Page 1

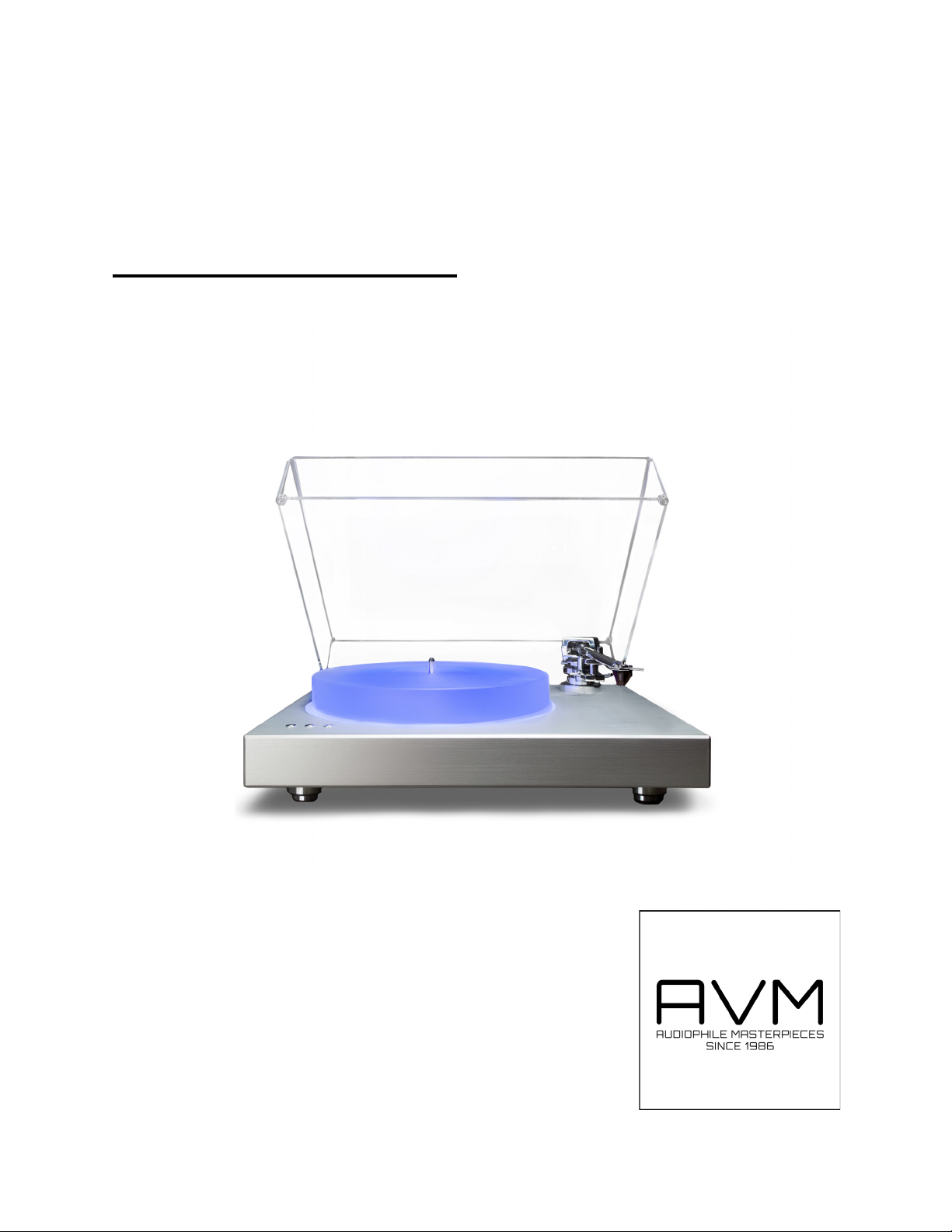

ROTATION R 5.3

Operating Instructions

Page 2

Declaration of conformity (for EC only)

We herewith confirm, that the unit to which this manual

belongs, fulfills the EC rules necessary to obtain the sign

the necessary measurements were taken with positive

results.

