AVL Industrial Dobby Loom User Manual

Industrial Dobby Loom

User's Manual

AVL Looms

2360 Park Ave.

Chico, CA

95928-8305 U.S.A.

530 893-4915

530 893-1372 (fax #)

info@avlusa.com www.avlusa.com

Copyright © 2018

All Rights Reserved Worldwide

Industrial Dobby Loom User's Manual Introductory Information

Introductory Information ................................................................................................................ 1

Safety .......................................................................................................................................... 2

Warnings: ................................................................................................................................ 2

Safety Features: ....................................................................................................................... 3

IDL Setup ........................................................................................................................................ 5

Introduction ................................................................................................................................. 6

About This Manual ..................................................................................................................... 6

Preparations................................................................................................................................. 6

Safety .......................................................................................................................................... 6

Stopping your loom safely ...................................................................................................... 8

Restarting After an "Emergency Stop" ................................................................................... 9

Additional Loom Setup ............................................................................................................. 10

Square and Level the Loom .................................................................................................. 10

Flexible Air Link ................................................................................................................... 11

Floor Brackets ....................................................................................................................... 11

Power Supply ........................................................................................................................ 11

Setup Your Computer ............................................................................................................... 11

Setup the Air System ................................................................................................................ 12

Compressor ........................................................................................................................... 12

Filter-Regulator (FR) ............................................................................................................ 12

Regulators ............................................................................................................................. 13

Cylinder Flow Controls (Speed Controls) ............................................................................ 14

Testing The Loom ..................................................................................................................... 14

Pre-Operation Checklist ............................................................................................................ 15

Normal Loom Firing Sequence ................................................................................................. 15

Using the IDL ............................................................................................................................... 17

Operating the Loom .................................................................................................................. 18

Manual Loom Control ........................................................................................................... 18

Automatic Loom Control ...................................................................................................... 19

Reversing Cloth Direction ........................................................................................................ 19

Adjustments .............................................................................................................................. 22

Synchronized Loom Motion ................................................................................................. 22

Automatic Cloth Advance Speed Adjustment ...................................................................... 22

Automatic Advance and Cloth Beam Gear Adjustment ....................................................... 23

Introductory Information Page | 3

Introductory Information Industrial Dobby Loom User's Manual

Dobby Cylinder Speed Adjustment (controls harness lifting) .............................................. 25

Shuttle Box Adjustment ........................................................................................................ 26

Cloth Storage Power Control ................................................................................................ 33

Establish Picks Per Inch (P.P.I.) ............................................................................................... 34

Pressure Roller .......................................................................................................................... 36

Temple System (To Prevent Draw-In) ...................................................................................... 37

Setting the Temple Rollers .................................................................................................... 37

Temple Rings ........................................................................................................................ 38

Warp Tension ............................................................................................................................ 38

Set Tension ............................................................................................................................ 39

Troubleshooting Tip.............................................................................................................. 39

Shuttle Box System ................................................................................................................... 40

Normal Mode ........................................................................................................................ 41

Special Mode ........................................................................................................................ 43

Extra Mode............................................................................................................................ 44

Maintenance .................................................................................................................................. 47

Maintenance .............................................................................................................................. 48

General .................................................................................................................................. 48

Square and Level the Loom .................................................................................................. 48

Maintenance .......................................................................................................................... 49

Trouble-shooting ........................................................................................................................... 51

Basic Troubleshooting Tips ...................................................................................................... 52

Shuttle Doesn't Fire ............................................................................................................... 52

Shuttle Won't Stay On Race .................................................................................................. 52

Shuttle Doesn't Box Completely ........................................................................................... 52

Loom Fires on Empty Box .................................................................................................... 52

Loom Stops -- Red Light Is On ............................................................................................. 52

Loom Stops -- Green Light Is On ......................................................................................... 52

Harnesses Drop or Don't Lift ................................................................................................ 53

Automatic Cloth Advance Inoperable ................................................................................... 53

Inconsistent Pick Count ........................................................................................................ 53

Loose Shed ............................................................................................................................ 53

Adjusting the Compu-Dobby .................................................................................................... 53

Adjusting the Shuttle Sensors ................................................................................................... 55

Page | 4 Introductory Information

Industrial Dobby Loom User's Manual Introductory Information

To make the adjustment ........................................................................................................ 55

Troubleshooting the Picker Cylinders ...................................................................................... 56

Diagram of the PLC .................................................................................................................. 57

The Fine Print ............................................................................................................................... 59

AVL Customer Service ............................................................................................................. 60

AVL Warranty .......................................................................................................................... 60

AVL Returns Policy .................................................................................................................. 61

Introductory Information Page | 5

Industrial Dobby Loom User's Manual Introductory Information

INTRODUCTORY

INFORMATION

NTRODUCTORY INFORMATION

I

Introductory Information Page | 1

Introductory Information Industrial Dobby Loom User's Manual

AFETY

S

Before Getting Started:

Please read the entire manual before using the loom.

