Page 1

AA

A

AA

BF100 ABF100 A

BF100 A

BF100 ABF100 A

VS ELECTRVS ELECTR

VS ELECTR

VS ELECTRVS ELECTR

CurCur

tartar

Cur

CurCur

wwwwww

www

wwwwww

olo (Polo (P

tar

olo (P

tartar

olo (Polo (P

.a.a

vselectrvselectr

.a

vselectr

.a.a

vselectrvselectr

adoado

ado

adoado

onicsonics

onics

onicsonics

vv

a) Itala) Ital

v

a) Ital

vv

a) Itala) Ital

ONICSONICS

ONICS

ONICSONICS

yy

y

yy

.com.com

.com

.com.com

SmokSmok

Smok

SmokSmok

detectiondetection

detection

detectiondetection

beambeam

beam

beambeam

ee

e

ee

In conformity to EN54 norms

CERTIFIED

QUALITY SYSTEM

ISO9001

IST0649V1/0

- 1 -

IST0649V1/0

Page 2

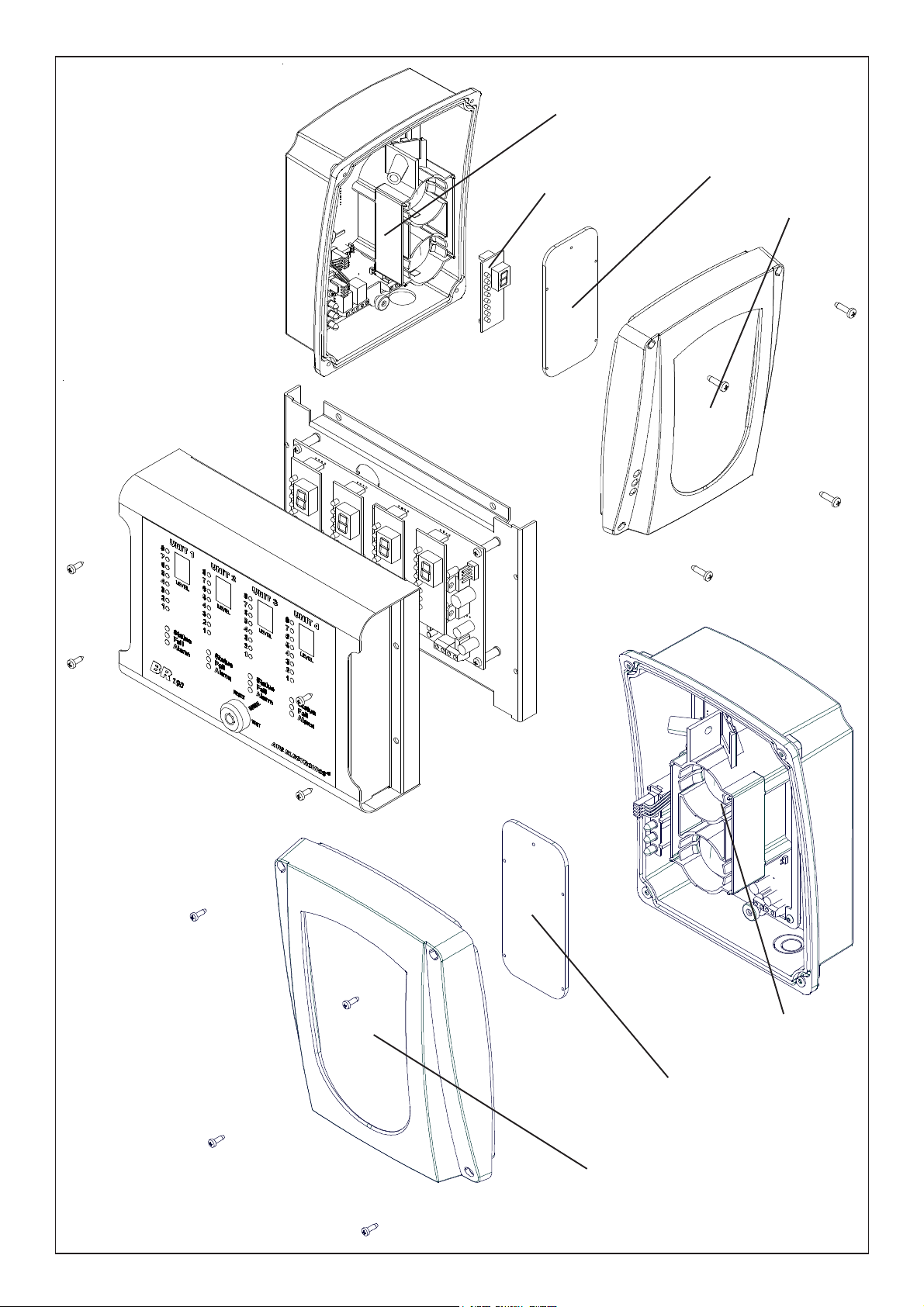

GENERAL FEATURES

6

ALLARME

S7

NO

NC

LD3

LD4

LD2

S3S2

321

ON

3

2

1

4

5

B

S8

NO

GUASTO

+F

CNCC

OUT

+

- A

S4

S9

S6

S5

4

8

7

S2

321

ON

+

-

S6

S5

4

-

+

LED

ROSSO

RX

TX

- Smoke detection beam made of a Transmitter and a Receiver, capable to detect and

determine the quantity of smoke which is present in the protected area.

- The board is equipped with a view-finder, placed on one side, allowing a rough alignement

with the reflector given within.

- The beam is equipped with a device (Led/display module) to use for calibration and check of

signal received.

- At first supplying, the board makes a self-calibration which will be repeated every 2 hours in

order to compensate masking caused by dust on lenses and reflector.

- Adjustable sensitivity to get a better intervention threshold according to distance.

- The beam has alarm outputs as well as fault condition and consumption-alarm outputs,

which allow connection to standard fire control units.

- The beam has a serial interface in order to connect up to 4 units to the remote panel (BR100)

showing the same indications as shown by led/display module and leds.

- 2 -

IST0649V1/0

Page 3

RECEIVER

LED/DISPLAY

MODULE

BF TEST

(NOT GIVEN WITHIN)

COVER

BR100 (OPTIONAL)

TRASMITTER

BF TEST

(NOT GIVEN WITHIN)

