ENGINE DIAGNOSTICS

AVL LIST GMBH

Hans-List-Platz 1

A-8020 Graz / Austria

Phone: +43 316 787-0

Fax: +43 316 787-550

http://www.avl.com

Ident. number: AT0391E

Revision no.: 04

Edition: January 1999

Subject to alteration

Printed in Austria by

AVL LIST GMBH Graz

Service Manual

A VL DiGas 4000

AVL DiCom 4000

AVL DiSmoke 4000

Copyright 1999 AVL List GmbH, all rights reserved.

The contents of this document may not be reproduced in any form or communicated to

any third party without the prior written consent of AVL.

While every effort is made to ensure correctness, AVL assumes no liability for errors and

omissions.

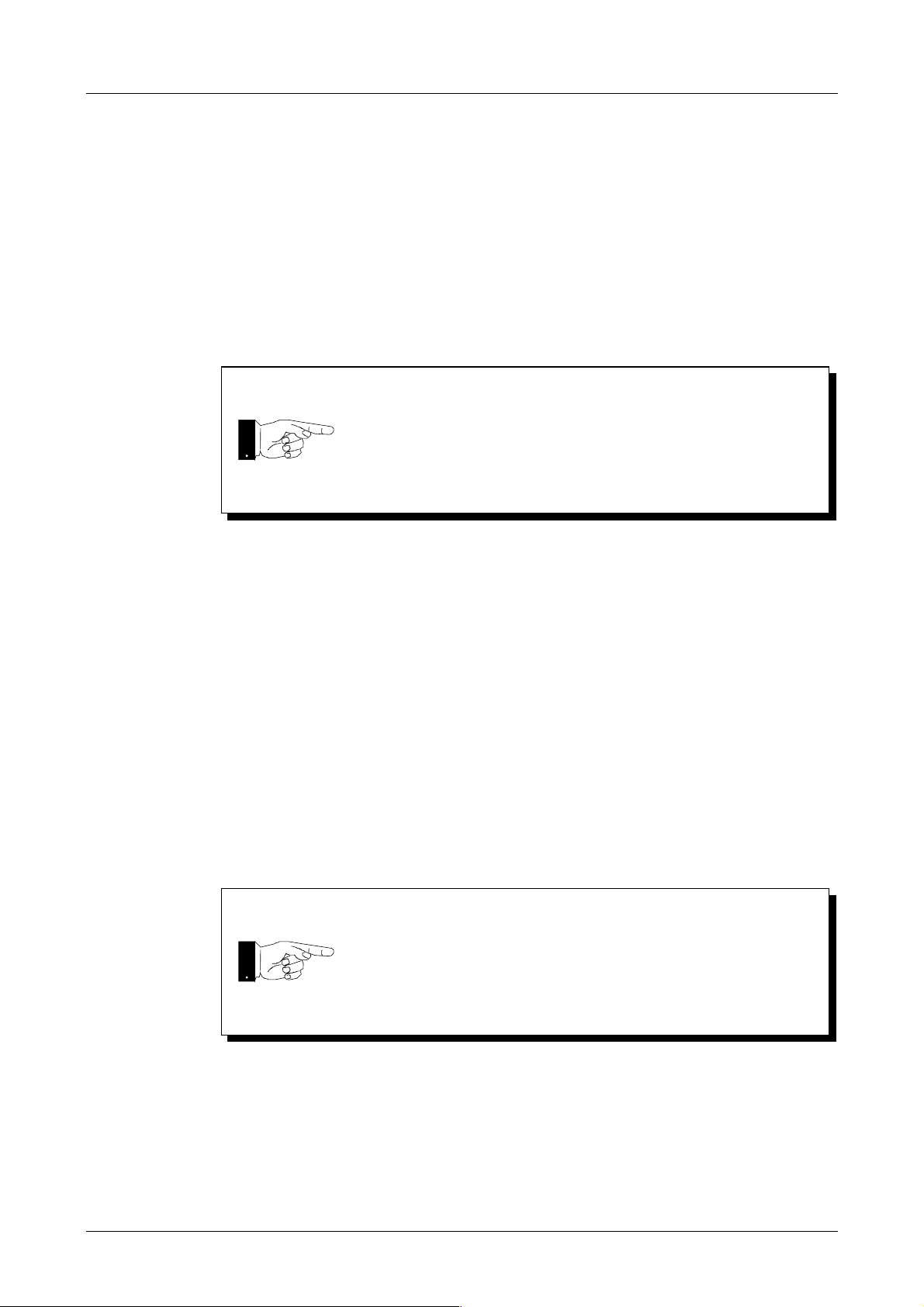

Important Notice! – Important Notice!

This manual contains important warnings and safety instructions to be observed

by the user.

The product described is intended for only one certain area of application which is

prescribed in the instructions. Furthermore, the manual explains the critical

prerequisites for application and operation as well as the safety measures to ensure

smooth operation. No warranty is granted or liability accepted if the prerequisites and

safety measures are not met.

The product is to be operated and used only by qualified personnel capable of

observing the required safety precautions. Only accessories and expendables either

supplied or approved by AVL are to be used with the product.

Due to the operating principle of this product, the accuracy of the measurement

results it produces not only depends on its correct operation and function but also

upon a variety of peripheral conditions beyond the control of the manufacturer. The

results obtained from this product must therefore be subjected to careful examination

by an expert (e.g. for plausibility) before any action is taken that is based on the

results.

Adjustments to and maintenance of devices when open and under voltage are only

to be carried out by a professional technician who is aware of the dangers involved.

Repairs to the product are to be carried out by the manufacturer or qualified service

personnel only.

When the product is used, a technical expert must ensure that neither the test object

nor the testing equipment is operated under conditions that may lead to damage or

injury.

LIST GmbH

Important Notice! – Important Notice!

Safety Instructions for Handling O2 and NO Sensors

The O2 and NO sensors are supplied fully sealed and under norma l circumstances do not

represent any hazard to health.

The following instructions apply in the event of a sensor developing a leak.

• Before you remove a sensor from the gas-tight original packaging, check it for leaks.

• If you detect damage caused by a leak, always av oid contact with the skin.

• In this event, use rubber gloves and goggles.

The O

are hazardous to health (e.g. caustic potash solution and lead).

When replacing sensors, check both the old and the new one for

leaks.

and NO sensors contain caustic and other substances that

2

First Aid

• Contact with the eyes

− Rinse eyes with water for at least 15 minutes - consult a doctor immediately.

• Contact with the skin

− Remove contaminated clothing immediately.

− Wash the affected pa rt of the body thoroughly with water.

− If a burning sensation is felt on the skin, consult a doctor immediately.

• Swallowing

− Drink a lot of cold water.

− Consult a doctor immediately.

4000 Table of Contents

Table of Contents

1. Periodic Maintenance

1.1 General......................................................................................................................................................1-1

1.2 Maintenance Plan.................................................................................................................................... 1-2

1.3 Minor Maintenance.................................................................................................................................1-4

1.3.1 AVL DiGas 4000.............................................................................................................................1-4

1.3.2 AVL DiSmoke 4000........................................................................................................................1-5

1.3.3 AVL DiCom 4000...........................................................................................................................1-6

1.4 Major Maintenance.................................................................................................................................1-8

1.4.1 AVL DiGas 4000.............................................................................................................................1-8

1.4.2 AVL DiSmoke 4000........................................................................................................................1-9

1.4.3 AVL DiCom 4000...........................................................................................................................1-10

2. Error Messages and Troubleshooting

2.1 4-/5-Gas Measuring Instruments Unit.................................................................................................2-1

2.1.1 Gas Flow Insufficient....................................................................................................................2-1

2.1.2 System Needs Restarting.............................................................................................................. 2-2

2.1.3 Measuring Chamber Temperature Too High.............................................................................2-2

2.1.4 Measuring Chamber Pressure Wrong.........................................................................................2-3

2.1.5 Leak Test Failed .............................................................................................................................2-3

2.1.6 Replace O

2.1.7 Replacing the NO Sensor..............................................................................................................2-4

2.2 Opacity Measuring Chamber................................................................................................................2-5

2.2.1 Measuring Chamber Too Hot/Too Cold....................................................................................2-5

2.2.2 Changeover Valve Error...............................................................................................................2-5

2.3 Linearity / Opacity Error,......................................................................................................................2-6

2.3.1 Opacity Measuring Chamber, Type A........................................................................................2-6

2.3.2 Opacity Measuring Chamber, Type 4000...................................................................................2-6

Sensor..........................................................................................................................2-4

2

3. Software

3.1 General......................................................................................................................................................3-1

3.2 Installation of Operating Software (Software update)....................................................................... 3-4

4. Evaluation Unit

4.1 General Description................................................................................................................................4-1

4.1.1 Basic Design...................................................................................................................................4-2

4.1.2 Evaluation Unit..............................................................................................................................4-3

4.1.3 Pneumatics Rear Panel / 4-/5-Gas Measuring Instruments Unit (5-Gas Option)................4-4

4.2 Hardware Setup......................................................................................................................................4-5

4.2.1 Main Board.....................................................................................................................................4-5

4.2.1.1 Digital System............................................................................................................................4-5

4.2.1.2 Analogue Data Acquisition......................................................................................................4-5

4.2.1.3 Remote Control Receiver..........................................................................................................4-5

4.2.1.4 Interfaces.....................................................................................................................................4-6

4.2.1.5 Display Control and Softkey Connection...............................................................................4-7

4.2.1.6 Generation of Auxiliary Voltage..............................................................................................4-7

4.2.1.7 Board Control.............................................................................................................................4-7

Service Manual I

Table of Contents AVL 4000

4.2.1.8 Printer Board (Option)..............................................................................................................4-8

4.2.1.9 Speed / Angle Board with Diagnostics Cable Concept (Option/Installation) .................4-8

4.2.1.10 Memory Adapter.......................................................................................................................4-11

4.2.1.11 Chamber Adapter (AVL DiCom 4000)....................................................................................4-11

4.2.1.12 Extension Slot.............................................................................................................................4-11

4.2.1.13 Mains Switch Assembly............................................................................................................4-11

4.2.1.14 Converting 230 V to 115 V Device...........................................................................................4-11

4.2.1.15 Power Supply Unit....................................................................................................................4-11

4.2.1.16 Fan...............................................................................................................................................4-12

4.3 Dismantling the 4-/5-Gas Measuring Instruments Unit....................................................................4-12

4.4 Housing....................................................................................................................................................4-12

4.5 Printer.......................................................................................................................................................4-13

4.5.1 Internal Printer Unit (Option/Installation)................................................................................4-13

4.5.2 External A4 Printer (Option)........................................................................................................4-14

4.6 LCD...........................................................................................................................................................4-14

4.7 Membrane Keypad.................................................................................................................................4-14

4.8 Fan............................................................................................................................................................. 4-14

4.9 Main Board...............................................................................................................................................4-15

4.9.1 Components Location Diagram...................................................................................................4-15

4.9.2 Circuit Diagrams...........................................................................................................................4-16

4.10 Speed Angle Board .................................................................................................................................4-21

4.10.1 Components Location Diagram...................................................................................................4-21

4.10.2 Circuit Diagrams ...........................................................................................................................4-22

4.11 Pneumatics Board....................................................................................................................................4-26

4.11.1 Components Location Diagram...................................................................................................4-26

4.11.2 Circuit Diagram.............................................................................................................................4-27

4.12 Printer Adapter........................................................................................................................................4-28

4.12.1 Components Location Diagram...................................................................................................4-28

4.12.2 Circuit Diagram.............................................................................................................................4-29

4.13 Memory Adapter.....................................................................................................................................4-30

4.13.1 Components Location Diagram...................................................................................................4-30

4.13.2 Circuit Diagram.............................................................................................................................4-31

4.14 Connector Adapter.................................................................................................................................4-32

4.14.1 Components Location Diagram...................................................................................................4-32

4.14.2 Circuit Diagram.............................................................................................................................4-33

4.15 Chamber Adapter (opacity measuring chamber type A)..................................................................4-34

4.15.1 Components Location Diagram...................................................................................................4-34

4.15.2 Circuit Diagram.............................................................................................................................4-35

4.16 Receiver Board (opacity measuring chamber type A)........................................................................4-36

4.16.1 Components Location Diagram...................................................................................................4-36

4.16.2 Circuit Diagram.............................................................................................................................4-37

4.17 Selenium Board (opacity measuring chamber type A)......................................................................4-38

4.17.1 Components Location Diagram...................................................................................................4-38

4.17.2 Circuit Diagram.............................................................................................................................4-39

II Service Manual

4000 Table of Contents

4.18 Chamber Adapter (opacity measuring chamber 4000)......................................................................4-40

4.18.1 Components Location Diagram...................................................................................................4-40

4.18.2 Circuit Diagram.............................................................................................................................4-41

4.19 Transmitter Board (opacity measuring chamber 4000)......................................................................4-42

4.19.1 Components Location Diagram...................................................................................................4-42

4.19.2 Circuit Diagram.............................................................................................................................4-43

4.20 Receiver Board (opacity measuring chamber 4000) ...........................................................................4-44

4.20.1 Components Location Diagram...................................................................................................4-44

4.20.2 Circuit Diagram.............................................................................................................................4-45

4.21 Fan Board (opacity measuring chamber 4000).................................................................................... 4-46

4.21.1 Components Location Diagram...................................................................................................4-46

4.21.2 Circuit Diagram.............................................................................................................................4-47

4.22 Wiring Diagrams.....................................................................................................................................4-48

4.23 Internal Cabling.......................................................................................................................................4-51

4.24 4-/5-Gas Section......................................................................................................................................4-52

4.24.1 Pneumatics Board..........................................................................................................................4-52

4.24.2 Multi-gas Measuring System - General Requirements.............................................................4-52

4.25 Service Mode...........................................................................................................................................4-54

4.25.1 Changing O

and NO Sensor.......................................................................................................4-54

2

4.25.2 Gas Calibration..............................................................................................................................4-54

4.25.3 4-/5-Gas..........................................................................................................................................4-54

4.25.4 Diesel - Opacity Measuring Chamber Type A ...........................................................................4-60

4.25.5 Diesel - Opacity Measuring Chamber 4000...............................................................................4-62

5. 4-/5-Gas Measuring Instruments Unit

5.1 General......................................................................................................................................................5-1

5.2 Gas Analyzer...........................................................................................................................................5-2

5.2.1 Light Source...................................................................................................................................5-3

5.2.2 Motor Unit......................................................................................................................................5-3

5.2.3 Measuring Cell...............................................................................................................................5-4

5.2.4 Filter/Receiver...............................................................................................................................5-4

5.2.5 Pressure Sensor..............................................................................................................................5-4

5.2.6 Main Board and Lambda Piggyback ..........................................................................................5-5

5.2.7 Causes of Error..............................................................................................................................5-5

5.3 Layout of Pneumatics.............................................................................................................................5-5

5.3.1 Solenoid.......................................................................................................................................... 5-7

5.3.2 Valve Unit.......................................................................................................................................5-7

5.3.3 Particulate Filter ............................................................................................................................5-7

5.3.4 Pump...............................................................................................................................................5-8

5.3.5 Pressure Sensor..............................................................................................................................5-9

5.3.6 Pneumatics Board..........................................................................................................................5-9

5.4 Power Supply Unit for 4-/5-Gas Measuring Instruments Unit........................................................5-10

5.5 Power Supply Board...............................................................................................................................5-10

Service Manual III

Table of Contents AVL 4000

5.6 O2 Sensor and NO Sensor.......................................................................................................................5-10

5.6.1 Replacing the O

5.6.2 Replacing the NO Sensor..............................................................................................................5-11

