USER MANUAL

AVL DITEST DPM 800

ID number:

AT7639E

Revision:

02

Issued:

03 / 2018

Data subject to alteration. All

data valid at time of printing.

FUTURE SOLUTIONS FOR TODAY

AVL DiTEST GmbH

Alte Poststrasse 156

A-8020 Graz / AUSTRIA

Tel: +43 316 787 - 0

Fax: +43 316 787 - 1460

ditest@avl.com

www.avlditest.com

Copyright © 2016 AVL DiTEST GMBH, all rights reserved.

The contents of this publication, as a whole or in part, may not be reproduced in any form

or passed on to third parties without the prior written consent of AVL DiTEST. This

publication was written exercising reasonable care. AVL DiTEST can therefore not accept

any liability whatsoever for any errors or omissions as well as for any possible damage.

AVL DiTEST DPM 800

Warnings and safety information

User manual

I

Warnings and safety information

This equipment manual contains important warnings and safety information

which must be observed by the user.

The product is only intended for a very specific application described in the

equipment manual. Furthermore, the most important prerequisites and safety

measures required for the us e a nd oper ati on o f the pro duct are ex plai ned to e nsu re

smooth operation.

We do not accept any warranty and liability for applications other than the

application described and without observing the required preconditions and safety

measures.

The product may only be used and operated by personnel that due to its professio nal

qualification is able to observe the required safety measures when using and

operating the equipment. It may only be operated with the accessories and

consumables supplied by DITEST or approved by DITEST. Since with this product

the measuring resul ts not only depend on proper f unctioning of the product , but also

on a number of further conditions, it is necessary to have the results generated by

the product checked (e.g. plausibility check) by an expert prior to implementing

further measures based on the generated measured value.

Adjustments and maintenance of live, opened devices may only be carried out by

qualified personnel trained for that purpose and that is aware of the risks involved.

The product may only be repaired at the supplying factory or by the qualified

personnel trained for that pur pose.

When using the produc t, a sp ecialist must ens ure th at neither the tes t object nor th e

test facility can operate in such a manner that it might damage property or put

personnel at risk.

Warnings and safety information

AVL DiTEST DPM 800

II

User manual

AVL DiTEST DPM 800

Summarized of safety information

User manual

III

Summarized safety instructions

Risk of fatal injury from electric current on vehicles with high-voltage systems.

Dangerous high voltages capable of delivering fatal electric shocks are present on the HV energy

store (HV battery) and the components connected to it.

Make sure that nobody comes into contact with the connections of the HV battery, the connecting

leads or any other components connected to the high-voltage power supply.

Danger of electric shock on the ignition system

The ignition system is under life-threatening hi gh volta ge!

Do not touch the ignition system while engine is running!

Danger of electric shock on vehicles with xenon headlight

The lighting system with xenon headlight is under life-threatening high voltage!

Do not touch any component while the xenon light is switched on!

Danger due to harmful or irritating substances

Tests with engine running in closed rooms (workshops, test halls, etc.), the exhaust emission has

to be vented to the outside and the space should be adequately ventilated!

Risk of burns due to hot components

Perform measurements at normal engine operating temperature or follow the respective test

specification!

Do not touch any hot components such as engine, engine mountings and the entire exhaust

system! If necessary, use cooling fans!

DANGER

WARNING

WARNING

WARNING

WARNING

Summarized of safety information

AVL DiTEST DPM 800

IV

User manual

Risk of injury due to rotating parts

Perform any work in the engine compartment while engine and ignition are turned off!

Do not touch any rotating parts, such as, assemblies of electric generator, radiator fan and their

drives (e.g. V belt)!

With running engine ensure a safe installation of the measuring cables!

Risk of injury due to unsecured vehicle

Apply the hand brake or place the selector lever to P (automatic transmission)!

Secure vehicle adequately against rolling!

Explosion hazard due to pyrotechnic installation and restraint system

Test and installation work should only be carried out by trained personnel!

Under no circumstances should the igniter be tested with the multimeter!

System verification only with approved testing device!

Disconnect the battery when working on the airbag system!

When disconnecting the battery the ignition has to be switched off and there should be nobody in

the passenger compartment!

Always store dismounted airbag unit with discharge area up or according to the storage

instructions!

Airbag unit should never be left unattended!

Protect airbag unit against flying sparks, open fire and temperatures above 100°C!

Do not transport airbag unit in the passenger compartment!

Do not bring airbag unit in contact with oil, grease and cleaning agents!

Airbag unit that dropped more than 0.5m has to be replaced!

Dispose of untriggered airbag units!