COVER

- 3 -

IST0649V1/0

Page 4

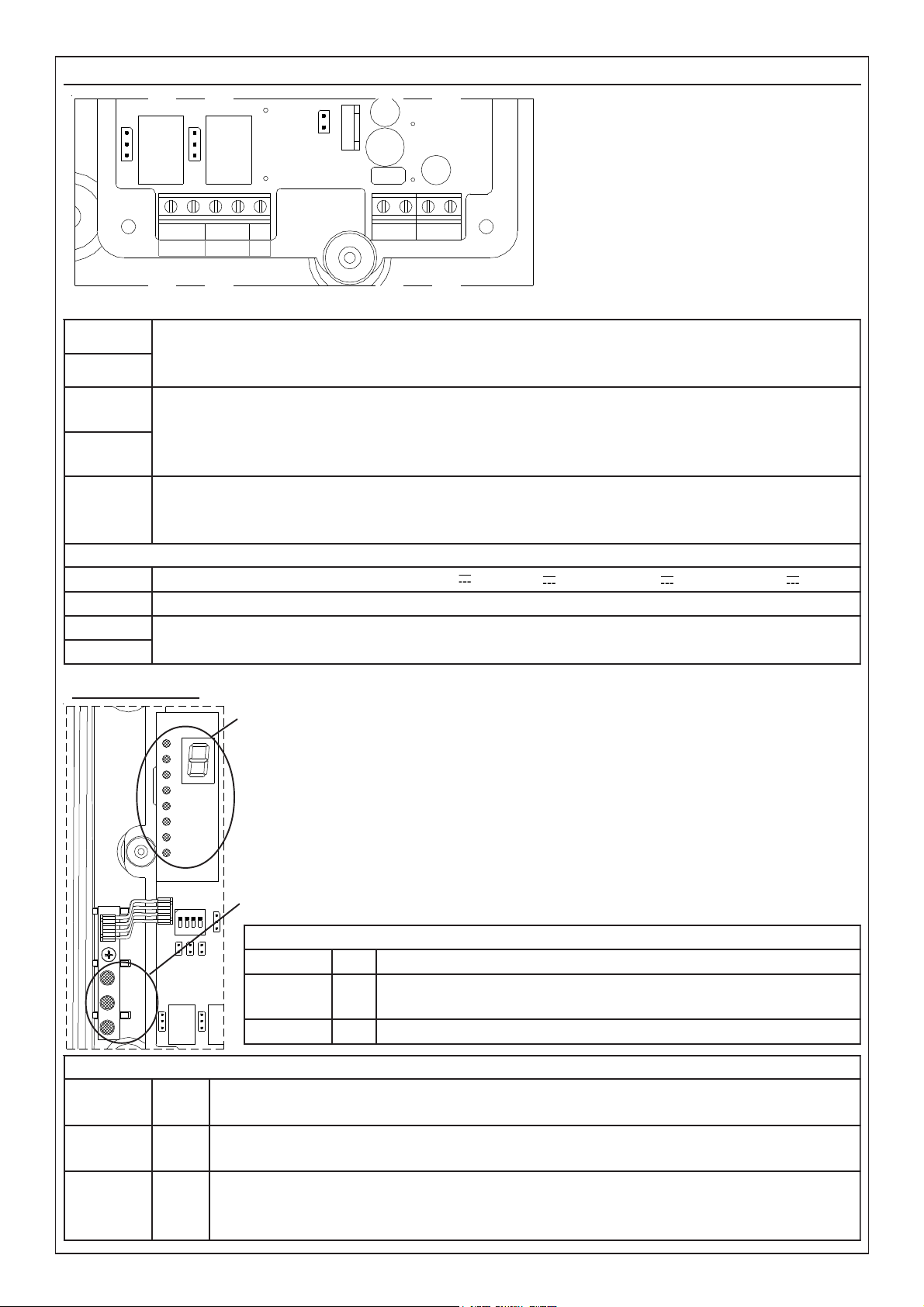

RECEIVER

A- B

C

GUASTOALLARME

S7

NC

C

NO

NC

NO

S8

OUT

+F

+

S6

ON/CN

MRALA

.yalerMRALAfoegnahcxE

.detcetedneebsahekomsretfasdnoces04tuobaevitcasitI

.ON/CroCN/Cegnahcxeehttesotredroni7SrepmujnotcA

ON/CN

TLUAF

-OITIDNOC

N

.yalerTLUAFfoegnahcxE

neddusadetcetedsahmaebehtretfaetunim1tuobaevitcas'tI

.levelmuminimehtrednulangisehtfoesaerced

.ON/CroCN/Cegnahcxeehttesot8SrepmujnotcA

C

F+TUO

fonoitcennoctceridehtswollatuptuosihT.yalermralaehtsasetavitcatI

ehtmralagniruD.tinulortnoceriflanoitnevnocfoenilenootmaebeht

.mho086siegrahcecnetsiser

+ )V8,72xam/V5,11.nim(V42roV21evitisopgniylppuS

- evitagengniylppuS

A

001RBeludomlanoitpootnoitcennocrofroodlaireS

B

EDOMNOITARBILAC

DER

2DL

FFO

NEERG

3DL

detcetedtonsirettimsnarTehtfolangisehtfi:FFO

detcetedsilangisrevieceRehtfi:NO

WOLLEY

4DL

FFO

EDOMLAMRON

DER

2DL

FFO

NO

noitidnoclamroN

mralA

NEERG

3DL

gnihsalfwolS

gnihsalfkciuQ

)sdnoces2yreve(noitidnoclamroN

dlohserhtmralaehtgnideecxeekomshtiW

WOLLEY

4DL

FFO

gnihsalfkciuQ

NO

noitidnoclamroN

mrala-erpnoitidnoctluaf(muminimrednulevellangiS )

noitavitcayalertluaffoemitemasehttA

S7 S8

1 2 3 4

S2 S3 S4

ON

S1

The terminal board is made of

two separate groups: the one

on the left concerns alarm

and fault-condition output

whilst the one on the right

concerns supplying input and

serial door.

Signalling Led

8

7

6

5

4

3

2

1

LD2

LD3

LD4

Module to visualize the signal:

– during normal working, the display will visualize the unit values while

the Led bar will visualize the decimanl values of the signal received.

– during alarm condition the letter A is visualized.

– during fault condition the letter F is visualized.

- during calibration the display visualizes the unit values whilst the Leds

bar visualizes the decimal values of signal received.

