Page 1

Curtarolo (Padova) Italy

www.avselectronics.com

CERTIFIED QUALITY

SYSTEM

ISO9001:2008

E

N

DIGITAL MICROWAVE BEAMS

FOR INDOOR AND OUTDOOR USE

BM 60 HP

BM 120 HP

BM 200 HP

G

BM 60 HP VAC

BM 120 HP VAC

BM 200 HP VAC

IST0772V2.2

- 35 -

Page 2

General Description.................................................................................................pag. 37

Transmitter................................................................................................................pag. 37

BM60HP - BM120HP - BM200HP Wiring systems receiver...................................pag. 38

AUX Input..................................................................................................................pag. 38

Extra power supply unit for BM 60-120-200 HPVAC..............................................pag. 39

DIP SWITCH - SW1...................................................................................................pag. 41

Serial addresses table - SW1...................................................................................pag. 41

DIP SWITCH - SW2...................................................................................................pag. 41

Frequencies Table - SW2.........................................................................................pag. 41

Description of working............................................................................................pag. 42

Positioning of the beams........................................................................................pag. 43

Advice for installation..............................................................................................pag. 49

Transmitter installation inside the wire system......................................................pag. 50

Receiver installation inside the wire system - UNIVERSAL..................................pag. 50

E

N

G

Receiver installation inside the wire system - SERIAL..........................................pag. 50

Adjustments..............................................................................................................pag. 51

Measurements of the signal by oscilloscope.........................................................pag. 52

Sensitivity Adjustment.............................................................................................pag. 53

Kit TERM (optional) Resistence fo inside heating.................................................pag. 54

Kit AMP (optional) Anti-removal...............................................................................pag. 54

Disqualification (Important warning)......................................................................pag. 55

Optional Brackets.....................................................................................................pag. 56

Special functions......................................................................................................pag. 57

Detectors Management............................................................................................pag. 58

Synoptic panel..........................................................................................................pag. 62

Events History..........................................................................................................pag. 63

Signals library...........................................................................................................pag. 65

Recordings Archive.................................................................................................pag. 66

System notes............................................................................................................pag. 66

Upgrade Firmware...................................................................................................pag. 66

Information in conformity to the Directive 1999/5/CEE for model BM_HP...........pag. 67

Technical Characteristics........................................................................................pag. 68

- 36 -

Page 3

DIGITAL MICROWAVE BARRIER

The BM60HP, BM120HP and BM200HP and BM 60-120-200 HPVAC models are microwave intrusion

detection systems which functioning is based on the “field interruption” principle and, also thanks to a

microprocessor managing the digital signals, they are instruments ideal for the protection of large

surfaces, indoor and outdoor, allowing for a high degree of safety.

Models BM 60-120-200 HPVAC are supplied on large containers and are equipped with a 230 V ~ 1A

power supply unit and a 12 V - 0.8 Ah buffer battery (optional).

General Description

The system is made by a Transmitter and a Receiver which must be installed as a couple,

choosing the same working frequency among the 5 available, in both units (tx and rx) ,

through SW1 (4 dip-switch module) on board.

Compatibility with existing models

In case of replacement, choose the same frequency on the beam to be replaced (F1 by F1, F3 by F3

etc.). In order to identify the corresponding frequency, use the chart “BEAMS CHANNELS”

Filter of selection and compensation

Any receiver is equipped with a selection filter choosing only the frequency of its channel and rejecting

the others, thus not making possible the elusion of the beam in case of use of a false transmitter.

Special self-adjusting and signal-elaboration circuits have been used in the receiver for automatic

compensation of temperature variations.

E

N

Detection Area

The shape of the irradiation area is very well defined and this allows a higher possibility of detection

and a reduction of false alarms risk.

These beams are manufactured exclusively with solid-state components and are tropicalyzed in

order to obtain a very good seal against weather conditions.

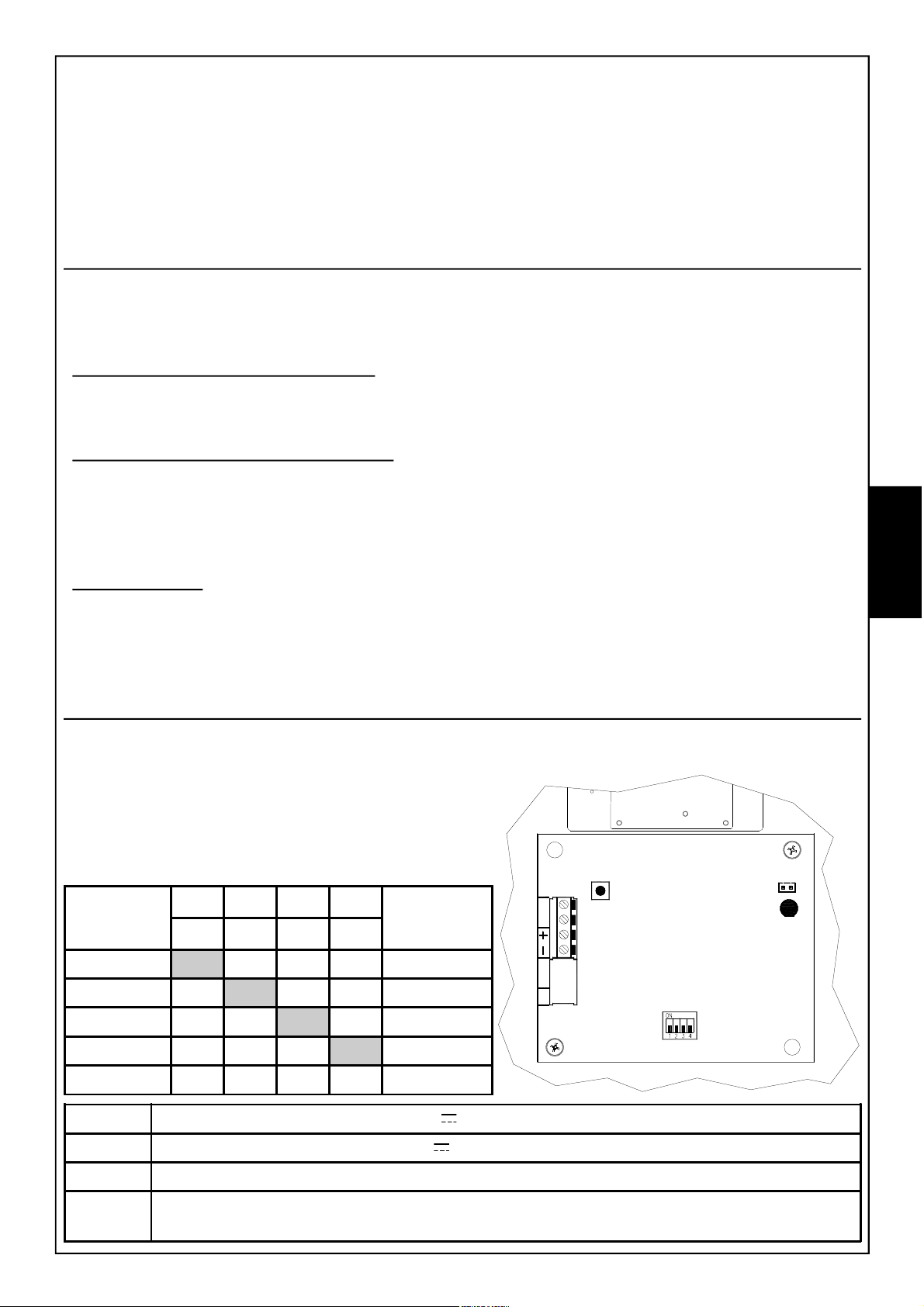

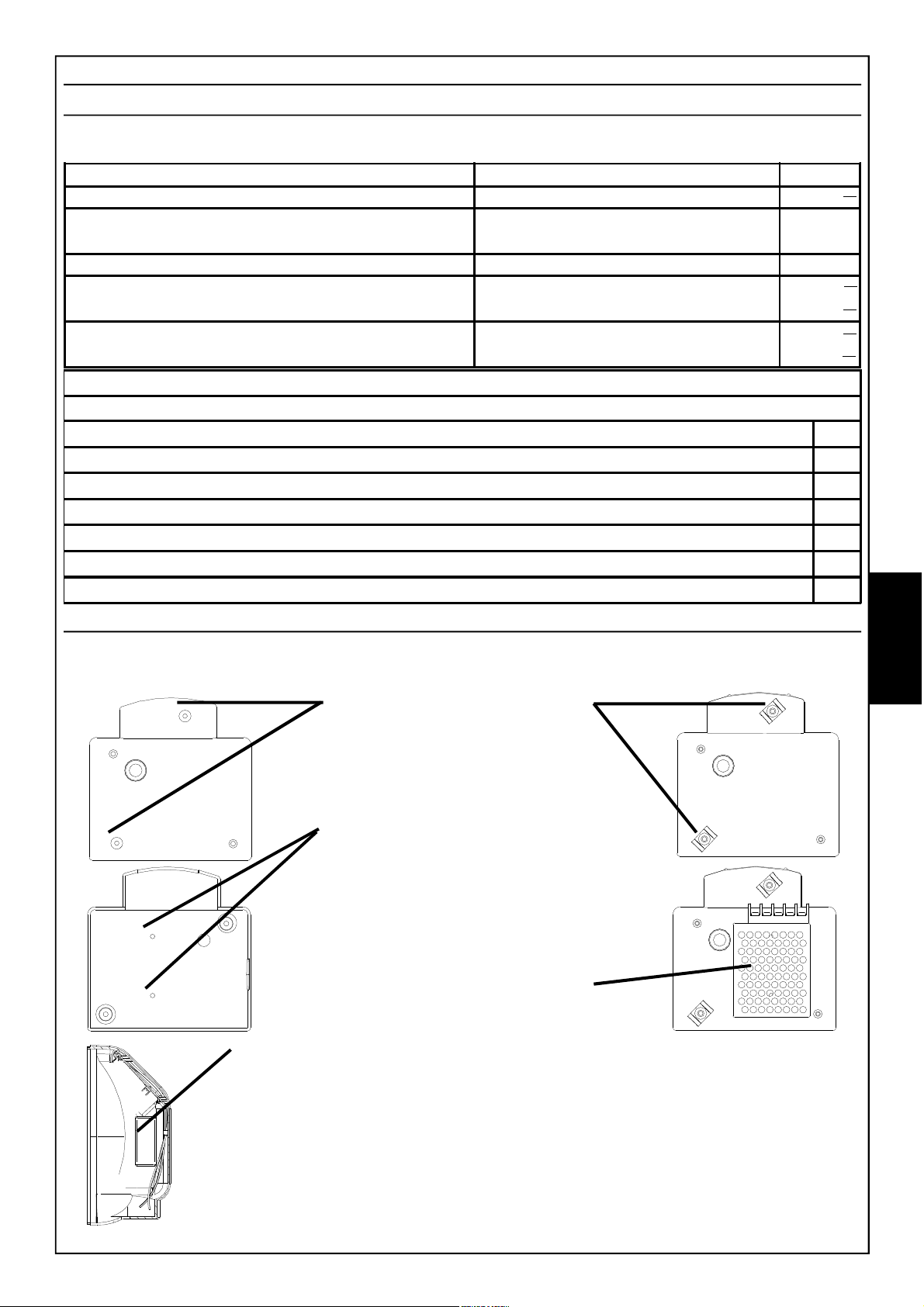

Transmitter

The transmitter is made of a planar microwave emitting a narrow and directional higly-stable low

power beam.