Do not open or repair airbag unit!

Observe the applicable manufacturer's specifications when holding the cutoff speed of diesel

engines!

Always switch off the ignition first before connecting and disconnecting the OBD plugs or the

different AVL vehicle adapters!

WARNING

NOTICE

WARNING

WARNING

NOTICE

AVL DiTEST DPM 800

Safety information

User manual

V

Safety information

AVL DiTEST DPM800 Piezo-electric pressure-sensing

sparkplug

Choice of piezo-electric pressure-sensing sparkplug:

Using the wrong piezo-electric pressure-sensing sparkplug can lead to electrical and mechanical

damage extending even to major engine damage.

Make sure that you choose the right piezo-electric pressure-sensing sparkplug to suit the engine

being tested.

(Physical dimensions, seal seat (tapered or flat), etc.)

Electrode gap:

The electrode gap is an important criterion for the production of a proper ignition spark. Please note

that the sparking section of the piezo-electric pressure-sensing sparkplug is a very slim design due

to the small amount of space available.

Because of that, the ignition voltages should not be as high as with normal sparkplugs in order to

prevent damage to the insulator. The correct choice of electrode gap substantially affects the

ignition voltage required.

Turbocharged/supercharged engines:

When turbocharged/supercharged engines are operating at very high boost pressures the required

ignition voltage is higher. This can be counteracted by reducing the electrode gap (approx. 0.5

mm).

(Due to the special construction of the piezo-electric pressure-sensing sparkplug, the insulation can

break down if the electrode gap is too large.)

AVL DiTEST DPM800 Piezo-electric glow plug pressure

sensor adaptor

Choice of piezo-electric glow plug pressure sensor adaptor:

Using the wrong piezo-electric glow plug pressure-sensor adaptor can lead to electrical and

mechanical damage extending even to major engine damage.

Make sure that you choose the right piezo-electric glow plug pressure sensor adaptor to suit the

engine being tested.

The glowplug adaptor is used only to hold the pressure sensor. Preheating the cylinder with the

piezo-electric glowplug pressure sensor adaptor when starting the engine is not possible.

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

Safety information

AVL DiTEST DPM 800

VI

User manual

AVL DiTEST DPM 800

Contents

User manual

VII

Contents

Warnings and safety information ................................................................ I

Summarized safety instructions ................................................................ III

Safety information ....................................................................................... V

1 General introduction ...................................................................... 1-1

1.1 General description ....................................................................................................... 1-1

1.2 Safety instructions ......................................................................................................... 1-2

1.3 Typographical conventions .......................................................................................... 1-2

1.4 Operation of PC programs ............................................................................................ 1-3

2 Initial use ........................................................................................ 2-1

2.1 Installing the software ................................................................................................... 2-1

2.2 Installing the AVL DiX 2.0 software .............................................................................. 2-1

2.3 Updating AVL DiX 1.0 to AVL DiX 2.0 .......................................................................... 2-2

2.4 Activating the AVL DiTEST DPM 800 with the AV L DiScope 802 present ............... 2-3

3 Measuring ....................................................................................... 3-1

3.1 Taking a reading ............................................................................................................ 3-1

3.1.1 Setting the pressure sensor sensitivity ....................................................... 3-7

3.1.2 Determining TDC ............................................................................................ 3-8

3.1.3 Signal representation ................................................................................... 3-11

3.1.4 Markings ........................................................................................................ 3-11

3.1.5 Setting DC offset in bar................................................................................ 3-11

3.2 Tips on testing ............................................................................................................. 3-12

3.3 Testing while the car is being driven ......................................................................... 3-12

3.4 AVL DiTEST DPM 800 Connection Box ..................................................................... 3-12

4 Care and maintenance ................................................................... 4-1

4.1 Visual check ................................................................................................................... 4-1

4.2 Cleaning .......................................................................................................................... 4-1

4.3 Replacing the battery .................................................................................................... 4-1

5 Product specifications ................................................................... 5-1

6 Warranty ......................................................................................... 6-1

6.1 New devices ................................................................................................................... 6-1

6.2 Exchange or loaned devices ........................................................................................ 6-1

6.3 Event of damage or loss ............................................................................................... 6-1

7 Technical data ................................................................................ 7-1

Contents

AVL DiTEST DPM 800

VIII

User manual

AVL DiTEST DPM 800

General introduction

User manual

1-1

1 General introduction

1.1 General description

The AVL DiTEST DPM 800 (DPM = dynamic pressure measurement) enables the progression of

the relative internal cylinder pressure to be measured using a sparkplug with an integral pressure

sensor (piezo-electric pr es sur e-sensing sparkplug) or, on diesel engines, using a glow pl ug ada ptor

with integral pressure sensor.