Module for visualization of detector condition:

IST0649V1/0

- 4 -

Page 5

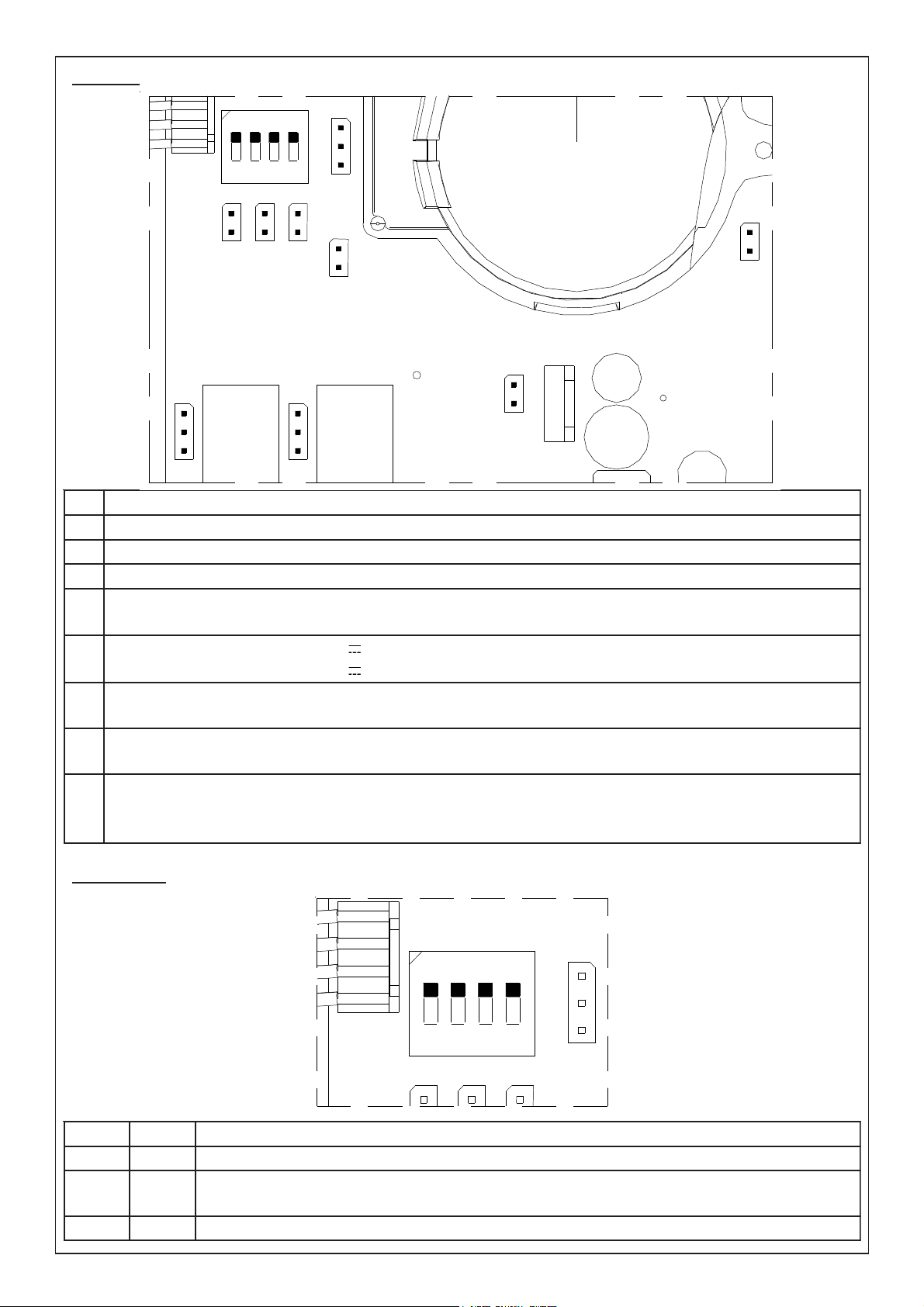

Jumper

1S

)repmuj-eriW(

ylnoesuyrotcaf,tuctonoD

2S 001RBeludometomerhtiweugolaidrofnoitcelessserddA

3S 001RBeludometomerhtiweugolaidrofnoitcelessserddA

4S 001RBeludometomerhtiweugolaidrofnoitcelessserddA

5S

rotaunettA

)repmuj-eriW(

desolC

nepO

rotcelferdnamaebneewteb.tm001ot53morfecnatsidroF

rotcelferdnamaebneewteb.tm53ot5morfecnatsidroF

6S

gniylppuS

)repmuj-eriW(

desolC

nepO

gniylppusV21

gniylppusV42

7S

yalerMRALA

tcatnocCN:2-1noitisopnI

tcatnocON:3-2noitisopnI

8S

yalerTLUAF

tcatnocCN:2-1noitisopnI

tcatnocON:3-2noitisopnI

9S

MRALA

TESER

desolC

nepO

lortnoceriflanoitnevnocafoenilehtotdetcennocF+tuptuofiylnO

gnillangismralarofdesusitinu

sedomnoitcennocrehtollanI

1

levelytivitisnesfognitteS

2 levelytivitisnesfognitteS

3

FFO

NO

gnikrowlamronfoedoM

gnikrownoitarbilacfoedoM

4 desutoN

S7 S8

S2 S3S9S4

S6

S5

ON

1 2 3S14

Dip switch

ON

1 2 3 4

S1

- 5 -

IST0649V1/0

Page 6

TRANSMITTER

2S

desolC

nepO

)ffodeLdeR(noitarbilaC

)nodeLdeR(gnikrowlamroN

5S

ecnatsiD

noitceleS

)repmuJ(

desolC

nepO

53neewtebdedulcnireviecerdnarettimsnartneewtebecnatsidroF

.sretem001dna

5neewtebdedulcnireviecerdnarettimsnartneewtebecnatsidroF

sretem53dna

6S

gniylppuS

desolC

nepO

gniylppuSV21

gniylppuSV42

+

-

1PID 2PID 3PID 4PID

EGNAR

)5Snepohtiw(

EGNAR

)5Sdesolchtiw(

0 0 0 0 5 tm83

1 0 0 0 51 tm55

0 1 0 0 02 tm86

1 1 0 0 32 tm87

0

0 1 0 72 tm78

1 0 1 0 03 tm69

0 1 1 0 33 tm501

1 1 1 0 73 tm311

-

+

S2

321

ON

S6

S5

4

LED

ROSSO

+ )V8,72xam/V5,11.nim(V42roV21evitisoPgniylppuS

- evitageNgniylppuS

Terminal board

Jumper e Dip Switch

It shows the presence of the supplyng

RED

LED

Trimmer

RV1

- 6 -

For a correct

adjustment of the

beam signal it is also

necessary to set the

distance between

receiver and

transmitter by use of

dip-switch.

