-

tuptuonoitacifilauqsiD noitpecerdooglangisfognikcehcroftuptuodezirotsisnart

tuptuotnioPtseT deviecerlangisfognikcehcrof

ycneuqerfgnikrowevaworiM )zHM02-/+(zHG525,01

noitaludoM hctiws-pidhguorhtnoitceles,slennahctnereffid5ni

rewopFRfonoitaidarrI mBd52:kaep

snoitidnocerutarepmeT C°55+otC°02-morf

.detseggussi)2mreT(tikgnitaehlanoitpoehtfoesueht,roodtuonoitallatsniroF

noitcetorPPI 43PI

nihtiwneviG ebutmm04nonoitaxifroftekcarB

Loading...

Loading...