(Piezo-electric glow plug pressure sensor adaptor).

The AVL DiTEST DPM 800 includes a signal converter/amplifier which conditions the signal from the

piezo-electric pressure-sensing sparkplug (piezo-electric glow plug pressure sensor adaptor) for the

AVL DiScope 802.

The data readings are processed by the AVL DiScope 802.

When doing so, it tracks the pressure progression in relation to the crankshaft position with the aid

of the on-board TDC engine speed sensor.

Measurement of the internal cylinder pressure can provide the following relative readings:

• indicated mean pressure of the cylinder tested (pmi)

• maximum pressure of the cylinder tested (pmax)

• position relative to engine TDC at which maximum pressure is achieved in the cylinder

tested (pmax/TDC)

• engine speed at which readings were taken

The product specifications also include an adaptor socket for fitting the piezo-electric pressuresensing sparkplug/glow plug pressure sensor adaptor.

Please note that Version 2.0 of AVL DiX is required to operate the AVL DiTEST DPM 800.

For general guidance on using the AVL DiScope 802, please refer to the AVL DiScope 802 device

manual.

Fig. 1-1

AVL DiScope

802

AVL DiTEST

DPM 800 power

supply unit

Piezo-electric

pressure-

sensing

Piezo-electric

pressure

sensor adaptor

Adaptor

socket

AVL DiTEST

DPM 800

amplifier

General introduction

AVL DiTEST DPM 800

1-2

User manual

1.2 Safety instructions

This documentation contains important warnings and safety instructions which have to be observed

by the user. Only through compliance with these requirements and safety measures it is possible to

ensure correct and safe operation.

Please note the safety instructions on the screen.

1.3 Typographical conventions

Safety instructions:

Indicates an extremely dangerous risk which - if not prevented - leads to death.

Indicates an imminent danger - if not prevented - can result in death or serious injury.

Indicate a danger that may lead to moderate or light injuries.

Additional danger signal:

Danger due to electrical current.

Notice:

This text draws attention to situations or operating error that can lead to property damage or loss of

data.

Information:

This text indicates important information or instructions. Failure to comply with these instructions

prevents or significantly hampers a successful finalization of the operations described in this

documentation.

WARNING

CAUTION

DANGER

NOTICE

Information

AVL DiTEST DPM 800

General introduction

User manual

1-3

Standard text formats:

bold Important text/text passages, parameter

italic On screen dialogs and messages

CAPITAL LETTERS Device designation and operating conditions

MenuMenu item Selection of menu command through tapping on buttons

List formats:

1.

2.

Step-by-step instructions in a specified sequence

•

Instructions, consisting of only one step

Listings without a specific order

-

1.4 Operation of PC programs

This manual assumes basic knowledge of Microsoft Windows.

Please turn to your Windows manual for details.

If necessary, contact your PC support/system administrator.

General introduction

AVL DiTEST DPM 800

1-4

User manual

AVL DiTEST DPM 800

Initial use

User manual

2-1

2 Initial use

2.1 Installing the software

To install the software you must have administrator permissions.

You must have Version 2.0 of AVL DiX installed on your AVL DiX station.

If necessary, update AVL DiX to Version 2.0.

2.2 Installing the AVL DiX 2.0 software

1. All connected modules must be switched off

(set AVL DiLink 480 master switch on rear panel to "0") as the current drivers are not

available at the point of installation.

2. Insert the DVD "AVL DiX 2.X BO7340" in the DVD drive.

3. The screen "AVL DIX SETUP" appears.

(If the screen does not appear, start Windows Explorer, right-click on your DVD drive and

click Autoplay (WIN XP) or Install or run program (Win Vista/Win 7)).

4. Click English and then AVL DiX Installation.

5. If not previously installed, install Windows Installer 4.5 for your operating system (Vista or

XP).

6. Restart the AVL DiX PC.

7. Repeat steps 3 and 4.

8. If not previously installed, install .NET Framework 3.5.

9. Restart the AVL DiX PC.

10. Repeat steps 3 and 4.

11. Click English and then AVL DiX Installation.

12. Click DiX Installation.

13. Accept the licence agreement.

14. Select the version for your country.

15. Select Measuring and testing.

16. Confirm each step by pressing Next or OK.

17. Restart the AVL DiX PC.

18. After completing installation, switch on all AVL DiX modules.

(Set power switch on back of AVL DiLink 480 to "1".)

19. Plug the AVL DiX dongle (silver) into a USB socket.

20. The operating system will automatically detect the new hardware and install the appropriate

drivers.