Trimmer RV1 for trimming the

emitted signal.

It increases clockwise.

IST0649V1/0

Page 7

INSTALLATION RULES

The beam and the reflector must be installed on plane wall, not subject to vibrations or deformation.

Please keep in mind these basic rules:

- In order to obtain total coverage,

the distance (D) between more

TX/RX couples must not

exceed 15 meters.

- distance from the walls

must be about the half

of the distance between

two beams (1/2 D).

- distance from the ceiling (H)

must be between min. 40 cm.

and max 1 meter.

- check the possibility of installing

reflectors in axis with beams.

H

1/2 D

TX/RX TX/RX

D

1 mt

D

TX/RX

In case of sloping roofs, install the first beam at H

distance from the highest side of the roof.

Install other beams maintaining distance D

between them and distance H from the ceiling.

Check to have the max distance of 1/2D

between the beam and the wall from the

lowest side of the roof.

Check that Receiver and

Transmitters can be installed on

the same axis.

In case of inclination of the roof, install the first beam at about 1

meter from the highest wall and at H distance from the

ceiling.

D

TX/RX

TX/RX

TX/RX TX/RX

Install other beams maintaining distance D

1/2 D

between them and distance H from the

ceiling.

Check to have max 1/2 D

distance between the beam

and the lowest side of the

wall from the ceiling.

Check that Receiver and

Transmitters can be

installed on the same axis.

H

TX/RX

1/2 D 1/2 DD D

- 7 -

IST0649V1/0

Page 8

INSTALLATION

For installation onto the wall either reflector and beam need flat cylindrical-head

screws.

Install the Receiver in the chosen point and keep it in axis

to the Transmitter as much as possible

Alignment hole

Fixing holes

Insert the calibration accessory BF TEST

(necessary for a correct calibration) in the proper

openings, as shown on the drawing on the side,

keeping the alignment hole on the top.