A 4-dip-switch for setting working frequency is on board.

Check that the transmitter working frequency set is the

same as in the receiver coupled

BM M

CHANNELS

F1

F2

F3

DIP DIP DIP DIP

1 2 3 4

ON OFFOFFOFF

OFF ON OFFOFF

OFFOFF ON OFF

BM Q PLUS

CHANNELS

GOLD

BLUE

SILVER

TAMPER

PB1

B A TT

SW1

S1

OFF

LED

LED

G

F4

F5

-

+

T T

S1

OFFOFFOFF ON

OFFOFFOFFOFF

supplying negative 12 V

supplying positive 12 V

n.c. output for protection agaist detector opening

closed

open

supplying Led enabled

supplying Led disabled

YELLOW

-

- 37 -

Page 4

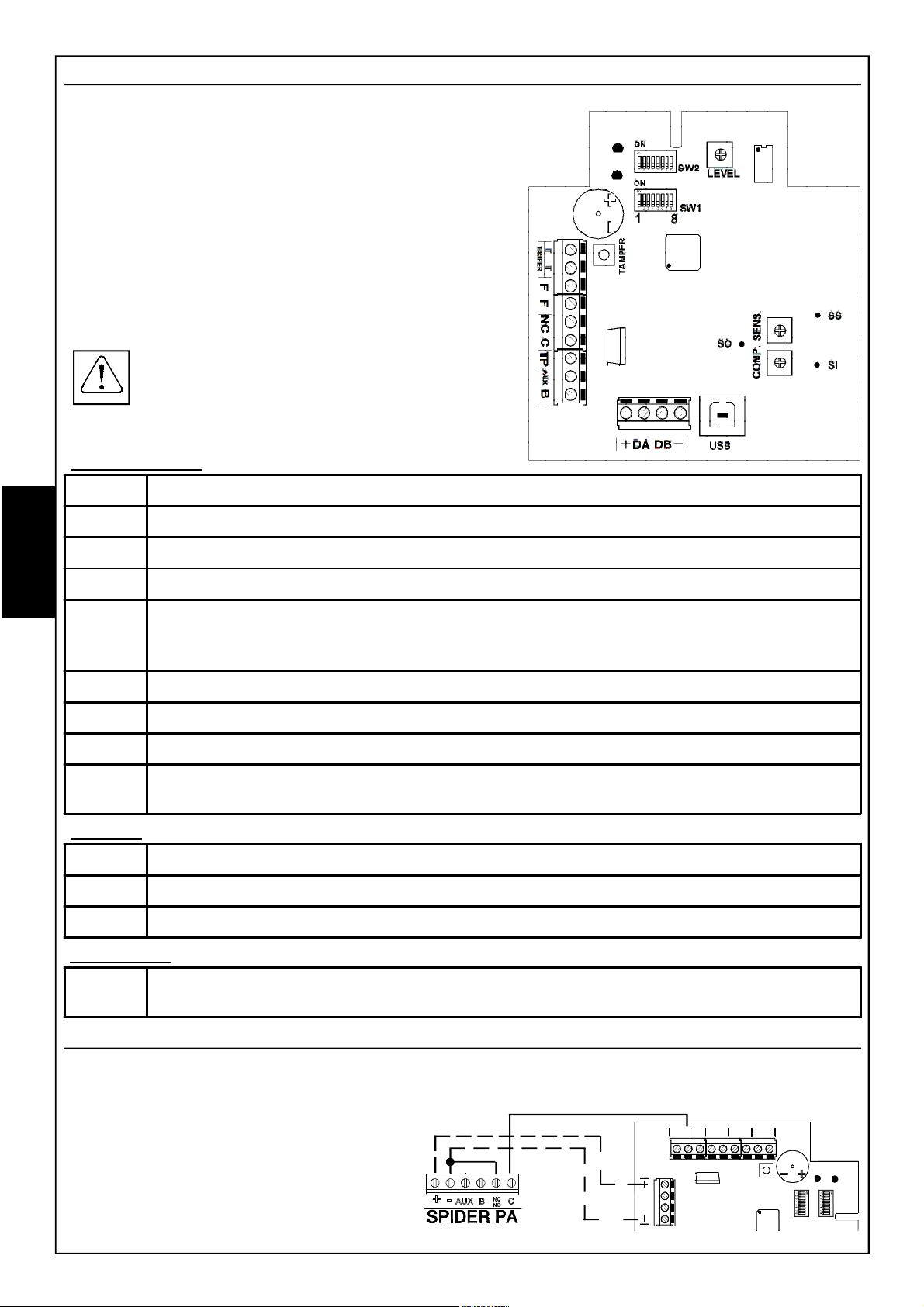

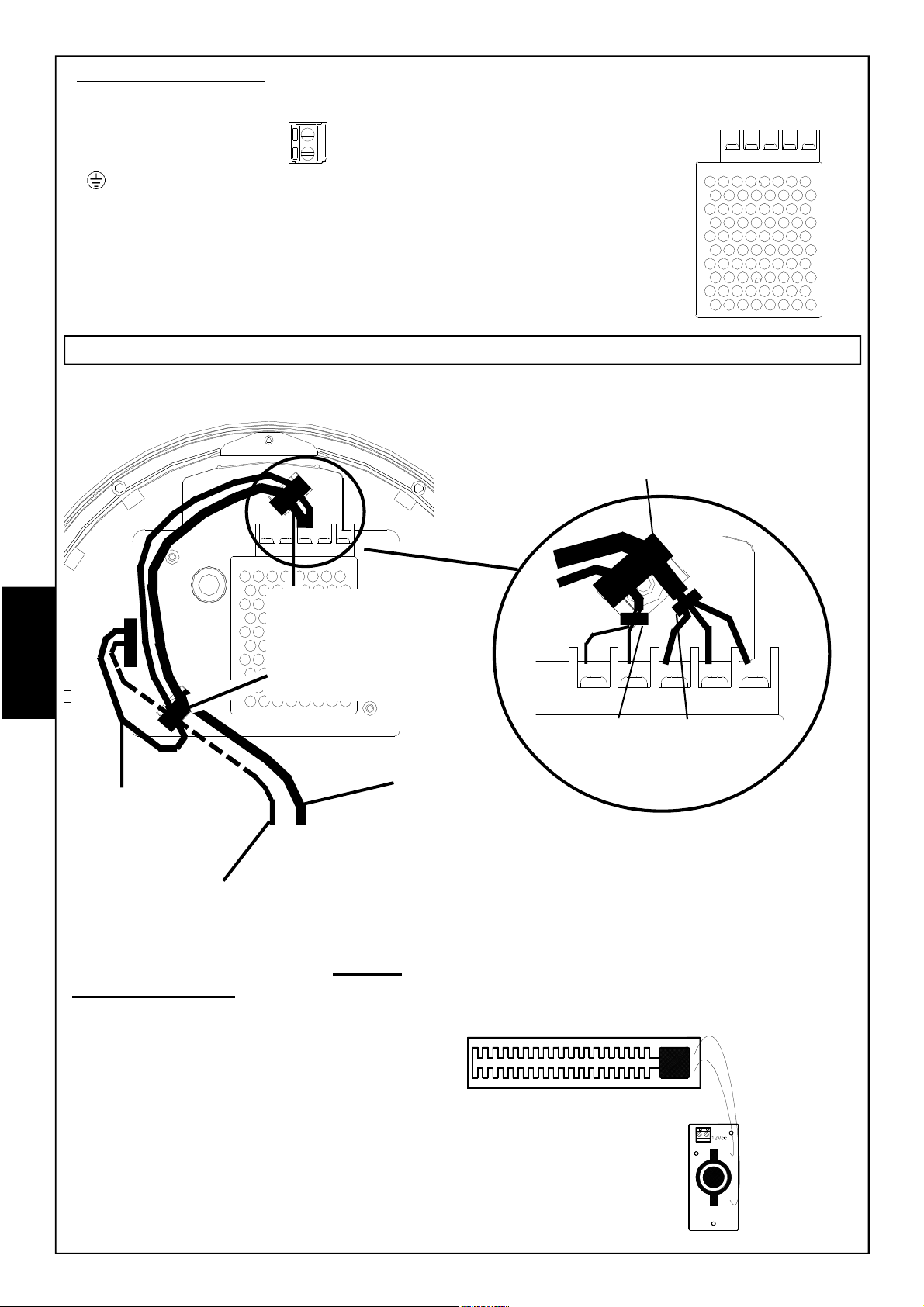

BM60HP - BM120HP - BM200HP Wiring systems receiver

SW1

SW2

The Receiver is made of a high sensitivity electronic circuit

coupled with the antenna; it captivates the signal transmitted

on its own channel and measures its intensity. Special

signal processing techniques enable compensating the

variations of the surrounding environment and

minimising the effect of any disturbances produced

by small animals or birds.animals or birds.

The electronic board contains two consoles with 8 dipswitches; the first 4 dips, of console SW2, are for the

setting of the work frequency.

Check that the working frequency of the

receiver is the same as set in the transmitter

coupled.

Terminal board

GREEN

LED

RED

LED

E

N

G

-

DA-DB

+

T T

F

F

C / NC

TP

AUX

B

Trimmer

LEVEL

SENS.

