1

D

E

F

1 2

A

B

C

D

E

20.43

8

.

5

0

4

5

6

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

DRAWING NO:

TITLE:

A0

6

PROXIMITY WARNING & ALERT SYSTEMS

The ZoneSafe System

User Manual

www.zonesafe.net

sales@zonesafe.net

Document Name

ZoneSafe™ User Manual

Document Number

14/6784

Original Issue Date

17-07-2017

Issue No. Date of Issue Details of Changes

1 17/07/2017 Original Version

2

3

4

5

12/10/2017 updated images

12/10/2017 updated info

16/01/2018 DoC and FCC info added

23/01/2018 Added TufTag & Wireless Charger Information

Information in this document is subject to change without notice.

You do not have permission to reproduce, publish or share any part of this document either electronically or printed in part or

full without prior written consent from Avonwood Developments Ltd.

Contents

1 Introduction 4

2 What’s in the Box 4

3 How the System Works 4

4 System Components 5

4.1 Control Unit 5

4.3 Tags 6

4.4 Driver Tag 6

4.5 Wireless Tag Charger 6

4.5.1 Wireless Charger Charging Instructions 7

4.6 TufTags 7

4.6.1 TufTag Installation 7

4.7 Plus Tag Tester 7

4.8 Fixing 8

4.8.1 AMPS 8

4.8.2 Adapter plates 8

5 System Operation 9

5.3 Conguration 9

5.3.1 Connection 9

5.3.2 Summary 9

5.1 On Sequence 9

5.2 O Sequence 9

5.3.3 Conguration of Wi-Fi Proles 10

5.3.4 Conguration of Event Upload Settings 10

6 Hardware Installation 10

6.1 Requirements 10

6.2 Installation Considerations 10

6.2.1 Antenna Mounting 10

6.2.2 Distance between Antennas 11

6.2.3 Optimum Tag Position 12

6.3 Control Unit 12

6.4 Antenna Unit 13

6.5 Tags 13

7 Example Installation 13

8 Connections 14

8.1 Control Unit 14

8.2 Antenna Unit 15

8.2.1 Antenna Connections 15

8.2.2 Antenna Switches 15

8.3 Hardware Setup & Test 15

8.3.1 Installation of Units 15

8.3.2 Conrm Antenna Range 16

8.3.3 System Monitoring 16

9 System Specication 16

9.1 Control Unit 16

9.2 Antenna Unit 16

9.3 Tags 17

9.4 Tag Tester 17

10 Troubleshooting 17

11 WEEE Directive 17

12 Disclaimer 17

13 Approvals 18

14 FCC Compliance Information 18

14.1 Applicable FCC IDs: 18

15. Declarations of Conformity 19

15.1 Control Unit 19

15.2 Antenna Unit 20

15.3 Standard Tag 21

15.4 VibraTag 22

15.5 Plus Tag Tester 23

2 3

1 Introduction

ZoneSafe is a proximity warning and alert system for minimising collision risks to workers and assets in a working

environment.

The system uses Active RFID tags worn by workers or tted to assets. These are detected when in close proximity and activate

an audible visual alarm to indicate a risk to equipment operators.

Antenna units installed on the equipment produce a 360° detection zone. This is user congurable and can be set to detect

tags from a range of 3m to 9m distance. Using antenna units either single, multiple or overlapping detection zones can be set

up and congured depending on vehicle type and detection requirements.

Driver tags are placed into a tag holder located on the top of the control unit when the machine is operational. This enables

the drivers tag to be logged and prevent it from being detected. If a driver tag is not inserted in the holder, an audible alarm

will sound.

The system is typically installed on to materials handling equipment, industrial lift equipment, support equipment and heavy

plant.

Disclaimer:

As supplied the ZoneSafe system oers an indication to risk via audible and visual warnings only. ZoneSafe is not to be

used as a protective device, initiate or perform safety related functions or take over control to prevent accidents.