Warnings:

WARNING:

EQUIPMENT SHOULD ONLY BE USED FOR TEXTILE MANUFACTURING. IF

THE EQUIPMENT IS USED IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY

BE IMPAIRED.

WARNING:

ELECTRICAL SHOCK HAZARD. DO NOT TAMPER WITH ELECTRICAL WIRES

OR OPERATE THE LOOM WITH SAFETY PANELS OPENED OR REMOVED.

WARNING:

PINCH, CRUSH, AND FINGER CUT-OFF HAZARDS. DO NOT OPERATE THE

LOOM WITH SAFETY PANELS OPENED OR REMOVED. DO NOT PLACE

HANDS IN MOVING MECHANISMS OR SCISSORS.

Page | 2 Safety

Industrial Dobby Loom User's Manual Introductory Information

WARNING:

EQUIPMENT PANELS ARE AWKWARD AND HEAVY. TO AVOID MUSCLE

STRAIN OR INJURY, USE PROPER LIFTING TECHNIQUES AND A HELPER.

WARNING:

DO NOT POSITION EQUIPMENT IN A WAY TO BLOCK OR IMPEDE ACCESS

TO DISCONNECTING DEVICES, EMERGENCY STOPS, OR ON/OFF BREAKER

SWITCHES

WARNING:

USE OF CONDUCTIVE FIBER OR YARN ON OR AROUND THIS EQUIPMENT

WILL VOID WARRANTY AND MAY DAMAGE EQUIPMENT.

WARNING:

THIS EQUIPMENT IS CLASSIFIED FOR LIGHT INDUSTRIAL ENVIRONMENT

ONLY. OPERATION OF HIGH-CURRENT DRAW EQUIPMENT (EX. MIG

WELDER) ON THE SAME ELECTRICAL CIRCUITS MAY CAUSE EQUIPMENT

FAILURE.

Safety Features:

Covers and shielding separate weaver from moving components where pinch

hazards exist. Do not reach under covers and shielding while the loom is

operating.

Safety Page | 3

Industrial Dobby Loom User's Manual IDL Setup

IDL SETUP

IDL S

ETUP

IDL Setup Page | 5

IDL Setup Industrial Dobby Loom User's Manual

NTRODUCTION

I

Your Industrial Dobby Loom (IDL) is designed to be low-maintenance and

easy to use. If you are an experienced power loom weaver, you may initially

think this loom is a little quaint. If you’re more familiar with handlooms, it

may seem impossibly busy and complicated. With a little hands-on

experience, however, you’ll find that the IDL is just right. Considerable

attention has been paid to the needs of the weaver. In addition to those

things we know you’ll need, we’ve provided features that we think you’ll

want. For example, the cloth beam can be removed so that you’ll have more

working room when sleying the reed and we’ve placed the main operating

controls conveniently front-and-center. Feature for feature, you’ll soon

discover that the IDL is the best loom in its class.

BOUT THIS MANUAL

A

While the IDL is simple to use, there is some information you need to know,

like how to start the IDL, how to make adjustments, and what you’ll need to

do to keep your loom in top working condition.

We have provided detailed steps to follow and illustrations to guide you.

You will also find a Maintenance and Troubleshooting section in the back of

the manual.

REPARATIONS

P

Your IDL will have been assembled and tested before it left the factory. An

AVL technician will, in most cases, have uncrated and installed the loom at

your facility, run it, and made any necessary adjustments. It is also likely

that someone on your staff will have been oriented to the loom.

AFETY

S

The first part of this manual shows the safety warnings and features that

apply to the IDL. Anyone who has access to the IDL must be aware of these

warnings.