AVM Audio Video Manufaktur GmbH

Daimlerstraße 8

76316 Malsch

Germany

www.avm.audio

info@avm.audio

Page 3

TABLE OF CONTENTS

1. Getting started

1.1 Important (1)

1.2 What’s in the box? (2)

1.3 Packaging (2)

1.4 Control and operating elements (3)

1.5 Setup (5)

1.5.1 Feet assembly (5)

1.5.2 Platter, sub-platter and drive belt installation (5)

1.5.3 Speed control (6)

1.5.4 Light control (6)

1.5.5 Output connection (7)

1.5.6 Tonearm setting (7)

1.5.7 Cartridge installation (8)

1.5.8 Counterweight assembly (8)

1.5.9 Vertical Tracking Force setting (VTF) (9)

1.5.10 Vertical Tracking Angle setting (VTA) (10)

1.5.11 Azimuth setting (11)

1.5.12 Anti-skating assembly and adjustment (13)

2. Appendix

2.1 Technical specifications (16)

2.2 Accessories list (18)

2.3 Troubleshooting (19)

2.4 Service (20)

2.5 Warranty (21)

Page 4

Page 5

CHAPTER

Getting started

1

1.1 Important

CAUTION

Throughout the manual,

the section labeled

CAUTION will alert you

to potential hazards for

the user or the unit, and

how to avoid possible

misuse.

Your turntable was shipped partially disassembled

in order to avoid damage to sensitive parts. Please

check immediately to make sure neither the packaging nor the device was damaged during transport. If

you miss parts or the unit is damaged, please do not

operate and contact your dealer.