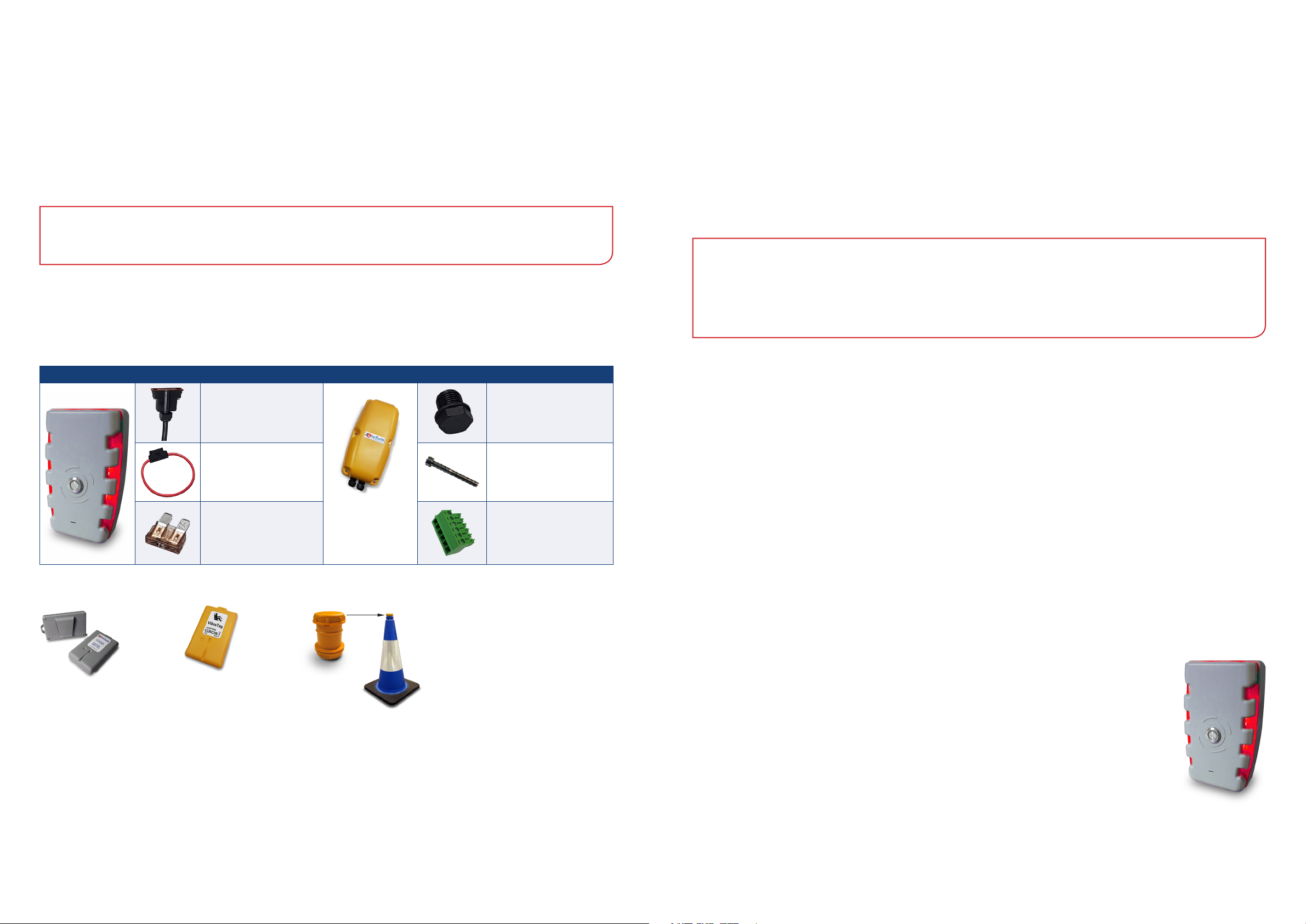

2 What’s in the Box

A standard system consists of:

Controller & Parts Antenna & Parts

Cable Loom & Connector

for Controller

Inline Fuse Holder

x2 per unit

7.5 Amp Blade Fuse

x2 per unit

Please note - tags are required for each ZoneSafe system to work. These are purchased seperately.

M16 Blanking Plug

(Note - part comes with controller)

M4 x 35mm Hex Screw

x6 per unit

6 Way Screw Terminal

x2 per unit

When a pedestrian tag or asset tag enters the 3m to 9m detection zone, an audible and visual alarm is activated from the incab control unit indicating to the equipment operator that a tagged person or asset is in close proximity to the vehicle.

The system maintains an event log and stores up to 4000 individual events. Events can be viewed either using an internet

browser connected to the control unit via Wi-Fi direct or by automatic upload via a Wi-Fi access point at my.zonesafe.net.

NOTE:

ZoneSafe must be tted and commissioned by an approved installer. No responsibility will be accepted for damage to

systems caused by incorrect installation or misuse.

Detection accuracy will depend on environmental and installation factors.

4 System Components

The ZoneSafe system comprises of the following standard components and accessories:

(for a more comprehensive range of our products please contact our sales team)

Standard Components

1. Control Unit

2. Antenna Unit

3. Standard Driver Tag - sold seperately

4. Standard Pedestrian Tag - sold seperately

Accessories (including but not limited to)

1. Plus Tag Tester (Tag battery level testing)

2. TufTag (Cone mounted tag for tagging assets)

3. VibraTag (Vibrating tag)

4. Fixing Plates (Installation)

5. Cloud Software (Identify, monitor and improve areas of risk such as near miss occurences throughout your work site)

4.1 Control Unit

Pedestrian Tag*

3 How the System Works

ZoneSafe is a tag based system using active radio frequency identication (RFID) technology. The system comprises of an

in-cab control unit with either single or multiple antenna units installed onto equipment, and active tags worn by workers or

tted to assets.

Three groups of active RFID tags are available, Driver Tags, Pedestrian Tags and Tuf Tags. A number of tag options are available

within these groups.

4 5

Driver Tag

TufTag

The Control unit provides the overall functionality of the system and acts as the user interface. The

unit contains a battery backed real-time clock for precisely logging tag detect events, internal memory

to store event data and a Wi-Fi interface for communication. A relay is available for additional external

sounders or beacons.

The Control unit is mounted in the driver cab next to the operator so it can be clearly visible at all

times. Audible alerts are emitted from a sounder located on the front, a light panel and button create

visual alerts and indicate various alarm states. The button can be congured to acknowledge the

detection of one or more tags.