COMP.

negative power supply 12 V

serial port for serial connection in RS485

positive power supply 12 V

output normally closed for protection against detector opening

Disqualification signal relay; normally closed during the quiet status.

This relay opens in case the signal from the Transmitter is not received for 30

seconds.

alarm relay exchange normally closed

Test Point positive output for the displaying of the received signal

NC input for the connection of an outdoor detector

positive input: 12 V for stand-by; giving a positive to this clamp, the alarm relay

locks in quiet status

trimmer for the adjustment of the received signal

trimmer for the sensitivity adjustment; increases by turning clockwise

trimmer for the compensation adjustment; increases by turning anti-clockwise

Connection

USB

USB connector for PC and programming software connections

AUX Input

The AUX input allows detecting the opening or not of an auxiliary detector connected to this

clamp. This input is not balanced, but is normally

closed with negative reference.

- 38 -

CONNECTION EXAMPLE

TP

CNC

B

AUX

DA

DB

FF

TAMPER

TAMPER

T T

LED

LED

ROSSO

VERDE

ON

1

8

ON

Page 5

Extra power supply unit for BM 60-120-200 HPVAC

Tropicalised power supply unit

The power supply unit is a 15W switch with an output voltage of 13.8V and a maximum current of 1

A.

Mains power supply 100-240V~ (+/-10%) 50/60Hz

Voltage Rated supply voltage 13,8 V

Max. current absorbed from the mains

Maximum current available Power supply unit 1A

Output voltage at 110-230V - 10%

Output voltage at 110-230V + 10%

115V~

230V~

empty

With maximum load

empty

With maximum load

100 mA

13,8 V

13,6 V

13,8 V

13,6 V

ACCESSORIES SUPPLIED

Clips

Cable locking clips

Wire locking clips

Battery fastening

Clip screws

4.5 mm wide - 120 mm long 2

2.5 mm wide - 98 mm long 2

7.5 mm wide - 250 mm long 1

ø 4.2 - 6.5 mm long 2

Power supply unit screws M3 x 4 2

Buffer battery connection wire with F 1 Amp L250V fuse 1

Installation

Both in the receiver and the transmitter, the power supply unit must be fastened to the protective

cover of the electronic board:

Fasten the two clips supplied to

the two turrets, with the Ø 4.2 x

6.5 mm self-threading screws

supplied.

Using the marks on the inside of

the cover, make two 3 mm holes

to fasten the power supply unit in

place.

2

E

N

G

Fasten the power supply unit in

place using the two M3 x 4 screws

supplied

The 12 V 0.8 Ah Y08A12 buffer battery (optional) (article code 1143118) (to be

fastened in place using the clip supplied) is housed on the lower part of the

back cover of the barrier, which must never exceed the dimensions of 65 mm

high, 96 mm wide and 25 mm deep.

To connect the Y08A12 battery, use the wire supplied, with the protective fuse

F 1A L250V and the connector for release if the cover comes open. If you use

a different battery with the same characteristics, it is necessary to eliminate the

connector in order to connect it to the power supply unit in the most appropriate

way.

- 39 -

Page 6

External connections

BATTERIA

The power supply unit must be connected as follows:

-

(1) V+

(2) V(3) Earth

(4) Neutral 220V ~ N

(5) Live 220V ~F

Insert an omnipolar network switch in the electric installation of the building.

Connect the input of the mains voltage to the terminals marked L N (AC) and

the + and the - of the barrier board to those marked V+ e V- respectively.

The input for the mains power supply must be connected with double insulation wires

IN ALIM.

To be connected to the entrance of

+

the TX and RX board, respecting the

polarities

To guarantee electric safety, the wires must be

fastened in place using the clip directly on the

protective sheath

1 2 3 4 5

E

N

G

Fasten the sheath of the

wires in the set points,

using the bigger clips

supplied.

Power supply

12 V board

Signals to the central control unit

In the case of serial connections, in

addition to the DA and DB clips, it is

necessary to connect the power

supply negative from the power

supply unit to the central control unit,

and we recommend the use of 0.5mm²

section sheathed wires.

Power supply

220 V ~ main

The 3 wires for the 230 V ~ mains power supply

and the 2 wires for the 13.8 V power supply must

fastened securely together with their own clip

(as shown in the figure) to stop them coming

into contact with sensitive parts of he barrier

if they come loose from the terminal.

Wire clip

(use the two small ones

supplied)

In the BM 60 - 120 and 200 HPVAC barriers it is possible to feed

the TERM 1 module (Optional) (Article code 1143102) directly with

the power supply unit on the barrier, inserting a protective fuse

F500mAL250V.

- 40 -

Page 7

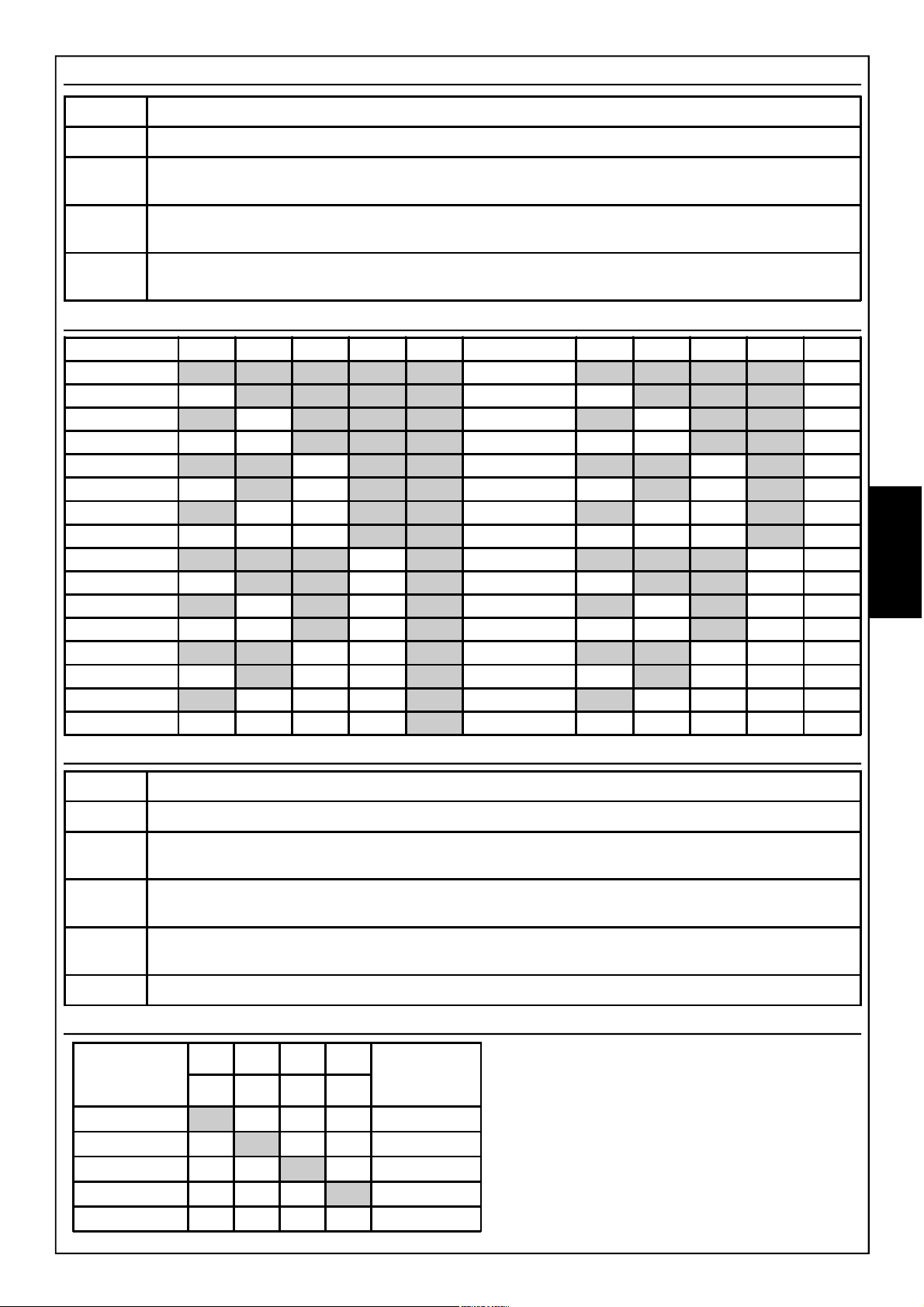

DIP SWITCH - SW1

DIP Associated function

1 .. 5

6

7

8 ON -Active AUX input, the barrier reads the input

Selection serial addresses of the barrier - see addresses table

ON - Compensation activated

OFF - Compensation deactivated

ON - enables recording of the events even with lock engaged (B)

OFF - events recording disabled with lock engaged(B)

OFF - Excluded AUX input, the barrier does not consider the input

Serial addresses table - SW1

Detector DIP1DIP2DIP3 DIP4DIP5 Detector DIP1DIP2 DIP3DIP4DIP5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ON ON ON ON ON