EVOLUTION R 5.3 | 1 |

Page 6

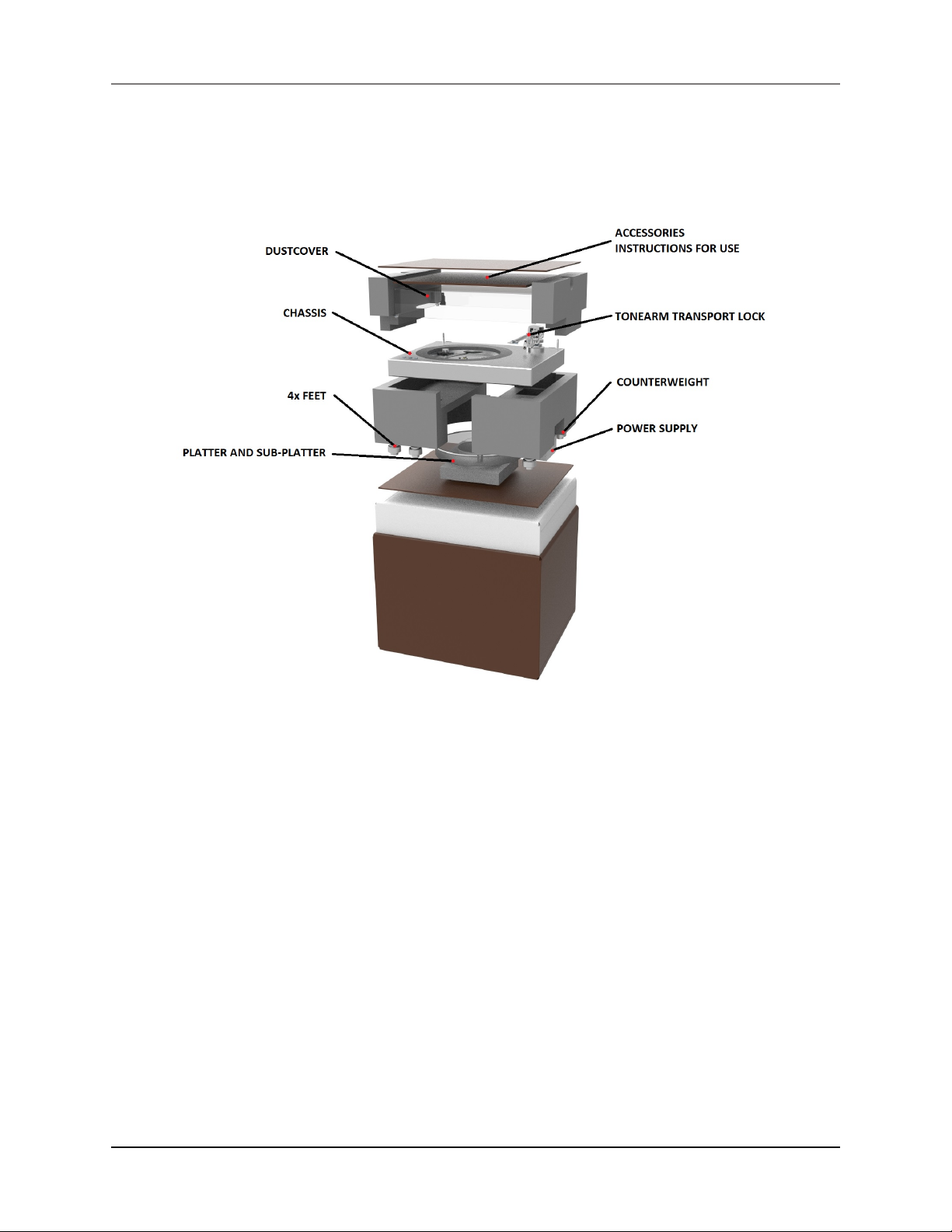

1.2 What’s in the box?

Getting started

1.3 Packaging

AVM packaging is carefully designed to protect your

component from damage during transport. We

highly recommend you keep the original packaging

in order to safely ship or otherwise transport your

turntable going forward.

The packaging materials were chosen to be environmentally friendly. In case you need discard the packaging material, please do your part to help protect

the environment and recycle properly.