Click OK when asked to confirm installation of unsigned drivers.

The summary of the system update is then displayed.

Press F8 Confirm to finish the system update.

Information

Initial use

AVL DiTEST DPM 800

2-2

User manual

2.3 Updating AVL DiX 1.0 to AVL DiX 2.0

1. All connected modules must be switched off

(set AVL DiLink 480 master switch on rear panel to "0") as the current drivers are not

available at the point of installation.

2. Insert the DVD "AVL DiX 2.X BO7340" in the DVD drive.

3. The screen "AVL DIX SETUP" appears.

(If the screen does not appear, start Windows Explorer, right-click on your DVD drive and

click Autoplay (WIN XP) or Install or run program (Win Vista/Win 7)).

4. Click English and then AVL DiX Installation.

5. If not previously installed, install Windows Installer 4.5 for your operating system (Vista or

XP).

6. Restart the AVL DiX PC.

7. Repeat steps 3 and 4.

8. If not previously installed, install .NET Framework 3.5.

9. Restart the AVL DiX PC.

10. Repeat steps 3 and 4.

11. Click DiX Installation.

12. Accept the licence agreement.

13. Select the version for your country.

14. Select Measuring and testing.

15. Confirm each step by pressing Next or OK.

16. Select Update.

17. Restart the AVL DiX PC.

18. After completing installation, switch on all AVL DiX modules.

(Set power switch on back of AVL DiLink 480 to "1".)

19. The operating system will automatically detect the new hardware and install the appropriate

drivers.

Click OK when asked to confirm installation of unsigned drivers.

The summary of the system update is then displayed.

Press F8 Confirm to finish the system update.

AVL DiTEST DPM 800

Initial use

User manual

2-3

2.4 Activating the AVL DiTEST DPM 800 with the

AVL DiScope 802 present

1. Restart the AVL DiX PC.

2. Start AVL DiX.

3. The screen “Licence Update” appears.

4. Click Extras I Update system I Licence.

5. Click F2 File.

6. Insert the disk/CD in the drive.

7. Select the licence file (.lic) for the dongle.

8. Click Open.

9. The screen "Licence Update" appears.

Click Transfer licence to dongle].

10. Clicking Shows the contents of the dongle shows the contents of the dongle, which should

include the following entries:

LIC SCOPE [XA7003]

LIC DIX SCOPE DPM [XA7038]

11. Finish activation of the AVL DiTEST DPM 800 by clicking Next.

Initial use

AVL DiTEST DPM 800

2-4

User manual

AVL DiTEST DPM 800

Measuring

User manual

3-1

3 Measuring

3.1 Taking a reading

1. Switch off the vehicle's engine.

2. Unscrew the sparkplug (glow plug).

3. Carefully feed the lead for the piezo-electric pressure-sensing sparkplug (glow plug pressure

sensor adaptor) through

the adaptor socket (A).

In the adaptor socket there is a slot (B) through which the lead can pass through the socket

without being damaged.

Fig. 3-1

4. Carefully screw the piezo-electric pressure-sensing sparkplug (glowplug pressure sensor

adaptor) carefully into the engine.

Take care not to damage the lead.

5. Carefully route the lead for the piezo-electric pressure-sensing sparkplug (glow plug

pressure sensor adaptor) through the engine compartment.

Route the leads so that they

- do not come into contact with any hot parts

- are not close to any hot parts (radiant heat)

- do not come into contact with any rotating parts

- are not kinked or damaged

(B)

(A)

NOTICE

Measuring

AVL DiTEST DPM 800

3-2

User manual

6. Carefully screw the lead (C) for the piezo-electric pressure-sensing sparkplug (glow plug

pressure sensor adaptor) to the AVL DiTEST DPM 800 amplifier (D), see Fig. 3-2.

Take care not to cross the thread when screwing on the lead.

Fig. 3-2

7. Screw the lead from the AVL DiTEST DPM 800 power supply unit SIGNAL OUT connection

(E) to the AVL DiTEST DPM 800 amplifier (D), see Fig. 3-3.

Take care not to cross the thread when screwing on the lead.

Fig. 3-3

(C)

(D)

(E)

(D)

AVL DiTEST DPM 800

Measuring

User manual

3-3

8. Connect the CH1 connection on the AVL DiSco pe 802 to the SIGNAL OUT socket on the

AVL DiTEST DPM 800 power supply unit using the connecting lead (F), see Fig. 3-4.

Fig. 3-4

9. Connect the on-board engine speed/TDC sensor to connection CH2 (I) on the

AVL DiScope 802.