5.7 Cleaning the Condensate Part of the 4/5-Gas Bench.........................................................................5-12

5.8 Error Symptom List - Remedies............................................................................................................5-14

Sensor................................................................................................................5-11

2

6. Opacity Measuring Chamber Type A

6.1 System Check with Filter........................................................................................................................6-1

6.2 Upgrading an AVL DiGas 4000 to an AVL DiCom 4000....................................................................6-3

6.3 General Configuration............................................................................................................................6-4

6.4 Dismantling the Opacity Measuring Chamber...................................................................................6-6

6.4.1 Housing Cover 1 (on Exhaust Gas Outlet Side)........................................................................6-6

6.4.2 Housing Cover 2 (on Exhaust Gas Inlet Side) ...........................................................................6-7

6.4.3 Half-shells 1 and 2.........................................................................................................................6-9

6.5 Fans...........................................................................................................................................................6-12

6.6 Heating Blocks and Orifice Plates.........................................................................................................6-13

6.7 Changeover Valve with Geared Motor.................................................................................................6-15

6.8 Temperature Sensor................................................................................................................................6-17

6.9 Lamp Module (BO1135) .........................................................................................................................6-19

6.10 Detector (BO1134)...................................................................................................................................6-21

6.11 Purging Air Panels (YM2691)................................................................................................................6-23

6.12 Electrical Wiring......................................................................................................................................6-24

6.13 Reassembly of the Opacity Measuring Chamber................................................................................6-32

7. Opacity Measuring Chamber 4000

7.1 System Check with Filter........................................................................................................................7-1

7.2 Upgrading an AVL 4000 DiGas to an AVL 4000 DiCom..................................................................7-2

7.3 Assembling and Disassembling the Opacity Measuring Chamber..................................................7-4

7.4 Design and Details of Assemblies.........................................................................................................7-5

7.4.1 Fan Unit (BO2189)......................................................................................................................... 7-5

7.4.2 Measurement Cell (BO2138)........................................................................................................7-6

7.4.2.1 Replacing the Temperature Sensor in the Heating System..................................................7-6

7.4.3 Valve Unit (BO2139)......................................................................................................................7-7

7.4.3.1 Replacing the Temperature Sensor..........................................................................................7-7

7.4.4 Transmitter and Detector Unit.....................................................................................................7-8

7.4.4.1 Checking the Light Sources (green LEDs) and the Receiver ...............................................7-8

7.4.4.2 Checking the Reference Receiver............................................................................................7-8

7.5 Assembling the Opacity Measuring Chamber....................................................................................7-10

8. Spare Parts Lists

8.1 General......................................................................................................................................................8-1

8.2 Standard List............................................................................................................................................8-2

8.3 AVL 4000 with Opacity Measuring Chamber Type A........................................................................8-6

8.4 AVL 4000 with Opacity Measuring Chamber Model A France.........................................................8-10

9. Tools for the Service Technician

IV Service Manual

4000 Periodic Maintenance

1. Periodic Maintenance

1.1 General

This Service Manual describes the following instruments:

− AVL DiGas 4000 (= AVL DiTest 5400)

− AVL DiSmoke 4000 (= AVL DiTest 5430)

− AVL DiCom 4000 (= AVL DiTest 5460)

Some areas are described in detail in the respective Operating Manual and therefore not

dealt with in this Service Manual.

We therefore advise always using the Service Manual

together with the respective Operating Manual.

Service Manual 1-1

Periodic Maintenance AVL 4000

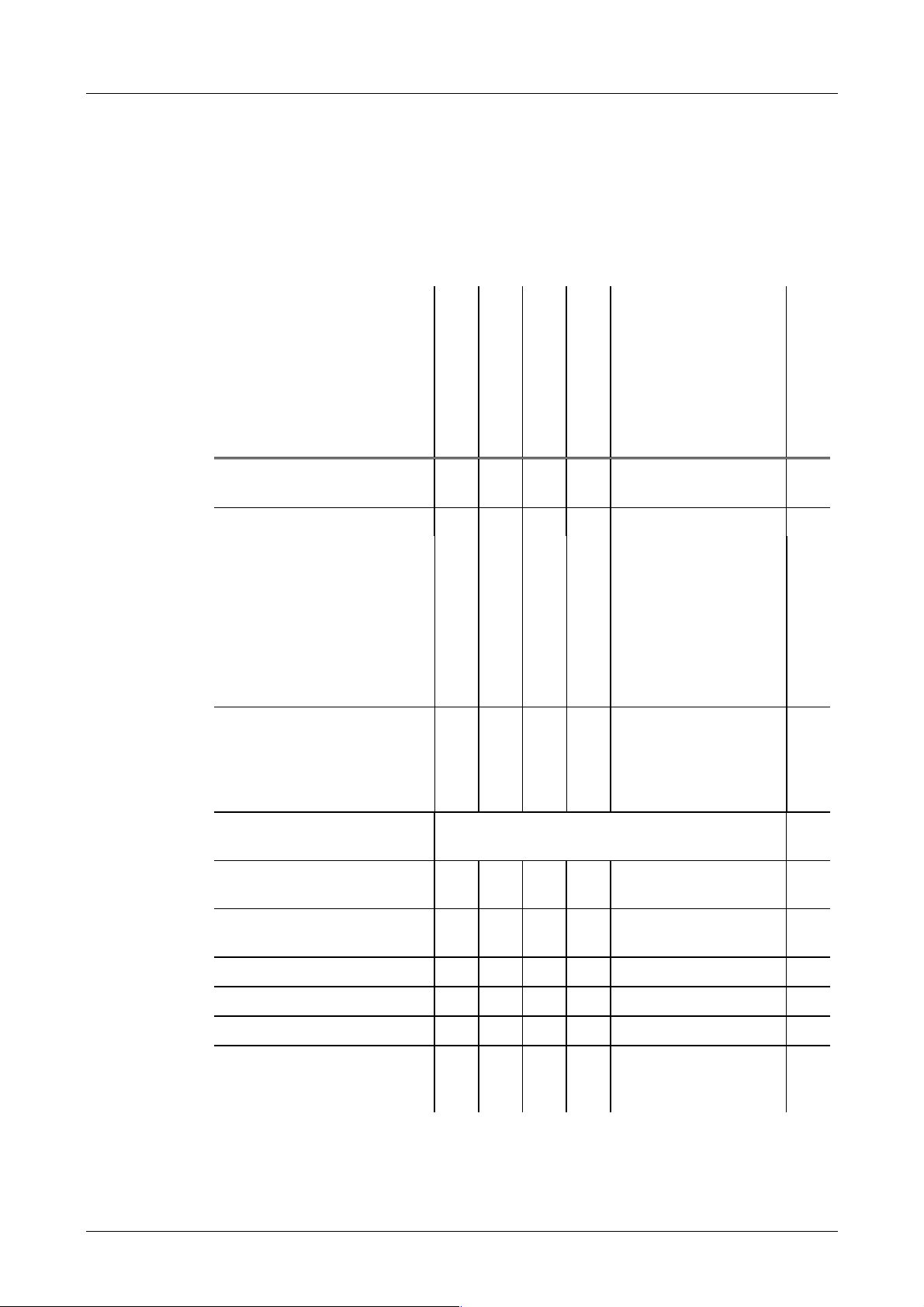

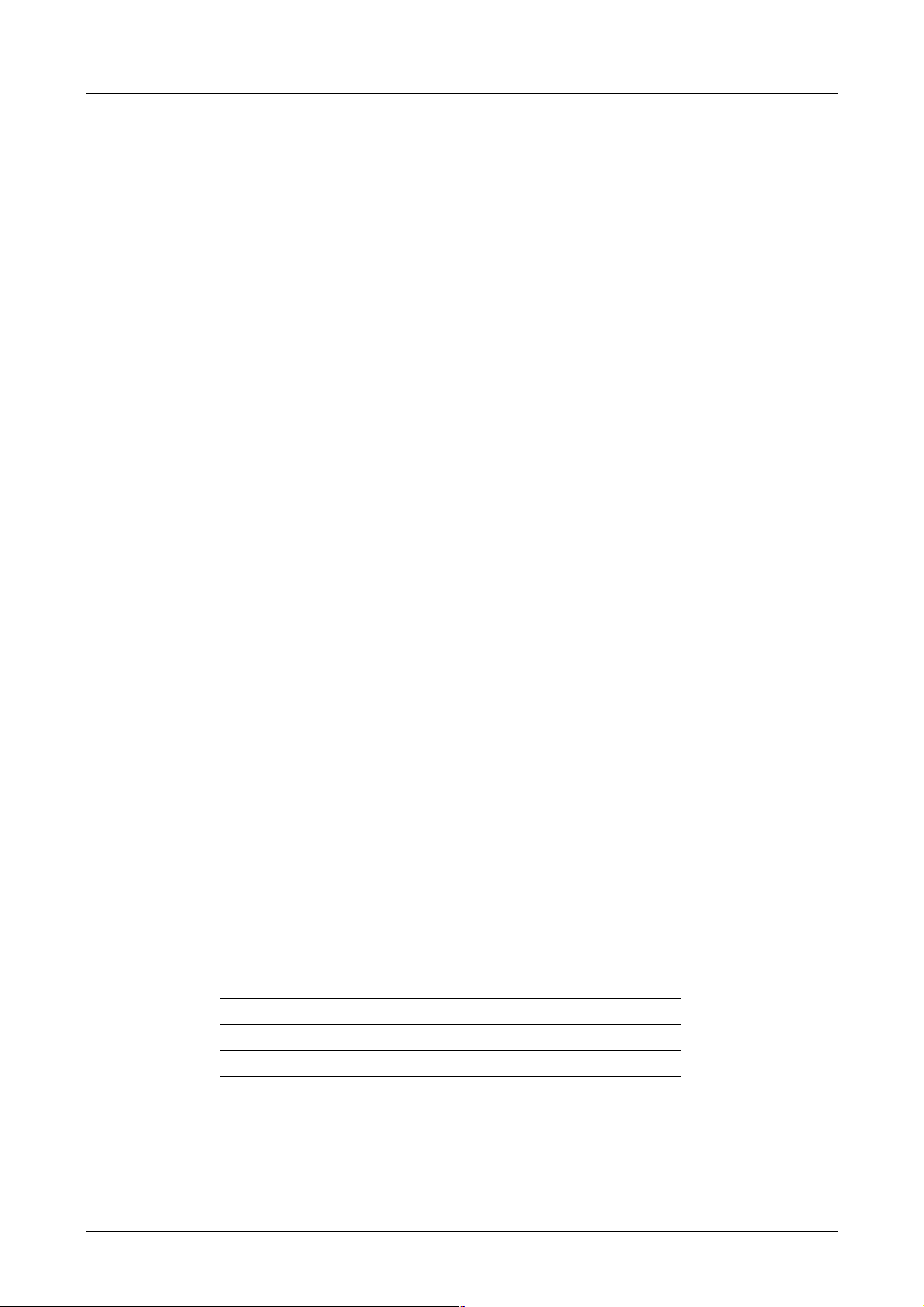

1.2 Maintenance Plan

To ensure that the te ster always functions properly, maintenance must be carried out at

regular intervals.

Maintenance work

Leak test

Filter replacement

Pre-filter on probe

Particulate filter

Condensate filter

Activated carbon filter

Cleaning

Daily

Weekly

One a year

Six-monthly

(minor maintenance)

(major maintenance)

Comment

Automatically required

by tester every day

Replace in good time

when soiled by HC

vapour (e.g. petrol

vapour).

Entry in main-

tenance log book

Probe and hose

Condensate pump

(cleaning kit)

Calibration with calibrating

gas

Replacing O2 sensor

Replacing NO sensor Replacement is

Visual check of outside

Check using software

Software update (as required)

Open tester, visual inspection

of PCBs, clean, close housing,

seal with service seal

as per statutory requirements

see Operating Manual

see Operating Manual

Replacement is

requested by tester

requested by tester

Service engineer

Service engineer

Service engineer

1-2 Service Manual

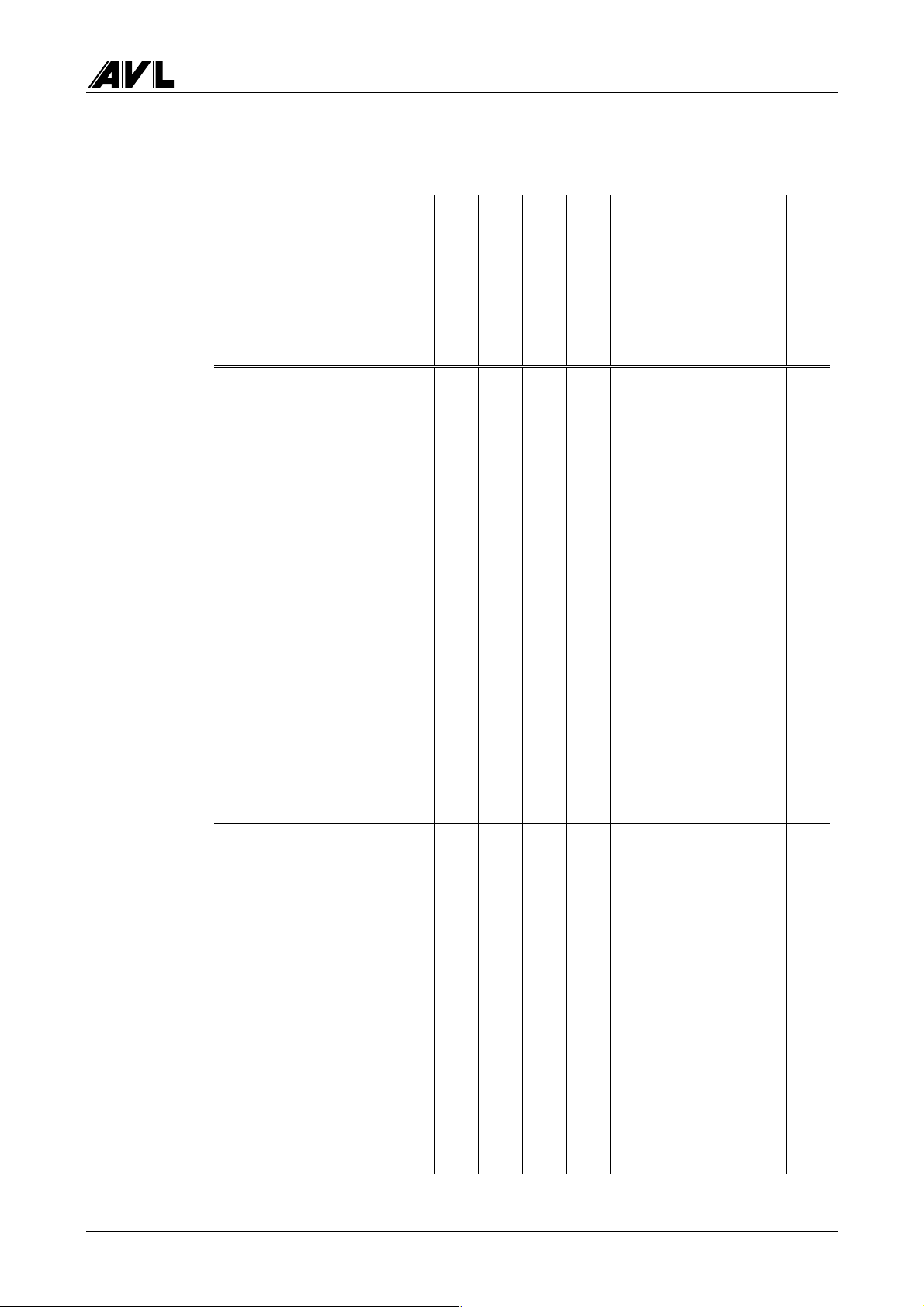

4000 Periodic Maintenance

Maintenance work

Opacity measuring chamber

type A

Visual check

(silicon seal, leaks in

housing, housing

components, closure

fittings, snap mechanism

of the optical elements,

electrical connections,

probe connection plate

O-ring, electrical cables,

soiling of measuring

chamber and purging air

channel)

Daily

Weekly

Six-monthly

Comment

One a year

(major maintenance)

(minor maintenance)

Entry in main-

tenance log book

Function check (fans,

heating, changeover

valve)

Cleaning of optical

elements

Linear check

Change lamps

Opacity measuring chamber

type 4000

Visual check

(silicon seal, leaks in

housing, housing

components, closure

fittings, snap mechanism

of the optical elements,

electrical connections,

electrical cables)

Function check (fan,

heating, changeover

valve)

Cleaning of optical

elements

Linear check

Service Manual 1-3

Periodic Maintenance AVL 4000

1.3 Minor Maintenance

1.3.1 AVL DiGas 4000

•

Evaluation unit

Check using software

− Raw data from 4-/5-gas measuring instruments unit OK?

