AVL E-Lift II+ Upgrade Installation

A V L L O O M S

1

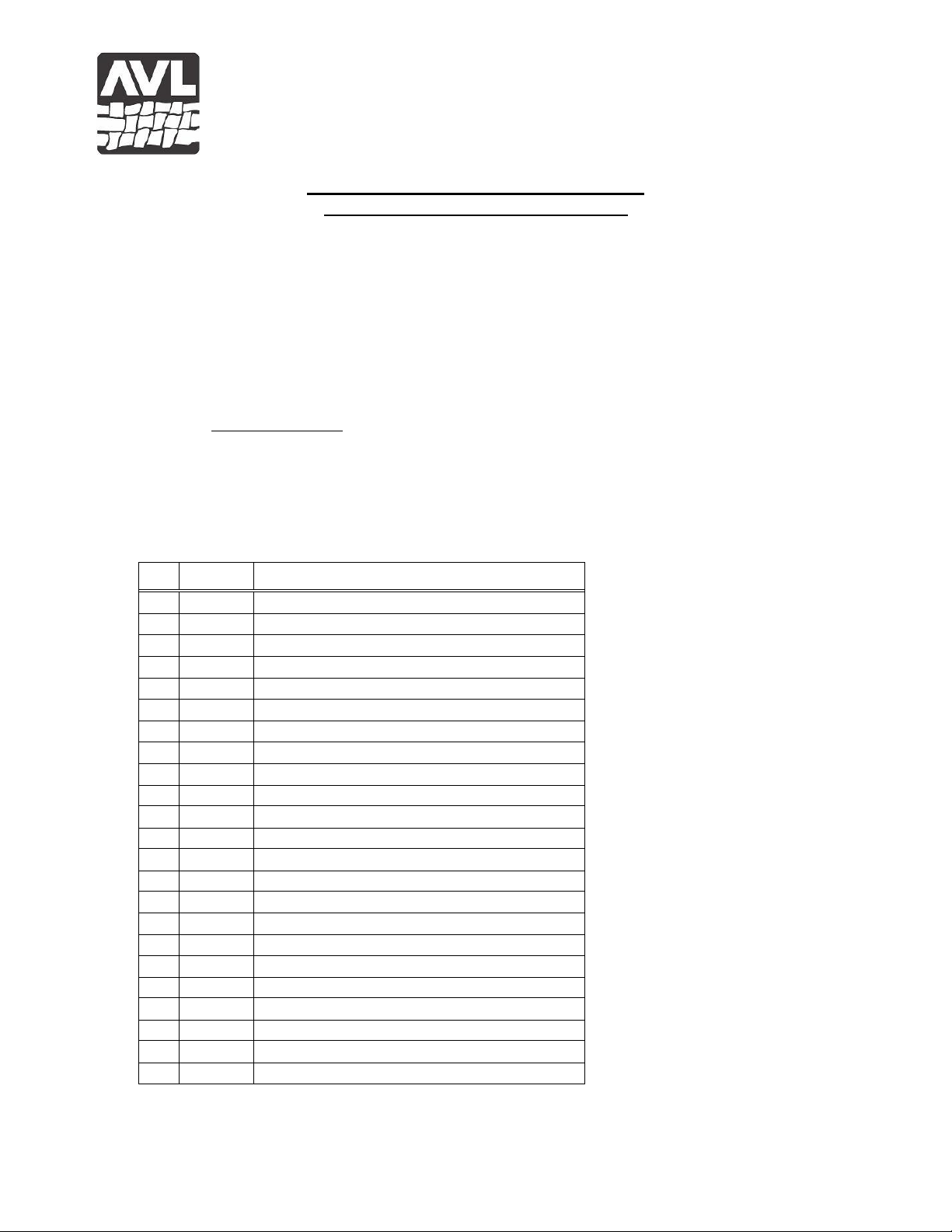

Quantity

Description

1 E-Lift II+ Motor/ Pulley Box – Fig. 1a, 1b

1 Spring Lever Assembly

1 Spring Lever Stand-off Bushing

1 1/2"OD x 5/16"ID x 3/8" L Bushing

1 # 8350 Spring

2 SDL E-Lift II+ Mount Block

1 Cam/Cylinder Assembly

1 Cord, Motor Pulley to Cam

1 Cord, Dobby Arm to Spring Lever

4 1/2" Stop Collar

1 1/4-20 x 2-5/8" Eye Bolt

1 1/4-20 Hex Nut

1 1/4-20 Nylock Nut

2 1/4 Flat Washers

4 5/16-18 x 2 3/4" Hex Bolt

1 5/16-18 x 3-1/2" Hex Bolt

5 5/16-18 Nylock Nut

12

5/16 Flat Washer

4 5/16-18 x 2 Hex Bolt

4 5/16-18 Square Nut

4 5/16 Split Lock Washer

1 Foot Switch and Attached Cord

1 Power Cord

AVL Looms, Incorporated

2360 Park Avenue, Chico, California 95928-8305

Phone: 530-893-4915 Fax: 530-893-1372 www.avlusa.com

E-LIFT II+ UPGRADE INSTALLATION

FOR STUDIO DOBBY LOOM (SDL)

SUPPORT AND WARRANTY

Congratulations on your purchase of an AVL E-Lift II+, for your Studio Dobby

Loom. Your new E-Lift II+ takes the work out of lifting your harnesses and is designed

to provide years of dependable service.

Your E-Lift II+ comes with a lifetime of phone and e-mail support and a standard AVL

One-Year Warranty for the original owner. For a complete warranty statement, to have

warranty service performed, or to get support, please contact AVL at 530-893-4915 or by

e-mail to info@avlusa.com.