Let’s talk about some safety rules that you need to follow to safely use the

loom. Remember that any piece of equipment, from a hammer to a buzz

saw, can be hazardous if it’s misused or misunderstood. The IDL is fitted

with a variety of safety devices, but the critical element in using this

machine safely is your ATTENTION TO THE RULES. The rules are:

Page | 6 Introduction

Industrial Dobby Loom User's Manual IDL Setup

.

1.

Never, under any circumstances, remove or disable one of your

loom’s safety devices.

2.

Err on the side of caution: if something seems wrong, assume it

is. Stop the loom until you’ve figured it out.

3.

4.

Don’t take chances — be particularly careful about your hands.

Disconnect both electrical power and air before you do any

maintenance on your loom.

5.

Don’t guess. If you’re unsure about anything, and this manual

doesn’t help, call our technical support number at 800 626-9615.

6.

Never stand at the end of the shuttle boxes when the loom is in

motion.

BE SAFE!!! You’ll come across other safety tips as you read more about your

IDL. PLEASE, if you read nothing else in this manual, read this safety

information!

Safety Page | 7

IDL Setup Industrial Dobby Loom User's Manual

Stopping your loom safely

It is important to understand how to stop your loom safely, especially if an

emergency occurs. Always pay attention to where you are in relation to the

moving parts of the loom. Normally, you will use Stop or Pause to stop the

loom when weaving.

In an emergency where the loom needs to be stopped immediately, you

should use the Emergency Stop. However, anything that has already been

placed in motion will complete that motion. For instance, if the shuttle has

been thrown, it will not stop until it hits something.

1)

There are three ways to stop your loom:

a.

b.

Press

Press PAUSE

STOP

c. Press EMERGENCY STOP

Each of these actions will bring the loom to a standstill; but, different

situations call for different methods.

Page | 8 Safety

Figure 1 - Control Panel

Industrial Dobby Loom User's Manual IDL Setup

end of the present cycle.