− O

sensor is OK?

2

− NO se nsor is OK?

Visual check of outside

Entry in maintenance log book

• Cleaning

Replace particulate filter

(see section 5.3.3 Particulate Filter)

Check O-ring paper filter

Visual inspection of probe and hose

Function check

− Leak test

(see Operating Manual)

− Gas calibration

(see Operating Manual)

1-4 Service Manual

4000 Periodic Maintenance

1.3.2 AVL DiSmoke 4000

•

Evaluation unit

Visual inspection

Enter in maintenance log book

• Opacity measuring chamber, type 4000

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe hose, probe clamp

Function check

(each test is described in the Operating Manual)

− Test function of fan

− Test function of heating

− Check cha ngeover va lve

− Clean the optical elements (by wiping)

− Linear check

Service Manual 1-5

Periodic Maintenance AVL 4000

1.3.3 AVL DiCom 4000

•

Evaluation unit

Check using software

− Raw data from 4-gas measuring instruments unit OK?

− O

sensor is OK?

2

− NO se nsor is OK?

Visual inspection

Enter in maintenance log book

• Cleaning

Replace particulate filter

(see section 5.3.3 Particulate Filter)

Check O-ring paper filter

Visual inspection of probe and hose

• Opacity measuring chamber type A

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe connection plate O-ring

− Probe hose, probe clamp

− S oiling of measuring chamber, purging air channel

Function check

(each test is described in the Operating Manual)

− Test function of fans

− Test function of heating

− Check cha ngeover va lve

("Calibration", "Test", "Deactivate" settings - visual check or diesel service mode)

− Clean the optical elements (by wiping)

− Linear check

1-6 Service Manual

4000 Periodic Maintenance

• Opacity measuring chamber type 4000

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe hose, probe clamp

Function check

(each test is described in the Operating Manual)

− Test function of fan

− Test function of heating

− Check cha ngeover va lve

− Clean the optical elements (by wiping)

− Linear check

Function test

− Leak test

(see Operating Manual)

− Gas calibration

(see Operating Manual)

Service Manual 1-7

Periodic Maintenance AVL 4000

1.4 Major Maintenance

1.4.1 AVL DiGas 4000

•

Evaluation Unit

Check using software

− Raw data from 4-gas measuring instruments unit OK?

− O

sensor is OK?

2

− NO sensor is OK?

Open evaluation unit (remove cover)

Visual inspection, clean pcb

If necessary update setpoint data and software

Close housing, seal with service seal

Enter in maintenance log book

• Cleaning

Replace particulate filter

(see section 5.3.3 Particulate Filter)

Check O-ring paper filter

Visual inspection probe and hose

Clean condensate pump

(using cleaning kit)

Function test

− Leak test

− Gas calibration

1-8 Service Manual

4000 Periodic Maintenance

1.4.2 AVL DiSmoke 4000

•

Evaluation unit

Open evaluation unit (remove cover)

Visual inspection, clean pcb

If necessary update setpoint data and software

Close housing, seal with service seal

Enter in maintenance log book

• Opacity measuring chamber

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe hose, probe clamp

− S oiling of measuring chamber, purging air channel

Function check

(each test is described in the Operating Manual)

− Test function of fan

− Test function of heating

− Check cha ngeover va lve

− Clean the optical elements (by wiping)

− Linear check

• Cleaning

Visual inspection probe and hose

Service Manual 1-9

Periodic Maintenance AVL 4000

1.4.3 AVL DiCom 4000

•

Evaluation unit

Check using software

− Raw data from 4-gas measuring instruments unit OK?

− O

sensor is OK?

2

− NO sensor is OK?

Open evaluation unit (remove cover)

Visual inspection, clean pcb

If necessary update setpoint data and software

Close housing, seal with service seal

Enter in maintenance log book

• Opacity measuring chamber type A

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe connection plate O-ring

− Probe hose, probe clamp

− S oiling of measuring chamber, purging air channel

Function check

(each test is described in the Operating Manual)

− Test function of fans

− Test function of heating

− Check cha ngeover va lve

("Calibration", "Test", "Deactivate" settings - visual check or diesel service mode)

− Clean the optical elements (by wiping)

− Cha nge la mps

− Linear check

1-10 Service Manual

4000 Periodic Maintenance

• Opacity measuring chamber type 4000

Visual check

− Silicon seal

− L eaks in housing

− Housing c ompone nts (cracks, faults)

− C losure f ittings, snap mechanism of optical elements

− E lectrical plug connections and cables

− Probe hose, probe clamp

− S oiling of measuring chamber, purging air channel

Function check

(each test is described in the Operating Manual)

− Test function of fans

− Test function of heating

− Check cha ngeover va lve

− Clean the optical elements (by wiping)

− Linear check

• Cleaning

Replace particulate filter

(see section 5.3.3 Particulate Filter)

Check O-ring paper filter

Visual inspection probe and hose

Clean condensate pump

(using cleaning kit)

Function test

− Leak test

− Gas calibration

Service Manual 1-11

Periodic Maintenance AVL 4000

1-12 Service Manual

4000 Error Messages and Troubleshooting

2. Error Messages and Troubleshooting

2.1 4-/5-Gas Measuring Instruments Unit

2.1.1 Gas Flow Insufficient

Check the following:

• Is the exhaust gas probe nozzle blocked?

− Clean the probe out with compressed air.

CAUTION - before doing so, always disconnect the probe from the tester!

• Is the measurement gas outlet blocked?

• Is the flexible probe hose kinked or is there a heavy object on the hose that is stopping

the gas flow?

• Check the paper filter in the filter housing

− If the filter is black, replace it.

− Always carry out a leak test after replacing a filter.

A soiled filter can cause soiling or even damage to the

measurement cell.

If the above measures do not solve the problem, the hose system must be blocked (in the

measuring instruments unit) or the pump is defective.

Remove the measuring instruments unit (see Dismantling the 4-/5-Gas Measuring

Instruments Unit) and check the hose system and pump (see 4-/5-Gas Measuring

Instruments Unit).

Service Manual 2-1

Error Messages and Troubleshooting AVL 4000

2.1.2 System Needs Restarting

If two consecutive attempts at restarting do not return the tester to normal operating

mode, the measuring instruments unit must be defective.

• Remove the unit (see Dismantling the 4-/5-Gas Measuring Instruments Unit) and

check the

− measuring cell

− receiver

− light source

• Check the cable between the main board and the measuring instruments unit

2.1.3 Measuring Chamber Temperature Too High

•

Remove the probe from the exhaust pipe (because when this error occurs, the tester

switches to zero calibration mode and needs to draw in fresh air).

• Do not switch the tester off!

• Wait at least 10 min

• Acknowledge the error by pressing >>,

− Select “Measurement” again.

• If the same error message appears again, there is a fault in the measuring instruments

unit.

• Remove the unit (see Dismantling the 4-/5-Gas Measuring Instruments Unit).

• Check the cable to the receiver / replace the unit if necessary (i.e. filter/receiver).

2-2 Service Manual

4000 Error Messages and Troubleshooting

2.1.4 Measuring Chamber Pressure Wrong

•

Check whether the measurement gas outlet is blocked.

• If it is, remove blockage and acknowledge by pressing >>.

• If you are unable to remedy the error, the measuring instruments unit must be

defective.

• Remove the unit (see Dismantling the 4-/5-Gas Measuring Instruments Unit).

• Check whether the hose system is blocked (with deposits or conde nsate; see Layout of

Pneumatics).

• Check or replace the pressure sensor (see Pressure Sensor).

2.1.5 Leak Test Failed

• If the tester fails its own leak test, check the entire sampling line for lea ks from the tip

of the probe to the inlet on the rear panel of the tester.

• If you find no leaks, disconnect the probe hose from the tester.

• Connect a 2 m hose that is guaranteed leakproof to the inlet port of the teste r, close it

off and carry out another le ak test.

− If the system passes the test, the leak must be in the probe/hose assembly.

− If the system fails the leak test, check the O-rings in the filter housing and

condensate trap and check whether the connections for the probe hose and

condensate drainage hose are leaking. Replace the tester’s filter, including the

probe pre-filter.

− If the system still fails the leak test, there must be a lea k inside the system or the

pump is too weak.

• Also check whether the tester has been stored with condensate in it at temperatures

below 0° C (leaks may be caused by ice).

Service Manual 2-3

Error Messages and Troubleshooting AVL 4000

2.1.6 Replace O2 Sensor

When the O2 sensor needs replacing, the appropriate message is output on the display.

• Switch the tester off and disconnect it from the mains.

• Remove the O

sensor (see section 5.6.1 Replacing the O2 Sensor).

2

Observe the safety instructions for handling O2 sensors at the

front of this manual.

Old sensors must be properly disposed of

(they are highly toxic special waste).

Every time the O

(i.e. entered in the maintenance book).

sensor is replaced, this must be recorded

2

Whenever the O2 sensor is replaced it must be reparametrised - see Operating Manual.

2.1.7 Replacing the NO Sensor

A message appears on the display when the NO sensor needs replacing.

• Switch the instrument off and disconnect the mains cable.

• Remove the NO sensor (see section 5.6.2 Replacing the NO Sensor).

Observe the safety instructions for ha ndling O2 sensors at the front

of this manual.

Old sensors must be properly disposed of

(they are highly toxic special waste).

Every time the O

(i.e. entered in the maintenance book).

sensor is replaced, this must be recorded

2

2-4 Service Manual

4000 Error Messages and Troubleshooting

2.2 Opacity Measuring Chamber

2.2.1 Measuring Chamber Too Hot/Too Cold

If the error message "Measuring chambe r too hot" occurs during operation, remove the

probe from the exhaust pipe and wait until the temperature returns to the permitted

range. Acknowledge the message by pressing >>.

If the error message "Measuring chamber too cold" is displayed, the chamber has been

cooled by cold exhaust gas. Wait until the measuring chamber has heated up again to at

least 80° C and acknowledge the message by pressing >>.

If the measuring chamber temperature does not return to the permitted range after

several attempts (2 to 3 times), there must be a fault.

• If the temperature is still too low, one of the heating blocks has probably fa iled (see

Operating Manual - Heating Function Test or section 6.6 Heating Blocks and Orifice

Plates) or a temperature sensor has failed (see section 6.8 Temperature Sensor).

• If the temperature is still too high, the feedback control system is malfunctioning (see

section. 4.2.1 Main Board). But check the temperature sensor as well, just in case.

2.2.2 Changeover Valve Error

This message suggests failure of the changeover valve in the opacity measuring chamber.

• Replace changeover valve.

Do not lubricate the changeover valve.

Service Manual 2-5

Error Messages and Troubleshooting AVL 4000

2.3 Linearity / Opacity Error,

2.3.1 Opacity Measuring Chamber, Type A

If either of these messages occur, proceed as follows.

• Fold the optical elements of the opacity measuring chamber to the side, out of the

way;

• Check that both lamps are working - they must both be on.

Replace lamps, if necessary (see section 6.9 Lamp Module).

• Clean the glass disc in front of the optical elements.(see Operating Manual, Cleaning

the Optical Elements of the Opacity Measuring Chamber).

• Fold the optical elements back into place and acknowledge the message by pressing

>> - you will then see the main opacimeter menu.

2.3.2 Opacity Measuring Chamber, Type 4000

Remove the lens protector from the opacity measuring chamber and check the windows –

clean if necessary.

• Press << to start an automatic calibration.

− If the instrument calibrates itself successfully, you will find yourself in the main

menu.

− If the calibra tion f ails, the error message is displayed again. Press >> to call up the

diesel service screen for further error diagnosis.

2-6 Service Manual

4000 Software

3. Software

3.1 General

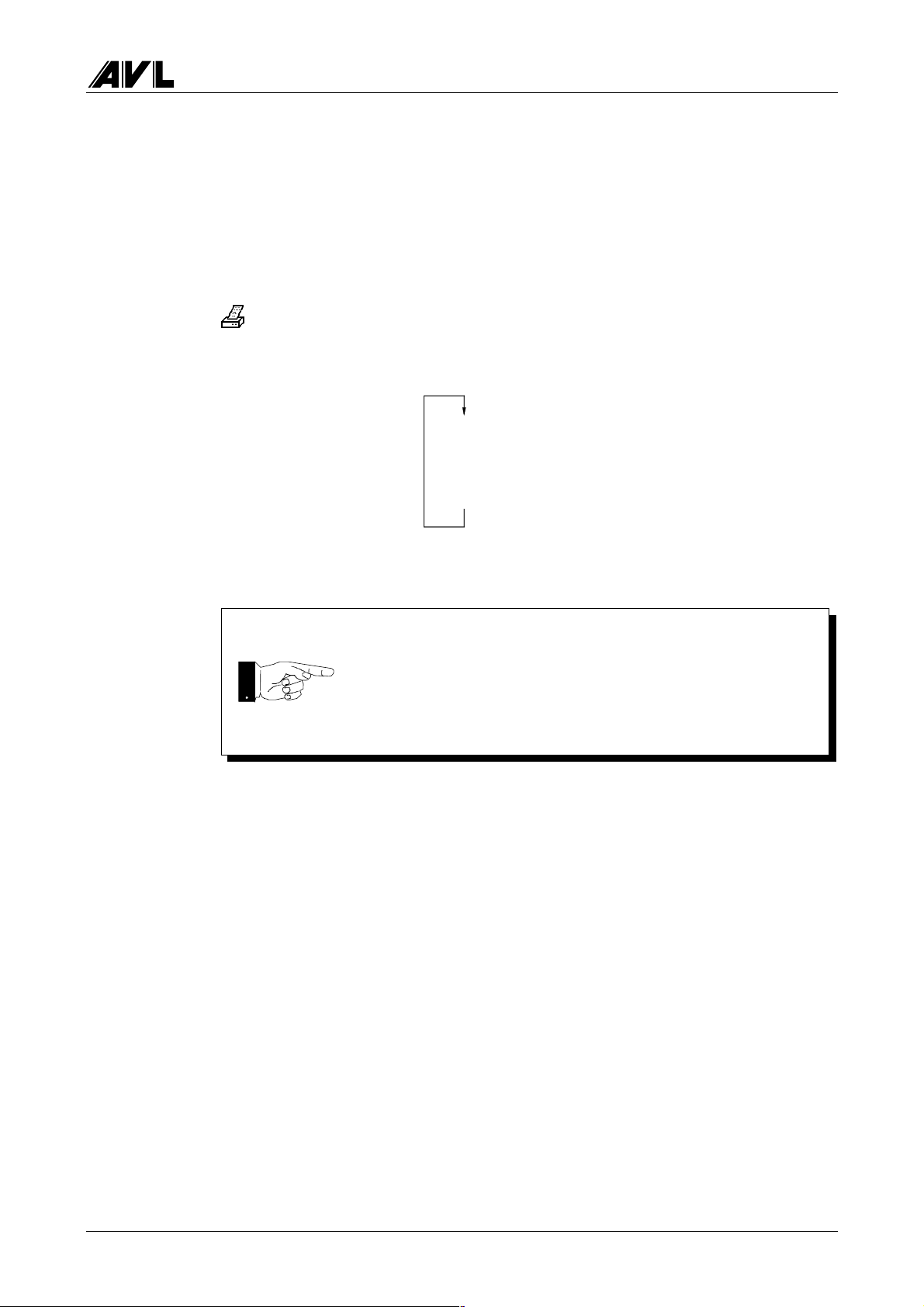

The instrument carries out an automatic self-test when it is powe red up at the ON/OFF switch.