EVOLUTION R 5.3 | 2 |

Page 7

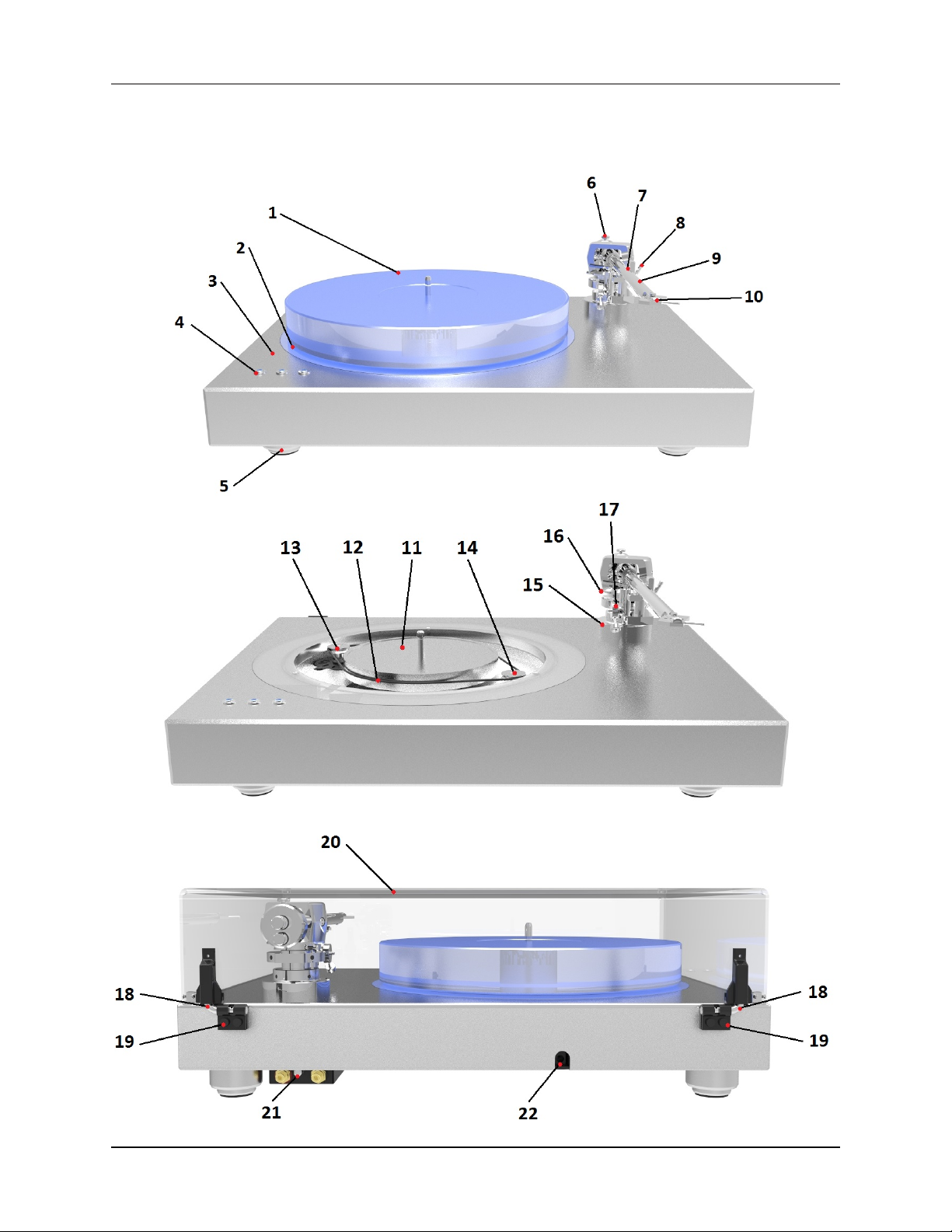

1.4 Control and operating elements

Getting started

EVOLUTION R 5.3 | 3 |

Page 8

Getting started

1. Acrylic platter

2. Acrylic lighting panel

3. Aluminium / MDF chassis

4. Speed control buttons

5. Damped adjustable feet

6. Tonearm counterweight

7. Tonearm rest and removable transport lock

8. Tonearm lift

9. Tonearm tube

10.Head shell with finger lift

11.Sub-platter

12.Drive belt

13.Motor with pulley

14.Guide pulley

15.Tonearm flange

16.Hook screw for anti-skating thread

17.Anti-skating mechanism

18.Dustcover hinge

19.Hinge fasteners

20.Dustcover

21.RCA output with earth connection

22.Power supply socket

EVOLUTION R 5.3 | 4 |

Page 9

1.5 Setup

1.5.1 Feet assembly

Remove the three feet (5) from the grey foam insert

which holds the turntable chassis. Carefully lift the

turntable and screw the feet into the thread inserts

Getting started

on the bottom of the turntable. Balance the turntable by using a spirit level before next steps.

1.5.2 Platter, sub-platter and drive belt installation

Remove the protective cover from the sub-platter

(11). Install the sub-platter (11), drive belt (12) and

platter (1) as shown in the above illustration.

EVOLUTION R 5.3 | 5 |

Page 10

1.5.3 Speed control

To start the rotation of the platter for 33 r.p.m.,

press the left speed control button (4). To play 45

r.p.m., press the right-speed control button (4). To

stop the motor of the turntable, press the middle

speed control button and the turntable will switch to

standby mode.

Getting started

1.5.4 Light control

The turntable is equipped with blue LED diodes

under the platter controlled by a 3-way switch.

Left position – light LED back light

Middle position – no light

Right position – full LED back light

EVOLUTION R 5.3 | 6 |

Page 11

1.5.5 Output connection

Connect the tonearm cable provided with the accessories to the RCA tonearm output that is located at

the rear of the turntable, behind the tonearm. Con-

Getting started

nect a grounding cable on the earth connection

screw.

1.5.6 Tonearm setting

EVOLUTION R 5.3 | 7 |

Page 12

1.5.7 Cartridge installation

Install the cartridge into the aluminium head shell,

using the appropriate hardware included with your

cartridge.

Connect the cartridge as indicated below:

• White: Left channel L+

• Red: Right channel R+

• Green: Right channel R-

• Blue: Left channel L-

Getting started

If unfamiliar with cartridge setups, please refer to

your dealer.

1.5.8 Counterweight assembly

The counterweight has two separate main parts:

EVOLUTION R 5.3 | 8 |

Page 13

The first part is the counterweight itself. The second part is an additional insert that enables optimal

balancing of heavier cartridges.

The counterweight without the additional insert can

balance cartridges from 5 to 8 g. The weight of the

counterweight itself is 104 g.