OFF ON ON ON ON

ON OFF ON ON ON

OFF OFF ON ON ON

ON ON OFF ON ON

OFF ON OFF ON ON

ON OFF OFF ON ON

OFF OFF OFF ON ON

ON ON ON OFF ON

OFF ON ON OFF ON

ON OFF ON OFF ON

OFF OFF ON OFF ON

ON ON OFF OFF ON

OFF ON OFF OFF ON

ON OFF OFF OFF ON

OFF OFF OFF OFF ON

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

ON ON ON ON OFF

OFF ON ON ON OFF

ON OFF ON ON OFF

OFF OFF ON ON OFF

ON ON OFF ON OFF

OFF ON OFF ON OFF

ON OFF OFF ON OFF

OFF OFF OFF ON OFF

ON ON ON OFF OFF

OFF ON ON OFF OFF

ON OFF ON OFF OFF

OFF OFF ON OFF OFF

ON ON OFF OFF OFF

OFF ON OFF OFF OFF

ON OFF OFF OFF OFF

OFF OFF OFF OFF OFF

E

N

G

DIP SWITCH - SW2

DIP Associated function

1 .. 4

5

6

7 ON - Enabled alarm signal red LED

8 Unused, for future uses.

Microwave frequency selection - see frequencies table

ON - Enabled microwave signal quality green LED

OFF - Disabled microwave signal quality green LED

ON - Enabled alarm signal buzzer

OFF - Disabled alarm signal buzzer

OFF - Disabled alarm signal red LED

Frequencies Table - SW2

BM HP

BARRIER

CHANNELS

F1

F2

F3

F4

F5

DIP DIP DIP DIP

1 2 3 4

ON OFFOFFOFF

OFF ON OFFOFF

OFFOFF ON OFF

OFFOFFOFF ON

OFFOFFOFFOFF

OLD

BARRIER

CHANNELS

GOLD

BLUE

SILVER

YELLOW

-

- 41 -

Page 8

E

N

G

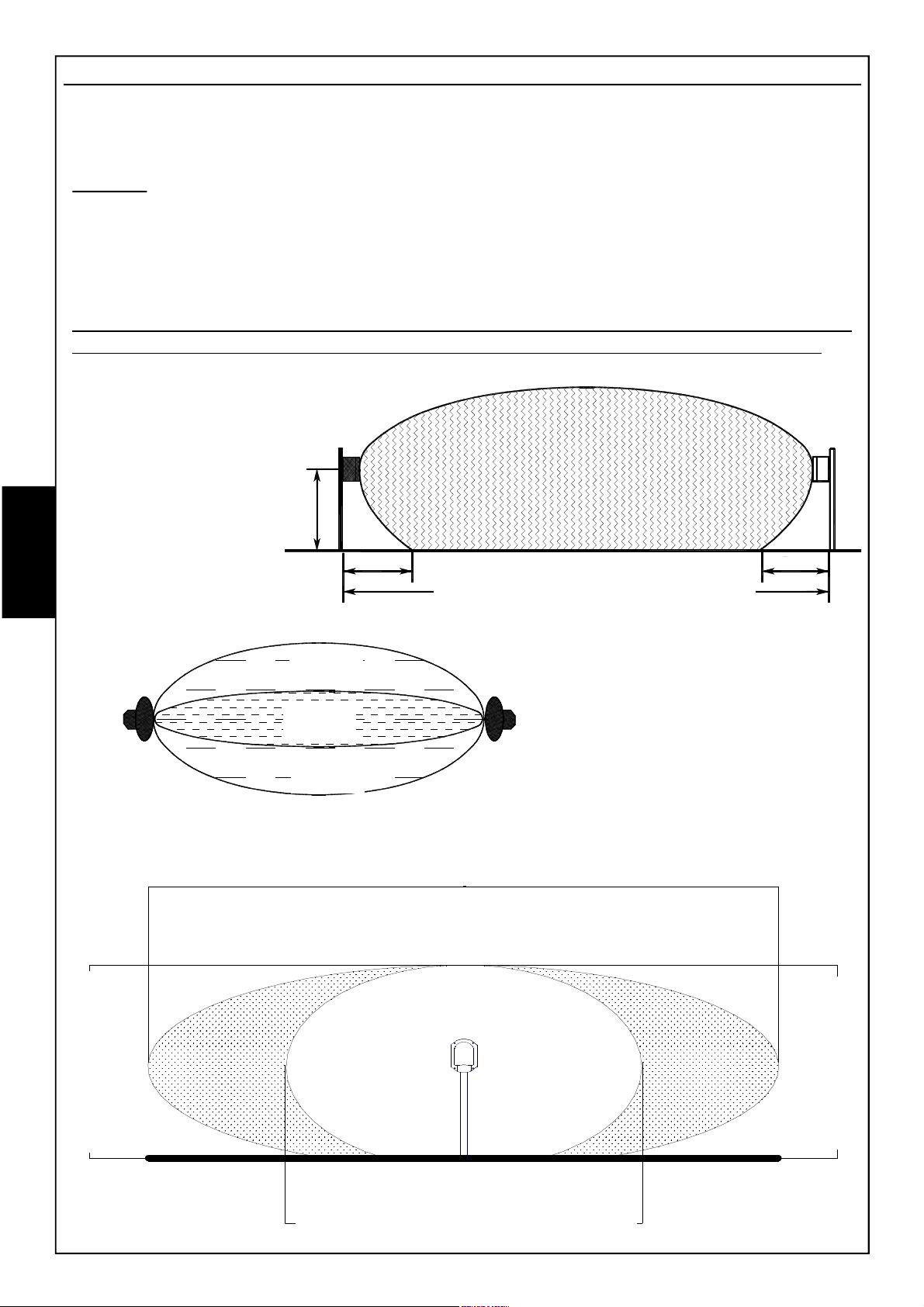

Description of working

The two units (transmitter: TX and receiver: RX) must be positioned facing each other at the two

ends of the distance to protect. Be aware that the nature of the ground underneath, or special

weather conditions might affect the real range.

Working

The transmitter emits a modulated microwave signal (10,525 GHz), which is received by the

receiver and whose amplitude is compared with the programmed alarm threshold.

When an intruder crosses the microwave area, it causes a signal-intensity decrease under a

minimum level fixed; the receiver shows the alarm condition, lighting up a red Led indicator and

opening the contat of the alarm relay.

If the signal of the transmitter is not received for over 30 seconds, the alarm relay could go back

to quiet condition and the negative to terminal D (disqualification) fails until signal restoring.

For this reason, in the hard-wired system, it is suggested to make the connection described

in the chapter concerning

disqualification.

The drawings identify the

natural shadow areas in

the immediate

sorroundings of the

two units, which extend

for about 3 meters, in a

typical installation at 1 - 1,2 m height.

1 - 1,2 mt

3 meters

3 meters

BM60HP : max 60 meters

BM120HP : max 120 meters

BM200HP : max 200 meters

sensitive

zone

alarme

zone

sensitive

zone

Note: the diagrams of the patterns shown in the drawings are an indication and a guide

during installation. They do not represent the real radiation diagram of the antennas as

they may be subject to variations due to environmental context.

BM120HP

10 meters

Alarm zone

Sensitive zone

2 meters

BM60HP

BM60HP

6,5 meters

The sensitive zone shown in the drawings is to

be taken into consideration, as a big target.

Overpassing this area might cause the

same perturbations as a small body

passing the alarm area, that’s to say might

cause false alarms.

BM200HP

16 meters

Sensitive zone

3 meters

BM60HP 1,2 meters

BM120HP 3 meters

BM200HP 4 meters

- 42 -

BM120HP-BM200HP

Page 9

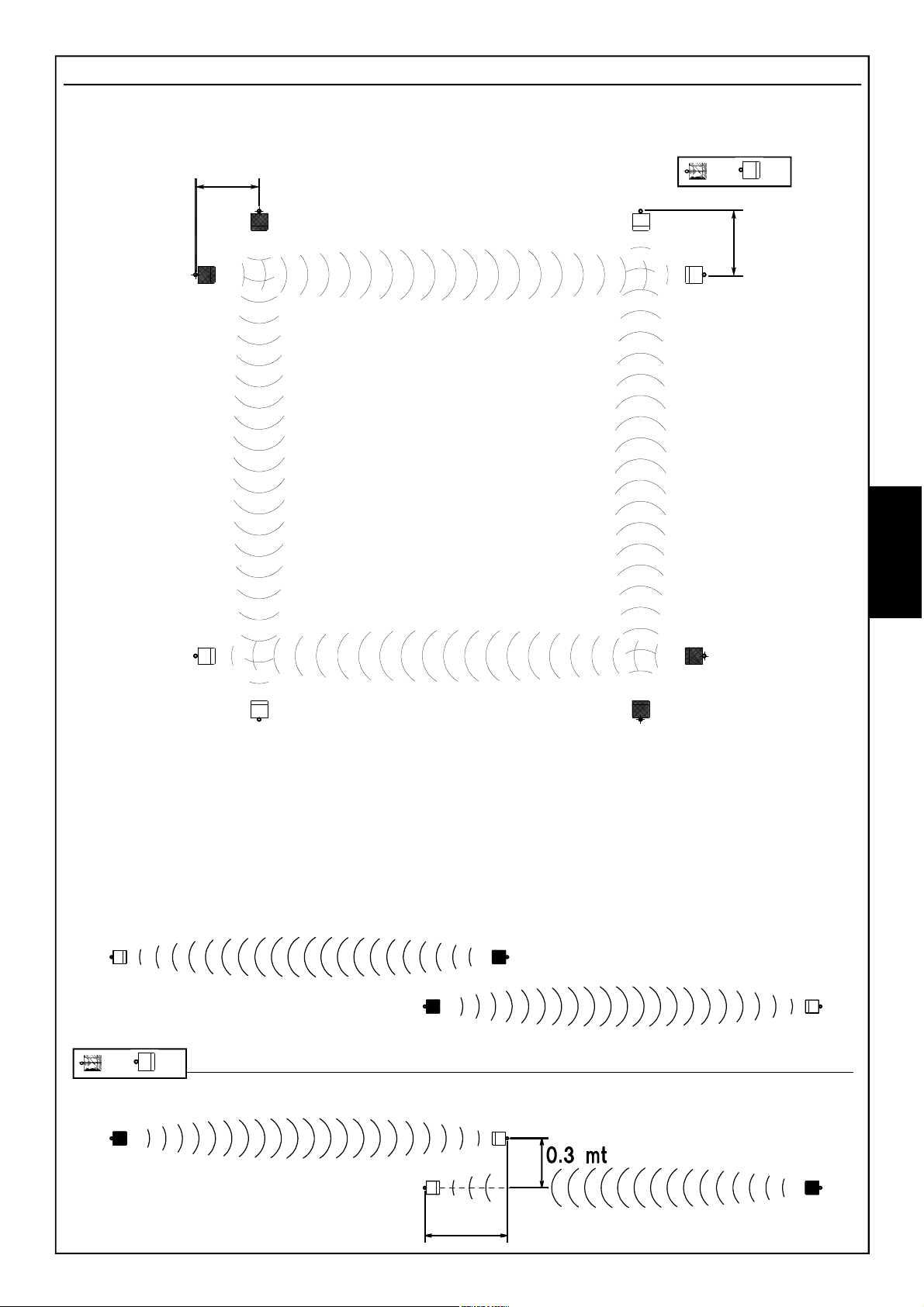

Positioning of the beams

For a correct installation of the system, choose carefully the positioning of the two units, according

to following advice:

3 mt

The typical installation of

BM HP system consists in

sorrounding the area to be

protected by use of more

beams couples in order to

obtain a proper perimetric

fence

TX

RX

3 mt

E

N

G

Drawings identify the correct positioning of transmitters and receivers, in order to eliminate any

possible shadow area.