The following data is displayed during the self-test:

VERSION

MEMORY/OPTIONS:

CHECKSUM:

PRINTER INTERN:

KEYBOARD INTERN:

MEAS.CHAMB.4GAS:

MEAS.CHAMB.DIES:

DICOM A

HARDWARE:

SELF TEST

EXTERN:

EXTERN:

Fig. 3-1

1. Installed software version

2. Checksums (depending on the country-specific software, allows the calibrating

authorities to monitor)

The following checksums are displayed

− me mory (checksums for petrol and diesel)

Customer memory Checksum

Not available 0002

500 KB 0036

1 MB 00F6

Service Manual 3-1

Software AVL 4000

Petrol

Diesel

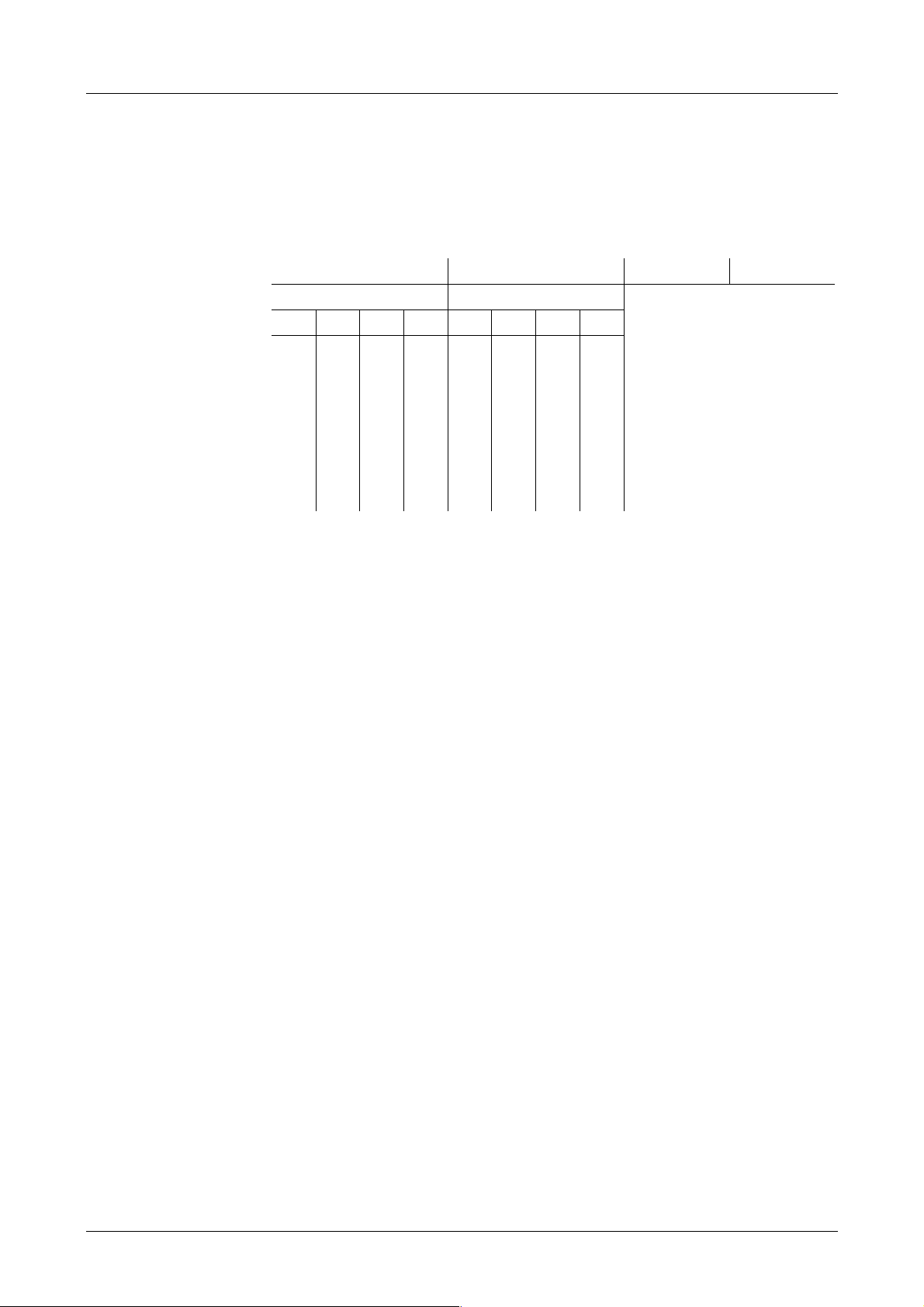

− Software options

The first two hexadecimal digits of the four-digit checksum indicate the software

options installed (i.e. available for use).

st

1

hex. digit 2nd hex. digit 3rd hex digit 4th hex digit

Bit

*)

Bit

*)

no significance

4 3 2 1 4 3 2 1

**)

Speed Angle Board

Diagnostics Plus

Diagnostics Plus

Diesel

Emission Expert Petrol

Emission Expert

—

—

BMW option

*)Bit = 0: Option not available

Bit = 1: Option available

Exception: BMW option

(bit = 0: option available, bit = 1 : option not available)

**)

The Speed Angle Board is absolutely necessary for the software options!

e.g. all options installed

01xx ....... no options installed

− The f ollowing checksums a re also displayed

checksum for sections of the petrol program that are relevant to the

measurement technology

checksum for sections of the diesel program that are relevant to the

measurement technology

checksum for official measurement

supplementary checksum

3. Printer (internal dot matrix or external A4 printer)

4. Keyboard

5. 4 or 5-gas measuring chamber

6. Measuring head for diesel (opacity measuring chamber)

7. Hardware self-test result

3-2 Service Manual

4000 Software

Troubleshooting when hardware self-test fails

The error or status code is represented by a special error code.

Code Problem

1Printer fault

2Keyboard fault

3 Opacity measuring chamber not connected

4 4-gas measuring chamber fault

5 rtc_bat_test

6 Voltage test

7 Fan control unit

8 Pneumatics valve

9 Serial silicon number - motherboard

10 Serial silicon number - opacity measuring chamber

11 Fan opacity measuring chamber 4000

12 Fan opacity measuring chamber 435

17 Communication

18

ü

ý Power supply

19

20

21 Breaker channel

22 TDC channel

23 TDCANA channel

24 Peak meter TDC

25 Peak meter

26 Integrator

27 TDCANA channel filtering

28 TDC sensor, current-fed

29 Stroboscope control

opacity measuring

ï chamber

ü

ï

ï

ï

ï

ï

ï

ï

ý speed angle board

ï

ï

ï

ï

ï

ï

ï

Service Manual 3-3

Software AVL 4000

3.2 Installation of Operating Software (Software update)

The AVL 4000 has an externally accessed slot for memory cards which is compatible with

the PCMCIA PC industry standard. The card has a memory of up to 56 MB.

AVL identification no. EN0339 (4 MB memory)

Basic functions:

− First-time progra mming during production

− Software update during production and service

− Backup medium for customer files

− Data exchange with PC

− Carrier for software options

Installation procedure

Note: Depending on the country specific legislation, this procedure is not supported by

every hardware (France ) or is not allowed (Switzerland).

• Switch the tester off.

• Connect the installation adapter to the 5-pin keyboard port (AVL identification no.

BV2150) an.

• Plug the memory card into the PCMCIA slot.

• Switch the tester on.

The software on the memory card is then installed automatically.

− During installation the installation adapter will output short beeps.

− On completion of the software installation, the tester will output a long beep.

− A continuous sound indicates that the software cannot be installed.

− If the installation fails, you will hear an intermittent signal.

A brief pause between the sounds indicates errored software installation. A long

pause indicates that the customer memory is missing (necessary in Germany and

for the customer memory option).

• Now switch the tester off again.

• Remove the memory card from the PCMCIA slot and disconnect the installation

adapter from the keyboard port.

The installation procedure is now completed. Switch the tester on and check that the new

software is properly installed (Self-test after power-on – software version, checksums).

Instruments destined for Germany must be equipped with

a memory extension!

(See Section 4.2.1.10 Memory Adapter)!

3-4 Service Manual

4000 Evaluation Unit

4. Evaluation Unit

4.1 General Description

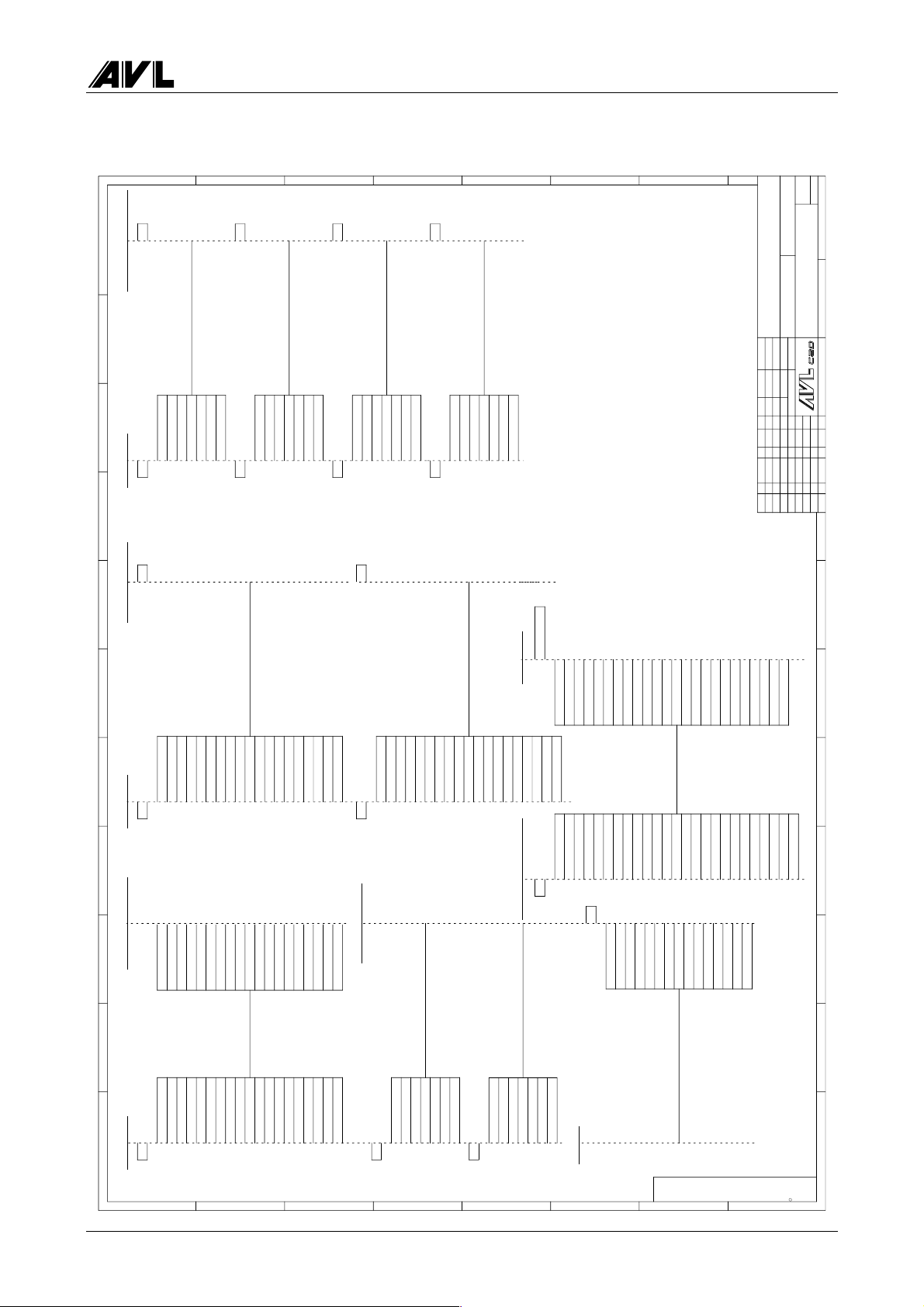

Fig. 4-1

The 4000 Evaluation Unit basically consists of the following components:

− housing cover

− rear panel

− front panel

− frame

− LC display

− membra ne keypad

− printer unit

− power supply board

− main boa rd

− speed / angle board

− measuring instruments block

− 4-/5-gas measuring instruments unit

− O

sensor

2

− fan

− rating label

− rubber feet

− memory e x tension (memory adapter)

Service Manual 4-1

Evaluation Unit AVL 4000

4.1.1 Basic Design

The housing consists of a central metal f rame which is d rawn up at the front to the inside

front panel which contains the instruments. Inside the fra me are the power supply unit,

the main board, optional electronics pcbs, speed/angle board, printer adapter,

pneumatics board and chamber adapter.

The display is mounted on the front panel. The front of the housing consists of 2 plastic

cover sections, the display with integrated plexiglass and membrane keypad and the

printer cover. The printer itself is fitted to the inside front panel.

All of the evaluation unit’s connection sockets are on the right-hand side of the housing.

To cater for the various configurations that require different plugs, the side plate is a

cover plate with the relevant socket symbols printed on it.

If the evaluation unit is used as a four-gas (or five-gas) or combination gas tester, the fourgas analyzer with integral power supply unit and the pneumatics rear panel are also

integrated.

The pneumatics rear panel is designed so that the four-gas analyzer sits on a metal

bracket and all the pneumatics elements, such as the condensate trap, particulate filter,

measurement and condensate pump, various filters and non-return valve are

accommodated on the rear panel.

The cover closes the entire housing and has built-in finger grips to make it easier to carry.

The screws are situated in the cover in such a way as to permit the housing to be sealed

for official calibration and subse que nt se aling purposes.

The four-gas tester can be upgraded to a combination tester by connecting a diesel

measuring chamber, installing the necessary electronics pcb and replacing the back panel.

The display is mounted on the outside of the housing and has a plastic cover. The centre

section of the plastic front has the membra ne keypad and an anti-glare, tinted wind ow

through which the LCD display can be seen.

The front panel is suitable for mounting two alternative types of LCD display.

The printer (Epson 5F181) is located on the outside of the housing and (as a dot matrix

printer) sealed in an EMC-quality housing. The paper is fed from above and printed on

the back.

The pcbs are arranged one ab ove the other in the right-hand par t of the housing para llel

to the tester base in the following order:

− main boa rd

− speed/angle board

− option board (free slot)

− The chamber adapter board (for the AVL DiCom 4000) is located on the main

board at slots J4, J6, J10 and J14.