INSTALLATION

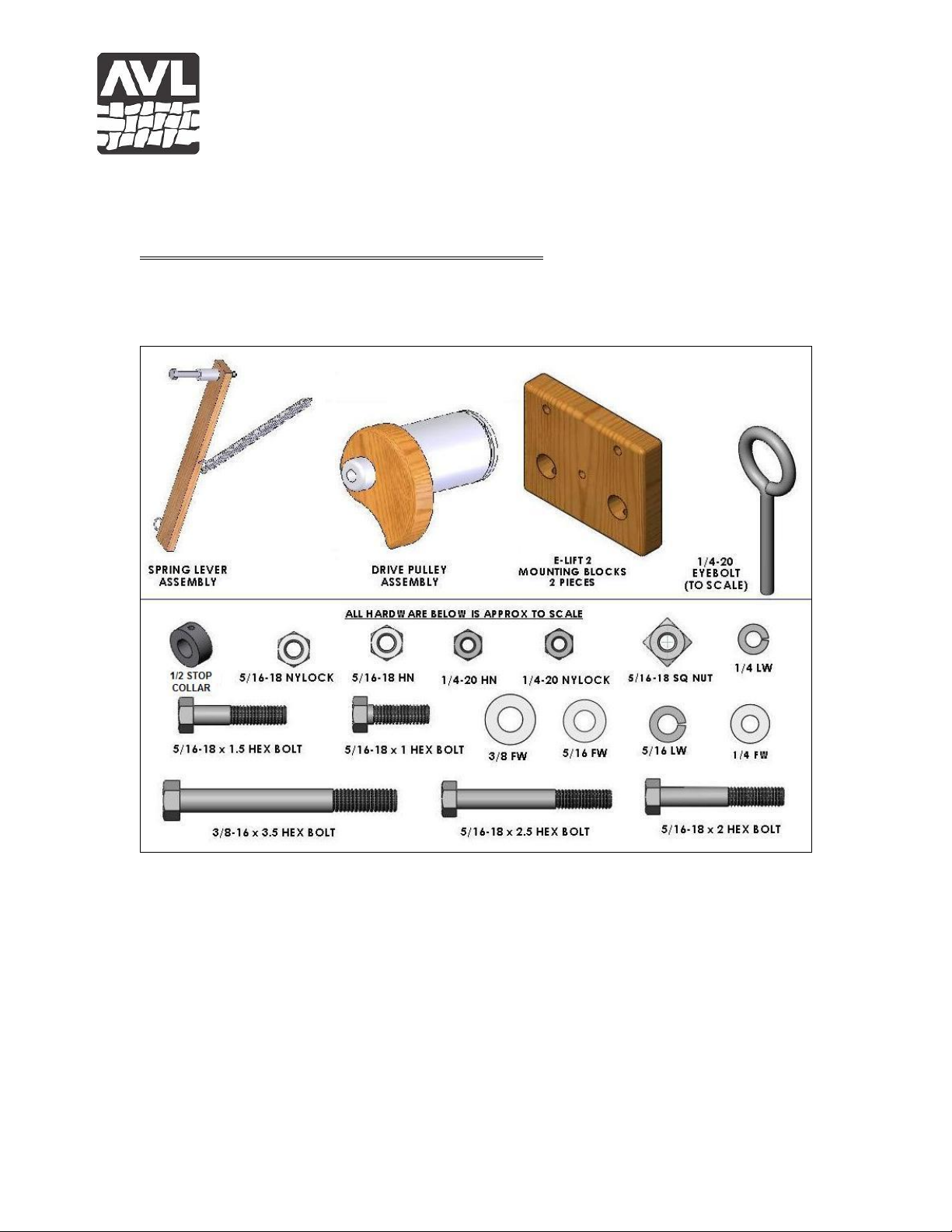

Package Contents: Note: If, upon your inspection of the contents of your package, all

pieces listed here are not represented, please contact AVL Looms immediately, prior to

installation. See Figure 2 for help with identification of these components and hardware.