The counterweight with the additional insert can

balance cartridges from 8 to 16 g. The weight of the

counterweight with the additional insert is124 g.

1.5.9 Vertical Tracking Force setting (VTF)

Getting started

Before setting the Vertical Tracking Force (VTF),

confirm the exact weight of your cartridge. Depending on your cartridge weight, determine whether to

use the counterweight with or without the additional

insert, in accordance with the specifications above.

Pushing carefully, turn the counterweight onto the

rear end of the counterweight support rod as shown

in the illustration above. Place a stylus pressure

gauge (not supplied) onto the platter. To set the

required VTF, lower the tonearm lift lever as indicated in the illustration and place the tip of the stylus on the pressure gauge.

EVOLUTION R 5.3 | 9 |

Page 14

As viewed from the head shell, turning the movement screw counterclockwise (closer towards the

tonearm) increases the VTF, turning it clockwise

(away from the tonearm) reduces the VTF. Turn the

counterweight appropriately until the VTF shown on

the pressure gauge matches your cartridge’s recommended vertical tracking force specifications.

When the VTF is set for a required value, lock the

counterweight by its locking screw. Please make

sure to lock the additional weight if used.

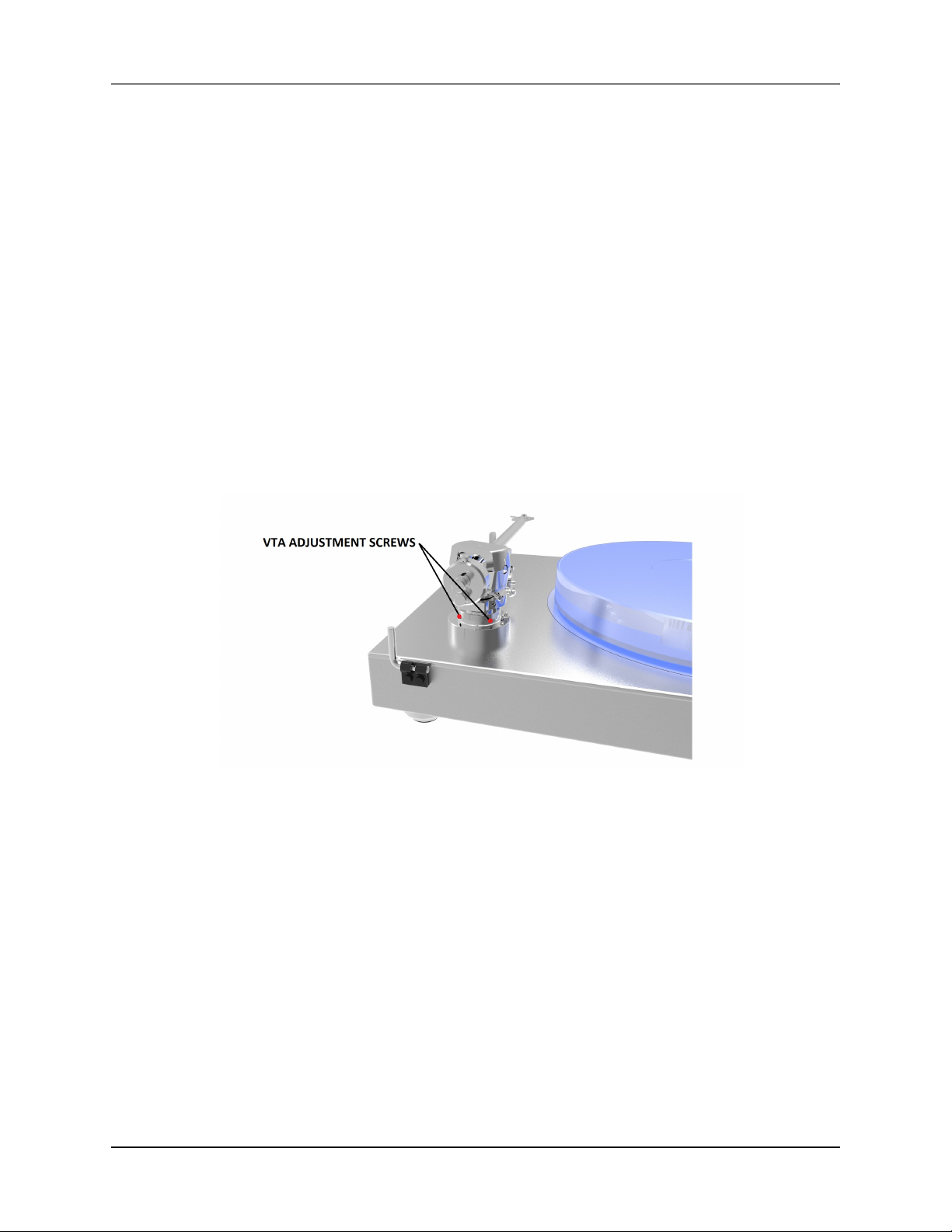

1.5.10 Vertical Tracking Angle setting (VTA)

Getting started

To set the Vertical Tracking Angle (VTA), first put a

record (VTF) on the platter. When the needle is lowered into the record groove, the tube of the tonearm

should be parallel to the surface of the record. If it

is not, loosen both hexagonal screws in the tonearm

base, just enough to allow vertical movement of the

arm pillar without force, and slide the arm up or

down until it is parallel.

Carefully and evenly re-tighten the hexagon screws

without applying excessive force (which may deform

the arm pillar).

EVOLUTION R 5.3 | 10 |

Page 15

1.5.11 Azimuth setting

Getting started

CAUTION

Do not remove the

Azimuth setting

screw completely!

The cartridge needle must be perpendicular to the

record in order to trace the groove wall modulations

correctly.

The azimuth (angle) is precisely set by the factory.

In the event you need to modify this setting, please