− The printer board is also on the main board at slots J27 and J28.

− The pneumatics board is fixed to the rear panel.

4-2 Service Manual

4000 Evaluation Unit

4.1.2 Evaluation Unit

The evaluation unit hardware consists of:

− the user interface with displays, softkeys, remote control (optional), memory card

connection, strip printer (optional)

− electronic circuits with main board and the option pcbs, printer board, opacity

board, speed/angle board including interfaces and sensor connections.

− free slot for future expansions and the

− power supply assembly with mains switch components, power supply unit, fan

and wiring.

Service Manual 4-3

Evaluation Unit AVL 4000

4.1.3 Pneumatics Rear Panel / 4-/5-Gas Measuring Instruments Unit (5-Gas Option)

The entire pneumatic unit is mounted on the rear wall. The 4-gas measuring instruments

unit is screwed to the rear panel.

probe

The condensate trap, particulate filter, O

mounted directly on the outside of the rear panel.

Condensate trap

Particulate filterConnection for

Control cable connect.

(to opacity measuring

chamber type A only)

Pump

(NO- 5-gas option) sensor and pump are

2

Zero gas

inlet

(pure air)

Activated carbon filter

O

sensor

2

NO sensor (option)

Condensate filter

Inlet for

calibration gas

Heating cable connection

(opacity measuring chamber type A)

or control cable connection

(opacity measuring chamber type 4000)

Fig. 4-2

4-4 Service Manual

Power supply

for pump

Non-return

valve

Analog output

(analog signal of exhaust opacity;

0…5 V

Mains connection

with ON/OFF switch

and fuse box

Condensate

outlet

0…100 % opacity)

=

4000 Evaluation Unit

4.2 Hardware Setup

4.2.1 Main Board

The main board represents the heart of the electronics and uses predominantly SMD

technology. The most important function blocks are described below.

4.2.1.1 Digital System

The digital system is built around the highly integrated Intel I80C196NT controller with

20 MHz clock frequency.

The program memory is a flash eprom with 0.5 MB (16 bit bus, 0 wait states, several

independent program and parameter blocks) and can therefore be reprogrammed in the

field.

Two static RAMs are used to store data with a total of 256 KB (16 bit access, 0 wait states).

A further 256 K area of the address space is used as a page area for the internal expansion

memory (on a module receptacle) a nd the e xter nal me mory ca rd. The slot f or the memory

card is welded to the main board.

The address coding is by programmable logic.

The RTC (real-time clock) has a ten-year function guarantee on the lithium cell.

The main board (and therefore the evaluation unit) is unambiguously identified by a

silicone serial number which carries an individual 48-bit code. The internal temperature

of the instrument is monitored by an NTC.

4.2.1.2 Analogue Data Acquisition

The necessary analogue values are measured by the 10-bit ADC installed in the 196NT.

The values measured are the opacity signal, various temperatures, analogue channels

from the speed/angle board and from the free slot and various values for self-diagnostic

purposes (supply voltages, valve motor current). Where necessary, the data is reprocessed

digitally (in particular linearisation, demodulation, digital filtering). This allows, for

example, the filter parameters for the opacity signal to be adjusted to the various

directives.

4.2.1.3 Remote Control Receiver

An integrated receiver/pre-amplif ier is conne cted to the ma in boa rd by a short ca ble. The

output signals are conditioned by the 196NT via an EPA channel.

Service Manual 4-5

Evaluation Unit AVL 4000

4.2.1.4 Interfaces

All external interfaces a re c onne c t e d directly to the pcbs.

The connection for an external PC ke yboard is a standard five-pin plug and is processed

by the 196NT via the timer EPA channels.

An A4 printer can be connecte d by a 25-pin SU B-MIN-D socket as a standard Centronics

parallel interface.

A TRUART module serves the interna l serial interfa ce to the 4- gas measuring instruments

unit in the AVL DiGas and AVL DiCom.

The interface to a host computer (PC, SilverDat computer, Bilanmatik, test bed

computer,…) is also via a standard 9-pin SUB-MIN-D socket and implemented by the

asynchronous serial interface installed in the 196NT. This allows maximum flexibility for

various requirements (such as baud rate, parity check).

Interface socket 9-pin D-sub socket

Interface RS232 serial

Data transfer format 8 bit, 1 stop bit, no parity

Data transfer rate 9600 bit/s

Transfer code ASCII

Pin assignment 1

Provided the instrument has the requisite software installed, measurement data can be

transmitted via this interface to a computer (Isotec interface). The data is transferred a s

ASCII code.

The interface can be set in the service menu under User data/Configuration.

Parameters: 9600 baud, 8 data bits, 1 stop bit, no parity

3…no. of repeats on transfer (= max. 2 repeats)

2 sec. timeout for RS232 (applies to each repeat)

The following operating modes can be selected:

PRG

TxD

2

RxD

3

DTR

4

GND

5

6

DSR

7

RTS

8

CTS

9

RI

Connected to GND

Transmit data (output)

Receive data (input)

Not used

Ground

Not used

− MASTER

The instrument transmits a defined data block to the computer at the touch of a

button or after an event. The computer must be ready to receive the data.

4-6 Service Manual

4000 Evaluation Unit

− SLAVE (Isotec mode)

The computer periodically sends a query to the instrument. If the instrument is

not ready for data transfer, NAK is transmitted to the computer. If measurement

data is available, a data block is transmitted to the computer.

− NO (interface not activated)

Serial interface cable:

Pin assignment pin assignment

AVL 4000 PC

(9-pin SubD) (9-pin SubD)

TxD

2

3

5

2

RxD

3

GND

5

4

6

Bridge 4-6-8

8

Fig. 4-3

4.2.1.5 Display Control and Softkey Connection

The display is operated by means of the SED 1335 LCD Controller with 32 to 128 KB of

display RAM.

In addition, the contrast voltage and the supply voltage for the CCFL background

illumination is generated by an inverter module on the main board. The contrast voltage

can be fine-tuned via an EPA channel of the 196 NT and temperature-compensated by

display-dependent characteristic curves.

The connection cables of the various displays are coded for ease of identification.

The 8 keys (softkeys and permanent keys) are addressed by ESD-protected drivers.

4.2.1.6 Generation of Auxiliary Voltage

Various voltages are generated from the 4 power supply unit voltages (5 V, ±15 V, 24 V):

± 15 V analogue filtered voltages for powering the analogue circuits

Vpp (+12 V) switchable programming voltage for flash eproms

+ 5.12 V analogue precision reference voltage for ADC channels in the 196NT

- 5 V analogue negative supply for low-cast multiplexer and op amps

4.2.1.7 Board Control

The printer board (optional) and chamber adapter board (for AVL DiCom 4000) are

plugged straight into the main board, whereas the pneumatics board, speed/angle board

and free slot are connected via control or ribbon cables.

The speed/angle board and free slot are served by fast, synchronous, serial interfaces

(SSIO) of the 196NT which means that both intelligent pcbs with their own processors

and non-intelligent boards can be connected via parallel- serial converter I/O mod ules. In

addition, digital synchronisation signals, interruption inputs, analogue channels and

timer channels (EPA ports) are available for both boards.

The various equipment configurations are registered automatically which reduces the

time and cost of programming and set-up.

Service Manual 4-7

Evaluation Unit AVL 4000

4.2.1.8 Printer Board (Option)

If the printer option has been purchased, the printer board is inserted in the main board

at right angles to it (slots J27 and J28). It contains the control circuit for the integral strip

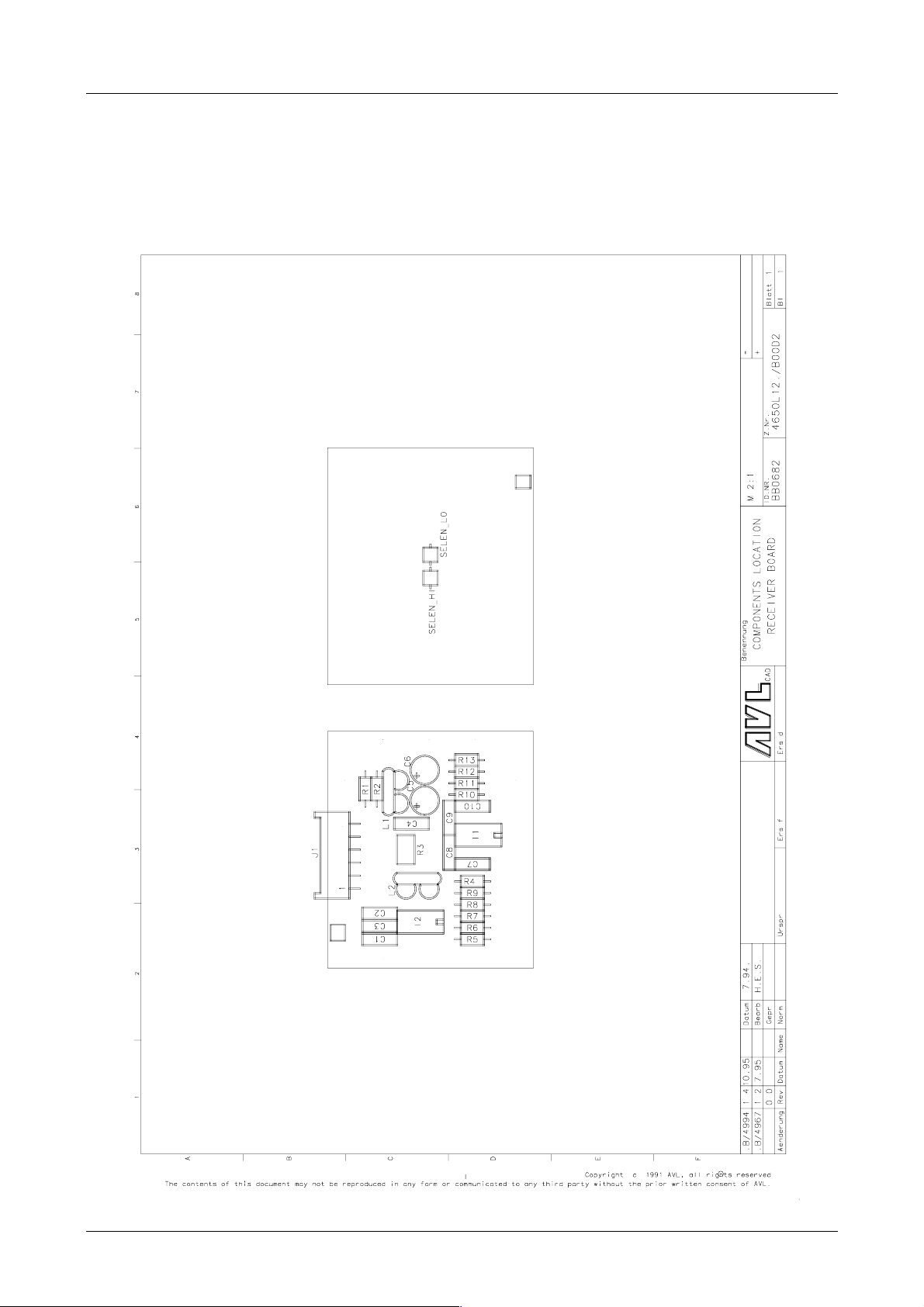

printer (dot matrix printer driver, motor, fast paper feed and evaluation of tachogenerator and home switch).

Because most of the pcb is taken up with power transistors, the boards are manufa ctured

using wired technology.

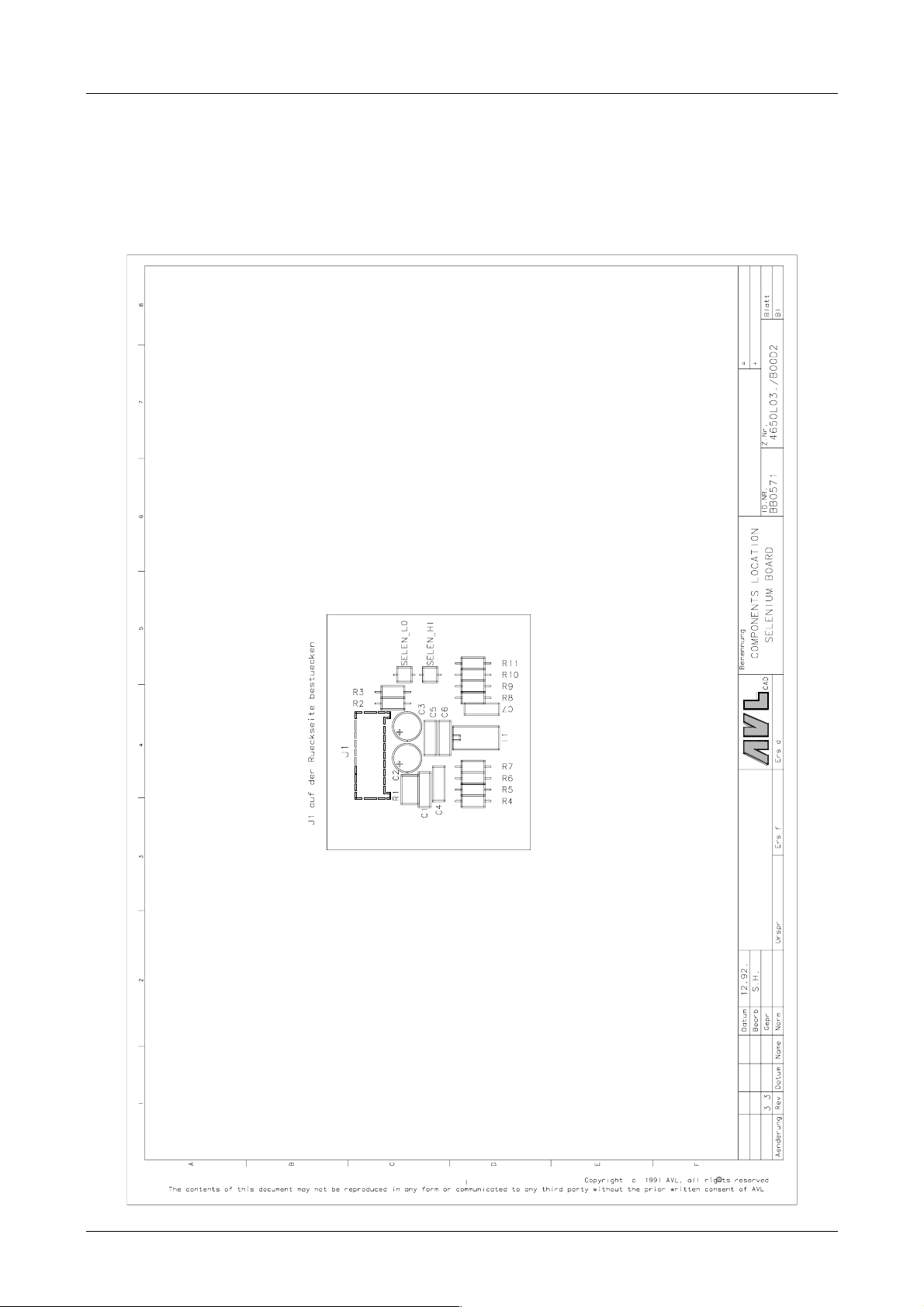

For installation, see section 4.5.1 Internal Printer Unit.