Wire the on-board engine speed/TDC sensor connection parallel, i.e. without disconnecting

the wiring loom.

10. Switch on the AVL DiTEST DPM 800 power supply unit at the ON/OFF switch (G).

The PWR LED (H) should show blue.

(F)

(G)

(H)

(I)

Measuring

AVL DiTEST DPM 800

3-4

User manual

11. Start AVL DiX as described in the AVL DiScope 802 device manual.

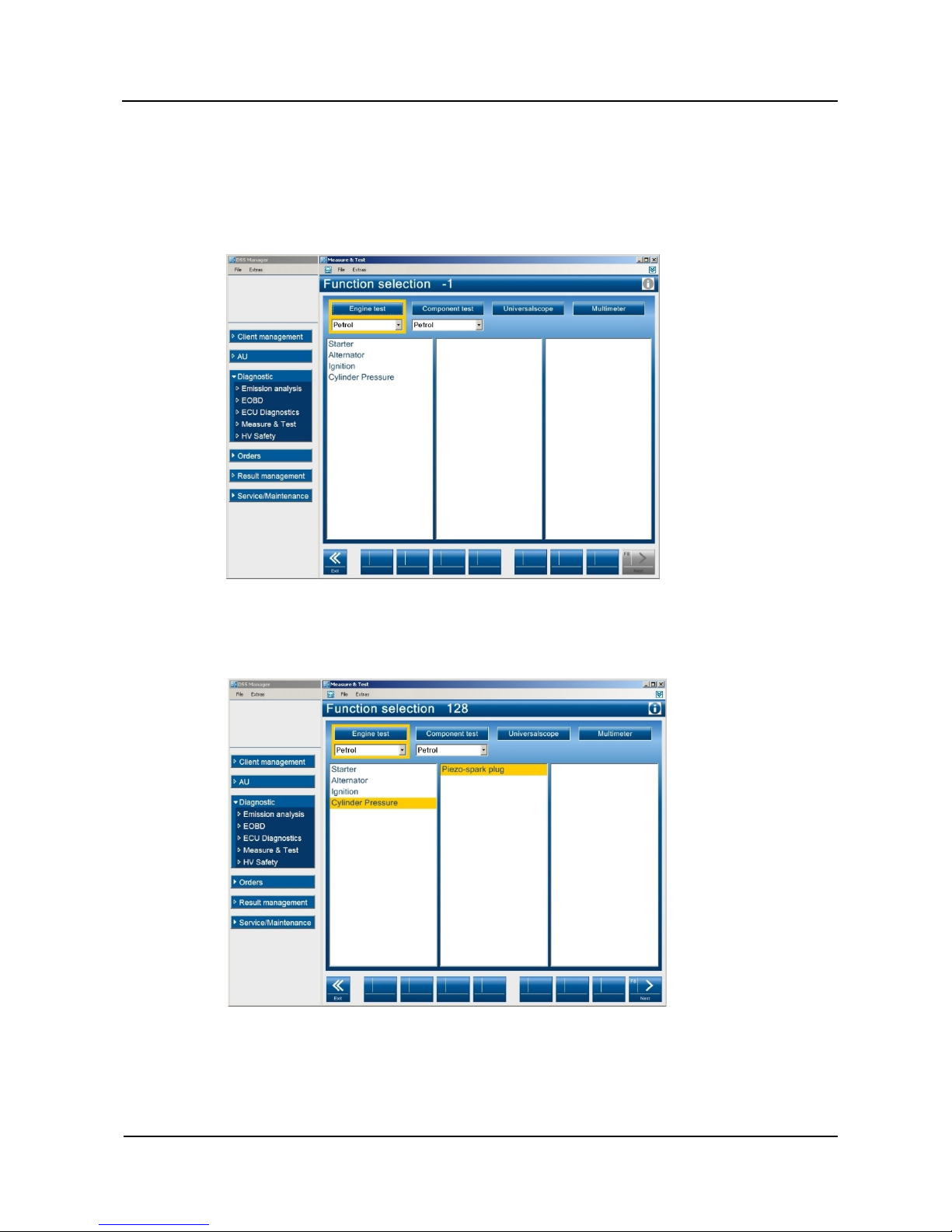

12. Select the mode Diagnostic I Measure & test I Enginetest I Petrol (if testing cylinder

pressure with the piezo-electric pressure-sensing sparkplug)

or Diesel (if testing cylinder pressure with the piezo-electric glow plug pressure sensor

adaptor), see Fig. 3-5.