MIN 5 MT

MAX 100 MT

Check not to have reflecting bodies, such as glasses, mirrors etc. possibly affecting

the signal, in the area nearby.

Install the Transmitter in the chosen point and keep it in axis to

the Receiver as much as possible

Alignment hole

Fixing holes

Insert the calibration accessory BF

TEST (necessary for a correct calibration)

in the proper openings, as shown on the

drawing on the side, keeping the alignment hole

on the top.

- 8 -

IST0649V1/0

Page 9

WORKING MODE “CALIBRATION”

leveL foegatnecreP

gniksam

dnamaebneewtebecnatsiD

rotcelfer

1PID 2PID

1 %02 sretem53ot5morF NO NO

2

%52 sretem05ot01morF FFO NO

3 %03

sretem07ot02morF NO FFO

4

%53 sretem001ot03morF FFO FFO

- In order to make a first rough alignement, use optical

view-finder, visualizing the centre of the concerned

reflector in the centre of the framed area. In order to

move orientation towards right, rotate the horizontal

adjuster clockwise, in order to move orientation

towards left, rotate the horizontal adjuster

counter-clockwise.

- To move orientation upwards rotate the

vertical adjuster counter-clockwise, to move

it downwards rotate the adjuster

clockwise.

- Make the same with the Transmitter

- Before supplying the beam check

jumper S6 condition:

• keep it closed for 12V supplying

• cut it for 24 V supplying

DX

UP

SX

REFLECTOR

- Before supplying the beam units, check S6

jumper in both Receiver and Transmitter:

• cut jumper for distance from 5 to 35 meters.

• keep jumper closed for distance from 35 to 100 meters.

- Set properly dip switch 1 - 2 - 3 in the Transmitter according to the distance from Receiver as

shown in chart on page 6

- At firs supplying, the beam is blocked for about 30 seconds. Wait before following step.

- At power up, the beam units remain inhibited for about 30 seconds. Wait for this delay before

proceeding to following step.

- Close S2 jumper in the Transmitter in order to get the beam units to Calibration mode.

• the green Led in the Receiver will remain on if the signal is received from Transmitter

• the display/Led module will visualize the recived signal

- During calibration process avoid the visualized value exceeding 7,1V (7 display - 1 led).

Should this occur, act on the trimmer RV1 to decrease the signal under the threshold.

- Adjust both Receiver and Transmitter until obtaining the max signal value on the display/Led

module in the Receiver.

- Act on Transmitter RV1 Trimmer until obtaining the value of 6,5 V on the display/led module

(6 display and 5 Leds on) of the Receiver.

VERTICAL

ADJUSTER

HORIZONTAL

ADJUSTER

- Considering that the longer is the range, the longer is the beam, it is necessary to set the

sensitivity level in the Receiver according to the distance between Receiver and Transmitter,

following the rules below:

At the end of calibration, open jumper S2 in the Transmitter and take away the BF Test small

glasses before inserting the covers.

The 4 fixing screws of the covers can be “hidden” by using the screw-covers given within, just for

esthaetical reasons.

- 9 -

IST0649V1/0

Page 10

WORKING MODE “NORMAL”

1

3

2

5

4

7

6

8

1

3

2

5

4

7

6

8

1

3

2

5

4

7

6

8

Here are the indications given by the three Leds on the left:

– during normal working: green Led flashes about every 2 seconds, red Led is off, yellow

Led is off.

– during alarm: as soon as the beam detects presence of smoke, green Led will flash quickly,

red Led and yellow Led will be off. After about 40 seconds if the event causing the alarm

continues, green Led will keep on flashing quickly, red Led will be on and alarm relay will be

activated, yellow Led will be off.

When the event causing the alarm is over, green Led will start again flashing every 2 seconds,

red Led will remain on and alarm relay will remain activated.

The alarm signalling is reset:

– if the output +F connected to a conventional fire control unit (Jumper S9 closed)

has been used for the alarm signalling, the reset will be automatic resetting the

control unit.

– For all other connection modes (Jumper S9 opened), the reset is made taking off

supplying from barrier for few seconds.

– In any case, if the module BR100 is used, reset can also be made by use of the

mechanical key on board.