4.2.1.9 Speed / Angle Board with Diagnostics Cable Concept

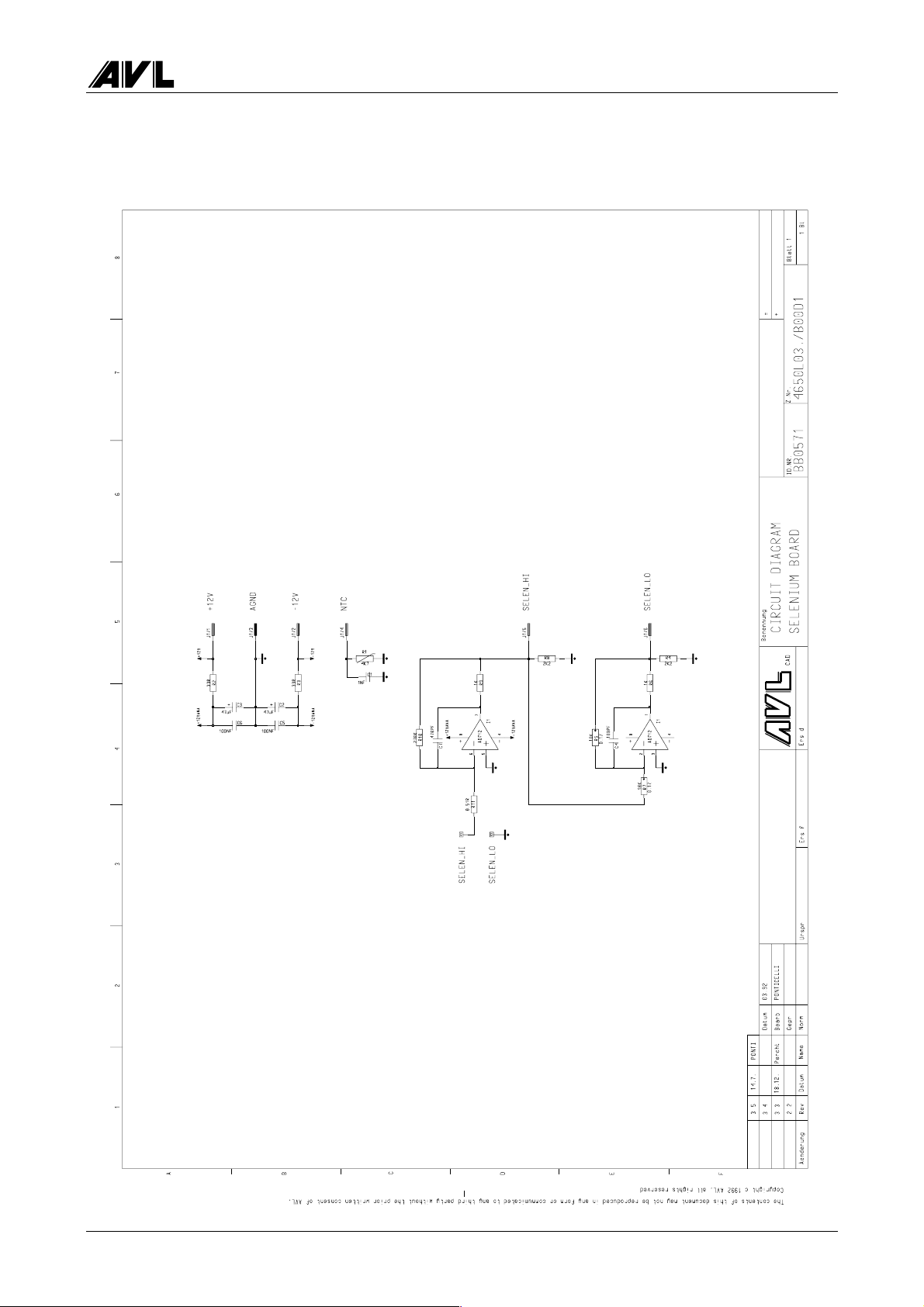

(Option/Installation)

The speed/angle board is an option that can be used to record speed, angle, oil

temperature, the lambda probe voltage and the voltage of the vehicle electric system. The

speed/angle board is basically non-intelligent, i.e. does not have its own processor. All

speed and angle signals are converted via two processing channels to digital pulses which

are evaluated by the 196NT on the main board.

Measurements:

• RPM measurements

Supported sensors:

− inductive sensors (e.g. T DC sensors) with different timings

(incl. Motronic flywheel)

− optical sensor

− digital pulses from engine management system

− AVL clamp-on transducers (AVL DiGas 4000 and AVL DiCom 4000)

− RIV sensors (AVL DiGas 4000 and AVL DiCom 4000)

− needle movement sensors (AVL DiGas 4000 and AVL DiCom 4000)

− inductive trigger clamp (AVL DiGas 4000 and AVL DiCom 4000)

− AVL DiSpeed 490 (AVL DiGas 4000 and AVL DiCom 4000)

Measurement range 250…6000 rpm (diesel engines)

250…8000 min

Resolution: 10 rpm

Accuracy: ± 2 rpm (rounded to nearest 10 rpm)

• Angle measurement

The start of delivery, sta rt of injection and ignition a ngle are measured by processing

a cylinder 1 sensor signal in conjunction with a reference signal.

-1

(petrol engines)

Supported cylinder 1 sensors:

− AVL clamp-on transducers (AVL DiSmoke 4000 and AVL DiCom 4000)

− RIV sensors (AVL DiSmoke 4000 and AVL DiCom 4000)

− needle movement sensors (AVL DiSmoke 4000 and AVL DiCom 4000)

− inductive trigger clamps (AVL DiGas 4000 and AVL DiCom 4000)

(Customer-specific) special signals can be conditioned with an external black box as an

option.

4-8 Service Manual

4000 Evaluation Unit

Supported reference sensors:

− inductive sensors (TDC sensors) with var ious timings

(incl. Motronic flywheel)

− optical sensors

− digital pulses from engine management system

− strobe with engine marks

Measurement range: 0…59.9° CA (strobe mode)

-9.9…99.9° CA (other reference sensor)

Resolution: 0.1° CA

Accuracy: 1.0° CA (strobe mode)

0.5° CA (other reference sensor)

• Measurement of dwell angle in petrol engines

Interrupter signal (ignition primary) (AVL DiGas 4000 and AVL DiCom 4000)

Measurement range: 0.0…99.9%

Resolution: 0.1%

Accuracy: 1.0%

• Oil temperature measurement

The temperature is measured by inserting the AVL oil temperature sensor, available

in various lengths, into the sump (or more rarely, into the cooling water).

Measurement range: 0…120° C

Resolution: 1 °C

Accuracy: ± 4° C

• Lambda probe voltage and voltage of vehicle electric system:

A voltage can be measured (lambda probe voltage or the voltage of the vehicle

electric system).

Measurement range: 0.00...32.00 V DC

Resolution: 40 mV

Accuracy: 160 mV

Graphical representation (lambda probe voltage only)

Amplitude: 0…1.8 (5.0) V -40 (120) mV resolution

Representation time: 10 (20) sec -20 (40) msec resolution

Frequency evaluation: 0.1…10 Hz -0.01 Hz resolution, ±0.02 Hz

Service Manual 4-9

Evaluation Unit AVL 4000

• Diagnostics cable concept:

There are five plugs to connect the supported sensors:

− clamp-on transducer/RIV plug

− cyl1 plug for needle movement sensor, inductive trigger clamp and interrupter

connection (black box for special signals)

− reference plug for inductive sensors, optical sensor, digital pulses and strobe

(black box for special signals, e.g. universal rpm measurement)

− voltage plug for c onnecting lambda sensor and vehicle electric system

− oil temperature plug

There are short adapter cables for the connection to the engine, which can easily be

accommodated on the instrument trolley. Alter natively, a de dicated connection cable

can be used without an extension lead.

The speed angle board option (ident. number BO1721) consists of the following

components:

− speed angle board

− ribbon cable

Installation

• Switch the instrument off and disconnect from the mains.

• Open the instrument.

• Remove the side housing sections

(undo 4 Phillips screws on the outside; one hexagon nut on the inside).

• Remove the GND connector.

• Insert the speed angle board.

• Reconnect GND connector.

• Connect the speed angle board to the main board using the r ibbon c able / slot J16

(SPEED/ANGLE).

• Mount the speed angle board

(4 Phillips screws on the outside; one hexagon nut on the inside).

• Connect analogue OUT socket (on rear panel) (red lead to AN_OUT and lead to GND

of speed angle board).

• Enter the speed angle board option on the option sticker.

• Reassemble the instrument.

• Connect the mains cable and switch the instrument on.

4-10 Service Manual

4000 Evaluation Unit

4.2.1.10 Memory Adapter

The Memory Adapter (AVL identification no. BB0730) is installed on the main board.

• Insert the Memory Adapter at slots J8 and J9 on the main board

• Mark the memory adapter option on the options stic ke r.

4.2.1.11 Chamber Adapter (AVL DiCom 4000)

The Chamber Adapter is needed to operate the opacity measuring chamber.

4.2.1.12 Extension Slot

There is a free extension card slot for future upgrading as the result of product

development. An option installed in this slot is located above the Speed/Angle Board.

If an extension card is installed, the side panel of the housing has to be changed.

4.2.1.13 Mains Switch Assembly

The mains switch assembly consists of the mains ca ble connection as an inlet connector

for non-heating appliances, the power switch, externally accessed mains f use and a filter

required by the statutory provisions for mains pollution.

4.2.1.14 Converting 230 V to 115 V Device

• Replace 230 V pump (on the real panel) with 115 V pump

The hose lengths must not be changed!

• Both fuses in the mains switch group must be replaced by 3.15 A slow-blow fuses.

• The modification from 230 V to 115 V must be indicated clearly on the rating plate

(with a warning on a sticker)

The power supply unit can continue to be used without any modif ic ations.

4.2.1.15 Power Supply Unit

All members of the instrument family contain the same purchasable power supply unit.

Technical data

− Computer Products NFS80-7606

− long-range input 90…260V AC, 125…360V DC

− outputs (short-circuit-proof):

+5V / 8A (±2%, ripple 1%) for digital part

+15V / 2.5A (±3%, ripple 1%) mainly analogue supply

-15V /2.5A (±3%, ripple 1%) mainly analogue supply

+24V / 2A (+10/-5%, ripple 1%) power (heating, fan, solenoid valve,

strobe,…)

− Output: 80 W (110 W with forced cooling)

− UL, CSA, VDE, IEC1010, IEC 950 approved

− mains pollution under VDE limit B

Service Manual 4-11

Evaluation Unit AVL 4000

4.2.1.16 Fan

The machine is ventilated at the sides and also at the rear to keep the pneumatic pump

cool. The angle of the air flow near the display has been kept as small as possible to

prevent the screen from becoming dirty too quickly.

The fan speed depends on the temperature.

4.3 Dismantling the 4-/5-Gas Measuring Instruments Unit

• Disconnect the plug from the mains!

• Open the housing cover (3 screws on the sides of the evaluation unit). Push the cover

towards the back until it is released from the mounting clamps.

• Disconnect all cables from the main board, power supply unit and ignition board to

the rear panel.

• Remove the 4 fixing screws on the rear panel.

• Remove the 3 fixing screws on the base plate.

• Remove the solenoid valve from the rear panel.

• Disconnect the hoses to the pneumatics module.

• Remove the rear panel pulling towards the back. Remove the activated carbon filter

from the rear panel.

• Disconnect the mains wiring to the power supply unit of the measuring instruments

unit.

• Carefully lift the measuring instruments unit upwards.

• The measuring instruments unit can now be completely removed.

For a technical description of the measuring instruments unit, see section 5 4-/5-Gas

Measuring Instruments Unit.

4.4 Housing

Components

− Cover

− Lower shell

− Front panel, complete (including keypad and display)

− Front panel (without ele c tronic c ompone nts)

− Rear panel, complete

− Rear panel (with no devices)

− 4 rubber feet

4-12 Service Manual

4000 Evaluation Unit

4.5 Printer

A hardcopy can be printed out of all the measurement results displayed. The official

measurements end with an official results printout.

4.5.1 Internal Printer Unit (Option/Installation)

It takes about 30 seconds to printout a hardcopy. A results printout takes ½ to 1 minute

depending on how long it is. During this time, none of the instrument’s f unctions can be

activated.

Technical data:

− Seiko Epson, model M-181

− 6-nee dle miniature printer for normal paper

− max. 30 chars per line (5 × 7 matrix)

− average speed 1.3 lines/sec

− 180 pixels per pixel line in graphics mode

− carbon copy possible

− paper width approx. 57.5 mm

− typical service life > 1 million characters

− typical service life of long-life ribbon 1 million characters (violet), 600 000

characters (black)

The printer option (ident. number BO1720) consists of the following components:

− printer adapter BB0279

− printer cable (for printers with connection cable) BV1983

− paper shaft YM3388

− paper roll for dot matrix printer HP0057

− 3 metal screws DS1101

Instructions for conversion

• Switch off the instrument and disconnect the mains plug.

• Open the instrument completely.

• Insert the printer adapter onto the main board (slots J27 and J28).

• Remove the plastic cover at the front of the instrument

• Pull the fixing shaft out of the printer‘s plastic cover.

• Connect the connection cable to the printer adapter.

• Fasten printer in position with the 3 metal screws.

• Enter the printer option on the options sticker.

• Reassemble the instrument.

• Plug the mains cable back in and switch on again.

• Insert the paper roll and push the paper through.

Service Manual 4-13

Evaluation Unit AVL 4000

4.5.2 External A4 Printer (Option)

An external A4 printer can be connected via a sta ndard Centronics interface. When an

external printer is on-line, all outputs (hardcopy, results printout) are diverted to that

printer. The time required for printing depends very much on the printer’s buffer.

A standard Centronics cable is used for the printer (AVL identification no. EX0308).

4.6 LCD

The 320 × 240 display is controlled by a separate controller.

The display contrast can be adjusted in the Service menu.

4.7 Membrane Keypad

The integral membrane keypad contains the 6 softkeys and 2 permanent keys. The

softkeys are used by the operator to control the progra m run or me nu selections.

Rarely needed data (e.g. garage address, vehicle data etc.) can be input using the editor

which is also implemented by the softkeys. If more frequent input is required (e.g. data

input for country-specific variants), the external PC keyboard option should be used.

The software supports an external PC keyboard (connected to the 5-pin standard PC

keyboard interface). Function keys F1 to F6 have a parallel function with the softkeys.

When the instrument is powered up, the external keyboard is initialised during the selftest.

In the Service menu (User data/Languages) it is possible (depending on the software

version) to select the keyboard layout after selecting the language for the menu

prompting.

If a different keyboard layout is selected, the instrument is re-started and the keyboard reinitialised during the self-test. After the re-start, the instrument is immediately ready for

measurements – you do not have to wait for the 4-/5-gas measuring instruments unit to

warm up.

4.8 Fan

The axial fan is screwed onto the rea r panel with 4 M4×25 cheese-head screws.

The instrument is ventilated at the bottom and also at the rear to keep the pneumatic

pump cool. The angle of the air flow near the display has been kept as small as possible to

prevent the screen from becoming dirty too quickly.

The fan speed depends on the temperature.