Fig. 3-5

13. Select the mode Cylinder Pressure I Piezo-spark plug (Piezo- glow plug for diesel

engines), see Fig. 3-6.

Fig. 3-6

14. Click F8 Next.

AVL DiTEST DPM 800

Measuring

User manual

3-5

Enter the TDC offset, if known, and select the number of strokes per engine cycle,

see Fig. 3-7.

Only by entering the correct TDC offset can meaningful readings be obtained.

You can find out the TDC offset.

Proceed as described in Section 3.1.2 "Determining TDC".

Fig. 3-7

Information

Measuring

AVL DiTEST DPM 800

3-6

User manual

15. Click F8 Next. The results of the test are shown.

Fig. 3-8

As well as the internal cylinder pressure (red trace, channel 1)

and the on-board engine speed/TDC signal (blue trace, channel 2),

the following relative readings are shown in the area (A):

Mean pressure, imep:

This is the indicated mean pressure, i.e. essentially it is the averaged surplus pressure

prevailing between 0° and 180° of crankshaft rotation, see (B).

Max. pressure pmax:

The maximum pressure, in the example 7.5 bar, see (C).

pmax/TDC:

The crankshaft angle at which the maximum pressure occurs relative to the engine's TDC. in

the example -0.8° of crankshaft rotation, see (D).

RPM:

The engine speed while taking the pressure readings, in the example 860 rpm.

Ref/TDC:

The TDC offset entered or determined, in the example 20° of crankshaft rotation.

16. To go back, press << Cancel.

(A)

B C D

-

AVL DiTEST DPM 800

Measuring

User manual

3-7

3.1.1 Setting the pressure sensor sensitivity

To obtain optimum representation of the measured data, you have to set the sensitivity of the

piezo-electric pressure-sensing sparkplug (glow plug pressure sensor adaptor).

1. The figures are printed on the top of the

package containing the piezo-electric

pressure-sensing sparkplug (glow plug

pressure sensor adaptor), in the example

shown:

Sensitivity RT

0 – 140 BAR 16.24 pC/BAR

0 – 200 BAR 16.25 pC/BAR

see Fig. 3-9.

Fig. 3-9

2. On the results graph screen (display mode), see Fig. 3-8, click F8 Switching.

3. In the box "bar/mV" enter the rounded figure (see above), in the example shown 16mV

(16.24pC/BAR => 16mV).

Explanation:

The charge amplifier used has a signal voltage/charge ratio of

1mV per pC (pico coulomb).

If the pressure sensor produces a charge of 16.24 pC at 1 bar pressure and the change

amplifier connected generates a signal voltage of 1 mV/pC, then the signal voltage equates

to 16.24 mV per 1 bar of measured pressure.

Fig. 3-10

4. To return to the results graph screen (display mode), Fig. 3-8, click F8 Switching.

Measuring

AVL DiTEST DPM 800

3-8

User manual

3.1.2 Determining TDC

Only by entering the correct TDC offset can meaningful readings be obtained.

See also Fig. 3-7.

Starting from the results screen (display mode), see Fig. 3-8, proceed as follows:

1. Put the engine into non-firing overrunning mode.

- When stationary, that is done by revving the engine to a high speed and then releasing the

accelerator.

- On the road, it is done by driving downhill with your foot off the accelerator.

In addition, if possible, you can also shut off fuel injection into the cylinder being tested by

electrically disabling the fuel injector, e.g. by unplugging the lead.

2. Stop the test by clicking F2 Freeze.

3. Using the button, scroll back to when the cylinder was firing.

You can identify when the cylinder was firing by:

- a high cylinder pressure

- a high engine speed

see Fig. 3-11.

Fig. 3-11

Information

AVL DiTEST DPM 800

Measuring

User manual

3-9

4. Using the button, scroll forwards to when the cylinder was overrunning.

You can identify when the cylinder was overrunning by:

- a low maximum pressure

- a raised engine speed (>2000 rpm)

- a distinctly evident negative pressure following gas expansion after TDC

see Fig. 3-12.

Fig. 3-12

5. Activate TDC detection by clicking .

Green colour indicates: reference marker detected and related to TDC.

Red colour indicates: reference marker not detected,

reference marker could not be related to TDC

(TDC detection could not be completed).

If the reference marker is detected and related to TDC, the internal cylinder pressure is then shown

in correct relation to TDC.

Measuring

AVL DiTEST DPM 800

3-10

User manual

By selecting the option box you can display cursors marking the maximum

pressure and the detected reference marker position of the on-board engine speed/TDC sensor

signal.