Revision 4/9/14

A V L L O O M S

2

AVL Looms, Incorporated

2360 Park Avenue, Chico, California 95928-8305

Phone: 530-893-4915 Fax: 530-893-1372 www.avlusa.com

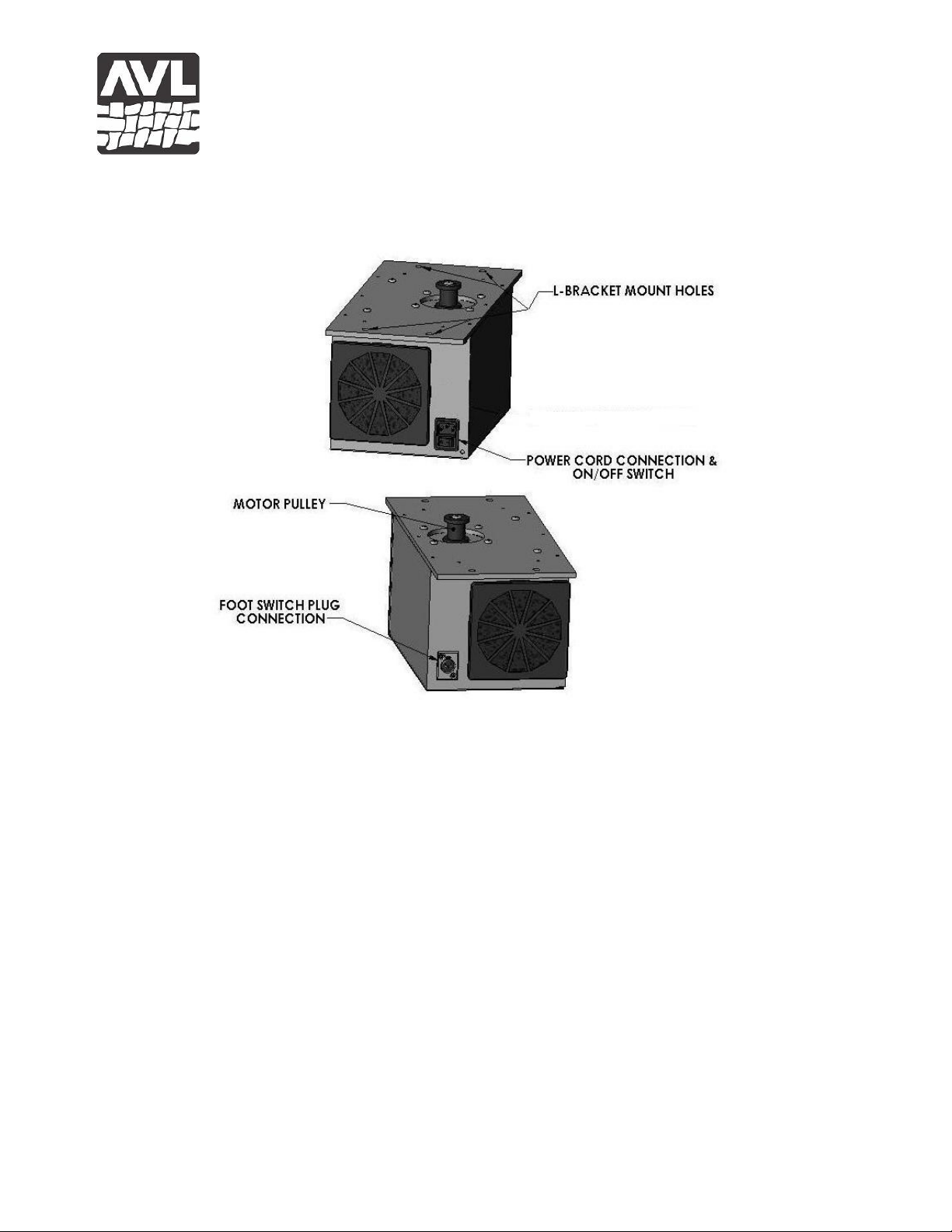

Figure 1 – E-Lift II+ Motor Box

Required Tools

7/16” and 1/2” Wrench or

Socket Wrench with 7/16” and 1/2” Sockets

5/32” Allen Wrench

Pliers

Drill with 21/64” Bit

Tape Measure

Masking or other type of Tape

Pencil

SDL IMAGES

The vast majority of SDLs made by AVL were configured with a 20” weaving width,

with a few produced with 30” weaving width. The images in this manual reflect the 20”

loom. For the 30” loom, the spring lever return and E-Lift position appear closer to the

center since the mounting of both is fixed from the right side of the loom.

Revision 4/9/14

A V L L O O M S

3

AVL Looms, Incorporated

2360 Park Avenue, Chico, California 95928-8305

Phone: 530-893-4915 Fax: 530-893-1372 www.avlusa.com

ORIENTATION**: All directional references are relative the Weaver’s position for

loom operation. This is the Front of the Loom.

PREPARING THE LOOM FOR THE E-LIFT II+

1) Remove the Treadle Assemblies - Disconnect the Left Treadle Cable and remove it

from the Dobby Arm (Keep the black retainer collar for this installation). Disconnect the

Figure 2 – Assembly Components and Hardware Identification

Right Treadle/Cam Cable from the Treadle, but do not disconnect the Cylinder Cable

from the Dobby Arm. Remove your Left and Right Treadle Assembly.

2) Remove the Treadle Cable Axle from the Treadle Pulley Support Crossmembers. If

your axles are fitted with black plastic caps, use pliers to distort and remove them. If

your axles have stop collars at the ends, remove them with the Allen Wrench.