4-14 Service Manual

4000 Evaluation Unit

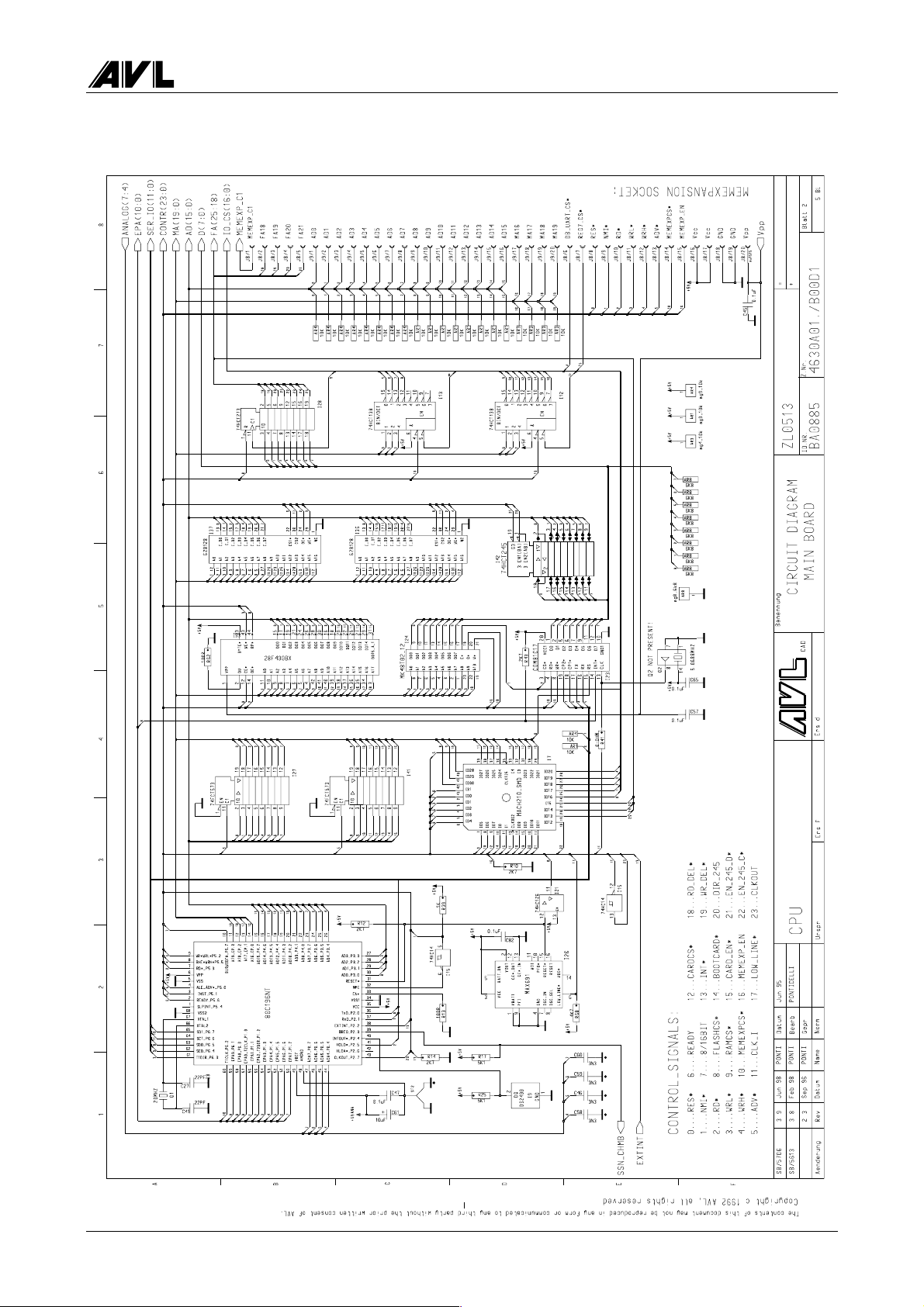

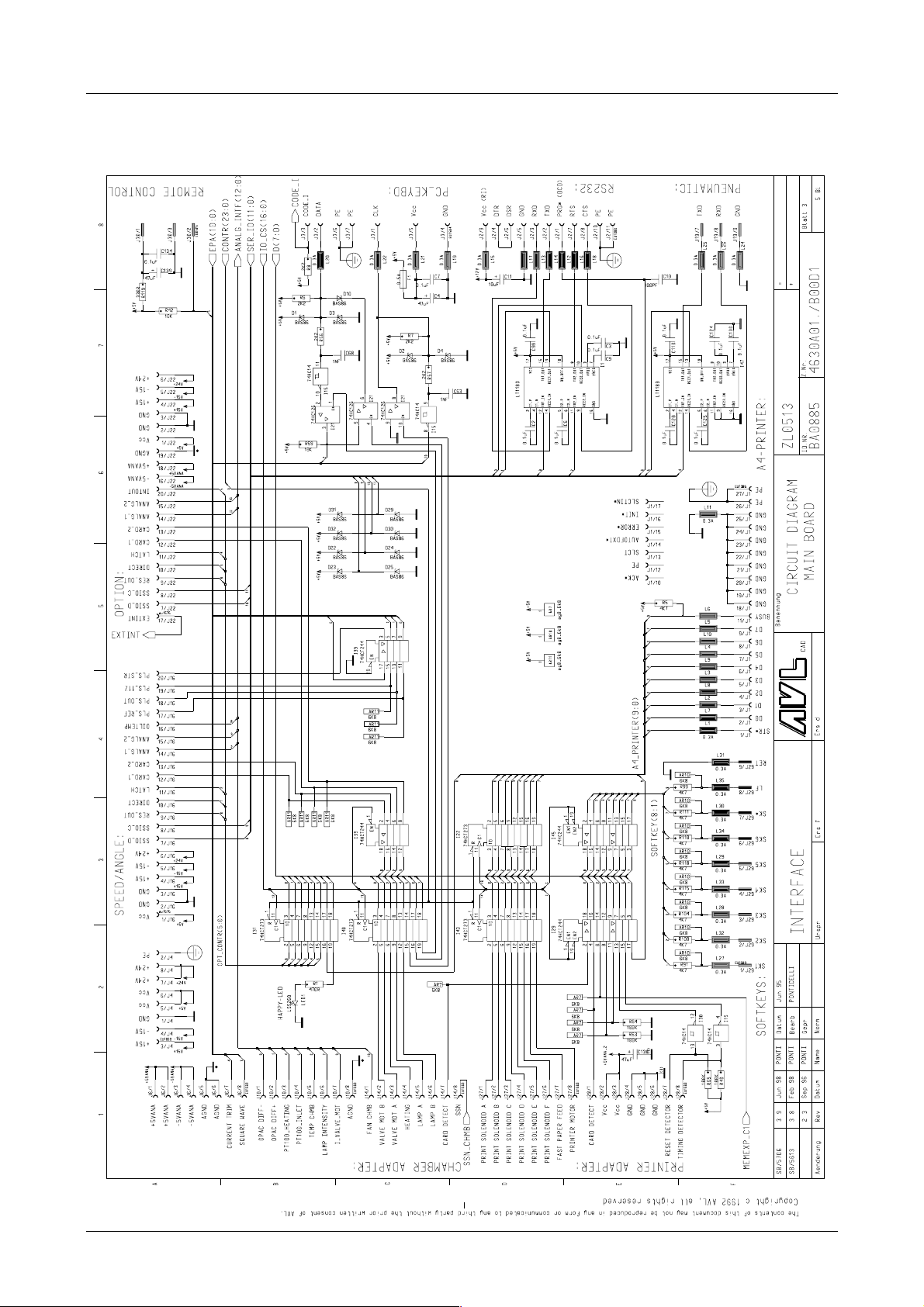

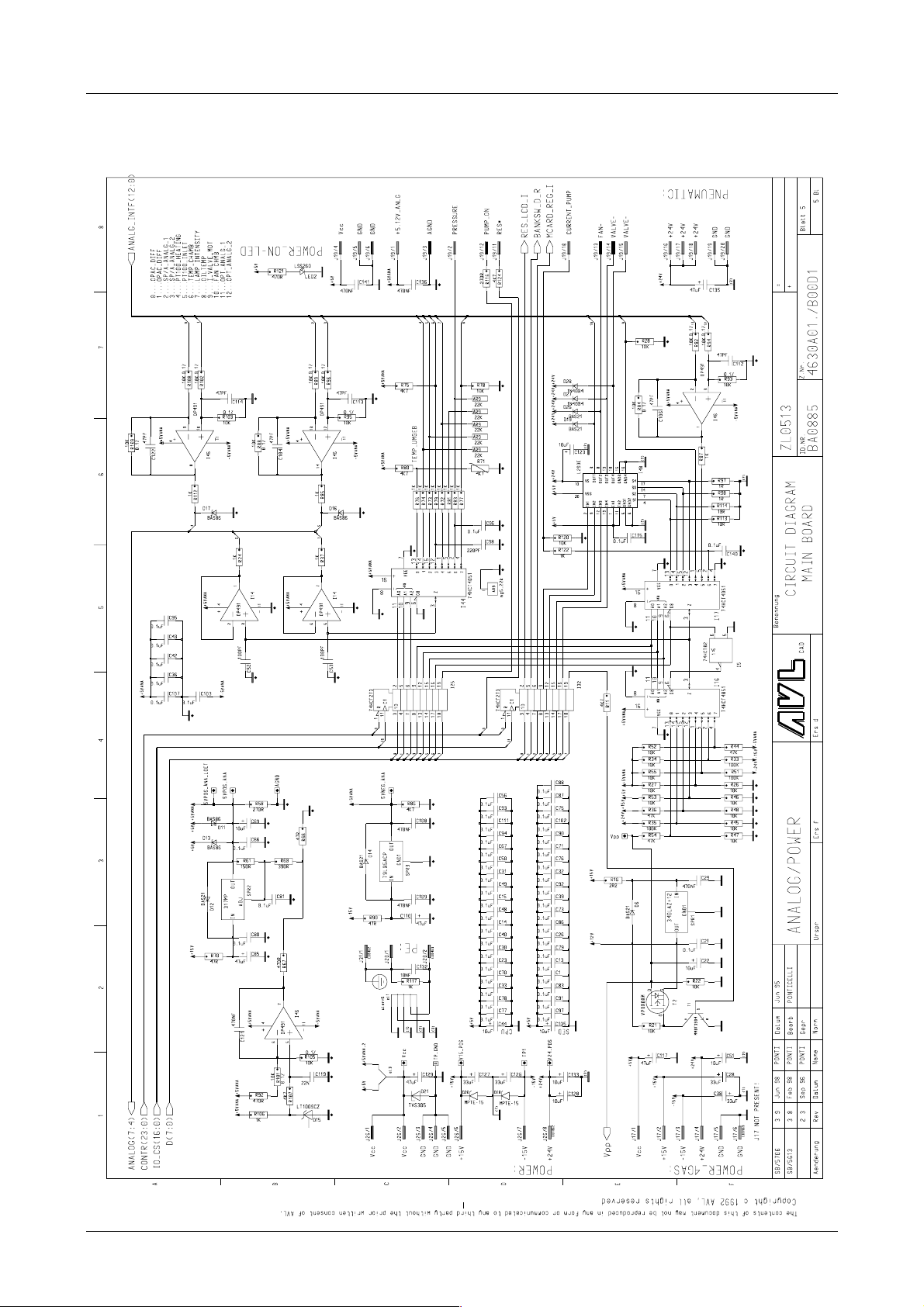

4.9 Main Board

4.9.1 Components Location Diagram

Service Manual 4-15

Evaluation Unit AVL 4000

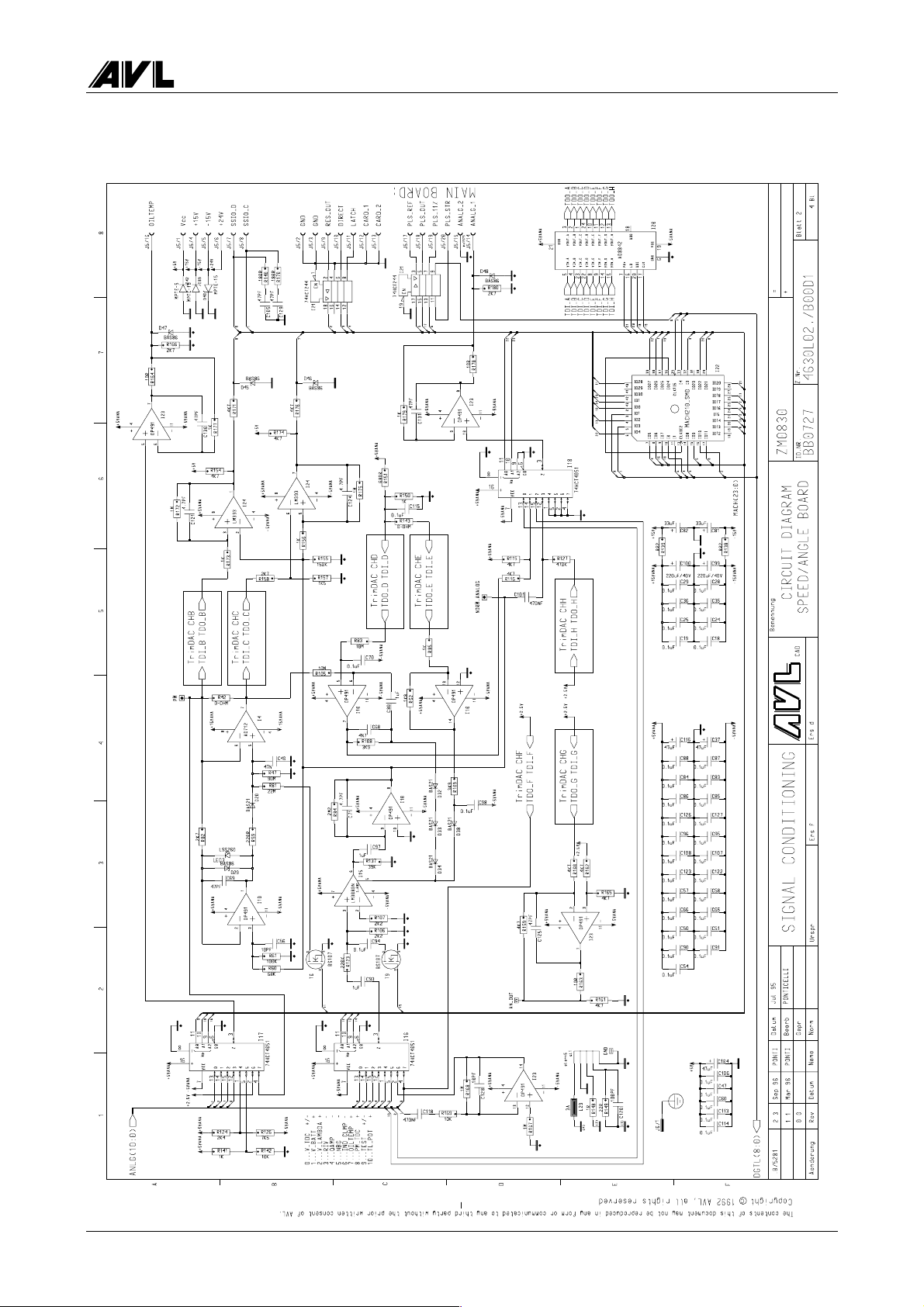

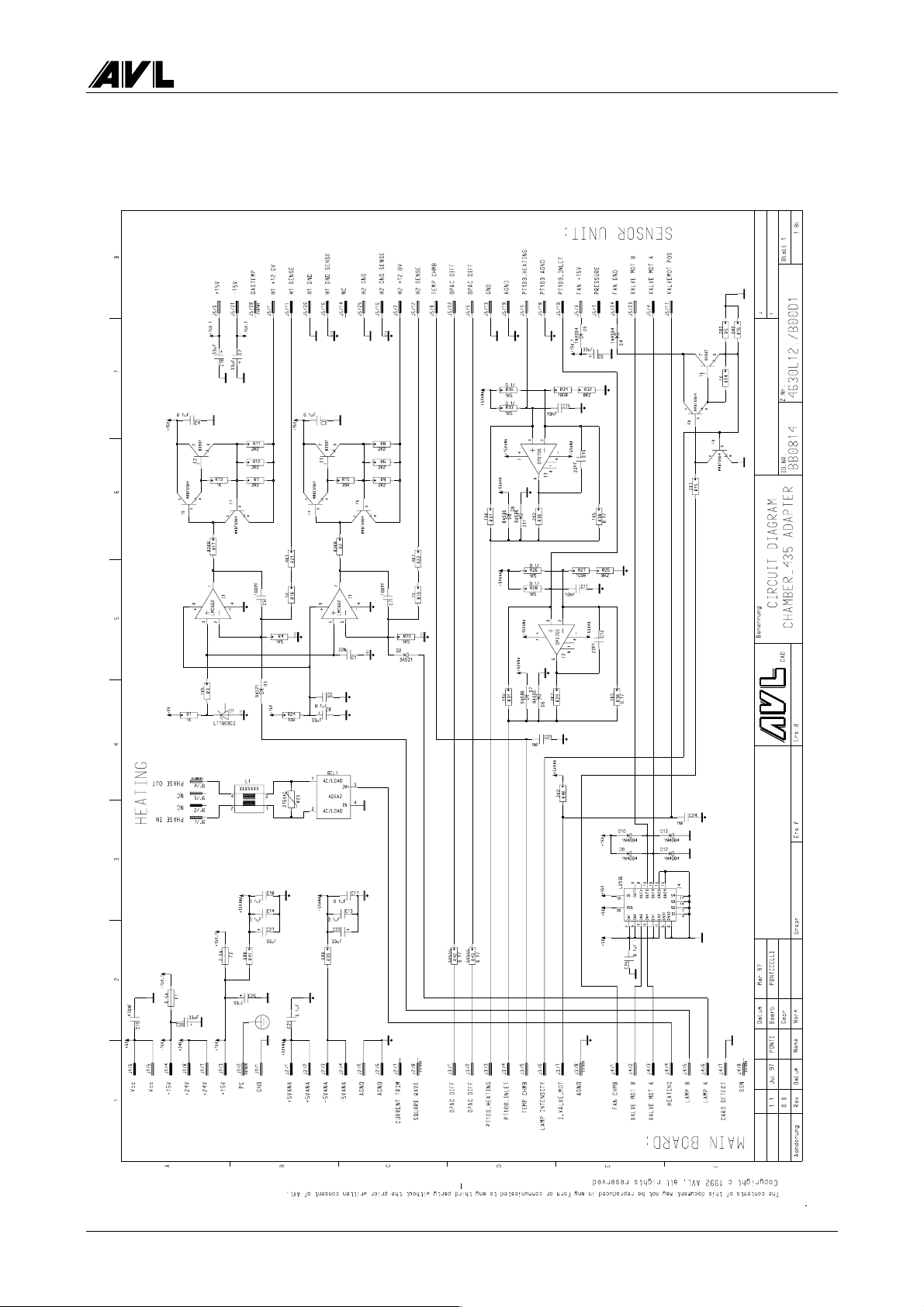

4.9.2 Circuit Diagrams

4-16 Service Manual

4000 Evaluation Unit

Service Manual 4-17

Evaluation Unit AVL 4000

4-18 Service Manual

4000 Evaluation Unit

Service Manual 4-19

Evaluation Unit AVL 4000

4-20 Service Manual

4000 Evaluation Unit

4.10 Speed Angle Board

4.10.1 Components Location Diagram

Service Manual 4-21

Evaluation Unit AVL 4000