if it is

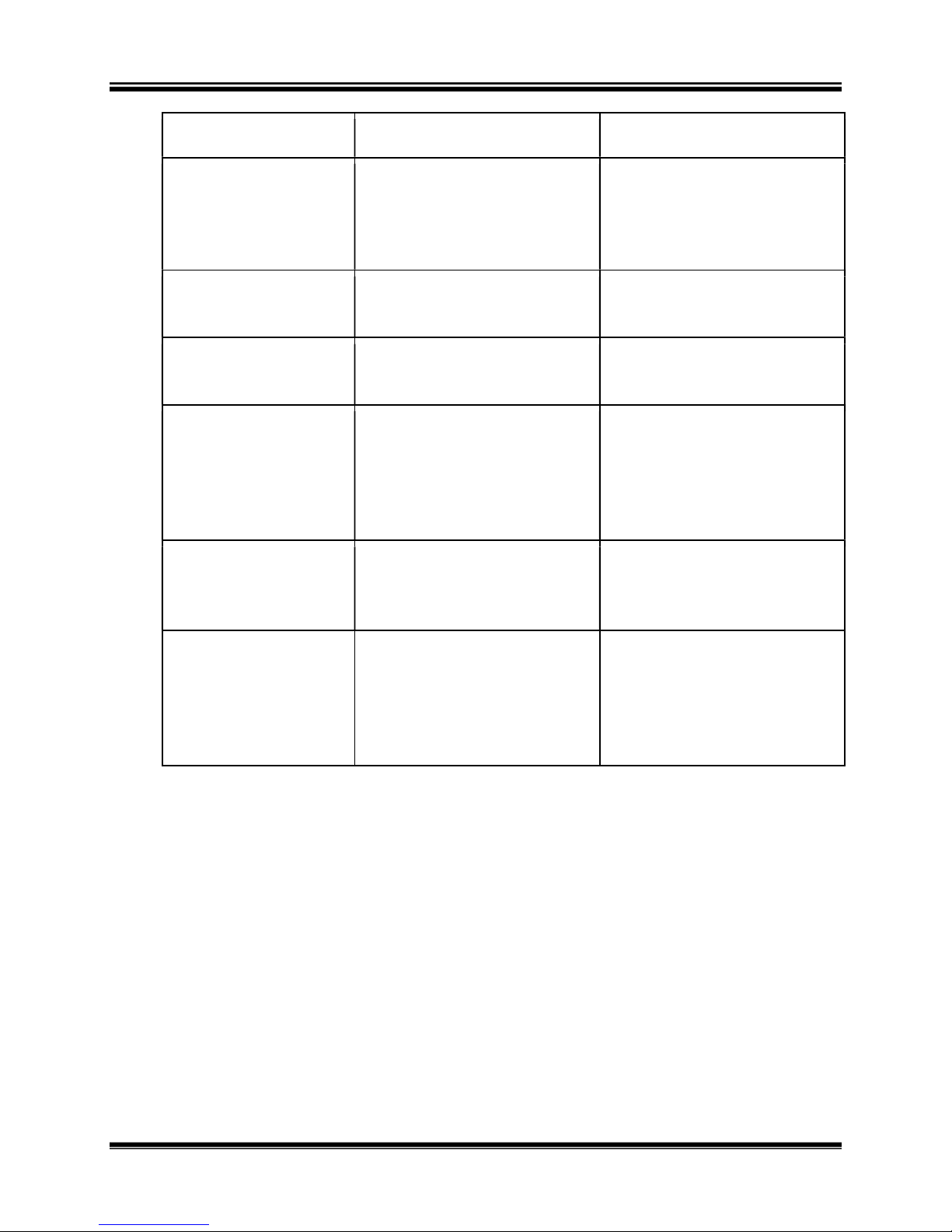

Control Application What Happens

STOP To stop the loom at the

Loom works to the end

of the cycle and stops.

Can be used for any

reason.

To resume, press RUN. The new cycle will begin

properly.

PAUSE To pause the loom mid-

cycle for any reason.

Interrupts the loom,

mid-cycle.

Press PAUSE to resume. The cycle should resume

with the next action.

Check to make sure the

next expected action

occurs.

EMERGENCY

STOP

To stop the loom

immediately.

Stops the loom at the

current action. The cycle

will not complete.

Turn the loom on, and

press RUN.

The loom resets to the

beginning of the next

cycle. This may result in

a flaw in the fabric

not accounted for.

Restarting After an "Emergency Stop"

If you’ve used this mode, your loom will have stopped somewhere midcycle; that is, anywhere between a cloth advance and a beater return.

However, when you re-start the loom, it will re- set automatically to the

beginning of the next cycle. Whatever weaving operations were yet to go

when it was shut down will not be completed. If you continue weaving in the

AUTO mode, you’ll develop a flaw in the fabric.

Note:

Before re-starting the loom, make sure the shuttles are firmly in their boxes

and the warp yarns are correctly in place.

1)

2)

Switch the loom to Manual at the Control Panel.

Determine where you are in the weaving sequence.

Safety Page | 9

IDL Setup Industrial Dobby Loom User's Manual

3)

4)

DDITIONAL LOOM SETUP

A

Normally, the IDL is setup by an AVL technician. Depending on the

circumstances of your particular installation, you may need to provide some

additional setup.

Use the hand control to advance through the remaining steps of the

cycle. As a reminder, each cycle consists of the following sequence

of steps:

ADVANCE —> DOBBY —> SHUTTLE —> DOBBY —> BEATER —>

BEATER

Return the loom to

Auto

, press

Run

, and continue.

Square and Level the Loom

Please make a note of this process, as it is an important part of the

maintenance of your loom. Your loom will perform better and give more

years of service if this process becomes a part of your regular loom

maintenance.

1)

2)

3)

4)

5)

6)

Using a tape measure, note these measurements:

a. The distance from the inside corner of the rear left vertical to

the inside corner of the front right vertical.

b. The distance from the inside corner of the rear right vertical

to the inside corner of the front left vertical.

These two measurements should match. If they do not, you will

need to adjust the frame slightly.

Now, using a level, check to see if the frame is level front-to-back,

place a carpenter’s level along the top of each Top horizontal.

Check side-to-side by placing the level along the length of the Cloth

beam and, again, along the Lower back framing member.

Depending on the flooring, you may need to use shims under the

four corner verticals in order to achieve level.

Once the loom is square and level, check and tighten all bolts and

nuts that connect the frame pieces.

Page | 10 Additional Loom Setup

Industrial Dobby Loom User's Manual IDL Setup

Over time, due to the shaking and movement the loom experiences during

use, these connections will shake loose, requiring periodic checking and

tightening. Make a check of these components a regular part of your loom

maintenance.