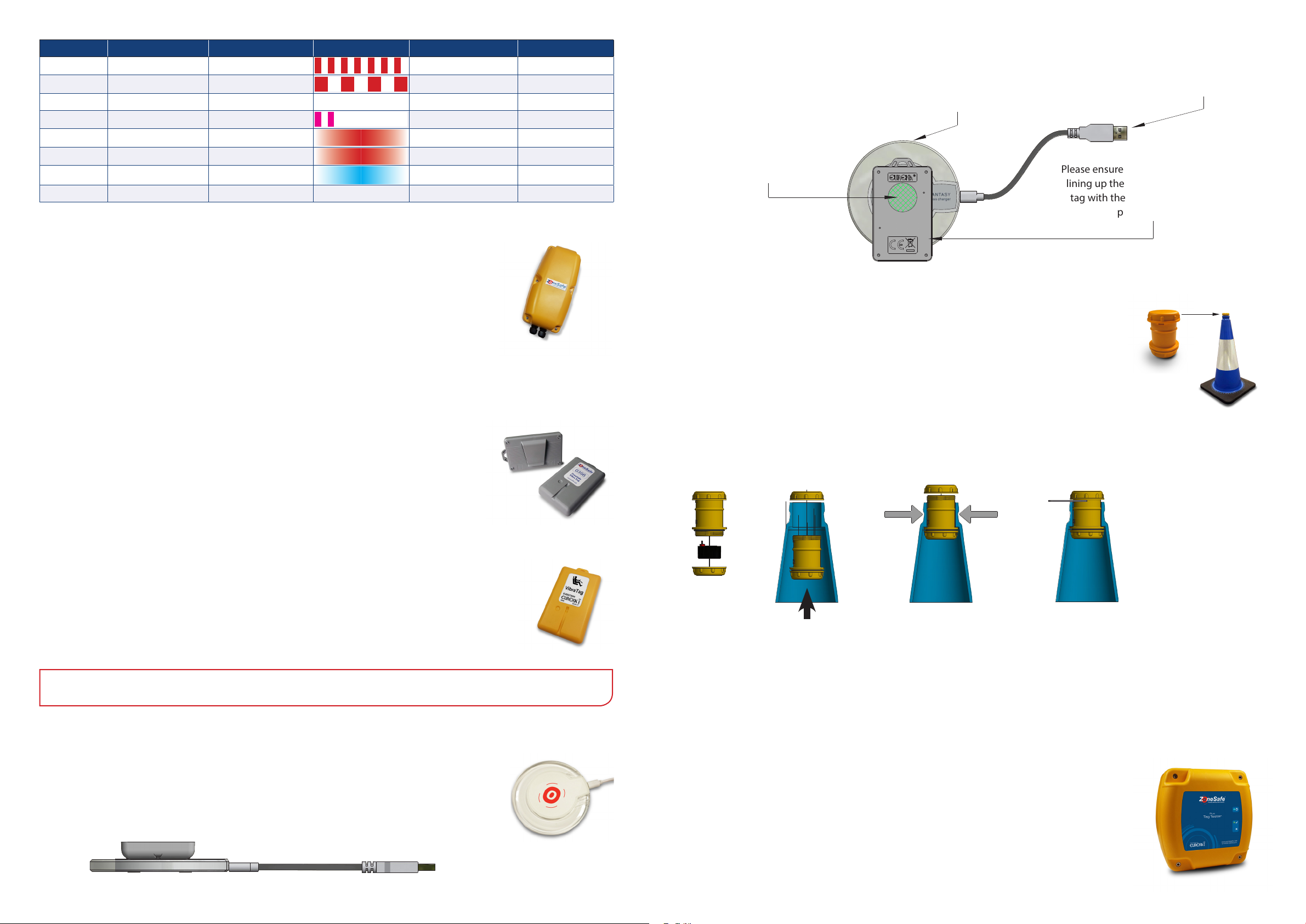

The table of alarms indicates the types of alarms that the control unit will highlight. The alarm state demonstrates each alarm

colour sequence (note- black indicates the light is o).

Priority State Alarm Colour Alarm State Sounder Button Colour

1

2

3 4 5 6

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

REV:

DRAWING NO:

TITLE:

SHEET

A1

AS INDICATED IN ISO 2768-1

TOLERANCE CLASS

LINEAR = f

ANGULA

R = f

BROKEN EDGES = f

1 / 1

LOCATION OF CHARGING

COIL IN OUR TAG. NEEDS

TO BE CENTRAL TO THE

CHARGER TO PAIR.

INPUT 5V - 2A

CHARGER PULSES BLUE

WHEN CHARGING. IF NO

LIGHT COMES ON THEN

TAG IS ALREADY CHARGED.

INPUT 5V - 2A

CHARGER PULSES BLUE

WHEN CHARGING. IF NO

LIGHT COMES ON THEN

TAG IS ALREADY CHARGED.

1

2

3 4 5 6

2

3 4 5 6

3 4 5 6

1 2+ Pedestrian Red (Flash) Two Tone Fast Red

2 1 Pedestrian Red (Flash) Two Tone Slow Red

3 Reserved x x x x

4 System Error Pink (Flash) System Beep Red

5 No Ignition Red (Pulse) One Tone Red

6 No Driver Tag Red (Pulse) One Tone Red

7 WiFi Connected Blue (Pulse) x Green

8 Ok x x x Green

4.2 Antenna Unit

The Antenna Unit creates a detection zone around the vehicle or asset. Antennas should be tted

at appropriate locations to provide the optimum detection zone required (see 6.2.1 Antenna

Mounting).

Antenna units are linked (in series) to the system Control Unit. The number of antennas

required depends on the size of the vehicle and detection zone around it. Each antenna detection

zone can be adjusted between 3 - 9 metres (see 8.2.2 Antenna Switches).

4.5.1 Wireless Charger Charging Instructions

Charger pulses blue when charging. If the light

doesn’t come on, the tag is fully charged.

Location of charging coil

in our tag. This needs to

be central to the charger

to pair.

Please ensure correct placement of tag

lining up the charging coil inside the

tag with the centre of the charging

4.6 TufTags

TufTag is our cone mounted active tag and integrates seamlessly with our ZoneSafe proximity

warning systems. Designed to protect static assets, the TufTag can be used in any situation

where a vehicle operator needs to be alerted to a potential hazard.

Input 5V - 2A

pad as shown.

4.3 Tags

Tags are worn by all personnel. When a tag enters the detection zone around a vehicle or asset, a

visual and audible alarm is provided from the in cab control unit to warn the machine operator.