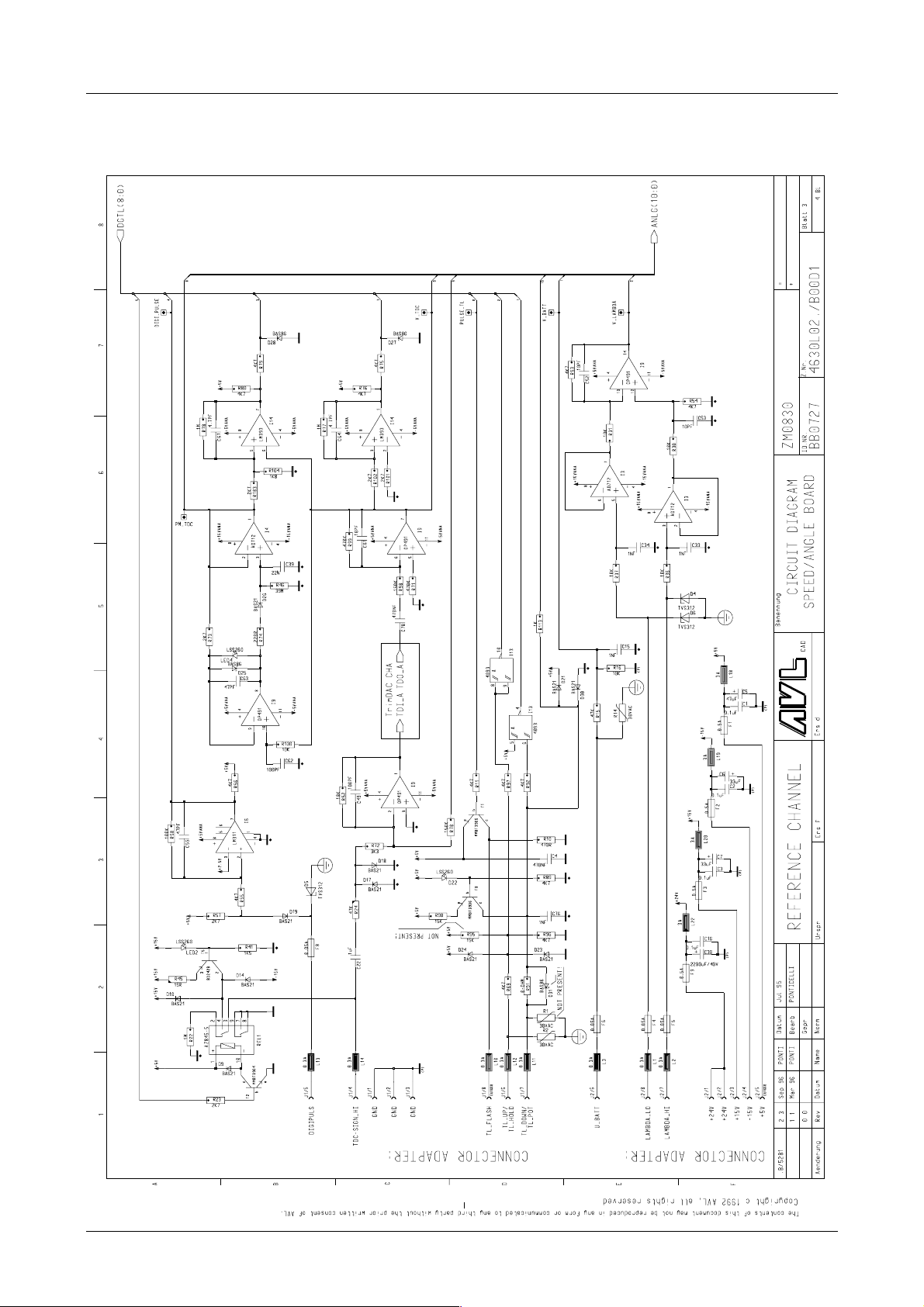

4.10.2 Circuit Diagrams

4-22 Service Manual

4000 Evaluation Unit

Service Manual 4-23

Evaluation Unit AVL 4000

4-24 Service Manual

4000 Evaluation Unit

Service Manual 4-25

Evaluation Unit AVL 4000

4.11 Pneumatics Board

4.11.1 Components Location Diagram

4-26 Service Manual

4000 Evaluation Unit

4.11.2 Circuit Diagram

Service Manual 4-27

Evaluation Unit AVL 4000

4.12 Printer Adapter

4.12.1 Components Location Diagram

4-28 Service Manual

4000 Evaluation Unit

4.12.2 Circuit Diagram

Service Manual 4-29

Evaluation Unit AVL 4000

4.13 Memory Adapter

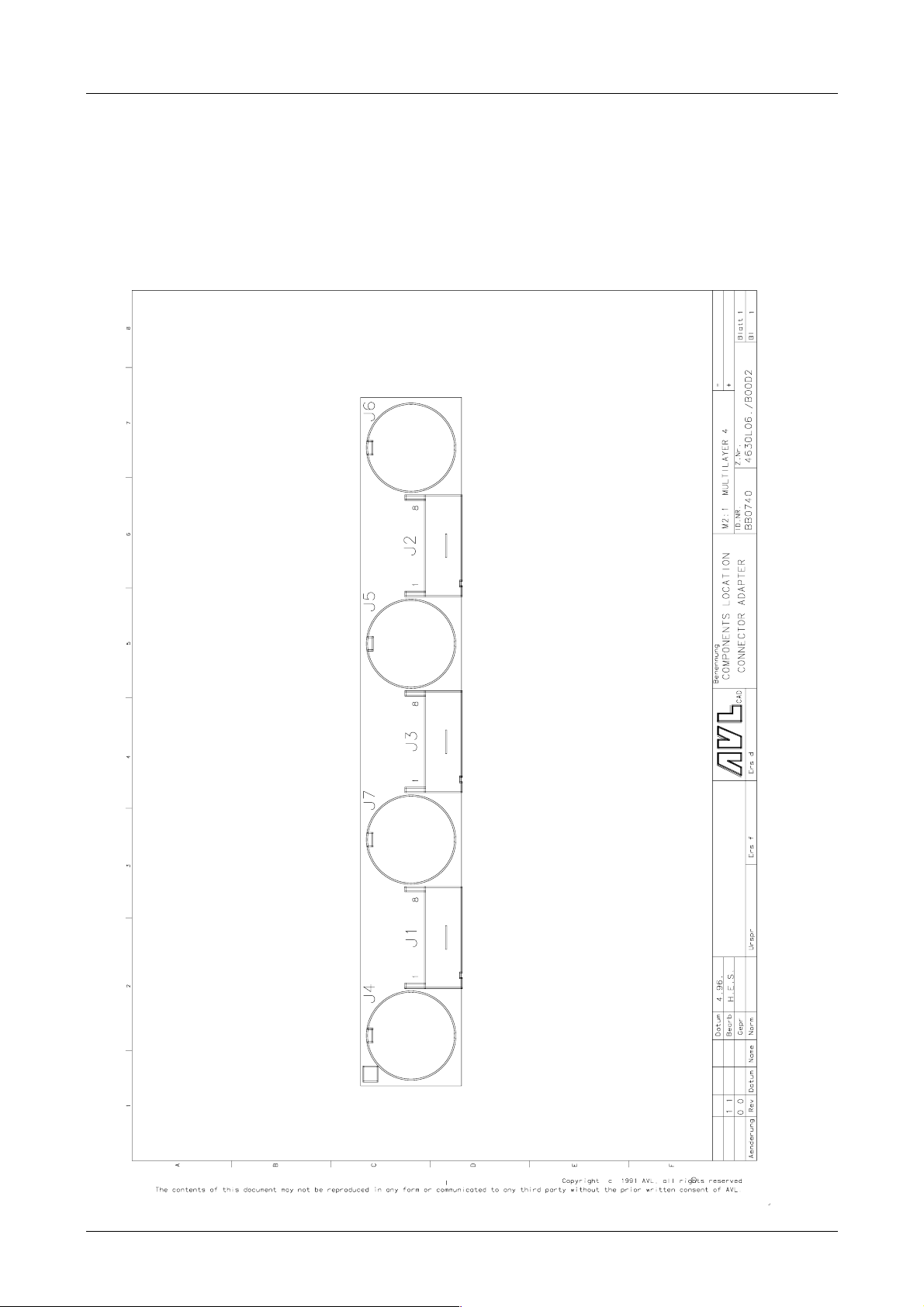

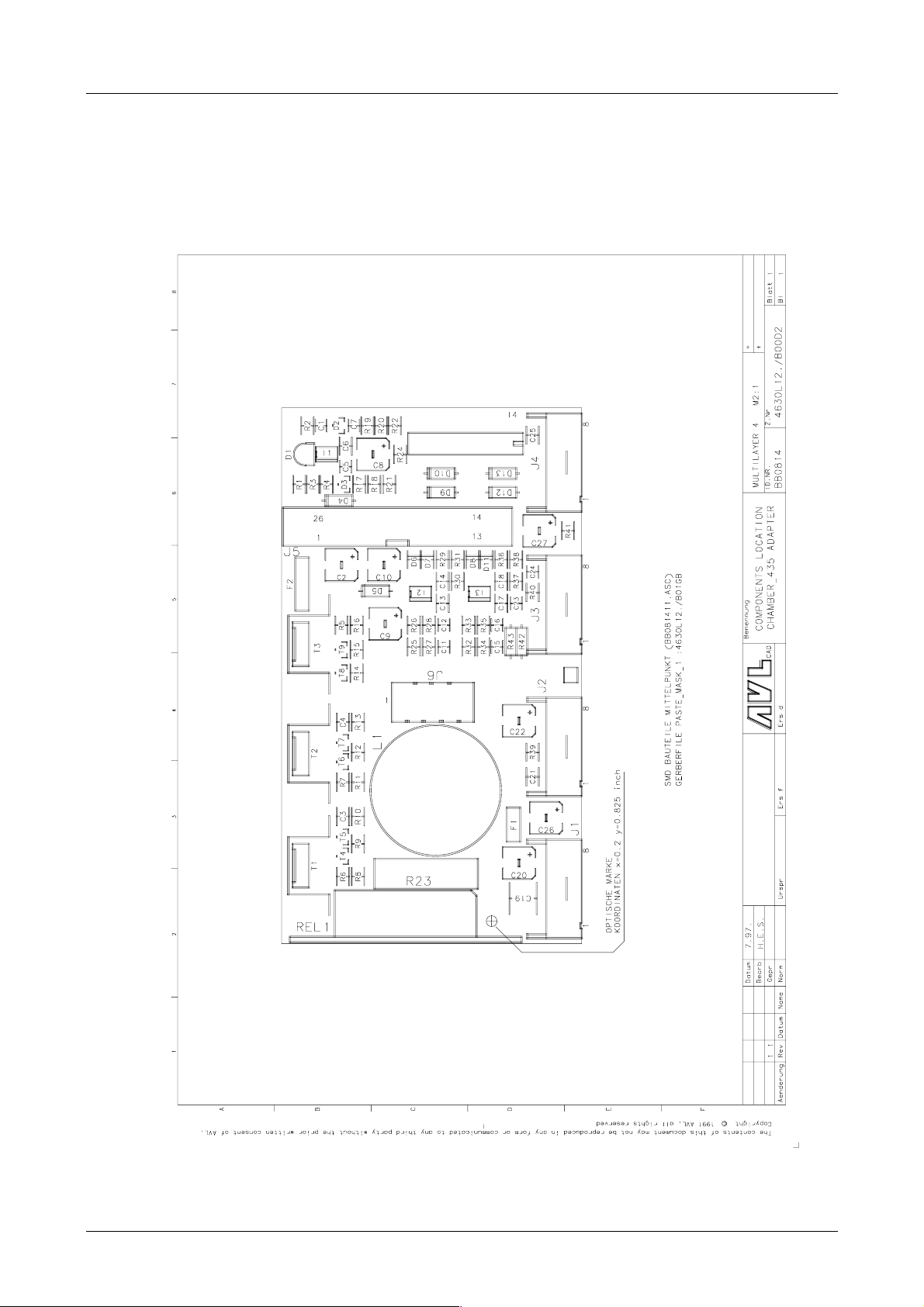

4.13.1 Components Location Diagram