Flexible Air Link

If the air line from your compressor is made of a rigid material (steel pipe,

PVC, copper), we suggest that you provide a flexible link between it and the

loom. Simply connect a foot or more of ½” air hose between the FR and the

end of the compressor line. This link will dampen vibration between your

loom and the incoming air line, lessening the possibility of loosened fittings.

Floor Brackets

Your loom is equipped with special shock absorbing pads which will retard its

tendency to “walk”. In some situations, the loom may need to be anchored

to the floor. Brackets made for this purpose are available from AVL.

If you opt to bolt your loom to the floor, be sure to first check that it is

square. Bolting the loom to the floor will, over time, reduce the need to

adjust the loom for square. It will also reduce the need to make adjustments

to the flyshuttle boxes.

Power Supply

AVL strongly recommends that you use a surge protector and an

Uninterruptable Power Supply (UPS) with your loom. These will protect the

electronics in your loom from power outages and fluctuations.

Note:

If the IDL stops unexpectedly due to a power outage, check the loom

carefully for any damage before restarting. Also check the warp and the

woven cloth to make sure nothing was damaged.

ETUP YOUR COMPUTER

S

Your AVL technician should have installed the software for the IDL on your

computer and connected it to the Compu-Dobby.

There are several ways to connect the Compu-Dobby to the computer. The

most common is with a USB cable.

For complete information on using the software, please see the software

manual.

Setup Your Computer Page | 11

IDL Setup

YSTEM

compressor must be able to deliver a minimum of 2

pounds per square

Regulator) is mounted on the back of the

This is where the air line coming from the compressor

The primary function of this device is to

Air pressure is measured in pounds

r with pneumatic systems, just think of air as

power.

see a gauge on the FR and an adjustment knob

this knob clockwise to increase pressure.

the FR at 105+ p.s.i. The operating pressure

FRL (may vary)

Industrial Dobby Loom User's Manual

Setup the Air System

cubic

Computer

connects to the loom.

the air pressure coming into

you’re not

you think of gas in your

immediately above it.