– In case of fault condition: as soon as the beam detects a sudden drop of signal, green Led

will flash quickly, red Led will be off, yellow Led will flash quickly. After about 1 minute, if the

the event causing it persists, green Led will keep on flashing quickly, yellow Led will be fix on

and concerned relay is activated.

– Fault signalling is automatically reset as soon as the event stops. The beam is automatically

back in condition of “normal working”.

You can use the display/Led module both keeping it in its position inside the Transmitter or

inserting it inside the remote panel BR100. In any case you can have to following additional

indications:

During normal working:

DISPLAY

- it shows the value of 6 corresponding to the signal received

LED BAR

- N° led on: 5 (or value shown during adjustment)

In case of alarm:

DISPLAY

- shows letter “A”

LED BAR

- not relevant (depending on signal received)

In case of faulty unit:

DISPLAY

- shows letter “F”

LED BAR

- not relevant (depending on signal received)

- 10 -

IST0649V1/0

Page 11

LD3

LD4

LD2

4321

ON

S1

S8

+F

OUT

NO

ALLARMENOGUASTO

CNCC

NC

S4S3S6S2

S7

+

- BA

S5

LD3

LD4

LD2

4321

ON

S1

S8

+F

OUT

NO

ALLARMENOGUASTO

CNCC

NC

S4S3S6S2

S7

+

- BA

S5

LD3

LD4

LD2

4321

ON

S1

S8

+F

OUT

NO

ALLARMENOGUASTO

CNCC

NC

S4S3S6S2

S7

+

- BA

S5

LD3

LD4

LD2

4321

ON

S1

S8

+F

OUT

NO

ALLARMENOGUASTO

CNCC

NC

S4S3S6S2

S7

+

- BA

S5

BR100

REIRRAB 1 2 3 4

2S

DESOLC NEPO NEPO NEPO

3S

NEPO DESOLC NEPO NEPO

4S

NEPO NEPO DESOLC NEPO

noisnetlanimoN V8,72-5,11

noitpmusnoC Am011xam

esuF V052LA5.0F

1S

:nepO

:desolC

gniylppusV42

gniylppusV21

In order to obtain signal visualizatioin in real time, it is possible to remote the display/led module

of any single beam, locating it in remote panel BR100.

Any BR100 remote panel can locate

up to 4 display/Led modules.

RESET: it makes a reset of alarm

condition.

NORMAL: during normal working of

beams.

TEST: not used

BR100 Connection

Dialogue between the remote panel and the beam occurs

thanks to a serial connection as shown on side drawing.

Connect A and B terminals of beam to concerned A and

B terminals on BR100 remote panel.

Single beams connected to BR100 must be addressed using

Jumpers S2, S3 and S4 on board (see chapter JUMPER), in

the following way:

BR100 supplying must be separate from beams

supplying as a possible short-circuit in remote panel

supplying may cause a cut in beams supplying

(EN54-12 norm). To this purpose use 500 mA fuse

together with its fuse-holder given within BR100 panel.

- 11 -

Fuse

-

A

B +

-

+

Supplying

TECHNICAL FEATURES

IST0649V1/0

Page 12

ALLARME

NO

NC

+FGUASTO

C

NO

NC

C

OUT

+

- BA

CONNECTIONS TO CONTROL UNITS

ALLARME

NO

NC

+F

GUASTO

C

NO

NC

C

OUT

BF100R beam is equipped with:

- OUT + F for direct connection to

AVS conventional fire control units

(charge of 680 ohm during alarm).

In order to reset the beam from

alarm condition, simply make a

reset operation on control unit

(Jumper S9 closed).

Side-drawing shows an example

of connection using these

contacts: R1 is the end-line

resistance usually given with

control unit. FAULT contact is set

on C/NC.

R1

- Relay ALARM output.

Contacts of this output can be C/NC or C/

NO according to setting of jumper S7 (see

chapter JUMPER).

In order to reset the beam from alarm

condition, it is necessary to take off supplying

from the beam for a few seconds (Jumper

S9 open).

An example of connection using these contacts is

shown on side-drawing where ALARM contact is

set on C/NO and FAULT relay is set on C/NC.

R1 is the end-line resistence which is usually given

within control unit.

R2 is the alarm resistence (for AVS control units

the value of this resistence is 680/1000 ohm –

3W) (not included).

R2

R1

In both cases, if module BR100 is used, reset can be done through mechanical key on board.