Each tag is factory congured with a unique ID and can be used on any ZoneSafe enabled job site.

Tags within the proximity of a detection zone will be logged by the control unit. The data logged

from the tag includes its unique ID, date/time and battery status.

4.4 Driver Tag

A Driver Tag is required for the driver of the vehicle and for the system to work. The tag is placed into

the Control Unit (see 5.1 On Sequence), which not only arms the system but also masks itself from the

antenna. If the vehicle is started, and there is no tag present, the control unit will automatically alarm

emiting the no tag alarm tone.The driver must take the tag with them when they exit the vehicle.

NOTE: It is essential that all personnel on the work site wear a tag.

4.6.1 TufTag Installation

1. 2. 3. 4.

1 2 3 4

Section view of a cone

1. Connect and t the battery and tighten the cap.

2. Take o the top cap and t the tag through the neck of the cone from the inside. Hold the cone horizontally and extend

your arm to help push it through the neck or place on top of another cone to push the tag through.

3. Squeeze the neck of the cone and screw the top cap on.

4. Tighten the top cap with the card spanner tool.

4.5 Wireless Tag Charger

The wireless tag charger is used to charge any style of ZoneSafe rechargable tag such as the VibraTag

by simply connecting the charger via the mini USB cable to a power source and placing the tag on

top of the charging pad. For further information, please see the following section.

6 7

4.7 Plus Tag Tester

The Plus Tag Tester provides an easy way to test the status of any ZoneSafe / Eureka tag. We

recommend personnel check their tag battery status daily before entering the job site. The unit

reads a tag and displays the status of the battery using indicator LEDs. Daily use of the tag test

unit ensures tag batteries are always in a serviceable condition.

VIEW D-D

SCALE 1 :3

5

6

0.00

200mm

200.00

SECTION C-C

SCALE 2:1

5

FIXTURE

DETAIL A

SCALE 1 : 1

A

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

REV:

DRAWING NO:

TITLE:

A1

THIS DRAWING IS THE PROPERTY OF AND MA Y EMBODY PROPRIETARY INFORMATION

OWNED BY AVONWOOD DEVELOPMENTS LTD. IT IS PRO VIDED UNDER A CONFIDENTIAL

RELATIONSHIP FOR A SPECIFIC PURPOSE. THE REC IPIENT AGREES TO USE IT ONLY FOR

AS INDICATED IN ISO 27 68-1

UNLESS OTHERWISE STA TED

30.00

3

8

.

0

0

0.00

200mm

5

6

5

6

Indicator LED’s include:

• Blue Flash - Indicates The Plus Reader is turned on

• Quick Blue Flash - Indicates the reader has identied the tag

• Green Light - Indicates tag battery is good

• Red Light - Indicates low tag battery

4.8 Fixing

For xing of the Controller and the Antenna, use the AMPS conguration xings on the back of the devices or use one of the

adapter plates.

4.8.1 AMPS

Both the in-cab control unit and antenna have M5 threaded inserts in the AMPS conguration on the rear. Engagement depth

of machine screw must not exceed 8mm.

30.00

30.00

5 System Operation

5.1 On Sequence

• Place the driver tag into the slot

• Turn the vehicle ignition ON

to initialise the system

• If the Push Button LED = GREEN

then the system is operational

(for any other indication

see the alarm table)

• Detection Zone is now ACTIVE

5.2 O Sequence

• Turn the vehicle ignition OFF

• Remove the driver tag from the holder

• Button LED turns o

• Detection Zone is now INACTIVE

M5 PLAIN

M5 PLAIN

M5 INT TOOTH SHAKEPROOF

M5 INT TOOTH SHAKEPROOF

M5 X 0.8mm PITCH

0

0

.

8

3

38.00

You can use the hole conguration to attach a 1.5” Ball RAM Mount base and any conguration of RAM mount xtures. Holes

can be made directly on the vehicle and xing can be done from the back through the vehicle body and into the xings.

Thread lock and shake-proof washers are recommended - always fasten securely but do not over-tighten.

M5 X 0.8mm PITCH

THREAD LOCK

4.8.2 Adapter plates

An adapter plate is available for the Control unit and the Antenna. This xes to each unit via four countersunk M5 screws with

thread lock.

The adapter plates provide four legacy holes for customers who want to use the existing holes they made following a previous

ZoneSafe system installation. The plates also provide slots top and bottom which are large enough for M8 xings.

The method for attaching the Control unit will vary from vehicle to vehicle, if the adapter plate is to be used then the slots

allow for front xing or as an example a U bolt clamp can be fastened to them.

NOTE: If the ignition remains on and no driver tag

is in detected in the holder for a period of time,

the “No Driver Tag” alarm will be raised. This is

intended to prevent the vehicle being operated by

an un-authorised driver.

NOTE: If the ignition is o and the driver tag

remains left in the holder for a period of time, the

“No Ignition” alarm will be raised. This is intended

to remind the driver to take the tag when leaving

the vehicle.

5.3 Conguration

The ZoneSafe Wi-Fi Controller can automatically connect to Wi-Fi infrastructure networks and upload ZoneSafe event data to

the ZoneSafe Insight website. The Wi-Fi connection also permits a direct connection to allow conguration and monitoring of

the device via its integral Web Server.

5.3.1 Connection

The ZoneSafe Wi-Fi Controller broadcasts a SSID of ZoneSafe_XXXXXX where

XXXXXX is the device’s serial number, as printed on the product label. From

your device, view available Wi-Fi connections and select this network and click

Connect. Enter the default security key “ZONESAFE” and click OK

admin

When the connection has been established open a web browser and enter URL

http://192.168.0.1/ This is the address of the ZoneSafe Wi-Fi Controller. When

prompted for credentials, enter the default user name “admin” and password

“PASSWORD”.