should start pressure

generally

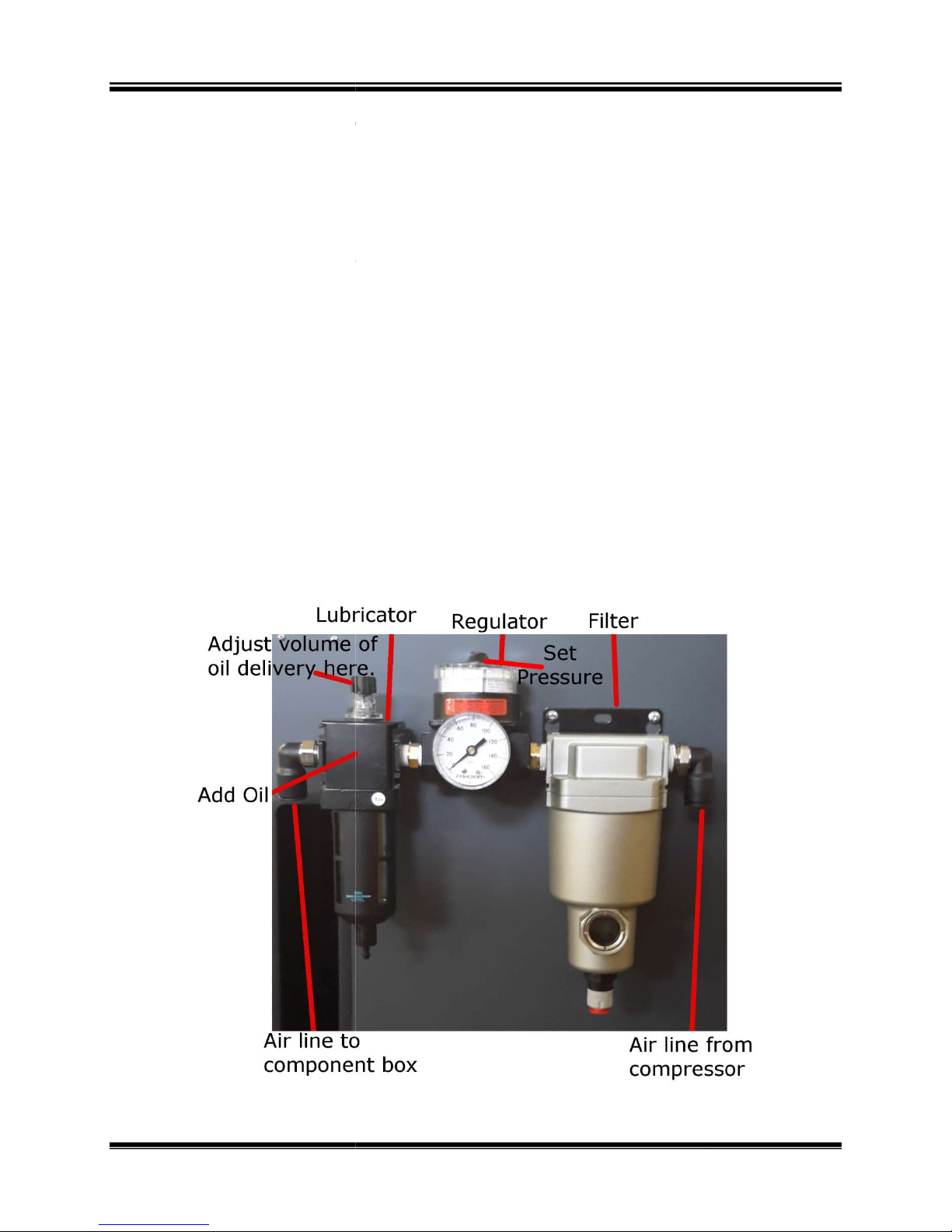

ETUP THE AIR

S

Compressor

S

Your

per minute at 115

Filter-Regulator (FR)

The FR (Filter,

the system.

familia

car. More air equals more

You’ll

Turn

from

around 120 p.s.i.

inch.

control

-per-square-inch (P.S.I.). If

You

should

5

feet of air

Cabinet.