- 12 -

IST0649V1/0

Page 13

- 13 -

IST0649V1/0

Page 14

- 14 -

IST0649V1/0

Page 15

Indice

GENERAL FEA TURES.................................................................................................pag. 2

RECEIVER....................................................................................................................pag. 4

Signalling Led.......................................................................................................pag. 4

Jumper ..................................................................................................................pag. 5

Dip switch .............................................................................................................pag. 5

TRANSMITTER ............................................................................................................pag. 6

Terminal board......................................................................................................pag. 6

Jumper e Dip Switch ............................................................................................pag. 6

Trimmer.................................................................................................................pag. 6

INSTALLATION RULES ...............................................................................................p ag. 7

INSTALLATION ............................................................................................................pag. 8

WORKING MODE “CALIBRA TION”............................................................................pag. 9

WORKING MODE “NORMAL” ..................................................................................pag. 10

BR100 Connection ....................................................................................................pag. 11

BR100.........................................................................................................................pag. 11

CONNECTIONS TO CONTROL UNITS .....................................................................pag. 12

TECHNICAL FEATURES...........................................................................................p ag. 16

- 15 -

IST0649V1/0

Page 16

:rotcetedfoepyT rotcetedekomsmaeb-derarfnideslupdnadetaludom

egnaR sretem5.nim

sretem001.xam

egarevoC xamsretem.qs000.1

noitarbilaC rabdeL/yalpsidfoesuyb

tiklanoitpO 001RB rabdel/yalpsidrofgnisuohetomer:

TSETFB noitarbilacrofrorrimllams:

gniylppuS tloV8,72ot5,11morf

noitpmusnoCXT eludomhtiwV21htiw- Am32

eludomhtiwV42htiw- Am6,32

noitpmusnoCXR eludomV21htiwnoitidnocteiuq- Am94

eludomV21htiwnoitidnocmrala- Am96

eludomV42htiwnoitidnocteiuq- Am35

eludomV42htiwnoitidnocmrala- Am87

rabdeL/eludomyalpsid- Am51

:stuptuO yalermrala- V21taAm005

yalertluaf- V21taAm005

stinulortnoceriflanoitnevnocotnoitcennoctcerid-

lenapetomerotnoitcennocrofroodlaires-

:erutarepmeT C°04+/C°5+

:eziS .mm112x951x69

:noitcudorP smron45NEINUotgnidrocca

eergedPI 46PI

TECHNICAL FEATURES

The product is in conformity to CE directives for electro-magnetic compatibility.

Power to this device must come from a SELV type power supply having characteristics of

current limitation and fuse protected output. (ref. EN 60950)

INSTALLATION MUST BE PERFORMED BY QUALIFIED PERSONNEL

AVS ELECTRONICS S.p.A. reserves the right to modify the technical and esthetical characteristic of the products at any time.

VS ELECTRVS ELECTR

AA

VS ELECTR

A

VS ELECTRVS ELECTR

AA

Tel. 049 9698 411 / Fax. 049 9698 407Tel. 049 9698 411 / Fax. 049 9698 407

Tel. 049 9698 411 / Fax. 049 9698 407

Tel. 049 9698 411 / Fax. 049 9698 407Tel. 049 9698 411 / Fax. 049 9698 407

Assistenza Tecnica: 049 9698 444Assistenza Tecnica: 049 9698 444

Assistenza Tecnica: 049 9698 444

Assistenza Tecnica: 049 9698 444Assistenza Tecnica: 049 9698 444

support@avselectronics.comsupport@avselectronics.com

support@avselectronics.com

support@avselectronics.comsupport@avselectronics.com

ONICS SONICS S

ONICS S

ONICS SONICS S

Via Valsugana, 63Via Valsugana, 63

Via Valsugana, 63

Via Valsugana, 63Via Valsugana, 63

35010 (Padova) ITALY35010 (Padova) ITALY

35010 (Padova) ITALY

35010 (Padova) ITALY35010 (Padova) ITALY

avs@avselectronics.comavs@avselectronics.com

avs@avselectronics.com

avs@avselectronics.comavs@avselectronics.com

www.avselectronics.comwww.avselectronics.com

www.avselectronics.com

www.avselectronics.comwww.avselectronics.com

- 16 -

.p.p

.p

.p.p

.A..A.

.A.

.A..A.

IST0649V1/0

Loading...

Loading...