The drawings here below show how one or more couples of beams have to be positioned for

reaching the distance required.

BE CAREFUL: only elements with different frequencies (F1, F2, F3, F4, F5) and of the

same type (TX/TX or RX/RX) can be installed in proximity one to the other; in order to

avoid interferences between transmitters and receivers belonging to different couples.

TX

RX

6 mt

- 43 -

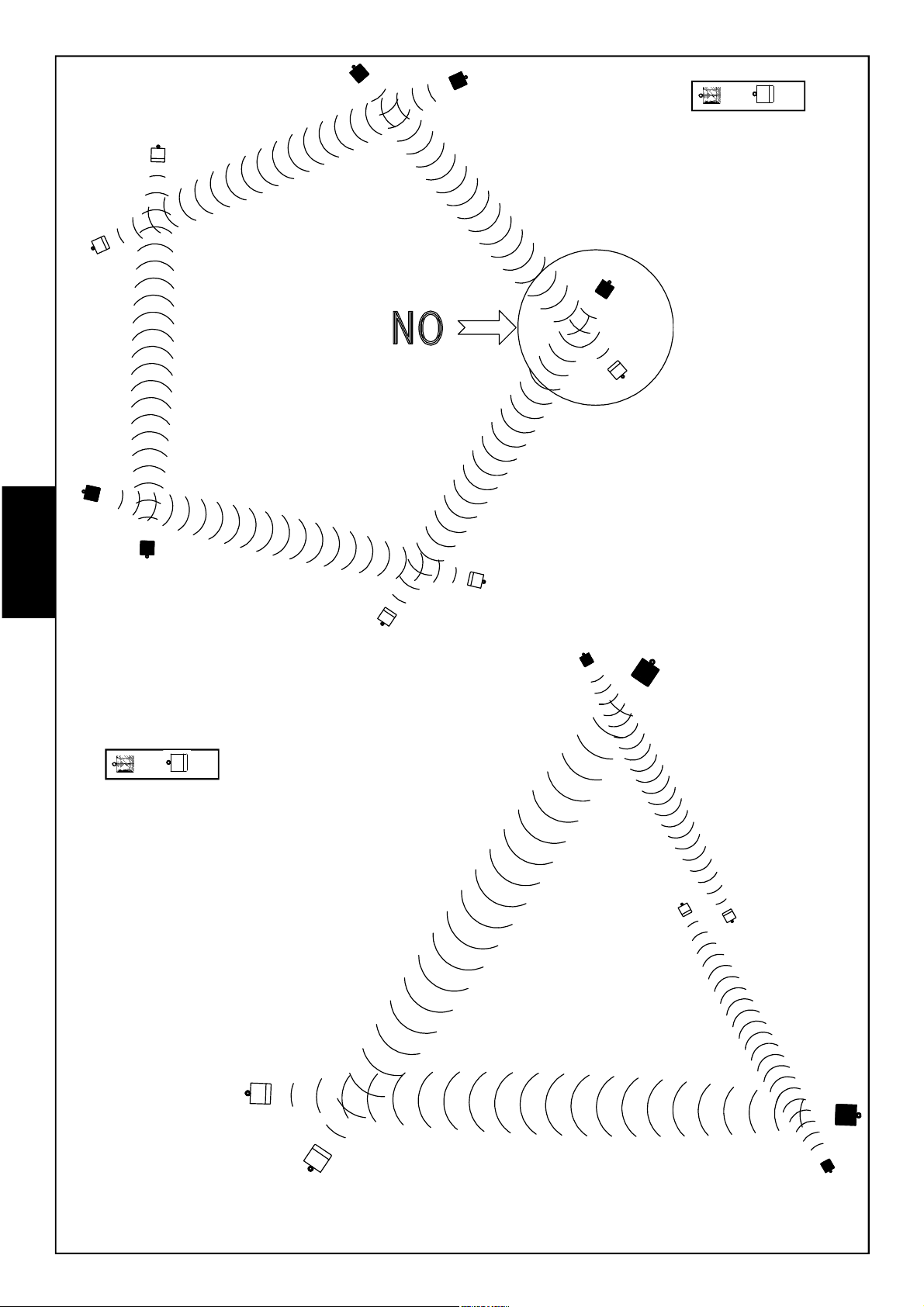

Page 10

E

TX

It is absolutely

necessary to

avoid installing a

transmitter near a

receiver belonging

to another couple

RX

N

G

TX

RX

If, in a perimetric installation, the

beams cross the patterns, they

must always be installed in

pair (2, 4, 6 etc.)

- 44 -

Page 11

In order to extend the height of the protection, two couples of beams

can be installed as shown in the picture. In this case, it is

suggested to use couples of beams having

close working frequency (two couples

with frequency F1 and F2 or F3 and

F4)

E

If the fence is made of bushes or metal fences

subject to possible movement, the minimum

distance must be 1 meter for BM60HP

and 10 meters for BM120HP and

BM200HP.

N

G

BM60HP : 1 meter

BM120HP : 10 meters

BM200MHP : 10 meters

- 45 -

Page 12

A corridor large not less than 0,6 meters for BM60HP

and not less than 2 meters for BM120HP and

BM200HP, must be left free from obstacles

between transmitter and receiver; a clear

visual must always be granted in this

area

E

N

G

BM60HP : 0,6 meters

BM120HP : 2 meters

BM200HP : 2 meters

BM60HP : 1 meter

BM120HP : 5 meters

BM200HP : 5 meters

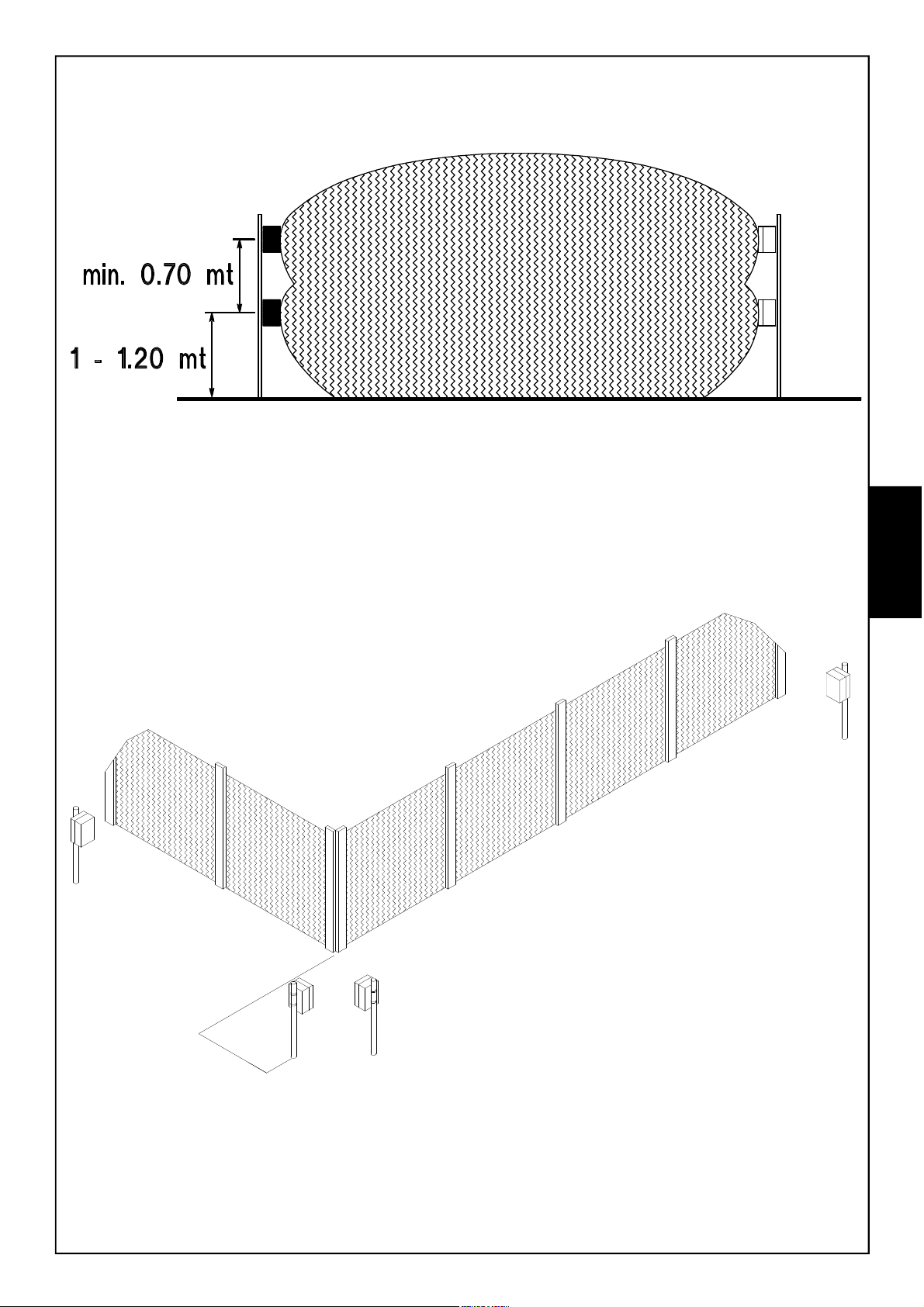

The suggested height for the installation is

between 1 and 1,2 meters.

If a couple must be installed

near a building or a fix fence, a

minimum distance of 1 meter for

BM60HP and 5 meters for BM120HP and

BM200HP must be kept.

This is required in order to avoid false alarms

caused by reflection of microwave

beam.

- 46 -

Page 13

It is possible to install the system BM60HP also to protect

walls. In this case, the system of installation shown

in the drawing can be used, in order to avoid

false alarms caused by cats or birds. In

this case also, the height from

ground must be between 1 and

1,2 meters.

happen to have a very high

sensitivity in the centre of the

protected area and near the ground,

because of special reflection of the ray.

Because of ground

characteristics, it may

E

N

BM60HP : 4 meters

BM120HP : 10 meters

BM200HP : 10 meters

BM60HP :1 meters

BM120HP : 5 meters

BM200HP : 5 meters

BM60HP) or 5 meters (or BM120HP and BM200HP) from the

fence.