be

Figure 2 -

Page | 12

Industrial Dobby Loom User's Manual

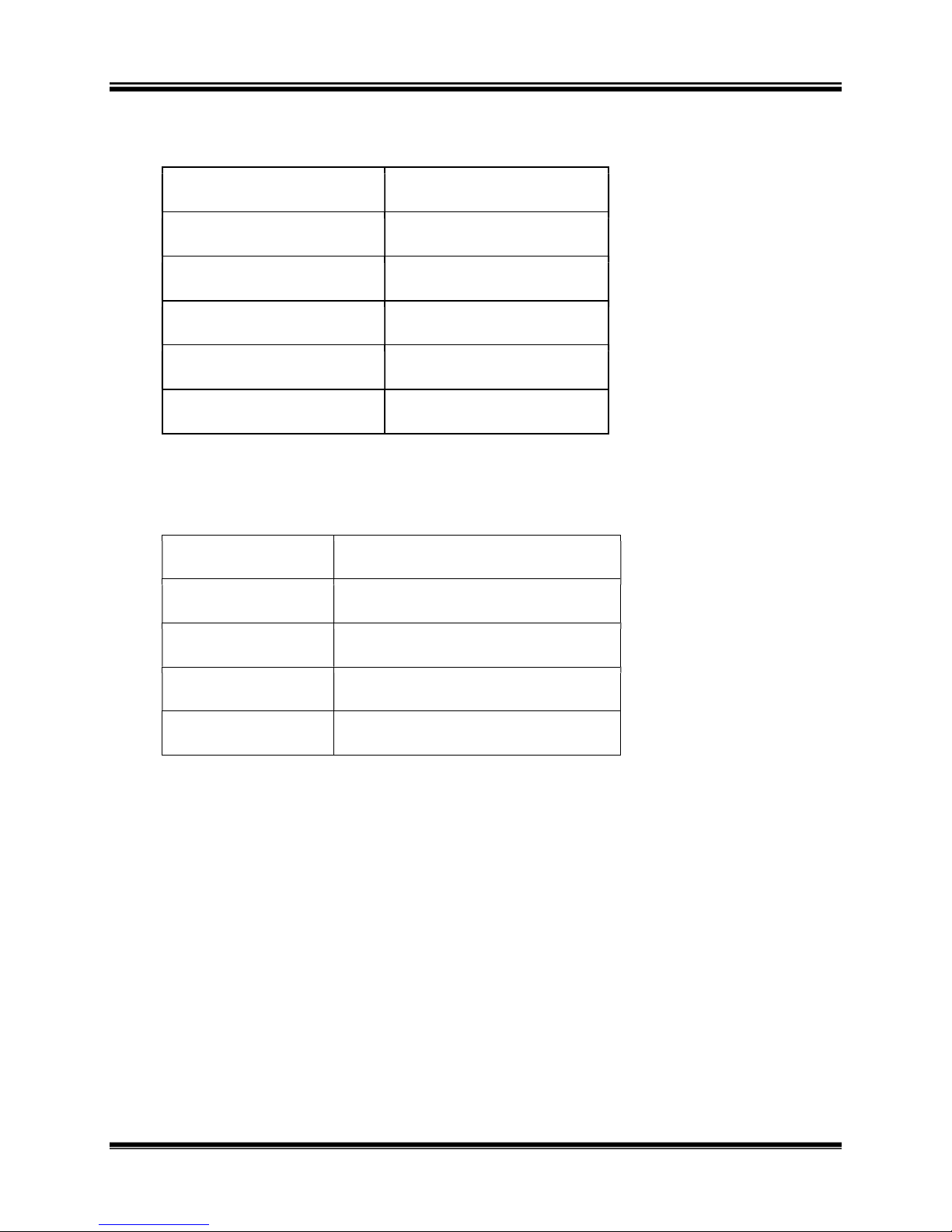

Regulators

In addition to the FR, there are other regulators that control the

air that is delivered to the di

component board in the computer cabinet in

of the FR. Each regulator has a

ntrol power. FLOW CONTROLS, discussed below, control the

speed at which your systems operate.

Each regulator controls one system and is labeled on the air board

computer cabinet. Consult the chart below to determine

You

are located on the

Component box, to the left

operating

settings need to be

fferent loom systems. These

the

gauge labeled with the name.

IDL Setup

amount of

REMEMBER:

Regulators co

Figure 3 - Regulators

values for each system.

may find that these

Setup the Air System

in the

initial

Page | 13

IDL Setup Industrial Dobby Loom User's Manual

modified, depending on the weight of your yarns, operating speed, and other

factors.

System P.S.I. Setting

Beater 60

Cloth Storage 10-20

Dobby 60

Right picker (shuttle) 50

Left picker (shuttle) 50

Cylinder Flow Controls (Speed Controls)

The speed at which each of the loom systems operates is regulated by “flow

controls” located at various points on the loom:

Loom System Flow Control

Cloth Advance Automatic Advance Cylinder

Harness Lifting Dobby Cylinder

Box Changing Box Changing Cylinders

Cloth Storage Cloth Storage Cylinder

These different systems will operate according to the choreography which

you establish. You’ll want the loom to lift, beat, and pick according to your

weaving needs at a particular moment. This means you’ll need to set the

controls for each of the systems. It sounds much more complicated than it

really is and, once you’ve made your initial setting, you won’t need to

change them for the balance of your warp. Your installer will make the initial

settings. We describe how to adjust these and what they control in more

depth later in the manual.

ESTING THE LOOM

T

You will want to test the loom before beginning to weave the first time, and

anytime it has been sitting idle for a long time. Generally when your loom is

Page | 14 Testing The Loom

Industrial Dobby Loom User's Manual IDL Setup

installed by an AVL technician, they will help you test and run the loom the first

time.

To test the loom, open or create a file for plain weave in the software program.

Set the software to Loom Control.

We advise that you first operate your loom with empty shuttles. This will

give you an opportunity to study the action of the loom and will point out

any operating deficiencies. When testing the loom, always start with Manual

Loom Control.

RE

P

Anytime you use the loom, you should run through this short checklist

before you put the loom in motion:

ORMAL LOOM FIRING SEQUENCE

N

There is a specific order of events that should successfully complete for the

IDL to operate correctly.

1)

PERATION CHECKLIST

-O

Check that the shuttle boxes align with the shuttle race.

Check that the shuttle boxes traverse their support rods without

rubbing or binding (move up and down by hand).

Check that the air line is connected.

Check that the power cord is connected.

Check that the Compu-Dobby is connected.

Check that the FR and system regulators are at the expected settings.

Auto Advance. The warp advances incrementally.

2)

3)

4)

5)

Pre-Operation Checklist Page | 15

Dobby Down and Beater Back. The harnesses are opened and the

beater is in the back position.

Shuttle Fires.

Dobby Up and Beater Forward. The harnesses close and the beater

moves forward, beating the new weft yarn in.

This sequence, 1-4, is repeated.

Loading...

Loading...