follow the instructions below.

Loosen the small Azimuth setting screw using the

1.5 mm hexagonal allen key.

Loosen the screw just enough to be able to gently

rotate the arm tube and set the azimuth to the correct position. The correct position can be checked

from the front view, preferably with the needle

placed on a mirror placed on the platter. Once the

azimuth setting is correct, gently re-tighten the Azi-

muth setting screw.

EVOLUTION R 5.3 | 11 |

Page 16

Getting started

Examples of incorrect and correct azimuth setups:

FALSE: Too much left angle

FALSE: Too much right angle

CORRECT: 100% perpendicular to the record.

EVOLUTION R 5.3 | 12 |

Page 17

1.5.12 Anti-skating assembly and adjustment

Getting started

CAUTION

Be careful when handing the anti-skating

thread in order to avoid

damaging it.

The anti-skating mechanism is shipped partially disassembled to avoid damage during transport. For

correct installation, please follow the steps below.

Step 1

Prepare the following parts supplied from the

accessories bag: Anti-skating sliding mechanism

with anti-skating weight and thread for mounting on

the tonearm.

Step 2

Put the anti-skating sliding mechanism on the end

of the anti-skating support rod.

EVOLUTION R 5.3 | 13 |

Page 18

Getting started

Step 3

The anti-skating sliding mechanism is supplied with

a pre-mounted anti-skating weight and anti-skating

thread. Put the eye of the anti-skating thread around

the hole for the HOOK SCREW and screw the HOOK

SCREW into the tonearm through the eye of the antiskating thread as shown in the illustration below.

Step 4

Anti-skating force adjustment

EVOLUTION R 5.3 | 14 |

Page 19

Getting started

Adjust the anti-skating force by positioning the

weight on the appropriate groove of the anti-skating

sliding mechanism. Anti-skating down force should

be adjusted in correspondence with the tonearm

down force as follows:

Tonearm

Downforce

Lower than 13

mN or 1.3 g

14-18 mN or 1.3-

1.8 g

19-25mN or 1.9-

2.5 g

Anti-Skating

Groove

1st groove from

bearing

2nd groove from

bearing

3rd groove from

bearing

EVOLUTION R 5.3 | 15 |

Page 20

CHAPTER

Appendix

2

2.1 Technical specifications

EVOLUTION R 5.3 | 16 |

Page 21

Appendix

Nominal speed 33/45 rpm, elec-

tronic speed

change (microprocessor controlled)