G

It is also possible

to install the system

BM HP along a transited

street with transit; in this case,

it is necessary to keep a minimum

distance of 4 meters (for BM60HP)

or 10 meters (for BM120HP and

BM200HP) between the sight-line of the

couple and the area of transit of the cars.

In case a metal fence is placed between the

transit area and the area to be protected, detectors

must be kept at a minimum distance of 1 meter (for

- 47 -

Page 14

E

N

•Should any pet be present and free in the installation area, it is suggested to carefully adjust

sensitivity, in order to avoid the risk of false alarms due to the passage of these small targets

in the areas which are very sensitive at the ground. To further decrease this risk, the height

of installation of the couple can be increased a little bit.

•Should trees or bushes affect the protection corridor because of the wind, false alarms

might occur. In the same way, if the system is installed near a hedge, this one must be

carefully attended to avoid darkening the protected area.

•High grass ad bushes decrease sensitivity at groud level.

•Any obstacle or important difference of level in the ground in the protected area, create

shadow-areas and very sensitive zones.

G

The BM HP system has a good tolerance against bad weather conditions and temperature

variations; nevertheless it is necessary to care for following situations:

• RAIN: strong rain only causes a decrease of signal power whilst water puddles may increase

sensitivity at ground level

• SNOW: snow fall does not affect beams sensitivity, but the system cannot work if it is entirely

covered by the snow; so take care in areas with frequent and abundant snow

• FOG: a very thick fog can decrease the signal for 1/3. Because of the limits of compensation

of the gain automatic control (C.A.G.) , it is suggested to install the beams couple at a

distance not exceeding 85% of max range,in the regions where a thick fog is frequent.

The temperature working concditions are between - 20°C and + 55°C; if the use is required in

areas where temperature goes lower than 0°C, it is necessary the permanent installation of the

heating kit, which requires an alternate current at 12 V for a consumption of 150 mA for any

element of the beam (see Kit TERM for installation of heating kit).

- 48 -

Page 15

Advice for installation

The fixing bracket

is pre-arranged

for the

installation

on a steel

pipe, whose

external

diameter is 40

millimeters

Thanks to the two slides on the sides of

the fixing bracket, it is possible to adjust

the inclination (max 5° upwards

and 5° downwards) in both

transmitter and

receiver.

Two

notches on

the slides indicate the

max inclination

E

•Use special care for the

cables entry, in order to avoid

moisture and rain penetrating

inside the box.

•For cable entry inside the

covers of board protection, use the

cable-loops given within (as shown in the

drawing)

• In the hard-wired system use anti-fire shielded cable (2 x 0,75 mm² + 8 x 0,22 mm²)

In the wireless system, connect the support pole to ground and use an additional

shield for the supplying cable 220 V ~ inside the pole, in order to create a double

isolation.

•Before installing the support poles in a definitve way, it is suggested to make a trail installation

in order to find out the best position of alignement for the best effective detection:

1 Position the beams couple in the centre of a free area, respecting the minimum distances

for beams positioning and the installation height

2 Supply the transmitter and the receiver with two batteries and orientate TX and RX one

towards the other

3 Check the signal on TP and adjust it at 7,3 V .

4 Move the two beams towards RIGHT/LEFT within 30 - 50 cm and Up/Downwards

checking the variations of signal of TP and identifying the signal max point.

5 Once identified the best position, fix the brackets.

N

G

•During positioning and adjusting of the Receiver, take care not to have big bodies inside the

sensitive zone, which will then be moved when the system is in use, such as lorries or cars;

the adjustment could be highly affected.

- 49 -

Page 16

E

N

Transmitter installation inside the wire system

1) Choose the position of the Transmitter, fix it at the wanted height and adjusted as precisely as

possible in the direction where the Receiver will be mounted.

2) Position the 4 dip-switches depending on the chosen work frequency.

3) Connect the power supply (from 11.5V to 15V ) and check the functioning of the Transmitter,

by switching on the red LED; by removing the bridge S1 (Led Off), the LED can be disabled to

decrease absorption.

4) Connect the TT clamps of the electronic board tamper to the tamper proof line of the control

unit.

Receiver installation inside the wire system - UNIVERSAL

1) Install the Receiver in the envisioned support point, at the same height as the Transmitter.

2) Position the 4 dip-switches depending on the chosen work frequency.

3) Connect the power supply (from 11.5V to 15V ) to the positive + and negative - clamps.

4) Upon commissioning, the LED and buzzer, if enabled, will flash for a stabilising time

5) Connect the C and N.C. alarm outputs and the "FF" disqualification signal output to the

detection line of the control unit and the electronic board tamper TT clamps to the tamper

proof line of the control unit.

Receiver installation inside the wire system - SERIAL

1) Install the Receiver in the envisioned support point, at the same height as the Transmitter.

G

2) Position the 4 dip-switches depending on the chosen work frequency.

3) Connect the power supply (from 11.5V to 15V ) to the positive + and negative - clamps.

4) Upon commissioning, the LED and buzzer, if enabled, will flash for a stabilising time

5) Connect the DA and DB serial communication clamps on the barrier, to the respective on

the satellite. The alarm signals, tampering, fault and all technical signals will be reported

using this connection.

• It is possible to connect on the same serial port RS485, up

to 32 barriers.

• For connection of serial communication terminals DA

and DB only, shielded cables of 0.5 mm² are suggested,

Towards the

other barriers

whilst the section of the supplying cables (+ and -) of the

devices connected to the serial has to be chosen by the

installer according to the system and to his experience

• The total length of the connection cable can be 600 meters

and must be subdivided for all connected electronic boards.

Addressing

Should installation envision more points, the installed barriers must be addressed using

the dip-switch, on the electronic board of the same barriers.

The numbering of the barriers must be progressive and there cannot be more peripherals

with the same serial address.

Main warning for the wiring system

We recommend reaching the two units by means of flexible and water proof plastic

piping and carry out connections using shielded conductors.

The choice of section of the conductors to use for the connections must be carried out

depending on the distance from the power supply source, to guarantee a continuous

minimum voltage of 12 Vol, on both units. Malfunctioning may occur should the power

supply voltage drop below such value.

- 50 -

Page 17

Adjustments

1)Orientate at sight the device in the

direction of the transmitter and

connect a voltmeter betwen the negative (-) and TP terminal (Test

Point) on board

GREEN

LED

RED

LED

2) Orientate the device in horizontal

7,3 Volt

way, looking for the position giving

the max reading; in case it is over

7,3 Volt tthe signal level must be

reduced by use of LEVEL trimmer,

in such a way as to bring the signal

to the best point of working, that’s

to say 7,3 Volt

•It is possible to have a high value

also with receiver not aligned to

transmitter; in this case it could be

a reflection of the beam

transmitted, which must most be

taken into consideration.

•In case the signal does not reach 6,8 V having LEVEL trimmer at max, move the device in

vertical way within a limit of 10-20 cm.

•Shouldn’t it be possible to reach the min. value, it will be necessary to decrease the distance

between receiver and transmitter or look for a better alignement position

E

N

G

3)Check the quality of the signal received, keeping in mind that in absence of seeming

movements inside the protected area:

LED

LED

GREEN

VERDE

LED

ON

•Green Led on fix: there is no signal noise

•Green Led quick or slow flashing: the signal noise is low but

RED

ROSSO

LED

ON

is anyway detected by the beam

•Green Led slow flashing (off for about 1 second) , the signal noise

is more important and it is near to the intervention threshold of the beam

In order to have a more precise indication on the quantity of noise and to have the possibility

of making adjustments according to the environmental context, we suggest to use the software

HPSOFT

4) after all tests, LEDs can be deactivated in order to reduce the consumption of the receiver

Note: Thanks to the digital trimmer, the barrier has the possibility of self-calibrating the signal

level (LEVEL) and to compensate the environmental variations, guaranteeing the stability of

the signal. Fog, snow, gradual variations of the reflecting surface will be automatically

compensated by the barrier, both in positive and in negative, within certain values. Should

the requested variation be above that tolerated by the system, the disqualification signal

(FF) will be had.

- 51 -

Page 18

Measurements of the signal by oscilloscope

In the drawing below, the points where to connect

the oscilloscope are shown:

Punto A

(ss)

Indicates the range

of the received

signal

Punto C

(SO)

Indicates the alarm

threshold

GREEN

LED

RED

LED

E

N

G

Punto B

(SI)

Indicates the quality

of the received

signal

In the graphic here below the wave shapes concerning the signal quality are shown:

1- the beam is in quiet condition and there is no passage of people or any perturbation due to

moving objects, the level is fix . Check that the quiet condition is as described.

2- the beam is disturbed or we are crossing a sensitive area (partial darkening)

3- the beam has been darkened and there is an alarm situation

.2 s

Point B shows the quality

0.5 V

.2 s

0.5 V

B

of the signal received

Sensitivity

range

0 V ž

.2 s

2 .1 V DC

3 .1 V DC

Point C shows the alarm

C

threshold (trimmer sens.).

In this case the sensitivity

is adjusted at the half

x

10

x

10

- 52 -

Page 19

Sensitivity Adjustment

1) Turn the SENS trimmer anti-clockwise in the minimum sensitivity position and carry out a

test by walking in the central point of the covered zone (point with lower system sensitivity)

and check the behaviour of the green LED.

2) If required, progressively increase sensitivity until the wanted reply degree is obtained.

3) 3) After each sensitivity adjustment, wait for approx. 20 seconds for all signals to be set and,

therefore, carry out a new test.

Attention: an excessive sensitivity can cause unwanted alarms in critical conditions (intense rain,

snow, etc.).

4) 4) A special compensation circuit has been included in the BMHP system, adjustable by

means of the COMP trimmer (turning it clockwise increases compensation); this circuit

records the disturbances produced within the microwave field when the target is nearing or

moving away, transversally at lobe, and automatically increases the sensitivity of the Receiver

to facilitate detection when the target crosses the central line of the lobe. The compensation

circuit can be completely excluded using DIP6=OFF of SW1. An excessive compensation

can cause an unwanted alarm of the barrier when objects move near the lobe.

If wanting the complete management of the adjustments, using the software (mod.