PASSWORD

5.3.2 Summary

‘D’ Adapter Plate

tted to Controller Unit

8 9

‘A’ Adapter Plate

tted to Antenna

Exhaust ‘U’ Bolt Clamp

tted to Controller Unit

The Summary page displays the Control Unit and a separate box for each of the congured antennas. Click the Settings button

on the respective unit to open the conguration page for this unit.

5.3.3 Conguration of Wi-Fi Proles

5

6

5

6

DETAIL A

SCALE 1 : 1

VIEW D-D

SCALE 1 :3

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

REV:

DRAWING NO:

TITLE:

UNCONTROLLED

SHEET

A1

THIS DRAWING IS THE PROPERTY OF AND MAY EMBODY PROPRIETARY INFORMATION

OWNED BY AVONWOOD DEVELOPMENTS LTD. IT IS PROVIDED UNDER A CONFIDENTIAL

RELATIONSHIP FOR A SPECIFIC PURPOSE. THE RECIPIENT AGREES TO USE IT ONLY FOR

SUCH PURPOSE.

AS INDICATED IN ISO 2768-1

TOLERANCE CLASS

LINEAR = f

ANGULA

R = f

BROKEN EDGES = f

1 / 1

UNLESS OTHERWISE STATED

30.00

3

8

.

0

0

0.00

200mm

200.00

5

6

VIEW D-D

SCALE 1 :3

5

6

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

TITLE:

A1

200.00

ZoneSafe2™ User Manual

1.1.1 Distance between Antennas

Choose the size of the detection zone prior to fitting the system to the machine/object. The distance

between antennas should equal the detection zone minus 20%.

It is highly recommended to add at least one Wi-Fi network prole to your ZoneSafe device to allow automatic event

uploading and remote monitoring. The ZoneSafe Wi-Fi Controller can store up to 4 Wi-Fi network proles that it will

automatically connect to.

Click WI-FI from the menu. The device will perform a scan of Wi-Fi networks and display the list of networks found in order of

signal strength. Click the Add button on the row for the network you wish to add and enter the network passphrase when

prompted. Click Delete to remove the prole from the device.

5.3.4 Conguration of Event Upload Settings

Click Admin – Upload Settings from the menu.

The Upload Interval is specied in seconds. Set this value to zero to disable event uploading. After entering the required value,

click the Save button to apply the changes.

The other settings should only be changed under instruction from Avonwood Developments.

• No metal should be within 200mm of the top, bottom and sides of the antenna.

• No metal should be in front of the wakeup antenna, for example a grille.

200mm

0.00

200mm

6 Hardware Installation

Before installation please read the following guide lines to ensure that the system is correctly installed and provides optimum

performance.

NOTE: We recommend the installation of ZoneSafe™ is carried out by a fully authorised ZoneSafe™ installatio engineer.

The ZoneSafe Control Unit must be installed to be at least 20cm away from any person when in normal use.

6.1 Requirements

• 12V or 24V DC battery supply (protected by a 7.5A anti-surge fuse)

• 0V Earth location

• 12V or 24V DC ignition supply (protected by a 7.5A anti-surge fuse)

• Cable & tools

6.2 Installation Considerations

6.2.1 Antenna Mounting

• Antennas can be mounted vertically (best) or horizontally. For vertically mounted antennas in high positions, angle unit

downwards

6.2.2 Distance between Antennas

Choose the size of the detection zone prior to tting the system to the machine/object. The distance between antennas

should equal the detection zone minus 20%. Use the table to help set up an optimum detection zone. This setup will help

reduce lobe eects and provide an optimum detection zone.

Antenna Seperation vs Detection Zone

10

9

8

7

6

5

4

Detection Zone (M)

3

2

1

0

3.2 4 4.8 5.6 6.4 7.2

Max Antenna Seperation (M)

10 11

6.2.3 Optimum Tag Position

5

6

5

6

6.4 Antenna Unit

The optimum detection range of the tag can be achieved when the tag and wakeup antenna are level to each other. Changing

the angle of the antenna can overcome high mounting issues, but may reduce the eective read range.

Detection Zone

Antenna

Optimum Tag

Position Level to

Centre of Antenna

Tag

Detection Zone

Changing the Angle

of the Antenna can

Overcome High

Mounting Issues

Tag

Identify suitable locations for the Antenna Units and install the wiring loom from the Control Unit to the rst Antenna Unit

location. Then install the wiring from the rst antenna location to the second antenna location, then the second location to

third location etc.

The incoming power and data cable from the Control Unit enters via one cable gland and leaves via the other cable gland to

the next Antenna Unit in series.

6.5 Tags

Tags should be worn or attached vertically if possible to ensure best detection range. Tags can be worn using a lanyard, a

belt clip add on, an armband or integrated into PPE such as a high visibility vest. All personnel on the job site must wear an

working tag in order to be picked up by our system.

7 Example Installation

Depending on the size and shape of the vehicle, more than one antenna may need to be tted to provide a well dened

detection zone. Below illustrates a range of dierent vehicle types with at least one antenna tted to each vehicle. The larger

the vehicle, the more antennas will need to be tted to create an adequate detection zone around the vehicle. Antennas can

also be tted to moving parts such as the boom or dipper arm of a vehicle to create a moving detection zone.

One Antenna System

Fitted to Forklift Truck

Two Antenna System

Fitted to Bulldozer

6.3 Control Unit

The Control Unit should be located within the machine operator’s view and reach, but must not restrict the operator’s view of

the working area or any operational controls. The Control Unit must not be located within 75cm of an Antenna Unit. The unit

should preferably be installed in a vertical position or in clockwise tilt to allow water to freely drain.