Fig. 3-13

AVL DiTEST DPM 800

Measuring

User manual

3-11

3.1.3 Signal representation

The basic signal setting is chosen so that analysable signals are displayed at idling speed.

At higher speeds and loads, the pressure conditions change and the signals behave accordingly.

In order to obtain optimum signal representation for your particular application, proceed as follows:

1. On the results graph screen (display mode), Fig. 3-8, click F8 Switching.

2. Channel 1 (CH1):

Open the drop-down option box "Pressure/Div" and select a suitable pressure.

3. Channel 2:

Open the drop-down option box "Voltage/Div" and select a suitable vol tag e.

In this connection please also refer to the AVL DiScope 802 device manual.

3.1.4 Markings

By selecting the option box you can display cursors marking the maximum

pressure and the detected reference marker position of the on-board engine speed/TDC sensor

signal.

3.1.5 Setting DC offset in bar

Starting from the results screen (display mode), see Fig. 3-8, proceed as follows:

1. Click F8 Switching to change to settings mode.

The default setting is 31.8 bar (it is based on an amplifier offset voltage of 500 mV and an

average pressure sensor sensitivity).

If you take a reading under unpressurised conditions, e.g. with the pressure sensor removed

from the engine but connected, the reading trace should run along the zero line.

2. If that is not the case, you can re-read the offset by clicking .

3. Clicking F8 Switching again returns you to display mode.

Subsequently you can fine-tune the offset while a test is in progress by clicking inside the box

and entering a suitable figure until the neutral-pressure signal status (shortly

before induction pressure status) runs along the zero-bar line.

Information

Measuring

AVL DiTEST DPM 800

3-12

User manual

3.2 Tips on testing

During the starting sequence on petrol engines, the maximum cylinder pressure measured is

distinctly higher than in idling mode.

Due to the throttle being closed and the more dynamic conditions when the engine is running, the

throttle effect is greater, which in turn produces a low maximum pressure.

Example:

While the engine is being started, despite the throttle being closed, the intake air flow is not so

dynamic that it produces high throttle losses.

-> The maximum cylinder pressure is equal to the known final compression.

The throttle losses are different when the engine is idling as the intake air flow is much more

dynamic.

-> The maximum cylinder pressure drops to a substantial degree (e.g. 5 - 6 bar).

3.3 Testing while the car is being driven

Risk of injury

Never take readings when driving the car alone.

(Driver drives, passenger takes readings.)

Route the leads through the car so that they

- do not come into contact with any hot parts

- are not close to any hot parts (radiant heat)

- do not come into contact with any rotating parts

Secure the leads and the AVL DiTEST DPM 800 amplifier in the car.

3.4 AVL DiTEST DPM 800 Connection Box

The AVL DiTEST DPM 800 Connection Box is equipped with a 9V PP3 battery.

Switch off the AVL DiTEST DPM 800 Connection Box after completing the test.

(See also Fig. 3-4, item G.)

WARNING

AVL DiTEST DPM 800

Care and maintenance

User manual

4-1

4 Care and maintenance

4.1 Visual check

Regularly carry out a visual check of the AVL DiTEST DPM 800.

Examine all components for damage (e.g. breakages) and dirt contamination.

Regularly check the AVL DEM 800 amplifier, the piezo-electric pressure-sensing sparkplug, the

piezo-electric glow plug pressure sensor adaptor, the adaptor socket and all leads for damage and

dirt contamination.

4.2 Cleaning

Before cleaning the AVL DiTEST DPM 800, disconnect all leads and switch off the AVL DiTEST

DPM 800 amplifier.

Only clean the AVL DiTEST DPM 800 with a dry cloth.

Do not use any cleaning agents or solvents.

4.3 Replacing the battery

1. Switch off the AVL DiTEST DPM 800 Connection Box at the ON/OFF switch (K).

2. Unscrew the lead to the AVL DiScope 802 (L) from the AVL DiTEST DPM 800 Connection

Box SIGNAL OUT connection and the lead (M) from the AVL DiTEST DPM 800 amplifier.

Fig. 4-1

(M)

(L)

(K)

Care and maintenance

AVL DiTEST DPM 800

4-2

User manual

3. Carefully slide the battery cover (N) on the back of the AVL DiTEST DPM 800 Connection

Box downwards.

Fig. 4-2

4. Take out the battery (O) and disconnect the terminals (P).

Connect a new battery and insert it in the AVL DiTEST DPM 800 power supply unit.