Speed variance 33rpm: ± < 0.12%,

45rpm: ± < 0.10%

Wow and flutter 33rpm: ± < 0.10%,

45rpm: ± < 0.09%

Signal to noise S/N Ratio: -72 dB

Downforce range 0 - 35 mN

0 - 3.5 grams

Supplied counterweight system

Counterweight

104 g without

additional insert

> for cartridges

5 – 8 g

Counterweight

with additional

insert 123 g

> for cartridges

8 – 16 g

Effective tone-

15 g

arm mass

Head-shell 0,5‘‘ (12,7mm)

standard

Mounting

distance

Effective tone-

238mm (platter –

tonearm base)

254 mm

arm length

Overhang 16 mm

Power consumption

EVOLUTION R 5.3 | 17 |

5 W max/ 0.3W

standby

Page 22

Voltage Universal switch

mode power supply 15 V DC/

1.6 A (100-240 V

AC, 47 - 63Hz)

Appendix

Dimensions (W x

H x D)

Weight (without

box)

Weight (with box) 13 kg

2.2 Accessories list

• Instructions for use

• Power supply 15V DC / 1.6 A

• Anti-skating weight

• Single adaptor

470 x 390 x

175mm

12 kg (turntable)

5 kg (platter)

• RCA output cable

• White cotton gloves

• Cloth

• Allen keys (1.5,mm, 2mm, 2.5mm)

• Counterweight

• Counterweight insert

• 2 x Anti-skating thread

• Anti-skating sliding mechanism

EVOLUTION R 5.3 | 18 |

Page 23

2.3 Troubleshooting

The platter doesn’t turn although the unit is

switched on

• The unit is not connected to the mains power

supply (the building’s electrical system).

• No mains power is being delivered at the

socket.

• The drive belt is not fitted properly or has

slipped off.

No signal through one or both channels

Appendix

• No signal contact from the cartridge to the

internal tonearm wiring; or from that to the

arm lead; or from that to the phono box; or

between that and the amplifier. This could be

due to a faulty plug, broken wire or loose solder joint in the plug/socket connection.

• Phono input not selected at amplifier.

• Amplifier not switched on.

• Amplifier or speakers are defective or muted.

• No connection to the loudspeakers

Strong hum on phono input

• No ground connection from cartridge or arm

or arm cable to amplifier, or ground loop.

EVOLUTION R 5.3 | 19 |

Page 24

2.4 Service

Appendix

Distorted or inconsistent sound from one or both

channels:

• Turntable is connected to wrong input of

amplifier, or MM/MC switch is incorrectly set.

Needle or cantilever damaged. Wrong rpm;

drive belt overstretched or dirty; platter bearing needs lubrication or is dirty or damaged.

Should you encounter a problem that you are not

able to identify or alleviate despite the above information, please contact your dealer for further

advice. Only when the problem cannot be resolved

should the unit be sent to the responsible distributor in your country.

Guarantee repairs will only be effected if the unit is

returned in appropriate packaging. For this reason

we recommend keeping the original packaging.

Never return a turntable without making sure that is

it properly disassembled and correctly packaged in

the original packaging according to the supplied

diagram. Please: Remove the feet, counterweight,

platter, cartridge and belt and pack them separately.

Fit the cartridge protection cap. Insert the transport

lock for the tonearm prior to carefully packaging the

turntable.

EVOLUTION R 5.3 | 20 |

Page 25

2.5 Warranty

Appendix

The manufacturer accepts no responsibility for

damage caused by failing to adhere to these instructions for use and/or by transportation without the

original packaging. Modification or change to any

part of the product by unauthorized persons

releases the manufacturer from any liability over

and above the lawful rights of the customer.

The information above was correct at the time of

going to press. The manufacturer reserves the right

to make changes to the technical specifications

without prior notice as deemed necessary to uphold

the ongoing process of technical development.

This guide was produced by:

AVM Audio Video Manufaktur GmbH.

Copyright © 2018. All rights reserved.

August 15th 2018.

EVOLUTION R 5.3 | 21 |

Loading...

Loading...