Should you need to remove the tamper cover located at the bottom of the control unit covering the cable loom and

connection, please follow the instructions below.

Four Antenna System

Fitted to Shovel Loader

Gently insert

two small at

head drivers.

Angle screwdrivers

to release the clips

and lever cover out.

Detection

Zone

Five Antenna System Fitted to Excavator

with Antenna Fitted to Digger Arm

Detection

Zone

Antenna Location (Approx)

12 13

8 Connections

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

REV:

DRAWING NO:

TITLE:

SHEET

A0

THIS DRAWING IS THE PROPERTY OF AND MAY EMBODY PROPRIETARY INFORMATION

OWNED BY AVONWOOD DEVELOPMENTS LTD. IT IS PROVIDED UNDER A CONFIDENTIAL

RELATIONSHIP FOR A SPECIFIC PURPOSE. THE RECIPIENT AGREES TO USE IT ONLY FOR

SUCH PURPOSE.

AS INDICATED IN ISO 2768-1

TOLERANCE CLASS

LINEAR = f

ANGULA

R = f

BROKEN EDGES = f

1 / 1

UNLESS OTHERWISE STATED

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

DRAWING NO:

TITLE:

A0

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

DRAWING NO:

TITLE:

A0

NOTE: For 12V systems with long cable runs, a separate supply may be required to the Control Unit and each Antenna

Unit.

IMPORTANT: Ensure power is isolated & vehicle ignition is OFF before making connections.

8.2 Antenna Unit

Antenna Units are linked together using the IN and OUT 6 way headers, CONN2

and CONN3.

• Cable: 3 pair individually screened, Core: 7/0.2 (i.e. Belden 8777, Alpha

6010C, Cable Hub/ FS cables 2203PIFRD)

CONN2 CONN3

345

1

6

2

12345

6

8.1 Control Unit

Recommended ALPHA Wire 6010C

Mandatory Wiring:

Description Colour To

VBAT_IN Red Vehicle battery +ve

0V_IN Black Vehicle battery 0V

VIGN_IN White Vehicle ignition +ve

0V_OUT Red/Brown Wakeup CONN2/1

VIGN_OUT Red/Black Wakeup CONN2/2

SYNC_B Violet Wakeup CONN2/3

SYNC_A Yellow/Red Wakeup CONN2/4

RS485_B Yellow Wakeup CONN2/5

RS485_A Green/Red Wakeup CONN2/6

8.2.1 Antenna Connections

Pin numbering and descriptions for CONN2 and CONN3 are identical. CONN2 can be used for the outgoing cable and CONN3

for the incoming cable or vice-versa.

Wiring:

1

CONN2/3 Pin Number Description Colour*

1 0V_IN Black/Red

6

5

2

4

3

2 VIGN_IN Red

3 SYNC_B Black/White

4 SYNC_A White

5 RS485_B Black/Green

6 RS485_A Green

*Wiring Colours Based on Alpha Wire 6010C

3 Pair Foil Screened

(7/0.2,22AWG,.35mm²)

+

Antenna 1

SW2 = 1

Antenna 2

SW2 = 2

-

Blanking Plug or Connection

to 2nd, 3rd, 4th Antenna etc

8.2.2 Antenna Switches

Locate SW1, SW2 & SW3 inside antenna unit.

Using a trim tool or a small at bladed screw driver, turn SW1 clockwise to increase power or anticlockwise to decrease power.

Set SW1 to give the desired tag detection range.

SW2 – ADDRESS (1=rst antenna unit: must be numbered sequentially to the last)

SW3 – SYNC (OFF=external (driven from controller) ON=internal)

SW2

MIN. POWER

AUTO / WIFI

SW1

ADDRESS 1

Optional Wiring:

MAX. POWER

Description Colour

IN2+ Pink

IN1+ Blue

8.3 Hardware Setup & Test

IN2- Green

RL_NC Orange

RL_NO Brown

14 15

IN3+ Turquoise

IN3- Grey

IN1- Red/Blue

RL_COM White/Red

8.3.1 Installation of Units

Connect Control Unit and Antenna Unit cables before connecting to vehicle systems. Make sure switches SW1 to SW3 are set

on the Antenna Units as described in the previous section.

8.3.2 Conrm Antenna Range

9.3 Tags

Using an LED Test Tag (supplied separately), walk around the detection zone that has been set. An LED on the test tag will

illuminate when it is in the detection zone providing a visual illustration of the zone. The LED on the test tag may pulse

but should not be o for more than 1 second. As necessary, adjust TX power on each Antenna Unit to alter the size of the

detection zone. If one or more Antenna Units are installed incorrectly they can oppose each other and detection free zones

may exist.

8.3.3 System Monitoring

The system continuously monitors data communication & status from each Antenna Unit while in operation.

9 System Specication

9.1 Control Unit

ZoneSafe Control Unit

Electrical Voltage

Current Consumption

Memory

Mechanical Dimensions (incl. glands)

Material

Weight

Connectors

Relay (for additional

sounders / beacons)

Digital Input

Communications Wi-Fi IEEE 802.11b/g/n (2.4GHz)

Environment Ingress Protection

Temperature

12V - 24V DC nom (11-32V max)

1A max

4000 Events

180mm x 102mm x 58mm

ABS

0.5kg

IP D-type

N/O N/C

0.5A @125VAC, 2A@ 30VDC

3 x Opto-Isolated inputs

IP65

-10OC to +50OC

Contact our sales team for a more comprehensive guide to our range of tags. All our tags are hermetically sealed to withstand

the harshest environments.