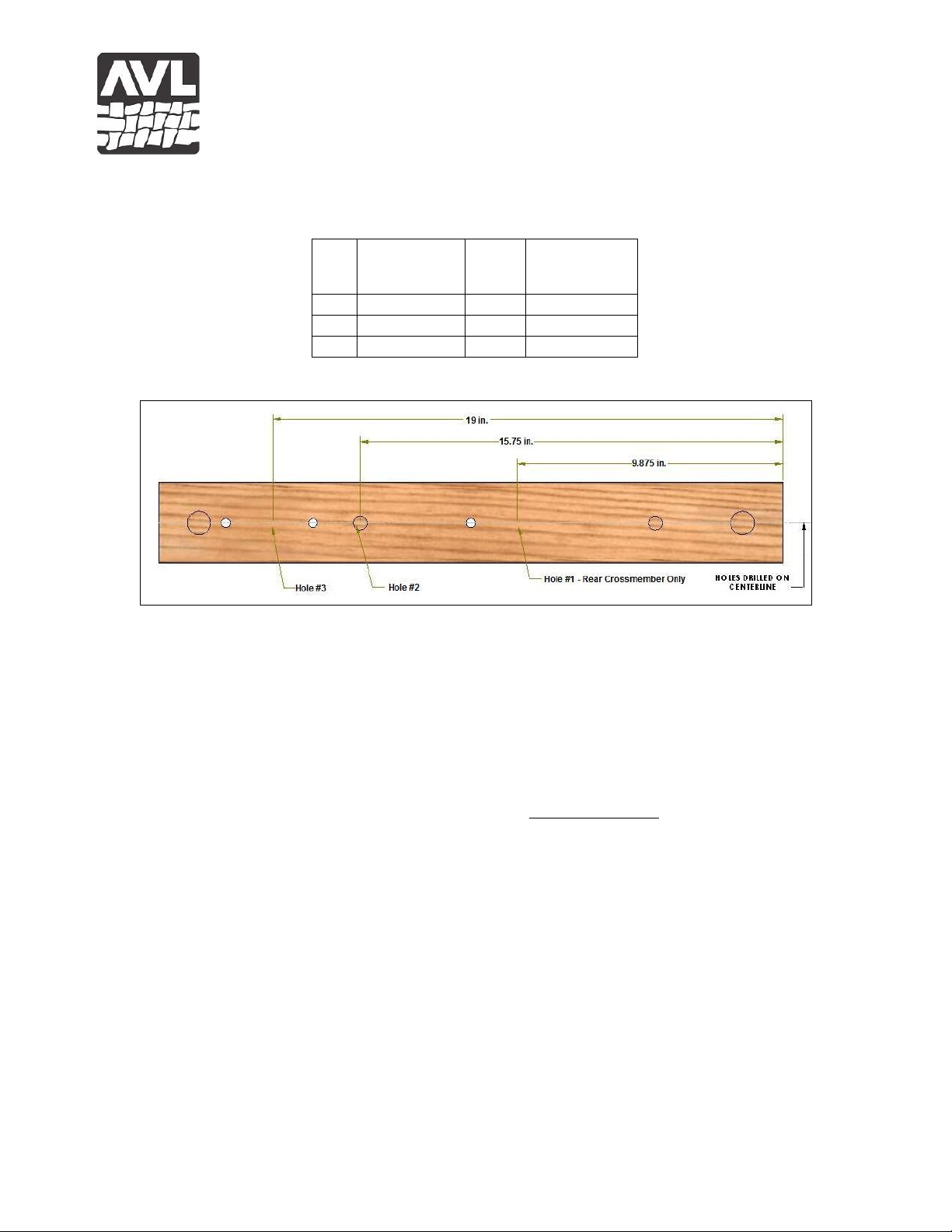

3) Drill Instructions/Hole Orientation (see Figure 3)

Revision 4/9/14

A V L L O O M S

4

HOLE

No.

HOLE

ORIENTATION

HOLE

SIZE

DISTANCE

FROM

RIGHT** EDGE

1

Horizontal

21/64"

9-7/8“

2

Horizontal

21/64"

15-3/4"

3

Horizontal

21/64"

19"

AVL Looms, Incorporated

2360 Park Avenue, Chico, California 95928-8305

Phone: 530-893-4915 Fax: 530-893-1372 www.avlusa.com

Check to see if your front and rear Treadle Pulley Support Crossmembers have the

following mounting holes:

Figure 3 – Placement of Drilled Holes

If the three (3) holes are not already present, they will need to be drilled at this time. You

may wish to remove the Crossmembers in order to complete this task. If so, you can

remove the two (2) hex bolts holding each of the Treadle Pulley Support Crossmembers

to your loom. Be sure to mark the left and right sides and the inside and outside face of

both Crossmembers with tape and pencil prior to removing them and place on a suitable

work surface.

Locations for the three (3) holes are measured from the right-side end of the Treadle

Crossmember. Drill any holes that are not already in place (see Figure #3).

Revision 4/9/14

Loading...

Loading...