HPSOFT), the trimmers "SENS" and "COMP" and DIP6=ON must be set halfway

E

Signal

Alarm

thresold

Signal

Alarm

thresold

N

G

ALARM

Extreme Compensation

ALARM

Correct Compensation

CAUTION

(BM120HP and BM200HP ONLY)

Due to larger pattern and to compensation circuit, BM HP beams are more sensitive to

perturbations caused by moving objects in the areas near the corridor protected.

Consequently, the security distance to be kept in the installation, especially in respect to

the transit of vehicles, trains, or presence of big trees or bushes, must be increased. In the

special case of a street with vehicles transit, parallel to the protected area, it is suggested

to keep a minimum security distance of 10 meters.

- 53 -

Page 20

E

N

G

Kit TERM (optional) Resistence fo inside heating

•For installation in an indoor or outdoor place where

temperature can go lower than 0°C, it is

necessary to use the heating kit Term 1 in

both Receiver ad Transmitter. This has to

be done in order to avoid formation of

condensation which might affect the good

working of the electronic circuit.

•The optional heating kit, is made of a circuit

where an electromechanical thermostat, a

heating resistence and a terminal board for

connection to supplying, are placed.

•Supplying must be given by means of an

external trasnformer with output at alternate 12V ; the consumption of any heating

resistence is 150 mA at the tension of alternate 12 V.

•The thermostate intervention occurs taking

off supplying to the resistence when the temperature of 30° C is reached inside the box.

Supplying: alternate 12 V

Consumption: 150 mA max

Transformer: input: 220 V ~

output: 12 V ~

for 4 couples of beams: 20 W power

Kit AMP (optional) Anti-removal

The anti-removal kit AMP is made of two bulbs,

whose function is sending an alarm in case of

tampering or removal of the beam from its support.

This kit must be positioned in such a way that one of

the bulbs is installed in vertical position compared

to the device and the other one in horizontal position

as shown in the picture.

This system allows a complete protection against any

attempt of :

- removal of the beam from the support

- removal of the supports from fixing points

The horizontal bulb must be positioned in such a way

that the contact opens as soon as there is an attempt

of moving the beam.

Before connecting the tamper line to the control panel,

check that the contact of single bulbs as well as

tamper line is closed .

Example: RX BEAM

- 54 -

Page 21

Disqualification (Important warning)

In order to prevent and signal misalignments caused with the system disarmed or by obstacles

interposed within the action beam of the barriers, for installations envisioning the UNIVERSAL

connection, it is essential to connect the disqualification output (FF clamps) in series to the alarm

relay exchange.

NOTE

The FF output supplies a normally closed relay exchange that opens when the signal level

drops below a minimum level for more than 30 seconds.

In the examples below, the control unit will signal the open zone, both in alarm and in

disqualification.

Balancing

resistance

SINGLE BALANCING

CONNECTION

Balancing

resistances

E

N

G

DOUBLE BALANCING

CONNECTION

The power supply must come from very low safety voltage circuit with the characteristics

of a limited power source protected by a fuse.

INSTALLATION AND MAINTENANCE MUST BE EXECUTED BY QUALIFIED

PERSONNEL

- 55 -

Page 22

Optional Brackets

The optional bracket mod. SB20 and mod.

SB60 can be used for installation to the wall

E

N

G

SB20

4 cm

14 cm

The bracket mod. SB20 has a wheelbase

of fixing holes in the wall of 4 cm

Optional bracket mod. SB60 can be used with

BM60HP

The bracket mod. SB60 has a base

rectangular 14x18 cm wheelbase of fixing

holes in the wall of 11x15 cm.

11 cm

SB60

15 cm

60 cm

SB130

130 cm

Optional brackets mod. SB120 and mod.

SB130 can be used for installation to the floor

The bracket mod. SB120 has a square base

of side 18 cm with a wheelbase of fixing holes

in the floor 14 cm.

SB120

120 cm

14 cm

14 cm

- 56 -

14 cm

Page 23

Special functions

Return to initial screen

Activation of the USB/Telephone connection, for the displaying and

Activation of the USB/Telephone connection, for the displaying and

Activation of the USB/Telephone connection for the customisation of

Access to the local archive of the signals recordings carried out

Access to the personal notes per system

Activation of the firmware upgrade procedure of the barrier

Thanks to the software from PC HPSOFT, it is possible to make the best use of the potential of

digital technology.

HPSOFT allows, for each digital barrier:

- Check:

- microwave signals

- outputs status (alarm - disqualification - tamper)

- input status (AUX)

- barrier diagnostic (temperature - test point - compensation on/off - power supply)

- alarms history with over 3600 recordings complete of time and date

- customised archive by the installer

- synoptic barriers status (if connected in RS485 to satellite)

- signals recording archive per barrier

- Management:

- sensitivity adjustment

- compensation adjustment

- valid signal threshold adjustment

- customisation archive dedicated to "FALSE ALARMS"

- customisation archive dedicated to "ALARMS"

- signals recording

- select the detection method:

- traditional detection mode

- ALARMIDENTIFY detection mode

- upgrade firmware (not active in PSTN/GSM)

E

N

G

These functions are active with USB connection in local, meaning directly connected on to the

digital barrier receiver, or in USB on XSATHP satellite or PSTN/GSM telephone connection.

Once the management software is installed, it is necessary to create a numerical "New Code" in

"Clients Master" and define that it is BM 60 - 120 - 200 HP.

management of the barrier settings

Activation of the USB/Telephone connection, for the simultaneous

displaying of the barrier status

management of the barrier alarms history

the signals library dedicated to the "Alarms/False Alarms"

manually by the installer

- 57 -

Page 24

E

Detectors Management

Access to this menu imposes to choose the type of connection; USB - PSTN/GSM.

For a connection in local it is necessary:

1- to power the barriers

2- to connect the barrier receiver to the computer using the USB connection.

note: if first connection, carry out the drivers loading procedure for the recognition of the peripheral.

3- to select the barrier address on HPSOFT and then choose "connect"

Once connected, it will be possible to display the information relating to the barrier in real time,

from the field signal to the outputs status; it will also be possible to vary the functioning parameters

and adjust the date and time like on a PC.

Adjust time and date

Select "Align time" to synchronise the time and date to that of the PC.

This setting is important for managing the events history of the barrier

N

G

Parameters displaying

These parameters highlight:

Temperature: : indicates the

functioning temperature of the receiver.

Test Pont: indicates the value of the

received signal.

Compensation: indicates, if the function is active (DIP 6 = ON), the integration value.

Power supply: indicates the power supply present on the receiver

Outputs Status

This section indicates the status of the receiver:

Alarm: if the barrier is in alarm, the red LED activates

Tamper: if the barrier is tampered with, the red LED activates

Disqualification: if the barrier is in disqualification (lowering of

the constant signal (>30sec.)), the red LED activates

Aux: if the barrier's auxiliary input is open, the red LED activates (DIP 8 =OFF the barrier does

not consider the input)

Recording

The "REC" button allows the installer to start recording what happens to the

barrier on the PC. All signals will be directly saved on to an archive on the

PC that can be accessed at any time. This function is very interesting when

wanting to check the detection zones of the barrier or monitor its behaviour.

The "STOP" button interrupts the recording.

It will be requested to "Enter a note" used to distinguish

the various files of the recordings history.

To display, it is necessary to consult "Recordings

Archive" and select the file.

- 58 -

Page 25

Oscilloscope function

This application enables checking the barrier signals in real time.

Timescale: it selects the timescale on the axis of ordinates.

Traces to display: it enables the displaying of traces.

Traces to display

Green L.

Yellow L.

Red L.

White line: it indicates the signal received from the barrier

Red line: it indicates the set threshold alarm

Green/yellow line: it indicates the valid signal threshold; the signals inside the two lines do not

start the integration circuit of the signal (compensation)

Signal received

Œ

The quality of the signal depends on many factors, mainly

environmental. A stable installation passes through the research

•

Ž

•

for minimum disturbance on the barrier. For a correct installation,

it is important to keep away all those objects that might oscillate in the presence of wind, for example, hedges, branches,

metal nets, etc. It is some times sufficient to slightly adjust both

pairs from the opposite side compared to the possible

disturbance to make the barrier stable, being careful that this

does not jeopardise the signal level.

EXAMPLES OF RECEIVED SIGNALS

ΠGood signal

•

• Slightly disturbed signal

E

N

G

‘

Ž Disturbed signal - it is necessary to check if, by

adjusting, the disturbance reduces.

• Very disturbed signal - it is necessary to check there

are no oscillating objects within the zone of interest

of the barrier; it may be necessary to move the

barriers away from the disturbance.

• Very disturbed signal with accentuated risk of

unwanted alarms.

‘ Alarm signal.

- 59 -

Page 26

Low Sensitivity

Middle Sensitivity

Hight Sensitivity

E

Sensitivity management

To obtain maximum possibility of managing the barrier settings, we recommend setting the

SENS trimmer on the receiver at halfway of its run.

This setting on the barrier allows the complete management of the sensitivity, even with connection

from PC.

The graphic displaying is had by checking the position of the RED line on the oscilloscope. The

closest the line to the upper part and, therefore, to the barrier signal (white line), the more sensitivity

increases.

The numerical indications (127 / - 127) indicate by how much, in percentage, the signal increases

or decreases, compared to the trimmer position adjusted in barrier.

The setting at (0) zero, displays the exact adjustment of the sensitivity on the barrier without any

influence by the management software.

N

G

Compensation management

To obtain maximum possibility of managing the barrier settings, we recommend setting

the COMP trimmer on the receiver at halfway of its run.

This setting on the barrier allows the complete management of the compensation, even with

connection from PC.

The "Compensation" value (xx) indicates that the alarm threshold line (Red line) rises by xx Volts

per second only when the microwave signal is disturbed enough to come out from the window

fixed by the two yellow and green lines.

The numerical indications (127 / - 127) indicate by how much compensation increases or

decreases, compared to the trimmer position adjusted in barrier.

The setting at (0) zero, displays the exact adjustment of the compensation on the barrier without

any influence by the management software.

Cursor position Compensation V/sec. Description

High compensation

intervention.

Average compensation

intervention.

Compensation does not

intervene.

- 60 -

Page 27

Valid signal threshold management

This particular function, called WIND UP can be programmed only with the use of the HPSOFT

software; it enables selection of the intervention zone of the barrier. It is possible to virtually

reduce the analysis lobe, enabling to select all those situations that might create system instability.