9.4 Tag Tester

See Plus Tag Tester Manual 14/6667 for more information

10 Troubleshooting

Description Diagnosis Solution

Alarm does not mute. More than one tag in detection zone. Check detection zone for all tags.

With driver tag and ignition on, there is

a constant tone.

With no tag in the zone, the alarm still

pulses.

Alarm goes o in certain locations. Tag detection.

All vehicles in the area alarm at the

same time.

Why is the alarm a constant tone when

leaving the vehicle?

If a fault cannot be identied in the above table, or the solution does not resolve your fault, please contact your Zonesafe

qualied installation engineer.

It is the responsibility of the end user to keep a record of unique vehicle wake up ID if altered from the manufacture supplied

ID.

Wiring fault on ignition.

Driver tag is being detected.

Vehicle ID (wakeup address) is the

same.

Driver tag left in holder. Remove driver tag.

Check ignition and power is connected

correctly.

Contact a qualied installation

engineer, check driver search time and

masking eld.

Is there a tag behind a wall, on the

second oor or behind an obstacle?

Using Zonesafe software change

wakeup address.

11 WEEE Directive

9.2 Antenna Unit

ZoneSafe Antenna Unit

Electrical Voltage

Current Consumption

Mechanical Dimensions (incl. glands)

Material

Weight

Connectors

Mounting

Communications Wired RS485

Environment Ingress Protection

Temperature

Radio TX Frequency

RX Frequency

Range

16 17

12V - 24V DC nom (11-32V max)

2A max

245mm x 105mm x 90mm

ABS / PC

1.4kg

Nylon Glands

AMPS Conguration

IP67

-10OC to +50OC

125kHz

868.3MHz

TX: adjustable 3-9m approx

RX: 50m typ

The Waste Electrical and Electronic Equipment Directive (WEEE Directive) was introduced into UK law in

January 2007 by the Waste Electronic and Electrical Equipment Regulations 2006.

This product shall not be treated as household waste. It must be treated in accordance with the Waste

Electronic and Electrical Equipment Regulations 2006.

Avonwood Developments Limited is a WEEE registered producer WEE/EFO483SX.

12 Disclaimer

The ZoneSafe™ proximity warning systems manufactured by Avonwood Developments Limited are supplied as an audible

and/or visual alert system only. The ZoneSafe™ proximity warning system is not a protective device, it does not initiate or

perform safety related functions and it does not provide control to reduce risk.

ZoneSafe™ should not be used to replace proper job site organisation, safeguards, operator training and the application of

Reference & Date

Title

EN 300 220-2 V3.1.1 (2017-02)

Short Range Devices (SRD) operating in the frequency range 25

MHz to 1 000 MHz

EN 300 330 V2.1.1 (2017-02)

Short Range Devices (SRD); Radio equipment in the frequency

range 9 kHz to 30 MHz

Draft EN 301 489-1 V2.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-3 V2.2.1 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-17 V3.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

relevant vision standards that addresses safety and the safety of people on job sites.

15. Declarations of Conformity

Due to the nature of radio frequency, wireless communications and possible interference, data can never be guaranteed. Data

can be corrupted, have errors or be totally lost. Avonwood Developments Limited ZoneSafe™ systems should not be used in

situations where failure to transmit or receive data could result in damage of any kind to the user or any other party, including

but not limited to personal injury, death or loss of property. Avonwood Developments Limited accepts no responsibility for

damages of any kind resulting from errors in data transmitted or received using Avonwood’s ZoneSafe™ systems, or for the

failure of the Avonwood’s ZoneSafe™ systems to transmit or receive such data.

Avonwood Developments Limited accepts no liability for any and all direct, indirect, special, general, incidental, consequential,

punitive or exemplary damages including, but not limited to, loss of prots or revenue or anticipated prots or revenue arising

out of the use or inability to use any Avonwood Developments Limited products.

Information in this document is subject to change without notice.

13 Approvals

(a) For a Class A digital device or peripheral, the instructions furnished the user shall include the following or similar statement,

placed in a prominent location in the text of the manual:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Over the following pages you will nd Declarations of Conformity for each piece of equipment in The ZoneSafe Manual.

15.1 Control Unit

EU Declaration of Conformity (DoC)

We,

Company Name: Avonwood Developments Ltd

Address: Knoll Technology Centre, Stapehill Road,

Wimborne, Dorset. BH21 7ND

Declare that the DoC is issued under our sole responsibility and belongs to the following

product:

Product: ZoneSafe Standard Control Unit

Part Number: ZSR6783-EU

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

14 FCC Compliance Information

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Changes or modications to ZoneSafe™ systems not expressly approved by Avonwood Developments

Limited may void the user’s authority to operate the equipment.

The ZoneSafe Control Unit must be installed to be at least 20cm away from any person when in normal use.