Fig. 4-3

5. Carefully replace the cover, see Section 3, Fig. 4-2.

(N)

(P)

(O)

AVL DiTEST DPM 800

Product specifications

User manual

5-1

5 Product specifi cations

Component

Order number

System consists of:

Station AVL DiX 102 (if not already present)

VS8128

AVL DiTEST DPM 800

VS8755

Consisting of:

Connection Box not includin g 9V PP3 batt er y

BO7725

Battery, 9V, PP3 E

HI0001

AVL DiTEST DPM 800 amplifier

GG1407

Adaptor socket to fit piezo-electric pressure-sensing sparkplug or

glow plug pressure sensor adaptor ordered

E.g. GG7405 or

WG0140 or

WG0200 …

Piezo-electric pressure-sensing sparkplug or glow plug pressure

sensor adaptor ordered

Lead, BNC 0.5m black RG 58

EX7528

DiX software CD

BO7340

DiX manual CD

VM7777

Product specifications

AVL DiTEST DPM 800

5-2

User manual

AVL DiTEST DPM 800

Warranty

User manual

6-1

6 Warranty

6.1 New devices

New devices have a 12-month warranty period.

The batteries have a six-month warranty period.

The agreements with your supplier apply.

Principally wear parts and accessories are excluded from the warranty.

For the execution the date of the shipping note to the final customer does apply.

The warranty expires due to:

■ Mechanical damage (e.g. fall, etc.)

■ Pen etr at ion of moistur e (e. g. water , o il, acids, etc .)

■ External intervention (e.g. repairs carried out by non-authorized people)

■ Improper operation (e.g. control of touch screen with sharp or pointed

object, cleaning with compressed air)

■ Improper storage, care and maintenance (e.g. cleaning the device with solvent-based

cleaners)

6.2 Exchange or loaned devices

The agreements with your supplier apply.

For the execution the date of the shipping note to the final customer does apply.

6.3 Event of damage or loss

In the event of damage or loss, please contact the respective AVL DiTEST office / the respective

AVL DiTEST partner in your country.

Warranty

AVL DiTEST DPM 800

6-2

User manual

AVL DiTEST DPM 800

Technical data

User manual

7-1

7 Technical data

Piezo-electric pressure-sensing

sparkplug

Piezo-electric pressure-sensing

sparkplug:

Sparkplug with integral pressure sensor manufactured to

customer specifications

(Order form – AT7657D/E)

Piezo-electric glow plug pressure

sensor adaptor

Piezo-electric glow plug pressure

sensor adaptor:

Glow plug adaptor with integral pressure sensor

manufactured to customer specifications

(Order form – AT7656D/E)

Adaptor socket

Adaptor socket:

Adaptor socket for fitting the piezo-electric pressuresensing sparkplug with slot for the pressure sensor lead

AVL DiTEST DPM 800

Connection Box

Dimensions (WxHxD):

60x120x20mm

Weight:

Approx. 500g

Operating temperature:

+5 … +35 °C

Transportation temperature:

-25 … +60 °C

Power suppl y:

9V PP3 battery supplied

Connections:

Input:

- SIGNAL IN (piezo-electric pressure-sensing

sparkplug/glow plug pressure sensor adaptor)

Outputs:

- SIGNAL OUT (AVL DiScope 802)

Controls and displays:

Button:

- ON/OFF

LED:

- PWR (blue)

Technical data

AVL DiTEST DPM 800

7-2

User manual

AVL DiTEST DPM 800 amplifier

Input range

6000 pC

Signal ratio

1mV/pC

(1mV output voltage at 1pC coulomb input voltage)

Zero line

0.5 V

Signal variation

0.5 … 4.5V

Linearity

<0.1 %

Frequency response (-3dB)

10 kHz

Error at 20°C

0.25 %

Overall error over complete

temperature range

1 %

Temperature range

-10 … 120 °C

Signal noise

<2 mVpp

Output resistance

<100 Ω

Load resistance

≤500 Ω

Power suppl y voltage

8 … 32 V

Dimensions (length x dia.):

131x13.8mm

Plug

M12

Connections

Input:

- Piezo-electric pressure-sensing sparkplug/glow plug

pressure sensor adaptor

Outputs:

- AVL DiScope 802, CH1 or CH2

CE mark:

CE mark:

The manufacturer hereby declares that the AVL DiTEST

DPM 800 complies with the provisions of the EC Directives

cited below including all relevant am endments:

- EN 61010-1 (Safety Requirements)

- EN 61326-1 (EMC)

- 2006/95/EC Low-voltage Elec tr ic al Equipment Directive

Disposal:

Disposal

This AVL DiTEST product is a high-quality electrical and

electronic device which must not be disposed of as normal

household waste.

For disposal, it is essential to comply with local lega l

obligations!

Loading...

Loading...