Often the generated lobe interests lateral zones where, the presence of hedges, metal nets or

other, create continuous disturbance. The WIND UP function enables modulating the lobe at

software level, until it becomes 20%-30% smaller than that declared. Usually the lobe creates a

sort of cigar effect between TX and RX; by activating the WIND UP function, the cylindrical

shape of the lobe will be amended creating a real and proper ellipse.

This function ensures that the compensation is not activated for signals inside the yellow and

green lines, indicating the valid signal threshold.

The signal is considered valid when it overcomes the reference lines.

The graphic displaying is had by checking the position of the YELLOW AND GREEN lines on the

oscilloscope. The greater the distance between the lines, the more the barrier rejects signals that

would activate compensation with factory adjustments.

The numerical indications (15 - 30 - 60) indicate by how much the valid signal threshold of the

barrier increases or decreases.

Graphic displaying on the management software.

E

Green L.

Œ

•

Yellow L.

Green L.

Yellow L.

Green L.

Ž

Yellow L.

Graphic indication of the possible reduction of the signal threshold.

The indications below are merely indicative. Only a field test will precisely indicate the coverage

zone and the valid signal thresholds.

BM60HP

6,5 meters

BM120HP

10 meters

BM200HP

16 meters

N

G

2 meters

BM60HP

•Ž

Œ

Sensitive zone

Alarm Zone

BM60HP 1,2 meters

BM120HP 3 meters

BM200HP 4 meters

- 61 -

•Ž

Sensitive zone

Œ

3 meters

BM120HP - BM200HP

Page 28

Detection mode

The possibility of alternating between the two functioning methods is possible only with the use

of the HPSOFT software.

Detection mode NORMAL: as the term indicates, the barrier behaves as describes up to now,

generating the alarm when the signal drops below the sensitivity threshold line and this does not

coincide with the waveforms customised library, relating to possible "False alarms".

Detection mode ALARM IDENTIFY: the barrier will go in alarm only if the detected signal coincides

with one of those recorded in the waveforms customised library as "real alarm".

This detection mode can be used when wanting to detect only particular types of crossings. To

use this opportunity, carry out a series of passages to generate alarms. Once a sufficient number

of alarm signals have been caused, check the "events history" in barrier and transfer the alarm

signals on to the "real alarm" customised library.

The barrier will then generate the alarm only for signals similar to those saved in this library;

every other signal will not generate an alarm.

This solution can be of interest if wanting to detect only the transiting of heavy means (cars/

articulated lorries, etc.), but not the transiting of persons or other.

E

N

G

Synoptic panel

Access to this menu imposes to choose the type of connection; USB - PSTN/GSM.

For a connection in local it is necessary:

1- to power the barriers

2- to connect the barrier receiver to the computer using the USB connection.

note: if first connection, carry out the drivers loading procedure for the recognition of the peripheral.

3- to select the barrier address on HPSOFT and then choose "connect"

Once connected, it will be possible to display in real time, the information relating to all connected

barriers.

If we were connected to a barrier in USB its status would be verified, but if we were connected to

the serial satellite, we would be able to see the status of all active barriers in the system.

Displayed elements:

- Barrier's time and date settings

- power supply

- Test point

- Temperature in barrier

- Barrier status: Alarm - Tamper - Disqualification

- 62 -

Page 29

Events History

Access to this menu imposes to choose the type of connection; USB - PSTN/GSM.

For a connection in local it is necessary:

1- to power the barriers

2- to connect the barrier receiver to the computer using the USB connection.

note: if first connection, carry out the drivers loading procedure for the recognition of the peripheral.

3- to select the barrier address on HPSOFT and then choose "connect"

Once connected, access will be gained to the alarm events history recorded in barrier.

Data loading procedure

1- Select the satellite - the barrier: "current satellite"-"current detector"

2-Define the number of events to load, with a maximum of 3840: "Max n. events"

3- Start the process: press "Load Record List"

4- The events complete with Record Number, Date and time, will be displayed.

•

•

Signals displaying procedure

5- 5- Click on show signal; the software will load the information directly from the barrier

The displaying is complete of certain information recorded at the time of alarm:

- Alarm signal - Test Point - Power supply - Temperature.

6- Press Ok to close the screen

Ž

Œ

•

E

N

G

- 63 -

‘

Page 30

E

"False Alarm" library customisation

It is possible to create a waveforms customised archive to modulate the reply of the barrier

depending on the environmental contexts.

The signals transferred in the archive called "False Alarm", are verified by the microprocessor

before activating the real and proper alarm signal. If there were a correspondence between the

recorded signal and the generated waveform, the barrier will not activate any signal, considering

the event a false alarm.

We recommend setting in this archive only the ascertained false alarm signals.

Procedure:

1- Click on "False Alarm"; it will be requested to confirm the operation.

2- Press Yes to confirm; the wording "sample added to the library with success" confirms the

operation. If the procedure is rejected, it means that signal is not recognised among those that

can be customised.

3- Press No to desert the procedure

N

G

•

Ž

Œ

"Alarm" library customisation

This library is linked to the detection mode of the barrier.

The barrier checks this archive when the barrier is set in "ALARM IDENTIFY" detection mode;

the barrier will be alarmed only if the detected signal coincides with one of those recorded in this

archive.

Procedure:

1- Click on "Alarm"; it will be requested to confirm the operation.

2- Press Yes to confirm; the wording "sample added to the library with success" confirms the

operation.

3- Press No to desert the procedure

Œ

- 64 -

•

Ž

Page 31

Signals library

Access to this menu imposes to choose the type of connection; USB - PSTN/GSM.

For a connection in local it is necessary:

1- to power the barriers

2- to connect the barrier receiver to the computer using the USB connection.

note: if first connection, carry out the drivers loading procedure for the recognition of the peripheral.

3- to select the barrier address on HPSOFT and then choose "connect"

Once connected, access is gained to the library of signals recorded in barrier by the installer.

Signals considered "FALSE ALARM" and others considered as "ALARM" can be found in this

customised library.

Symbols:

FALSE ALLARM

ALLARM

Data loading procedure

1- Select the satellite - the barrier: "current satellite"-"current detector"

2- Select which type of signal is to be loaded

3- Start the process: press "Load Record List"

4- The events complete of Record Number and "ALARM/FALSE ALARM" symbol will be displayed

5- To completely delete the signals library: press "Empty Library"

E

N

G

•

‘

Signals displaying procedure

6- Click on show signal; the software will load the information directly

from the barrier and the saved signal will be displayed.

7- Press Ok to close the screen

8- Press "Delete" to delete this signal from the library and confirm.

9- Confirm deletion of the signal.

Œ

•

Ž

•

”

’“

- 65 -

Page 32

E

N

G

Recordings Archive

The archive of the recordings enables

displaying the signals recorded by the installer

on PC using the "recording" procedure

described in the "Detectors Management"

chapter.

By entering this archive, access will be gained

to a database where the various files will be

saved with date/time, description and duration

of recording.

Data access procedure

1- Select: "Recordings Archive"

2- Select the file to be loaded

3- To scroll the oscilloscope trace, drag the

cursor found on the lower section

System notes

In this section it is possible to load an image

reminding us, for example, where the barriers

are installed. It is also possible to enter notes

on the editable paragraph.

•

Œ

Ž

Access procedure

1- Select: "System Notes"

2- Select "Change image" to load a file.

3- "Select "save notes" to confirm

Œ

•

Ž

Upgrade Firmware

In this section it is possible to upgrade the barrier firmware. This procedure is only necessary if

AVS Electronics issues upgraded firmware versions. There is a section on the site dedicated to

the DOWNLOAD of files (http://www.avselectronics.com/PHP/login.php).

Access procedure

1- Select: "Upgrade Firmware"

2- Select the barrier to be upgraded

3- Select "Upgrade"

4- Select the file and confirm

Œ

•

•

Ž

- 66 -

Page 33

E

N

G

Information in conformity to the Directive 1999/5/CEE for model BM_HP

The product here described is in conformity to the essential prescriptions of the Directive 1999/5/CEE

operation.

(R&TTE) on the radio-transmitting devices of low power and on the use of frequencies of the radioelectrical

spectrum, in accordance with CEPT 70-03 recommandation.

NOTICE:

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

Changes or modifications made to this equipment not expressly approved by AVS Electronics S.p.A.

may void the FCC authorization to operate this equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

- 67 -

Page 34

Technical Characteristics

E

N

G

BM60HP

BM60HPVAC

Max range 60 meters 120 meters 200 meters

Nominal tension 12 V 12 V 12 V

Min tension 11.5 V 11.5 V 11.5 V

Max tension 15 V 15 V 15 V

Consumption during quiet TX : 31 mA

RX : 100 mA

Consumption during alarm TX : 31 mA

RX : 100 mA

Size: (P x L x H) 150 x 105 x 195 136 x 225 x 225 136 x 225 x 225

Block of detector relay by appointed terminal B

Auxiliary input Negative input for detector

Alarm output n.c. exchange with 500 mA range at 12 V

Disqualification output normally closed good reception control exchange of signal with range

Tamper output n.c. exchange with 500 mA range at 12 V

Optional kit for anti-removal

(AMP)

Serial output - RS485 yes

Selectable serial addresses Maximum 32

Events memory Up to 3600 events recorded with time and date

Stop recording with system

disarmed

Filter false alarms yes

Test Point output for checking of signal received

Mirowave working frequency 10,525 GHz (+/-20MHz)

Modulation in 5 different channels, selection through dip-switch

Irradiation of RF power peak: 25 dBm

Temperature conditions from - 20°C to + 55°C

For installation outdoor, the use of the optional heating kit (Term2) is

IP Protection IP 34

Given within Bracket for fixation on 40 mm tube

no yes yes

BM120HP

BM120HPVAC

TX : 31 mA

RX : 100 mA

TX : 31 mA

RX : 100 mA

500 mA at 12 V

yes

suggested .

BM200HP

BM200HPVAC

TX : 31 mA

RX : 100 mA

TX : 31 mA

RX : 100 mA

Via Valsugana, 63

35010 (Padova) ITALY

Tel. +39 049 9698 411 / Fax. +39 049 9698 407

avs@avselectronics.it

www.avselectronics.com

Assistenza Tecnica: +39 049 9698 444

support@avselectronics.it

AVS ELECTRONICS S.p.A. reserves the right to modify the technical and esthetical characteristic of the products at any time.

- 68 -

Loading...

Loading...