14.1 Applicable FCC IDs:

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

Radio Equipment Directive 2014/53/EU

The following harmonised standards and technical specifications have been applied:

range 9 kHz to 25 MHz and inductive loop systems in the frequency

Signed for and on behalf of: Avonwood Developments Ltd

Place of issue: Knoll Technology Centre

th

Date of issue: 16

January 2018

ZoneSafe Control Unit 2ACWNZSR6783

ZoneSafe Antenna Unit 2ACWNZSA6782

VibraTag 2ACWNZST6687

Standard Tag 2ACWNZS6277

18 19

Name: Adrian Nash

Position: Engineering Manager

Signature:

Reference & Date

Title

EN 300 220-2 V3.1.1 (2017-02)

Short Range Devices (SRD) operating in the frequency range 25

MHz to 1 000 MHz

EN 300 330 V2.1.1 (2017-02)

Short Range Devices (SRD); Radio equipment in the frequency

range 9 kHz to 30 MHz

Draft EN 301 489-1 V2.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-3 V2.2.1 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-17 V3.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

15.2 Antenna Unit

Reference & Date

Title

EN 300 220-2 V3.1.1 (2017-02)

Short Range Devices (SRD) operating in the frequency range 25

MHz to 1 000 MHz

EN 300 330 V2.1.1 (2017-02)

Short Range Devices (SRD); Radio equipment in the frequency

range 9 kHz to 30 MHz

Draft EN 301 489-1 V2.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-3 V2.2.1 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-17 V3.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

15.3 Standard Tag

EU Declaration of Conformity (DoC)

We,

Company Name: Avonwood Developments Ltd

Address: Knoll Technology Centre, Stapehill Road,

Wimborne, Dorset. BH21 7ND

Declare that the DoC is issued under our sole responsibility and belongs to the following

product:

Product: ZoneSafe Antenna Unit

Part Number: ZSA6782-EU

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

Radio Equipment Directive 2014/53/EU

The following harmonised standards and technical specifications have been applied:

EU Declaration of Conformity (DoC)

We,

Company Name: Avonwood Developments Ltd

Address: Knoll Technology Centre, Stapehill Road,

Wimborne, Dorset. BH21 7ND

Declare that the DoC is issued under our sole responsibility and belongs to the following

product:

Product: Standard Tag

Part Number: ZST6735-EU

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

Radio Equipment Directive 2014/53/EU

The following harmonised standards and technical specifications have been applied:

range 9 kHz to 25 MHz and inductive loop systems in the frequency

Signed for and on behalf of: Avonwood Developments Ltd

Place of issue: Knoll Technology Centre

th

Date of issue: 16

January 2018

Name: Adrian Nash

Position: Engineering Manager

Signature:

range 9 kHz to 25 MHz and inductive loop systems in the frequency

Signed for and on behalf of: Avonwood Developments Ltd

Place of issue: Knoll Technology Centre

th

Date of issue: 16

January 2018

Name: Adrian Nash

Position: Engineering Manager

Signature:

20 21

Reference & Date

Title

EN 300 220-2 V3.1.1 (2017-02)

Short Range Devices (SRD) operating in the frequency range 25

MHz to 1 000 MHz

EN 300 330 V2.1.1 (2017-02)

Short Range Devices (SRD); Radio equipment in the frequency

range 9 kHz to 30 MHz

Draft EN 301 489-1 V2.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-3 V2.2.1 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-17 V3.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

15.4 VibraTag

Reference & Date

Title

EN 300 220-2 V3.1.1 (2017-02)

Short Range Devices (SRD) operating in the frequency range 25

MHz to 1 000 MHz

EN 300 330 V2.1.1 (2017-02)

Short Range Devices (SRD); Radio equipment in the frequency

range 9 kHz to 30 MHz

Draft EN 301 489-1 V2.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-3 V2.2.1 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

Draft EN 301 489-17 V3.2.0 (2017-03)

ElectroMagnetic Compatibility (EMC) standard for radio equipment

and services

15.5 Plus Tag Tester

EU Declaration of Conformity (DoC)

We,

Company Name: Avonwood Developments Ltd

Address: Knoll Technology Centre, Stapehill Road,

Wimborne, Dorset. BH21 7ND

Declare that the DoC is issued under our sole responsibility and belongs to the following

product:

Product: VibraTag Series

Type Designations: ZST6687-EU-P VibraTag – Pedestrian (EU)

ZST6687-EU-D VibraTag – Driver (EU)

ZST6687-EU-RP Rechargeable Tag – Pedestrian (EU)

ZST6687-EU-RD Rechargeable Tag – Driver (EU)

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

Radio Equipment Directive 2014/53/EU

The following harmonised standards and technical specifications have been applied:

EU Declaration of Conformity (DoC)

We,

Company Name: Avonwood Developments Ltd

Address: Knoll Technology Centre, Stapehill Road,

Wimborne, Dorset. BH21 7ND

Declare that the DoC is issued under our sole responsibility and belongs to the following

product:

Product Range: Plus Reader Series

Type Designations: ZSR6663-EU Plus Reader

ZSR6663-EU-T Plus Tag Tester

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

Radio Equipment Directive 2014/53/EU

The following harmonised standards and technical specifications have been applied:

range 9 kHz to 25 MHz and inductive loop systems in the frequency

Signed for and on behalf of: Avonwood Developments Ltd

Place of issue: Knoll Technology Centre

Date of issue: 16

th

January 2018

Name: Adrian Nash

Position: Engineering Manager

Signature:

range 9 kHz to 25 MHz and inductive loop systems in the frequency

Signed for and on behalf of: Avonwood Developments Ltd

Place of issue: Knoll Technology Centre

th

Date of issue: 16

January 2018

Name: Adrian Nash

Position: Engineering Manager

Signature:

22 23

1

D

E

F

1 2

A

B

C

D

E

20.43

8

.

5

0

4

5

6

REV: DATE: CHANGE:

STATUS:

CUSTOMER:

SCALE @

DRAWN BY:

DRAWING NO:

TITLE:

A0

6

ZoneSafe is a registered trademark of Avonwood Developments Ltd.

24

14 6784E

Avonwood Developments Ltd

Knoll Technology Centre,

Stapehill Road,

Wimborne,

Dorset, United Kingdom,

BH21 7ND

www.avonwood.co.uk

sales@avonwood.co.uk

+44 (0) 1202 868000

Loading...

Loading...